Experimental Investigation of the Behaviour of Short-Span FRP-Reinforced Glulam Beams with Hoops and Tension Anchoring

Abstract

Highlights

- What are the main findings?

- Hoops and tension anchoring effectively prevented stress concentration failures at the FRP termination points while also providing improvements in strength, stiffness, and displacement at failure compared to the unreinforced specimens.

- The reinforcement scheme consisting of tension anchoring contributed to an enhancement of the post-peak behaviour. Unlike tension anchoring, specimens reinforced with hoops did not see an improvement in post-peak behaviour.

- What are the implications of these findings?

- Tension anchoring is a promising reinforcement configuration where partial access to all four sides of the member while minimizing the overall quantity of reinforcement in comparison to full-length confinement.

- The favourable behaviour exhibited by the tension anchoring should be further evaluated on larger glulam specimens, in addition to investigating the potential of using FRP anchoring when access to all four sides is not possible.

Abstract

1. Introduction

2. Experimental Programme

2.1. Description of Materials

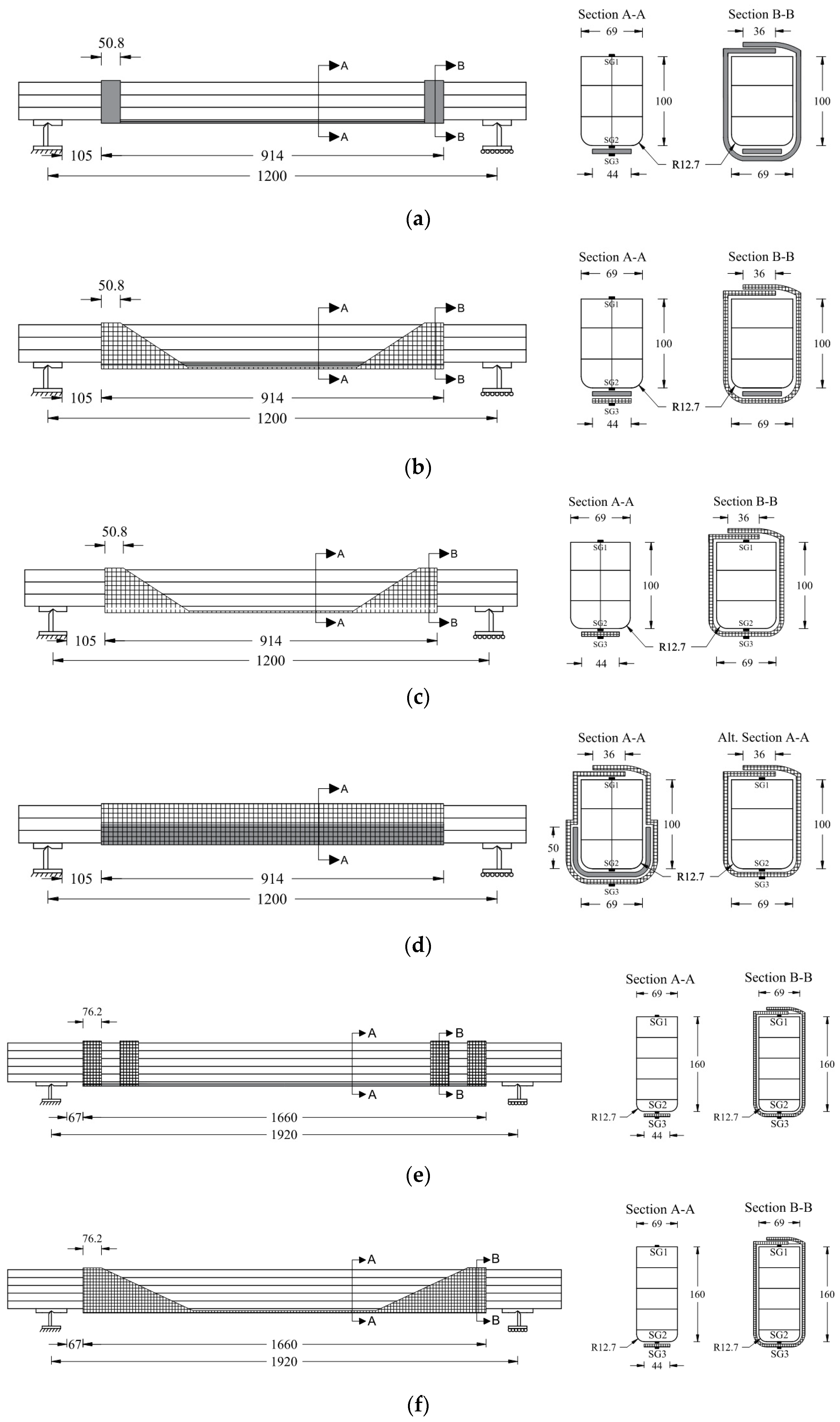

2.2. Reinforcement Configurations

2.3. FRP Application Process

2.4. Full-Scale Four-Point Bending Test Set-Up

3. Experimental Results

3.1. Overview of Flexural Tests on GFRP-Reinforced Glulam Beams

3.2. Effects of Hoops and Simple Tension Reinforcement

3.3. Effects of Tension Anchoring

3.4. Effects of Full-Length Confinement

3.5. Effects of Beam Depth

3.6. Enhancement of Wood Tensile Failure Strain Due to FRP

4. Discussion

5. Conclusions

- The hoops consisting of unidirectional and bidirectional fabrics were both successful in preventing previous premature failures due to stress concentration at the termination point; however, in order to leverage the full potential of hoops, unidirectional fabric should be used as it provided a higher clamping pressure than that provided by the hoops using bidirectional fabrics.

