Spanish broom Production Chain Improvement with a View to Sustainable Development

Highlights

- Broom plants are a source of fiber obtained by a natural method, thus moving away from the use of sodium hydroxide, which has been the conventional method for fiber extraction.

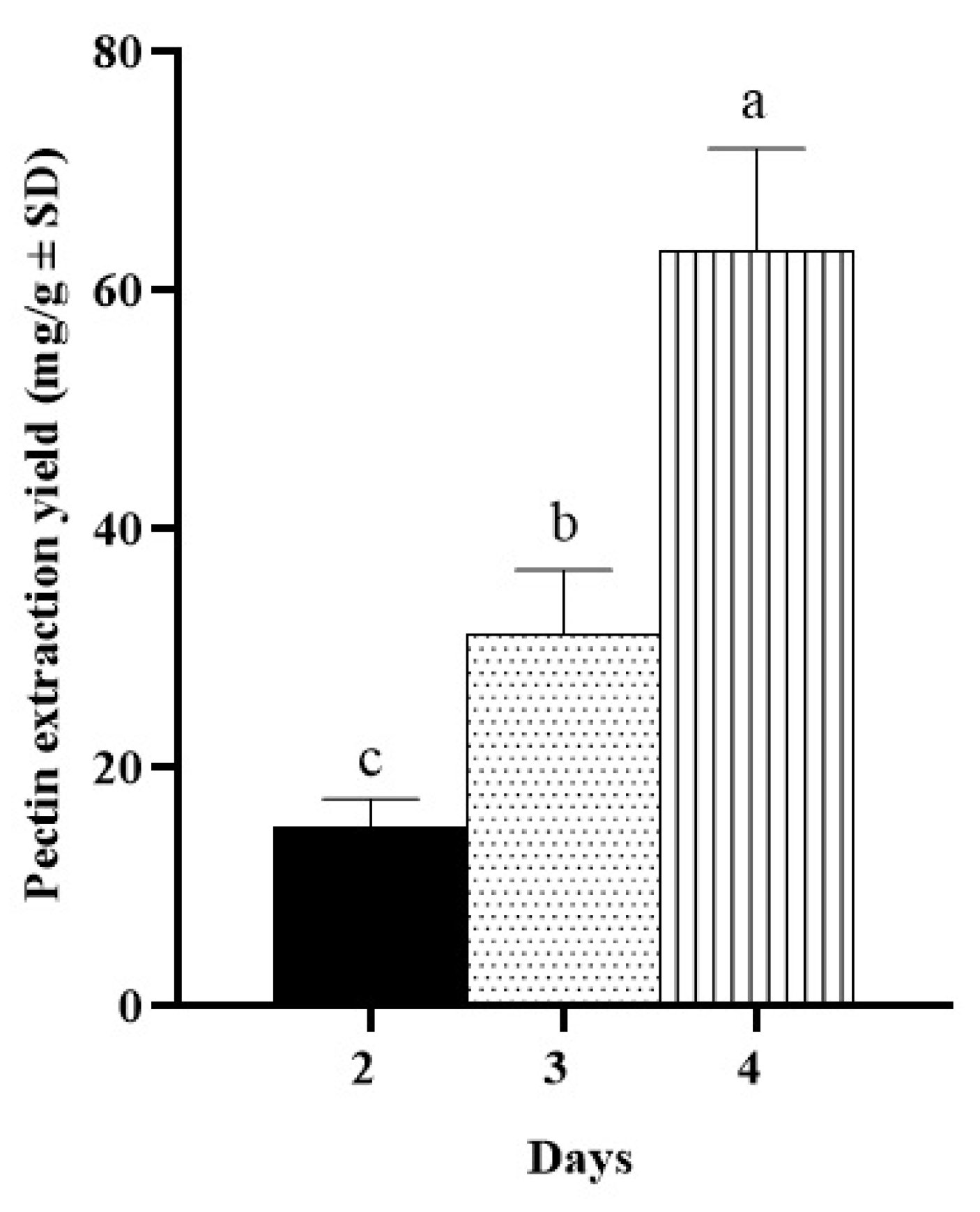

- The rehydration time, of the plant, 4 days, is crucial for the recovery of significant amounts of cellulose. Additionally, the residual biomass from the broom plant is a significant source of pectin, comprising approximately 6%.

- Broom plants do not need any treatment; they are wild plants that do not need irrigation.

- It is possible to reduce the environmental impact by eliminating the use of sodium hydroxide and by extracting additional soluble fiber, pectin, from the plant’s waste. Pectins obtained are valuable polysaccharides widely utilized in the food industry as gelling agents, thickeners, and stabilizers, thereby enhancing the economic viability of broom cultivation.

- This discovery not only promotes sustainable practices but also highlights the potential for utilizing natural resources more efficiently!

