Effective Flexural Strengthening of Reinforced Concrete T-Beams Using Bonded Fiber-Core Steel Wire Ropes

Abstract

Highlights

- What are the main findings?

- Bonded fiber-core steel wire ropes (FC-SWRs) effectively enhanced the flexural performance of reinforced concrete (RC) T-beams by increasing their crack initiation load, yield load, ultimate load, stiffness, and energy absorption capacity.

- Analytical modeling based on the Modified Compression Field Theory (MCFT) accurately predicted the experimental behavior, enabling parametric studies that confirmed the beneficial effects of increasing FC-SWR diameter and optimizing steel reinforcement ratio.

- What are the implications of these findings?

- The bonded FC-SWR technique provides a promising, durable method for retrofitting under-reinforced RC beam members, enhancing their load-carrying capacity and structural resilience while maintaining manageable levels of ductility.

- This study demonstrates that FC-SWRs can be a viable alternative to conventional strengthening materials, offering practical solutions for extending the service life of aging infrastructures with relatively simple application methods.

Abstract

1. Introduction

2. Experimental Program

2.1. Geometry of the Specimens

2.2. Strengthening Procedure

2.3. Properties of Materials

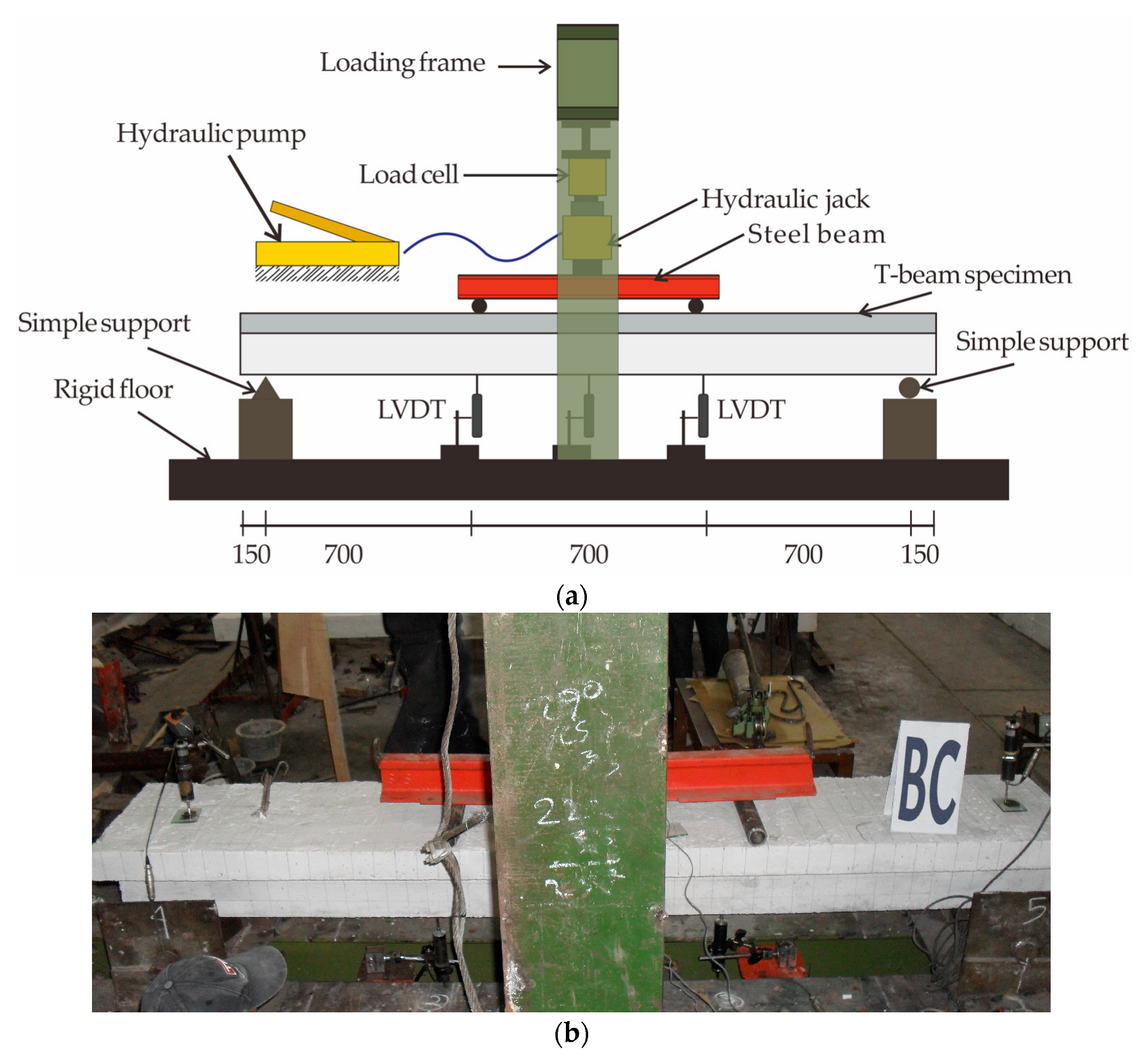

2.4. Testing Setup and Instrumentation

3. Results and Discussion

3.1. Flexural Load Carrying Capacity

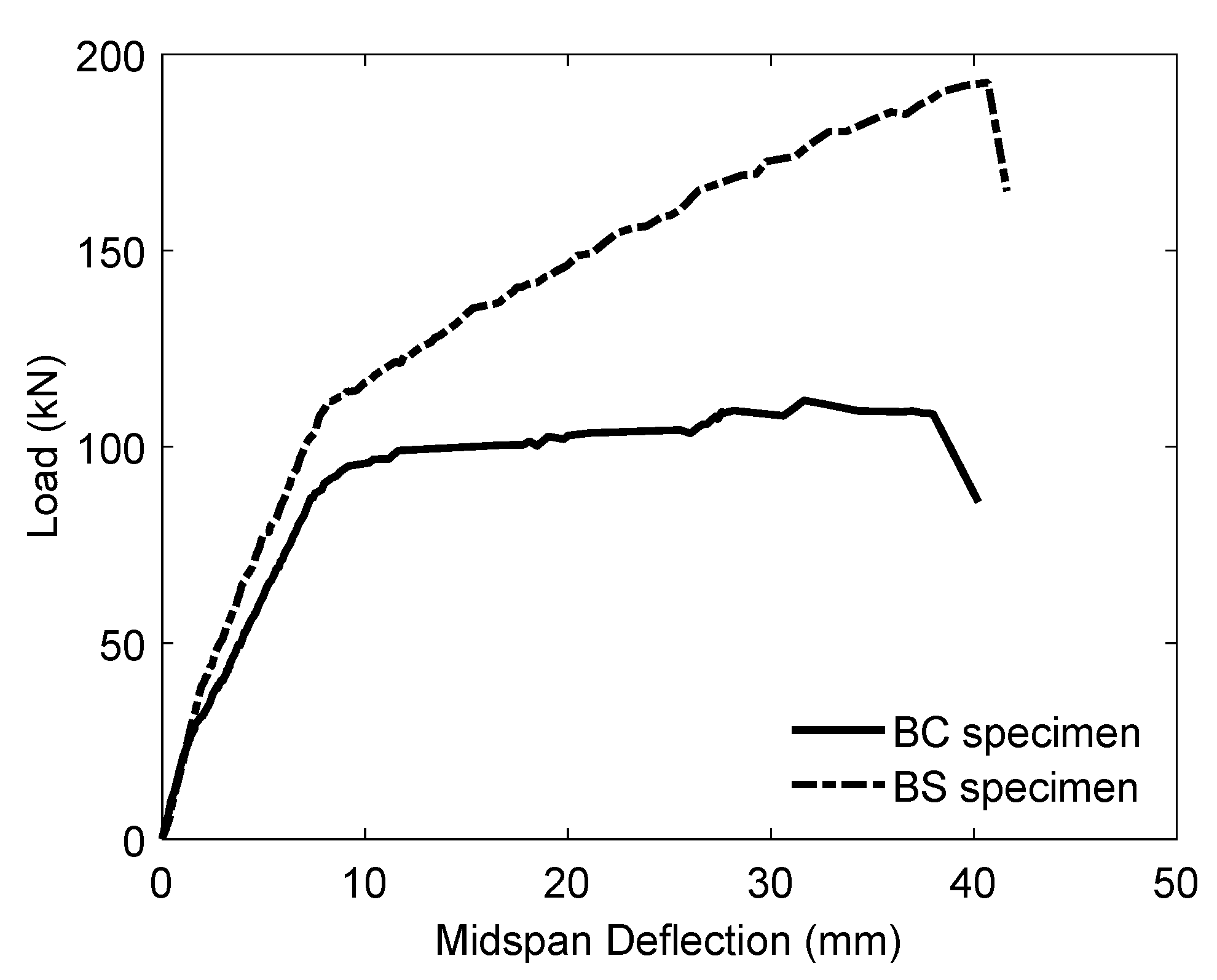

3.2. Load–Deflection Curves

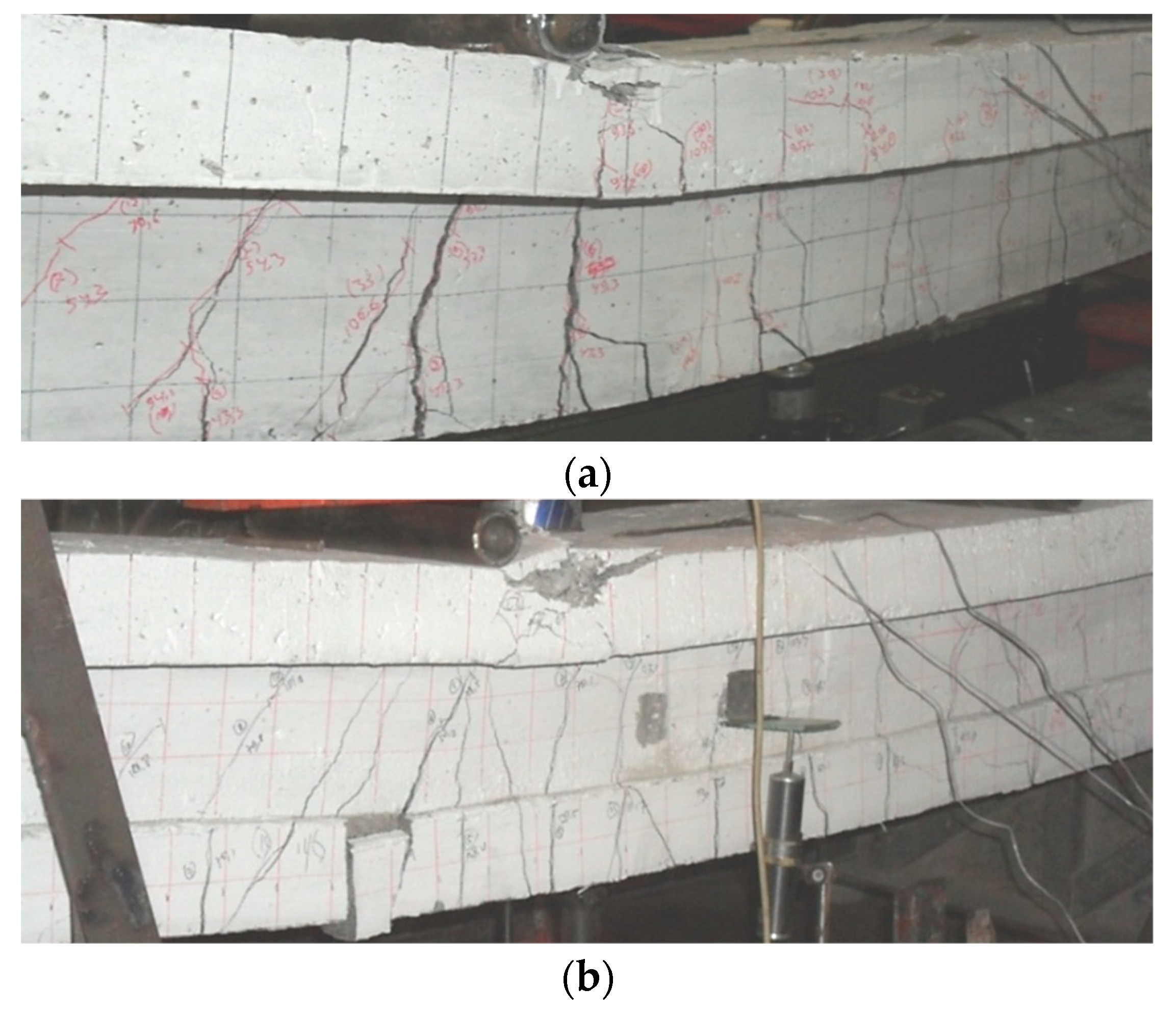

3.3. Failure Modes

3.4. Ductility Index and Stiffness

3.5. Energy Absorption

