Highlights

What are the main findings?

- Visual and haptic assessments of naturally aged, historical weighted silks, conducted by trained conservators, exhibit a strong correlation with both the degree of fiber weighting and the crystallinity index, supporting their use as reliable parameters for evaluating the condition of historic silk textiles.

- A differing degree of weighting in the warp and weft of the same fabric provides insight into the manufacturing technique and allows differentiation between piece-weighting and skein-weighting processes

What is the implication of the main finding?

- A non-destructive, minimally invasive, protocol for assessing the condition and degradation of historic weighted silk was developed. The evaluation combines instrumental analytical techniques—mostly FTIR-ATR (Fourier-Transform Infrared Spectroscopy in Attenuated Total Reflection)—with the expertise of trained textile conservators.

Abstract

Silk weighting is a process used to compensate for the weight loss caused by degumming, achieved by adding agents such as metallic salts to enhance the hand feel and appearance of the fibers. With the development of tin weighting procedures (ca. 1870s), the production of weighted silk tremendously increased, as the fast decay of such fabrics was attributed to the process itself. The weighted silk was largely used for evening wear and high-fashion garments, many of which nowadays are stored in textile collections, and often characterized by poor conservation conditions. Within the present work, a multi-analytical and interdisciplinary non-destructive protocol was established for studying the finishing techniques, characterizing the materials as well as the state of preservation of historic tin-weighted silk. The protocol involves a visual and haptic approach typical of conservation professionals, as well as analytical investigations such as X-Ray Fluorescence analyses, 3D digital microscopy, Scanning Electron Microscopy with Energy Dispersive Spectroscopy, and Fourier-transform Infrared Spectroscopy (FTIR) in Attenuated Total Reflection. Elemental analyses are effective for studying the technology of production, while FTIR emerged as a powerful tool for assessing the condition, through the carbonyl and crystallinity indices.

1. Introduction

In historic textile collections, it is very common to encounter garments, flags, and silk textiles from the mid-19th to early 20th century presenting specific damage patterns. These textiles appear particularly fragile and require care for exhibitions and storage [1].

The advanced degradation and fragility of such textiles are strongly dependent on their production techniques.

Silk is a natural animal-derived fiber, primarily obtained from the larvae of domesticated silkworms, particularly Bombyx mori. It is composed of two main proteins: fibroin and sericin. Fibroin forms the structural core of the silk filaments and features alternating crystalline β-sheet and amorphous domains, which contribute to silk’s remarkable mechanical properties. The fibroin core is coated with sericin, a gelatinous protein often referred to as “silk gum”. Before silk can be used in textiles, it undergoes a degumming process involving hot alkaline baths that remove the sericin coating and separate the individual fibroin filaments [2]. Degumming causes the silk to lose approximately 25% of its weight. Because silk was sold by weight and to impart specific characteristics to the final fabric, fibers underwent finishing procedures called “weighting” or “loading”. Although weighting has been part of silk production for centuries (with the first written sources dating back to the 16th century), it was initially performed using natural products such as tannins, gums, sugars, and protein glue [3]. In the mid-19th century, weighting processes were developed, using mineral salts loading the yarns. Right from the commercialization and usage of such fabrics, it was noted that fabrics treated with these new methods decayed faster compared to unweighted silks [4].

The most well-known weighting processes used tin salts, such as stannous and stannic chloride (the latter known as the “pinking method”). In these processes, fibers were subjected to cycles of baths alternating among tin chloride baths, alkaline fixing baths, and rinsing cycles. These loading methods increased the weight of the silk by over 100%.

In 1892/1893, a new method was developed allowing for even higher loading percentages, and became widely spread and popular as the “Neuhaus”, “dynamite”, or “tin-phosphate-silicate” method. The process was used on both white and colored silks, and involved alternating stannic chloride (pH 1) and sodium phosphate (pH 10) baths, followed by a final silicate bath, with rinsing cycles in between. The process leads to the formation of a sodium tin (IV) aluminophosphosilicate complex, evenly dispersed within the amorphous portion of the fibroin [5].

Until 1920, most weighting was performed in the skein [6], and the average weighting levels were higher for yarns used in the tram (weft) than for organzine (warp). From the 1920s onwards, thanks to the Clavel and Lindenmeyer improvements, piece goods were processed, weighting the fabrics [7].

Many studies dating back to the 1980s aimed to understand the mechanisms leading to the poor conservation conditions of weighted silk, especially in comparison to non-weighted silk, and to find ways to assess their conservation condition. Further studies were then carried out in the 2000s, and a recent project (Safesilk) focusing on metal salt-induced degradation of silk in heritage collections, has shed new light on the structural changes in tin-weighted silks, and its increased hydrophilicity [8,9].

For investigations mostly naturally aged samples from different collections and self-made piece-weighted silks were analyzed using various analytical methods [3,10,11]. X-Ray Fluorescence (XRF) analyses could be a good preliminary approach for identifying and qualitatively characterizing weighted silk in collections and mechanical testing (yarn tenacity, elongation, and energy at initial rupture), as well as viscosity, could be used for assessing fiber degradation, whereas microscopy is a powerful tool for categorizing the fiber fracture patterns and surface damages [12,13]. Scanning Electron Microscopy with Energy Dispersive Spectroscopy (SEM-EDS) was also successfully employed for the characterization of the metal complexes and chemical species formed within the silk fibers with increasing weighting degree [5]. Finally, X-ray diffraction (XRD) and X-ray scattering analyses clarified the structural changes in weighted silk [9].

For condition and damage assessment, studies were conducted considering UV exposure, temperature, and relative humidity on piece-weighted silk subjected to several cycles of weighting [14]. Acidity measurements, usually applicable on untreated silk (where increased pH values are registered on degraded fabrics), do not seem to correlate with the aging of weighted silk [15]. In contrast, tensile testing appears to be the only reliable method for evaluating the condition of fibers, since weighting strongly affects their mechanical properties. However, this method is destructive and generally requires several squared centimeters of sample, which may not always be available on historical objects. Fourier-transform Infrared Spectroscopy in Attenuated Total Reflection (FTIR-ATR) and polarized-FTIR-ATR have proven to be powerful methods for studying the degradation mechanisms [16], as well as for classifying weighted garments in collections [17,18]. These methods correlate well with the results of tensile testing. FTIR is also widely used for studying silk, as it allows for the calculation of estimators that evaluate the degradation of the fibers based on the FTIR spectra. This enables the study of structural and chemical changes through indices associated with the oxidation and relative crystallinity of the fibroin molecules, thereby allowing for the analysis of both hydrolytic and oxidative degradation [19,20].

Conclusively, the most recent studies [5] would suggest that the weighting and the surface damage do not always correlate with the overall extent of degradation and that it appears that the cycles of extreme pH baths during the production process might be the primary cause of the fragility of weighted silk fibers.

The studies conducted so far have not accounted for the varying degrees of weighting within the same fabric (weft and warp), which is often observed in original historical garments. Moreover, spectral markers for condition assessment and their correlation with the degree of weighting have not yet been utilized. In addition, a comprehensive and accessible protocol for conservation and damage assessment has yet to be fully established. While analytical methods can aid in evaluating the condition by quantifying chemical and physical degradation, the history and use of the garments play a significant role. Therefore, evaluation by a trained conservator with expertise in the materiality of the object remains crucial and can be considered complementary to the analytical techniques [21].