Abstract

1. Introduction

2. Materials and Methods

2.1. Isolation of Cellulose

2.2. Isolation of Pectin

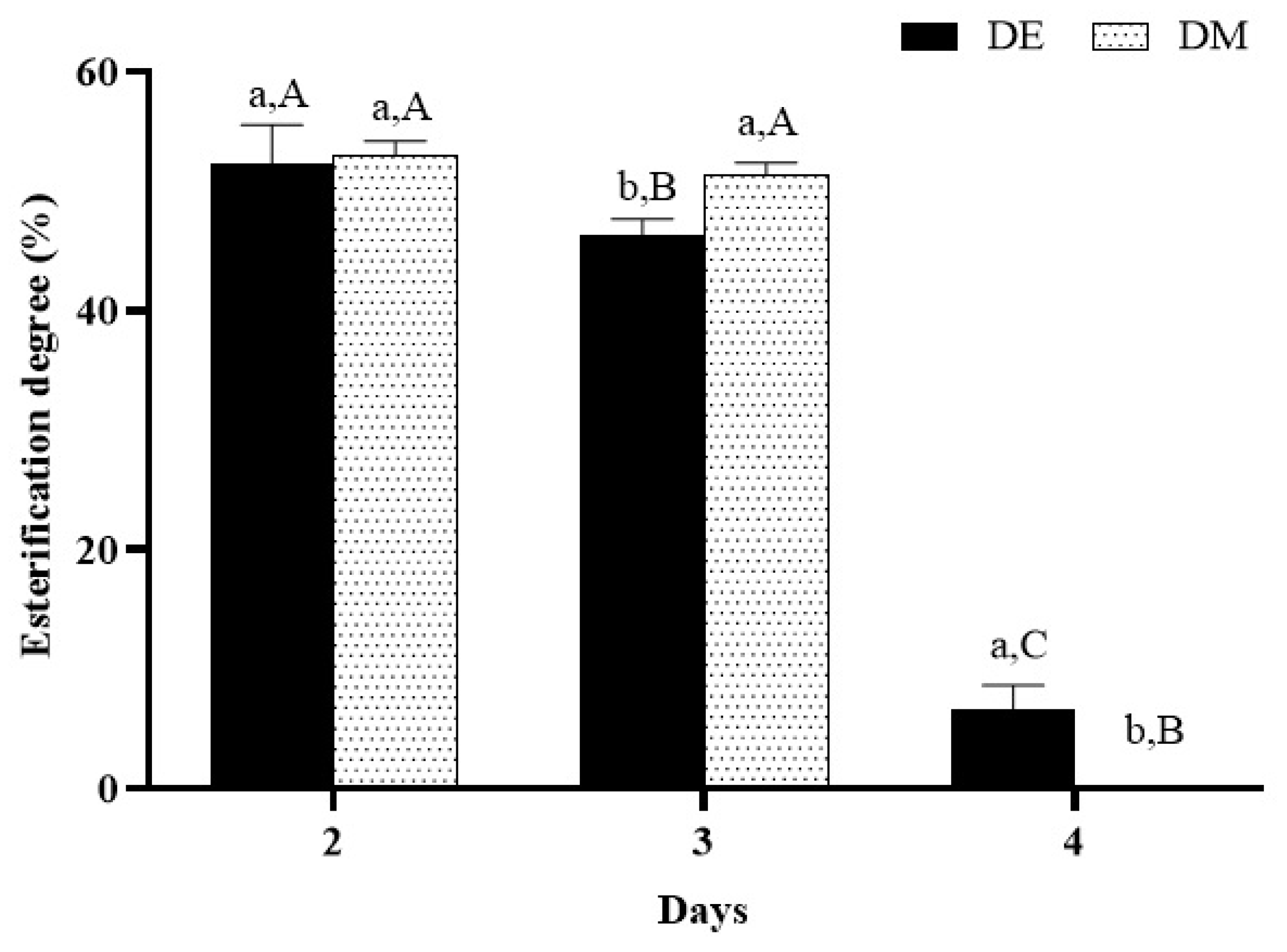

2.3. Determination of Esterification Degree

2.3.1. Potentiometric Titration Method

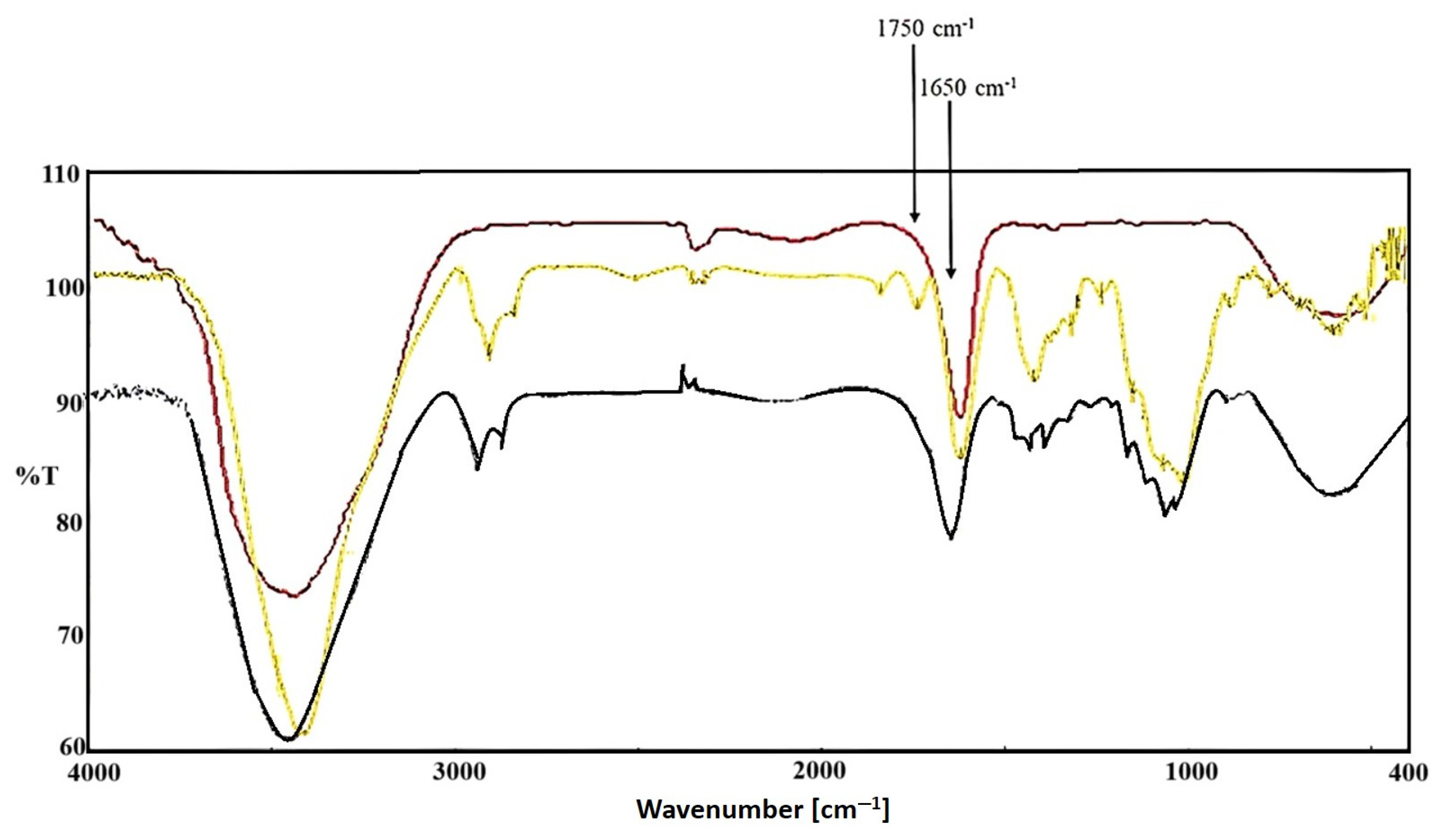

2.3.2. Instrumental FT-IR Method

2.4. Scanning Electron Microscopy (SEM)

2.5. Statistical Analysis

3. Results and Discussion

3.1. Cellulose Extraction

3.2. Pectin Extraction

3.3. FT-IR Analyses

3.4. Esterification Degree

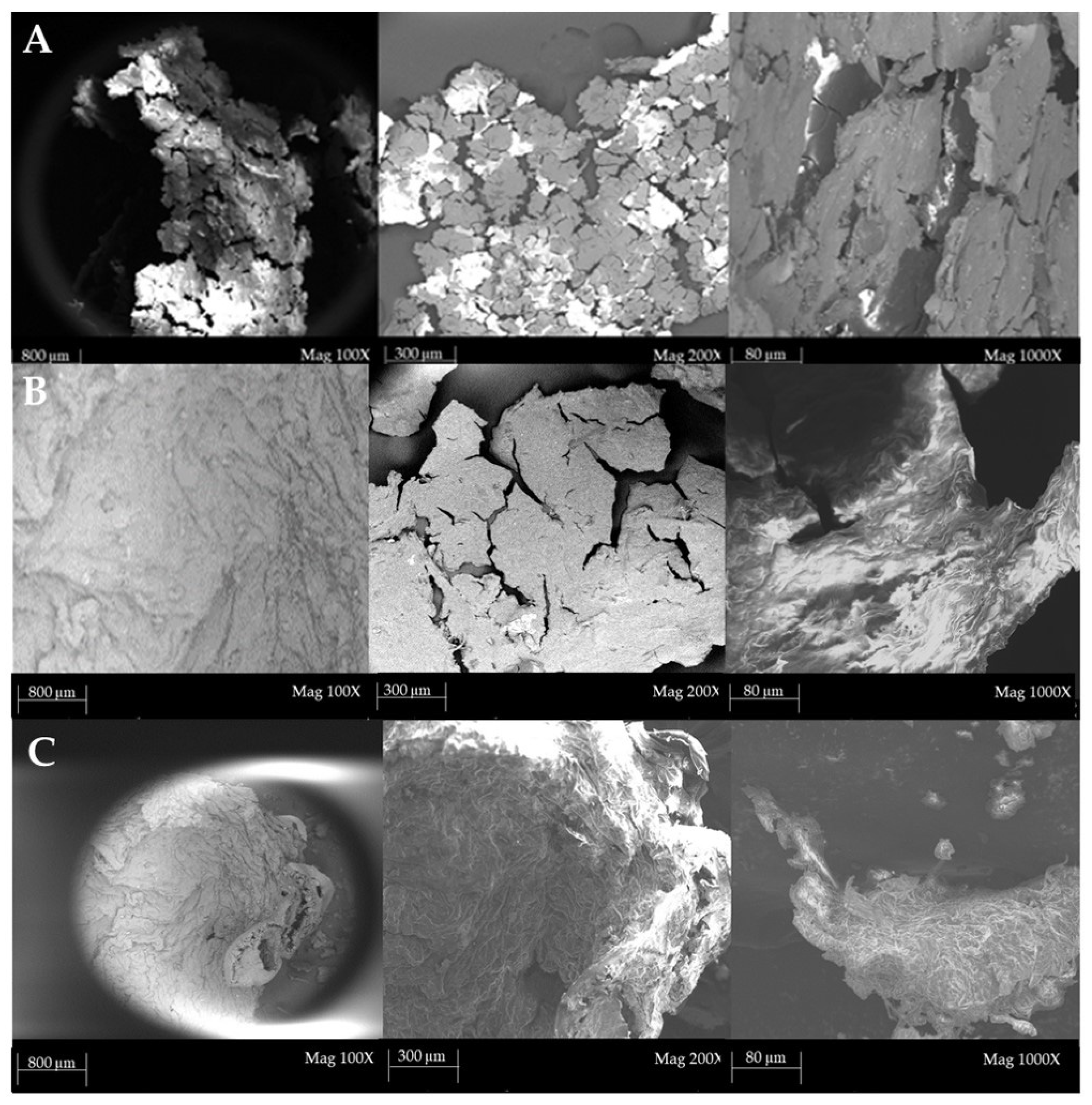

3.5. Scanning Electron Microscopy (SEM) of Pectin

4. Conclusions

- SDG 6 “Clean Water and Sanification” (target 6.4 “By 2030, substantially increase water-use efficiency across all sectors and ensure sustainable withdrawals and supply of freshwater to address water scarcity and substantially reduce the number of people suffering from water scarcity”);

- SDG 9 “Industry, Innovation and Infrastructure” (target 9.4 “By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities”;

