1. Introduction

In view of recent global environmental issues, scientists worldwide have begun to show interest in exploiting the full potential of natural fibers and their diverse uses [

1,

2]. There are plenty of renewable resources obtainable from the plant kingdom [

3,

4], and a vast resource for different natural fibers viz. Jute, Banana, Coir,

etc., which are abundantly available in many parts of world. However, there are still a number of other vegetable fibers which have not been used as textile fibers [

2]. From the plant kingdom, one of the abundant sources of strong natural fiber is “Agave Americana”. Agave Americana fibers are also called “Pita Fibers”. These fibers are cellulosic in nature [

3,

4]. The Agave Americana plant is shown in

Figure 1.

Figure 1.

Agave Americana plant. Illustration courtesy: crop production guide Tamil Nadu Agricultural University, Coimbatore.

Figure 1.

Agave Americana plant. Illustration courtesy: crop production guide Tamil Nadu Agricultural University, Coimbatore.

Common names for Agave Americana are: century plant, maguey or American aloe, which is a species of flowering plant in the family Agavaceae [

3,

4,

5,

6,

7]. The plant is originally native to Mexico, Arizona and Texas but cultivated worldwide as an ornamental plant. It has become naturalized in many regions of the world [

2,

6,

8]. The genus Agave has about 275 species [

9]. Agave blossoms only once during its life time and then dies, but produces suckers or adventitious shoots from the base, which continue its growth [

5,

6,

9]. Agave plants are grown along railway lines, roadsides, and river banks and as hedge plants in dry land areas throughout many regions of the world. To date it has been grown in patches and as a border crop even in neglected conditions [

9]. It has grown naturally, especially in arid and semi-arid climates [

2,

8]. The crop is able to grow on dry soils unsuitable for crop cultivation, and grows vigorously on dry, well drained sandy loam soils [

9].

The leaves are ready for harvesting from the 3rd year onwards and the older leaves with length not less than a meter are harvested. Each plant yields 40–50 leaves/year. The life cycle of the plant is up to 8–30 years [

5,

6,

7,

9,

10]. The content of fiber varies with variety from 2.5%–4.5%. The fiber color varies from milky white to golden yellow [

3,

4,

9], and it has a hard touch due to the existence of lignin on its surface. The yield per hectare of this plant is 300 tons per annum, which gives about 6 tons of fiber [

3,

4].

Agave is a short stemmed plant bearing a rosette about 1.2 m wide of gray-green leaves up to 1.8 m long erect fleshy leaves, each with a spiny margin and a heavy spike at the tip. When it flowers, the spike has big yellow flowers and may reach 2.4 m to 7.6 m in height [

2,

5,

6,

9,

10,

11,

12].

3. Evaluation of Fibers

Agave is noted for its strong and coarse fibers, which are superior and more flexible than Manila hemp [

9]. These natural cellulosic fibers are characterized by high moisture absorbency up to 9%, low-density of 1.36 gm/cm

3 and high tenacity in the range of 16–41 cN/tex. The fibers obtained are flexible, smooth and lustrous and had similar burning characteristics like other known cellulosic fibers [

2]. The fibers contain about 73%–78% of lignified form of cellulose [

9]. Fiber surface is covered with lignin. After removal of lignin from fiber surface, fibers becomes flexible, smooth and lustrous. The fibers are very long with a mean length of 652 mm and coarser with an average linear density equal to 24 tex [

3,

4,

13]. Generally, natural fibers are hydrophilic in nature and this was evident with Agave Americana fiber with a moisture regain and moisture content up to 9%. Agave Americana fibers greatly vary in their properties with grade as well as within the same leaf. These fibers disintegrate when exposed to strong acid and alkalis, but were resistant to weak acids and alkalis [

3,

4,

13].

Each Agave Americana fiber consists of a number of cells, generally referred as ultimates or ultimate cells. The overlapping ultimates are held together with a waxy film to form the filament fibers. This implies that an individual fiber is made up of a complete vascular bundle or group of vascular bundles. The vascular bundle consists of transportation tissue vessels surrounded by a thick sheave of fibers cells. Each ultimate is polygonal in shape and has a lumen. Agave Americana fibers in a leaf consist of both xylem and phloem and various ensheafing cells, found scattered through a leaf pithy matrix. The cells are lignified to a greater or lesser degree and are hard in comparison with soft fibers. The entire fibro-vascular bundle serves as a unit fiber [

23]. The diameter of Agave Americana fibers varies throughout the length and depends on how many ultimates are there in the cross section [

24].