In this paper, several of the methods described in the literature are applied to characterize the finishing techniques and to carry out damage and condition assessment of a two-piece summer dress, dated to the end of the 19th century. The dress is made of light batiste with silk appliqués, and its cream-colored silk lining was found extremely fragile and deteriorated, presenting characteristic shattering.

XRF analyses, 3D digital microscopy, SEM-EDS, and FTIR-ATR were used to study four different silks found on the dress, which exhibited different weighting degrees in the warps and wefts. These silks, due to their positions on the dress, were exposed to varying sunlight conditions. Markers in the FTIR-ATR spectra were used to assess the weighting degree and to calculate the carbonyl and the crystallinity indices, which are used for evaluating the state of preservation of historic weighted silks.

The multi-analytical and interdisciplinary approach aimed to establish a minimally invasive protocol for condition and damage assessment of weighted silks, using easily accessible scientific methods, commonly available in laboratories that routinely handle historical objects. This protocol is useful for supporting conservators in understanding the production technology and developing tailored conservation strategies [22].

2. Materials and Methods

A 19th-century two-piece summer dress made of light batiste with silk appliqués, and cream-colored silk lining was examined. Preliminary XRF analyses were conducted using a Tracer5i analyzer (Bruker, Billerica, MA, USA) equipped with a Rhodium (Rh) excitation source, an 8 μm beryllium detector window, a large area silicon drift detector (SDD), and a 3 mm collimator. Analyses were performed in air with settings of 40KV, 10 μA, and a 30 s measurement time.

The dress presented four different weighted silks, each sampled and analyzed: the silk lining of the top and the silk lining of the skirt (both not exposed to sunlight during the dress’ lifetime), as well as two silks (pink and beige), found on the outer part of the dress, as decorative elements. The outer silks, due to their location, were exposed to sunlight. The diameter of the silk fibers was 15–20 μm. Samples were first observed under a 3D digital microscope Keyence VHX-6000 (Keyence, Osaka, Japan) with a VH-Z100 objective (1000× magnification), equipped with a LED light source (5700 K). The observations were made in both reflection and polarized transmission modes.

For the pH measurements, a sample was collected from the shattered lining of the skirt and separated into three fragments, 0.05 g each. To each fragment, 0.5 mL of deionized water was added and left for 1 h [23]. The so-obtained solutions were placed in a two-point calibrated LAQUAtwin-pH-33 m (Horiba Scientific, Kyoto, Japan). Additionally, in order to test a non-destructive method of measuring the pH, 2% Agarose type VII pellets (Sigma-Aldrich, St. Louis, MO, USA) were prepared and left in contact with the fabric for 2 min [24] and then placed in the pH meter with an additional drop of deionized water.

