Flexural Behavior of R-UHTCC and Recycled Concrete Composite Beams Reinforced with Steel Bars

Abstract

1. Introduction

2. Experimental Program

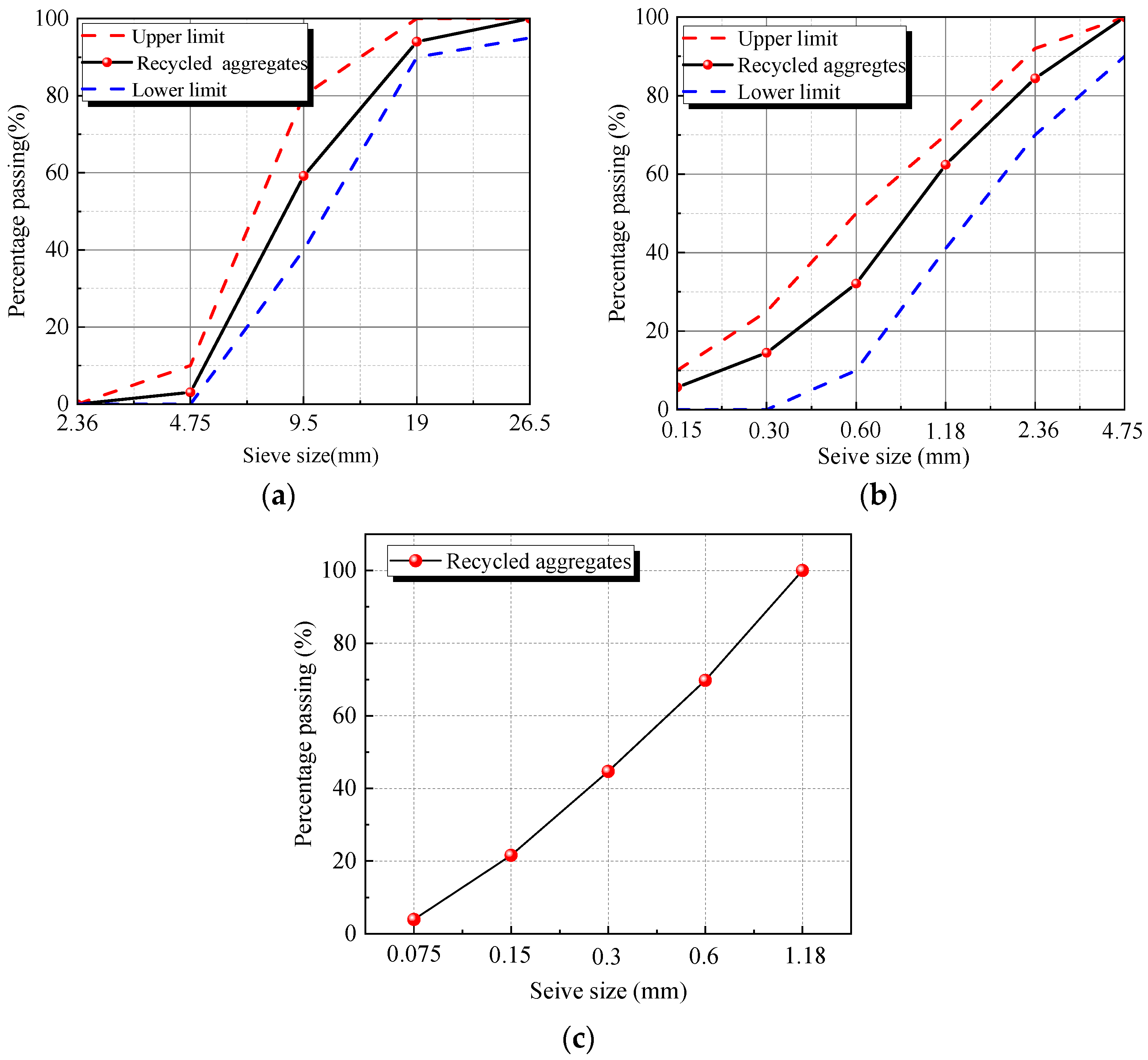

2.1. Materials

2.2. Mix Proportion Design

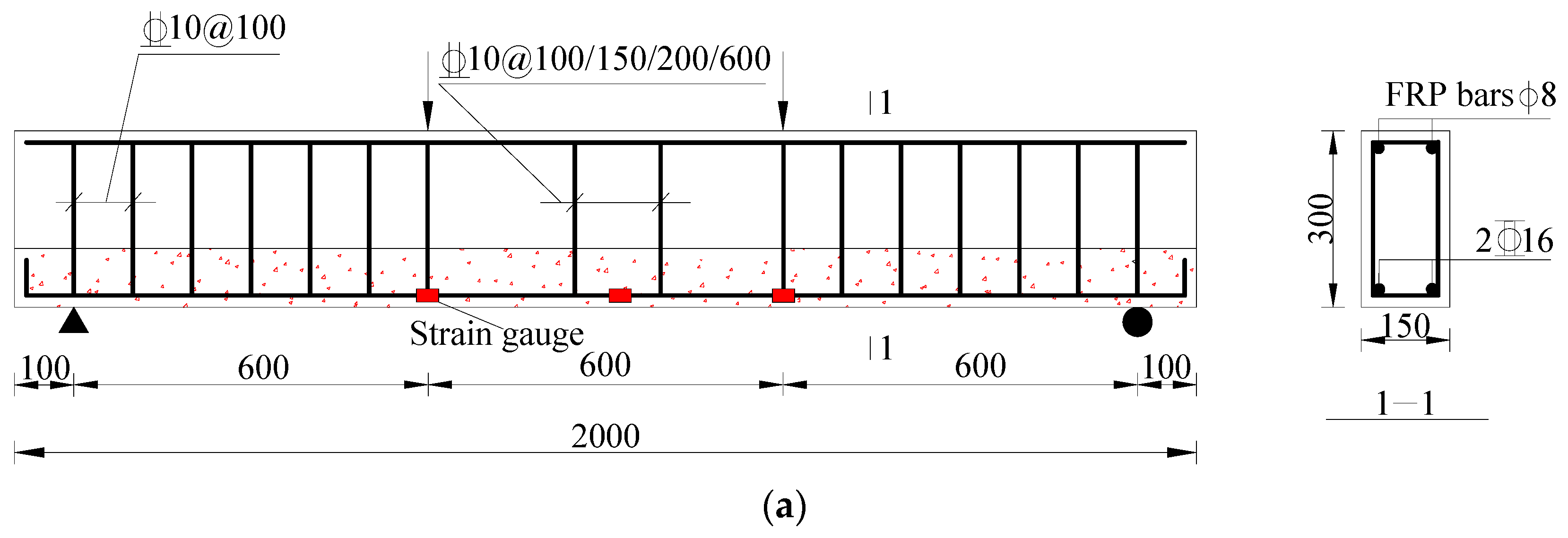

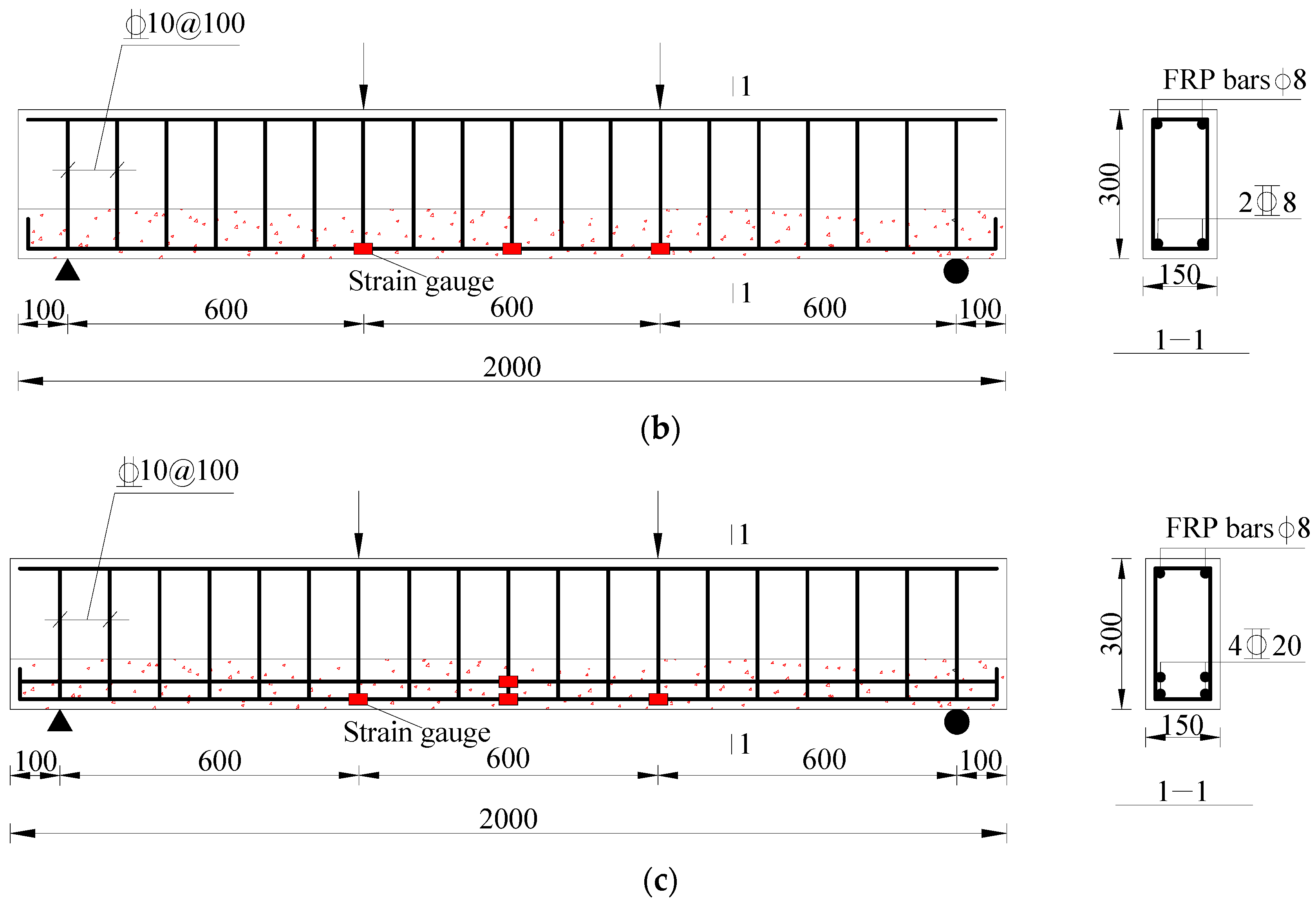

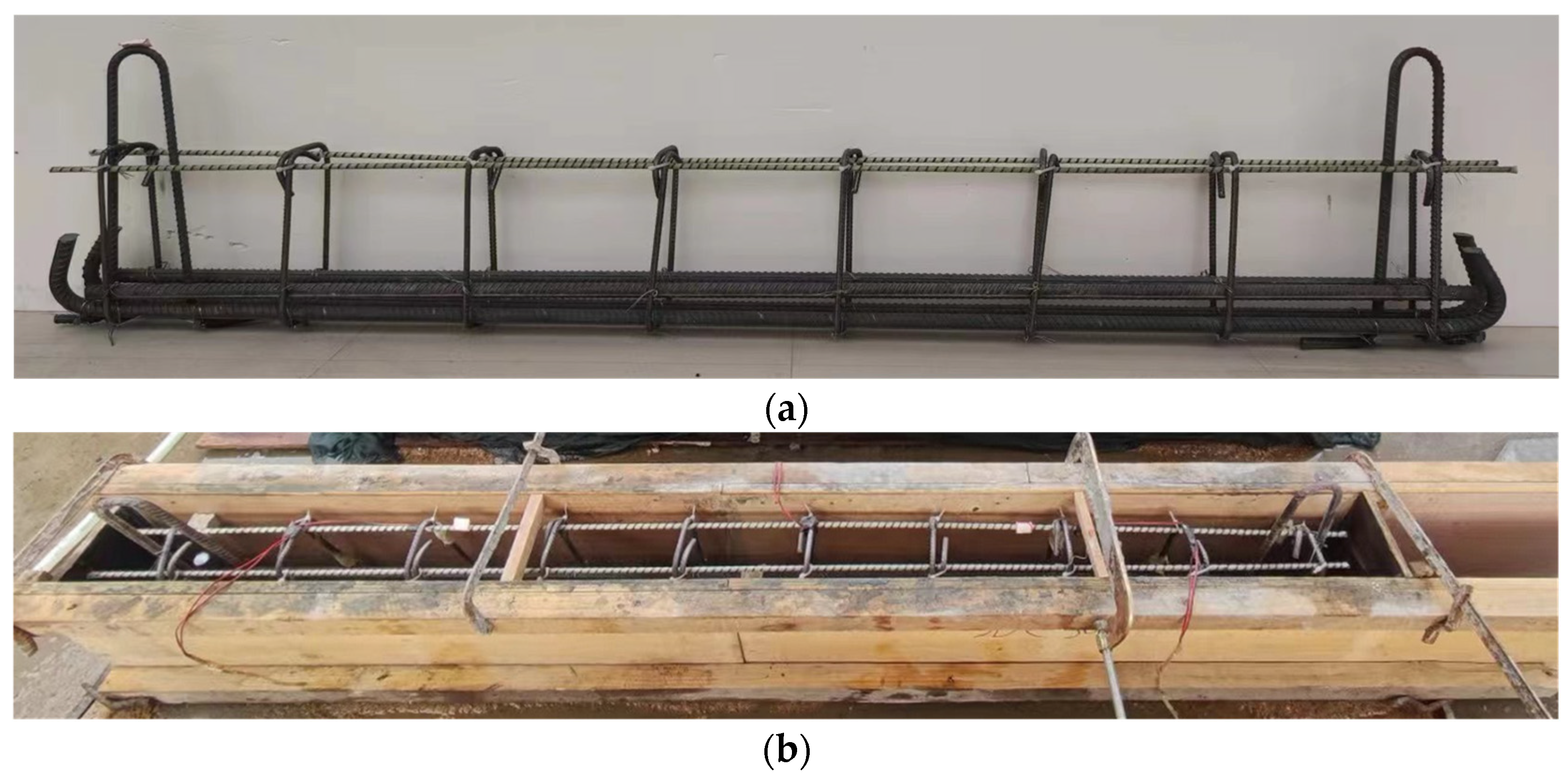

2.3. Specimen Design and Reinforcement

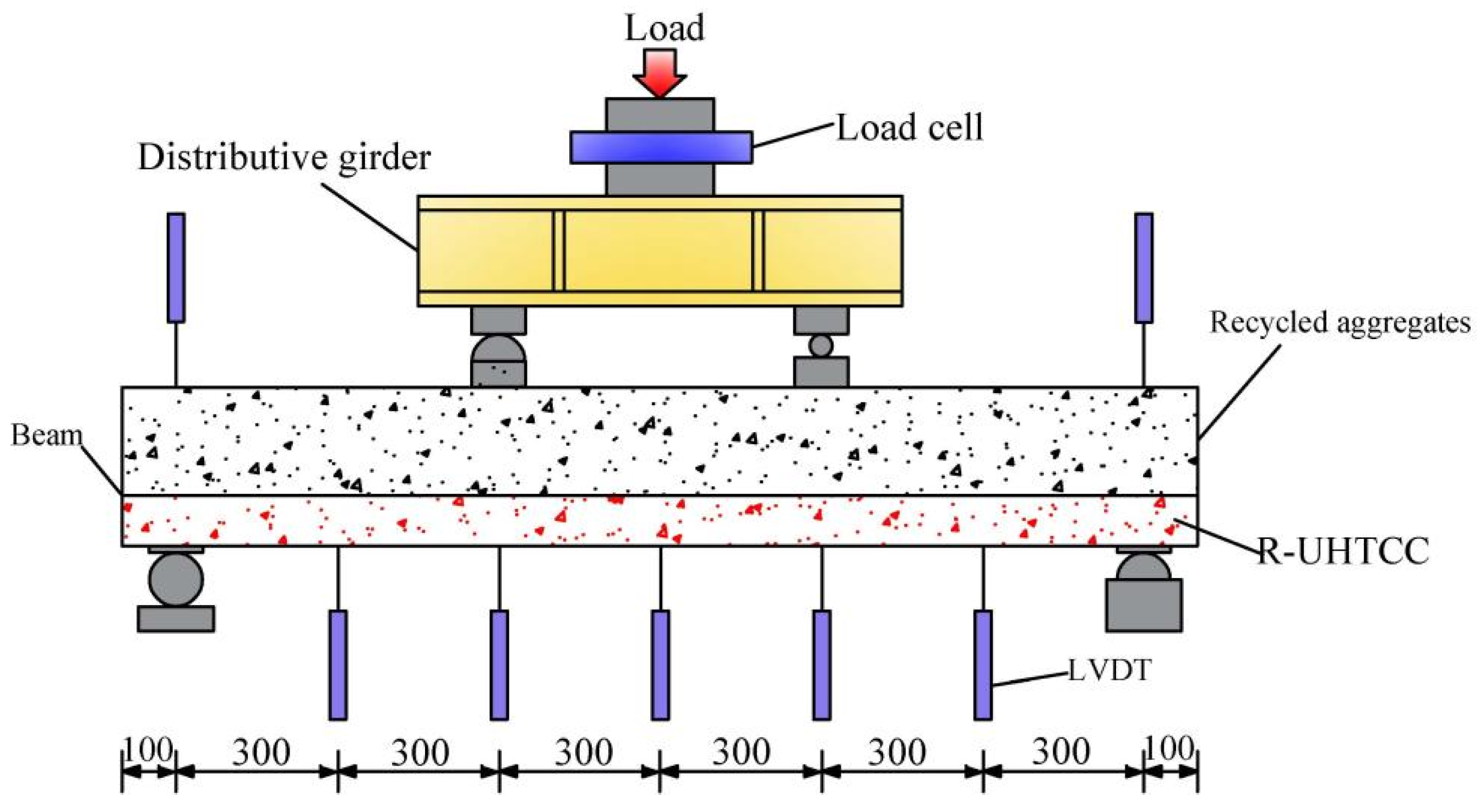

2.4. Specimen Testing and Basic Mechanical Properties

3. Experimental Results and Discussion

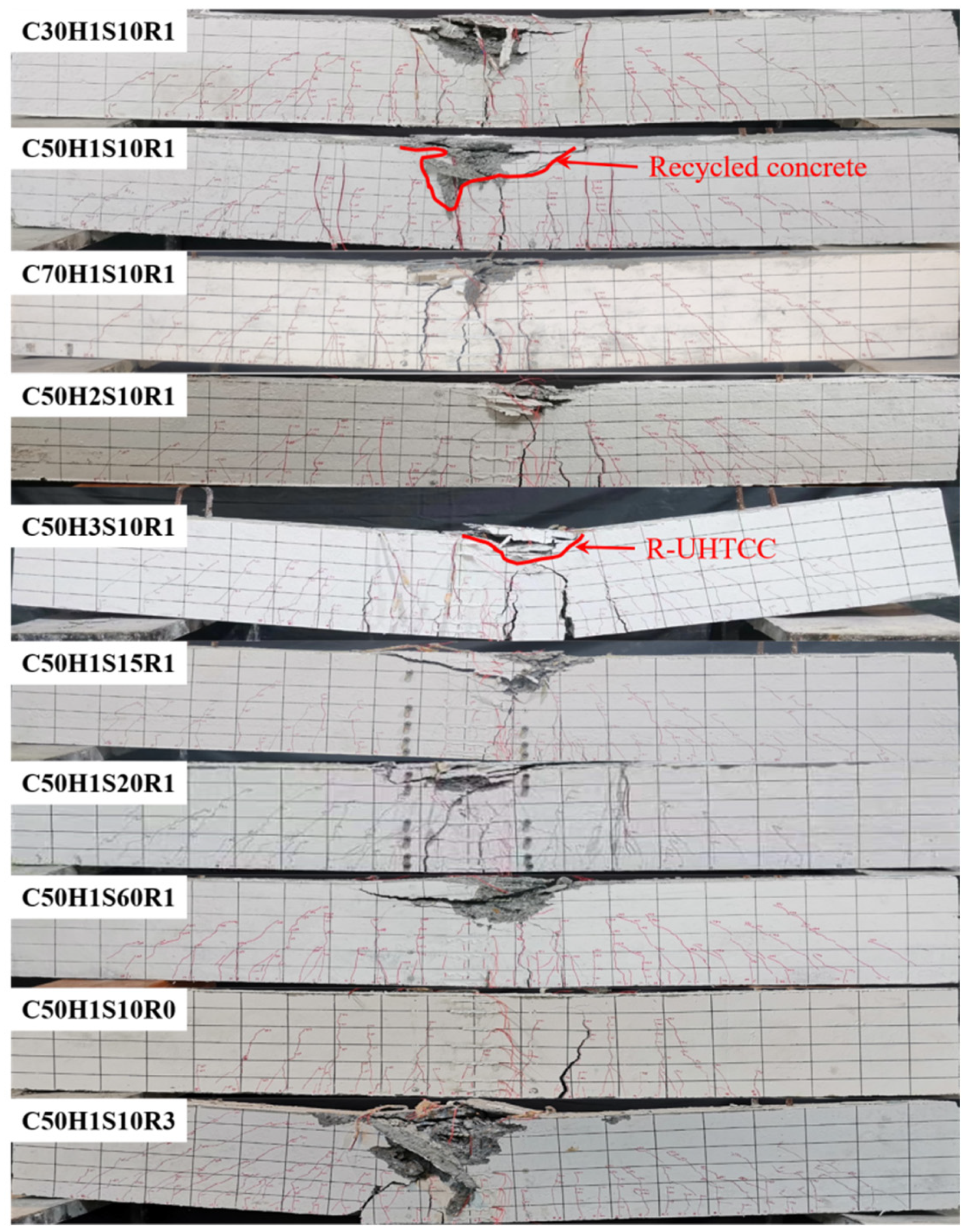

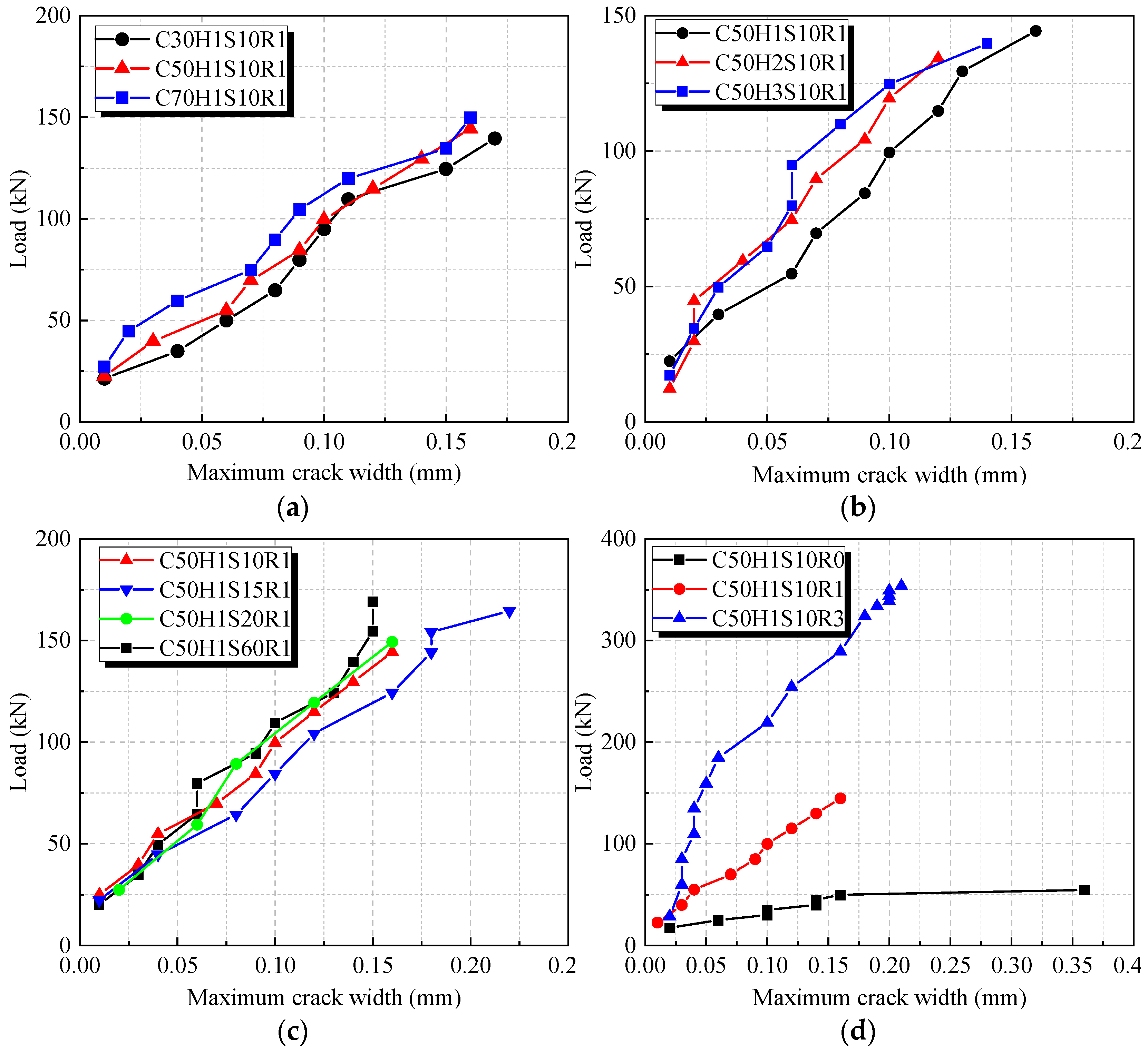

3.1. Failure Mode and Crack Width

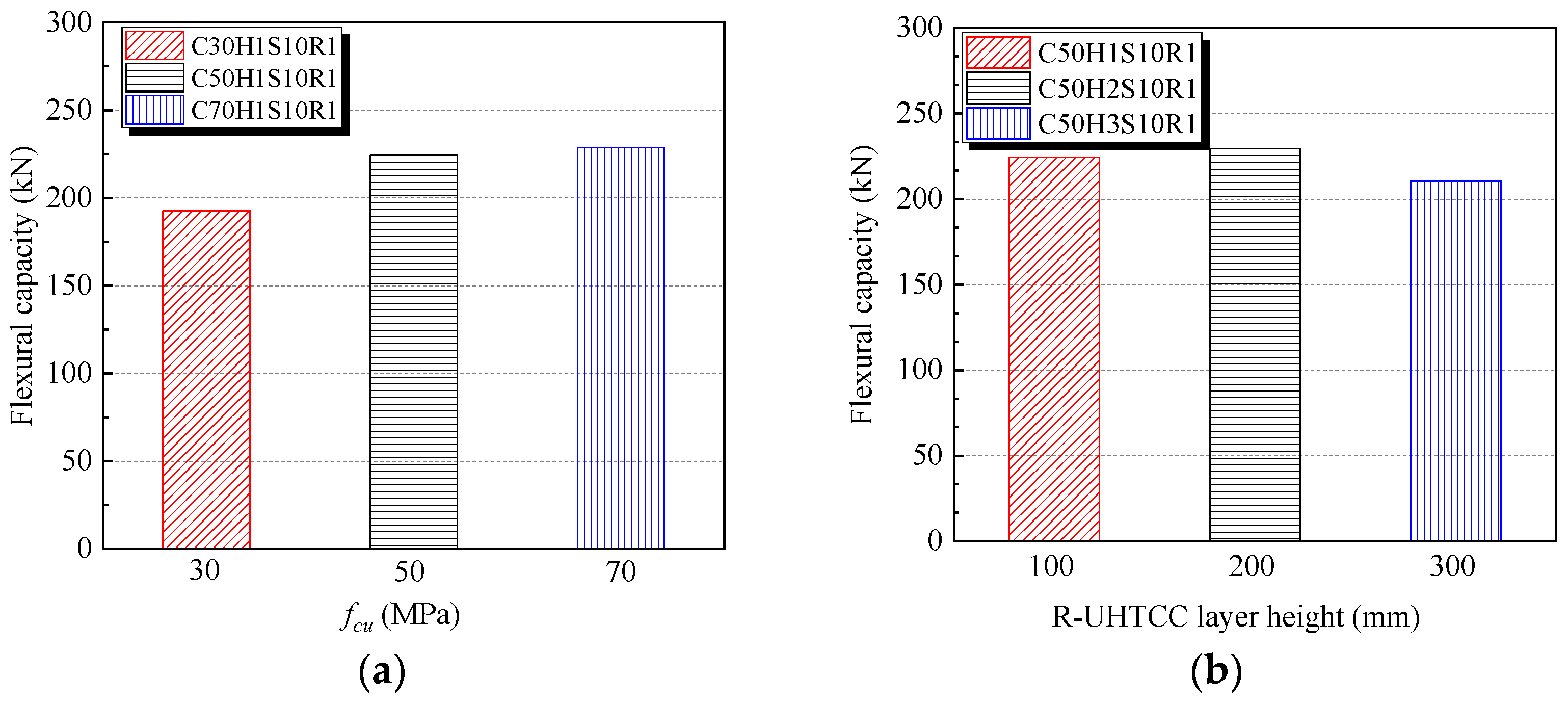

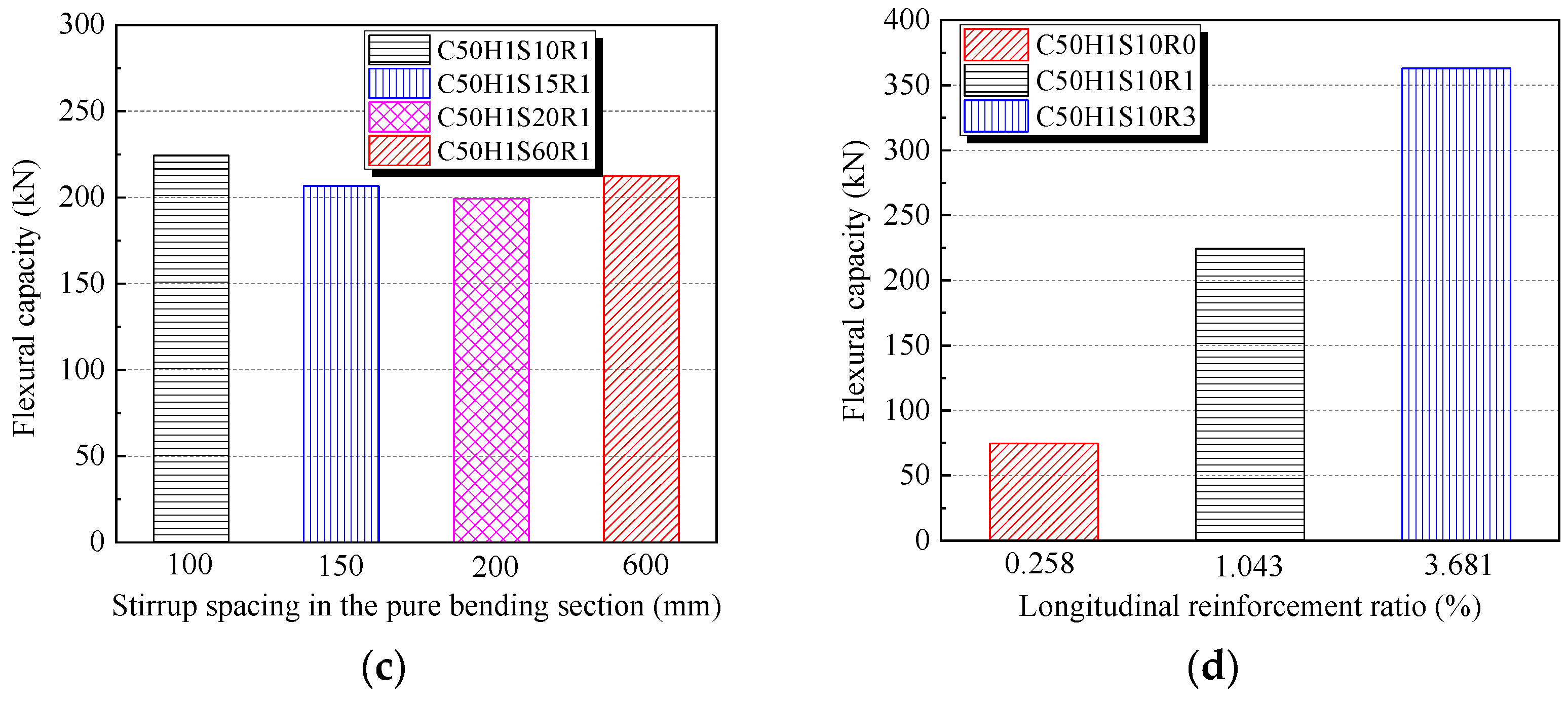

3.2. Flexural Capacity of Beams

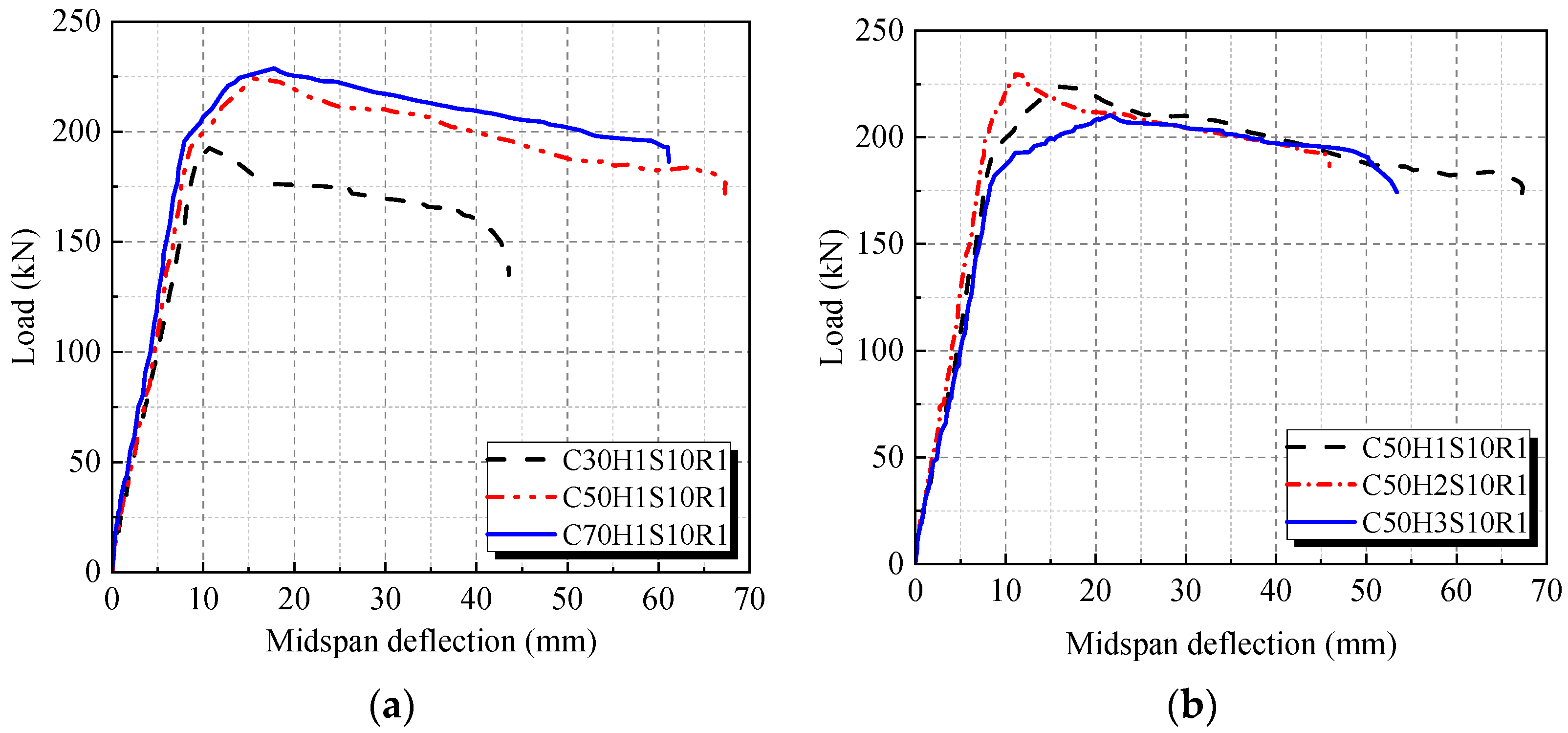

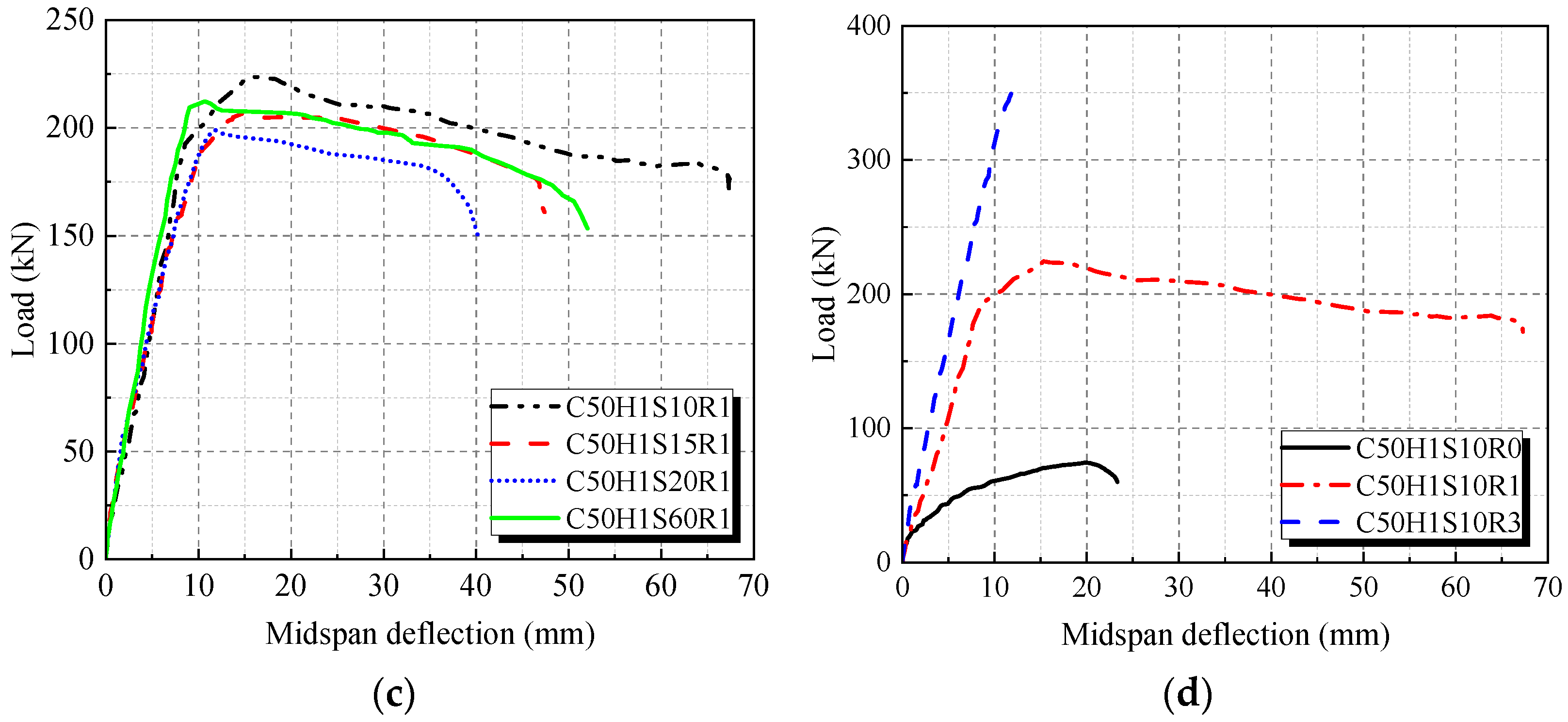

3.3. Load Deflection Response of Beams

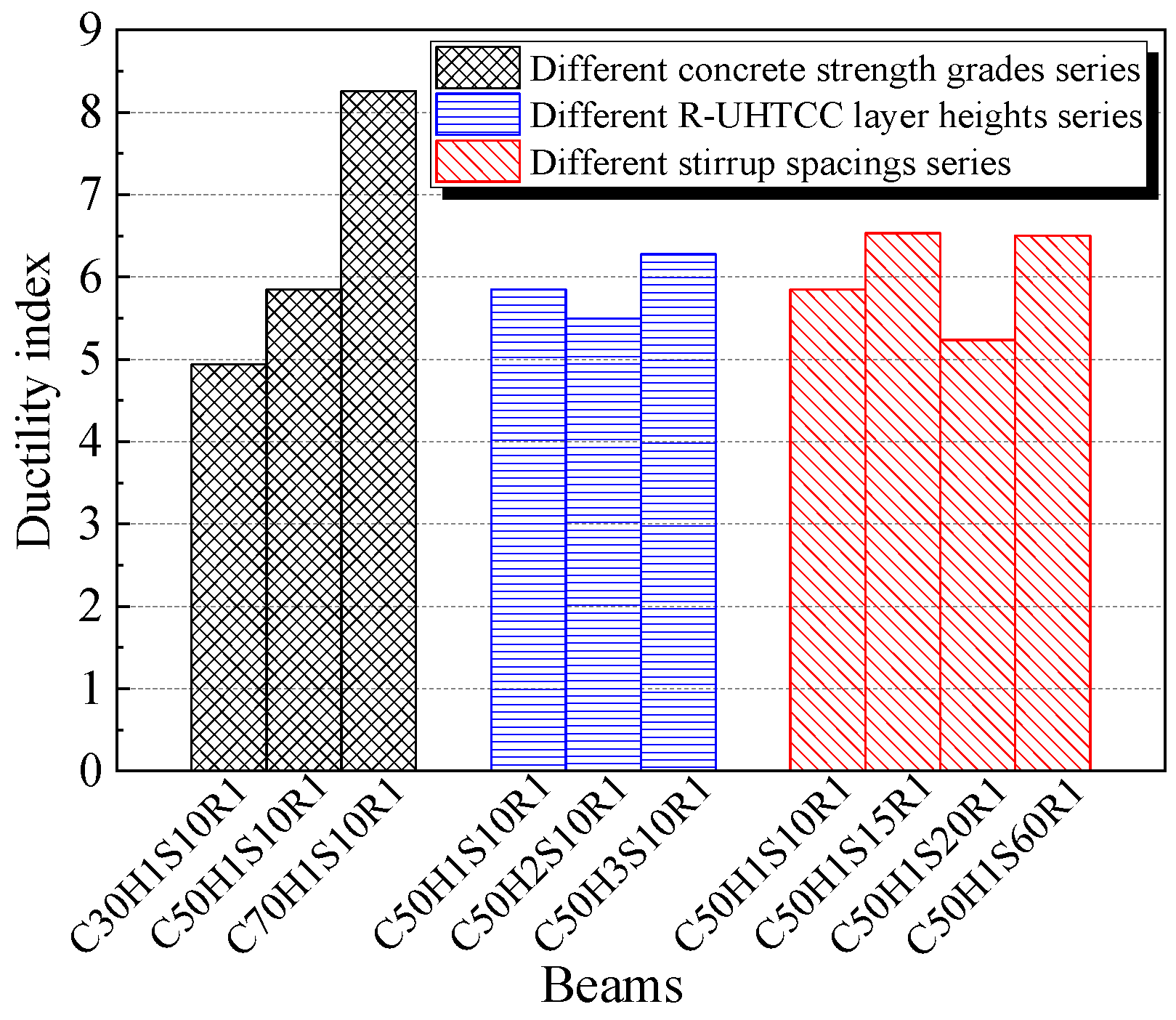

3.4. Ductility of Beams

