Use of Fiber-Reinforced Cements in Masonry Construction and Structural Rehabilitation

Abstract

:1. Introduction

Scope and Goal of This Paper

2. Background on FRC and FRM

2.1. Why Are Fibers Used in Cementitious Materials?

2.2. Important Factors Affecting the Performance and Characteristics of FRCs

- Base matrix characteristics: matrix composition, aggregate size, strength;

- Fiber characteristics: fiber type (elastic modulus, strength, surface bonding characteristics) and fiber size (length, diameter, and their ratio, i.e., fiber aspect ratio);

- Composite mixture characteristics: fiber content, distribution, and orientation.

- Low volume fraction (less than 1%) is used to reduce shrinkage cracking primarily in slabs and pavements.

- Moderate volume fraction (between 1% and 2%) is used in structures that require increased energy absorption capability. At this volume fraction, the fibers increase the modulus of rupture, fracture toughness, and impact resistance of the FRC.

- High volume fraction (greater than 2%) also known as high-performance or ultra-high-performance FRC. The increased amount of fibers in these mixtures requires the addition of admixtures to achieve practical workability of the material.

- Macro fibers are reinforcing fibers with lengths varying from 0.5 to 2.5 inches (12.7 to 63.5 mm).

- Micro fibers are defined as reinforcing fibers with lengths less than 0.5 inches (12.7 mm or smaller).

- -

- According to Banthia and Soleimani [19], hybrid fiber reinforced concrete specimens exhibit flexural strength greater than conventional FRC mixtures and plain concrete.

- -

- Sorelli et al. [20] illustrate that both the crack control and flexural strength characteristics of structural members can be improved using steel fibers of two different sizes.

- -

- Lawler et al. [21] carry out a study combining steel macro fibers paired with steel or polyvinyl alcohol fibers and conclude that the combination of macro and micro fibers increases the flexural strength, crack control performance, tensile capacity, toughness, and resistance to fluid infiltration beyond what can be achieved by FRC incorporating only one size of fiber.

3. Summary of the Author’s Research on the Use of FRM in Masonry Applications

3.1. FRM as Joint Reinforcement in Traditional Masonry

- Positive effects resulting from the addition of fibers to the mortar would be more pronounced in weaker base matrices. Higher lime content means less cement in a cement-lime-sand mortar mixture and results in weaker mortars.

- In these projects, the underlying scope was the potential use of FRMs in scenarios of rehabilitation or reconstruction of existing masonry structures. If FRM is to be considered for improving mortar strength in the rehabilitation of masonry, the binding matrix should be compatible with the original mortar mixture.

- (1)

- Compatibility of chemical properties: The binding matrix of the new mortar should be similar to the original mortar in composition to ensure mechanical and chemical characteristics that are compatible with the existing structure. Banfill and Forster [22] suggest that modern materials and repair techniques applied to historic buildings can cause deterioration due to the difference in permeability between historic mortars and modern mortars. For example, if the original matrix is lime based, the less porous cement mortar resists the transport of moisture through the masonry that in some cases may lead to deterioration. In the field, this is also considered the older structure’s “breathing”. The new cement-based mortars do not “breathe” as much; they “seal” the walls in a different way and may cause molding or other issues, as the moisture inside is no longer able to escape through the joints. While this may be fine for a newer structure where the sealed joints are taken into account by other means, such as cavity walls, it creates a “new” problem for the renovated structures.

- (2)

- Compatibility of Mechanical Properties: Masonry is a heterogeneous material in that the overall strength of the wall is affected by the strength of mortar, strength of blocks, and the thickness of mortar joints. As such, it is important to keep in mind the strong unit, weak mortar philosophy of masonry design. In rehabilitation projects, since repairing the mortar is easier and more economical than replacing masonry units, the compressive strength of the mortar should not be increased excessively during repair [6]. According to Johnston [3], fibers do not directly affect the compressive strength of the mortar. However, we found out that in some cases, as cracks develop parallel to the loading axis due to lateral dilation of the masonry wall under uniaxial loading, fiber-reinforced elements may exhibit an increase in strain capacity due to their ability to resist these cracks. However, the inclusion of micro fibers is also shown to reduce the compressive strength of the mix relative to plain mortar due to increases in the air content of the mixture. This means there is a reason for the mortar strength to both increase and decrease due to existence of fibers in the mortar. As will be discussed later, the author’s observation on this topic is that any increase in the compressive strength of mortar due to addition of fibers is not significant unless a relatively large percentage of larger fibers is utilized. Therefore it is possible to maintain the weak mortar-strong unit balance with FRMs.

- (3)

- Aesthetic Compatibility: There are two common conservation and retrofit philosophies when historical structures are concerned. One suggests that the new materials should attempt to match the appearance of the existing materials as much as possible to preserve the overall building aesthetic, while the other suggests that the new materials should be clearly identifiable to the observers. In the author’s experience, relatively newer structures with or without historical value tend to fall into the first category. In such cases, reinforcing fibers can be added to practically any binding matrix without any effect on the appearance. Furthermore, sophisticated mortar tinting solutions are commercially available, so it is possible to match the FRM aesthetic to a wide variety of existing structures. The interactions of different fibers within different matrices, however, should always be studied before a mixture is used on an existing structure.

| Mixture | Fiber type | Fiber % | Specimen | F’c (psi) | fr (psi) |

|---|---|---|---|---|---|

| 1 | None | 0 | 24 in beam | 900 | 234 |

| 2 | PVA 18 mm | 1.2 | 24 in beam | 630 | 206 |

| 3 | PVA 8 mm | 0.6 | 24 in beam | 780 | 323 |

| 4 | PVA 6 mm | 0.6 | 24 in beam | 970 | 434 |

| 5 | PVA 18 mm + PVA 8 mm (hybrid) | 1.2 | 24 in beam | 1370 | 557 |

| 6 | PVA 18 mm + PVA 6 mm (hybrid) | 1.2 | 24 in beam | 800 | 437 |

| Mixture | Fiber type | Fiber % | Specimen | fr (psi) | Modified fr (psi) (using a coefficient of 3.33) |