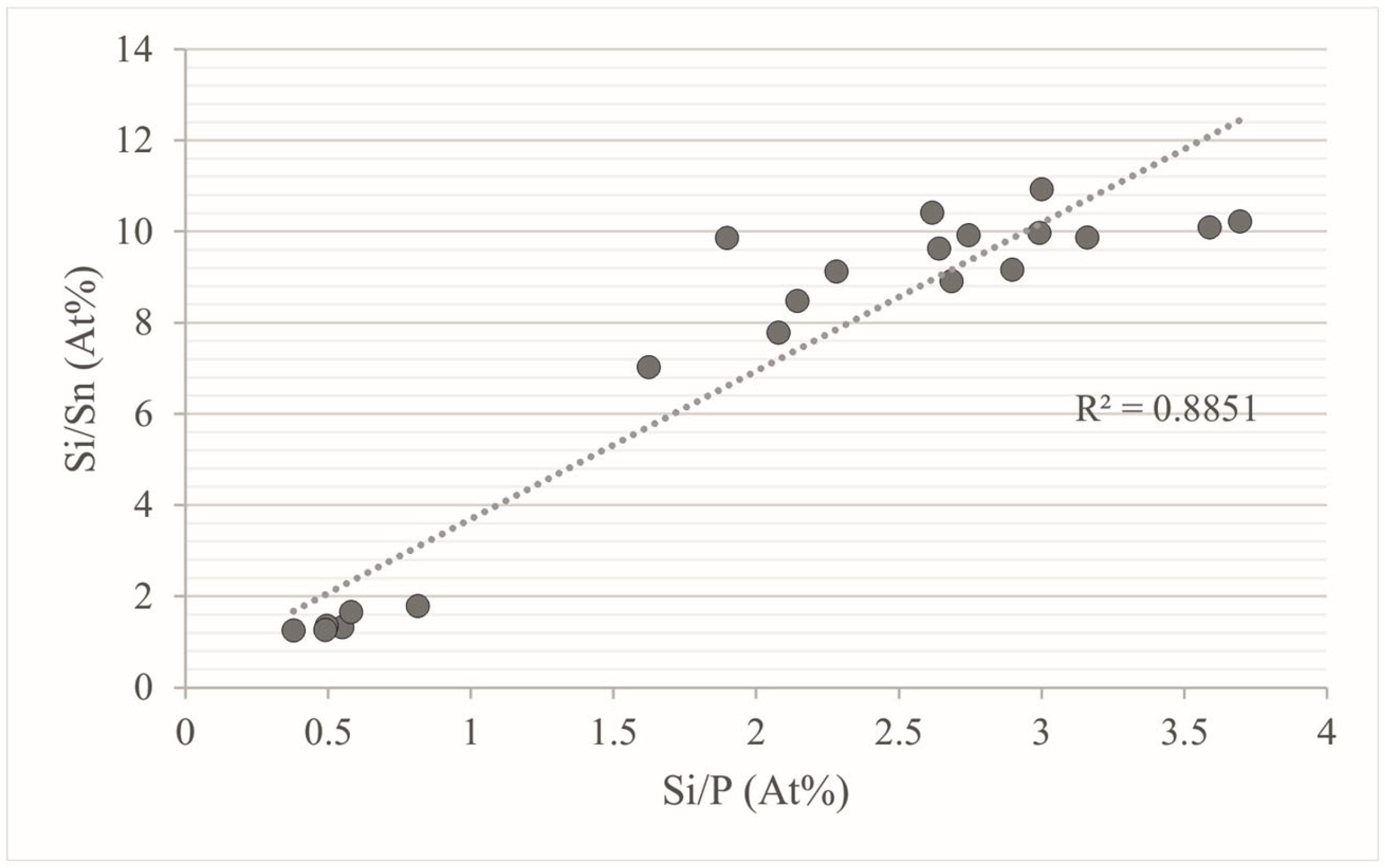

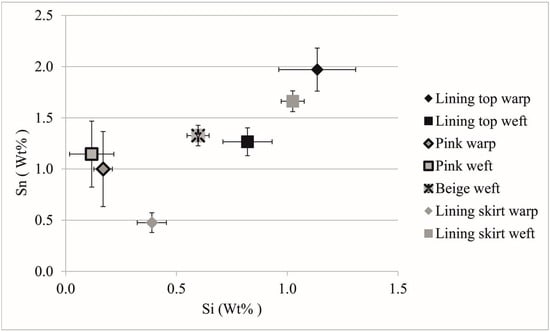

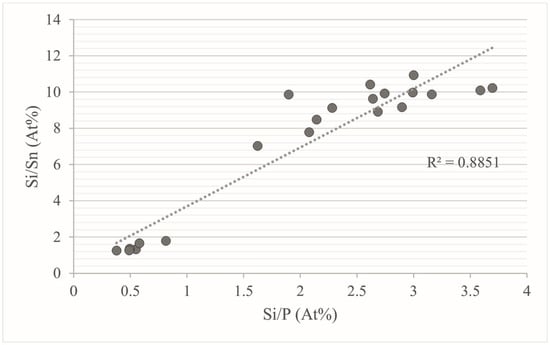

SEM-EDS analyses were performed using a QUANTA FEG250 (FEI, Hillsboro, OR, USA) equipped with an Apollo X EDX analyzer (Ametek/EDAX, Mahwah, NJ, USA). Analyses were conducted in high vacuum mode with a 20 KV electron beam on carbon-coated samples. Secondary electron mode (SE) was utilized to characterize the degradation patterns, while backscattered mode (BSE) was used to reveal the different degrees of weighting in the warp and weft. Further evaluation of the weighting technique and degree was achieved through punctual semi-quantitative analyses, with each warp and weft analyzed at three different spots. Given that the original composition of the fibers is unknown, a semi-quantitative evaluation was employed to understand and compare the degree of weighting. The weight percentage (wt%) of elements related to the weighting agent (Sn and Si) was normalized against the nitrogen (N) signal, which is related to the silk fiber. To characterize the metal complex formed within the fibers, Si/Sn and P/Si atomic percentages (at%) were used to calculate the correlation coefficient, considering all individual measurements.

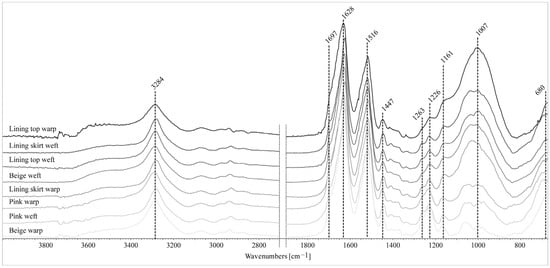

Finally, FTIR-ATR analyses were carried out using a Nicolet iN10 Microscope (Thermo Scientific, Waltham, MA, USA) equipped with a Ge ATR crystal, a cooled MCT detector, 4 cm−1 resolution, 64 scans, with no sample treatment. Three spectra were acquired for each warp and each weft and average spectra were calculated. These analyses were employed to evaluate both the weighting degree and the condition of the silks. Since the beige warp was identified as unweighted, it was used as a historical silk reference due to its comparable aging conditions.

To study the weighting, the areas under the curves of PO43− and SiO44− vibrations bands were considered (A1100–600).

To assess the degradation of the fibers and quantify the chemical changes, the carbonyl index was used as an estimator of oxidative degradation [20]. This index is calculated from the intensity of the band at 1732 cm−1, which is assigned to free carbonyl moieties, normalized against the maximum height of the amide I band at 1620 cm−1 (IC=O/IAmideI). A higher carbonyl index indicates greater oxidative degradation of silk. The crystallinity index is affected by structural changes due to aging and weighting [9,20]. The index does not express the true crystallinity, but rather refers to the relative content of crystalline and amorphous domains in the fibroin.

The crystallinity index is here calculated as the ratio of the heights of the amide III bands at 1263 and 1226 cm−1 (I1263/I1226). These bands are assigned to crystalline β-sheet and amorphous structures in fibroin, respectively. The crystallinity index estimates structural changes and depolymerization associated with hydrolytic degradation: a higher index indicates changes in the amorphous portion of the fibers and a relative increase in β-sheet structure content [14,16,20,25,26,27].

3. Results and Discussion

The visual examination of the two-piece summer dress revealed characteristic brittleness and a directional shattering pattern, particularly evident in the skirt lining. This condition is often associated with weighted silks. The visual and haptic–tactile assessment conducted by a trained conservator suggested that the fabric is indeed weighted, with the lining being evaluated as the most deteriorated among the textiles examined.

Preliminary XRF investigation identified the presence of Sn, P, and Si indicating the use of the dynamite (tin–phosphate–silicate) weighting method. This result confirms that XRF is an effective tool for the in situ non-destructive characterization of weighted garments in collections.

pH measurements were conducted directly on the skirt lining using agarose pellets, as well as on solutions extracted from three fragments, with both methods yielding consistent results. For comparison, a piece of new silk was also measured. The pH of the skirt lining was found to be 6.2 ± 0.1, while the new silk had a pH of 6.5 ± 0.2. The comparison between the two measurement methods—one involving sampling and the agarose pellets—demonstrates the feasibility of a non-destructive assessment of the acidity of silk. Additionally, the pH value aligns with the findings in the literature, confirming that the acidity of weighted silk does not directly correlate with the aging and degradation of the fabric. This lack of correlation is likely due to the buffering effect of the weighting agents [15].

The condition and damage of the collected samples were assessed using a multi-analytical approach to complement the visual and haptic evaluations.

