1. Introduction

The use of Fiber-Reinforced Polymer (FRP) composites as wraps for upgrading existing masonry columns has become increasingly popular in recent years. These wrapping techniques allow obtaining large increases of the strength and deformation capacity, and are effective for columns with poor structural features. FRP wrapping allows an outstanding combination of properties, such as ease of handling, speed of installation and the use of a material with a high strength-to-weight ratio. Despite these advantages, some critical issues are involved in this method, including ensuring a durable bond between FRP and masonry and the stress concentration near the column’s edges.

For these reasons, several research works have been carried out in the recent past with the aim of investigating the compressive behavior of FRP-confined masonry columns. One of the first studies on the effect of external FRP wrapping on masonry columns was carried out by Corradi

et al. [

1]. Researchers performed compressive tests on FRP-confined clay brick columns and proposed an adaptation of the model of Campione and Miraglia [

2] for masonry members. Similarly, Aiello

et al. [

3] performed compressive tests on masonry columns built with clay or calcareous blocks, and reinforced with external FRP wrapping or internal FRP bars. Based on obtained results, they proposed a calibration of some design expressions for obtaining the strength of confined masonry columns. Di Ludovico

et al. [

4] presented the results of an experimental investigation on the compressive behavior of tuff or clay brick masonry columns confined with carbon or glass FRP and proposed new expressions for evaluating the strength enhancement in these members. Faella

et al. [

5] tested 54 natural stone and artificial brick masonry columns under uniaxial compression and investigated the effects of three different kinds of composite systems applied for confinement. Researchers observed several failure modes in the various tests and values of the confined-to-unconfined strength ratio ranging between 1.22 and 3.94.

As general findings, most of the experimental studies pointed out that the strength increase is generally higher in the case of weak masonry columns and for stiffer wrapping layers, confirming the influence of the basic parameters on the behavior of confined members; the stress concentration at the corners induces brittle failure, and it does not allow the column to reach the maximum confining stress; and the bond between masonry and FRP depends on the kind of resin and tissue adopted.

From a theoretical point of view, recent studies investigated the strength increase due to FRP confinement of masonry columns. Koksal

et al. [

6] developed a Drucker-Prager–type constitutive model for the nonlinear finite element analysis of FRP-confined masonry columns, while Lignola

et al. [

7] summarized previous literature studies and proposed a theoretical approach based on the Mohr-Coulomb strength criterion for determining the strength increase due to FRP confinement. Despite the advantages of this method highlighted by this large amount of research works, some drawbacks were spotted when organic resins were used to bind the fibers, such as poor behavior at high temperatures, inapplicability on wet surfaces, high costs and problems of compatibility between materials for long-term effects.

To solve these problems, different techniques were developed to be used as alternative methods for enhancing the structural performances of poor masonry columns. Among these, the use of wraps with Basalt Fiber–Reinforced Cementitious Matrix (BFRCM) allows obtaining an external surface that is easy to finish, and with a material compatible with that of the column. In fact, basalt fibers are obtained from basalt rocks through a melting process and contain no other chemical components in the manufacturing process, and thus are low in cost. Basalt fibers show mechanical features comparable to that of glass fibers and exhibit good resistance to chemical and high temperature exposure [

8]. The ultimate strain of basalt is higher compared to other common FRP materials and thus it is interesting to use this advantage in column strengthening to enhance the seismic performance. There is little research concerning the application of basalt fibers in civil engineering and their strengthening efficiency on masonry elements. Yilmaz

et al. [

9] investigated the efficacy of external confinement with open-grid basalt-reinforced mortar on the axial behavior of masonry columns by testing five specimens. Their results showed that the open-grid BFRCM provided a fairly small compressive strength gain but, on the other hand, basalt jacket–reinforced mortar improves energy dissipation of the masonry columns notably. Similarly, Carloni

et al. [

10] performed an experimental investigation on the compressive behavior of polyparaphenylene benzobisoxazole (PBO) FRCM–reinforced masonry columns, finding small increments of strength but a noticeable increase of ultimate strain.

