1. Introduction

Electrospun fibers are gaining attention in the advancement of wound dressings. Their high surface area and surface-to-volume ratio make them outstanding platforms compared to conventional fibers. Electrospun fibers are created from polymer solutions or melts, often resulting in nanoscale fibers with appropriate mechanical and biological properties [

1].

Synthetic biopolymers are materials used to build matrices for fiber fabrication due to their superior mechanical properties compared to natural biopolymers. However, these materials present limitations. For instance, synthetic polymers such as polyesters are often hydrophobic and lack adequate biocompatibility because they do not mimic extracellular matrix (ECM) components, such as polysaccharides, glycosaminoglycans, and proteoglycans [

2].

On the other hand, natural biopolymers, such as proteins and polysaccharides, provide biocompatibility by mimicking the chemical composition of the extracellular matrix of tissues [

3]. Nevertheless, they often fail to produce durable fibers due to their limited mechanical properties and water solubility. Therefore, a common strategy is to combine natural and synthetic biopolymers to form polymer blends [

2]. Alternatively, synthetic polymers can be electrospun and subsequently functionalized with natural biopolymer coatings, or water-soluble biopolymers can be electrospun and then crosslinked to achieve stability and applicability [

3,

4,

5,

6,

7].

The main challenge is modulating wound dressings’ biocompatibility and mechanical properties [

8,

9,

10]. Another critical challenge is the development of wound dressings with antimicrobial activity. This property often requires incorporating additives, especially metallic compounds, drugs, or surfactants [

5,

6]. Electrospun fiber-based wound dressings must exhibit antimicrobial properties, as wounds are entry points for bacteria into the body and may lead to severe infections [

11,

12,

13,

14,

15].

An effective electrospun wound dressing should meet several critical criteria: (1) possess antimicrobial activity, (2) have desirable mechanical properties, and (3) exhibit biocompatibility to support cell growth and tissue repair [

16,

17,

18,

19]. Therefore, this review highlights recent advancements in developing electrospun wound dressings to achieve these three required properties.

Section 2 presents the fundamental aspects of wound healing and material requirements;

Section 3 discusses the role and importance of wound dressings;

Section 4 focuses on fiber production and explains why electrospun fibers are promising candidates for wound dressing applications;

Section 5 highlights the main synthetic and natural polymers used to produce electrospun fibers with the necessary properties for wound healing;

Section 6 provides a classification of nanofiber-based wound dressings;

Section 7 explores the application of nanofiber dressings for different types of wounds;

Section 8 reviews current clinical trials;

Section 9 discusses limitations and critical challenges in the field;

Section 10 presents the conclusions, and

Section 11 outlines future trends and directions for research.

2. Fundamental Aspects

2.1. Skin Structure

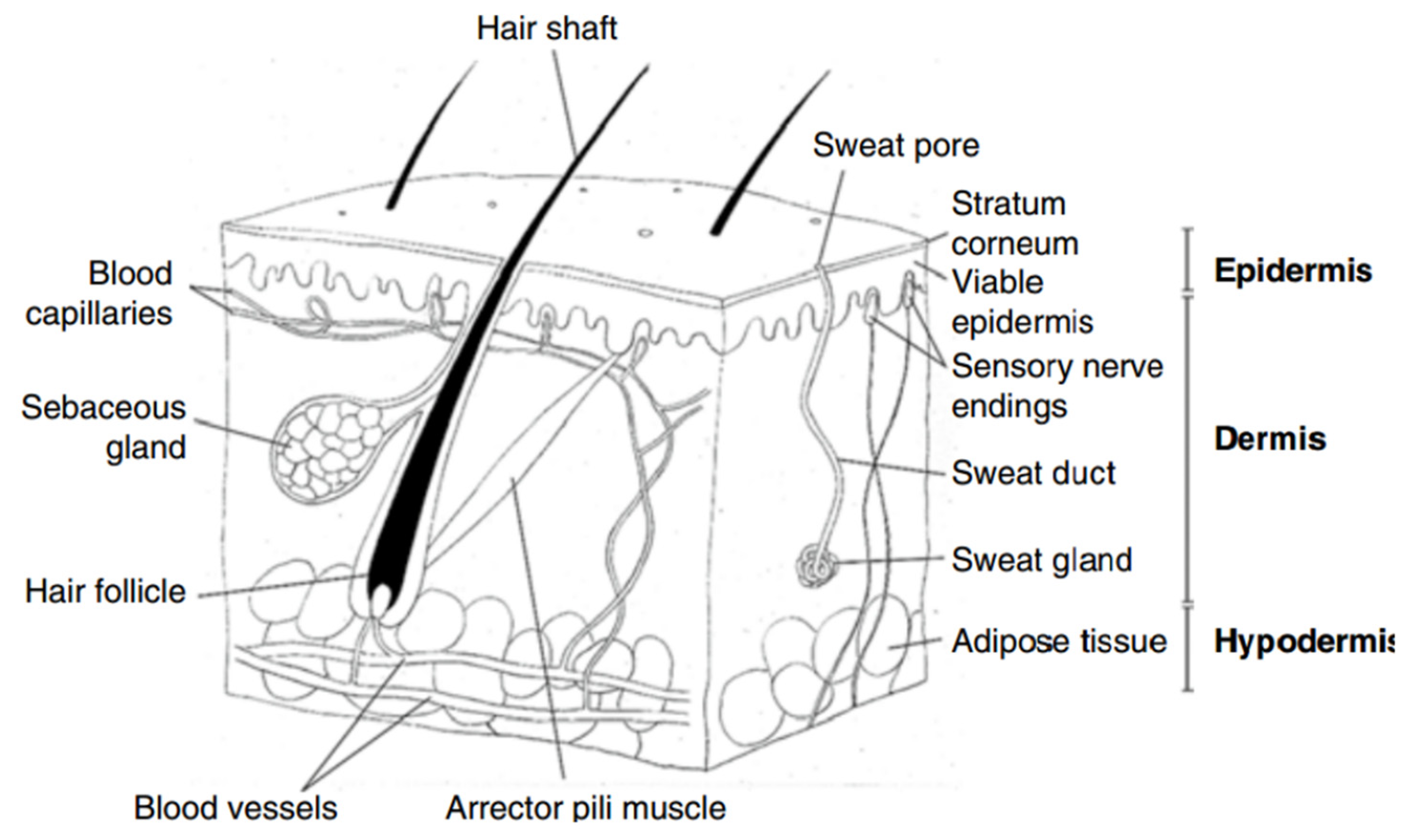

The assessment of a wound’s severity can be achieved through an understanding of the skin’s structure, the epidermis, dermis, and hypodermis (

Figure 1) [

4,

5]:

Epidermis: It is the outermost layer of the skin, comprising keratinocytes, melanocytes, Merkel cells, and Langerhans cells. These cells play crucial roles in protection, pigmentation, sensation, and immune response.

Dermis: It lies just beneath the epidermis and includes sweat glands, hair follicles, sebaceous glands, and an extensive network of lymphatic and blood vessels. These components support the skin’s flexibility and resilience, allowing it to withstand pressure and stress.

Hypodermis: It is not technically part of the skin; the hypodermis, or subcutaneous tissue, occurs below the dermis. It consists of fibroblasts, adipocyte cells, macrophages, and nerves. This layer connects the dermis to essential muscles and bones, providing structural support and insulation.

Understanding these layers is essential for evaluating wound characteristics and guiding appropriate treatment strategies.

2.2. Skin Damage

Skin damage can arise from physical, thermal, electrical, or mechanical sources, resulting in wounds that disrupt the function and anatomical structure of the skin. These factors influence the classification of wounds, including healing time, depth, causative agents, and the mode of injury (

Figure 2) [

6,

20,

21,

22,

23]:

I. Healing Time and Wound Types

Acute Wounds: These often result from injury, burns, and surgery and are expected to heal within eight to twelve weeks, depending on the wound’s size and severity. Acute wounds are classified into traumatic and surgical.

Chronic Wounds: These heal within twelve weeks or more. Chronic wounds are often associated with poor blood flow, diabetes, persistent local pressure, tumors, infections, or compromised blood circulation. Common types of chronic wounds include bedsores (pressure ulcers), diabetic ulcers, and foot ulcers.

II. Depth of Wounds: Wounds can also be classified based on their depth:

Superficial Wounds: Affect only the epidermis.

Deep Dermal Wounds: Extend into the dermis.

Full-Thickness Wounds: Penetrate through the epidermis and dermis, reaching the hypodermis.

III. Causative Agents: Wounds are further categorized by their causative agents:

Traumatic Wounds: Result from external force or injury.

Iatrogenic Wounds: Arise from medical procedures or interventions.

Burns: Caused by exposure to heat, chemicals, or electrical sources.

IV. Wound Classification by Cleanliness: Based on postoperative infection risk, wounds are classified into four categories [

24,

25,

26]:

Clean Wounds (Class 1): Incisions made under sterile conditions with minimal risk of infection.

Clean/Contaminated Wounds (Class 2): Surgical wounds that involve organs or systems where contamination is controlled.

Contaminated Wounds (Class 3): Wounds with a higher risk of infection due to exposure to contaminants.

Dirty Wounds (Class 4): Wounds with established infection or significant contamination.

V. Mode of Injury: Wounds are also classified by the mode of injury:

Abrasion: Superficial damage where the skin is scraped or rubbed off.

Incision: Clean, straight cuts typically made by sharp objects.

Laceration: Irregular, jagged tears in the skin.

Degloving: Severe injury where the skin is peeled away from the underlying tissue.

VI. Color of Contaminated Tissue: The appearance of the wound can also be categorized by the color of the tissue present [

4,

5,

6,

7]:

Black (Necrotic Tissue): Indicates dead tissue that must be removed for healing to progress.

Green (Infected Tissue): Signifies the presence of infection.

Yellow (Sloughy Tissue): Characterized by a moist, yellowish tissue often associated with inflammation or infection.

Red (Granulating Tissue): Represents healthy new tissue forming in the healing process.

Pink (Epithelial Tissue): Indicates newly formed skin tissue covering the wound.

Understanding these classifications aids in effectively assessing and managing wounds, guiding appropriate treatment strategies to optimize healing and recovery.

2.3. Wound Infection and Pain

Microorganisms, such as bacteria and fungi, can significantly impair the host’s natural immune system and induce infections in injured areas.

Streptococcus pyogenes (S. pyogenes),

Staphylococcus aureus (S. aureus),

Pseudomonas aeruginosa (P. aeruginosa), and particularly Clostridium species are prominent bacterial pathogens that cause delayed wound healing. Additional factors contributing to wound infection include hypoxia, ischemia, and immune deficiencies, which may be induced by viral infections or chemotherapy [

27].

Neglecting proper wound care can lead to severe consequences, including fatalities resulting from bacteremia and septicemia [

28]. In healthy individuals, microorganisms may proliferate on the surface of a wound without eliciting an immune response or clinical symptoms. However, when the colonization of microorganisms penetrates the host’s living tissues, a series of local and systemic responses is triggered [

29]. This invasion can result in purulent discharge, symptomatic cellulitis, and subsequent soft tissue injury [

30].

It has been documented that the formation of bacterial biofilms is a critical factor in delayed wound healing, attributed to the high microbial load at the wound site [

29]. Burn wounds, in particular, are highly susceptible to contamination, with approximately 75% of such wounds being prone to infection. This susceptibility is due to microorganisms already present in sebaceous glands and hair follicles, and the frequent presence of

P. aeruginosa and

S. aureus [

31].

Chronic wounds are more vulnerable to infection compared to acute wounds. This increased susceptibility occurs due to leukocyte migration and reduced phagocytic activity in the presence of microbial biofilm [

32]. The infections and biofilm in chronic wounds impart a challenging environment for effective healing, necessitating medical interventions and antibiotics to treat infections.

Effective pain management is essential for the patient’s recovery. Excessive pain can impede the healing process by causing the accumulation of stress hormones induced by anxiety, resulting in prolonged physical and mental burdens and extended hospital stays [

33]. It is essential to address each patient’s expression of pain individually, as pain perception varies greatly and is subjective, rather than relying solely on clinical assessments.

There are two primary types of wound pain: nociceptive and neuropathic pain. Nociceptive pain is a natural physiological response to tissue damage. This type of pain typically resolves within a specific period; however, the inflammatory response may be prolonged if the healing process is delayed. In such cases, patients may experience primary hyperalgesia (heightened sensitivity at the wound site) and secondary hyperalgesia (increased sensitivity in the surrounding tissues) [

34].

On the other hand, neuropathic pain is associated with nerve damage, which may occur due to a primary lesion. This pain is primarily linked with infections and cancer and can result in chronic pain over an extended period [

35]. Skin transplants can also cause severe pain because of the exposure of nerve endings during skin harvesting, necessitating management at the wound sites [

36].

Primary hyperalgesia, caused by prolonged inflammation or repeated stimuli to the wound and surrounding area, may be treated with a combination of nonsteroidal anti-inflammatory drugs (NSAIDs) and mild opioids [

35]. NSAIDs reduce local inflammation, while opioids modulate pain at the spinal cord level. Wound dressings serve two fundamental functions: covering the wound to prevent infection and alleviating pain by reducing the bacterial contact and the inflammatory response [

36].

Topical drug delivery to the wound site is preferred for pain alleviation, as oral medications can take several days to provide significant relief. Ibuprofen, in particular, has been extensively studied for its local pain reduction effects [

37]. Arapoglou et al. (2011) designed a foam dressing loaded with ibuprofen and compared its effects with local best practices on various wound types [

38]. Based on patient scores, their study reported significantly higher pain relief with ibuprofen-loaded foam dressings. They concluded that ibuprofen should be applied to acute and chronic wounds for pain reduction, indicating that pain relief with ibuprofen could be an alternative to pain treatments [

38].