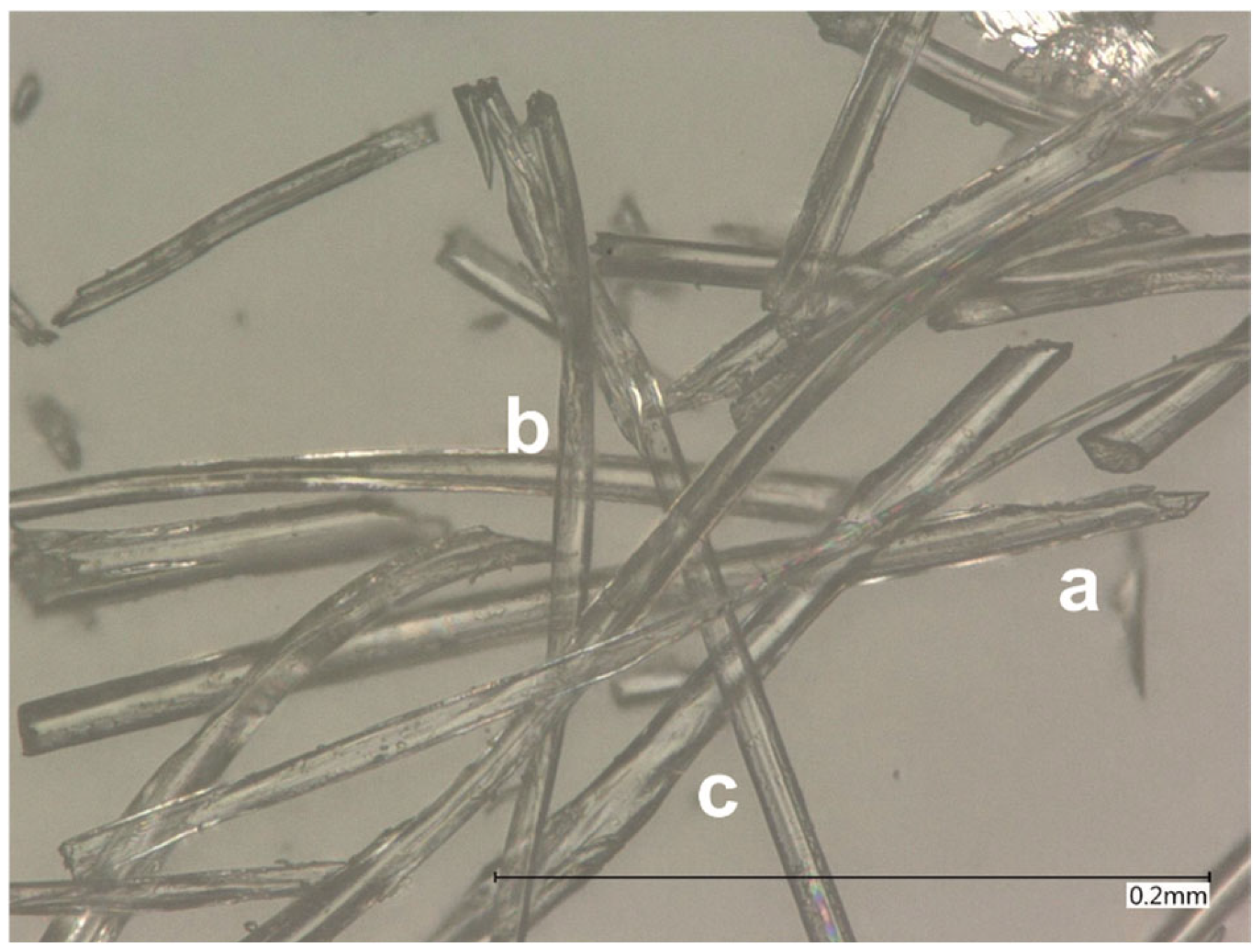

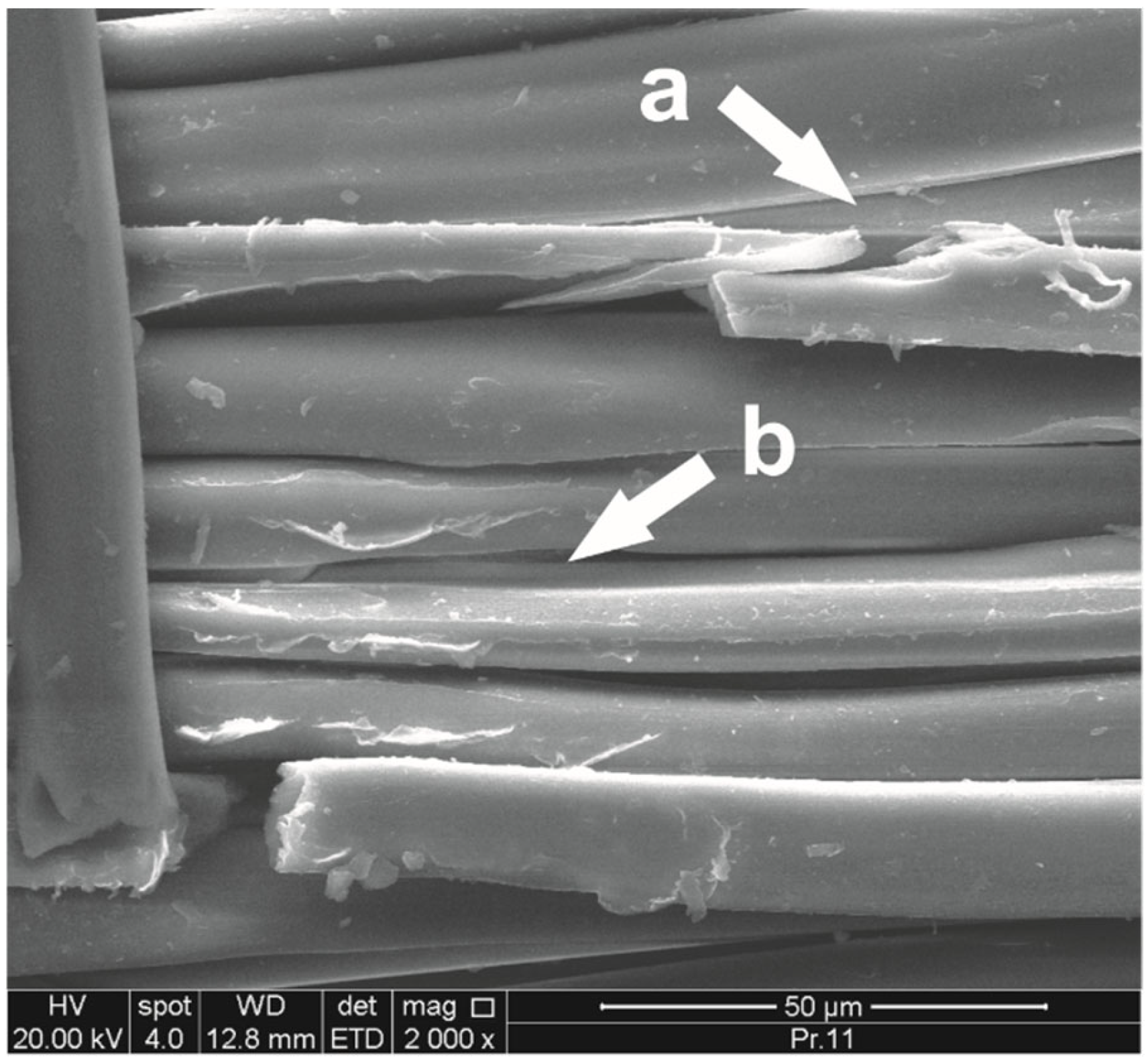

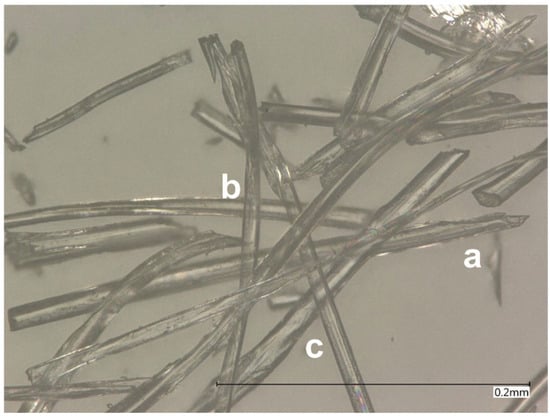

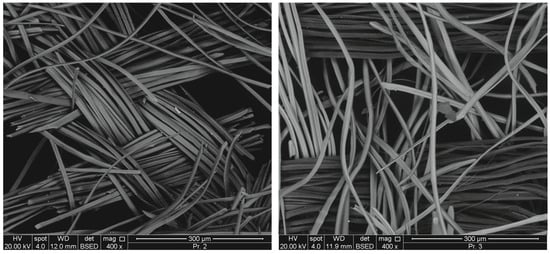

Surface damage on the fibers, such as fractures, defibrillations, and deformations, was clearly observed on both wefts and warps by using a 3D digital microscope (Figure 1). This non-destructive tool is also suitable for in situ analysis. The damages were further confirmed by SEM/SE images (Figure 2) [13]. The surface damage patterns were consistent across all the samples examined, and thus could not relate to the quantification of the degradation.

Figure 1.

3D micrograph acquired in transmission on fibers collected from the lining of the skirt. Fractures (a), defibrillation (b), and deformation (c) are present.

Figure 2.

SEM/SE micrograph showing characteristic surface damage such as fractures (a) and defibrillation (b).