Another alternative method is the application of steel wires in the correspondence of mortar joints, to provide overlapping hoops at every course over the entire height of the column. The main advantages of this technique are related to the low costs and the reduced aesthetical impact, which makes this method suitable for buildings of historical and/or architectural interest. The idea was initially proposed by Jurina [

11,

12], who performed an experimental investigation, showing the capabilities of the technique in enhancing the axial capacity of the column.

Borri

et al. [

13,

14] developed the technique proposed in [

11] by using prestressed high-strength steel cords, applied with mortar or with resin to masonry columns with various cross-section shapes. Strength gains of up to three times were recorded, with higher values for octagonal sections, while square and rectangular specimens proved to be more sensitive to stress concentrations at the corners.

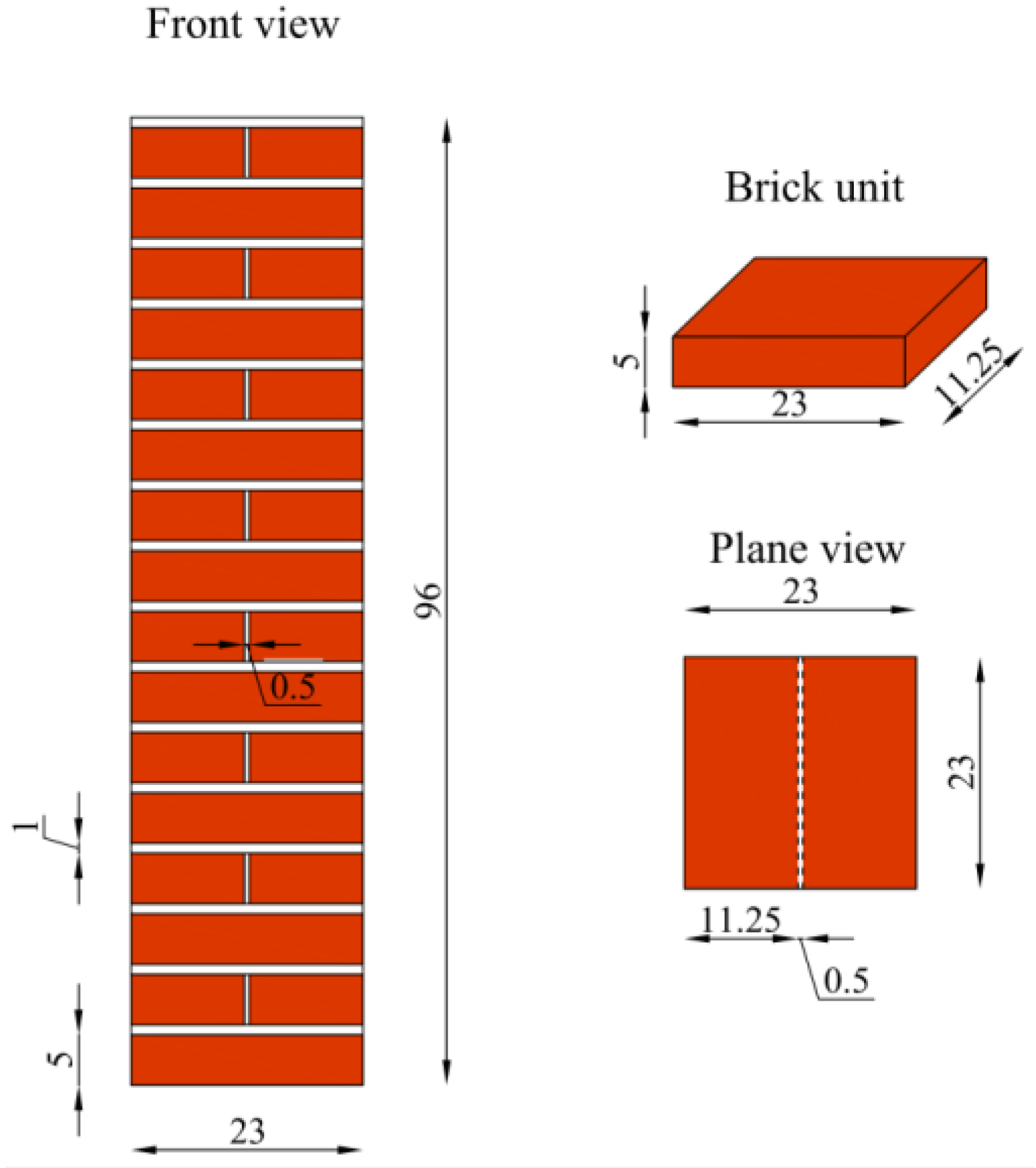

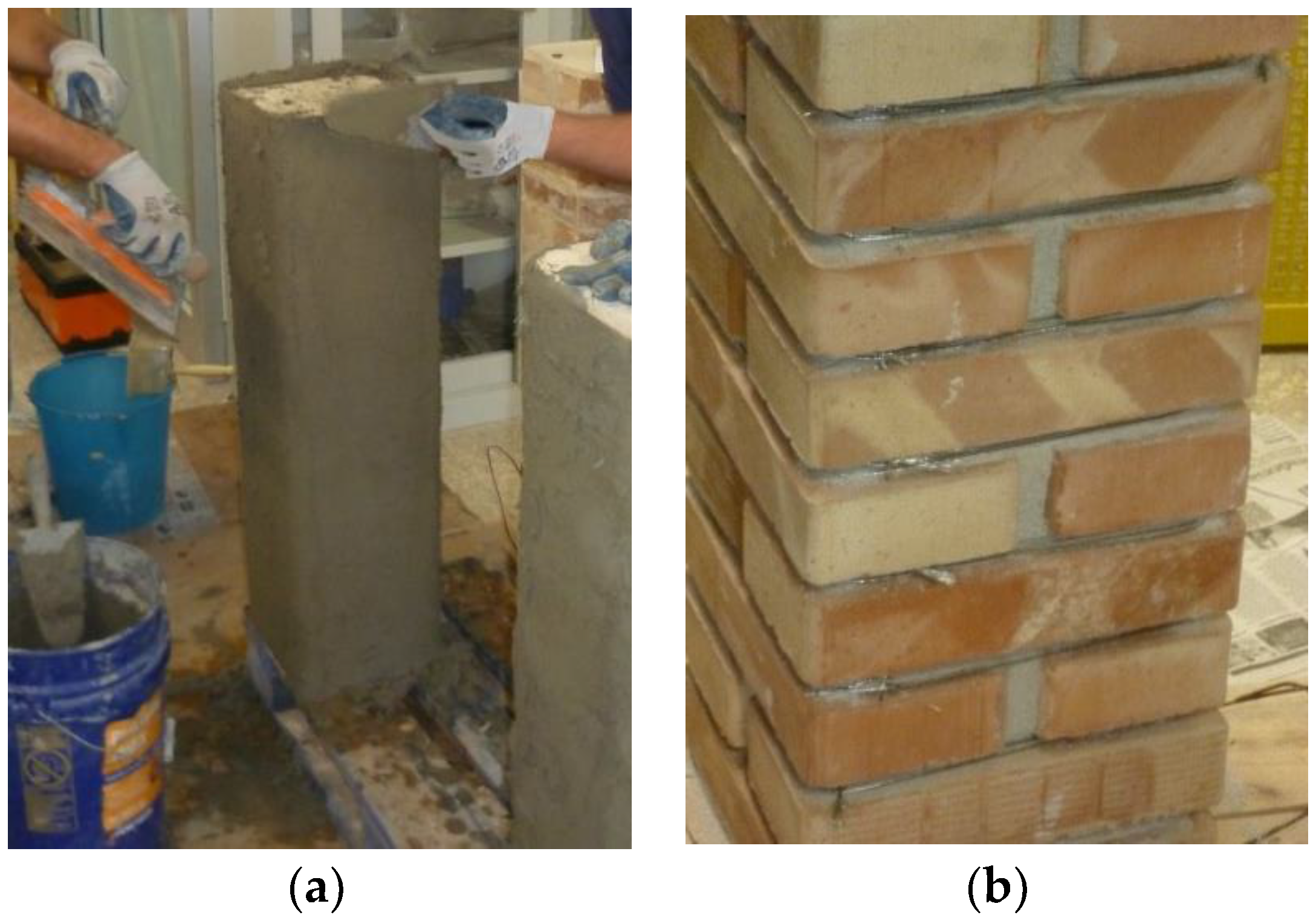

This paper presents the results of an experimental comparative analysis on the compressive behavior of confined masonry columns reinforced with different techniques. In particular, four clay brick masonry columns wrapped with BFRCM (series BF) and four specimens strengthened by high-strength steel wires placed in the joints (series SW) were tested until failure.