3.1. Fiber Morphology

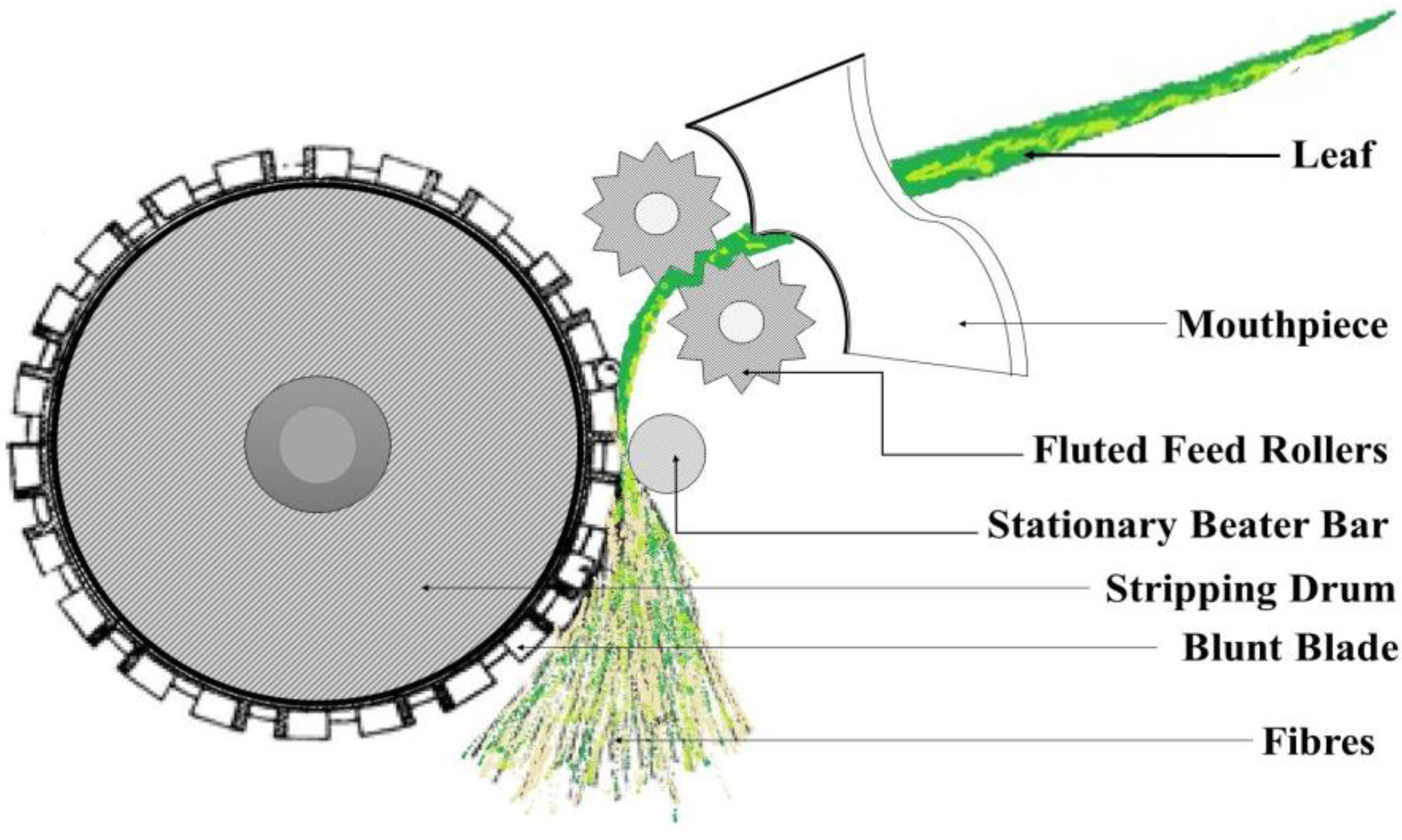

Figure 3 depicts the longitudinal (

Figure 3a) and cross-section (

Figure 3b) views of an agave Americana fiber. By examining Agave Americana fibers with an SEM (Scanning Electron Microscope), we can observe longitudinal streaks which are characteristics of long vegetable fibers. The fiber has a composite structure. Ultimate fibers (