- Tension anchoring using bidirectional fabrics showed promising results with increased peak loads, displacement at peak load, stiffness, and post-peak behaviour. The tension anchoring used in combination with simple tension reinforcement that consist of unidirectional fabrics did not perform as well due to the improper FRP bond (wood-to-FRP, FRP-FRP) arising from the fabrication and epoxy mix. Future studies should investigate the potential of the configuration.

- Full-length confinement showed the most significant improved response as anticipated; however, the tension anchoring provided the closest response with lesser FRP materials.

- The reinforcement schemes consisting of hoops and tension anchoring showed favourable and promising response at larger spans and beam depth.

- An average increase in wood tensile failure strain in the reinforced beams compared to the unreinforced beams of 1.16 was obtained, showing that the reinforcement configurations allowed for a flexural failure rather than shear failure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| glulam | Glued-Laminated Timber |

| CLT | Cross-Laminated Timber |

| FRP | Fibre-Reinforced Polymer |

| AFRP | Aramid Fibre Reinforced Polymer |

| BFRP | Basal Fibre Reinforced Polymer |

| CFRP | Carbon Fibre Reinforced Polymer |

| GFRP | Glass Fibre Reinforced Polymer |

| CSA | Canadian Standards Association (CSA Group) |

| ASTM | American Society for Testing and Materials |

References

- CSA O86; Engineering Design in Wood. CSA: Toronto, ON, Canada, 2019.

- CSA S6; Canadian Highway Bridge Design Code. CSA: Toronto, ON, Canada, 2019.

- Karagöz İşleyen, Ü.; Ghoroubi, R.; Mercimek, Ö.; Anıl, Ö.; Tuğrul Erdem, R. Investigation of impact behavior of glulam beam strengthened with CFRP. Structures 2023, 51, 196–214. [Google Scholar] [CrossRef]

- Lacroix, D.; Doudak, G. Towards enhancing the post-peak performance of glued-laminated timber beams using multi-directional fibre reinforced polymers. Eng. Struct. 2020, 215, 110680. [Google Scholar] [CrossRef]

- Lacroix, D.N.; Doudak, G. Experimental and Analytical Investigation of FRP Retrofitted Glued-Laminated Beams Subjected to Simulated Blast Loading. J. Struct. Eng. 2018, 144, 04018089. [Google Scholar] [CrossRef]