- SDG 17 “Partnerships for the Goals” (target 17.16 “Enhance the Global Partnership for Sustainable Development, complemented by multi-stakeholder partnerships that mobilize and share knowledge, expertise, technology and financial resources, to support the achievement of the Sustainable Development Goals in all countries, in particular developing countries”).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aguado, J.; Carlos, J.; Serrano, D. European trends in the feedstock recycling of plastic wastes. Glob. Wastes NEST J. 2007, 9, 12–19. [Google Scholar] [CrossRef]

- Foschi, E.; Bonoli, A. The Commitment of Packaging Industry in the Framework of the European Strategy for Plastics in a Circular Economy. Adm. Sci. 2019, 9, 18. [Google Scholar] [CrossRef]

- Dhanraj; Abdulla, M.H.; Shanavas, J. Biodegradation of petroleum based and bio-based plastics: Approaches to increase the rate of biodegradation. Arch. Microbiol. 2022, 5, 204–258. [Google Scholar] [CrossRef] [PubMed]

- Alessandra, S.; Malyzhenkov, P.; Maurizio, M.; Mosconi, E.; Fabrizio, R. A Hazardous Materials Treatment Business Modelling in the Industry 4.0 Perspective. Int. J. Bus. Perform. Manag. 2024, 18, 127. [Google Scholar] [CrossRef]

- Al-Suhaibani, N.; Selim, M.; Alderfasi, A.; El-Hendawy, S. Integrated Application of Composted Agricultural Wastes, Chemical Fertilizers and Biofertilizers as an Avenue to Promote Growth, Yield and Quality of Maize in an Arid Agro-Ecosystem. Sustainability 2021, 13, 7439. [Google Scholar] [CrossRef]

- Hirsch, R. The Inevitable Peaking of World Oil Production; The Atlantic Council of the United States: Washington, DC, USA, 2005; Volume 16. [Google Scholar]

- Klai, N.; Yadav, B.; El Hachimi, O.; Pandey, A.; Sellamuthu, B.; Tyagi, R.D. 18—Agro-Industrial Waste Valorization for Biopolymer Production and Life-Cycle Assessment Toward Circular Bioeconomy. In Biomass, Biofuels, Biochemicals; Pandey, A., Tyagi, R.D., Varjani, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 515–555. [Google Scholar]