Figure 3c) are held together by sticky and waxy substances such as lignin, pectin and hemicelluloses. The fiber surface is also covered with these substances. Due to this natural coating, Agave Americana fibers present a high resistance when they are exposed to the influence of some external factors like weak chemical agents such as acids and alkalis, as well as to UV (108 h). Agave Americana fibers occur as a technical fiber, having oval and irregular sections with a large lumen and appears as a helical structure of square shape spires. These fibers can be characterized by two parameters: the average length of a spiral side which is about 10.1 μm and the average diameter which is equal to 3.1 μm. The average diameter is very small compared to other natural fibers such as flax, sisal and alfa. This particular structure will be used to explain the mechanical behavior of the technical fibers [

12,

25].

Figure 3.

(a) Longitudinal view of fiber; (b) cross-sectional view of fiber; (c) single elementary fiber.

Figure 3.

(a) Longitudinal view of fiber; (b) cross-sectional view of fiber; (c) single elementary fiber.

3.2. Fiber Length

Agave Americana fibers are somehow longer than sisal fibers. The bundles have a long effective length. If fiber is removed from the full length of leaf sheaths by hand stripping, the fiber strands from the middle sheaths may run as long as 2.8 m.

3.3. Fiber Diameter

The Agave Americana fibers appear as in bundles, which contain many ultimate fibers imperfectly held together by some sticky and waxy substances. The thickness of the fiber when determined using projection microscope, it was in the range of 100–150 µm. Agave Americana fibers are relative thick fiber as a result of the numerous cell ultimates that form the fiber bundle [

14].

3.4. Moisture Absorption Properties

The fiber shows hydrophilic properties. This fiber absorbs more water than its own weight. Moisture content as well as moisture regain of Agave Americana fiber is found to be around 8%–9%, which is comparable to other cellulosic fibers [

1,

13].

3.5. Visual and Hand Evaluation

In visual and hand evaluation of Agave Americana fibers, the observation of fiber shape, color, surface texture are visually evaluated [

14].

3.5.1. Physical Shape

The fiber is long, round and generally taper to a point, having one side thicker. The fibers from the lower side of the leaf are particularly finer.

3.5.2. Color

The color of the Agave Americana fiber ranges from off-white to yellowish, which is depending upon the processing technique and the processing time used for fiber extraction. The retted fiber was darkened, which can be discolored with a naturally looking light brown color, which is due to bacterial action.

3.5.3. Luster

The fibers are semi dull in appearance and one has a reason to believe that this is due to the fact that they have the uneven surface and cross-sectional shape. A fiber with an irregular cross-section scatters light in all directions, resulting in a dull appearance with few high lights. Whereas properly extracted fibers appear lustrous.

3.5.4. Texture

The fiber feels strong and durable. The dry Agave Americana fiber is stiff, harsh, coarse and hard-surfaced, which is typical characteristic of all the leaf fibers. However when fibers are wet, they become flexible, smooth and slippery.

3.6. Burning Test

When the fiber sample was brought near the flame, it burnt brightly. In the flame the fiber continued burning readily with a yellow-bright flame and continued burning even after removal of flame. The smell of burning Agave Americana fiber is like burning paper. Agave Americana fiber becomes very fragile when exposed to high temperature of up to 108 °C. The burning behavior of Agave Americana fibers is similar to that of other natural cellulosic fibers [

13].

3.7. Tensile Properties

3.7.1. Mechanical Behavior

Tenacity of Agave Americana fiber is in the range of 16–41 cN/tex. The elongation of fiber at rupture is in the range of 2%–4%. This implies that Agave Americana fiber can perform well where instantaneous forces act on the fibers during the use of end product. Higher values of tensile properties of these fibers indicated that it is strong enough to be a textile fiber. It is thought that its strength is due to high degree of cellulose polymerization and crystallization processes that may be due to many years of growth. This tensile strength implies that Agave Americana fiber can function well for furnishing fabrics, carpets, floor mats, rugs, upholstery fabrics as well as in nonwovens and fiber reinforced composites.