- Davids, W.G.; Nagy, E.; Richie, M.C. Fatigue Behavior of Composite-Reinforced Glulam Bridge Girders. J. Bridge Eng. 2008, 13, 183–191. [Google Scholar] [CrossRef]

- Buell, T.W.; Saadatmanesh, H. Strengthening timber bridge beams using carbon fiber. J. Struct. Eng. 2005, 131, 173–187. [Google Scholar] [CrossRef]

- Dorey, A.B.; Cheng, J.J.R. Glass Fiber Reinforced Glued Laminated Wood Beams; Natural Resources Canada, Canadian Forest Service, Northern Forestry Centre: Edmonton, AB, Canada, 1996; p. 88. [Google Scholar]

- Gentile, C.; Svecova, D.; Rizkalla, S.H. Timber beams strengthened with GFRP bars: Development and applications. J. Compos. Constr. 2002, 6, 11–20. [Google Scholar] [CrossRef]

- Hernandez, R.; Davalos, J.F.; Sonti, S.S.; Kim, Y.; Moody, R.C. Strength and Stiffness of Reinforced Yellow-Poplar Glued Laminated Beams; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1997; p. 30. [Google Scholar]

- Raftery, G.M.; Harte, A.M. Low-grade glued laminated timber reinforced with FRP plate. Compos. Part B Eng. 2011, 42, 724–735. [Google Scholar] [CrossRef]

- Shrimpton, C.; Siciliano, S.; Chen, H.; Vetter, Y.; Lacroix, D. An Experimental Investigation of Failure Modes in Short-Span FRP Reinforced Glulam Beams. In Proceedings of the World Conference on Timber Engineering, Oslo, Norway, 19–22 June 2023; pp. 1–7. [Google Scholar]

- Sonti, S.S.; GangaRao, H.V.S.; Superfesky, M.C. Rehabilitation and Strengthening of Glulam Stringers for Bridge Superstructures. In Proceedings of the First International Conference on Composites in Infrastructure, Tucson, AZ, USA, 15–17 January 1996. [Google Scholar]

- İşleyen, Ü.K.; Ghoroubi, R.; Mercimek, Ö.; Anıl, Ö.; Togay, A.; Erdem, R.T. Effect of anchorage number and CFRP strips length on behavior of strengthened glulam timber beam for flexural loading. Adv. Struct. Eng. 2021, 24, 1869–1882. [Google Scholar] [CrossRef]

- Johns, K.C.; Lacroix, S. Composite reinforcement of timber in bending. Can. J. Civ. Eng. 2000, 27, 899–906. [Google Scholar] [CrossRef]

- Plevris, N.; Triantafillou, T.C. FRP-Reinforced wood as structural Material. J. Mater. Civ. Eng. 1992, 4, 300–317. [Google Scholar] [CrossRef]

- Yang, H.; Liu, W.; Lu, W.; Zhu, S.; Geng, Q. Flexural behavior of FRP and steel reinforced glulam beams: Experimental and theoretical evaluation. Constr. Build. Mater. 2016, 106, 550–563. [Google Scholar] [CrossRef]

- Goodwin, J.; Woods, J.E. Shear and Flexural Strengthening of Glued-Laminated Timber Beams Using Externally Bonded Fiber-Reinforced Polymer Sheets. J. Compos. Constr. 2025, 29, 04025019. [Google Scholar] [CrossRef]

- Shrimpton, C.; Chen, H.; Vetter, Y.; Lacroix, D. Analytical Modelling of Short Span FRP Reinforced Glulam Beams. In Proceedings of the Canadian Society of Civil Engineering Annual Conference 2024, Niagara Falls, ON, Canada, 5–7 June 2024; pp. 303–315. [Google Scholar]

- Vetter, Y. Investigating the Behaviour of Short-Span FRP-Reinforced Glulam Beams. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2022. [Google Scholar]

- ASTM D198-21; Standard Test Methods of Static Tests of Lumber in Structural Sizes. ASTM: West Conshohocken, PA, USA, 2022; p. 29. [CrossRef]