2.4. Wound Healing Stages

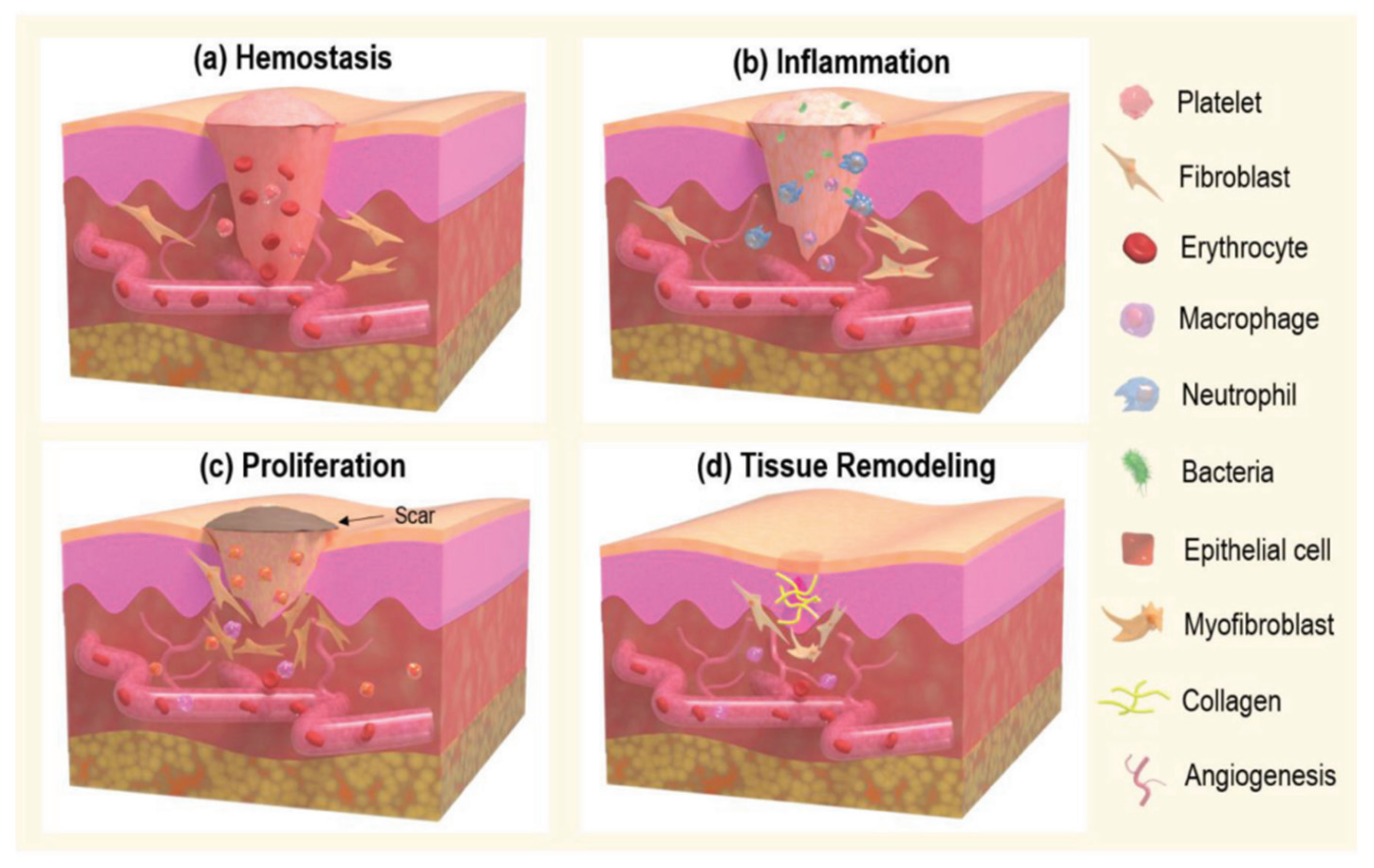

Wound healing progresses through four stages: hemostasis, inflammation, proliferation, and remodeling (

Figure 3). Understanding these stages is important to identify factors that can prevent healing:

2.4.1. Hemostasis

This is the immediate response to injury, crucial for halting blood loss and maintaining the function of other organs. This phase involves the formation of a temporary scaffold plug (

Figure 3a). The process begins with microvascular lesions, leading to vasoconstriction mediated by neuronal reflexes, which minimize blood loss from the arterioles. The initial response to skin injury involves the accumulation of thrombocytes (platelets) and inflammatory cells, which adhere to structural proteins such as collagen within the extracellular matrix [

39]. Thrombocytes release a range of proteins, including thrombospondin, von Willebrand factor (vWF), sphingosine-1-phosphate, and fibronectin. These proteins enhance platelet activation and the subsequent release of growth factors such as insulin-like growth factors (IGF), platelet-derived growth factor (PDGF), interleukin 1 (IL-1), and transforming growth factors (TGF-α and TGF-β). These factors are essential for wound healing beyond the hemostatic phase. The secretion of clotting factors promotes the deposition of a fibrin matrix, stabilizing the temporary scaffold plug [

40]. This scaffold provides an environment for the subsequent stages of healing by facilitating the recruitment of fibroblasts, leukocytes, keratinocytes, and endothelial cells. It serves as a reservoir of growth factors. Additionally, by releasing chemical signals, thrombocytes influence the migration of leukocytes from blood vessels to the injury site. Research by Zhang et al. explored the drug release properties of captopril-loaded poly (lactic-co-glycolic acid) (PLGA) biodegradable nanofibers. Captopril is known for its vasodilatory effects, which can further support the hemostatic and healing processes [

41].

2.4.2. Inflammation

It plays a critical role in wound healing by recruiting leukocytes to the injury site by activating various mediators and chemotactic factors. This phase typically spans 24 to 48 h post-injury, with the complete resolution of inflammation generally occurring within three days. Critical signs of inflammation include the release of enzyme-filled fragments by mast cells, such as histamine. Histamine acts as a mediator by inducing vasodilation, facilitating the efficient migration of neutrophils to the wound site, as illustrated in

Figure 3b. The increased blood flow and swelling observed at the wound site indicate inflammation resulting from the accumulation of interstitial fluid. Neutrophils, the primary responders in the inflammation phase, work to eliminate foreign bodies, pathogens, dead cells, and damaged matrix components through phagocytosis [

42]. They also release proteinases and antimicrobial substances to cleanse the wound further. Thrombocytes release chemical signals that attract neutrophils to the injury site, promoting their adherence to endothelial cells and facilitating their migration via cell adhesion molecules. Following 48 h of injury, cytokines, growth factors, and chemokines stimulate the migration of monocytes and lymphocytes, which differentiate into macrophages. Macrophages are crucial in phagocytosing surviving pathogens, necrotic tissue, and debris, initiating granulation tissue formation. While macrophages and neutrophils are involved in clearing debris, macrophages are more effective in proteolytic degradation. Macrophages and inflammatory cytokines (e.g., TNF-α, transforming growth factor-beta (TGF-β), and platelet-derived growth factor (PDGF)) produce growth factors (e.g., vascular endothelial growth factor (VEGF), transforming growth factor-alpha (TGF-α), hepatocyte growth factor (HGF), and others) that are essential for the subsequent proliferation phase and growth of fibroblasts, endothelial cells, and other cell types after an inflammation response. The phagocytosis of neutrophils by macrophages and the subsequent reduction in inflammatory cells signal the transition to the proliferation stage [

40]. Research by Merrell et al. demonstrated that curcumin-loaded polycaprolactone (PCL) nanofibers present potential for wound dressing applications [

43]. Curcumin is noted for its antioxidant, antimicrobial, and anti-inflammatory properties, enhancing wound healing.

2.4.3. Proliferation

The proliferation phase of wound healing transforms the temporary scaffold plug into a more durable tissue plug, encompassing sub-stages such as angiogenesis, tissue formation, re-epithelialization, and wound contraction (

Figure 3c).

Angiogenesis: Involves the formation of new blood vessels. Endothelial cells bind to growth factors via their receptors, initiating the migration and proliferation of these tissues. The basal lamina must be dissolved by proteolytic enzymes released by the activated endothelial cells, a process known as sprouting. These sprouts form interconnected channels, which are stabilized by smooth muscle cells and pericytes [

44]. Once blood flow is established, angiogenesis is considered complete. This process supplies the wound with oxygen and nutrients for the subsequent granulation tissue formation [

45].

Granulation Tissue Formation: Granulation tissue, composed of capillaries and fibroblast cells, supports new tissue growth. The newly established blood vessels supply essential nutrients and oxygen, which support the re-epithelialization process [

46].

Re-epithelialization: In this sub-stage, fibroblasts produce growth factors such as hepatocyte growth factor, keratinocyte growth factor, and epidermal growth factor, which stimulate keratinocytes to migrate and proliferate across the wound bed. This process leads to a new epithelial layer over the wound [

47].

Wound Contraction: Myofibroblasts, a combination of fibroblasts and smooth muscle cells, play a key role in wound contraction. These cells pull the edges of the wound together, facilitating closure. This contraction reduces the wound’s size [

48].

Research by Xie et al. highlighted the use of chitosan nanofibers incorporated with vascular endothelial growth factor (VEGF) to enhance wound healing. VEGF is a crucial mediator of angiogenesis and granulation tissue formation [

49].

2.4.4. Remodeling

This phase is the final stage of wound healing, commencing approximately two weeks post-injury and extending up to one year (

Figure 3d). This phase consolidates the processes initiated during the inflammation and proliferation stages, completing the healing process [

50].

Resolution of Cellular Components: During remodeling, macrophages, endothelial cells, and myofibroblasts exit the wound site or undergo apoptosis. This phase is characterized by a decline in the metabolic activity associated with wound healing as smaller arterioles aggregate into larger blood vessels [

51].

Extracellular Matrix (ECM) Remodeling: The ECM undergoes significant changes as part of the remodeling process. Collagen type III, prevalent during the proliferation stage, is replaced by collagen type I. This transition is facilitated by lysyl oxidase and matrix metalloproteinases (MMPs) secreted by fibroblasts. These enzymes aid in the realignment of collagen fibers to enhance the tensile strength of the newly formed tissue. Despite this improvement, the tensile strength of the remodeled tissue typically reaches only about 80% of that of uninjured skin [

52,

53].

Cellular Apoptosis and ECM Degradation: The final steps in wound repair involve the apoptosis of residual cells, migration away from the wound site, and the degradation of the ECM by MMPs [

52,

53].

Scar Formation: Scar formation occurs due to the lack of proper anchoring of the subcutaneous tissue to the epidermis, precisely the absence of rete pegs, which are critical for the tight connection between the epidermis and dermis. Scar formation can be minimized by maintaining a proper balance between ECM synthesis and degradation, thus promoting optimal tissue repair and functional recovery [

51,

52,

53].

Understanding these processes is essential for developing strategies to improve wound healing and minimize scar formation, ultimately enhancing patient outcomes and tissue regeneration.

2.5. Factors Affecting Wound Healing

Several critical factors influence the wound healing process, especially in aged patients, where delayed leukocyte migration to the wound site and reduced phagocytic capacity of macrophages correlate with prolonged wound healing [

54]. Research has shown that stress significantly delays wound healing by regulating glucocorticoids and decreasing growth factors produced by macrophages and cytokines such as TNF-α and IL-6. Additionally, stress reduces the levels of chemoattractants like IL-1α and IL-8, which are essential for the inflammatory phase of wound healing [

55,

56,

57,

58].

In obese patients, there is a higher risk of surgical wound infections. The friction between skin folds often leads to ulceration. The primary caloric storage in adipose tissue influences wound healing, as adipose tissue secretes adipokines that affect the body’s inflammatory response [

59,

60,

61,

62].

Tobacco smoke, containing thousands of substances, significantly impacts wound healing. Key components such as nicotine, hydrogen cyanide, and carbon monoxide play significant roles [

63,

64,

65,

66]. Nicotine induces vasoconstriction, reducing blood flow to tissues; hydrogen cyanide decreases tissue oxygen consumption; and carbon monoxide leads to tissue hypoxia, suppressing wound healing [

67].

2.5.1. Factors Impacting Wound Healing in Aged Patients

Leukocyte Migration: The migration of these cells is slower in aged individuals, leading to a delayed inflammatory response.

Macrophage Function: The phagocytic capacity of macrophages is reduced.

2.5.2. The Role of Stress in Wound Healing

Glucocorticoid Regulation: Stress regulates glucocorticoids, decreasing the concentration of macrophage growth factors and cytokines such as TNF-α and IL-6.

Reduction of Chemoattractants: Stress reduces levels of IL-1α and IL-8, crucial for the inflammatory phase, delaying healing.

2.5.3. Obesity and Wound Healing

Increased Infection Risk: Obese patients have a higher risk of wound infections.

Friction and Ulceration: Skin friction in obese individuals often leads to ulceration.

Adipokines and Inflammation: Adipose tissue secretes adipokines that negatively impact the body’s inflammatory response.

2.5.4. Effects of Tobacco Smoke on Wound Healing

Nicotine: Causes vasoconstriction, reducing blood flow in tissues.

Hydrogen Cyanide: Decreases tissue oxygen consumption.

Carbon Monoxide: Leads to tissue hypoxia.

Understanding these factors is important to improve wound healing, primarily in populations with vulnerabilities, such as the elderly, obese, and smokers [

67].

3. Wound Dressing

3.1. The Role and Criteria of Wound Dressings in the Healing Process

Wound dressings can reduce pain and protect against infections, creating an optimal environment for healing. An ideal wound dressing should present the following properties [

68,

69]:

Provide a Moist Environment: Maintaining moisture at the wound site promotes faster healing and prevents the wound from drying out, which can cause further damage.

Allow Gas Exchange: The dressing should be permeable to gases, such as oxygen and carbon dioxide, to support cellular respiration and prevent anaerobic bacterial growth.

Eliminate Excess Exudates: The dressing must absorb excess wound exudates while preventing them from saturating the outer surface and maceration of the surrounding skin.

Protect Against Microorganisms: Create a barrier against bacteria and other microorganisms, preventing diseases.

Provide Mechanical Protection: To protect the wound from physical damage and external trauma, supporting the healing process.

Control Local pH and Temperature: To maintain optimal cellular activities and enzymatic processes involved in healing.

Easily Replaceable and Removable: The dressing should be easy to apply and remove without causing additional pain or damage to the wound.

Minimize Wound Pain: Alleviate pain associated with the wound, making the recovery comfortable.

Non-Allergenic: Avoid allergic reactions.

Economically Viable and Cosmetically Acceptable: The dressing should be cost-effective and aesthetically pleasing, ensuring it is accessible and acceptable to patients.

Stimulate Growth Properties: Support cell proliferation and tissue regeneration.

High Biocompatibility and Elasticity: It must be biocompatible to avoid adverse reactions and elastic enough to conform to the wound area without restricting movement [

70].

