Advances on Polymer Optical Fiber Gratings Using a KrF Pulsed Laser System Operating at 248 nm

Abstract

1. Introduction

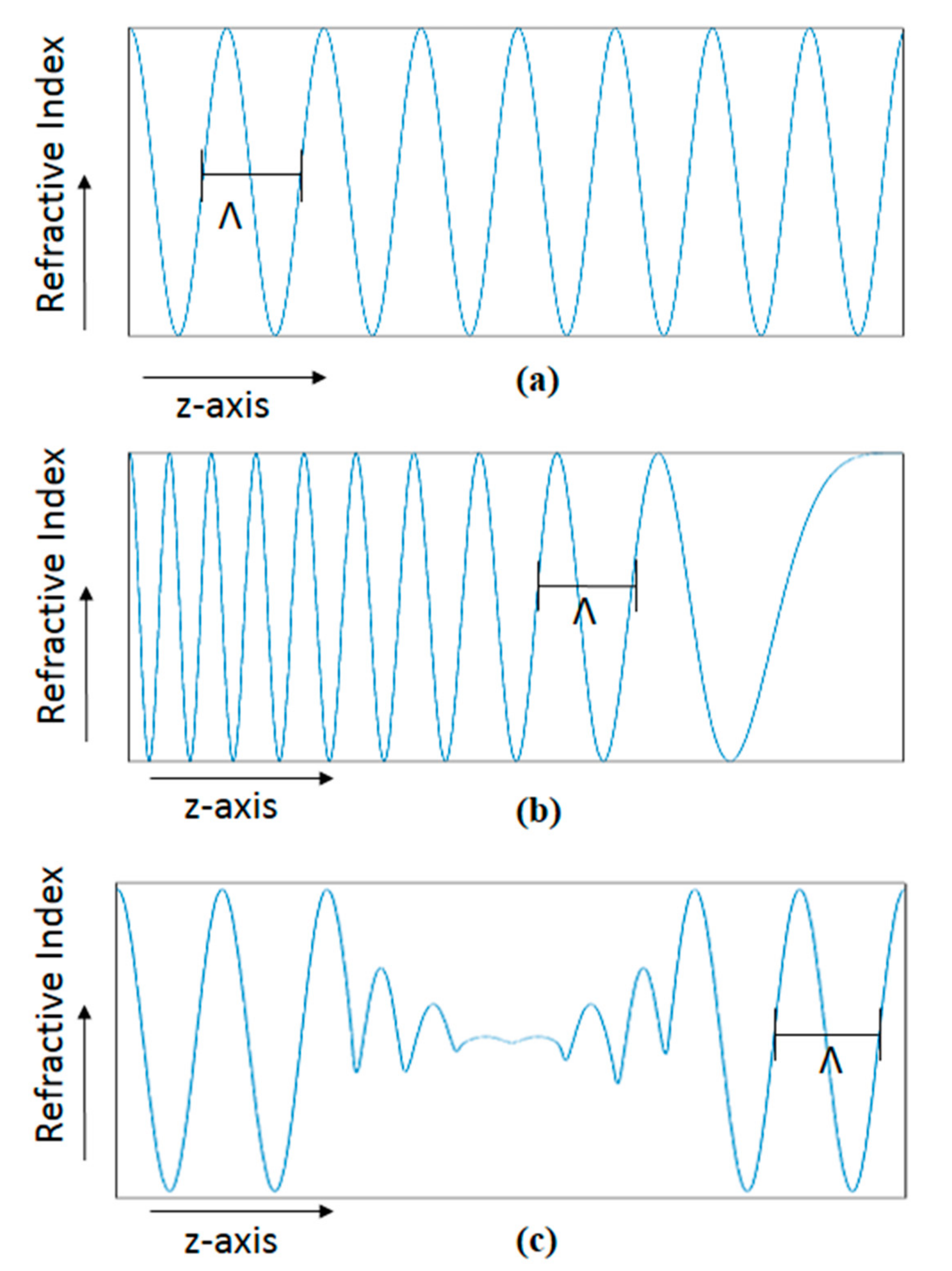

2. Theoretical Background of FBGs and LPGs

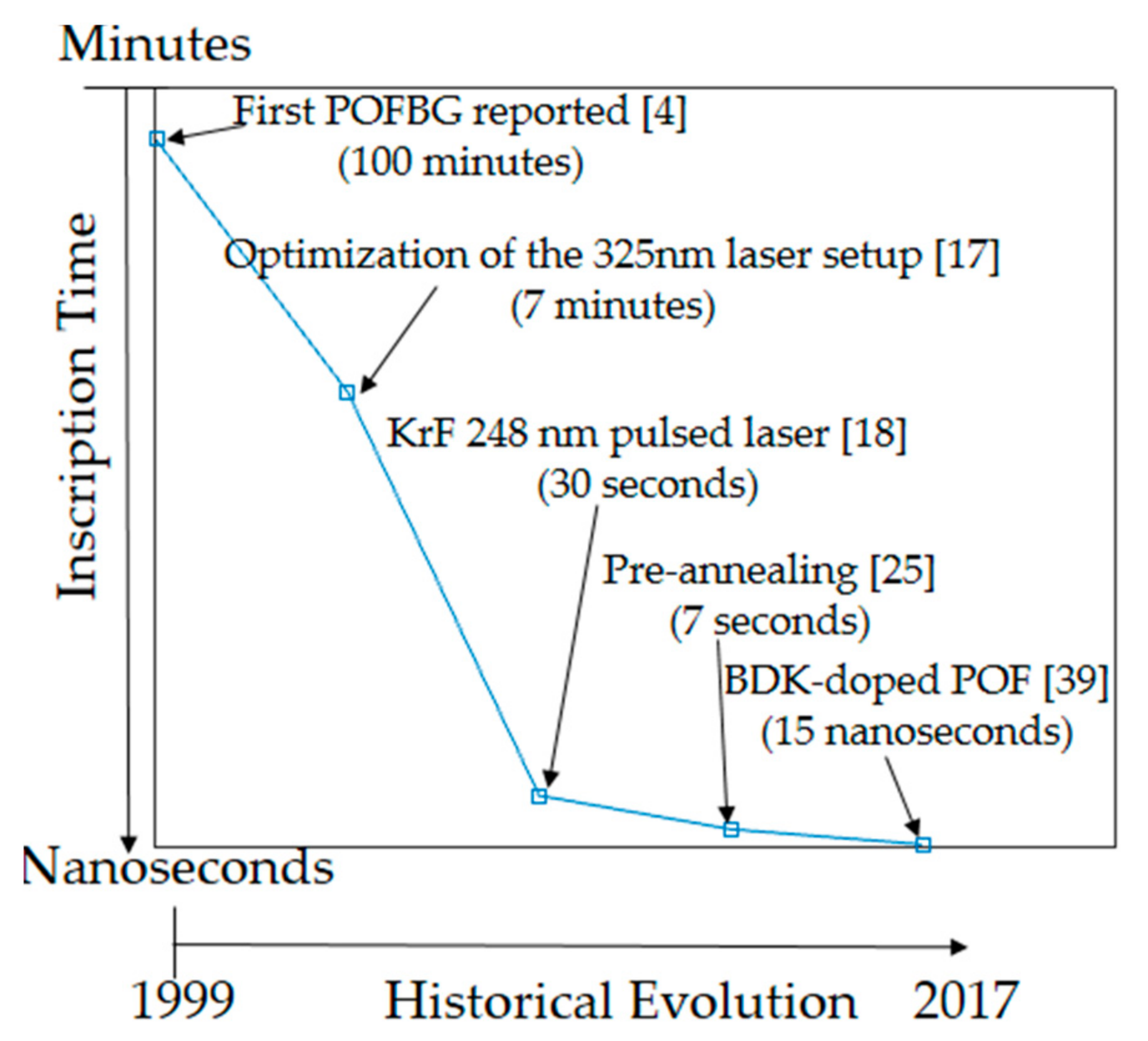

3. State-of-the-Art of HeCd 325 nm Laser Inscription