|---|---|---|---|---|---|

| 1 | None | 0 | small specimen | 87 | 290 |

| 2 | Nano | 0.25 | small specimen | 69 | 230 |

| 3 | Nano | 0.5 | small specimen | 78 | 260 |

| 4 | PVA 6 mm | 0.25 | small specimen | 91 | 303 |

| 5 | PVA 6 mm | 0.5 | small specimen | 122 | 406 |

| 6 | PVA 8 mm | 0.25 | small specimen | 109 | 363 |

| 7 | PVA 8 mm | 0.5 | small specimen | 143 | 476 |

| 8 | Nylon 6 mm | 0.25 | small specimen | 77 | 256 |

| 9 | Nylon 6 mm | 0.5 | small specimen | 107 | 356 |

| 10 | Horse hair | 0.25 | small specimen | 69 | 230 |

| 11 | Horse hair | 0.5 | small specimen | 62 | 206 |

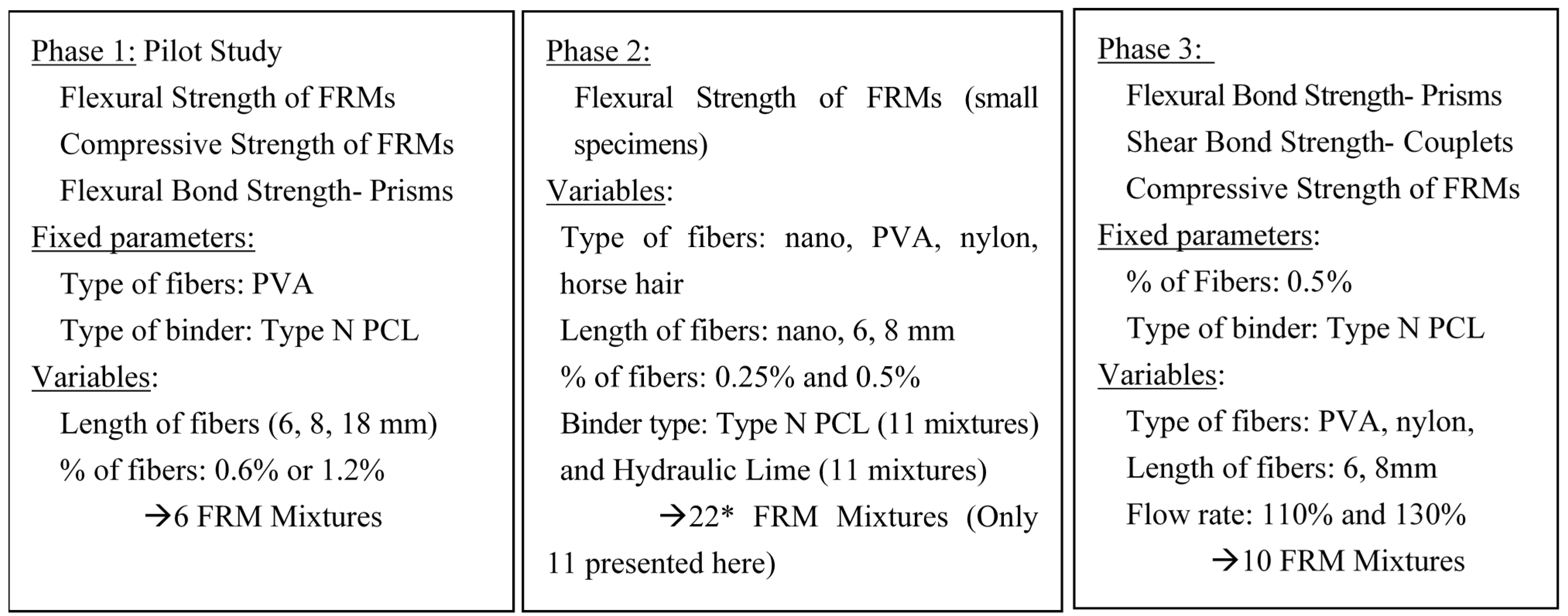

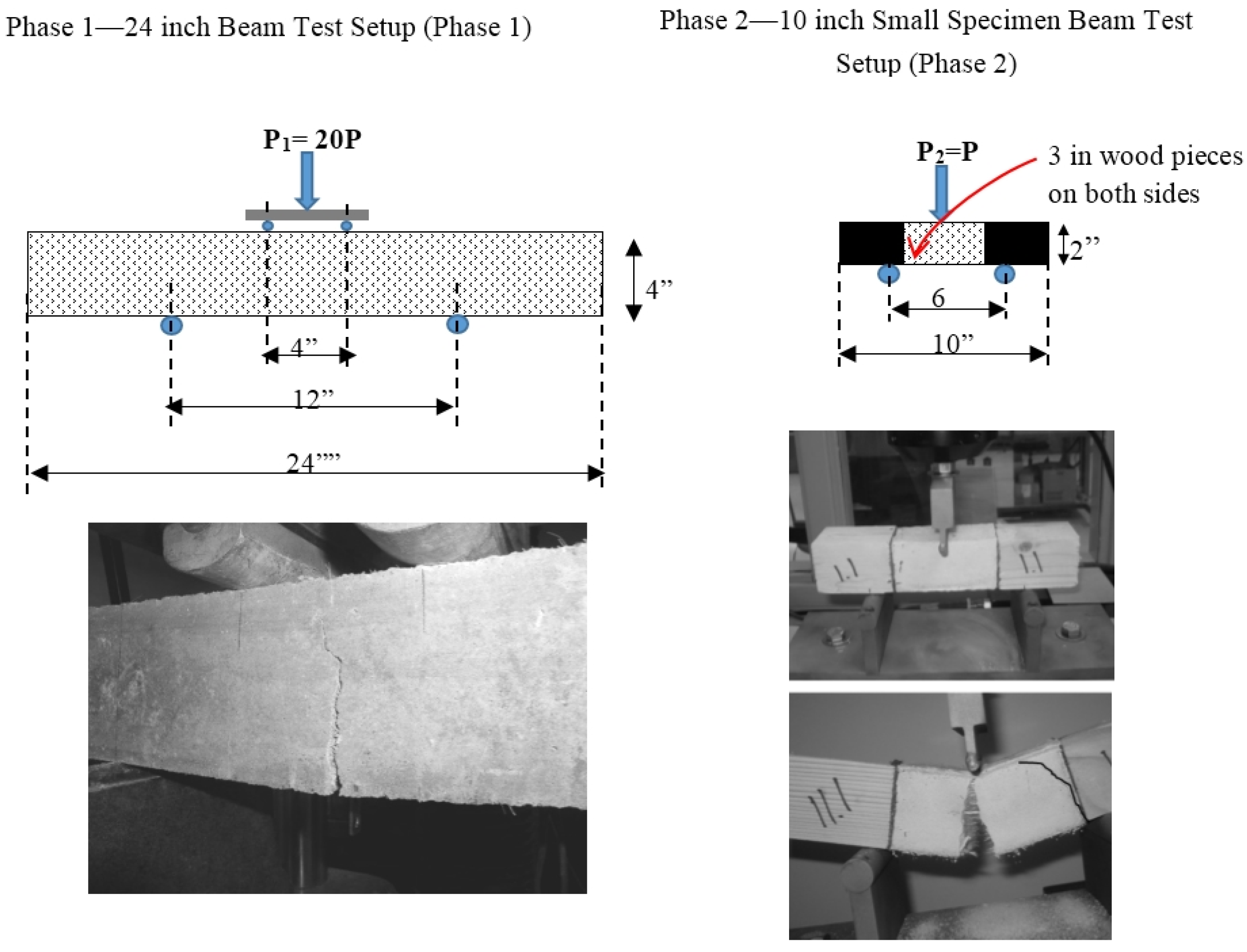

- Phase 1 proved the hypothesis that there will be a significant improvement in flexural strength of relatively weak PCL mortar mixtures by addition of fibers, and led to the following observations and suggestions:

- ○

- As presented in Skourup and Erdogmus [6], ductility and toughness were also both improved by addition of fibers.