All the columns were manufactured with binding mortars typical of existing masonry buildings, which require structural retrofitting. In particular, two masonry strengths were targeted by varying the mortar grade and composition: series M1 for low-strength mortar, and series M3 for medium-strength mortar. Adopted nomenclature follows the definition of mortar classes of Eurocode 6 [

15]. In addition to the reinforced specimens, two unconfined clay brick columns were prepared as control specimens (denoted as U) for each series, M1 and M3, of specimens.

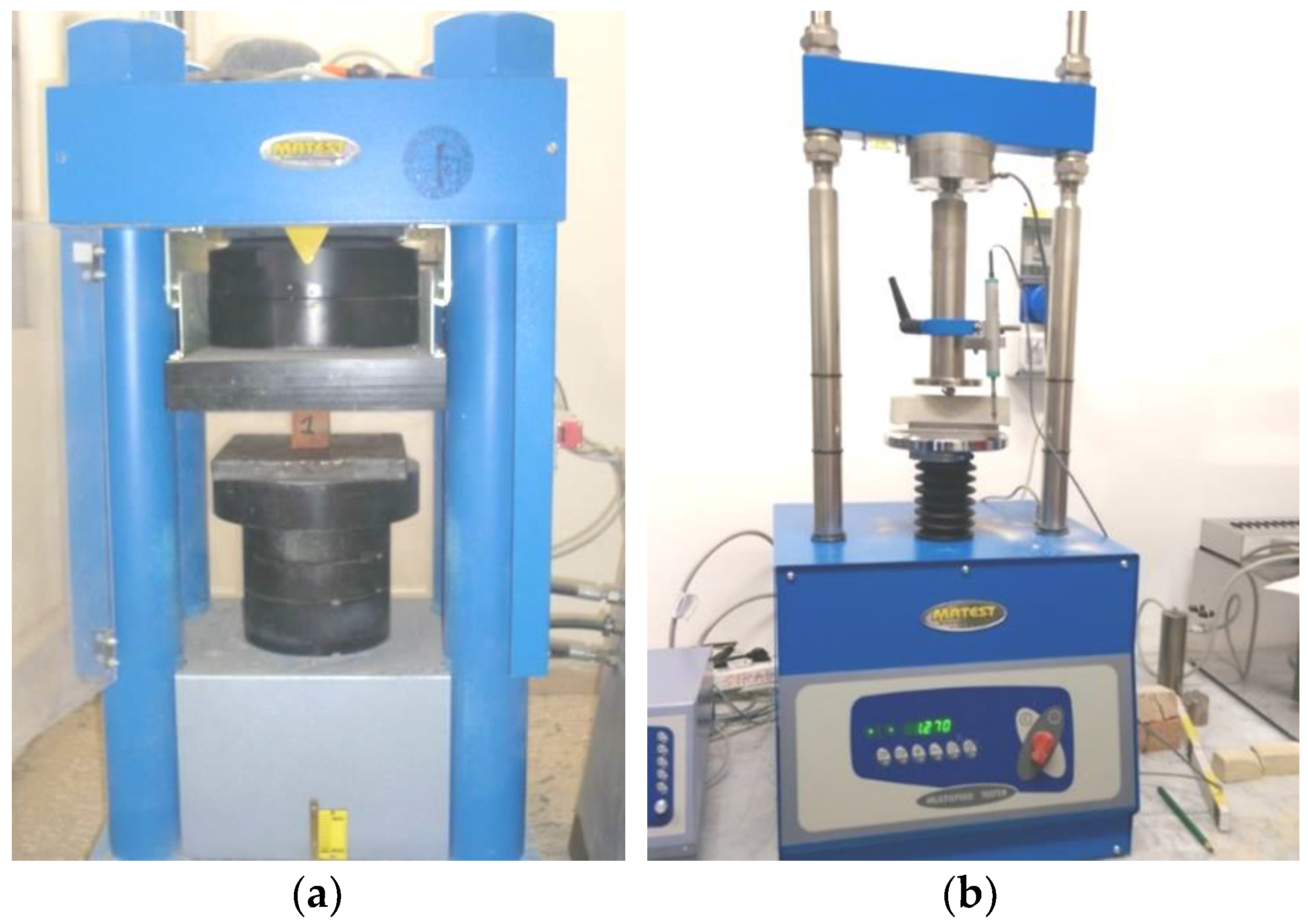

In this paper, after describing the geometry and construction of test specimens, the characterization of constituent materials is presented by discussing the results of bending tests on mortar samples and compressive tests on clay brick and mortar cubes. The preparation of test specimens is also described in detail, by examining the construction stages of the specimens. Results of the compressive tests are finally presented and discussed by analyzing the axial stress-strain curves, strength and ultimate strain gains and failure modes. Results of performed tests allow the examination of the efficiency of the investigated reinforcing techniques, BFRCM wrapping and steel wire collaring, in a comparative manner. Results obtained could be useful to clarify the structural performances of these strengthening techniques, which could be efficient and economical alternatives to traditional FRP wrapping.