4. State-of-the-Art of Femtosecond Laser Inscription

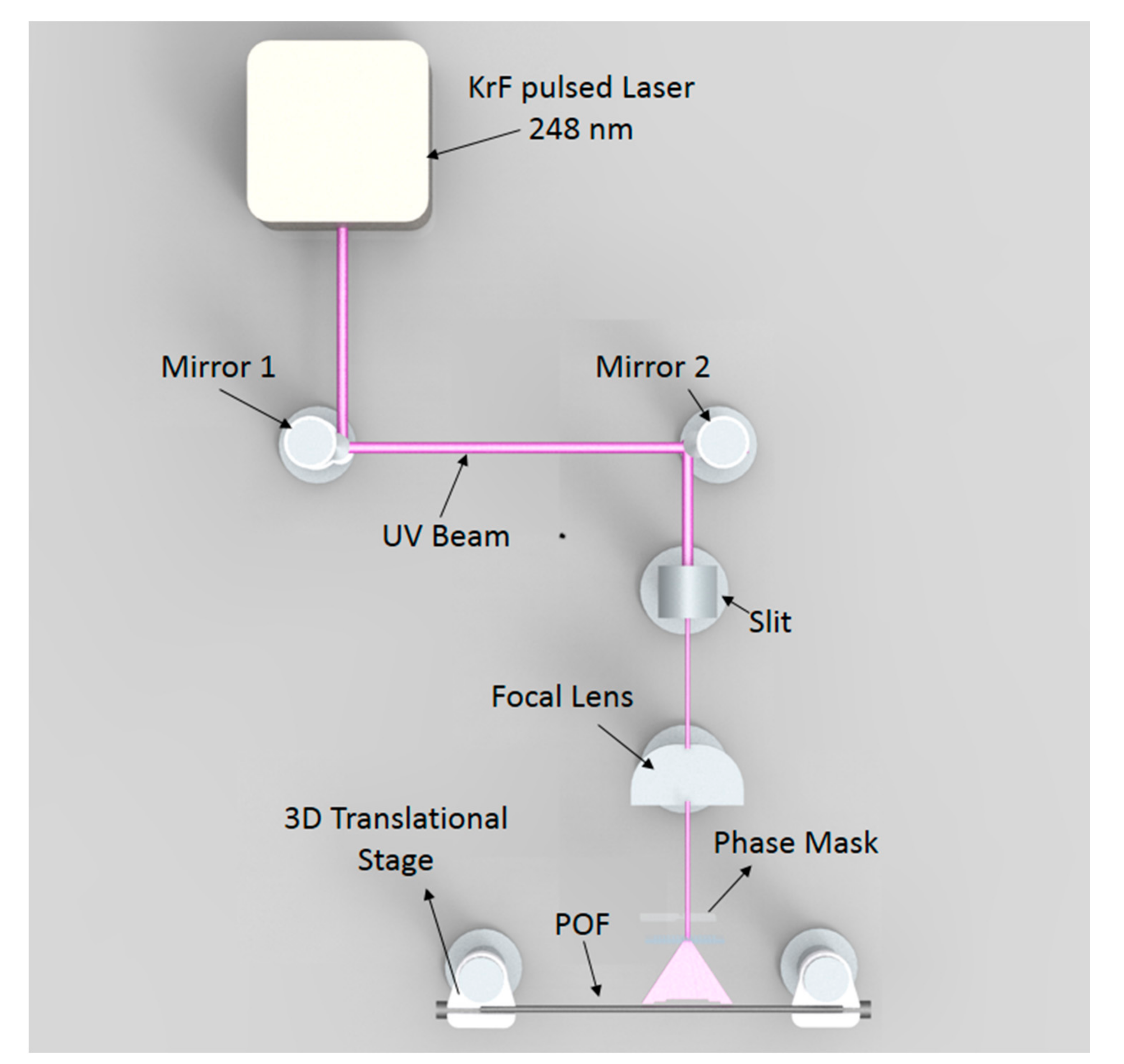

5. KrF 248 nm Pulsed Laser Inscription

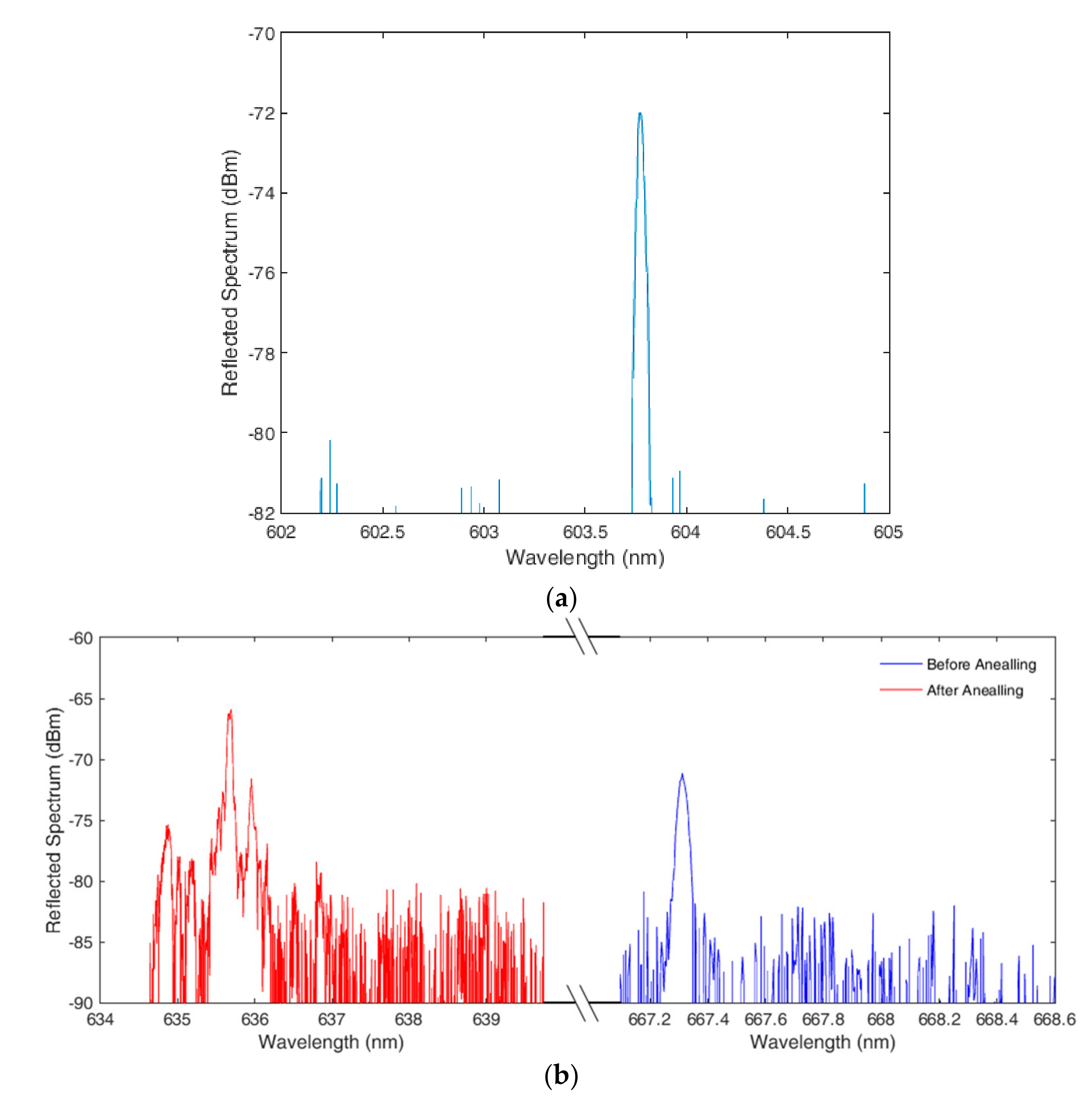

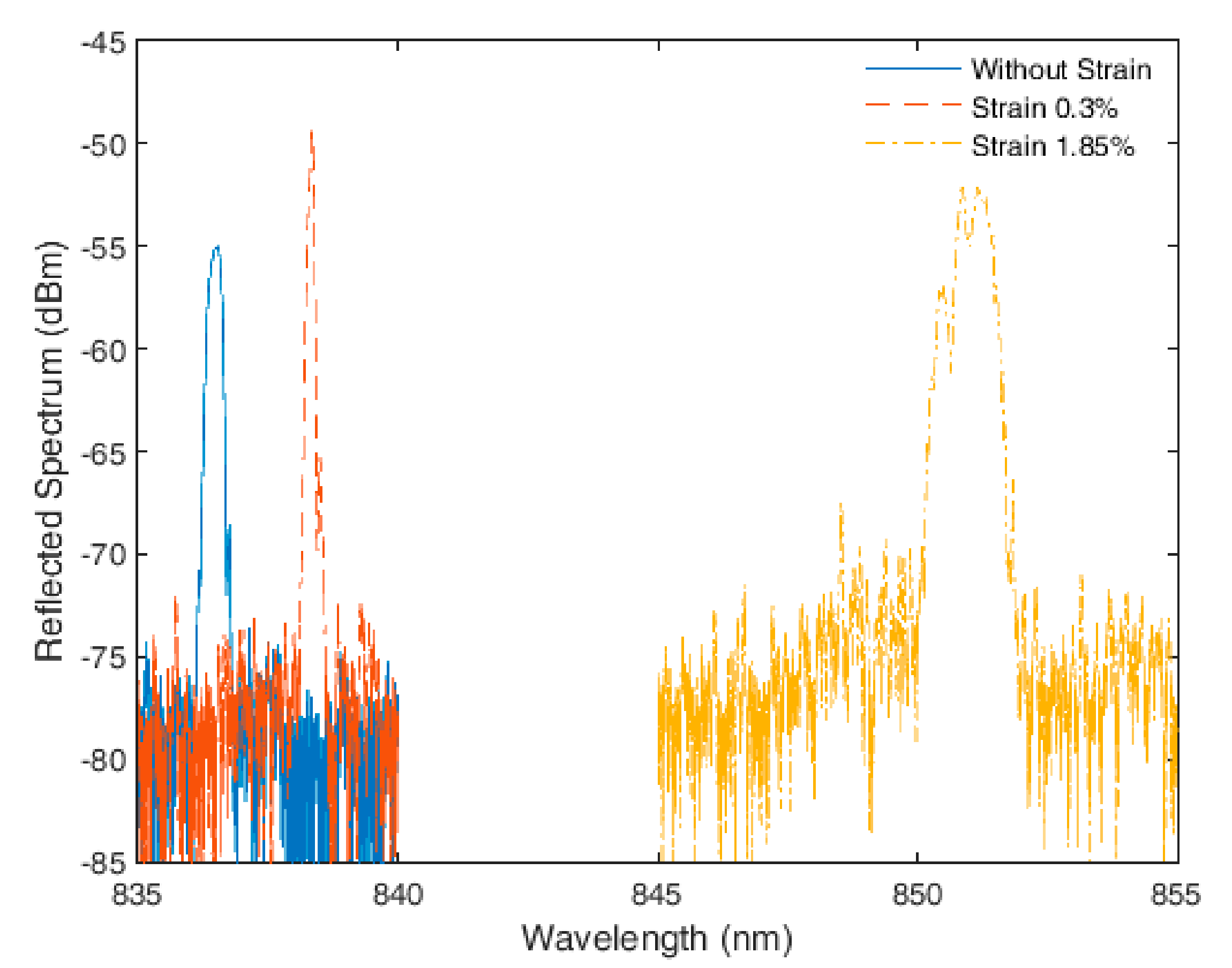

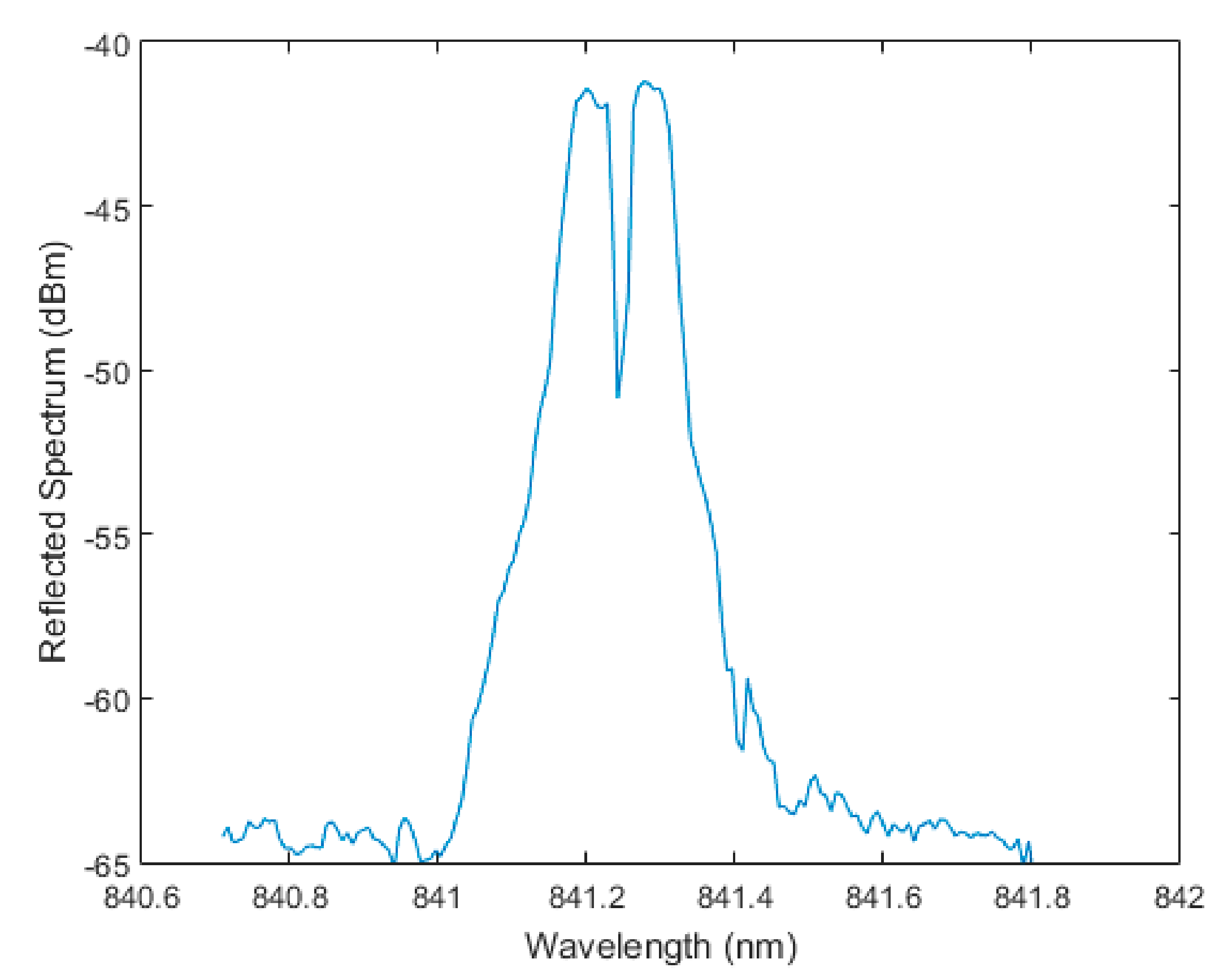

5.1. Fiber Bragg Gratings

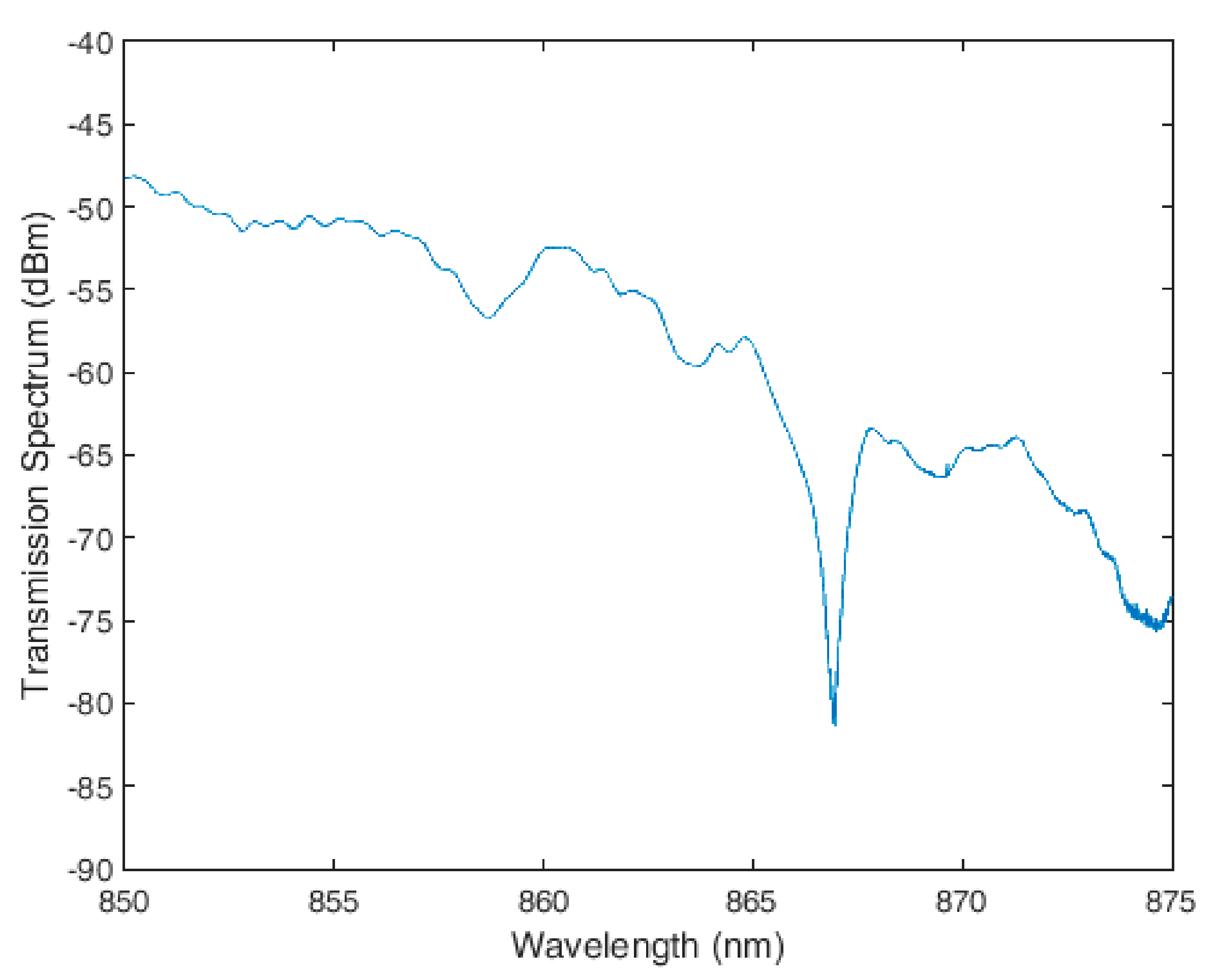

5.2. Long Period Gratings

6. Final Remarks

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Webb, D.J. Fibre Bragg grating sensors in polymer optical fibres. Meas. Sci. Technol. 2015, 26, 92004. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Webb, D.J.; Andre, P. Polymer optical fiber sensors in human life safety. Opt. Fiber Technol. 2017, 36, 144–154. [Google Scholar] [CrossRef]

- Yuan, W.; Khan, L.; Webb, D.J.; Kalli, K.; Rasmussen, H.K.; Stefani, A.; Bang, O. Humidity insensitive TOPAS polymer fiber Bragg grating sensor. Opt. Express 2011, 19, 19731–19739. [Google Scholar] [CrossRef] [PubMed]

- Peng, G.D.; Xiong, Z.; Chu, P.L. Photosensitivity and Gratings in Dye-Doped Polymer Optical Fibers. Opt. Fiber Technol. 1999, 5, 242–251. [Google Scholar] [CrossRef]

- Hiscocks, M.P.; van Eijkelenborg, M.A.; Argyros, A.; Large, M.C.J. Stable imprinting of long-period gratings in microstructured polymer optical fibre. Opt. Express 2006, 14, 4644–4649. [Google Scholar] [CrossRef] [PubMed]