- ○

- When looking at the compressive strength test results in Phase 1 (Table 1), hybrid macro-18 mm micro fiber mixtures could potentially be too much (Mixture 5), in that the strong unit-weak mortar balance may be negatively affected. Because Mixture 5 was also the least workable, it is not recommended for further consideration.

- ○

- Both increases and decreases are recorded in compressive strength when fibers are added. It is suggested that the decrease in strength happens due the increases in the air content of the mixture relative to plain mortar, while the increase in strength happens due to fibers oriented horizontally stitching the micro-cracks caused by internal tensile stresses that occur as the test specimens dilate laterally during compression testing.

- ○

- A useful general recommendation from Phase 1 was that micro fibers (rather than macro or hybrid fibers) at a 0.6% or lower volume fraction are better for masonry applications when all tested parameters (workability, modulus of rupture of FRM, compressive strength of FRM, and flexural strength of prisms) are considered.

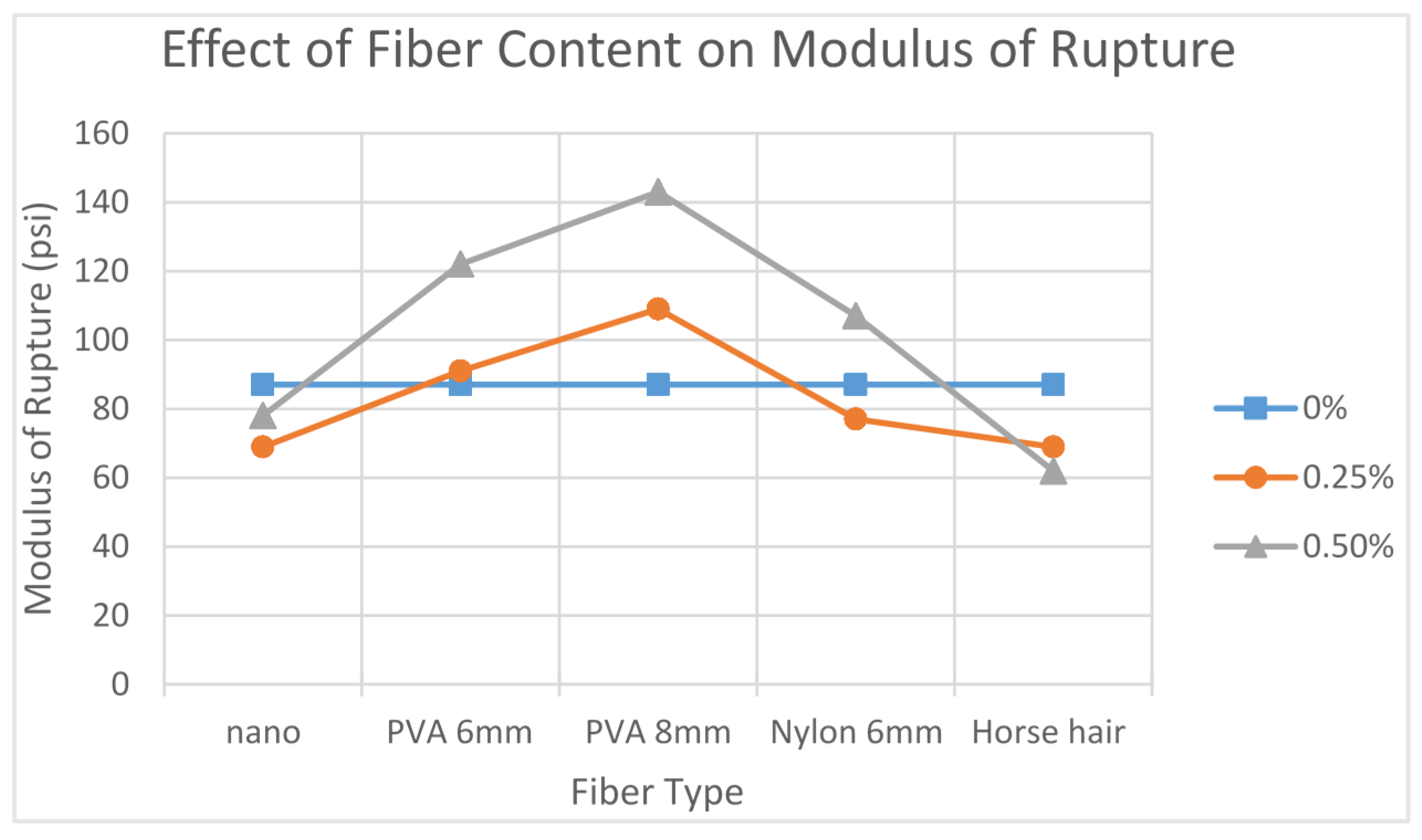

- Phase 2 built upon the first phase and considered the following: only micro fibers or smaller (nano) at volume fractions of 0.5% or less. Since Phase 2 also included more variables, so the effects of these parameters could be individually studied. Figure 3 shows the effect of fiber content and fiber type on the modulus of rupture of FRMs, and the resulting observations are summarized below:

- ○

- Nano fibers do not provide any benefits to the FRM. These small fibers almost identical in size to the cement particles and reduce the strength of the mixture by breaking bonds between hydrates.

- ○

- Likewise, horse hair fibers are ineffective for FRMs. The cause of this is determined to be the smooth and oily texture of the fibers resulting in pull-out at the failure surface instead of stitching the cracks.

- ○

- All other fiber lengths, percentages, and types (except 6mm nylon fibers at 0.25%) increase the flexural strength of FRMs.

- ○

- The optimal mixture for the flexural strength of FRM among all those considered in Phase 2 is that with 8 mm PVA fibers at a 0.5% volume fraction.