3.2. Classification of Wound Dressing

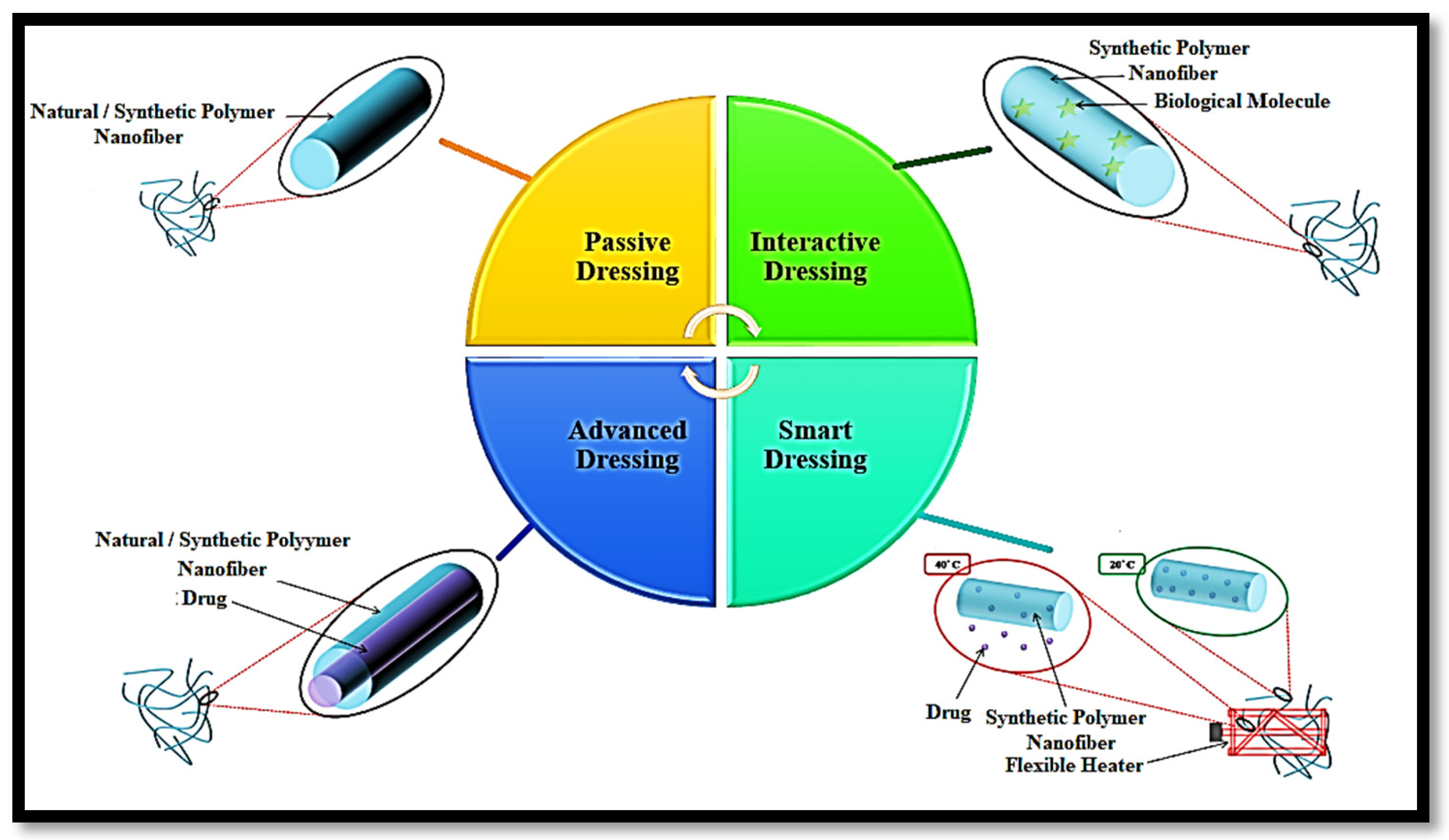

Wound dressings are classified as passive, interactive, advanced, and smart (

Figure 4).

Passive Dressings: The intricate network of fibers in passive dressings establishes an ideal environment for wound healing by enabling oxygen permeability through their porous structure. These dressings, which can be engineered from both natural and synthetic polymers, are highly regarded for wounds that demand an optimal healing milieu and robust protection against mechanical damage. In a pivotal study by Uppal et al., hyaluronic acid was electrospun to rigorously evaluate the impact of key electrospinning parameters, such as applied voltage, spin length, and flow rate, on the fiber diameter. The study conclusively demonstrated that the air permeability of electrospun hyaluronic acid significantly outperformed that of conventional gauze treated with Vaseline [

70].

Interactive Dressings: Dressings that provide a suitable environment and assist in controlling bacterial growth are called interactive dressings. An interactive dressing combines non-biological polymer (synthetic polymer) and biological molecules owing to ease of processing, anti-bacterial characteristics, and wound site affinity. The possibility of immunogenic reactions and impurities moderates the scope of the dressing. Liu et al. investigated a polylactide–polyglycolide (PLGA)/collagen nanofiber with a 250 nm diameter. They postulated that their ternary nanofiber composites have an excellent affinity towards human fibroblasts, which is important for improving wound healing in the initial stage [

71].

Advanced Dressings: Drug-loaded nanofibers represent a cutting-edge advancement in interactive dressings, offering a powerful approach to treating bacterial infections. There are three primary types of nanofibers into which drugs can be incorporated: drug-loaded uniaxial electrospun nanofibers, drug-loaded biaxial electrospun nanofibers, and drug-loaded triaxial electrospun nanofibers. Among these, drug-loaded nanofibers are most frequently fabricated using the coaxial electrospinning technique, which produces a core/shell structure. The core comprises the drug in this configuration, while the shell comprises the polymer matrix. The drug release profile of these core/shell nanofibers is influenced by several factors, including shell thickness, the wettability of the polymer and drug, the nature of the matrix (whether linear or crosslinked), biodegradability, and porosity.

He et al. successfully fabricated PLLA/tetracycline hydrochloride (TCH) nanofibers via coaxial electrospinning, where PLLA served as the shell, acting as a drug release carrier, and tetracycline hydrochloride functioned as the core, providing the antibiotic effect. Their study demonstrated sustained drug release over a period of 30 days [

72]. Similarly, Soltanova et al. investigated coaxial nanofibers with a hydrophilic drug, ampicillin, as the core and polycaprolactone (PCL) as the sheath [

73]. Their comparison of blend nanofibers with coaxial nanofibers revealed that the blend nanofibers released 85% of the drug within 4 h, while the coaxial nanofibers exhibited a significantly slower release of 7% over the same period. A zero-order kinetic mechanism supports this controlled release profile.

Smart Dressings: This dressing can perform the real-time monitoring of wound healing by sensors integrated within the dressing. These sensors provide continuous feedback on the wound’s healing status. Schueren et al. demonstrated that PCL/chitosan nanofibers functionalized with Nitrazine yellow have significant potential for application in wound healing [

74]. Additionally, Tamayol et al. developed a thermoresponsive nanofiber mesh designed for on-demand drug delivery, where the release of the drug is triggered by biodegradable metallic heaters embedded within the nanofiber mesh. This innovative approach allows for precise, controlled drug administration directly at the wound site, enhancing the overall effectiveness of the treatment [

75].

Table 1 summarizes the advantages and disadvantages of these wound dressings.

4. Fiber Production Methods

Several advanced techniques are utilized in producing fibers, each distinguished by its unique mechanism and application. They include stretching, phase separation, template synthesis, self-assembly, force-spinning, and electrospinning. Each technique offers distinct advantages and is selected based on the desired properties and functionalities of the produced fibers.

4.1. Drawing

The drawing method is a meticulous and highly controlled technique for producing nanofibers, where a polymer solution is applied linearly to a designated surface or substrate. In this process, the polymer droplet is precisely drawn into a capillary tube at the critical juncture where the droplet meets the substrate. Subsequently, the capillary tube is methodically rotated, facilitating the gradual evaporation of the solvent as the tube is carefully withdrawn. This sequential action culminates in the formation of nanofibers with high precision [

76].

While the drawing method can produce exceptional uniformity and quality fibers, it is inherently labor-intensive and time-consuming [

77]. The method’s intricate nature limits its scalability, making it more suited for applications requiring small quantities of nanofibers or for research purposes rather than large-scale industrial production. Despite these limitations, the drawing method remains valuable when precision and control over fiber morphology are paramount [

76,

77].

4.2. Template Synthesis

The template synthesis method is a sophisticated technique for fabricating nanofibers, wherein a polymer solution is directed through a meticulously crafted mold or template. During this procedure, the solvent component of the solution either undergoes evaporation or diffuses into an alternative solvent medium. This transition culminates in the formation of nanofibers that precisely replicate the dimensions and morphological characteristics of the template’s pores [

77].

While this method offers unparalleled control over the size and shape of the resulting nanofibers, it is encumbered by significant practical challenges [

68]. Foremost among these is the intricate and labor-intensive template fabrication process, often requiring advanced materials and precise engineering. The complexity associated with creating such templates not only escalates production costs but also limits the scalability of the method. Consequently, despite its capability to produce nanofibers with high precision and uniformity, the template synthesis method remains primarily confined to specialized applications and research settings, where its benefits can outweigh the logistical and economic constraints [

78].

4.3. Phase Separation

The phase separation method is a sophisticated approach for fabricating nanofibers, wherein gelation occurs within a specially prepared polymer solution under controlled temperature conditions. During this process, polymer chains are induced to form a specific arrangement within the solution, developing a structured network. Subsequently, a selective solvent is employed to extract the original solvent from the system, leaving behind a three-dimensional lattice composed of interconnected fibers [

68].

This method is notable for its ability to create intricate fibrous structures with a high degree of control over the morphology and spatial arrangement of the fibers. The resulting three-dimensional network is characterized by its fused fibers, contributing to the structure’s overall mechanical stability and integrity. However, the phase separation method requires precise control over temperature and solvent conditions to achieve the desired fiber architecture. It is a technique best suited for specialized applications where such detailed control is essential [

78].

4.4. Self-Assembly

The self-assembly method is predominantly employed in fabricating protein and peptide nanofibers, leveraging the inherent ability of these biological molecules to organize themselves into structured configurations. In this method, a solution of proteins and peptides is carefully prepared. Under specific temperature and concentration conditions, the polymers naturally arrange themselves into an organized and stable structure [

78].

This self-organization process forms protein and peptide nanofibers, which retain their structural integrity and exhibit specific functional properties [

78]. The method is particularly valued for producing nanofibers with precise molecular arrangements without external templating or mechanical intervention. However, achieving the optimal conditions for self-assembly requires meticulous control of environmental factors, as even slight variations can significantly impact the final structure of the nanofibers. Despite these challenges, the self-assembly method is a powerful tool in nanotechnology, especially in developing biomimetic materials and applications where the unique properties of protein and peptide nanofibers are desired [

79].

4.5. Force-Spinning

The force-spinning method is innovative for producing nanofibers, utilizing centrifugal force to propel materials through a series of precisely engineered threaded holes. As the material is driven outward by centrifugal force, it is extruded through these apertures, forming nanofibers [

79].

A significant advantage of the force-spinning method is its ability to produce nanofibers from a wide range of materials, including those with low dielectric constants, which are often challenging to process using other techniques. This versatility makes force-spinning a promising approach in various applications, mainly where traditional methods may fall short [

79].

However, despite its potential, the force-spinning method still needs to be explored, with many aspects of the process still needing to be fully understood. Ongoing research is required to elucidate these unknown dimensions and optimize the technique for broader industrial applications. The method’s novel approach and capability to work with diverse materials make it a compelling study area within nanotechnology [

75,

76,

77].

4.6. Electrospinning

In recent years, nanofibers have garnered significant attention in biomedical applications, including tissue engineering, drug delivery, and wound dressing, due to their unique properties, such as a high aspect ratio, extensive surface area, customizable features, and consistent diameter. Among the various methods of fabricating nanofibers, electrospinning has emerged as the most widely utilized technique, favored for its simplicity, reproducibility, and cost-effectiveness [

78,

79,

80].

The electrospinning method involves the application of a high electric field between a polymeric solution and a collector plate. In this setup, the polymer solution acts as an electrode carrying a positive charge, while the metallic collector functions as a negatively charged counter-electrode. The substantial potential difference between these two electrodes generates electrostatic forces that draw the polymer solution into fine nano/microfibers [

80,

81,

82,

83].