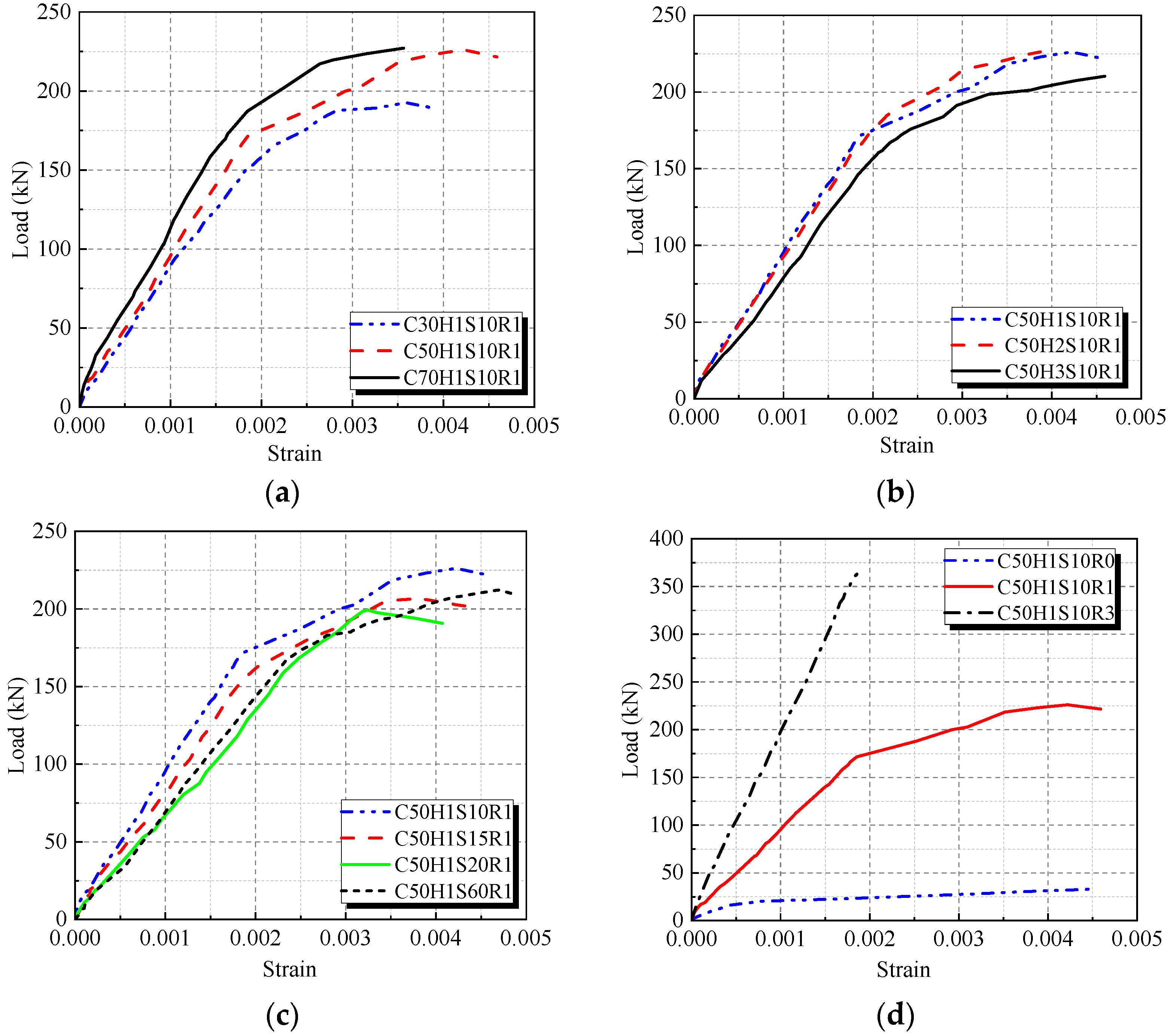

3.5. Load-Strain Curves

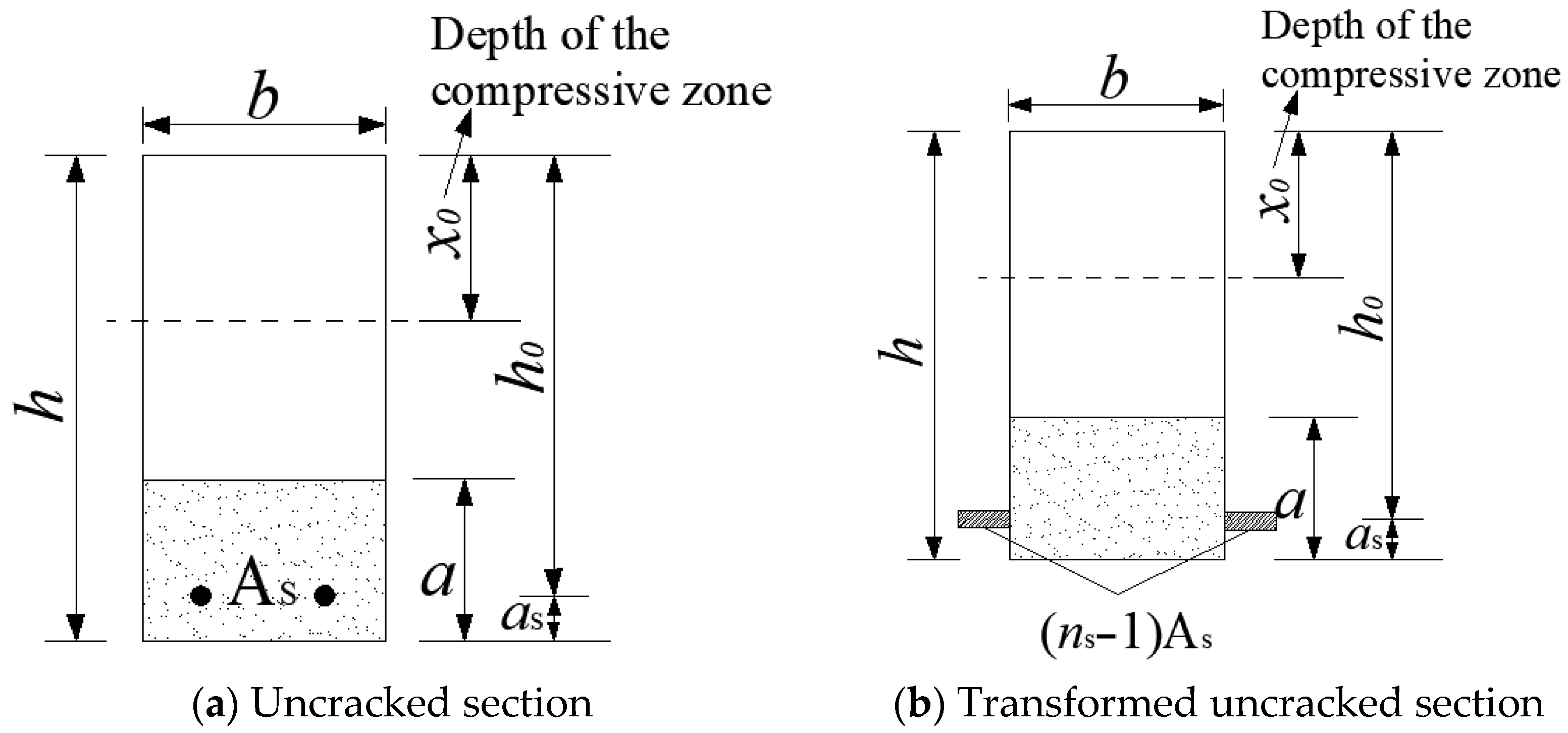

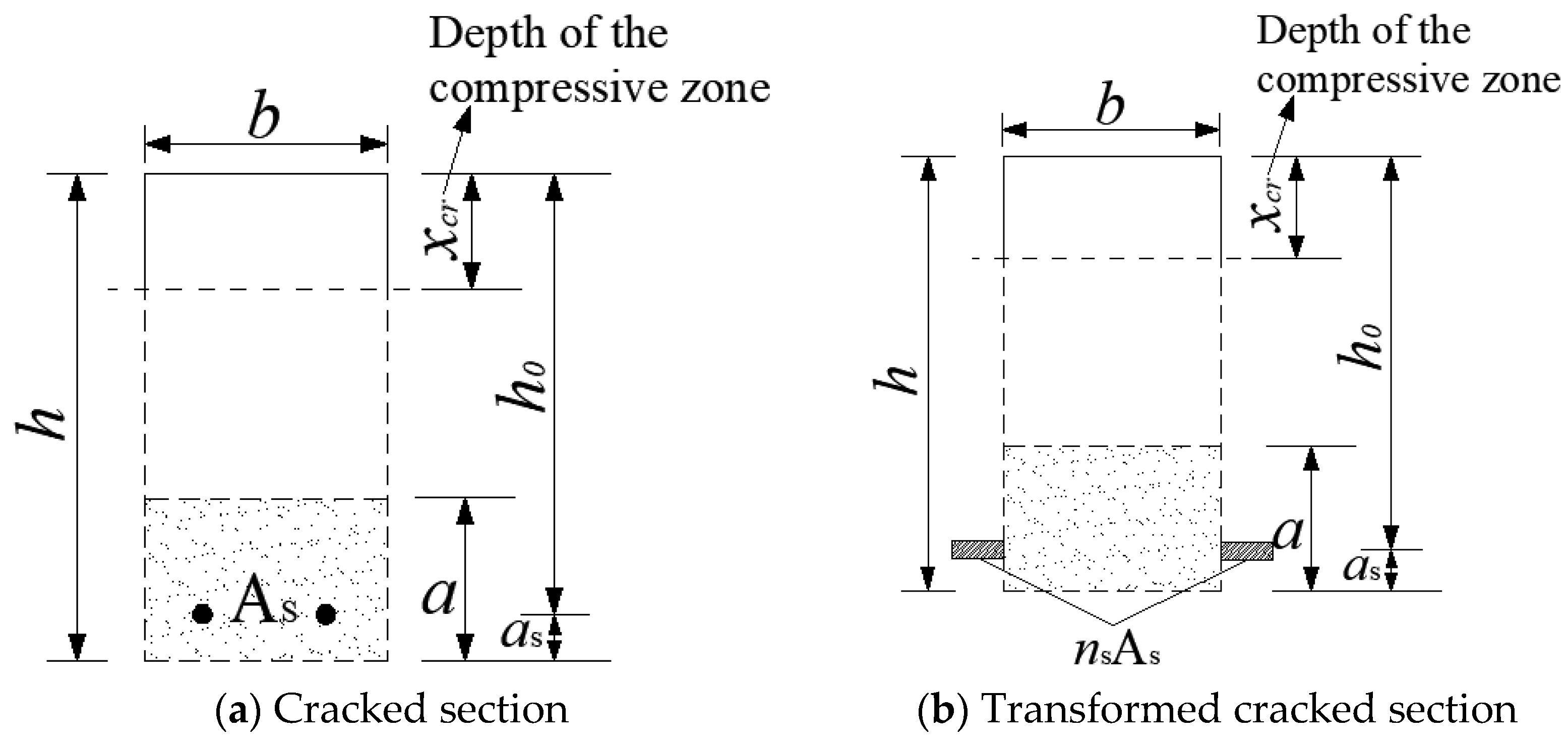

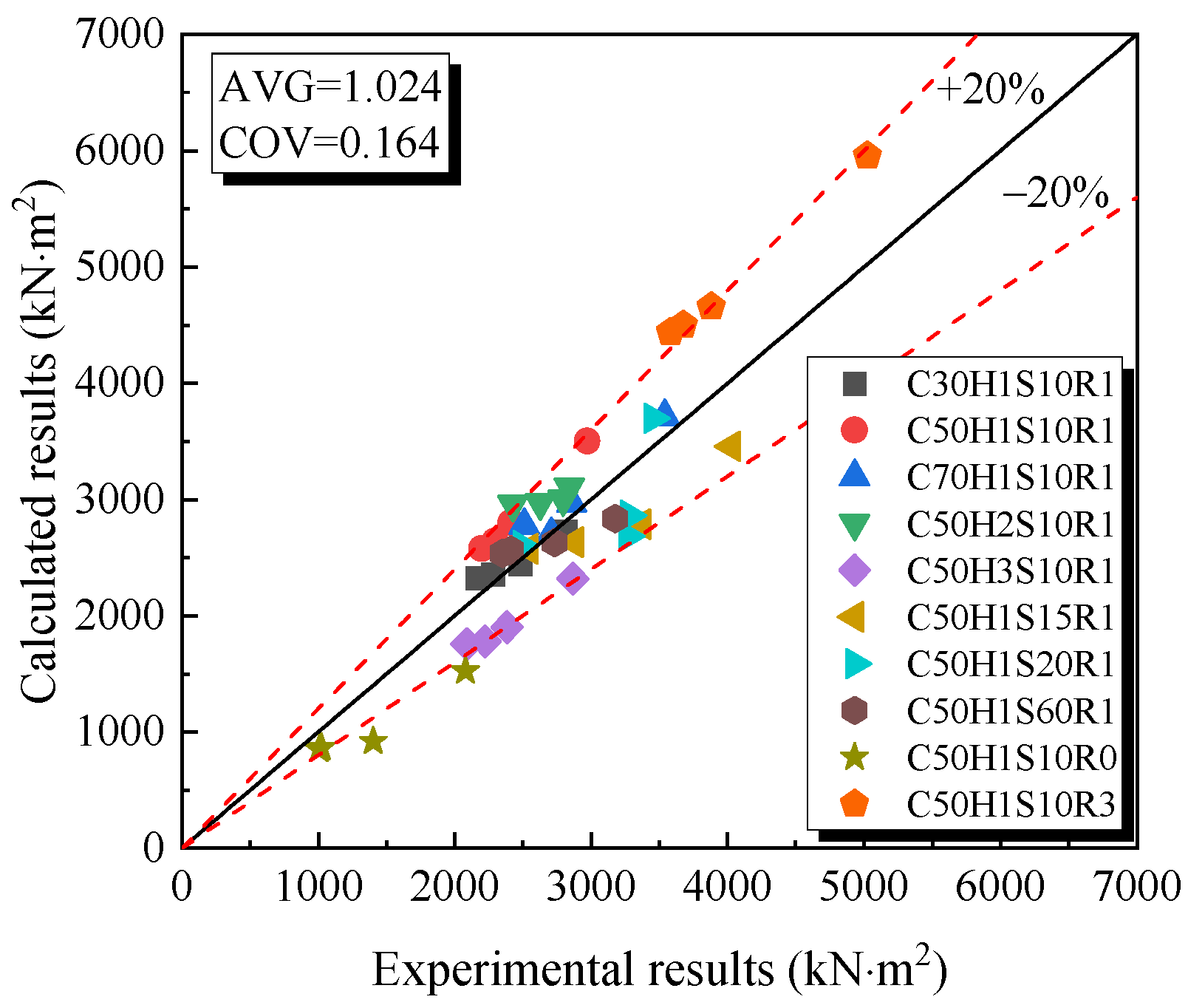

3.6. Stiffness Calculation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Liu, X.; Asghari, V.; Lam, C.; Chien Hsu, S.; Xuan, D.; Cirelli Angulo, S.; John, V.M.; Basavaraj, A.S.; Gettu, R.; Xiao, J.; et al. Discrepancies in life cycle assessment applied to concrete waste recycling: A structured review. J. Clean. Prod. 2024, 434, 140155. [Google Scholar] [CrossRef]

- Hao, J.; Ma, W. Evaluating carbon emissions of construction and demolition waste in building energy retrofit projects. Energy 2023, 281, 128201. [Google Scholar] [CrossRef]

- Wu, L.; Sun, Z.; Yan, C. Modification of recycled aggregate and conservation and application of recycled aggregate concrete: A review. Constr. Build. Mater. 2024, 431, 136567. [Google Scholar] [CrossRef]