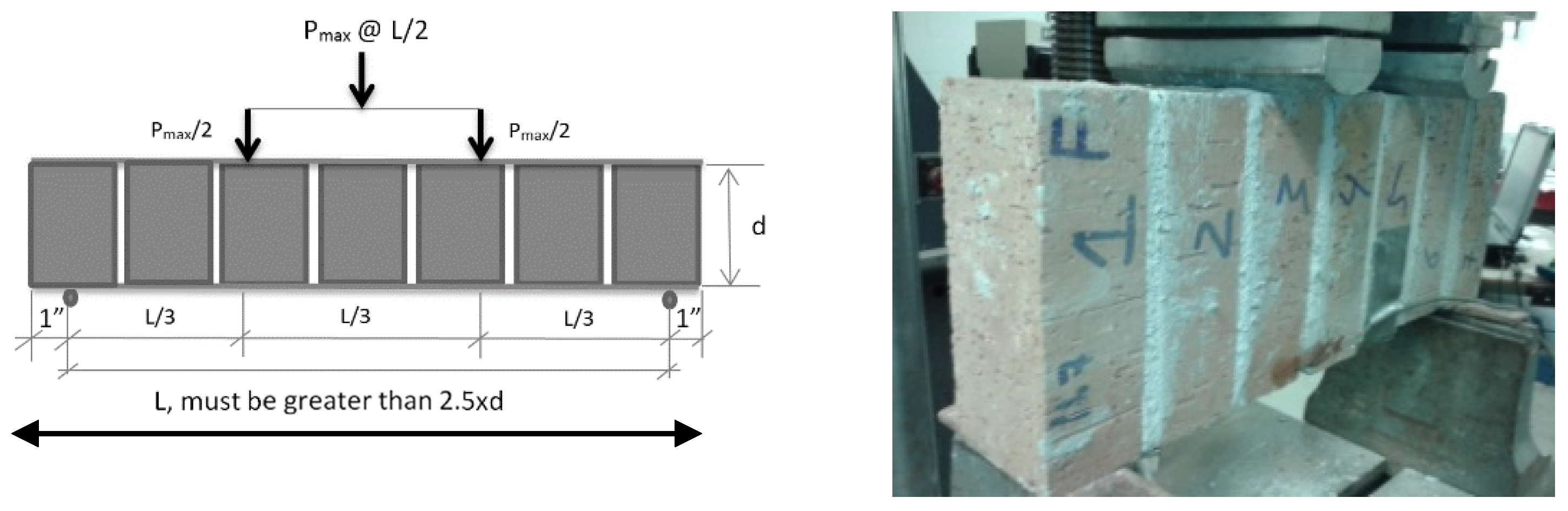

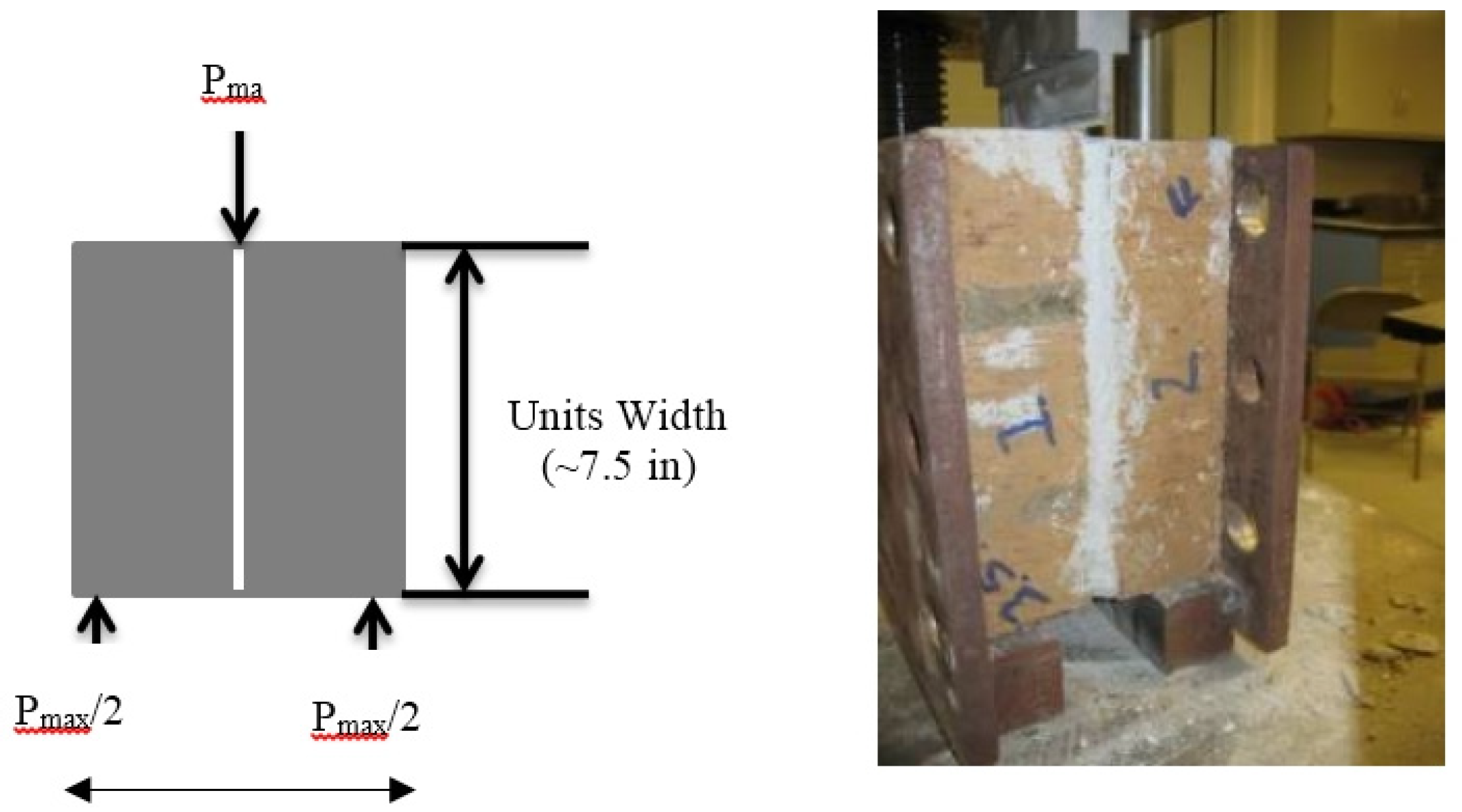

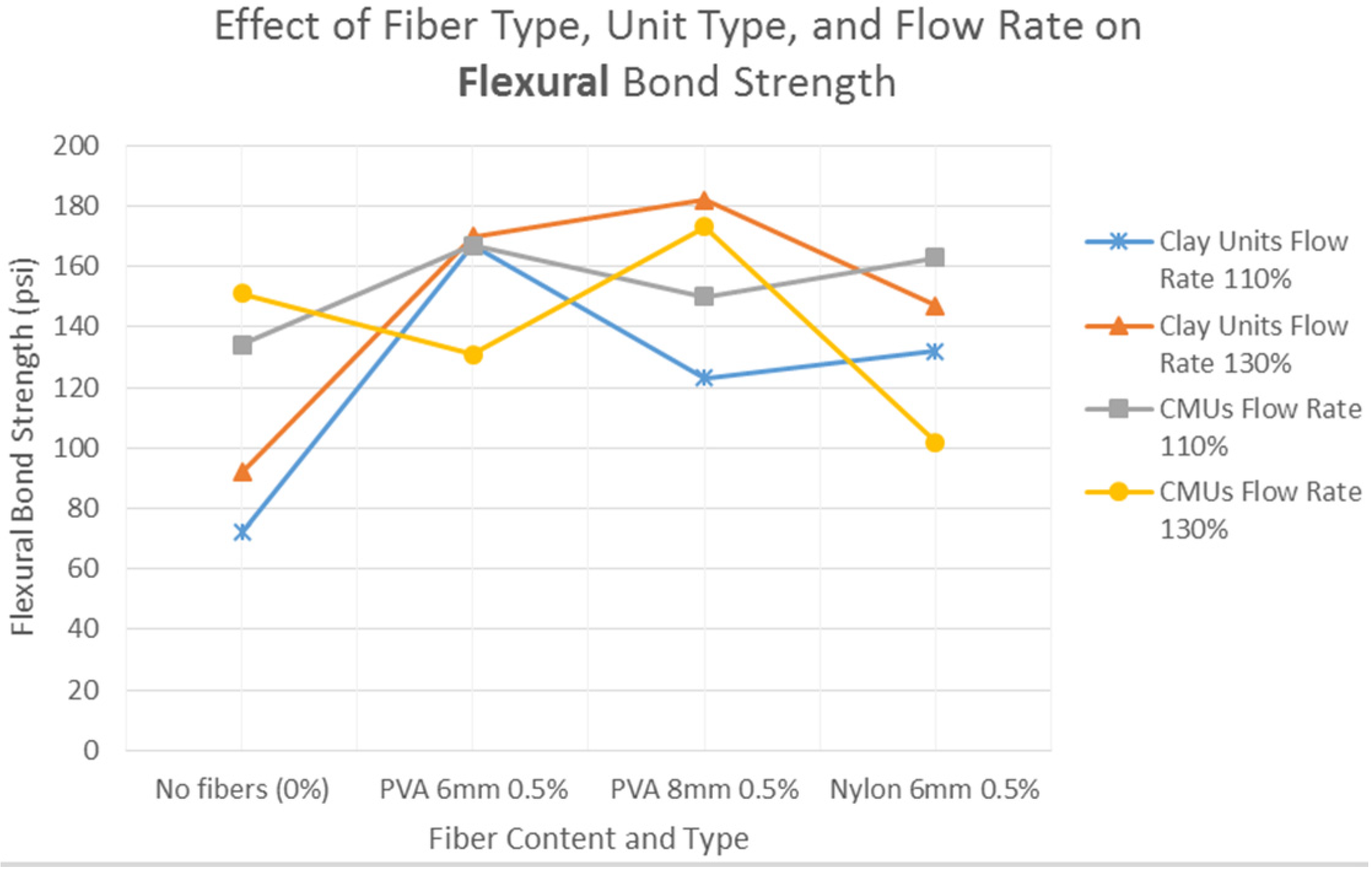

- Observations on flexural bond strength results (Figure 6):

- ○

- In general, clay units perform better with high water content (target flow rate 130%) mortars. CMUs did not present as consistent a relationship between water content and fiber use.

- ○

- With clay units, at both 110% and 130% target flow rates, the flexural bond strength of FRMs were always greater than that of control specimens with no fibers in the mortar. It can be suggested that to keep the flow rate constant while adding fibers, one has to add more water, and as a result, the more absorptive clay units (compared to CMUs) and the mortar form a stronger bond. The fact that all of the 130% target flow rate values are higher than those of the 110% values also supports this argument.

- ○

- With CMUs, at 110% target flow rate, addition of fibers always improved the flexural bond strength when FRMs are compared to the control mixture. However, at 130% flow rate, two out of three FRMs resulted in lower flexural bond compared to the control (no fiber) mortar. Only the FRM with 8 mm PVA fibers (at 0.5% fraction) presented improved flexural bond strength compared to the control mixture. While further research is needed, one explanation may be that the slightly longer fiber may be absorbing more water causing a drier mixture and improving the bond with CMUs.

- ○

- At 130% target flow rate, the FRM with 8 mm PVA fibers showed the greatest increase in flexural bond strength both with clay units and CMUs, and therefore may be suggested as the optimal fiber type and length for this FRM water content.

- ○

- At 110% target flow rate, the FRM with 6 mm PVA fibers showed the greatest increase in flexural bond strength, both with clay units and CMUs, and therefore may be suggested as the optimal fiber type and length for this FRM water content.