The electrospinning apparatus consists of three fundamental components: a high-voltage power source to charge the electrodes, a syringe equipped with a metallic needle to deliver the polymer solution, and a metallic collector or counter-electrode where the spun nanofibers are deposited (

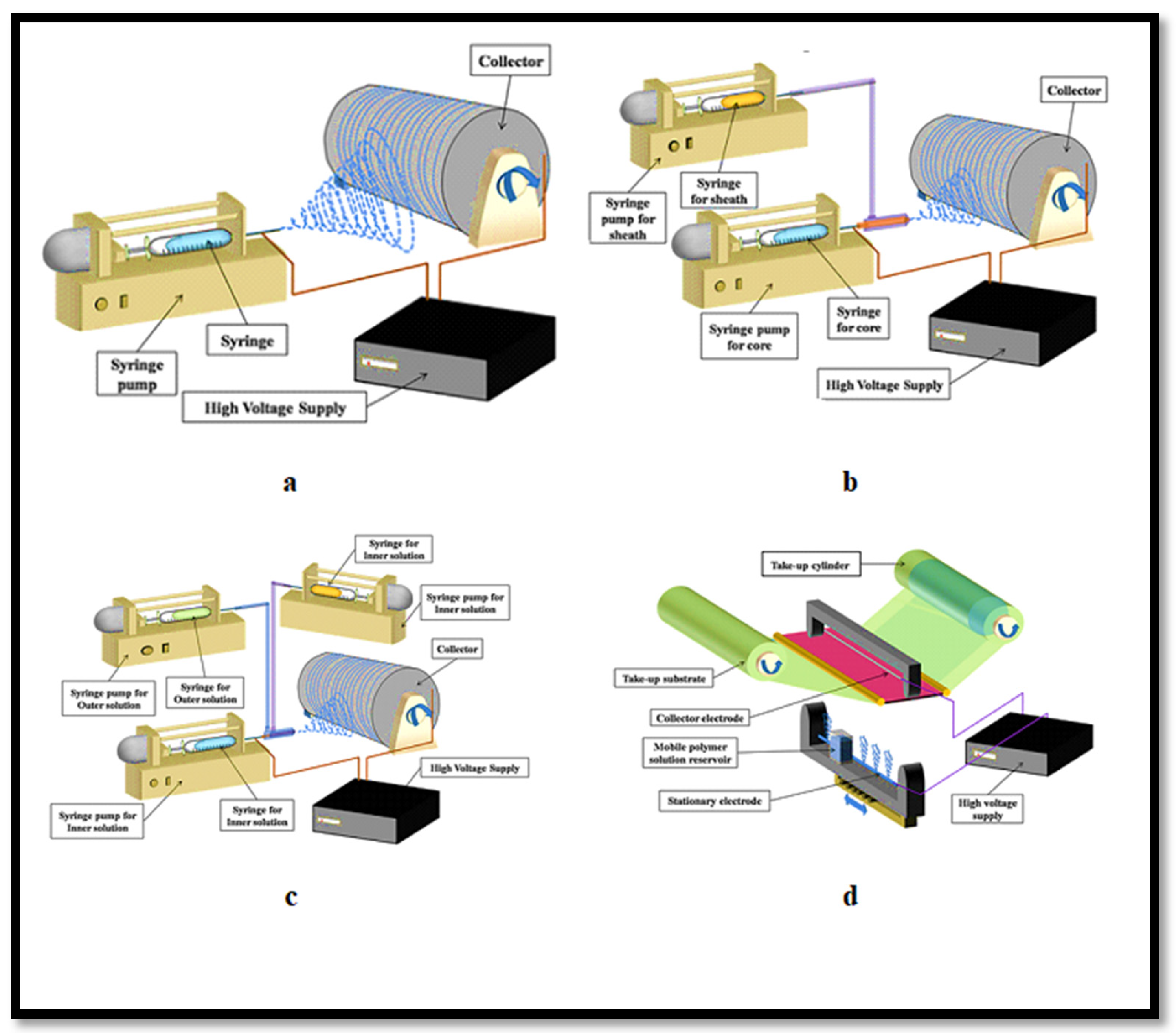

Figure 5a) [

80,

84,

85].

Several factors influence the characteristics of the resulting electrospun fibers. These include the following [

86,

87,

88,

89,

90]:

Solution properties: Viscoelasticity, surface tension, conductivity, dielectric properties, and solvent volatility.

Processing variables: Applied voltage (kV), the distance between the needle tip and the collector (cm), and the flow rate of the polymer solution (µL/min).

Environmental variables: Room temperature (°C) and humidity (%).

As the solvent evaporates, the nanofibers deposited on the metallic collector mimic the extracellular matrix (ECM) in size and geometry, making them particularly suitable for biomedical applications [

91,

92,

93,

94,

95]. Detailed parameters for electrospinning various biopolymers are outlined in

Table 2, providing a comprehensive guide for optimizing fiber production.

Table 2.

Parameters of electrospinning of different biopolymers.

Table 2.

Parameters of electrospinning of different biopolymers.

| Polymer | Solvent | Voltage (kV) | Flow Rate (mL/h) | Tip Collector Distance (cm) | Fiber Diameter (nm) | Ref. |

|---|

| PDDA | Ethanol | 17 | 0.8 | 16 | 93.5 | [26] |

| PLLA | Dichloromethane:Acetone (2:1) | 15 | 0.8 | 15 | 1153 ± 112 | [41] |

| PCL | Chloroform | 21 | 0.1 | 6 | 250–300 | [89] |

| Chitosan | Acetic acid | 40 | 20 µL/min | - | 130 | [90] |

| PVA | Deionized water | 22 | 1 | 10 | 240 | [91] |

| Cellulose Acetate | Acetone | 25 | 3 | 10 | 1000 | [92] |

Electrospinning offers the remarkable ability to produce fibers across a wide range of diameters, from micrometers (10–100 µm) to sub-micrometers or nanometers (10–100 nm) [

93,

94,

95]. Research by Chew et al. and Wang et al. has demonstrated that aligned electrospun scaffolds can significantly influence cellular behavior, guiding cells to elongate and orient themselves along the central axis of the nanofibers [

96,

97,

98]. However, uniaxial electrospinning, while effective for fiber alignment, may damage sensitive fillers or drugs.

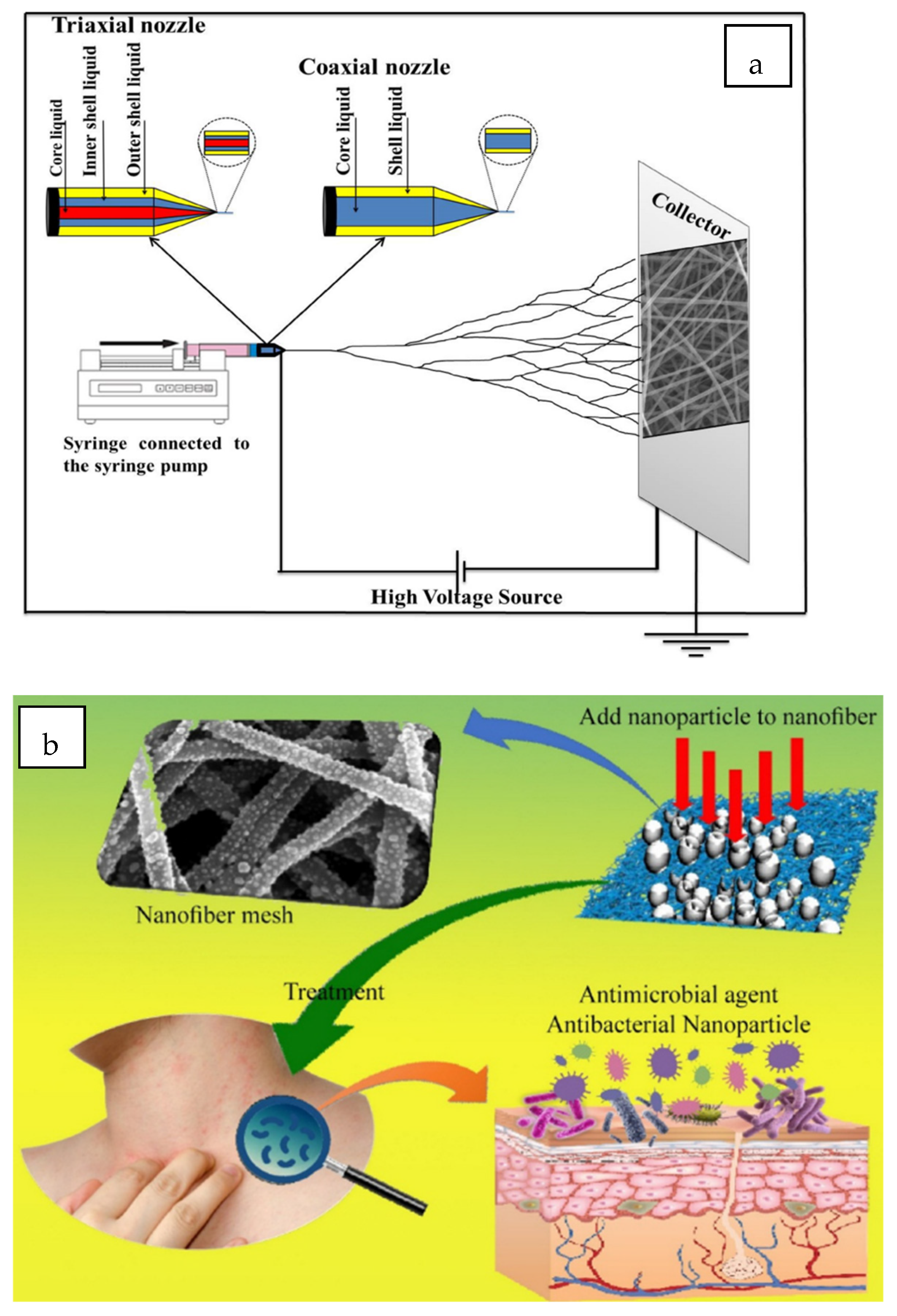

To address this limitation, the uniaxial electrospinning process has advanced to coaxial electrospinning, also known as the core–sheath electrospinning technique (

Figure 5b). In coaxial electrospinning, the sheath polymer solution primarily encases the core, and the conical shape of the sheath at the needle tip induces deformation of the core layer. This modification has gained popularity because the sheath layer helps maintain the structural integrity of the core materials, such as drugs or fillers [

99].

Coaxial electrospinning has also been utilized to fabricate hollow nanofibers through two primary approaches: (1) spinning the sheath polymer solution alone, without a core solution, and (2) selecting a core polymer solution that can be subsequently dissolved in a solvent, leaving behind a hollow structure with the sheath layer remaining intact [

100,

101,

102,

103]. For example, Srivastava et al. successfully created core/shell nanofibers with an average diameter of 100 nm using a heavy mineral oil/PVP + TiO

2 core/shell configuration. The core was removed by dissolving it in octane, leaving behind hollow fibers.

Despite their advantages, core/shell nanofibers are limited in providing sustained drug delivery due to having only a single breathable barrier layer of polymer matrix [

104]. Consequently, multi-barrier-layer nanofibers are preferred for applications requiring prolonged and controlled drug release, offering enhanced performance in sustaining and extending drug delivery.

The tri-axial electrospinning method produces multilayer fibers with three distinct layers: an outer solution, a middle solution, and an inner solution (

Figure 5c). This method facilitates complex functionalities such as sustained and dual drug delivery within a single fiber and allows for the incorporation of multiple properties by layering different materials [

105].

However, Khalf et al. identified critical challenges associated with the tri-axial electrospinning technique [

106]. The solvent choice for the sheath layers influences the fiber formation. The production rate of these fibers was also limited. These issues were overcome by introducing multi-needle and needleless electrospinning systems, significantly enhancing production efficiency. Needleless electrospinning, also known as tip-less electrospinning (

Figure 5d), represents a significant innovation. Wu et al. demonstrated that this technique, which utilizes a circular cylindrical electrode, can achieve a yield of PEO nanofibers that is 260 times greater than that obtained with the traditional single-jet electrospinning method [

107]. This substantial increase in yield underscores the effectiveness of needleless electrospinning in scaling up production while maintaining the high quality and consistency of the nanofibers.

Figure 5.

Various electrospinning fabrication methods: (

a) uni-axial electrospinning technique, (

b) coaxial electrospinning technique, (

c) tri-axial electrospinning technique, (

d) needleless electrospinning. Reprinted from Ref. [

105].

Figure 5.

Various electrospinning fabrication methods: (

a) uni-axial electrospinning technique, (

b) coaxial electrospinning technique, (

c) tri-axial electrospinning technique, (

d) needleless electrospinning. Reprinted from Ref. [

105].

4.7. Advantages of Nanofibers as Wound Dressing

4.7.1. Nanofibers and Hemostasis

Fibers produced through electrospinning often present small interstices and a high surface-area-to-volume ratio. Specifically, electrospun nanofibers’ increased surface area and fine porosity facilitate improved hemostasis at injury sites by providing a conducive environment for clot formation and wound healing [

108].

The superior hemostatic capabilities of these nanofibers make them a promising alternative to traditional hemostatic agents, which may carry the risk of adverse effects when introduced into the body. Nanofibers support effective hemostatic outcomes because of their high surface area and interconnected pore structure. This approach offers an efficient solution for managing bleeding and promoting tissue repair in clinical settings [

109].

4.7.2. Absorption of Exudates from the Wound

Nanofibers made of polymers absorb exudates and support wound healing. These nanofibers absorb significantly more water, swelling between 18% and 213%, compared to films made from the same polymers. This enhanced water absorption capacity manages exudate removal and prevents wound desiccation [

109]. By maintaining a moisture balance, nanofibers facilitate a favorable environment for healing, reducing risks associated with dry or overly wet wounds. This makes nanofibers a practical choice for wound dressing materials [

110].

4.7.3. Maintaining a Moist Environment and Permeability

Electrospun mats composed of nanofibers form a mesh-like structure that creates an environment for cellular activities, including respiration, proliferation, and viability. [

109]. The gas permeation in electrospun mats ensures that oxygen can diffuse freely through the fibers. This prevents tissue dehydration and maintains a moist environment, which supports cellular function and accelerates tissue regeneration [

110].

4.7.4. Drug-Controlled Release

Nanofibers can be associated with bioactive compounds to improve the healing process by delivering these to the wound site [

109]:

4.7.5. Flexibility and Density in the Dressing Mat

Polymeric fibers are often flexible, supporting an effective healing process, offering some advantages [

109], such as

Adaptability: The flexibility allows them to conform to the contours of various wound sites, providing consistent protection and support.

Comfort: Soft fibers minimize discomfort, and the porous structure reduces irritation, enhancing overall comfort during wear.

Compliance: Nanofiber dressings provide a comfortable and adaptable fit to the wound site. This adherence enhances the healing process and reduces the need for frequent dressing changes.

Nanofiber mat density: While the fibers’ size may affect the material’s overall functionality as a wound dressing, the density of fiber mats/meshes also plays a role in cell adhesion and proliferation and exudate removal. Lower fiber densities enhance fibroblast infiltration and exudate absorption, whereas higher densities improve mechanical support but limit cellular penetration [

112].

4.7.6. Scar-Reduction Strategies

While complete scar-free healing is impossible in significant or deep wounds, minimizing scar formation is the objective in advanced wound care. Achieving minimal scarring with wound dressings remains a challenge. Fibers are engineered to support skin regeneration by providing a biodegradable fiber matrix as a tissue repair scaffold. The fibers mimic the skin’s natural structure, enhancing biocompatibility with surrounding tissues for wound healing and tissue regeneration. By mimicking the ECM architecture, fibers can be integrated into the wound site, promoting more efficient healing and reducing the risk of excessive scar formation. Such advanced nanofiber-based dressings offer a promising strategy for improving wound healing outcomes, potentially resulting in smoother, less prominent scars and more effective tissue repair [

110,

111,

112].