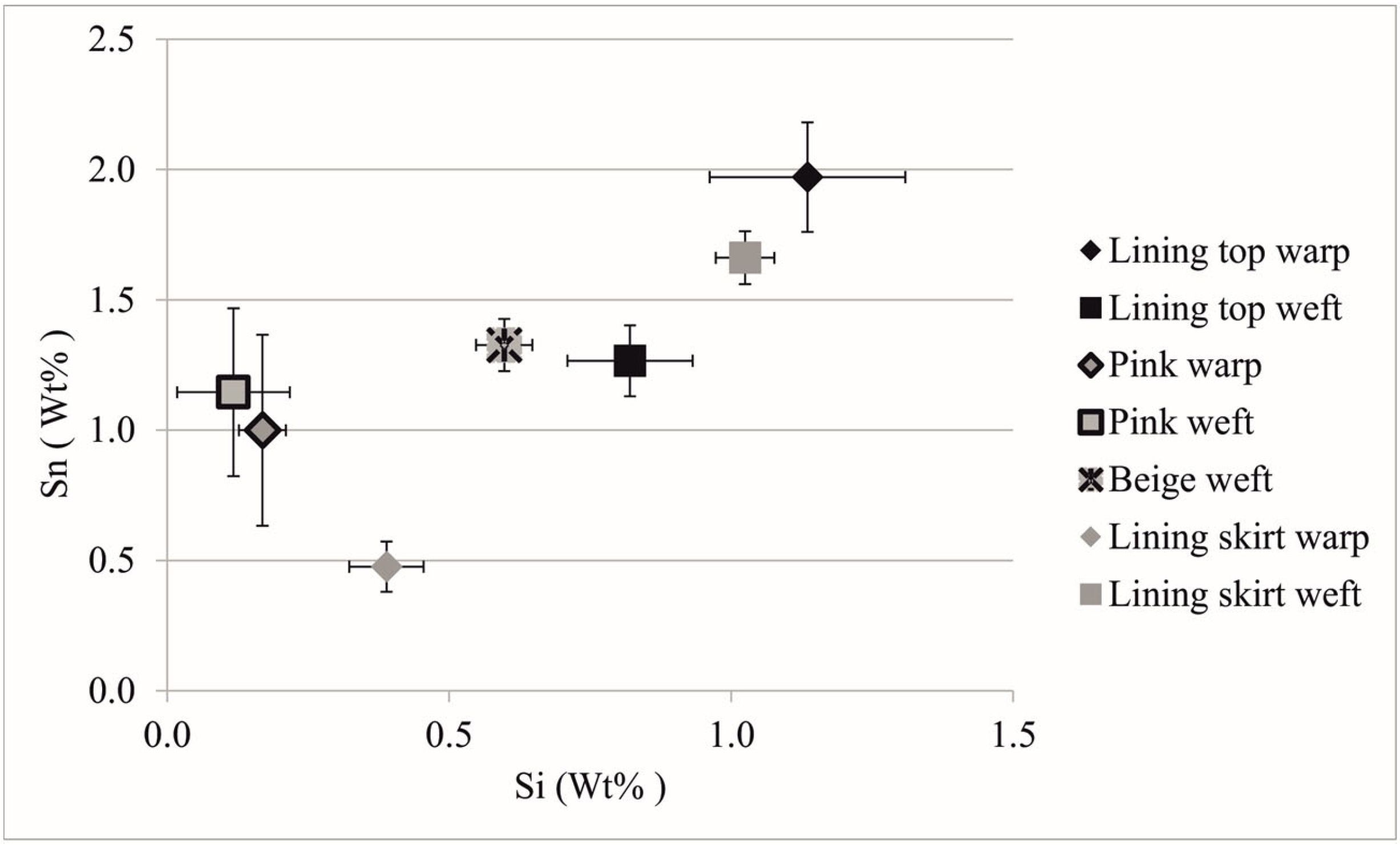

To better understand the production technology, specifically the degree of weighting and its relation to fiber degradation, a semi-quantitative evaluation of the weighting agent on both warp and weft was conducted. By plotting the weight percentage (wt%) of Sn and Si content normalized to the N content in each fiber, it was possible to distinguish the different degrees of weighting (Figure 3). Differences were found in warp and weft of the same weighted silk fabric.

Figure 3.

Relative content of Sn and Si, elements attributed to dynamite weighting process, in warp and weft of four different silks present on the dress. The pink silk was weighted as piece good, whereas the other silks were weighted in skein.

The results show that only the pink silk was piece-weighted, presenting the same weighting in both warp and weft. This suggests that this silk was likely produced later (after 1920) [4], or that the same skein was used for both tram and organzine. The skirt and top linings of the dress exhibited slightly different degrees of weighting between warp and weft, as well as between each other, implying that these fabrics may have different origins. Additionally, the beige silk was found to be weighted only in the weft, while the warp consisted of unweighted silk.

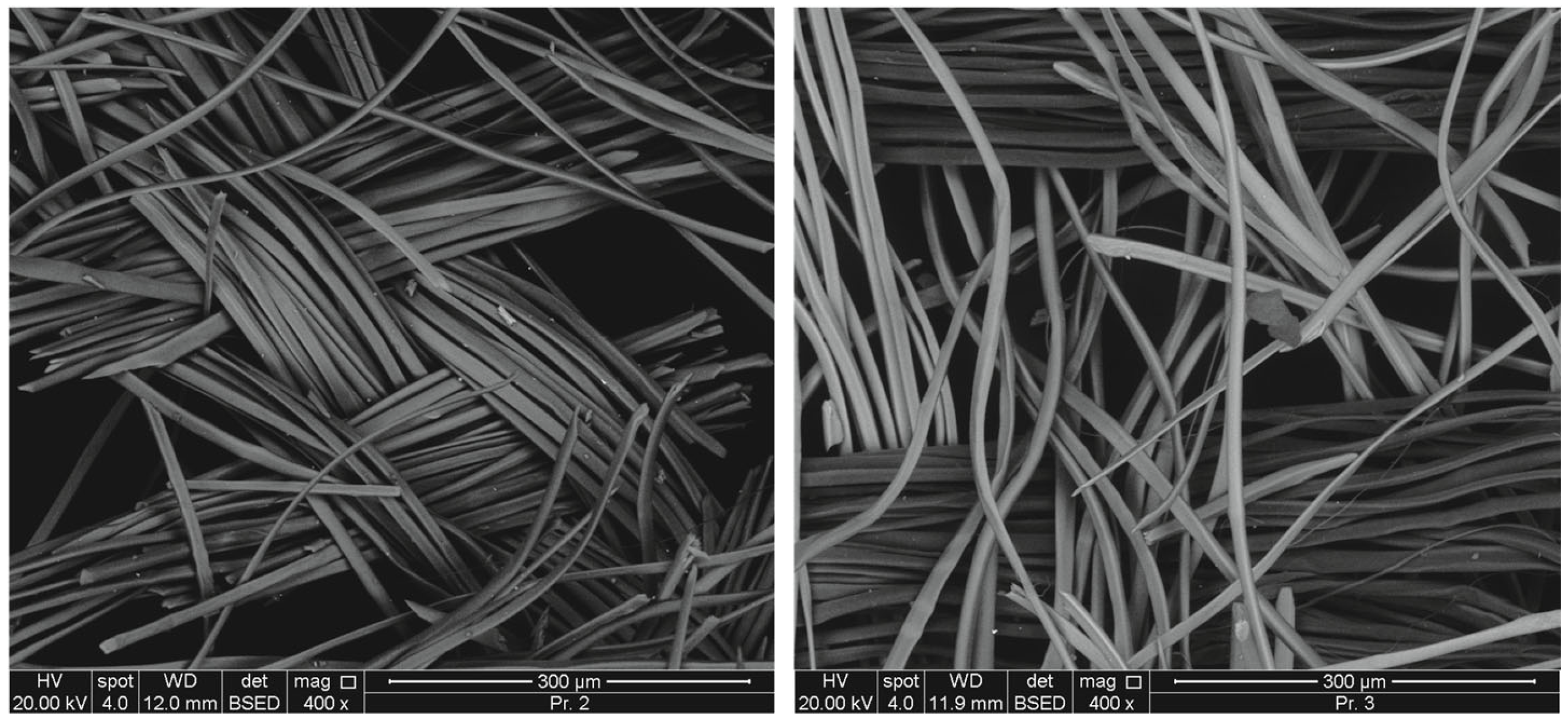

The difference in the degree of weighting between warp and weft is also observable in SEM/BSE micrographs (Figure 4).