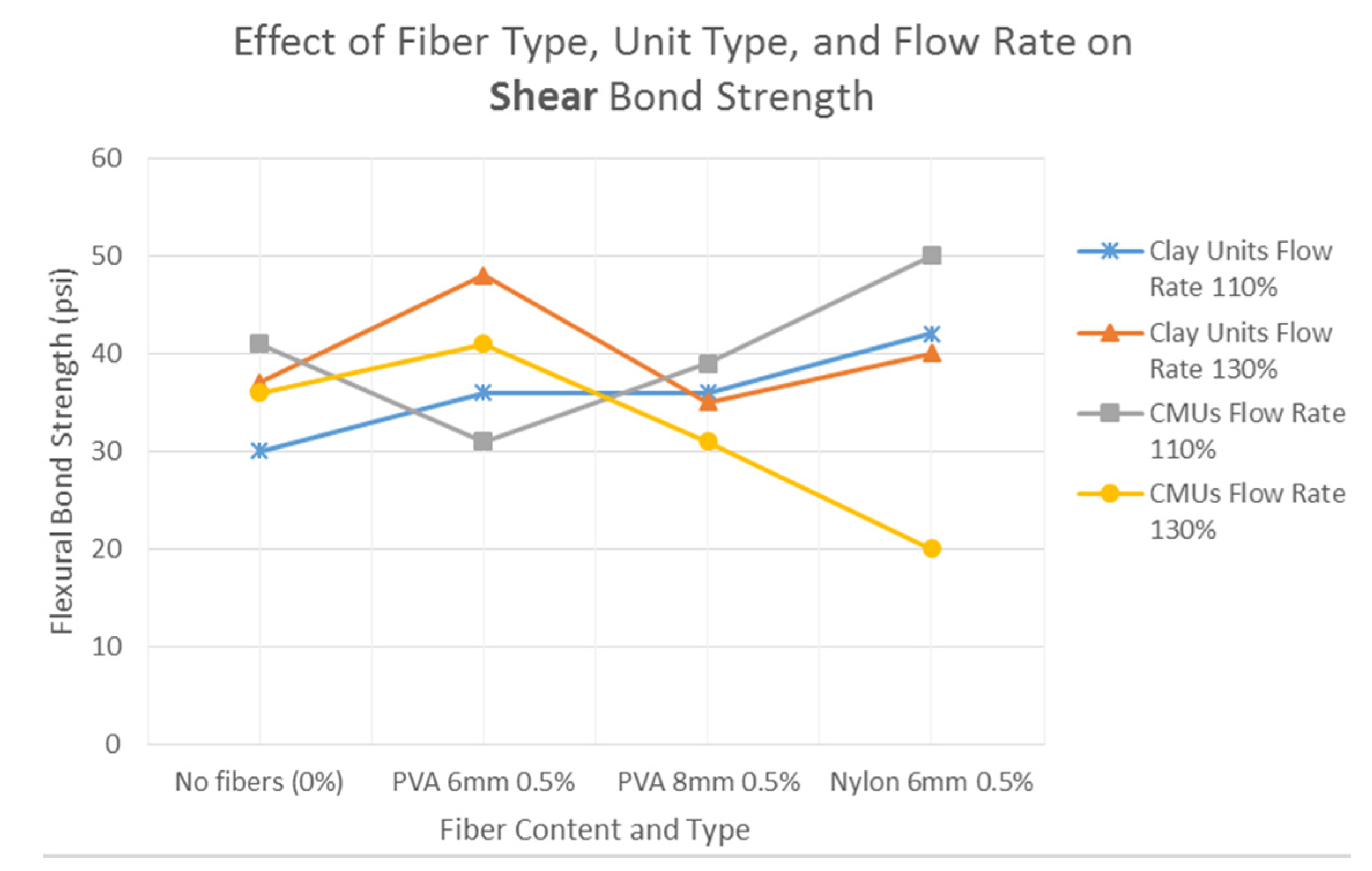

- Observations on shear bond strength results (Figure 7):

- ○

- With clay units, at 110% target flow rate, the shear bond strengths of FRMs were always greater than those of control specimens with no fibers in the mortar. This finding is similar to that concerning flexural bond strength. At 130% target flow rate, both 6 mm PVA and 6 mm nylon fibers resulted in increased shear bond strength, while 8 mm PVA fibers resulted in reduced shear bond strength. While this suggests shorter lengths are more optimal, it should also be noted that another indirect variable between the two mixtures is the actual amount of fibers.

- ○

- With CMUs, at 110% target flow rate, i.e., drier mixtures, the addition of fibers seem to break bond in shear for both PVA fibers. Only an increase in capacity is observed for 6 mm nylon fibers. At 130% target flow rate, only 6 mm PVA fibers improved shear bond strength.

- ○

- In general, shear bond strength results are not as consistent as those for flexural bond. However, 6 mm fibers demonstrated the best performance with both units. Specifically, 6 mm PVA fibers at 130% flow rate with clay units and 6 mm nylon fibers at 110% flow rate with CMUs showed the greatest increase in capacity. Most likely this has to do with the individual absorption characteristics of the two different types of fibers.

3.2. Use of Fiber-Reinforced Composites in Earthen Masonry Construction

3.2.1. Effect of Stabilization and Inclusion of Recycled Plastic Fiber Reinforcement on Flexural and Tensile Strength of Earth Blocks

| Specimen ID | Description | Flexural strength (psi) | Compressive strength (psi) |

|---|---|---|---|

| 1 | Un-stabilized, no fibers (Control) | 45 | 228 |

| 2 | 6% cement stabilized, no fibers | 90 | 712 |

| 3 | 6% cement stabilized, 0.5% fibers | 84 | 680 |

| 4 | 9% cement stabilized, no fibers | 144 | 1517 |

| 5 | 9% cement stabilized, 0.5% fibers | 122 | 1539 |

3.2.2. Effect of Inclusion of Recycled Plastic Fiber Reinforcement on Water Resistance of Earth Blocks

| Specimen description | Block ID | Percent cement by weight (%) | Percent fiber by weight (%) | Water to binder ratio | Water absorption (%) | Average surface erosion (in/min) |

|---|---|---|---|---|---|---|

| Control | CEB | 0 | 0 | 0.25 | N/A | N/A |

| Cement stabilized | CSEB(5) | 5 | 0 | 0.25 | 13 | 0.01 |

| CSEB(8) | 8 | 0 | 0.25 | 11 | 0.001 | |

| CSEB(10) | 10 | 0 | 0.25 | 10 | 0.0011 | |

| CSEB(15) | 15 | 0 | 0.25 | 9 | 0 | |

| Cement stabilized & PET fiber reinforced | FCSEB(5) | 5 | 0.25 | 0.20 | 16 | 0.0063 |

| FCSEB(8) | 8 | 0.25 | 0.20 | 15 | 0.0046 | |

| FCSEB(10) | 10 | 0.25 | 0.20 | 12 | 0 | |

| FCSEB(15) | 15 | 0.25 | 0.20 | 14 | 0 |

- (1)

- Un-stabilized (CEB) samples eroded quickly when soaked in water during the absorption tests, proving these particular CEBs inappropriate to be used in highly wet climates. Part of this is due to prevalence of a special type of clay, i.e., dispersive clay, in Nebraska soil utilized in this sub-project. This type of clay is highly unstable under water.

- (2)

- Cement stabilization indeed stabilizes the blocks, and helps with the negative effects of dispersive clays.

- (3)

- Cement stabilization is observed to reduce the water absorption of compressed earth blocks by 1% on average, while addition of fibers increase the water absorption by 2% on average. All specimens without fibers met the water absorption requirement suggested by International Labor Organization with less than 15% absorption rate. FCSEBs met the requirements only with 10% and 15% cement stabilization, and not with 5% and 8% stabilization. As such, it can be concluded that when 0.25% of PET fibers are added to the earth blocks, the cement percentage should be kept at 10% or higher.

- (4)

- All 24 specimens tested for surface erosion met the requirements, and none of the blocks recorded erosion greater than 0.04 in/min, which was designated as an upper limit by Obonyo et al. [35]. Cement stabilization contributed to the reduction of surface erosion, with 0.1% reduction per percent of cement addition.

- (5)

- After conducting the experiments presented in this project and reviewing the related literature, the following recommendations can be made:

- Un-stabilized earth blocks (CEB) are not appropriate for water-prone areas. A minimum of 8% cement stabilization is suggested when dispersive clays are prevalent.

- PET fibers (at 0.25% fraction) increase the absorption rate of CSEB, but the absorption rate stays at acceptable levels when the blocks are stabilized with a minimum of 10% cement content.

- At 10% cement stabilization without fiber reinforcement, there was zero penetration of water in the surface erosion test and only a 10% absorption rate. These blocks are a good option for water prone areas when only water absorption and water surface erosion are considered.