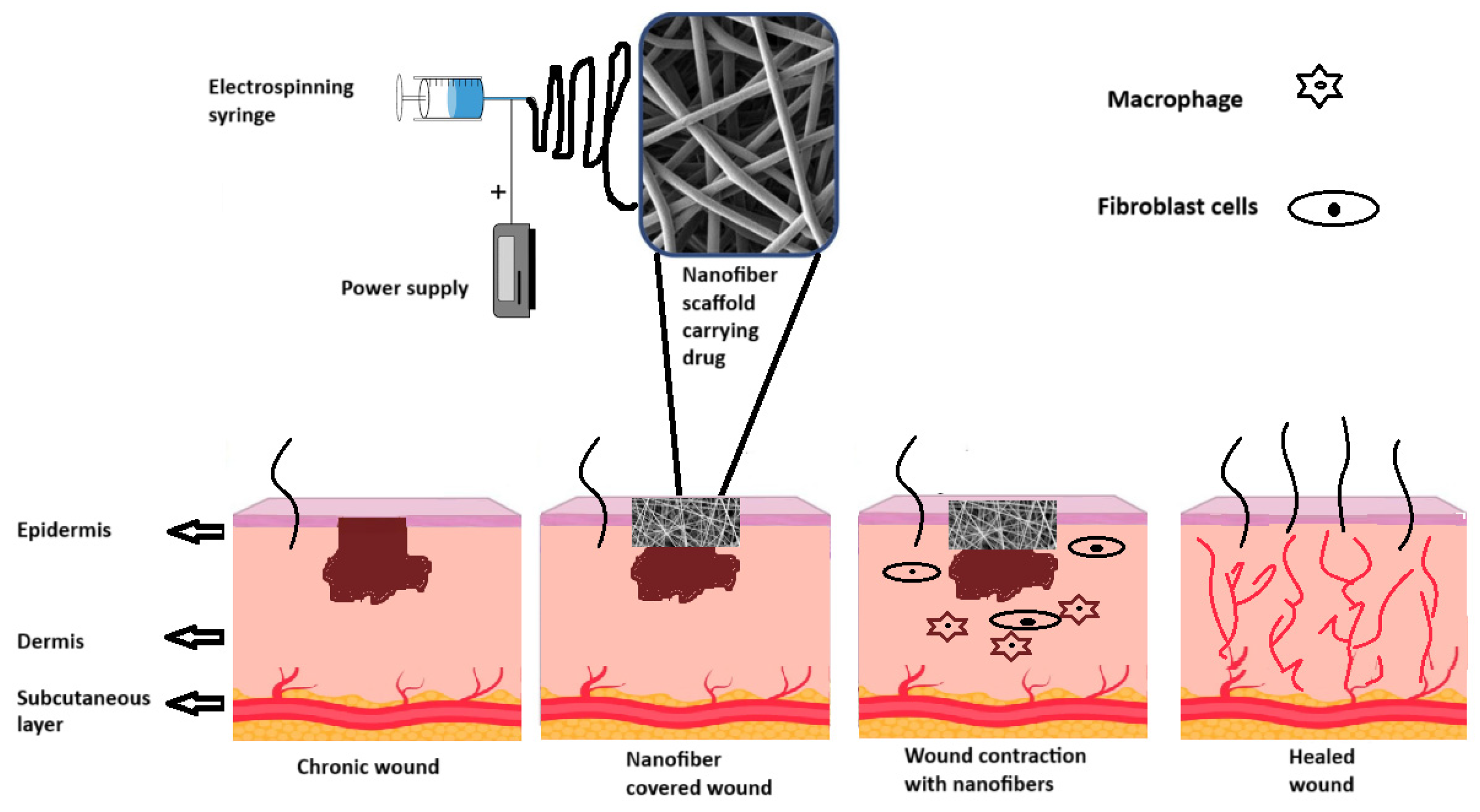

Figure 6 illustrates different stages of wound healing following the application of nanofiber-based dressings. In general, the scaffolds facilitate the recruitment of fibroblasts and macrophages that contribute to synthesizing ECM components and resolving inflammation, helping to reestablish the dermal tissue and contract the wound, respectively [

110]. Fibers are materials that support cellular infiltration and integration, enhancing healing and reducing scar formation (

Figure 6).

5. Polymers to Produce Electrospun Nanofibers

Polymers can be classified into natural and synthetic types. The selection of the appropriate polymer system is critical, as these nanofiber-based patches are intended for direct contact with wound tissue. For optimal wound healing outcomes, these patches must possess properties that closely mimic the ECM and support the healing process effectively.

Natural polymers, including proteins and polysaccharides, have gained considerable attention due to their inherent similarity to the macromolecules recognized by the human body. These natural polymers are advantageous because they offer a high degree of ECM biomimicry, which enhances biocompatibility and promotes better integration with the wound site. Moreover, many natural polymers possess additional beneficial properties such as antimicrobial, anti-inflammatory, and hemostatic effects, which can further contribute to wound healing and protection [

111,

112].

On the other hand, synthetic polymers can be engineered to provide specific mechanical properties, controlled degradation rates, and tailor-made functionalities. However, balancing mechanical performance and biological compatibility often requires careful design and modification [

112].

5.1. Electrospinning of Natural Polymers for Wound Healing

Natural polymers are essential to impart biocompatibility in wound dressings. Some natural polymers also often exhibit antiadhesive and anti-inflammatory properties, which enhance tissue repair. However, there are challenges associated with using natural polymers for electrospinning. These include higher costs, more complex processing requirements, and inferior mechanical properties compared to synthetic polymers [

112,

113,

114,

115]. Researchers often combine natural and synthetic polymers to address these limitations. By blending these polymers in solution or co-electrospinning them from different solutions, it is possible to enhance the physical and chemical properties of the resulting nanofibers to meet specific requirements for wound healing applications [

116,

117,

118].

Some of the main natural polymers used to promote wound healing include [

115,

119,

120]

Collagen: Supports cell adhesion and tissue regeneration, mimicking the ECM composition that comprises proteins and proteoglycans.

Gelatin: Is derived from collagen, offering similar benefits for tissue repair.

Chitosan: Presents antimicrobial activity and enhances wound healing.

Fibrinogen: Supports blood clotting, assisting in hemostasis and tissue repair.

Fibronectin: Supports cell adhesion and migration, supporting wound repair.

Silk Fibroin: Provides mechanical performance and biocompatibility.

Elastin: Contributes to the elasticity and flexibility of tissues.

Hyaluronic Acid: Supports hydration and tissue repair and has anti-inflammatory properties.

Cellulose: Offers high mechanical strength and biocompatibility.

Alginate: Provides gel-forming properties and aids in moisture control [

120].

5.1.1. Collagen

Collagen, the most abundant animal protein, is a critical structural component in connective tissues such as the dermis, tendons, and bones. It is pivotal in the extracellular matrix (ECM), providing tissue structural stability and tensile strength. Collagen type I, in particular, supports a wide range of cell types, including hepatocytes, spinal ganglion cells, fibroblasts, nerve cells, Schwann cells, epithelial cells, and embryonic lung cells [

121]. It is fundamental in studies of tissue morphogenesis, as well as cell growth, differentiation, and migration.

Given its essential role in tissue repair and regeneration, collagen has been extensively researched for its applications in wound healing. A notable study developed a novel scaffold using collagen-based biocompatible electrospun nanofibers (NFs), demonstrating effectiveness against key wound pathogens like

Pseudomonas aeruginosa and

S. aureus. The scaffold, comprising PHB–Gel–OSA–Col, was highly effective for wound healing and reconstruction, exhibiting high infection tolerance in both in vitro and in vivo evaluations [

122].

Electrospun collagen fibers have proven superior to traditional wound dressings in the biomedical field. The crosslinking of collagen electrospun fibrous membranes under aqueous conditions has increased Young’s modulus, enhancing their mechanical properties and mimicking the native ECM more effectively. This results in improved wound healing and tissue regeneration compared to conventional gauze and industrial collagen dressings, such as those used for bone and cartilage [

123].

Combined with topical agents or enzymes, hybrid collagen-based fiber dressings can further accelerate healing and improve recovery. One study investigated incorporating silver nanoparticles (NPs) into collagen nanofiber mats through electrospinning. Silver NPs, synthesized by chemical reduction, were evaluated for their minimum inhibitory concentration (MIC) against

S. aureus and

P. aeruginosa, revealing significant antibacterial activity [

121].

Another study developed a novel antimicrobial nanofiber mat incorporating SSD into ethyl cellulose (EC)/PLA/collagen, demonstrating inhibition against

Bacillus and

Escherichia coli (

E. coli) bacteria [

124]. Similarly, electrospun nanofiber membranes composed of collagen and zein in an aqueous acetic acid solution showed controlled release and antibacterial action, making them suitable for wound healing applications [

125,

126].

Further advancements include the creation of zein/PCL/collagen nanofibers incorporating zinc oxide (ZnO) nanoparticles and aloe vera, which displayed inhibition activity against

S. aureus and

E. coli. These findings suggest that collagen-based nanofibers with added antimicrobial agents can be effective wound dressings [

127].