The tensile properties of Agave Americana fiber are not uniform. This can be explained by the fact that it is a natural fiber and natural fibers are subject to growth irregularities to the extent that fibers from the same plant are not uniform in size and properties. The outer leaf sheaths produce the strongest fibers while the inner sheaths produce the weakest fibers. The innermost fibers have a high fracture strain while the peripheral fibers have lower tensile strength [

14,

26]. The outermost fibers have more elongation before breaking than inner fibers. The fibers are difficult to extend. This means Agave Americana fiber is rigid and has low elongation. The fiber is having lower elongation at break values. Therefore the end product manufactured using this fiber will be rigid one. The wet strength of fiber is lower than that of dry fiber. However, elongation of the break is higher when the fiber is in wet conditions [

14,

16].

Table 1 exhibits the comparison of mechanical properties between textile fibers.

Table 1.

Comparison of mechanical properties between textile fibers.

Table 1.

Comparison of mechanical properties between textile fibers.

| Fibers | Tenacity (cN/tex) | Strain (%) | Initial modulus (N/tex) | Work fracture (mN/tex) |

|---|

| Agave Americana | 21–41 | 2–4 | 0.2–1.45 | 7.7–25.4 |

| Sisal | 40–49 | 2–3 | 25–26 | – |

| Flax | 25–26 | 2.7–3.3 | 18 | 8 |

| Jute | 29–56 | 1.2–1.9 | 17.2 | 2.7 |

| Cotton | 28–48 | 3–10 | 5 | 10.7 |

| E Glass | 82 | 2.5 | 29.4 | 9.8 |

| Polyester (HT) | 61 | 7 | 13.2 | 22 |

3.7.2. Rupture Behavior

The fiber is more or less cracked depending on the elongation and this phenomena generates the deformation of the elementary fibers in a bundle.

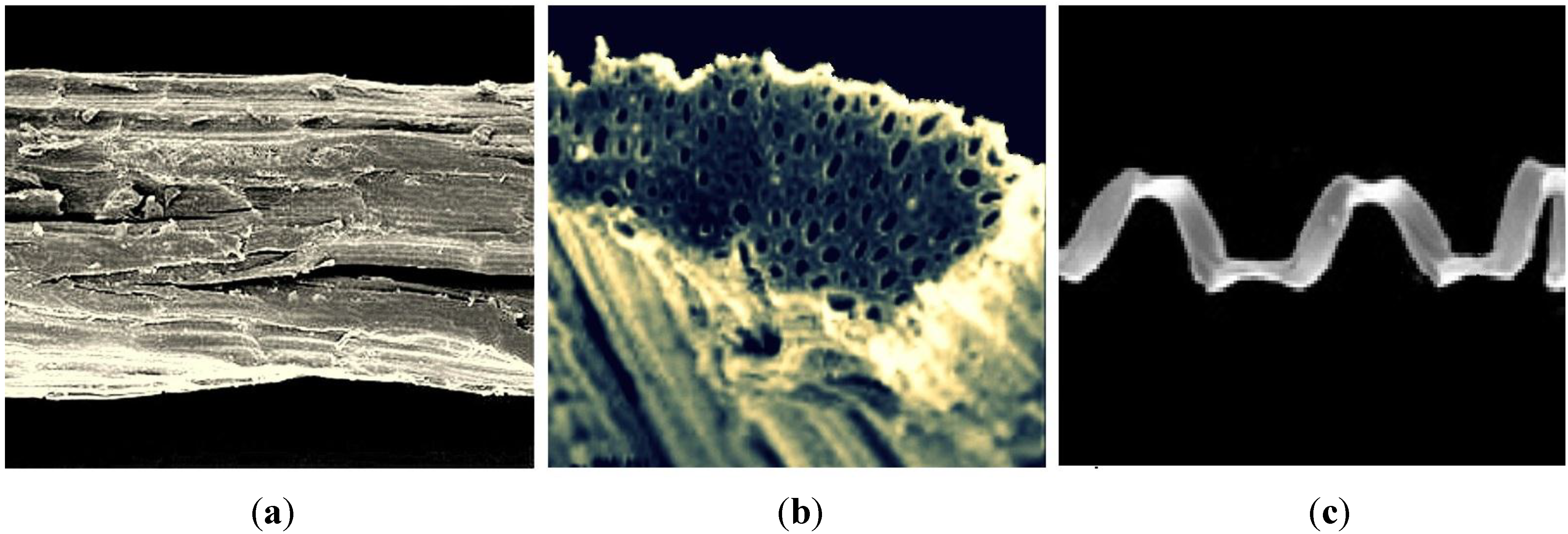

Figure 4 shows different levels of deformations of Agave Americana fibers. At small deformations (

Figure 4a), corresponding to elastic behavior, the lignin carries the applied load without passing it to the elementary fibers. Hence we can say that at small deformations, physical and mechanical properties of technical fiber are related to physical and mechanical properties of wax and gummy matter that link elementary fibers. At medium deformations (

Figure 4b),

i.e., viscoelastic deformation, the elementary fibers begin to switch on without being really deformed.