- Sáez-Rodríguez, D.; Cruz, J.L.; Johnson, I.; Webb, D.J.; Large, M.C.J.; Argyros, A. Water diffusion into UV inscripted long period grating in microstructured polymer fiber. IEEE Sens. J. 2010, 10, 1169–1173. [Google Scholar] [CrossRef]

- Liu, H.; Peng, G.; Chu, P. Polymer fibre Bragg gratings tunable laser. In Proceedings of the Optical Fiber Communication Conference and Exposition and the National Fiber Optic Engineers Conference, Anaheim, CA, USA, 5–10 March 2006; p. OWM7. [Google Scholar]

- Fasano, A.; Woyessa, G.; Stajanca, P.; Markos, C.; Stefani, A.; Nielsen, K.; Rasmussen, H.K.; Krebber, K.; Bang, O. Fabrication and characterization of polycarbonate microstructured polymer optical fibers for high-temperature-resistant fiber Bragg grating strain sensors. Opt. Mater. Express 2016, 6, 649. [Google Scholar] [CrossRef]

- Rajan, G.; Bhowmik, K.; Xi, J.; Peng, G.-D. Etched Polymer Fibre Bragg Gratings and their Biomedical Sensing Applications. Sensors 2017, 17, 2336. [Google Scholar] [CrossRef] [PubMed]

- Theodosiou, A.; Komodromos, M.; Kalli, K. Carbon cantilever beam health inspection using a polymer fibre Bragg grating array. J. Lightw. Technol. 2017, 8724. [Google Scholar] [CrossRef]

- Hu, X.; Pun, C.-F. J.; Tam, H.-Y.; Mégret, P.; Caucheteur, C. Tilted Bragg gratings in step-index polymer optical fiber. Opt. Lett. 2014, 39, 6835. [Google Scholar] [CrossRef] [PubMed]

- Yuan, W.; Stefani, A.; Bache, M.; Jacobsen, T.; Rose, B.; Herholdt-Rasmussen, N.; Nielsen, F.K.; Andresen, S.; Sørensen, O.B.; Hansen, K.S.; et al. Improved thermal and strain performance of annealed polymer optical fiber Bragg gratings. Opt. Commun. 2011, 284, 176–182. [Google Scholar] [CrossRef]

- Woyessa, G.; Pedersen, J.K.M.; Fasano, A.; Nielsen, K.; Markos, C.; Rasmussen, H.K.; Bang, O. Zeonex-PMMA microstructured polymer optical FBGs for simultaneous humidity and temperature sensing. Opt. Lett. 2017, 42, 1161. [Google Scholar] [CrossRef] [PubMed]

- Woyessa, G.; Nielsen, K.; Stefani, A.; Markos, C.; Bang, O. Temperature insensitive hysteresis free highly sensitive polymer optical fiber Bragg grating humidity sensor. Opt. Express 2016, 24, 1206–1213. [Google Scholar] [CrossRef] [PubMed]

- Pereira, L.M.; Pospori, A.; Antunes, P.; Domingues, M.F.; Marques, S.; Bang, O.; Webb, D.J.; Marques, C.A.F. Phase-Shifted Bragg Grating Inscription in PMMA Microstructured POF Using 248-nm UV Radiation. J. Lightw. Technol. 2017, 35, 5176–5184. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Peng, G.-D.; Webb, D.J. Highly sensitive liquid level monitoring system utilizing polymer fiber Bragg gratings. Opt. Express 2015, 23, 6058–6072. [Google Scholar] [CrossRef] [PubMed]

- Stefani, A.; Andresen, S.; Yuan, W.; Herholdt-Rasmussen, N.; Bang, O. High sensitivity polymer optical fiber-bragg-grating-based accelerometer. IEEE Photonics Technol. Lett. 2012, 24, 763–765. [Google Scholar] [CrossRef]

- Ruzek, R.; Kadlec, M.; Tserpes, K.; Karachalios, E. Monitoring of compressive behaviour of stiffened composite panels using embedded fibre optic and strain gauge sensors. Int. J. Struct. Integr. 2017, 8, 134–150. [Google Scholar] [CrossRef]

- Kuang, K.S.C. S. C.; Kenny, R.; Whelan, M.P.P.; Cantwell, W.J.J.; Chalker, P.R.R. Embedded fibre Bragg grating sensors in advanced composite materials. Compos. Sci. Technol. 2001, 61, 1379–1387. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Pospori, A.; Saez-Rodriguez, D.; Nielsen, K.; Bang, O.; Webb, D.J. Aviation Fuel Gauging Sensor Utilizing Multiple Diaphragm Sensors Incorporating Polymer Optical Fiber Bragg Gratings. IEEE Sens. J. 2016, 16, 6122–6129. [Google Scholar] [CrossRef]

- Diaz, C.A.R.; Leal-Junior, A.G.; Andre, P.S.B.; Antunes, P.F.da C.; Pontes, M.J.; Frizera-Neto, A.; Ribeiro, M.R.N. Liquid Level Measurement Based on FBG-Embedded Diaphragms with Temperature Compensation. IEEE Sens. J. 2018, 18, 193–200. [Google Scholar] [CrossRef]

- Vilarinho, D.; Theodosiou, A.; Leitão, C.; Leal-Junior, A.; Domingues, M.; Kalli, K.; André, P.; Antunes, P.; Marques, C. POFBG-Embedded Cork Insole for Plantar Pressure Monitoring. Sensors 2017, 17, 2924. [Google Scholar] [CrossRef] [PubMed]

- Markos, C.; Stefani, A.; Nielsen, K.; Rasmussen, H.K.; Yuan, W.; Bang, O. High-Tg TOPAS microstructured polymer optical fiber for fiber Bragg grating strain sensing at 110 degrees. Opt. Express 2013, 21, 4758–4765. [Google Scholar] [CrossRef] [PubMed]