- Kosre, A.; Koreti, D.; Mahish, P.K.; Chandrawanshi, N.K. Current Perspective of Sustainable Utilization of Agro Waste and Biotransformation of Energy in Mushroom. In Energy: Crises, Challenges and Solutions; Wiley: Hoboken, NJ, USA, 2021; pp. 274–302. [Google Scholar]

- Bisht, B.; Lohani, U.; Kumar, V.; Gururani, P.; Sinhmar, R. Edible hydrocolloids as sustainable substitute for non-biodegradable materials Edible hydrocolloids as sustainable substitute for non-biodegradable materials. Crit. Rev. Food Sci. Nutr. 2020, 62, 693–725. [Google Scholar] [CrossRef]

- Rahman, M.H.; Bhoi, P. An Overview of Non-biodegradable Bioplastics. J. Clean. Prod. 2021, 294, 126218. [Google Scholar] [CrossRef]

- Mohanaprasadh, S.V.; Singh, P.; Bahukhandi, K.D. Environmental Pollution and Natural Resource Management. In Disposal of Non-Biodegradable Waste Using Eco-Friendly Methods; Bahukhandi, K.D., Kamboj, N., Kamboj, V., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 345–363. [Google Scholar]

- Prasad, S.; Singh, A.; Korres, N.E.; Rathore, D.; Sevda, S.; Pant, D. Sustainable utilization of crop residues for energy generation: A life cycle assessment (LCA) perspective. Bioresour. Technol. 2020, 303, 122964. [Google Scholar] [CrossRef]

- Awogbemi, O.; Kallon, D.V.V. Valorization of agricultural wastes for biofuel applications. Heliyon 2022, 8, e11117. [Google Scholar] [CrossRef]

- Pharino, C. Chapter 31—Food waste generation and management: Household sector. In Valorization of Agri-Food Wastes and By-Products; Bhat, R., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 607–618. [Google Scholar]

- Segun Emmanuel, I.; Jen, T.-C.; Mahamood, R.; Akinlabi, E. Densification of agro-residues for sustainable energy generation: An overview. Bioresour. Bioprocess. 2021, 8, 75. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel sustainable hemp-based composites for application in the building industry: Physical, thermal and mechanical characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Mariana, M.; Alfatah, T.; HPS, A.K.; Yahya, E.B.; Olaiya, N.G.; Nuryawan, A.; Mistar, E.M.; Abdullah, C.K.; Abdulmadjid, S.N.; Ismail, H. A current advancement on the role of lignin as sustainable reinforcement material in biopolymeric blends. J. Mater. Res. Technol. 2021, 15, 2287–2316. [Google Scholar] [CrossRef]

- Zubair, M.; Rauf, Z.; Fatima, S.; Ullah, A. Lignin-derived bionanocomposites as functional food packaging materials. Sustain. Food Technol. 2024, 2, 945–966. [Google Scholar] [CrossRef]

- Ezeorba, T.P.C.; Okeke, E.S.; Mayel, M.H.; Nwuche, C.O.; Ezike, T.C. Recent advances in biotechnological valorization of agro-food wastes (AFW): Optimizing integrated approaches for sustainable biorefinery and circular bioeconomy. Bioresour. Technol. Rep. 2024, 26, 101823. [Google Scholar] [CrossRef]

- Wang, B.-T.; Hu, S.; Oh, D.N.; Jin, C.-Z.; Jin, L.; Lee, J.M.; Jin, F.-J. Insights into the Lignocellulose-Degrading Enzyme System Based on the Genome Sequence of Flavodon sp. x-10. Int. J. Mol. Sci. 2025, 26, 866. [Google Scholar] [CrossRef]

- Chopra, L. Extraction of cellulosic fibers from the natural resources: A short review. Mater. Today Proc. 2021, 48, 1265–1270. [Google Scholar] [CrossRef]

- Ng, H.-M.; Sin, L.T.; Tee, T.-T.; Bee, S.-T.; Hui, D.; Low, C.-Y.; Rahmat, A.R. Extraction of cellulose nanocrystals from plant sources for application as reinforcing agent in polymers. Compos. Part B Eng. 2015, 75, 176–200. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Briard, M.; O’ Brien, S.; Pelsy, F. A European Strategy for Plastics in the Circular Economy Local and Regional Dimension; European Committee of the Regions: Bruxelles, Belgium, 2018. [Google Scholar]

- Cerchiara, T.; Angela, A.; Nahui Palomino, R.; Vitali, B.; De Rose, R.; Chidichimo, G.; Ceseracciu, L.; Athanassiou, A.; Saladini, B.; Dalena, F.; et al. Spanish Broom (Spartium junceum L.) fibers impregnated with vancomycin-loaded chitosan nanoparticles as new antibacterial wound dressing: Preparation, characterization and antibacterial activity. Eur. J. Pharm. Sci. 2016, 99, 105–112. [Google Scholar] [CrossRef]