- Addition of fibers has a positive effect on improved surface toughness (zero surface erosion for various cement stabilization levels), and they also have an acceptable level of absorption with 10% or higher cement stabilization. When other structural benefits such as increased flexural strength, crack control capability and local toughness are considered, fiber-reinforced CSEB masonry is a very promising building construction solution, especially in projects where sustainability and/or economy are at the top of the priority list.

3.3. Structural Retrofit Applications of FRC

| Specimens | Strengthening method | Ultimate load | Ultimate load capacity increase with respect to control slab | Maximum deflection | Energy absorption | |

|---|---|---|---|---|---|---|

| Set | ID | |||||

| A | 1 | Control | 57.5 kips | - | 0.63 in | - |

| 2 | 0.5″ FRC | 68.0 kips | +18% | 1.38 in | 65.8 kip-in | |

| 3 | 1″ FRC | 88.2 kips | +53% | 1.16 in | 80.9 kip-in | |

| 4 | GFRP | 71.5 kips | +24% | 0.47 in | 21.9 kip-in | |

| B | 1 | Control | 59.2 kips | - | 0.78 in | 36.2 kip-in |

| 2 | 0.75″ FRC | 70.8 kips | +20% | 0.99 in | 53.5 kip-in | |

| 3 | GFRP—Ultimate Fail | 86.0 kips | +45% | 0.65 in | 64.8 kip-in | |

| GFRP—Initial Rupture | - | - | - | 35.6 kip-in | ||

| Strengthening system | Unit cost | Capacity gained per unit cost | Percent difference |

|---|---|---|---|

| GFRP | $6.70 per ft2 | 890 lb per dollar | - |

| 0.5″ FRC | $0.35 per ft2 | 1900 lb per dollar | 113% |

| 0.75″ FRC | $0.53 per ft2 | 1250 lb per dollar | 40% |

| 1″ FRC | $0.70 per ft2 | 2800 lb per dollar | 215% |

4. Conclusions

- The main factors that should be considered when using FRM or FRC are:

- ○

- Composition and strength of the initial cementitious matrix: as shown in both the masonry and the concrete structure application studies discussed in this paper, the lower strength matrices may benefit more from fiber addition compared to stronger base mixtures.

- ○

- The amount of fibers: previous literature [7] stated only a medium volume fraction (between 1% and 2%) can affect energy absorption, modulus of rupture, fracture toughness, and impact resistance of the resulting FRC. Our studies have shown significant impact in these characteristics with 0.25%–0.6% volume fractions of fibers, confirming that when the base matrix is of a lower strength, the effect of fibers may be amplified.

- ○

- The size of the fibers: our findings showed that nano fibers have negative effects on the FRM/FRC, and macro fibers do not fit well with masonry applications. Micro fibers should be preferred for masonry applications. For applications where additional improvements in strength and ductility are desired, hybrid mixtures of micro and macro fibers may be considered.

- ○

- Geometry and surface texture of the fiber: as stated when describing the problems when using horse hair, excessively oily and smooth fiber surfaces tend to pull out instead of stitching cracks. Further, fibers can be bundled or in the form of single strands. For all of the applications discussed in this paper, except the last study concerning retrofit of reinforced concrete slabs, single strands are suggested.

- FRM use in masonry as joint reinforcement:

- ○

- Compressive strength: previous literature [18] suggested that micro fibers reduce the compressive strength of the mix due to increases in the air content of the mixture relative to plain mortar resulting. We have noted both increased and decreased strength because of the following two potential behaviors in the specimen: (1) when the compression specimen dilates laterally, tensile stresses form in that direction, and the fibers that are oriented horizontally may then stitch the internal tensile cracks, increasing the compression capacity; (2) the fibers in general may cause air gaps in the FRM in addition to the naturally forming gaps in plain concrete. Plus, fibers oriented vertically may also break bond in horizontal tension and have no effect on vertical compression.

- ○

- Flexural strength, toughness, energy absorption, and ductility of the FRMs themselves are typically higher compared to the control mixture, even with lower fiber percentages.

- ○

- Bond strength with units in flexure and shear also seem to be positively affected from the addition of fibers, depending on the target flow rate (water content) and type of unit.

- ○

- All characteristics considered, a 0.5% volume fraction of 6 mm PVA micro fibers in type N PCL mortar appears to be a viable recipe for most masonry joint applications, both for clay units and CMUs, pending a larger data pool for optimization. In general, clay units perform better with high water content FRMs while CMUs perform better with drier mixtures, so 130% and 110% flow rates could be targeted, respectively.

- Fiber use in earth masonry

- ○

- The particular project presented in this paper showed negative effects in the flexural and compressive strength of CSEBs with the addition of PET fibers, however, it is suggested that part of the problem is the long (3 inch) and very stiff (PET) fibers. Shorter and more flexible fibers would produce better results. Even with slightly reduced strength, though, the change in the post-cracking flexural behavior from brittle to damage-tolerant shows the promise of using fibers for local impact resistance.

- ○

- The fibers also had a positive effect on the water pressure resistance (surface erosion resistance) of CSEBs.

- FRC as a retrofit technique in comparison to GFRP sheets

- ○

- Test results have shown that by applying a minimum one inch layer of FRC to the full tension face of a slab, a significant increase in the ultimate load carrying capacity and maximum deflection can be achieved for a lower material cost compared to conventional GFRP-strengthening methods.

- ○

- The FRC mixture utilized for such application be made of a relatively weak base-matrix, such as the pre-mixed type N PCL mortar used in this study.

Acknowledgments

Conflicts of Interest

References

- American Concrete Institute (ACI), ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary (318R-14); American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- ACI Committee 544. State-of-the-Art Report on Fiber Reinforced Concrete ACI544.1R-96, Reapproved in 2002; ACI Committee 544 Report; ACI: Farmington Hills, MI, USA, 2002. [Google Scholar]

- Johnston, C.D. Fiber-Reinforced Cements and Concretes; Gordon and Breach: Sydney, Australia, 2001. [Google Scholar]

- Naaman, A.E. Fiber reinforcement for concrete. Concr. Int. 1985, 7, 21–25. [Google Scholar]

- Balaguru, P.N.; Shah, S.P. Fiber-Reinforced Cement Composites; McGraw-Hill: New York, NY, USA, 1992. [Google Scholar]

- Skourup, B.N.; Erdogmus, E. Mechanical characteristics of PVA fiber-reinforced PCL mortars for masonry applications. ACI Mater. J. 2010, 107, 1–9. [Google Scholar]

- Mehta, P.K.; Montiero, P.J.M. Concrete Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- ASTM C1609/C1609M-05, 2005: Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM C1609/C1609M-12, 2012: Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, 2012.

- ASTM C1550-05, 2005: Standard Test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded Round Panel); ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM C1550-12, 2012: Standard Test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded Round Panel); ASTM International: West Conshohocken, PA, USA, 2012.