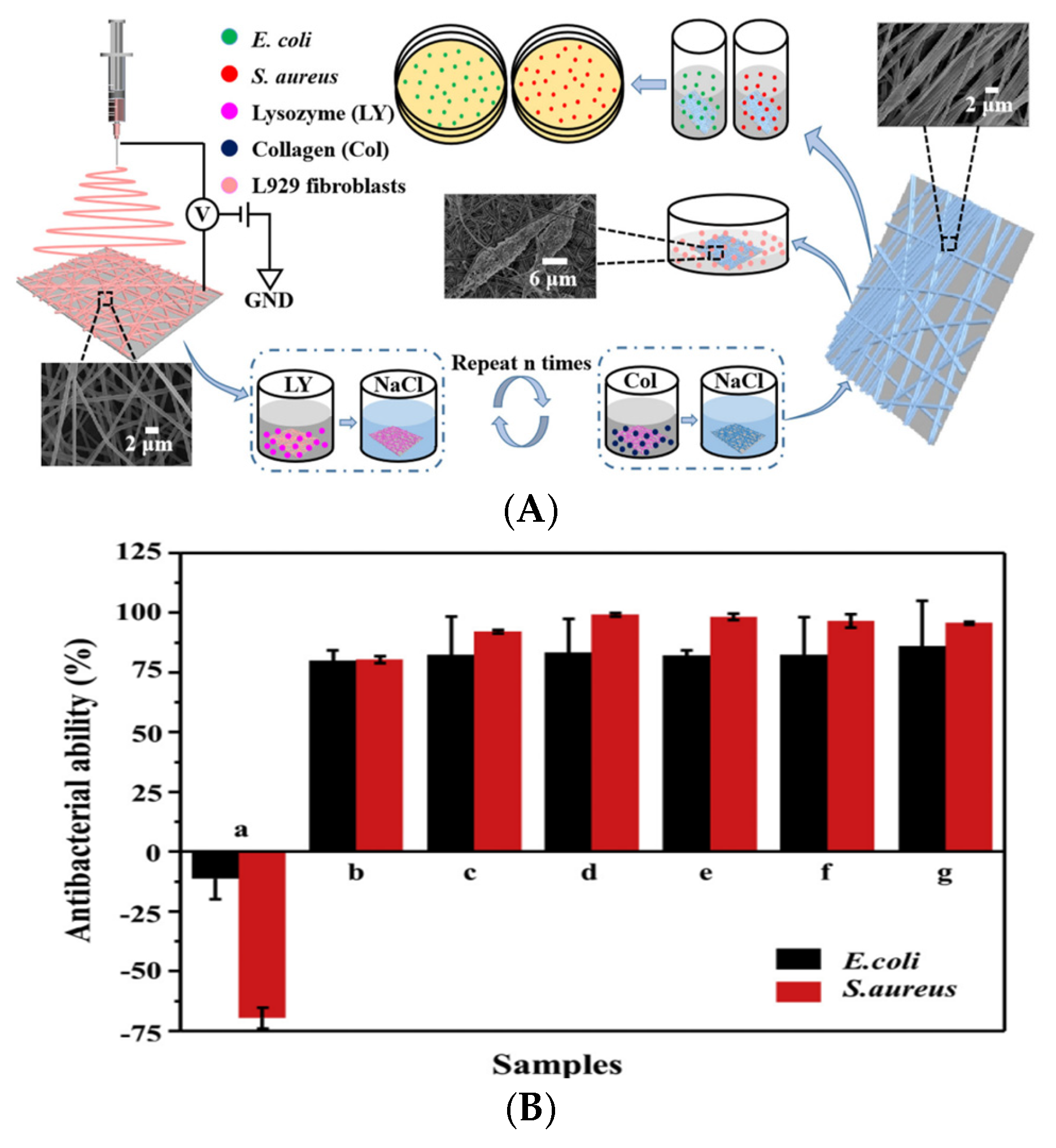

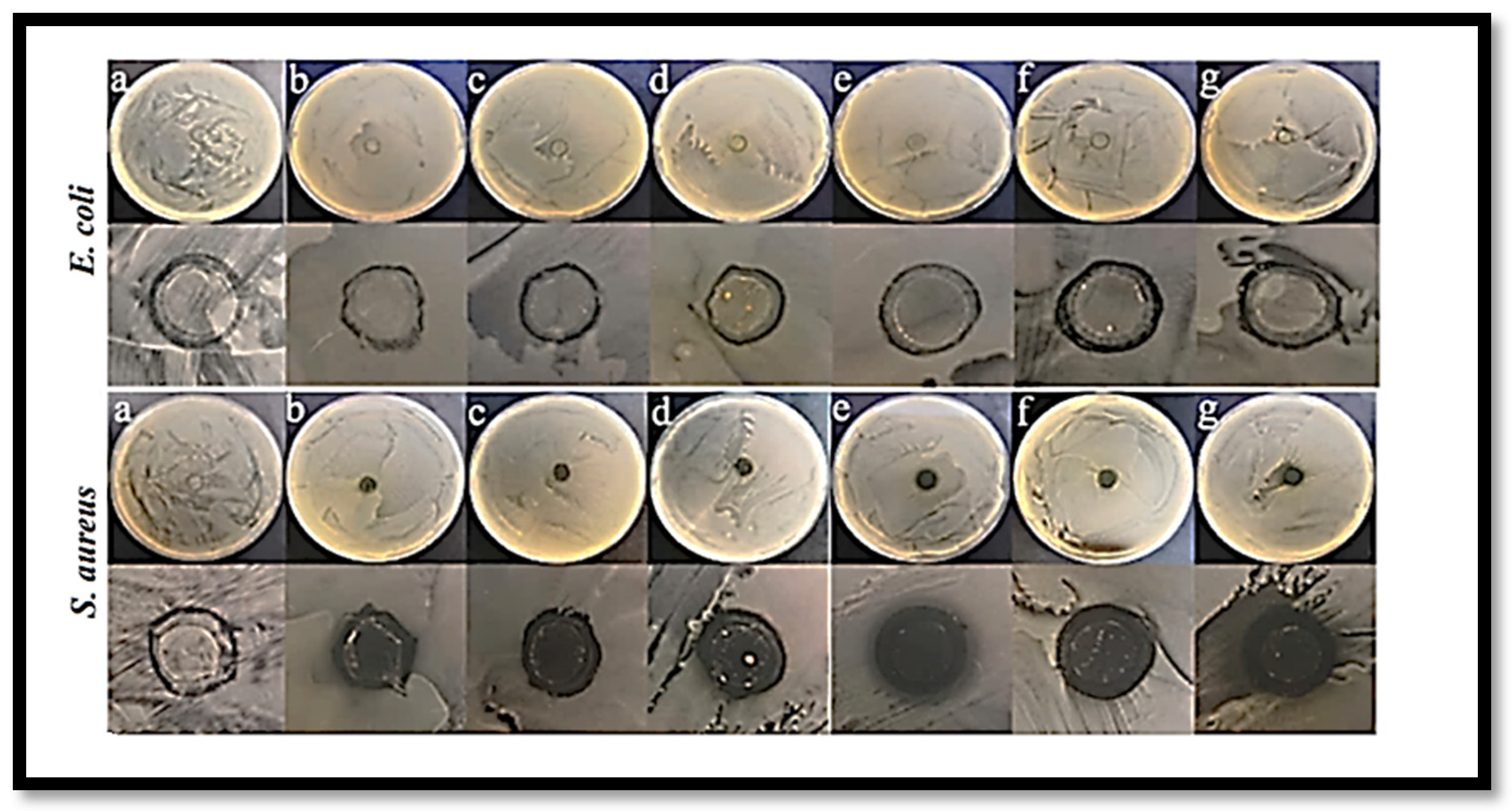

In a different approach, Yuan et al. employed a layer-by-layer (LBL) self-assembly deposition method to integrate lysozyme (LY) and collagen onto silk fibroin/nylon 6 (SF/N6) nanofiber mats [

128]. The LBL-structured mats exhibited superior antibacterial and biocompatibility properties compared to the SF/N6 nanofibers alone. The successful assembly of lysozyme significantly enhanced the antibacterial performance, contrasting with SF/N6 mats that promoted the proliferation of

E. coli (11.4%) and

S. aureus (69.6%) (

Figure 7) [

128].

Liu et al. developed composite nanofibers incorporating polylactide-polyglycolide (PLGA) with collagen, achieving an average fiber diameter of 250 nm [

129]. These as-spun nanofibers exhibited no cytotoxic effects and effectively promoted cell adhesion and proliferation in normal human fibroblasts. In vivo studies using full-thickness wounds in Sprague Dawley rats demonstrated that the PLGA-collagen nanofibers facilitated a faster healing process than conventional proprietary dressings, such as DuoDERM and gauze sponges. Specifically, the PLGA-collagen nanofibers resulted in a more rapid reduction in wound area, supported the formation of new fibrous tissue, exhibited minimal inflammatory cell infiltration, and achieved complete re-epithelialization [

129].

Rath et al. prepared collagen nanofibers loaded with silver nanoparticles, with fiber diameters ranging from 300 to 700 nm [

130]. These nanofibers were crosslinked through exposure to glutaraldehyde-saturated vapor for 24 h at room temperature. This effectively delayed the release of the encapsulated silver nanoparticles by reducing water influx into the fibers. The silver-loaded nanofibers demonstrated significant antibacterial activity in vitro against

S. aureus and

P. aeruginosa. Unloaded collagen nanofibers showed improved wound healing compared to control groups, but the silver-nanoparticle-loaded nanofibers exhibited even greater healing rates due to their antimicrobial properties. This resulted in accelerated wound healing and minimized scar formation. Histological analysis of the wound areas indicated that the silver-nanoparticle–collagen nanofibers significantly enhanced collagen production, wound contraction, and re-epithelialization compared to the unloaded collagen nanofibers [

130].

5.1.2. Gelatin

Gelatin, a polymer derived from collagen, is widely abundant and shares the composition and properties of collagen [

131]. Depending on the hydrolysis method employed, gelatin can be classified into two types: Type A gelatin, produced via acidic hydrolysis, which carries a positive charge at physiological pH, and Type B gelatin, obtained through alkaline hydrolysis, which is negatively charged under the same conditions [

132]. This biodegradable polymer is extensively utilized across various industries, including food, cosmetics, and medicine [

133]. Gelatin products can take the form of films, nanoparticles, or porous hydrogels, each serving distinct functions.

In particular, gelatin has been widely employed as a drug delivery system for growth factors, with crosslinking techniques being utilized to modulate the degradation and release rates of encapsulated substances [

134]. Given its broad molecular weight distribution, gelatin can adopt various conformations, such as hydrogels, microspheres, or microparticles, under appropriate temperature, solvent, or pH conditions. Gelatin nanofilms, for instance, can be produced through electrospinning [

134,

135]. However, due to its nature as a polyelectrolyte polymer with ionizable groups, gelatin forms strong hydrogen bonds that result in a three-dimensional macromolecular network, thereby restricting the mobility of gelatin chains [

135]. Consequently, electrospinning pure gelatin is challenging. To overcome this, solvents such as 2,2,2-trifluoroethanol, formic acid, and acetic acid are employed during the electrospinning process [

136]. Additionally, the stability of electrospun gelatin fibers can be enhanced through crosslinking with various chemicals, such as glutaraldehyde vapor [

137,

138] or hexamethylene diisocyanate [

139].

The potential of gelatin nanofibers, particularly those formed through electrospinning, for wound healing applications has been previously documented. For instance, Dubský et al. reported the successful electrospinning of gelatin nanofibers using a 10 wt% gelatin solution in acetic acid [

140]. The resulting fibers, with an average diameter of 110 μm, were crosslinked post-electrospinning by exposure to glutaraldehyde vapors for three hours in a sealed environment. The study demonstrated that human dermal fibroblasts, keratinocytes, and mesenchymal stem cells adhered to and proliferated on the crosslinked gelatin nanofibers, indicating the fibers’ non-cytotoxic nature and potential applicability in tissue engineering. In vivo studies involving full-thickness wounds in Wistar rats revealed that crosslinked gelatin nanofibers promoted more rapid wound closure than polycaprolactone (PCL) nanofibers or a control gauze treatment. Furthermore, these nanofibers facilitated greater epithelialization, granulation tissue formation, and myofibroblast presence in the wound area [

140].

Incorporating biomolecules as therapeutic agents into gelatin nanofibers has also been explored to enhance wound healing. Adeli-Sardou et al. encapsulated lawsone—a compound derived from

Lawsonia inermis, known for its antimicrobial activity against Gram-positive, Gram-negative, and biofilm-producing bacteria—into gelatin–PCL nanofibers through coaxial electrospinning [

141]. The diameter of the resulting nanofibers varied, with measurements of 238 ± 8, 259 ± 13, 246 ± 10, and 297 ± 5 nm for PCL–gelatin-lawsone nanofibers containing lawsone concentrations of 0, 0.5, 1, and 1.5%

w/

v, respectively. The lawsone-loaded nanofibers exhibited a sustained release of the compound over 20 days. They demonstrated antibacterial activity against

S. aureus, though they were ineffective against

P. aeruginosa, as the latter species is known to degrade lawsone [

141,

142]. These nanofibers also promoted the adhesion and proliferation of gingival fibroblast cells, accompanied by increased gene expression of transforming growth factor β (TGF-B1) and collagen (COL1). In vivo wound healing studies on Wistar rats indicated that lawsone-loaded nanofibers significantly accelerated wound closure, with near-complete closure observed for PCL-gelatin-lawsone 1%

w/

v and 1.5%

w/

v, outperforming both lawsone-free fibers and untreated controls [

141]. Histological evaluations further revealed that wounds treated with lawsone-loaded nanofibers displayed enhanced granulation tissue formation, increased fibroblast and collagen activity, and better-organized connective tissue, with angiogenesis completed by Day 14 post-treatment [

141].

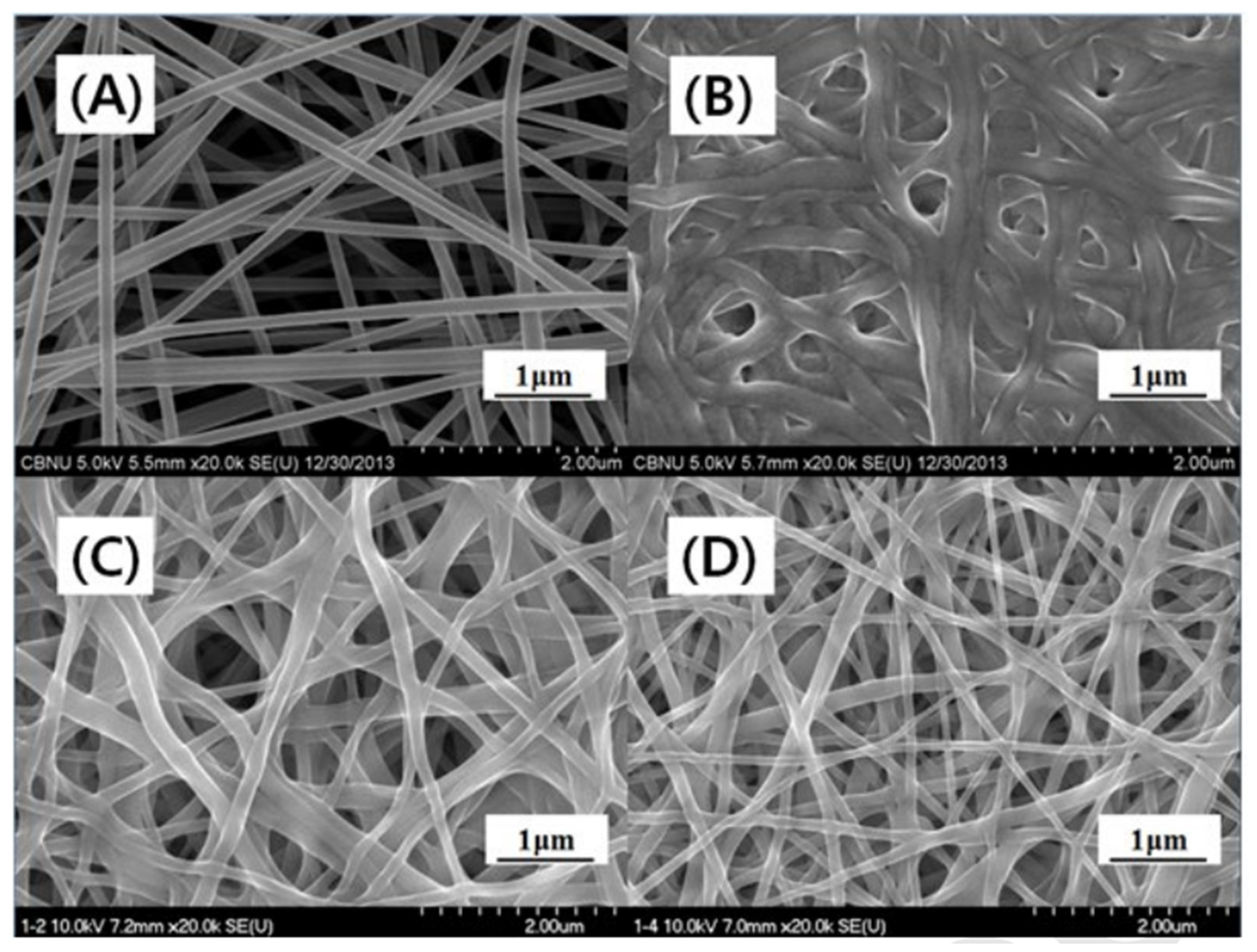

Lu et al. aimed to scale up the production of gelatin nanofibers by employing spiral electrospinning instead of the conventional single-needle electrospinning method, producing finer nanofibers in larger quantities [

143]. Two crosslinking methods were investigated: vapor-phase and liquid-phase glutaraldehyde. The fabricated nanofibers were characterized using scanning electron microscopy (SEM), transmission electron microscopy (TEM), and mechanical testing, revealing differences in their structures. The nanofibers crosslinked via the liquid-phase glutaraldehyde method exhibited superior uniformity, higher tensile strength, and improved morphology compared to those crosslinked using the vapor-phase method.

5.1.3. Chitosan

Chitosan (CS) is widely utilized as a wound dressing material and for its inherent therapeutic efficacy. Its beneficial properties, including biocompatibility, nontoxicity, biodegradability, hemostatic, bacteriostatic, and fungistatic characteristics make CS effective in promoting wound healing [

144]. In wound dressings, CS has been employed in various forms, such as membranes, nanofibers (NFs), and sponges. Owing to its unique biocompatibility, robust biodegradability, and remarkable antimicrobial properties, CS, a naturally occurring polysaccharide with abundant availability, has been extensively used in numerous medical applications, particularly in wound care.

Electrospinning techniques have been effectively employed to fabricate composite nanofiber membranes of CS and silk fibroin (SF). The antibacterial efficacy of these composite nanofibers against Gram-negative

E. coli and Gram-positive

S. aureus was assessed using the turbidity measurement method. The results indicated that the antimicrobial activity of the composite depended on the bacterium type [

145].

In one study, Huang et al. developed biomimetic nanofibrous matrices coated with positively charged CS and negatively charged Type I collagen using the layer-by-layer (LBL) assembly method [

146]. The LBL-architected nanofibrous membranes demonstrated enhanced cell migration in vitro and facilitated skin re-epithelialization and vascularization in vivo. These findings suggest that LBL-structured nanofiber matrices can restore the structural and functional properties of the skin [

146].