Figure 4.

SEM/BSE micrographs of silk weighted as piece good (left) and silk weighted in skein (right).

Finally, the correlation coefficient (R2 = 0.88) between Si/Sn and P/Si in atomic percentage in the individual SEM-EDS measurements (Figure 5) suggests that the same tin phosphosilicate complex [10] is present in all fibers, regardless of the degree of weighting.

Figure 5.

Correlation (R2) among Si/Sn and Si/P content in the single measurements of the fibers.

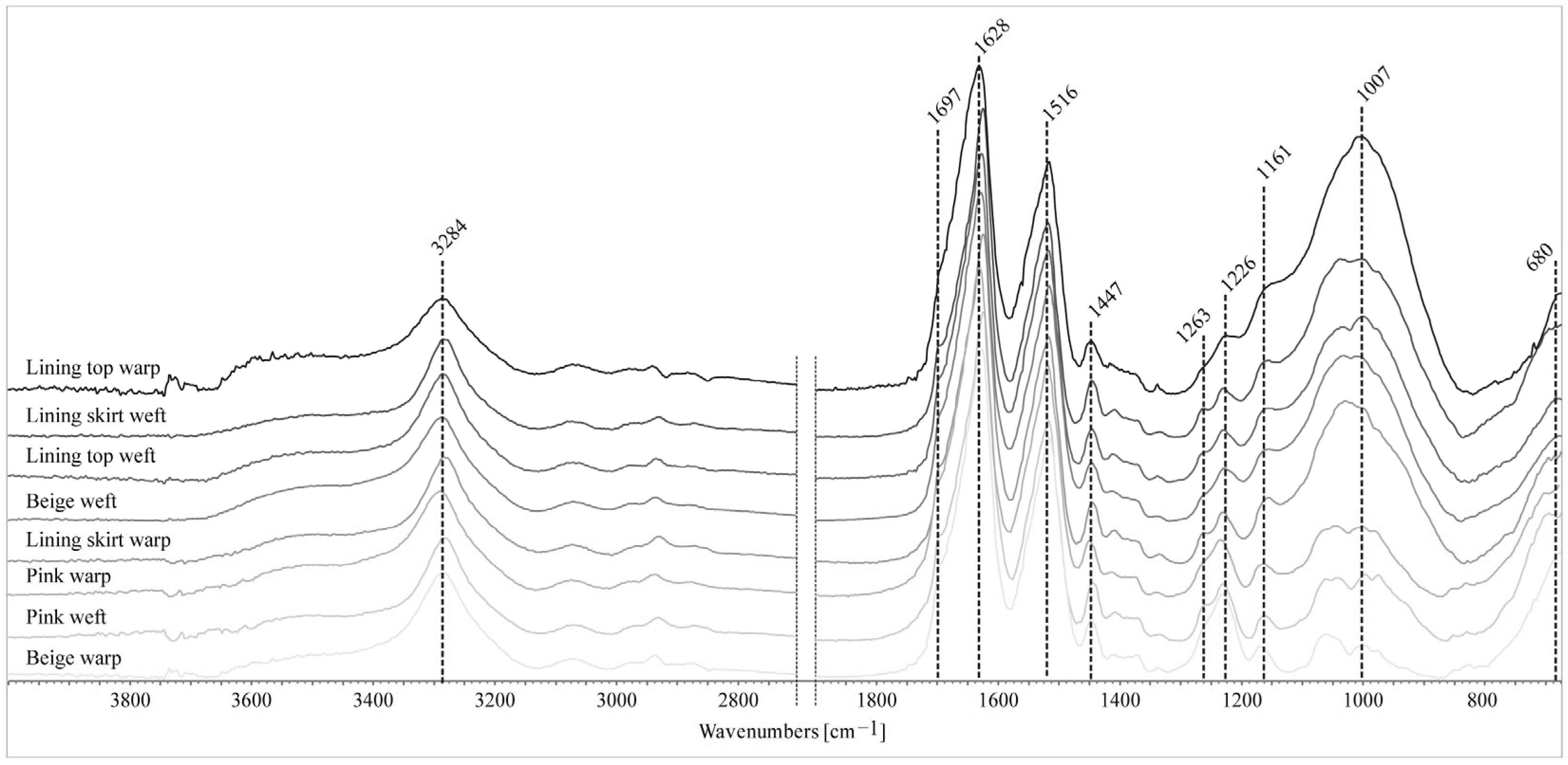

FTIR analyses in ATR mode were carried out on the weft and warp of each considered silk fabric, as well. The spectra confirmed the nature of the fibers showing characteristic NH stretching (3284 cm−1), amide I band (1628 cm−1), amide II (1516 cm−1), CH bending (1447 cm−1), and amide III β-sheet and random coil conformation (1263 and 1226 cm−1, respectively) [19,25,26]. The skeletal vibrations of fibroin are partially overlapped by the weighting agents’ spectral contributions: P=O vibrations occur at ca. 1161 cm−1, Si-O-Si stretching vibration occurs at 1100–1000 cm−1 and, finally, between 800 and 680 cm−1, overlapping P-O-Si and Si-O bending can be seen (Figure 6). Broad absorption bands assigned to hydroxyl content and oxidation products are visible between 3400 and 3600 cm−1 [9].

Figure 6.

FTIR-ATR spectra acquired directly on warp and weft of the different silks. Main absorption bands used for identifying the silk fibers and the weighting agents are highlighted, as well as bands used for calculating the indexes.

A relative quantification of the weighting degree on the fibers was achieved by considering PO4 3− and SiO44− anions vibrations through calculation of the area under the curve in the 1100 to 680 cm−1 range.