- Xiao, J.; Poon, C.; Wang, Y.; Zhao, Y.; Ding, T.; Geng Ye, T.; Li, L. Fundamental behavior of recycled aggregate concrete—Overview I: Strength and deformation. Mag. Concr. Res. 2022, 74, 999–1010. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Dai, S.P.; Zhao, S. Durability and microstructural properties of concrete with recycled brick as fine aggregates. Constr. Build. Mater. 2020, 262, 120032. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Abdo, A.; El-Zohairy, A.; Alashker, Y.; Badran, M.A.E.-A.; Ahmed, S. Effect of Treated/Untreated Recycled Aggregate Concrete: Structural Behavior of RC. Beams. Sustainability 2024, 16, 4039. [Google Scholar] [CrossRef]

- Soares, A.C.M.; Tavares, M.E.N. Shrinkage of concrete with recycled brick aggregates. Constr. Build. Mater. 2025, 491, 142485. [Google Scholar] [CrossRef]

- Liu, C.Y.; Qin, J.H.; Akbar, A. Study on flexural mechanical properties and size effect of recycled coarse aggregate concrete beams based on 3D mesoscopic simulation. Struct. Concr. 2025. [Google Scholar] [CrossRef]

- Ali, R.; El Ouni, M.H.; Liaqat, A.; Muhammad, A.; Babar, A.; Zeeshan, A.; Ben, K.N. Structural evaluation of recycled aggregate concrete circular columns having FRP rebars and synthetic fibers. Eng. Struct. 2022, 250, 113392. [Google Scholar] [CrossRef]

- Gu, Z.; Wang, J.; Gao, D.; Zhao, J. Effects of steel fibers on the flexural behavior of recycled concrete beam: Testing and analysis. J. Build. Eng. 2024, 85, 108718. [Google Scholar] [CrossRef]

- Niu, H.; Li, B.; Gao, J.; Xie, S. Effect of hybrid fibers on the flexural performance of high-strength recycled aggregate concrete beams. Struct. Concr. 2023, 25, 1. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, J.; Li, Y. 3D printing recycled concrete incorporating plant fibres: A comprehensive review. Constr. Build. Mater. 2024, 425, 135951. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, J.; Liu, W.; Ma, Z. Unloading and reloading stress-strain relationship of recycled aggregate concrete reinforced with steel/polypropylene fibers under uniaxial low-cycle loadings. Cem. Concr. Compos. 2022, 131, 104597. [Google Scholar] [CrossRef]

- Gao, D.; Zhu, W.; Gu, Z.; Yang, L. Flexural capacity prediction of steel fiber reinforced concrete beam with recycled fine and coarse aggregate. Adv. Struct. Eng. 2023, 26, 1042–1058. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, J.; Wang, J. Flexural performance of recycled concrete beam reinforced with modified basalt fiber and nano-silica. Case Stud. Constr. Mater. 2023, 18, e02022. [Google Scholar] [CrossRef]

- Samer, G.; Bilal, H.; Elie, A. Structural and life cycle assessments of recycled aggregate concrete beams incorporating industrial hemp fibers. Struct. Concr. 2023, 24, 1. [Google Scholar] [CrossRef]

- Ibrahim, Y.E.; Fawzy, K.; Farouk, M.A. Effect of steel fiber on the shear behavior of reinforced recycled aggregate concrete beams. Struct. Concr. 2021, 22, 1861–1872. [Google Scholar] [CrossRef]

- Hossain, F.M.Z.; Pal, A.; Ahmed, K.S.; Bediwy, A.; Alam, M.S. Shear behavior of polypropylene fiber-reinforced concrete beams containing recycled aggregate and crumb rubber. J. Clean. Prod. 2023, 412, 137370. [Google Scholar] [CrossRef]

- Kachouh, N.; Maaddawy, T.E.; Hassan, H.E.; Ariss, B.E. Shear Behavior of Steel-Fiber-Reinforced Recycled Aggregate Concrete Deep Beams. Buildings 2021, 11, 423. [Google Scholar] [CrossRef]

- Nguyễn, H.H.; Choi, J.L.; Park, S.E.; Cha, S.L.; Huh, J.; Lee, B.Y. Autogenous healing of high strength engineered cementitious composites (ECC) using calcium containing binders. Constr. Build. Mater. 2020, 265, 120857. [Google Scholar] [CrossRef]

- Khan, M.K.I.; Lee, C.K.; Zhang, Y.X. Parametric study on high strength ECC-CES composite columns under axial compression. Columns axial Compress. J. Build. Eng. 2021, 44, 102883. [Google Scholar] [CrossRef]

- Luo, Q.; Zhang, J.; Lu, Z.; Wang, F.; Zhang, Y.; Liu, Z.; Jiang, J. A prediction model of the tensile properties of engineered cementitious composites (ECC) based on the continuous crack tracking algorithm. J. Build. Eng. 2023, 79, 107903. [Google Scholar] [CrossRef]

- Wu, F.; Zhao, B.; Cao, J.; Shen, X.; Wang, Z.; Lei, H.; Cui, Z. Experimental and theoretical investigations on flexural performance of hybrid fiber reinforced ECC-NC composite beams. Case Stud. Constr. Mat. 2024, 20, e03178. [Google Scholar] [CrossRef]

- Ge, W.; Ashraf, F.A.; Lu, W.; Cao, D. Flexural Performance of Steel Reinforced ECC-Concrete Composite Beams Subjected to Freeze–Thaw Cycles. Int. J. Concr. Struct. Mater. 2020, 14, 1–20. [Google Scholar] [CrossRef]

- Ge, W.; Ashraf, F.A.; Ji, X.; Cai, C.; Cao, D. Flexural behavior of ECC-concrete composite beams reinforced with steel bars. Constr. Build. Mater. 2018, 159, 175–188. [Google Scholar] [CrossRef]