Another study explored the development of biocompatible antimicrobial nanofiber wound dressings by loading two natural extracts—Cleome droserifolia (CE) and Allium sativum aqueous extract (AE)—onto honey, polyvinyl alcohol (PVA), and hydroxypropyl chitosan (HPCS) matrices. In vitro antibacterial evaluations were conducted against

S. aureus,

E. coli, methicillin-resistant

S. aureus (MRSA), and multidrug-resistant

P. aeruginosa compared with the commercial dressing Aquacel Ag. The results revealed that HPCS–AE and HPCS–AE/CE nanofiber mats completely inhibited

S. aureus, while the HPCS–AE/CE mats exhibited moderate antibacterial activity [

147].

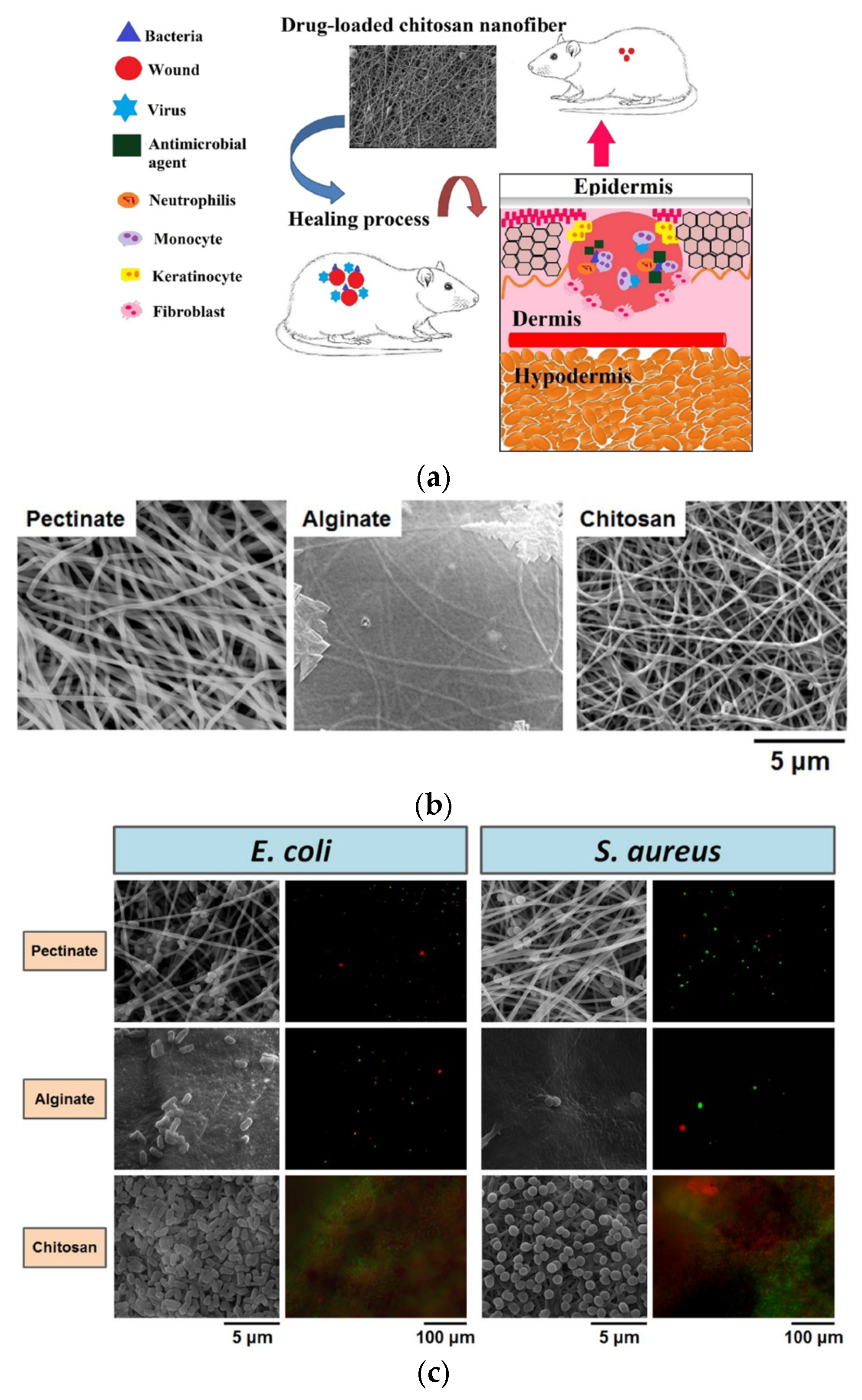

Polysaccharides such as pectin, alginate, and CS have been processed into micrometer-scale architectures (microfibers or particles) for clinical wound care. A comparative study described electrospun nanofiber dressings made from these polysaccharides, with results showing that the pectinate nanofiber mat demonstrated superior antibacterial efficacy. Consequently, the pectinate nanofiber mat may be considered equivalent to alginate and CS nanofiber mats as a wound dressing option [

148].

Additionally, a green synthesis method was reported for creating antibacterial nanofiber mats embedded with CS and loaded with silver nanoparticles (Ag-NPs, 25 nm in diameter) following reduction with glucose [

149]. In another research endeavor, a 30/70 blend of CS-ethylenediaminetetraacetic acid (CS 2 wt%–EDTA) and PVA solution (10 wt%) was electrospun to produce fibrous mats incorporating lysozyme at concentrations of 10, 20, and 30 wt% [

150]. These mats were investigated for their wound healing potential, with results indicating that this biomaterial nanofiber has a promising ability to facilitate wound repair [

151].

Ahmed et al. reported the successful fabrication of chitosan-polyvinyl alcohol (PVA) nanofibers encapsulating zinc oxide (ZnO) nanoparticles [

151]. These nanofibers exhibited an average diameter of 279.34 ± 7.23 nm and demonstrated significant antimicrobial activity against a spectrum of bacterial strains, including

E. coli,

P. aeruginosa,

Bacillus subtilis (B. subtilis), and

S. aureus. In vivo wound healing studies conducted on diabetic rabbits revealed that the chitosan-PVA-ZnO nanofibers substantially enhanced the wound closure rate compared to the control group. Histological analysis of the treated wounds further indicated that the chitosan-PVA-ZnO nanofibers facilitated superior re-epithelialization and accelerated scar tissue maturation, characterized by the absence of inflammatory infiltrates and increased collagen content [

151].

In a separate study, Khan et al. developed chitosan-polycaprolactone (PCL) nanofibers loaded with tinidazole [

152], an antibiotic commonly employed in the treatment of periodontitis due to its effectiveness against anaerobic bacteria such as Provotella species, Fusobacterium nucleatum, and Veillonella species [

153], which are often implicated in the disease. These chitosan-PCL-tinidazole nanofibers were evaluated in a clinical trial involving patients with periodontitis. The study compared three treatment approaches for each infected site: (1) scaling and root planing (SRP), the conventional therapy for periodontitis; (2) SRP combined with chitosan-PCL nanofibers; and (3) SRP combined with chitosan-PCL-tinidazole nanofibers [

153].

The results demonstrated that the drug-loaded nanofibers significantly improved recovery from periodontitis. Patients treated with the chitosan-PCL-tinidazole nanofibers exhibited reduced irritation at the injection site compared to the other treatment groups. This was evidenced by reduced periodontal pocket depth, gingival index, bleeding upon probing, and increased gingival tissue attachment to the tooth, indicating enhanced clinical outcomes [

153].

Naseri et al. developed an innovative wound dressing mat using chitosan combined with another polymer, polyethylene oxide (PEO) [

154]. The electrospun mat characteristics were evaluated, including its structural morphology, mechanical and thermal properties, water vapor permeability, and cytocompatibility. To enhance the mechanical properties of the mat while reducing cytotoxicity, the researchers opted to replace the commonly used crosslinking agent, glutaraldehyde—widely employed in various applications for strengthening organic materials—with genipin, a reagent known for its lower cytotoxicity [

154].

The wound dressing mat retained moisture and supported high tensile strength, contributing to its durability and effectiveness in wound care. Furthermore, cytocompatibility tests indicated that the fibers supported the high cell viability of adipose-derived stem cells for seven days. This combination of enhanced mechanical properties, biocompatibility, and prolonged stability positions the chitosan-PEO electrospun mat as a promising material for future wound care solutions [

154].

5.1.4. Fibrinogen

Fibrinogen, a soluble 340 kDa globular protein, is an inactive precursor to fibrin and circulates within the bloodstream. Upon disruption of the skin, fibrinogen plays a crucial role in hemostasis by forming insoluble fibrin fibers essential for clot formation [

155]. Beyond its role in clotting, fibrinogen is actively involved in wound repair processes, where it interacts with various enzymes, clotting factors, and different cell types such as endothelial cells, smooth muscle cells, fibroblasts, keratinocytes, and leukocytes. Fibrinogen contributes to inflammation, angiogenesis, and tissue remodeling [

155].

However, research focused on fibrinogen nanofibers for wound healing applications remains limited compared to studies on other natural compounds. Wnek et al. carried out one of the pioneering efforts to produce electrospun fibrinogen nanofibers [

156]. Their study prepared Type I bovine fibrinogen solutions in a hexafluoroisopropanol (HFP) solvent mixture and minimum essential medium (MEM). The fibrinogen concentrations used were 8.3%, 12.5%, and 16.7%

w/

v, resulting in nanofibers with average diameters of 80 ± 20 nm, 310 ± 70 nm, and 700 ± 110 nm, respectively [

156].

Subsequent research explored the effects of fibrinogen nanofiber orientation on human umbilical vein endothelial cells (HUVECs) [

157]. In this study, a supernatant derived from a centrifuged bovine fibrinogen solution in HFP/DMEM was electrospun to produce randomly oriented and aligned nanofibers. Randomly oriented fibers were obtained by electrospinning onto a stationary collector, whereas aligned fibers were created using a rotating drum. The results demonstrated that endothelial cells recognized and adhered to the fibrinogen nanofibers more rapidly than to surfaces with adsorbed fibrinogen. Furthermore, cell orientation and migration were significantly enhanced on the aligned nanofibers, whereas the randomly oriented nanofibers induced a stellate-like morphology in the cells, with locally restricted migration [

157].

Yuan et al. further expanded the potential applications of fibrinogen nanofibers by investigating the encapsulation of therapeutic agents to enhance wound healing [

158]. In their study, chitosan-PEO and fibrinogen solutions were independently and simultaneously electrospun onto the same metal mandrel. Platelet-derived growth factor (PDGF) was incorporated into both solutions before electrospinning, resulting in PDGF-loaded chitosan-PEO-fibrinogen nanofibers. Exudates collected from drug-loaded and drug-free nanofibers were tested for their ability to promote human dermal fibroblast migration. The results revealed that the drug-loaded nanofibers significantly enhanced fibroblast migration compared to the drug-free scaffolds, demonstrating the potential of fibrinogen-based nanofibers as advanced wound healing materials [

158].

5.1.5. Fibronectin

Fibronectin is a multifunctional glycoprotein composed of two nearly identical monomers, each with a molecular weight of approximately 250 kDa [

159]. Its primary role within the ECM is to provide structural support. Following tissue injury, a provisional ECM predominantly composed of fibrin and fibronectin is established, which is subsequently replaced by a mature ECM with a higher fibronectin content [

160]. Beyond its structural role, fibronectin is critically involved in several essential biological processes, including cell attachment, contractility, migration, differentiation, gene expression, and angiogenesis [

161,

162]. These functions underline the indispensable role of fibronectin in ECM formation, re-epithelialization, and tissue repair, making fibronectin-based nanofibers highly promising for incorporation into wound healing devices [

160,

163].

Despite its potential, the fabrication of fibronectin nanofibers through electrospinning has yet to be explored. This is mainly due to the challenge of replicating the natural pattern of fibronectin fibrillogenesis, which relies on an integrin activation mechanism requiring mechanical tension, an aspect not easily replicated by conventional electrospinning methods. Consequently, researchers have shifted their focus to coating electrospun polymer-based nanofibers with fibronectin rather than directly producing fibronectin nanofibers [

164].

For instance, Ji et al. developed electrospun hyaluronic acid nanofibers that were subsequently coated with human plasma fibronectin [

165]. These fibronectin-coated hyaluronic acid nanofibers demonstrated enhanced migration of NIH 3T3 fibroblasts, indicating their potential application in wound healing and tissue regeneration. In another study, fibronectin was grafted onto poly(L-lactide-co-caprolactone) (PLCL) electrospun nanofibers via a two-step chemical reaction [

166]. In vitro experiments with porcine esophageal epithelial cells showed that this scaffold could effectively promote epithelial regeneration [

167].

Moreover, fibronectin has improved the biocompatibility of silver sulfadiazine (SSD)-loaded polycaprolactone-polyvinyl alcohol (PCL-PVA) nanofibers. Coating these nanofibers with fibronectin reduced the cytotoxic effects of SSD and enhanced the initial attachment of human fibroblasts, further highlighting the utility of fibronectin in wound healing applications [

168].

In an innovative approach, Chantre et al. fabricated nanofiber-based scaffolds composed of pure fibrillar fibronectin using a rotary jet spinner. These as-spun fibers were designed to better mimic the conformation of fibronectin found in fetal skin, which is associated with scarless wound healing. In vivo studies on full-thickness wounds in C57BL/6 mice demonstrated that the fibronectin nanofibers significantly accelerated wound closure, achieving complete wound contraction 11 days post-injury, compared to 14 days for the control group. Additionally, the fibronectin nanofibers facilitated the restoration of typical epidermal and dermal structures within 20 days, whereas control wounds exhibited a thicker epidermis characteristic of scarred tissues [

168].

5.1.6. Hyaluronic Acid

Hyaluronic acid (HA) is a linear glycosaminoglycan composed of repeating disaccharide units of N-acetyl-D-glucosamine and glucuronic acid [

169,

170]. It is a highly hydrophilic, polyanionic biomolecule with a molecular weight ranging from 100 kDa to as much as 107 MDa [

169,

170]. HA is ubiquitously present in the extracellular matrix (ECM) of various tissues in the human body, particularly in the synovial fluid and the ECM of soft connective tissues like skin. HA is degraded into lower-molecular-weight fragments within the ECM during inflammatory responses [

169,

170].