- Cerchiara, T.; Blaiotta, G.; Straface, V.; Belsito, E.; Liguori, A.; Luppi, B.; Bigucci, F.; Chidichimo, G. Biological Activity of Spartium junceum L. (Fabaceae) Aromatic Water. Nat. Resour. 2013, 04, 229–234. [Google Scholar] [CrossRef]

- Santulli, C.; Giampaoli, G. Spanish Broom Fibres Properties and Extraction for Application in Composites: A Review. Appl. Sci. Eng. Prog. 2021, 14, 624–631. [Google Scholar] [CrossRef]

- Juradin, S.; Boko, I.; Netinger, I.; Jozić, D.; Mrakovcic, S.; Vukojević, I. Properties of Spanish Broom Fiber Reinforced Concrete. Solid. State Phenomena 2021, 322, 72–77. [Google Scholar] [CrossRef]

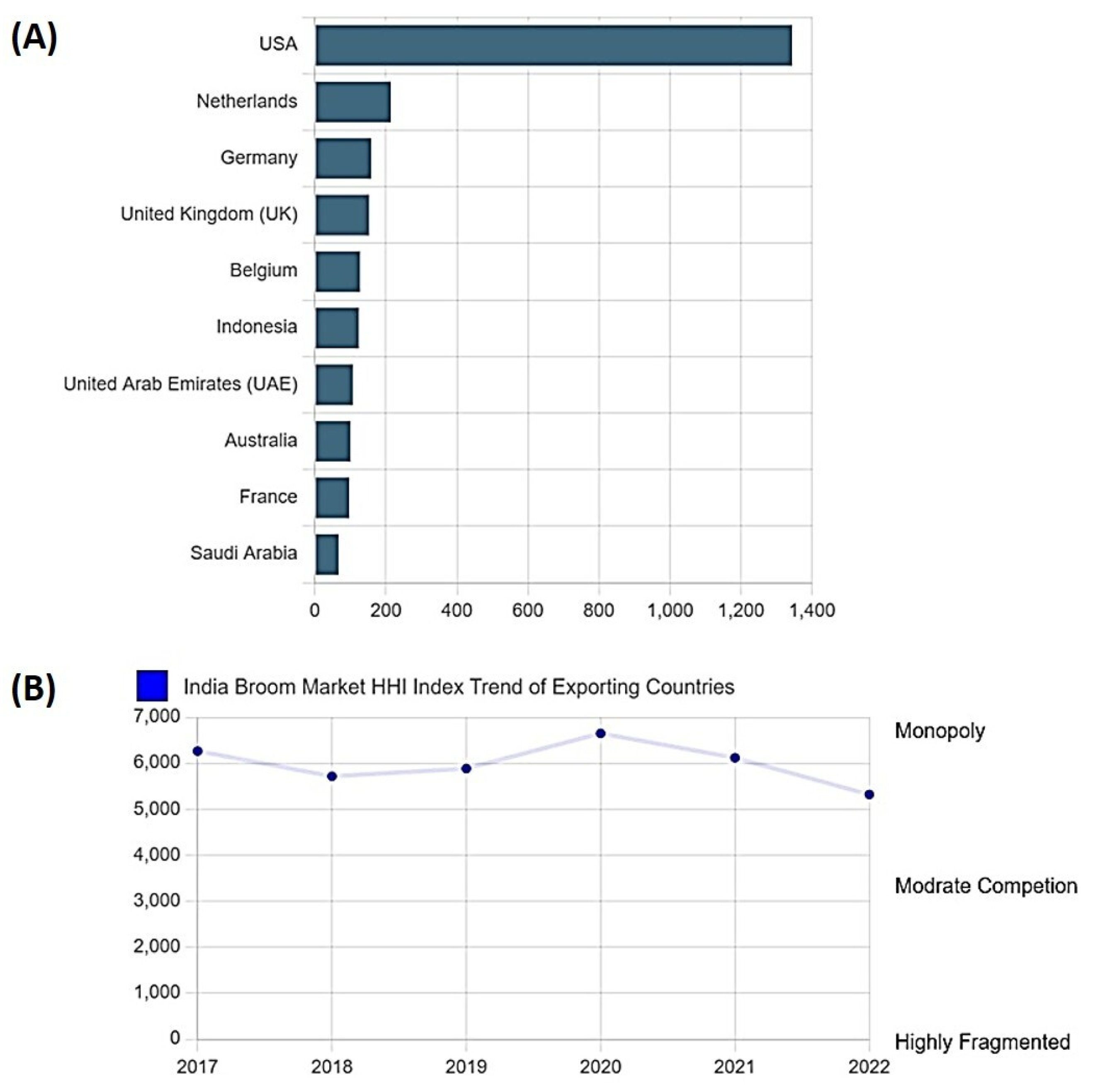

- Raje, K. Broom Market Report. 2025 (Global Edition); CMR534564; Cognitive Market Research: Chicago, IL, USA, 2025; p. 250. [Google Scholar]

- Ben-Othman, S.; Jõudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510. [Google Scholar] [CrossRef] [PubMed]