- Bundalo, I.-L.; Nielsen, K.; Markos, C.; Bang, O. Bragg grating writing in PMMA microstructured polymer optical fibers in less than 7 min. Opt. Express 2014, 22, 5270. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, R.; Bilro, L.; Nogueira, R. Bragg gratings in a few mode microstructured polymer optical fiber in less than 30 s. Opt. Express 2015, 23, 10181. [Google Scholar] [CrossRef] [PubMed]

- Berghmans, F.; Geernaert, T.; Baghdasaryan, T.; Thienpont, H. Challenges in the fabrication of fibre Bragg gratings in silica and polymer microstructured optical fibres. Laser Photonics Rev. 2014, 8, 27–52. [Google Scholar] [CrossRef]

- Luo, Y.; Yan, B.; Zhang, Q.; Peng, G.-D.; Wen, J.; Zhang, J. Fabrication of Polymer Optical Fibre (POF) Gratings. Sensors 2017, 17, 511. [Google Scholar] [CrossRef] [PubMed]

- Hill, K.O.; Meltz, G. Fiber Bragg Grating Technology Fundementals and Overview. IEEE J. Lightw. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Sáez-Rodríguez, D.; Nielsen, K.; Bang, O.; Webb, D.J. Photosensitivity mechanism of undoped poly(methyl methacrylate) under UV radiation at 325 nm and its spatial resolution limit. Opt. Lett. 2014, 39, 3421–3424. [Google Scholar] [CrossRef] [PubMed]

- Pospori, A.; Marques, C.A.F.; Bang, O.; Webb, D.J. Polymer optical fiber Bragg grating inscription with a single UV laser pulse. Opt. Express 2017, 25, 9028–9038. [Google Scholar] [CrossRef] [PubMed]

- Wochnowski, C.; Eldin, M.A.S.; Metev, S. UV-laser-assisted degradation of poly(methyl methacrylate). Polym. Degrad. Stab. 2005, 89, 252–264. [Google Scholar] [CrossRef]

- Xiong, Z.; Peng, G.D.; Wu, B.; Chu, P.L. Highly tunable Bragg gratings in single mode polymer optical fibers. IEEE Photon. Technol. Lett. 1999, 11, 352–354. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Bilro, L.B.; Alberto, N.J.; Webb, D.J.; Nogueira, R.N. Narrow bandwidth Bragg gratings imprinted in polymer optical fibers for different spectral windows. Opt. Commun. 2013, 307, 57–61. [Google Scholar] [CrossRef]

- Lacraz, A.; Polis, M.; Theodosiou, A.; Koutsides, C.; Kalli, K. Femtosecond Laser Inscribed Bragg Gratings in Low Loss CYTOP Polymer Optical Fiber. IEEE Photonics Technol. Lett. 2015, 27, 693–696. [Google Scholar] [CrossRef]

- Peters, K. Polymer optical fiber sensors—A review. Smart Mater. Struct. 2010, 20, 13002. [Google Scholar] [CrossRef]

- Stefani, A.; Yuan, W.; Markos, C.; Bang, O. Narrow Bandwidth 850 nm Fiber Bragg Gratings in Few-Mode Polymer Optical Fibers. IEEE Photonics Technol. Lett. 2011, 23, 660–662. [Google Scholar] [CrossRef]

- Yuan, W.; Stefani, A.; Bang, O. Tunable polymer fiber Bragg grating (FBG) inscription: Fabrication of dual-FBG temperature compensated polymer optical fiber strain sensors. IEEE Photonics Technol. Lett. 2012, 24, 401–403. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Pospori, A.; Demirci, G.; Çetinkaya, O.; Gawdzik, B.; Antunes, P.; Bang, O.; Mergo, P.; André, P.; Webb, D.J. Fast bragg grating inscription in PMMA polymer optical fibres: Impact of thermal pre-treatment of preforms. Sensors 2017, 17, 891. [Google Scholar] [CrossRef] [PubMed]

- Pospori, A.; Marques, C.A.F.; Sáez-Rodríguez, D.; Nielsen, K.; Bang, O.; Webb, D.J. Thermal and chemical treatment of polymer optical fiber Bragg grating sensors for enhanced mechanical sensitivity. Opt. Fiber Technol. 2017, 36, 68–74. [Google Scholar] [CrossRef]

- Fasano, A.; Woyessa, G.; Janting, J.; Rasmussen, H.K.; Bang, O. Solution-Mediated Annealing of Polymer Optical Fiber Bragg Gratings at Room Temperature. IEEE Photonics Technol. Lett. 2017, 29, 687–690. [Google Scholar] [CrossRef]

- Hu, X.; Pun, C.-F. J.; Tam, H.-Y.; Mégret, P.; Caucheteur, C. Highly reflective Bragg gratings in slightly etched step-index polymer optical fiber. Opt. Express 2014, 22, 18807. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Kinet, D.; Mégret, P.; Caucheteur, C. Control over photo-inscription and thermal annealing to obtain high-quality Bragg gratings in doped PMMA optical fibers. Opt. Lett. 2016, 41, 2930. [Google Scholar] [CrossRef] [PubMed]

- Sáez-Rodríguez, D.; Nielsen, K.; Rasmussen, H.K.; Bang, O.; Webb, D.J. Highly photosensitive polymethyl methacrylate microstructured polymer optical fiber with doped core. Opt. Lett. 2013, 38, 3769–3772. [Google Scholar] [CrossRef] [PubMed]

- Woyessa, G.; Fasano, A.; Markos, C.; Stefani, A.; Rasmussen, H.K.; Bang, O. Zeonex microstructured polymer optical fiber: Fabrication friendly fibers for high temperature and humidity insensitive Bragg grating sensing. Opt. Mater. Express 2017, 7, 286. [Google Scholar] [CrossRef]