The molecular weight of HA plays a crucial role in its biological activity. Specifically, low-molecular-weight HA (approximately 50 kDa) and medium-molecular-weight HA (approximately 1000 kDa) have been reported to induce proinflammatory responses by regulating the Toll-like receptor-4 (TLR-4) and activating the nuclear factor kappa B (NF-κB) pathway [

171]. HA’s presence in the skin supports dermal structure and regulates dermal volume through its hydrating ability [

171,

172]. Furthermore, HA supports cell proliferation, differentiation, and wound healing [

169]. Additionally, HA has been found to protect skin cells from ultraviolet-induced damage and mitigate wound impairment caused by oxygen-free radicals [

173,

174].

Due to its high biodegradability, HA is rapidly broken down by hyaluronidases, with tissue half-lives typically extending up to two days [

170,

175]. The unique properties of HA have led researchers to explore its use in producing nanofibers for wound healing applications. For instance, Huan-Ju et al. developed HA-collagen nanofibers encapsulating angiogenic growth factors using dual electrospinning techniques [

176]. In this approach, HA was dissolved in NaOH/DMF, and collagen was dissolved in acetic acid. Growth factors such as fibroblast growth factor (FGF), epidermal growth factor (EGF), vascular endothelial growth factor (VEGF), and platelet-derived growth factor (PDGF) were incorporated into the nanofibrous scaffold through two different methods: (1) direct incorporation of the growth factors into the polymer blend before electrospinning, or (2) encapsulation of the growth factors into gelatin nanoparticles, followed by incorporation into the polymer blend before electrospinning [

176].

In vitro studies conducted on human umbilical vein endothelial cells (HUVECs) revealed a significant increase in cell growth rate, capillary tube formation, and branching for groups treated with HA-collagen nanofibers loaded with growth factors compared to those treated with nanofibers without growth factors and the control group. Additionally, in vivo experiments involving full-thickness wounds in streptozotocin-induced diabetic Sprague Dawley rats demonstrated a faster healing rate in wounds treated with growth-factor-loaded nanofibers. This treatment also resulted in increased neovascularization and re-epithelialization rates [

176].

Further evaluation of mRNA levels in treated wounds indicated that the application of these as-spun nanofibers led to (1) a progressive increase in the gene expression of Type I collagen over six weeks, coupled with a progressive decrease in the gene expression of Type III collagen, aligning with the normal healing process, and (2) a decrease in Ki-67 expression over a four-week period, which is indicative of a reduction in cell proliferation. This decrease in Ki-67 suggests that the regenerating tissue was transitioning from the proliferative phase to the remodeling phase, marking the progression of wound healing [

176].

5.1.7. Cellulose

Cellulose, the most abundant biopolymer on Earth, is a polysaccharide derived from glucose, composed of 1000 to 1500 β-D-glucopyranose units linked by 1,4-β-glucosidic bonds [

177,

178,

179,

180]. This biopolymer is synthesized by plants and specific bacterial species, with the bacterial form particularly favored in industrial applications [

180,

181]. The preference for bacterial cellulose is mainly due to its extraordinary purity, as it is devoid of the by-products commonly found in plant-derived cellulose, such as hemicelluloses, lignin, pectin, and wax [

178,

182]. These characteristics and their non-toxic and biocompatible nature make cellulose invaluable in various biomedical applications [

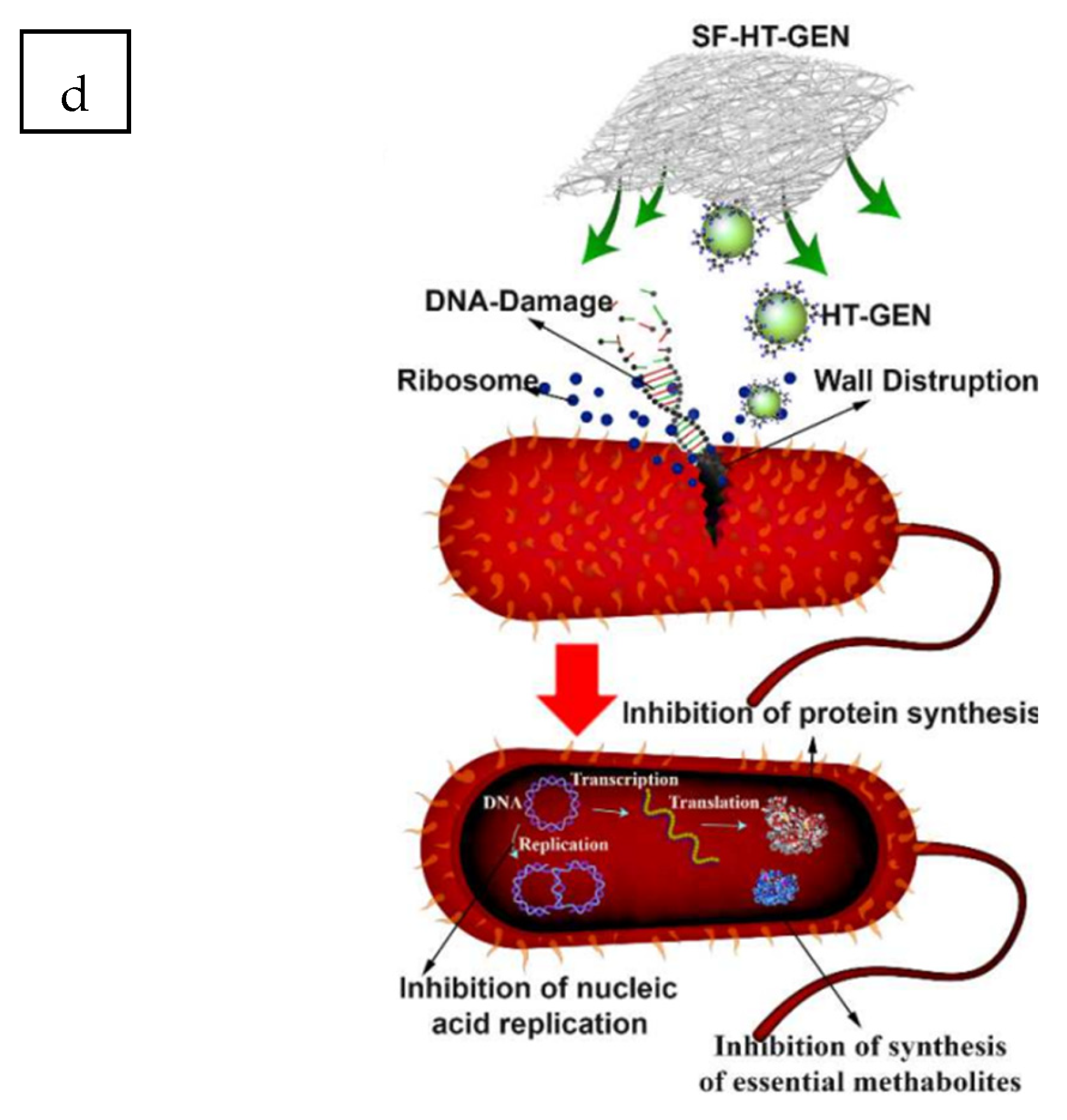

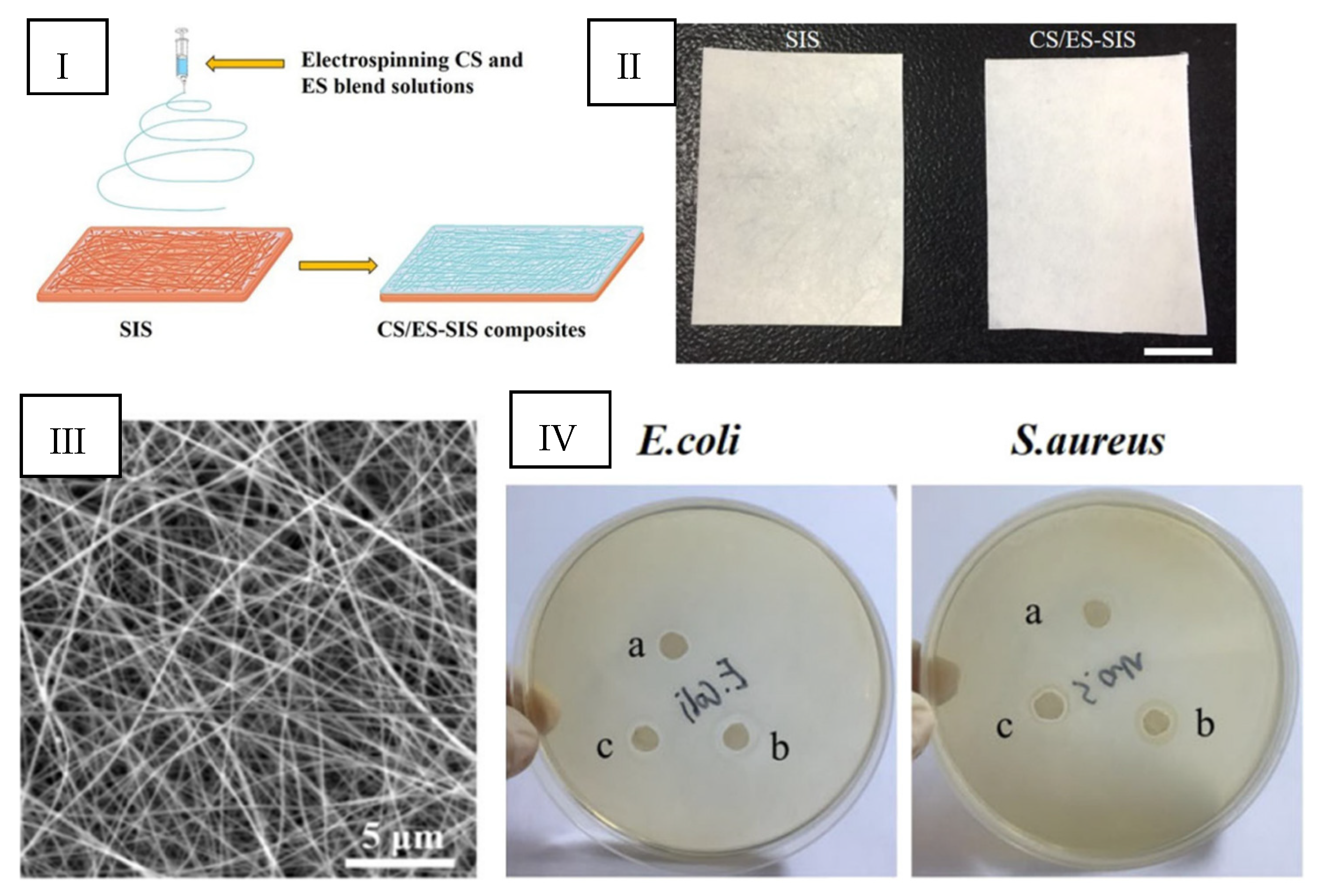

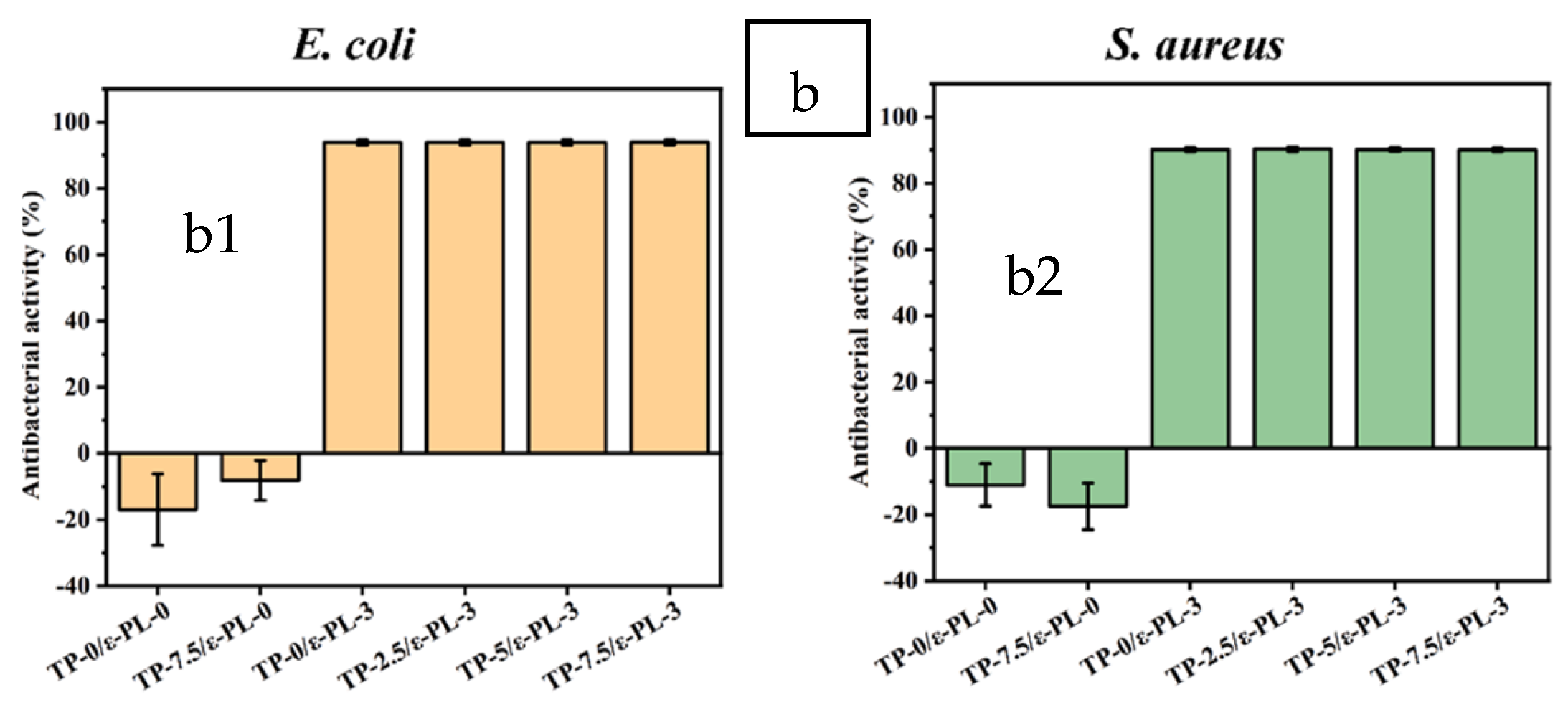

182].