- Brennan, C.S. Regenerative Food Innovation: The Role of Agro-Food Chain By-Products and Plant Origin Food to Obtain High-Value-Added Foods. Foods 2024, 13, 427. [Google Scholar] [CrossRef]

- Bala, S.; Garg, D.; Sridhar, K.; Inbaraj, B.S.; Singh, R.; Kamma, S.; Tripathi, M.; Sharma, M. Transformation of Agro-Waste into Value-Added Bioproducts and Bioactive Compounds: Micro/Nano Formulations and Application in the Agri-Food-Pharma Sector. Bioengineering 2023, 10, 152. [Google Scholar] [CrossRef]

- Cognitive Market Research. Available online: https://www.cognitivemarketresearch.com/broom-market-report (accessed on 30 April 2025).

- Vishwakarma, A.; Meena, M.; Dangayach, G.; Gupta, D.S. Identification of Challenges & Practices of Sustainability in Indian Apparel and Textile Industries. In International Conference on Evolution in Manufacturing; Springer: Singapore, 2022; pp. 149–156. [Google Scholar]

- Ma, Y.; Gam, H.J.; Banning, J. Implementation of lean production and environmental sustainability in the Indian apparel manufacturing industry: A way to reach the triple bottom line. Int. J. Fash. Des. Technol. Educ. 2017, 10, 254–264. [Google Scholar] [CrossRef]

- Vadicherla, T.; Saravanan, D. Textiles and Apparel Development Using Recycled and Reclaimed Fibers. In Roadmap to Sustainable Textiles and Clothing: Eco-Friendly Raw Materials, Technologies, and Processing Methods; Springer: Singapore, 2014; pp. 139–160. [Google Scholar]

- Phiri, R.; Mavinkere Rangappa, S.; Siengchin, S.; Oladijo, O.P.; Dhakal, H.N. Development of sustainable biopolymer-based composites for lightweight applications from agricultural waste biomass: A review. Adv. Ind. Eng. Polym. Res. 2023, 6, 436–450. [Google Scholar] [CrossRef]

- Lange, L.; Connor, K.O.; Arason, S.; Bundgård-Jørgensen, U.; Canalis, A.; Carrez, D.; Gallagher, J.; Gøtke, N.; Huyghe, C.; Jarry, B.; et al. Developing a Sustainable and Circular Bio-Based Economy in EU: By Partnering Across Sectors, Upscaling and Using New Knowledge Faster, and For the Benefit of Climate, Environment & Biodiversity, and People & Business. Front. Bioeng. Biotechnol. 2020, 8, 619066. [Google Scholar] [CrossRef]

- Okogwu, C.; Agho, M.; Adeyinka, M.; Odulaja, B.; Eyo-Udo, N.; Daraojimba, C.; Banso, A. Exploring the Integration of Sustainable Materials in Supply Chain Management for Environmental Impact. Eng. Sci. Technol. Int. J. 2023, 4, 49–65. [Google Scholar] [CrossRef]

- Gaminian, H.; Ahvazi, B.; Vidmar, J.J.; Ekuere, U.; Regan, S. Revolutionizing Sustainable Nonwoven Fabrics: The Potential Use of Agricultural Waste and Natural Fibres for Nonwoven Fabric. Biomass 2024, 4, 363–401. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, A.; Shome, A.; Sinha, R.; Sinha, S.; Jha, P.K.; Kumar, R.; Kumar, P.; Shubham; Das, S.; et al. Impacts of Plastic Pollution on Ecosystem Services, Sustainable Development Goals, and Need to Focus on Circular Economy and Policy Interventions. Sustainability 2021, 13, 9963. [Google Scholar] [CrossRef]

- Lyu, P.; Zhang, Y.; Wang, X.; Hurren, C. Degumming methods for bast fibers—A mini review. Ind. Crop Prod. 2021, 174, 114158. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.; Munawar, S.; Sudarwoko Adi, D.; Notowiharjo, I.; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Palanisamy, S.; Mani, T.; Palaniappan, M.; Santulli, C. Fostering Sustainability: The Environmental Advantages of Natural Fiber Composite Materials—A Mini Review. Environ. Res. Technol. 2024, 7, 380. [Google Scholar] [CrossRef]

- Zhu, S.; Xie, J.; Sun, Q.; Zhang, Z.; Wan, J.; Zhou, Z.; Lu, J.; Chen, J.; Xu, J.; Chen, K.; et al. Recent advances on bast fiber composites: Engineering innovations, applications and perspectives. Compos. Part B Eng. 2024, 284, 111738. [Google Scholar] [CrossRef]

- Santos, C.M.; Santos, T.F.; Aquino, M.S.; Mavinkere Rangappa, S.; Siengchin, S.; Suyambulingam, I. Era of bast fibers-based polymer composites for replacement of man-made fibers. Heliyon 2024, 10, e29761. [Google Scholar] [CrossRef]