- Maalej, M.; Li, V.C. Introduction of strain-hardening engineered cementitious composites in design of reinforced concrete flexural members for improved durability. ACI Struct. J. 1995, 92, 167–176. [Google Scholar] [CrossRef]

- Wang, N.; Xu, S. Flexural response of reinforced concrete beams strengthened with post-poured ultra high toughness cementitious composites layer. J. Cent. South Univ. 2011, 18, 932–939. [Google Scholar] [CrossRef]

- Yuan, F.; Pan, S.; Leung, C.K.Y. Flexural behaviors of ECC and concrete/ECC composite beams reinforced with basalt fiber-reinforced polymer. J. Compos. Constr. 2013, 17, 591–602. [Google Scholar] [CrossRef]

- Zhang, Y.; Ueda, N.; Nakamura, H.; Kunieda, M. Behavior investigation of reinforced concrete members with flexural strengthening using strain-hardening cementitious composite. ACI Mater. J. 2017, 114, 417–426. [Google Scholar] [CrossRef]

- Wu, C.; Li, V.C. CFRPECC hybrid for strengthening of the concrete structures. Compos. Struct. 2017, 178, 372–382. [Google Scholar] [CrossRef]

- Maalej, M.; Quek, S.T.; Ahmed, S.F.U.; Zhang, J.; Lin, V.W.J.; Leong, K.S. Review of potential structural applications of hybrid fiber engineered cementitious composites. Constr. Build. Mater. 2012, 36, 216–227. [Google Scholar] [CrossRef]

- Zhang, J.; Leung, C.K.Y.; Cheung, Y.N. Flexural performance of layered ECC-concrete composite beam. Compos. Sci. Technol. 2006, 66, 1501–1512. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Q.; Peng, X.; Xia, K.; Xu, B. A Review of Mechanical Performance Studies on Composite Concrete Beams and Slabs. Materials 2025, 18, 3259. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.W.; Ali, Y.; Khan, F.A.; Fahim, M.; Gu, A.; Ullah, Q.S. Shams-ul-Islam. Flexural Performance of Composite RC Beams Having an ECC Layer at the Tension Face. Period. Polytech. Civ. Eng. 2023, 67, 518–529. [Google Scholar] [CrossRef]

- Yousef, A.M.; Atef, N.H.; Tahwia, A.M. Flexural performance of functionally graded UHPFRC-NSC beams. Case Stud. Constr. Mater. 2024, 21, e03653. [Google Scholar] [CrossRef]

- Helal, K.A.; Tahwia, A.M.; Youssf, O. Assessment of the efficiency of hybrid basalt fibre sustainable ECC incorporating industrial waste materials. Constr. Build. Mater. 2025, 461, 139933. [Google Scholar] [CrossRef]

- Helal, K.A.; Tahwia, A.M.; Youssf, O. Performance of eco-friendly ECC made of pre-treated crumb rubber and waste quarry dust. J. Build. Eng. 2024, 97, 110820. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Aldulaimi, D.S.; Abdellatief, M.; Youssf, O. Physical, Mechanical and Durability Properties of Eco-Friendly Engineered Geopolymer Composites. Infrastructures 2024, 9, 191. [Google Scholar] [CrossRef]

- Wan, F.H.; Guo, Y.T.; Ge, K.; Zhuang, S.Y.; Elghazouli, A.Y. Mechanical properties of sustainable engineered geopolymer composites with sodium carbonate activators. J. Build. Eng. 2025, 105, 112486. [Google Scholar] [CrossRef]

- Gao, D.; Lv, M.; Pang, Y.; Tang, J.; Zhang, Y. Property analysis and mixture design of high ductility cementitious composites with totally recycled fine aggregate based on target strength and strain capacity. J. Clean. Prod. 2022, 337, 130492. [Google Scholar] [CrossRef]

- GB/T 1596–2017; Fly Ash Used for Cement and Concrete. AQSIQ 10: Beijing, China, 2017.

- ACI 318–19; Building Code Requirements for Structural Concrete. American Concrete Institute: Washington, DC, USA, 2019.

- Gao, D.; Lv, M.; Wei, D.; Pang, Y.; Tang, J. Trilinear tensile stress–strain constitutive model for high ductility cementitious composite with totally recycle fine aggregate. Constr. Build. Mater. 2022, 319, 126149. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, K.; Yu, J.; Xu, S. Structural behaviors of ultra-high performance engineered cementitious composites (UHP-ECC) beams subjected to bending-experimental study. Constr. Build. Mater. 2018, 177, 102–115. [Google Scholar] [CrossRef]

- Lopes, A.V.; Lou, T.J.; Lopes, S.M.R. On the ductility of RC beam section: A revision and up to date of conclusions. Eng. Struct. 2025, 322, 119105. [Google Scholar] [CrossRef]

| Particle Size (mm) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Crush Index (%) | Water Absorption (%) |

|---|---|---|---|---|

| 5–20 mm | 2661 | 1233 | 13.67 | 4.29 |

| 0–5 mm | 2593 | 1342 | 19.97 | 7.37 |

| 0–1.18 mm | 2536 | 1309 | 18.3 | 6.72 |

| Ultimate Tensile Strength (MPa) | Length (mm) | Diameter (mm) | Elongation (%) | Elastic Modulus (GPa) | Linear Density (g/cm3) |

|---|---|---|---|---|---|

| 1600 | 12 | 40 | 7.8 | 38 | 1.3 |

| Reinforcement Type | Diameter (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| HRB400 | 10 | 462 | 617 | 200 |

| HRB500 | 8 | 559 | 724 | 205 |

| HRB500 | 16 | 554 | 688 | 205 |

| HRB500 | 20 | 580 | 717 | 205 |

| Strength Grade | Cement | Recycled Fine Aggregate | Recycled Coarse Aggregate | Superplasticizer | Water |

|---|---|---|---|---|---|

| C30 | 390 | 645 | 1170 | 0 | 215 |

| C50 | 415 | 619 | 1201 | 2.08 | 185.2 |

| C70 | 520 | 625 | 1128 | 9.52 | 144.4 |

| Strength Grade | Cement | Fly Ash | Recycled Fine Aggregate | Polyvinyl Alcohol Fiber | Superplasticizer | Water |

|---|---|---|---|---|---|---|

| C30 | 503.9 | 503.9 | 403.1 | 19.5 | 0 | 453.5 |

| C50 | 758.9 | 325.2 | 433.7 | 19.5 | 1.1 | 433.7 |

| C70 | 852.8 | 365.5 | 487.3 | 19.5 | 4.3 | 365.5 |

| Beam Identifier | Concrete Strength Grade | R-UHTCC Layer Height (mm) | Stirrup Spacing (mm) | Reinforcement Ratio (%) |

|---|---|---|---|---|

| C30H1S10R1 | C30 | 100 | 100 | 1.043 |

| C50H1S10R1 | C50 | 100 | 100 | 1.043 |

| C70H1S10R1 | C70 | 100 | 100 | 1.043 |

| C50H2S10R1 | C50 | 200 | 100 | 1.043 |

| C50H3S10R1 | C50 | 300 | 100 | 1.043 |

| C50H1S15R1 | C50 | 100 | 150 | 1.043 |

| C50H1S20R1 | C50 | 100 | 200 | 1.043 |

| C50H1S60R1 | C50 | 100 | — | 1.043 |

| C50H1S10R0 | C50 | 100 | 100 | 0.258 |

| C50H1S10R3 | C50 | 100 | 100 | 3.681 |

| Strength Grade | Recycled Concrete (MPa) | R-UHTCC (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|

| fcu | fst | fco | Ec | fcu | fst | fco | Ec | |

| C30 | 33.84 [0.068] | 2.21 [0.055] | 27.92 [0.058] | 21,053 [0.007] | 31.30 [0.034] | 2.38 [0.082] | 25.24 [0.024] | 20,466 [0.039] |

| C50 | 52.35 [0.035] | 2.83 [0.031] | 40.69 [0.048] | 30,772 [0.045] | 54.69 [0.049] | 3.51 [0.005] | 47.16 [0.042] | 23,557 [0.085] |

| C70 | 72.07 [0.008] | 3.37 [0.024] | 57.74 [0.059] | 36,128 [0.041] | 71.04 [0.013] | 4.22 [0.082] | 61.88 [0.046] | 24,123 [0.046] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, D.; Li, Z.; Gu, Z.; Gao, D.; Yang, L.; Chen, G. Flexural Behavior of R-UHTCC and Recycled Concrete Composite Beams Reinforced with Steel Bars. Fibers 2025, 13, 110. https://doi.org/10.3390/fib13080110

Wei D, Li Z, Gu Z, Gao D, Yang L, Chen G. Flexural Behavior of R-UHTCC and Recycled Concrete Composite Beams Reinforced with Steel Bars. Fibers. 2025; 13(8):110. https://doi.org/10.3390/fib13080110

Chicago/Turabian StyleWei, Dong, Zuobiao Li, Zhiqiang Gu, Danying Gao, Lin Yang, and Gang Chen. 2025. "Flexural Behavior of R-UHTCC and Recycled Concrete Composite Beams Reinforced with Steel Bars" Fibers 13, no. 8: 110. https://doi.org/10.3390/fib13080110

APA StyleWei, D., Li, Z., Gu, Z., Gao, D., Yang, L., & Chen, G. (2025). Flexural Behavior of R-UHTCC and Recycled Concrete Composite Beams Reinforced with Steel Bars. Fibers, 13(8), 110. https://doi.org/10.3390/fib13080110