- ASTM E2126-19; Standard Test Methods for Cyclic (Reversed) Load Test for Shear Resistance of Vertical Elements of the Lateral Force Resisting Systems for Buildings. ASTM: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM D7199-20; Standard Practice for Establishing Characteristic Values for Reinforced Glued Laminated Timber (Glulam) Beams Using Mechanics-Based Models. ASTM: West Conshohocken, PA, USA, 2020.

| Specimens | Legend | ||

|---|---|---|---|

| Depth | ID and FRP Scheme | ||

| 100d | A-1 | S[0]2 H[0]2 | FRP Reinforcement Configurations |

| A-2 | S[0]4 H[0]2 | S—Simple Tension U—U-Shape H—Hoops C—Full-Length Confinement TA—Tension with Anchoring | |

| A-3 | S[0]2 H[0/90]2 | ||

| A-4 | S[0]4 H[0/90]2 | ||

| B-1, B-2 | S[0]2 TA [0/90]2 | ||

| B-3, B-4 | TA [0/90]4 | GFRP Layers Types | |

| C-1, C-2 | U [0]2 C [0/90]2 | 0—Unidirectional 0/90—Bidirectional | |

| C-3, C-4 | C [0/90]4 | Example: S[0]3 H[0/90]2 | |

| 160d | D-1, D-2 | S[0]3 H[0/90]2 | Three layers of unidirectional simple tension FRP with two layers of bidirectional hoops |

| E-1, E-2 | TA [0/90]6 | ||

| Specimen | Pmax a | ΔP,max b | K c | ɛt,max d × 10−4 | ɛc,max e × 10−4 | ɛFRP,max f × 10−4 | Glulam Primary Failure Modes | ||

|---|---|---|---|---|---|---|---|---|---|

| Depth | ID and FRP Scheme | (kN) | (mm) | (kN/mm) | (mm/mm) | (mm/mm) | (mm/mm) | ||

| 100d | Unreinforced g,h | 32.8 (0.11) | 26.0 (0.10) | 1.70 (0.13) | 47.9 (0.15) | −49.3 (0.18) | - | Splintering, shear | |

| Simple tension g,h | 34.7 (0.06) | 18.8 (0.25) | 2.14 (0.15) | 34.7 (0.22) | −44.9 (0.37) | 53.5 (0.38) | Shear, stress concentrations at FRP termination point | ||

| A-1 | S[0]2 H[0]2 | 39.5 | 18.3 | 2.36 | 43.6 | −11.4 | 59.8 | Splintering | |

| A-2 | S[0]4 H[0]2 | 36.8 | 27.4 | 1.72 | 42.4 | −28.3 | 73.9 | Brash | |

| Avg. | 38.2 | 22.8 | 2.04 | 43.0 | −19.8 | 66.8 | - | ||

| A-3 | S[0]2 H[0/90]2 | 35.0 | 15.1 | 2.42 | 56.8 | −45.4 | 67.2 | Splintering | |

| A-4 | S[0]4 H[0/90]2 | 40.0 | 16.5 | 2.50 | 36.3 | −42.9 | 40.3 | Splintering | |

| Avg. | 37.5 | 15.8 | 2.46 | 46.6 | −44.1 | 53.7 | - | ||

| B-1 | S[0]2 TA [0/90]2 | 36.4 | 24.8 | 1.86 | 45.4 | −45.6 | 74.1 | Brash at a knot within TA | |

| B-2 | 32.4 | 21.5 | 1.65 | 45.1 | - | 66.7 | Splintering | ||

| Avg. | 34.4 | 23.1 | 1.75 | 45.2 | −45.6 | 70.4 | - | ||

| B-3 | TA [0/90]4 | 47.2 | 31.8 | 2.38 | 41.2 | −37.5 | 51.4 | Splintering | |

| B-4 | 44.3 | 36.2 | 1.93 | 61.1 | - | 80.3 | Splintering, shear | ||

| Avg. | 45.7 | 34.0 | 2.16 | 51.1 | −37.5 | 65.9 | - | ||

| C-1 | U [0]2 C [0/90]2 | 56.1 | 36.2 | 2.76 | 62.8 | −43.5 | 71.2 | Splintering, localized | |