Figure 4.

Agave Americana fibers deformed at different levels. (

a) Small deformation; (

b) medium deformation; (

c) high deformation. Adapted from [

26]. Copyright NASA, 2007.

Figure 4.

Agave Americana fibers deformed at different levels. (

a) Small deformation; (

b) medium deformation; (

c) high deformation. Adapted from [

26]. Copyright NASA, 2007.

The spring form of the elementary fibers is responsible extension behavior of fiber at this stage. At high deformation (

Figure 4c) corresponding to plastic deformation, elementary fibers begin to be deformed until the rupture. Mechanical behavior of technical fiber of Agave Americana fiber is highly related to its fine structure. At high deformation, physical and mechanical properties are related to the properties of elementary fibers. In the rupture zone, the resistance of elementary fibers, their number, their dispersion and their adhesion to the natural matrix (lignin) explain the behavior of technical fiber [

26].

3.8. Chemical Properties

3.8.1. Chemical Composition

Agave Americana fibers can be considered as naturally occurring composites consisting mainly of cellulose fibrils embedded in a lignin matrix. The main constituents of these fibers are cellulose, lignin and hemicellulose. However constituents like pectin, waxes, water-soluble substances,

etc. are also present in small quantities. The chemical composition of natural fibers like Agave Americana depends on various factors such as type of soil used, weather conditions, age of the plants,

etc. The property of each constituent contributes to the overall properties of the fiber.

Table 2 exhibits the chemical composition of Agave Americana fibers [

1].

Table 2.

Chemical composition of Agave Americana fibers.

Table 2.

Chemical composition of Agave Americana fibers.

| Composition | Amount (%) |

|---|

| Cellulose | 68–80 |

| Hemicellulose | 15 |

| Lignin | 5–17 |

| Wax | 0.26 |

| Moisture | 8 |

3.8.2. Effect of Different Chemicals on Agave Americana Fibers

Agave Americana fibers are stable in weak acids and weak alkalis, and has no effect on structure and tenacity of Agave Americana fibers. Therefore these fibers can be safely treated with bleaches, detergents and dyes which are weak basic or weak acidic in nature. However, in strong acids and strong bases, fibers were dissolved or distorted. The bonds connecting the subunits (

i.e., ultimate fibers) are unstable to acid, which leads to loss in tensile strength of fibers. Reaction with concentrated sodium hypochlorite results in the bleaching of fibers, but after prolonged exposure, the fiber looses its strength and disintegrates. This indicates that oxidizing solutions like sodium hypochlorite should only be used when cold, diluted and according to instructions given by the manufacturer. Therefore, chlorine bleaches should be used for a short period of time and must be rinsed out thoroughly to avoid further damage to the fiber [

13].

4. Applications of Agave Americana Fibers

Agave Americana fibers exhibit high tensile strength and have low density. Because of this, historically, they were used in manufacturing twines and ropes for fishing and agricultural purposes. Further, these fibers can be used for the production of nets, carpets, rugs, doormats, bags, sacks, fish stringers, furniture webbing, drapes, upholstery padding, saddle pads, cushion stuffing, brush brittles, baskets, bracelets, headbands, sandals, decorative items, clothing and other woven objects. Papers also have been made from lower grade Agave Americana fibers. Agave Americana fibers are also used for embroidery of leather in a technique known as piteado [

3,

4,

5,

6,

9,

12,

13].

Research findings showed that Agave Americana fiber can also be utilized for other industrial purposes. There can be a potential application of Agave Americana fibers in composites as well as in nonwovens. Bio-plastics, geotextiles, carpets, fiber boards, dart boards and molded furniture can also be manufactured using Agave Americana fibers [

12,

14,

27,

28].