3. Results and Discussion

3.1. Unreinforced Columns

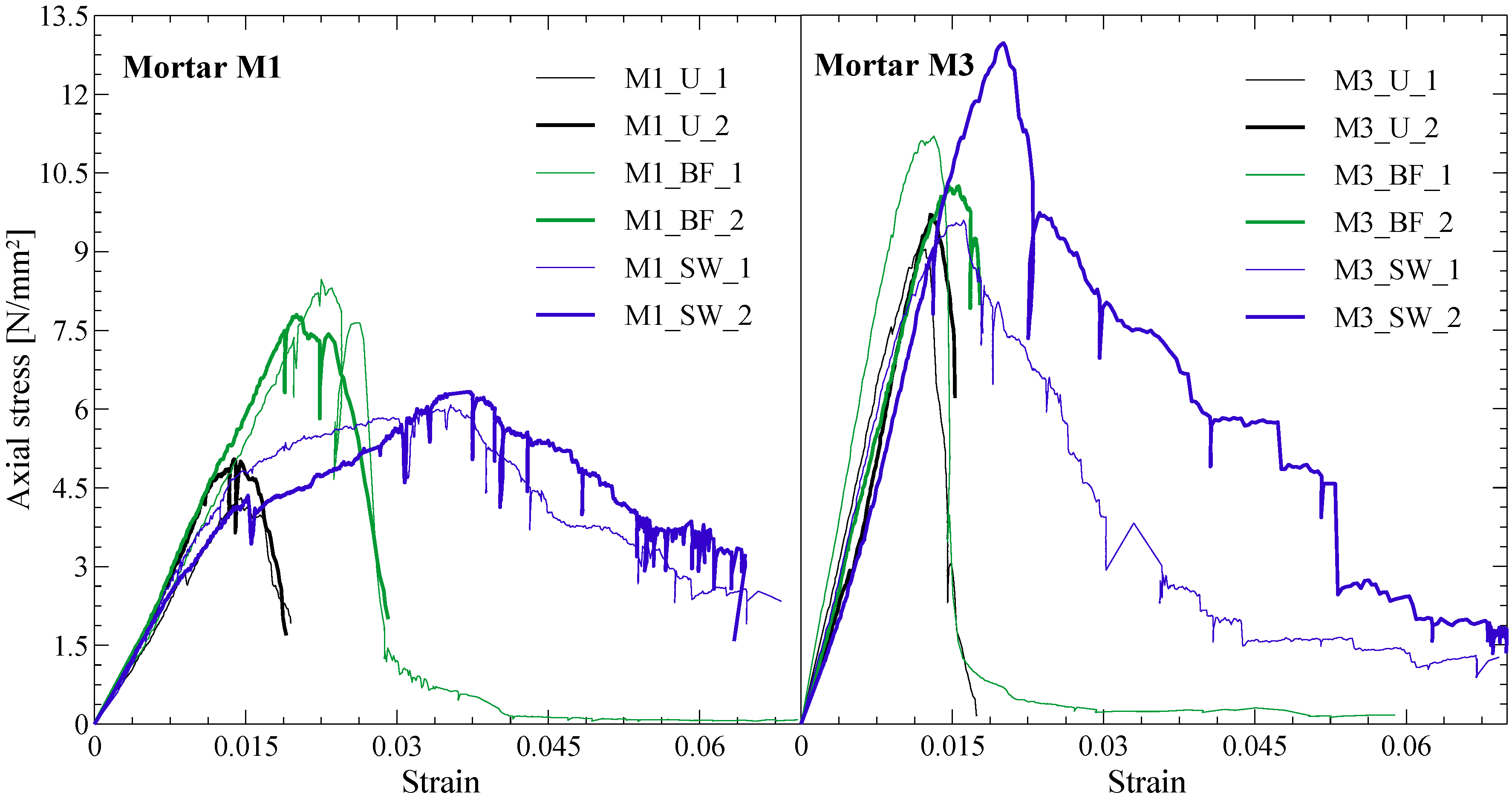

The monotonic stress-strain curves of the control specimens are shown in

Figure 5. Axial stress has been calculated by dividing the axial load by the cross-section area. The axial strain is obtained from the displacement transducer placed between the press plates.

Figure 5 plots the stress-strain curves for unreinforced clay brick masonry columns under axial compression characterized by an ascending branch up to the peak and by a rapidly descending post-peak branch until collapse (brittle failure). The peak stress f

co and the corresponding strain value ε

co are reported in

Table 1 for each control specimen. Similarly, the ultimate or failure values are defined as (

fuo, ε

uo). The conventional ultimate strains were fixed as the strain values at 85% of the maximum stress. Also, the energy absorption capacity (

Eo) measured for all specimens as Σ(dσ·dε) is reported in

Table 1.

It is worth noting that the use of high-grade binding mortars significantly influences the mean value of the maximum stress, ultimate stress and absorbed energy. For these parameters, increases of 101%, 98% and 57% were recorded by adopting the mortar grade M3 instead of M1.

3.2. Reinforced Columns

Table 2 shows the peak and ultimate stress, peak and ultimate strain, and absorbed energy values normalized to those relative to unreinforced specimens. They prove that strengthening by BFRCM wraps or by steel wires can enhance the performance of brick masonry columns with a substantial gain in strength, ductility and energy absorption capacity.

In particular, comparing the key results between reinforced and unreinforced columns (control specimens), the mean strength, ultimate strain and absorbed energy for series M1 increased respectively by 53%, 104% and 239%. In contrast, for series M3, the mean strength, ultimate strain and absorbed energy increased respectively by 16%, 32% and 69%.

In more detail, regarding series M1, the mean values of maximum stress, ultimate strain and absorbed energy increased respectively by 74%, 54% and 167% for BF specimens and by 33%, 154% and 312% for SW specimens. Similarly, for series M3 columns, they increased respectively by 14%, 15% and 45% for BF specimens and by 18%, 48% and 94% for SW specimens.

Concerning the overall effect of the two investigated techniques, an average increase of maximum stress of 44% was achieved for BF specimens, while it was equal to 25% for SW specimens. With reference to the ultimate strain and absorbed energy, observed increases were equal to 35% and 106% for BF specimens and 101% and 203% for SW specimens.