- Katović, D.; Katovic, A.; Antonović, A. Extraction Methods of Spanish Broom (Spartium junceum L.). Drv. Ind. 2011, 62, 255–261. [Google Scholar] [CrossRef]

- Greco, P.F.; La Greca, G.; Larocca, G.; Meduri, S.; Sinopoli, B.; Battaglia, D.; Caseti, A.; Aloise, A.; Chidichimo, G.; Danieli, G. Automatic System for Fibers Extraction from Brooms; Boschetti, G., Gasparetto, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 247–255. [Google Scholar]

- Beneduci, A.; Chidichimo, F.; Chidichimo, G.; Caruso, P.; Danieli, G.; Gullo, G.; Greco, P.F.; Larocca, G.; La Greca, G.; Tursi, A. New plant for the detachment of long fibers from macerated plants and their automated collection. 2021. [Google Scholar]

- Chidichimo, G.; Berardi, D.; Gullo, G.; De Filpo, G.; Tursi, A.; Basile, M.R.; Lania, I.; De Rose, R.; Gallo, V.; Perrotta, A. Process and Plant for the Extraction of Cellulosic Fibers from Liberian Plants. 2023. [Google Scholar]

- Xiang, T.; Yang, R.; Li, L.; Lin, H.; Kai, G. Research progress and application of pectin: A review. J. Food Sci. 2024, 89, 6985–7007. [Google Scholar] [CrossRef]

- La Torre, C.; Caputo, P.; Plastina, P.; Cione, E.; Fazio, A. Green Husk of Walnuts (Juglans regia L.) from Southern Italy as a Valuable Source for the Recovery of Glucans and Pectins. Fermentation 2021, 7, 305. [Google Scholar] [CrossRef]

- Fazio, A.; La Torre, C.; Caroleo, M.C.; Caputo, P.; Cannataro, R.; Plastina, P.; Cione, E. Effect of Addition of Pectins from Jujubes (Ziziphus jujube Mill.) on Vitamin C Production during Heterolactic Fermentation. Molecules 2020, 25, 2706. [Google Scholar] [CrossRef]

- La Torre, C.; Plastina, P.; Abrego-Guandique, D.M.; Caputo, P.; Oliviero Rossi, C.; Saraceno, G.F.; Caroleo, M.C.; Cione, E.; Fazio, A. Characterization of Exopolysaccharides Isolated from Donkey Milk and Its Biological Safety for Skincare Applications. Polysaccharides 2024, 5, 493–503. [Google Scholar] [CrossRef]

- Fazio, A.; La Torre, C.; Dalena, F.; Plastina, P. Screening of glucan and pectin contents in broad bean (Vicia faba L.) pods during maturation. Eur. Food Res. Technol. 2020, 246, 333–347. [Google Scholar] [CrossRef]

- Hong, T.; Yin, J.; Nie, S.-P.; Xie, M.-Y. Applications of infrared spectroscopy in polysaccharide structural analysis: Progress, challenge and perspective. Food Chem. 2021, 12, 100168. [Google Scholar] [CrossRef] [PubMed]

- Belkheiri, A.; Forouhar, A.; Ursu, A.V.; Dubessay, P.; Pierre, G.; Delattre, C.; Djelveh, G.; Abdelkafi, S.; Hamdami, N.; Michaud, P. Extraction, Characterization, and Applications of Pectins from Plant By-Products. Appl. Sci. 2021, 11, 6596. [Google Scholar] [CrossRef]

| Maceration Time (h) | Cellulosic Fiber (g) I | Fiber/Green Plant (%) II | Dry Cuticle Waste (g) III | Dry Cuticle/Green Plant (g) IV |

|---|---|---|---|---|

| 24 | 2.70 | 1.30 | 1.85 | 0.92 |

| 48 | 10.20 | 5.10 | 8.90 | 4.50 |

| 72 | 15.80 | 7.90 | 14.60 | 7.30 |

| 96 | 17.20 | 8.60 | 16.80 | 8.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malyzhenkov, P.; Chidichimo, G.; La Torre, C.; Fazio, A. Spanish broom Production Chain Improvement with a View to Sustainable Development. Fibers 2025, 13, 54. https://doi.org/10.3390/fib13050054

Malyzhenkov P, Chidichimo G, La Torre C, Fazio A. Spanish broom Production Chain Improvement with a View to Sustainable Development. Fibers. 2025; 13(5):54. https://doi.org/10.3390/fib13050054

Chicago/Turabian StyleMalyzhenkov, Pavel, Giuseppe Chidichimo, Chiara La Torre, and Alessia Fazio. 2025. "Spanish broom Production Chain Improvement with a View to Sustainable Development" Fibers 13, no. 5: 54. https://doi.org/10.3390/fib13050054

APA StyleMalyzhenkov, P., Chidichimo, G., La Torre, C., & Fazio, A. (2025). Spanish broom Production Chain Improvement with a View to Sustainable Development. Fibers, 13(5), 54. https://doi.org/10.3390/fib13050054