- Woyessa, G.; Fasano, A.; Stefani, A.; Markos, C.; Nielsen, K.; Rasmussen, H.K.; Bang, O. Single mode step-index polymer optical fiber for humidity insensitive high temperature fiber Bragg grating sensors. Opt. Express 2016, 24, 1253–1260. [Google Scholar] [CrossRef] [PubMed]

- Ortega, B.; Min, R.; Sáez-Rodríguez, D.; Mi, Y.; Nielsen, K.; Bang, O. Bandpass transmission filters based on phase shifted fiber Bragg gratings in microstructured polymer optical fibers. In Proceedings of the SPIE, Micro-structured and Specialty Optical Fibres V, Prague, Czech Republic, 16 May 2017; Volume 10232, p. 1023209. [Google Scholar] [CrossRef]

- Dobb, H.; Carroll, K.; Webb, D.J.; Kalli, K.; Komodromos, M.; Themistos, C.; Peng, G.D.; Argyros, A.; Large, M.C.J.; van Eijkelenborg, M.A.; et al. Grating based devices in polymer optical fibre. In Proceedings of the Spie, Optical Sensing Ii, Strasbourg, France, 19 April 2006; Volume 618901. [Google Scholar] [CrossRef]

- Kowal, D.; Statkiewicz-Barabach, G.; Mergo, P.; Urbanczyk, W. Microstructured polymer optical fiber for long period gratings fabrication using an ultraviolet laser beam. Opt. Lett. 2014, 39, 2242. [Google Scholar] [CrossRef] [PubMed]

- Stefani, A.; Stecher, M.; Town, G.; Bang, O. Direct writing of fiber Bragg grating in microstructured polymer optical fiber. IEEE Photonics Technol. Lett. 2012, 24, 1148–1150. [Google Scholar] [CrossRef]

- Theodosiou, A.; Member, S.; Lacraz, A.; Stassis, A.; Komodromos, M.; Member, S.; Kalli, K. Plane-by-Plane femtosecond laser inscription method for single—Peak Bragg gratings in multimode CYTOP polymer optical fibre. J. Lightw. Technol. 2017, 35, 5404–5410. [Google Scholar] [CrossRef]

- Hu, X.; Kinet, D.; Chah, K.; Pun, C.-F. J.; Tam, H.-Y.; Caucheteur, C. Bragg grating inscription in PMMA optical fibers using 400-nm femtosecond pulses. Opt. Lett. 2017, 42, 2794. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Woyessa, G.; Kinet, D.; Janting, J.; Nielsen, K.; Bang, O.; Caucheteur, C. BDK-doped core microstructured PMMA optical fiber for effective Bragg grating photo-inscription. Opt. Lett. 2017, 42, 2209. [Google Scholar] [CrossRef] [PubMed]

- Marques, C.A.F.; Antunes, P.; Mergo, P.; Webb, D.J.; Andre, P. Chirped Bragg Gratings in PMMA Step-Index Polymer Optical Fiber. IEEE Photonics Technol. Lett. 2017, 29, 500–503. [Google Scholar] [CrossRef]

- Min, R.; Ortega, B.; Marques, C. Fabrication of tunable chirped mPOF Bragg gratings using a uniform phase mask. Opt. Express 2018, 26, 4411–4420. [Google Scholar] [CrossRef]

- Min, R.; Marques, C.; Bang, O.; Ortega, B. Moiré Phase-Shifted Fiber Bragg Gratings in Polymer Optical Fibers. Opt. Fiber Technol. 2018, 41, 78–81. [Google Scholar] [CrossRef]

- Min, R.; Marques, C.; Bang, O.; Ortega, B. Fast inscription of long period gratings in microstructured polymer optical fibers. IEEE Sens. J. 2018, 99. [Google Scholar] [CrossRef]

| Material | Inscription Time (min) | Central Wavelength (nm) |

|---|---|---|

| PMMA [24] | 7 | 632 |

| PC [8] | 6 | 879 |

| TOPAS Low-Tg [3] | 58 | 870 |

| TOPAS High-Tg [45] | 4 | 853 |

| Zeonex [44] | 5 | 830 |

| Material | Inscription Time (s) |

|---|---|

| PMMA | 25 |

| PC | 14 |

| TOPAS Low-Tg | 25 |

| TOPAS High-Tg | 20 |

| Zeonex | 15 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marques, C.A.F.; Leal-Junior, A.G.; Min, R.; Domingues, M.; Leitão, C.; Antunes, P.; Ortega, B.; André, P. Advances on Polymer Optical Fiber Gratings Using a KrF Pulsed Laser System Operating at 248 nm. Fibers 2018, 6, 13. https://doi.org/10.3390/fib6010013

Marques CAF, Leal-Junior AG, Min R, Domingues M, Leitão C, Antunes P, Ortega B, André P. Advances on Polymer Optical Fiber Gratings Using a KrF Pulsed Laser System Operating at 248 nm. Fibers. 2018; 6(1):13. https://doi.org/10.3390/fib6010013

Chicago/Turabian StyleMarques, Carlos A. F., Arnaldo G. Leal-Junior, Rui Min, Maria Domingues, Cátia Leitão, Paulo Antunes, Beatriz Ortega, and Paulo André. 2018. "Advances on Polymer Optical Fiber Gratings Using a KrF Pulsed Laser System Operating at 248 nm" Fibers 6, no. 1: 13. https://doi.org/10.3390/fib6010013

APA StyleMarques, C. A. F., Leal-Junior, A. G., Min, R., Domingues, M., Leitão, C., Antunes, P., Ortega, B., & André, P. (2018). Advances on Polymer Optical Fiber Gratings Using a KrF Pulsed Laser System Operating at 248 nm. Fibers, 6(1), 13. https://doi.org/10.3390/fib6010013