3.3. Failure Modes and Crack Patterns at Failure

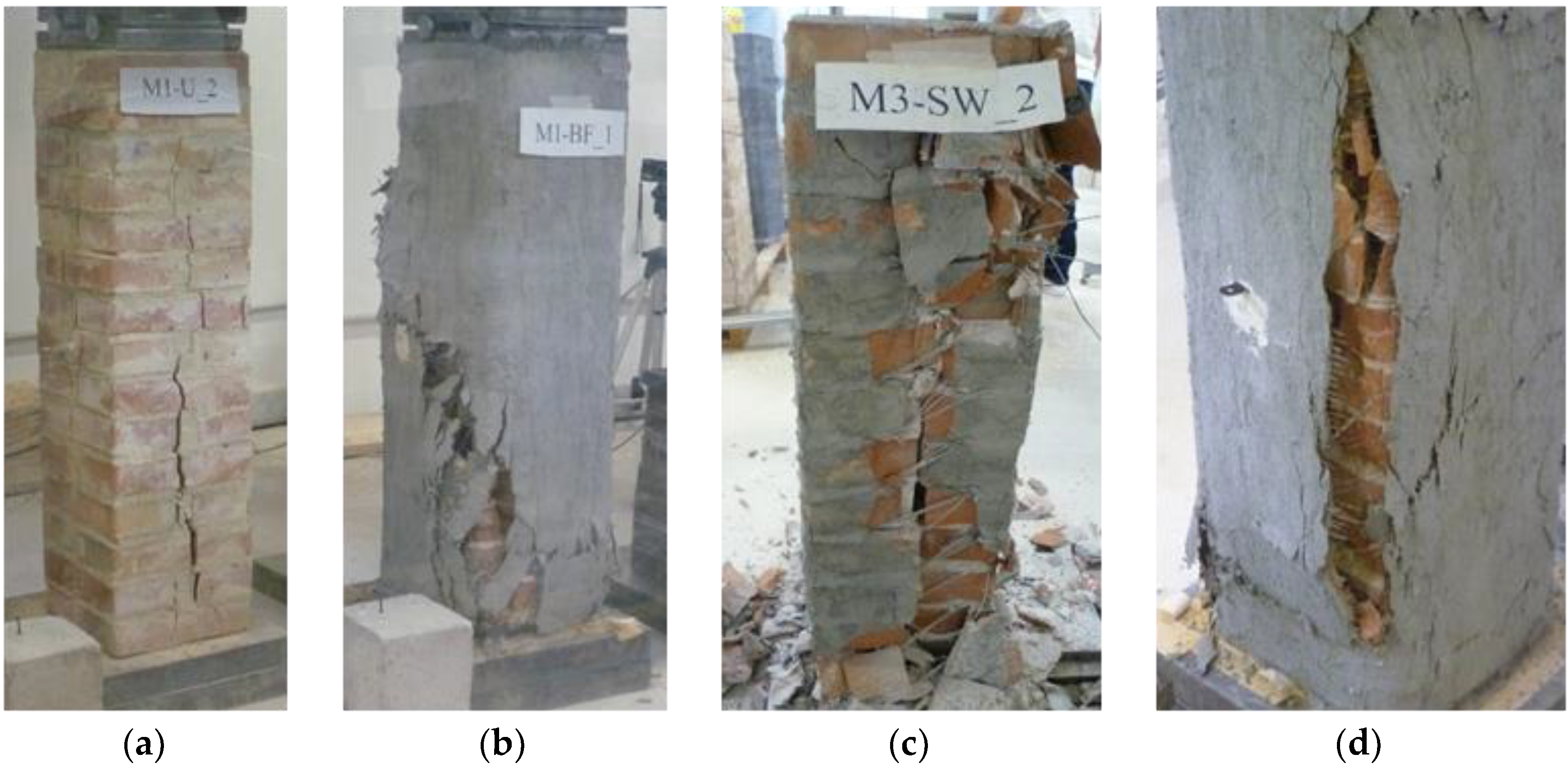

In order to describe and compare the main damage patterns and the failure mechanisms for unconfined and confined columns,

Figure 6 shows the failure mode observed for some specimens.

Unconfined specimens were characterized by brittle failure. In fact, the stress-strain curves of

Figure 5 were characterized by an almost linear ascending branch up to the peak, followed by a rapidly descending post-peak branch until collapse.

Generally, BF specimens behaved monolithically in the first stage, up to a strain value equal to about one-third of the peak strain. During this phase, no crack was observed in the external mortar layer and this load stage corresponded to an initial linear ascending branch of the stress-strain curves of

Figure 5. Afterwards, first cracking of the external layer occurred at the corners and the trend of the stress-strain curves assumed a non-linear shape up to the peak load. Failure of BFRCM-confined specimens occurred with the propagation of a unique fracture plane inclined at about 45 degrees across the mortar joints. Moreover, failure mechanisms occurred suddenly, when the jacket could not restrain the unstable expansion of the clay brick masonry core. In all cases the failure mechanisms were due to the jacket collapse at the corner.

Alternately, the behavior of the SW specimens was characterized by a slow damage process. First cracking occurred for a strain value similar to that recorded for unreinforced specimens. In particular, multiple sub-vertical cracks were observed in the brick units, while mortar joints were restrained by the wires. Progressive rupture of steel wires was also observed in the correspondence of knots and the failure of specimens occurred when all wires failed in one or two mortar joints.