- Shah, S.P. Do fibers increase the tensile strength of cement based matrices? ACI Mater. J. 1991, 88, 595–602. [Google Scholar]

- Shah, S.P.; Naman, A.E. Mechanical properties of glass and steel fiber reinforced mortar. ACI J. 1976, 73, 50–53. [Google Scholar]

- Fanella, D.A.; Naaman, A.E. Stress-strain properties of fiber reinforced mortar in compression. ACI Mater. J. 1985, 82, 475–483. [Google Scholar]

- Soroushian, P.; Khan, A.; Hsu, J.W. Mechanical properties of concrete materials reinforced with polypropylene or polyethylene fibers. ACI Mater. J. 1992, 89, 535–540. [Google Scholar]

- Balaguru, P.; Foden, A. Properties of Fiber-reinforced structural lightweight concrete. ACI Struct. J. 1996, 93, 62–78. [Google Scholar]

- Khaloo, A.R. Behavior of date-leaf fiber reinforced mortar. Concr. Int. 1998, 20, 59–61. [Google Scholar]

- Pierre, P.; Pleau, R.; Pigeon, M. Mechanical properties of steel microfiber reinforced cement pastes and mortars. J. Mater. Civ. Eng. 1999, 11, 317–324. [Google Scholar] [CrossRef]

- Banthia, N.; Soleimani, S.M. Flexural response of hybrid fiber-reinforced cementitious composites. ACI Mater. J. 2005, 102, 382–389. [Google Scholar]

- Sorelli, L.G.; Meda, A.; Plizzari, G.A. Bending and uniaxial tensile tests on concrete reinforced with hybrid steel fibers. J. Mater. Civ. Eng. 2005, 17, 519–527. [Google Scholar] [CrossRef]

- Lawler, J.S.; Zampini, D.; Shah, S.P. Permeability of cracked fiber-reinforced mortar under load. ACI Mater. J. 2002, 99, 379–385. [Google Scholar]

- Banfill, P.F.G.; Forster, A.M. A relationship between hydraulicity and permeability of hydraulic lime. In International RILEM Workshop on Historic Mortars: Characteristics and Tests; RILEM Publications SARL: Bagneux, France, 2000; pp. 173–183. [Google Scholar]

- Erdogmus, E.; Armwood, C. Feasibility of Fiber-Reinforced Mortar for the Reconstruction of an Ancient Roman Temple. In Proceedings of Historical Mortars Conference HMC08, Lisbon, Portugal, 24–26 September 2008.

- Armwood, C.K.; Erdogmus, E.; Haider, H. Effect of fibers on the flexural strength of masonry mortars. Mason. Soc. J. 2011, 29, 19–32. [Google Scholar]

- Armwood, C.A. Behavior of Fiber Reinforced Mortar Joints in Masonry Walls Subjected to In-Plane Shear and Out-of-Plane Bending. Ph.D. Thesis, University of Nebraska-Lincoln, Lincoln, NE, USA, 2014. [Google Scholar]

- ASTM C39/C39M-05. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM C1018-97. Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading.); ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM E518-03, 2003: Standard Test Methods for Flexural Bond Strength of Masonry; ASTM International: West Conshohocken, PA, USA, 2003.

- Drdácký, M.F.; Michoinová, D. Lime Mortars with Natural Fibres. In Proceedings of the Workshop on in Situ Evaluation of Historic Wood and Masonry Structures, Prague, Czech, 10–14 July 2006; RILEM Publications: Bagneux, France, 2006. [Google Scholar]

- ASTM C1437-13, 2013: Standard Test Method for Flow of Hydraulic Cement Mortar; ASTM International: West Conshohocken, PA, USA, 2013.

- Zhu, M.; Chung, D.D.L. Improving brick-to-mortar bond strength by the addition of carbon fibers to the mortar. Cem. Concr. Res. 1997, 27, 1829–1839. [Google Scholar] [CrossRef]

- Colley, E. Effects PF Polyethylene Terephthalate Fibers in the Water Resistance of Compressed Stabilized Earth Blocks. M.S. Thesis, University of Nebraska-Lincoln, Lincoln, NE, USA, 2014. [Google Scholar]

- Cuéllar-Azcárate, M.C.; Matta, F.; Erdogmus, E.; Obonyo, E. Earth Blocks with Recycled Plastic Reinforcement for Damage Tolerance against Flying Debris from Extreme Winds. In Proceedings of the 7th International Conference on Architecture and Construction with Earthen Materials (Earth USA 2013), 4–6 October 2013, Santa Fe, NM, USA, 2013; p. 7.

- ASTM C67-11: Standard Test Method for Sampling and Testing Brick and Structural Clay Tile; ASTM International: West Conshohocken, PA, USA, 2011.

- Obonyo, E.; Exelbirt, J.; Bashkaran, M. Durability of compressed earth bricks: Assessing erosion resistance using the modified spray test. Sustainability 2010, 2, 3639–3649. [Google Scholar] [CrossRef]

- Al-Salloum, Y.; Almusallam, T. Load capacity of concrete masonry block walls strengthened with epoxy-bonded GFRP sheets. J. Compos. Mater. ASCE 2005, 39, 1719–1745. [Google Scholar] [CrossRef]

- Ebead, U.; Marzouk, H. Fiber-reinforced polymer strengthening of two-way slabs. ACI Struct. J. 2004, 101, 650–659. [Google Scholar]

- Neale, K.W. FRPs for structural rehabilitation: A survey of recent progress. Prog. Struct. Eng. Mater. ASCE 2000, 2, 133–138. [Google Scholar] [CrossRef]

- Triantafillou, T.C. Strengthening of structures with advanced FRPs. Prog. Struct. Eng. Mater. ASCE 1998, 1, 126–134. [Google Scholar] [CrossRef]

- Radik, M.; Erdogmus, E.; Schafer, T. Strengthening of two-way reinforced concrete floor slabs using polypropylene fiber reinforcement. ASCE J. Mater. Civ. Eng. 2011, 23, 562–571. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erdogmus, E. Use of Fiber-Reinforced Cements in Masonry Construction and Structural Rehabilitation. Fibers 2015, 3, 41-63. https://doi.org/10.3390/fib3010041

Erdogmus E. Use of Fiber-Reinforced Cements in Masonry Construction and Structural Rehabilitation. Fibers. 2015; 3(1):41-63. https://doi.org/10.3390/fib3010041

Chicago/Turabian StyleErdogmus, Ece. 2015. "Use of Fiber-Reinforced Cements in Masonry Construction and Structural Rehabilitation" Fibers 3, no. 1: 41-63. https://doi.org/10.3390/fib3010041

APA StyleErdogmus, E. (2015). Use of Fiber-Reinforced Cements in Masonry Construction and Structural Rehabilitation. Fibers, 3(1), 41-63. https://doi.org/10.3390/fib3010041