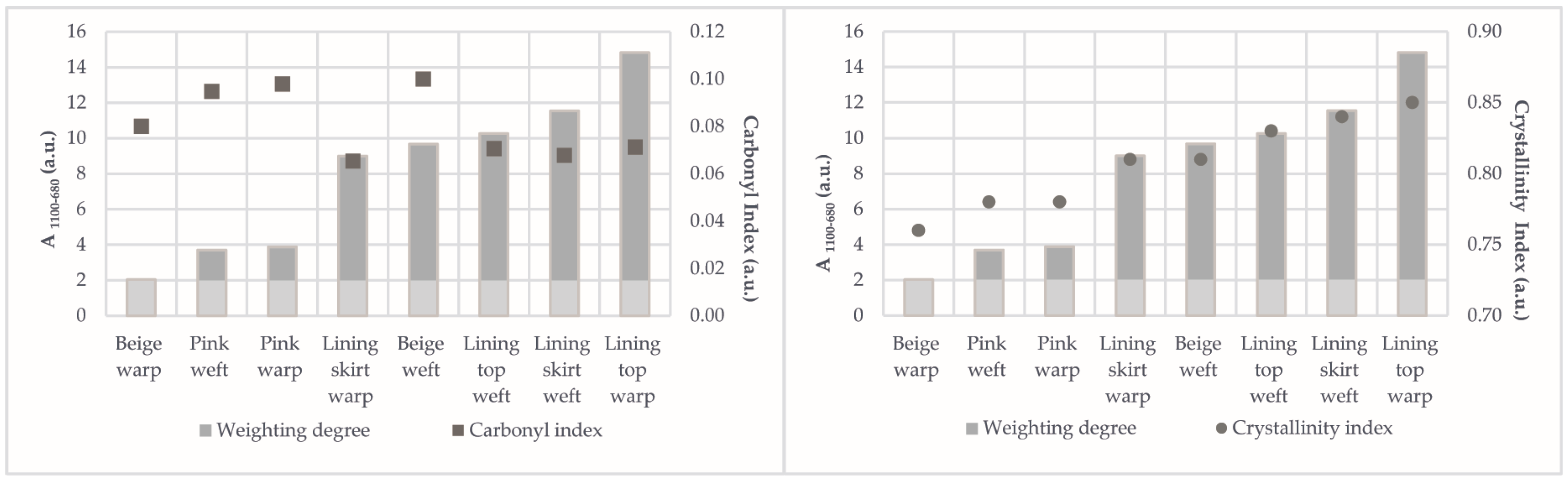

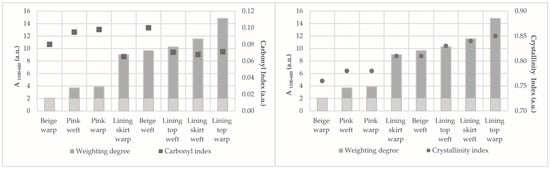

The results in Figure 7 show the different weighting degrees of the yarns and are consistent with the SEM-EDS data, suggesting that for such an evaluation, the sole non-invasive FTIR analyses might be sufficient.

Figure 7.

A1100–680 against carbonyl index (IC=O/IAmide I, left) and against crystallinity index (I1263/I1226, right). The values are calculated from the FTIR-ATR spectra acquired on warp and weft of the silk fabrics. The beige warp was identified as unweighted; therefore, the weighting degree of the other fibers is represented in dark gray.

The calculation applied to unweighted silk, such as the beige warp, must take into account the presence of skeletal vibrations of the fibers. Therefore, the area under the curve of the beige warp can serve as an approximate threshold to distinguish between weighted and unweighted silk (Figure 7).

Additionally, the FTIR spectra contain information related to the chemical and structural changes occurring in the fibers, mostly degradative oxidation and depolymerization, as well as changes in the relative β-sheet structure content of fibroin molecules [14,20,25]. To assess these changes, carbonyl, and crystallinity indices were calculated and compared with the degree of weighting.

The carbonyl index reflects the oxidation of the polypeptide to ketones, aldehydic, or carboxylic groups rather than its hydrolysis [19], and it is not influenced by exposing the fibers to extreme pH value, as is the case of the weighting processes [20].

By considering the weighting degree of each fiber, it can be noted that the fibers of the linings (top and skirt, warps, and wefts), even if differently weighted, present a similar carbonyl index. In contrast, the pink and beige silks exhibit higher carbonyl indices (Figure 7, left). This is mostly because these latter silks are found on the external part of the dress and, therefore, were exposed to sunlight. Piece-weighted silk, such as pink silk, can be rinsed much less effectively than skein-weighted silk during production. Remaining chemicals might also contribute to a more pronounced chemical degradation [28]. However, since the carbonyl indices are comparable to those of the beige silk, which is skein-weighted, this assumption does not hold. Considering the carbonyl indices of the beige silk, the warp (unweighted) and weft (weighted) show different carbonyl indices despite being subjected to the same aging conditions. The carbonyl index of the unweighted beige warp is lower than that of the weighted weft, suggesting that weighting negatively impacts the photostability of the fibers leading to increased oxidative degradation, contrary to recent findings in the literature [5]. Furthermore, the results show that the carbonyl index, and thus the oxidative degradation of silk fibers, is more closely related to the exposure to outdoor radiation rather than to the weighting degree.

On the contrary, examining the trend in crystallinity indices reveals that this estimator is mostly influenced by the degree of weighting (Figure 7, right). Specifically, a higher weighting degree is associated with a slight increment of the index. In unweighted silks, a higher crystallinity index is associated with structural changes due to hydrolysis and chain scission of the peptide bonds, which are expected to occur predominantly in the amorphous portion of the fibroin structure [20,25]. Both reactions were found to be largely promoted at extreme pH [20], such as the one associated with the weighting process. The amorphous portion of the fibroin is also where the metal complexes of the weighting are located within the fibers [5,10,13,14]. Therefore, the crystallinity index might be influenced by the presence of tin phosphosilicates within the amorphous interfibrillar matrix [4,13,29]. Additionally, on one hand, the crystallinity index correlates with the weighting degree showing changes in the structure of the amorphous fibroin, and on the other hand, it also correlates with the haptic evaluation of the linings, thus, confirming that depolymerization due to the degradative potential of exposure to extreme pH is the factor mostly influencing the physical stability of the fibers.

4. Conclusions

For the first time, a study was conducted on original historical skein-weighted silks to establish a simple and accessible protocol for determining the degree of weighting of warp and weft threads, as well as for assessing damage and state of preservation, in a minimally invasive manner. This study also enhances our understanding of the relationship between weighting degree, oxidative reactions, relative crystallinity, and the impact of sunlight on the degradation of weighted silk fibers. A non-destructive, minimally invasive protocol was developed using widely accessible analytical techniques, including XRF, 3D digital microscopy, and FTIR-ATR, and confirmed and supported by SEM-EDS.

Notably, the study adopted an interdisciplinary approach: the hands-on expertise and tactile–haptic evaluations of textile conservators played an integral role in the conservation assessment, complementing the instrumental analyses.

As reported in the literature, while microscopy can reveal surface damage and FTIR can detect chemical degradation, these observations do not always fully reflect the actual state of conservation. The object’s history and function can significantly influence its condition.

A 3D digital microscopy was employed to evaluate surface damage such as defibrillation, fractures, and deformations, typical of degraded weighted silks. SEM-EDS analyses were used to assess surface damage and to semi-quantify the weighting degree of warp and weft, distinguishing between skein-weighted and piece-weighted fabrics (the latter typically produced after 1920). The semi-quantitative analysis confirmed the formation of a similar tin phosphosilicate structure in all fibers, regardless of the degree of weighting.

FTIR-ATR provided insights into both the weighting degree and degradation process by calculating carbonyl and crystallinity indices.

The carbonyl index, which indicates oxidative degradation, was primarily influenced by aging conditions: fibers exposed to sunlight showed higher values, and weighted fibers exhibited increased oxidation compared to unweighted ones under similar conditions. This confirms that the presence of weighting agents promotes photooxidation.

Conversely, the crystallinity index correlated with the weighting degree, suggesting that structural changes in amorphous fibroin regions are influenced by the presence of weighting agents. Notably, the crystallinity index trend and weighting degree aligned with conservators’ tactile evaluations, offering a more comprehensive representation of the structural and physical changes relevant to condition assessment.

Author Contributions

M.A.: conceptualization, methodology, collection, analyses, interpretation, and evaluation of data, and writing—original draft preparation. C.D.: visual and haptic investigation and 3D microscope. T.K.: project administration and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available from the corresponding author upon request, due to legal restrictions and ownership rights related to the analyzed object.