| C-2 | 49.7 | 32.0 | 2.71 | 52.2 | −51.3 | 88.6 | Splintering, localized | ||

| Avg. | 52.9 | 34.1 | 2.74 | 57.5 | −47.4 | 79.9 | - | ||

| C-3 | C [0/90]4 | 58.1 | 26.5 | 2.80 | 116.0 | −45.2 | - | Splintering, localized | |

| C-4 | 58.8 | 25.8 | 2.76 | 63.7 | −34.7 | 65.8 | Splintering, localized | ||

| Avg. | 58.5 | 26.2 | 2.78 | 89.9 | −40.0 | 65.8 | - | ||

| 160d | Unreinforced-Theoretical i | 52.8 | 29.7 | 1.78 | - | - | - | - | |

| D-1 | S[0]3 H[0/90]2 | 62.9 | 36.2 | 2.11 | 60.1 | −43.8 | 44.4 | Splintering | |

| D-2 | 60.0 | 36.8 | 2.16 | 50.2 | −48.1 | 54.6 | Cross-grain at a knot | ||

| Avg. | 61.4 | 36.5 | 2.14 | 55.2 | −46.0 | 49.5 | - | ||

| E-1 | TA [0/90]6 | 63.8 | 36.2 | 2.22 | 57.9 | −50.4 | 55.7 | Splintering | |

| E-2 | 67.7 | 35.5 | 2.31 | 54.2 | - | 54.2 | Splintering | ||

| Avg. | 65.7 | 35.9 | 2.27 | 56.1 | −50.4 | 55.0 | - | ||

| Specimen | Wood Tensile Failure Strain, ɛt,max × 10−4 (mm/mm) | b |

|---|---|---|

| Unreinforced a | 47.9 | - |

| A-1 | 43.6 | 0.91 |

| A-2 | 42.4 | 0.88 |

| A-3 | 56.8 | 1.19 |

| A-4 | 36.3 | 0.76 |

| B-1 | 45.4 | 0.95 |

| B-2 | 45.1 | 0.94 |

| B-3 | 41.2 | 0.86 |

| B-4 | 61.1 | 1.27 |

| C-1 | 62.8 | 1.31 |

| C-2 | 52.2 | 1.09 |

| C-3 | 116.0 | 2.42 |

| C-4 | 63.7 | 1.33 |

| D-1 | 60.1 | 1.26 |

| D-2 | 50.2 | 1.05 |

| E-1 | 57.9 | 1.21 |

| E-2 | 56.1 | 1.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Vetter, Y.; Shrimpton, C.; Lacroix, D. Experimental Investigation of the Behaviour of Short-Span FRP-Reinforced Glulam Beams with Hoops and Tension Anchoring. Fibers 2025, 13, 80. https://doi.org/10.3390/fib13060080

Chen H, Vetter Y, Shrimpton C, Lacroix D. Experimental Investigation of the Behaviour of Short-Span FRP-Reinforced Glulam Beams with Hoops and Tension Anchoring. Fibers. 2025; 13(6):80. https://doi.org/10.3390/fib13060080

Chicago/Turabian StyleChen, Herry, Yannick Vetter, Catherine Shrimpton, and Daniel Lacroix. 2025. "Experimental Investigation of the Behaviour of Short-Span FRP-Reinforced Glulam Beams with Hoops and Tension Anchoring" Fibers 13, no. 6: 80. https://doi.org/10.3390/fib13060080

APA StyleChen, H., Vetter, Y., Shrimpton, C., & Lacroix, D. (2025). Experimental Investigation of the Behaviour of Short-Span FRP-Reinforced Glulam Beams with Hoops and Tension Anchoring. Fibers, 13(6), 80. https://doi.org/10.3390/fib13060080