Acknowledgments

The authors acknowledge Farkas Pintér and Johannes Weber (Institute of Conservation, University of Applied Arts Vienna, Austria) for operating the SEM-EDS, and Gabriela Krist (Institute of Conservation, University of Applied Arts Vienna, Austria) for making this project possible.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| FTIR-ATR | Fourier-transform Infrared Spectroscopy in Attenuated Total Reflection |

| XRF | X-Ray Fluorescence spectroscopy |

| SEM-EDS | Scanning Electron Microscopy with Energy Dispersive Spectroscopy |

References

- Horswill, M. Save The Silks! Protection for Weighted Silk Costumes. Dress 2013, 14, 93–97. [Google Scholar] [CrossRef]

- Chand, S.; Chand, S.; Raula, B. Usage of Silkworm Materials in Various Ground of Science and Research. J. Nat. Fibers 2023, 20, 2139328. [Google Scholar] [CrossRef]

- Ballard, M.; Koestler, R.J.; Indictor, N. Weighted silk observed using energy dispersive X-Ray spectrometry. Scanning Electron Microsc. 1986, 2, 499–506. [Google Scholar]

- Hacke, M. Weighted silk: History, analysis and conservation. Stud. Conserv. 2014, 53, 3–15. [Google Scholar] [CrossRef]

- Garside, P.; Wyeth, P.; Zhang, X. Understanding the ageing behaviour of nineteenth and twentieth century tin-weighted silks. J. Inst. Conserv. 2010, 33, 179–193. [Google Scholar] [CrossRef]

- Warner, F. The practice and ethics of silk weighting. J. Text. Inst. Proc. 1925, 16, 327–334. [Google Scholar]

- Mullin, C.E. The new Clavel and Lindenmeyer silk weighting process I & II. Silk J. Rayon World 1931, 28, 27–28. [Google Scholar]

- Elrefaey, I.; Mahgoub, H.; Vettorazzo, C.; Marinšek, M.; Meden, A.J.; Tomšič, M.; Strlič, M. Investigation of the Structural Changes in Silk Due to Tin Weighting. Polymers 2024, 16, 2481. [Google Scholar] [CrossRef]

- Elrefaey, I.; Kraševec, I.; Di Gianvincenzo, F.; Krotova, A.; Vettorazzo, C.; Ortega Saez, N.; Van der Snickt, G.; Janssens, K.; Menart, E.; Strlič, M. SAFESILK: Metal Salt-Induced Silk Degradation in Heritage Collections. In Proceedings of the 1st Conference of the Slovenian Node of the European Research Infrastructure for Heritage Science, Ljubljana, Slovenia, 22 November 2023; University of Ljubljana, Faculty of Chemistry and Chemical Technology: Ljubljana, Slovenia, 2023. [Google Scholar]

- Miller, J.E.; Reagan, B.M. Degradation in Weighted and Unweighted Historic Silk. J. Am. Inst. Conserv. 1989, 28, 97–115. [Google Scholar] [CrossRef]

- Becker, M.A.; Hersh, S.P.; Tucker, P.A. The influence of tin weighting agents on silk degradation. In Proceedings of the ICOM Committee for Conservation 8th Triennial Meeting, Sydney, Australia, 6–11 September 1987; Getty Conservation Institute: Los Angeles, CA, USA, 1987. [Google Scholar]

- Ballard, M.; Koestler, R.J.; Blair, C.; Indictor, N. Historical Silk Flags Studied by Scanning Electron Microscopy-Energy Dispersive X-ray Spectrometry. In Archaeological Chemistry IV; Amer Chemical Society: Washington, DC, USA, 1989; pp. 419–428. [Google Scholar]

- Garside, P.; Mills, G.A.; Smith, J.R.; Wyeth, P. An investigation of weighted and degraded silks by complementary microscopy techniques. E-Preserv. Sci. 2014, 11, 15–21. [Google Scholar]

- Garside, P.; Wyeth, P. Crystallinity and degradation of silk: Correlations between analytical signatures and physical condition on ageing. Appl. Phys. A Mater. Sci. Process. 2007, 89, 871–876. [Google Scholar] [CrossRef]

- Garside, P.; Wyeth, P.; Zhang, X. The inherent acidic characteristics of silk, part II—Weighted silks. E-Preserv. Sci. 2010, 7, 126–131. [Google Scholar]

- Garside, P.; Lahlil, S.; Wyeth, P. Characterization of Historic Silk by Polarized Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy for Informed Conservation. Appl. Spectrosc. 2005, 59, 1242–1247. [Google Scholar] [CrossRef] [PubMed]

- Richardson, E.; Garside, P. The use of near infrared spectroscopy as a diagnostic tool for historic silk artefacts. E-Preserv. Sci. 2009, 6, 68–74. [Google Scholar]

- Garside, P.; Wyeth, P.; Zhang, X. Categorizing tin phosphate/silicate-weighted silks on site by near-infrared spectroscopy. J. Inst. Conserv. 2012, 35, 40–49. [Google Scholar] [CrossRef]

- Koperska, M.A.; Pawcenis, D.; Bagniuk, J.; Zaitz, M.; Missori, M.; Lojewski, T.; Lojewska, J. Degradation markers of fibroin in silk through infrared spectroscopy. Polym. Degrad. Stab. 2014, 105, 185–196. [Google Scholar] [CrossRef]

- Vilaplana, F.; Nilsson, J.; Sommer, D.V.; Karlsson, S. Analytical markers for silk degradation: Comparing historic silk and silk artificially aged in different environments. Anal. Bioanal. Chem. 2015, 407, 1433–1449. [Google Scholar] [CrossRef]

- Nilsson, J. Ageing and Conservation of Silk: Evaluation of Three Support Methods Using Artificially Aged Silk. Acta Universitatis Gothoburgensis. Ph.D. Thesis, University of Gothenburg, Gothenburg, Sweden, 2015; p. 37. [Google Scholar]

- Nilsson, J. Evaluation of stitched support methods for the remedial conservation of historical silk costumes. E-Conserv. J. 2015, 3, 1–20. [Google Scholar] [CrossRef]

- Tse, S. Guidelines for pH measurement in conservation. In Technical Bulletin 28; Canadian Conservation Institute: Ottawa, ON, Canada, 2007. [Google Scholar]

- Hughes, A. Testing the waters: New technical applications for the cleaning of acrylic paint films and paper supports. Book Pap. Group Annu. 2013, 32, 43–51. [Google Scholar]

- Arai, T.; Freddi, G.; Innocenti, R.; Tsukada, M. Biodegradation of Bombyx mori silk fibroin Fibers and films. J. Appl. Polym. Sci. 2004, 91, 2383–2390. [Google Scholar] [CrossRef]

- Liu, J.; Guo, D.; Zhou, Y.; Wu, Z.; Li, W.; Zhao, F.; Zheng, X. Identification of ancient textiles from Yingpan, Xinjiang, by multiple analytical techniques. J. Archaeol. Sci. 2011, 38, 1763–1770. [Google Scholar] [CrossRef]

- Annis, P.A. Understanding and Improving the Durability of Textiles; The Textile Institute, Series in Textiles; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- van Oosten, T.B. The degradation of fibroin under the influence of weighting: A state of the art to the degradation of weighted silk. In Contributions of the Central Research Laboratory to the Field of Conservation and Restoration; Central Research Laboratory for Objects of Art and Science: Amsterdam, The Netherlands, 1991. [Google Scholar]

- Wen, Q.Y.; Chen, Y.; Su, Y.; Yu, J.; Chen, P.; Zheng, T. Novel Applications of Silk Proteins Based on Their Interactions with Metal Ions. Sustainability 2023, 15, 16053. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).