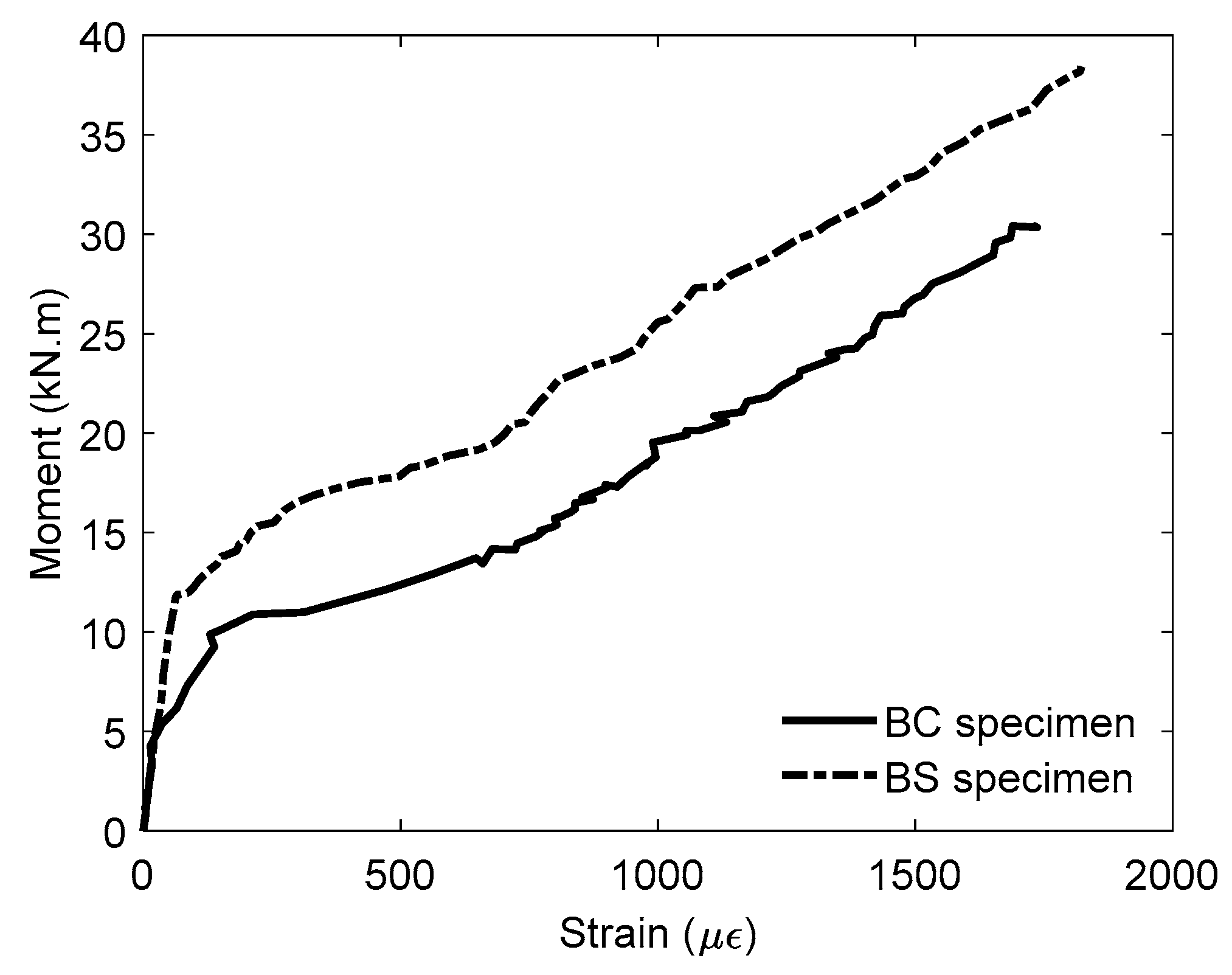

3.6. Steel Strain Response

4. Analytical Modeling

4.1. Constitutive Laws

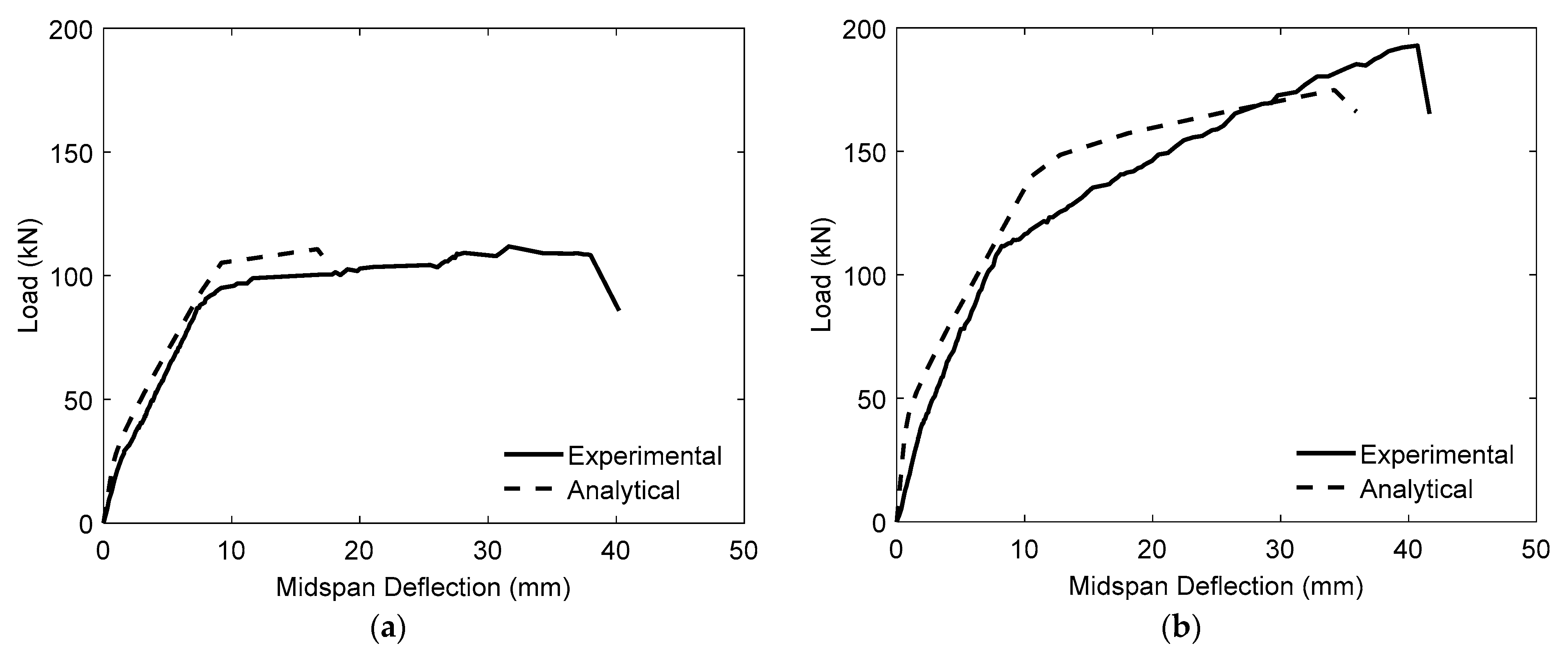

4.2. Model Validation

4.3. Parametric Study

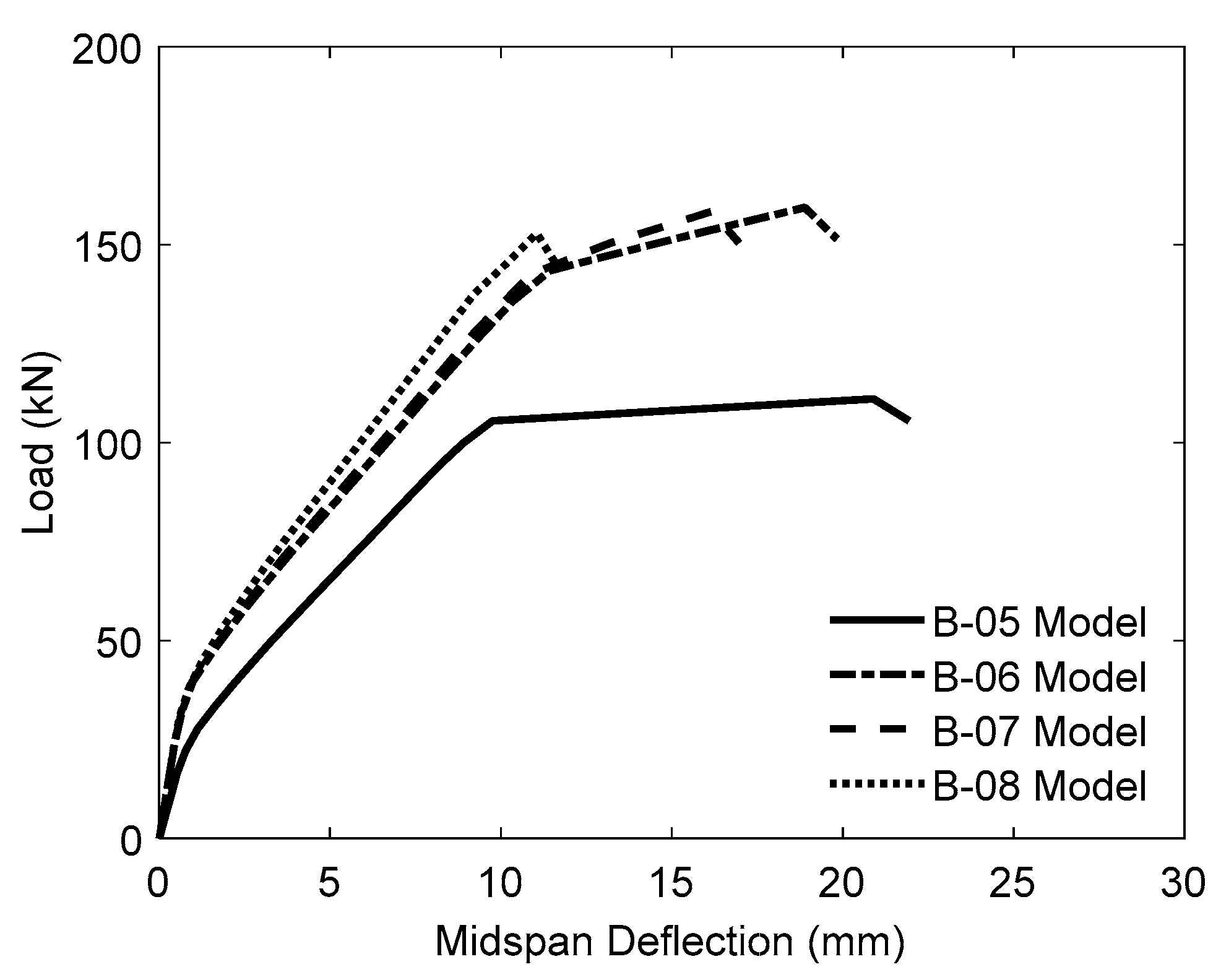

4.3.1. Effect of FC-SWR Diameter

4.3.2. Effect of FC-SWR Modulus of Elasticity

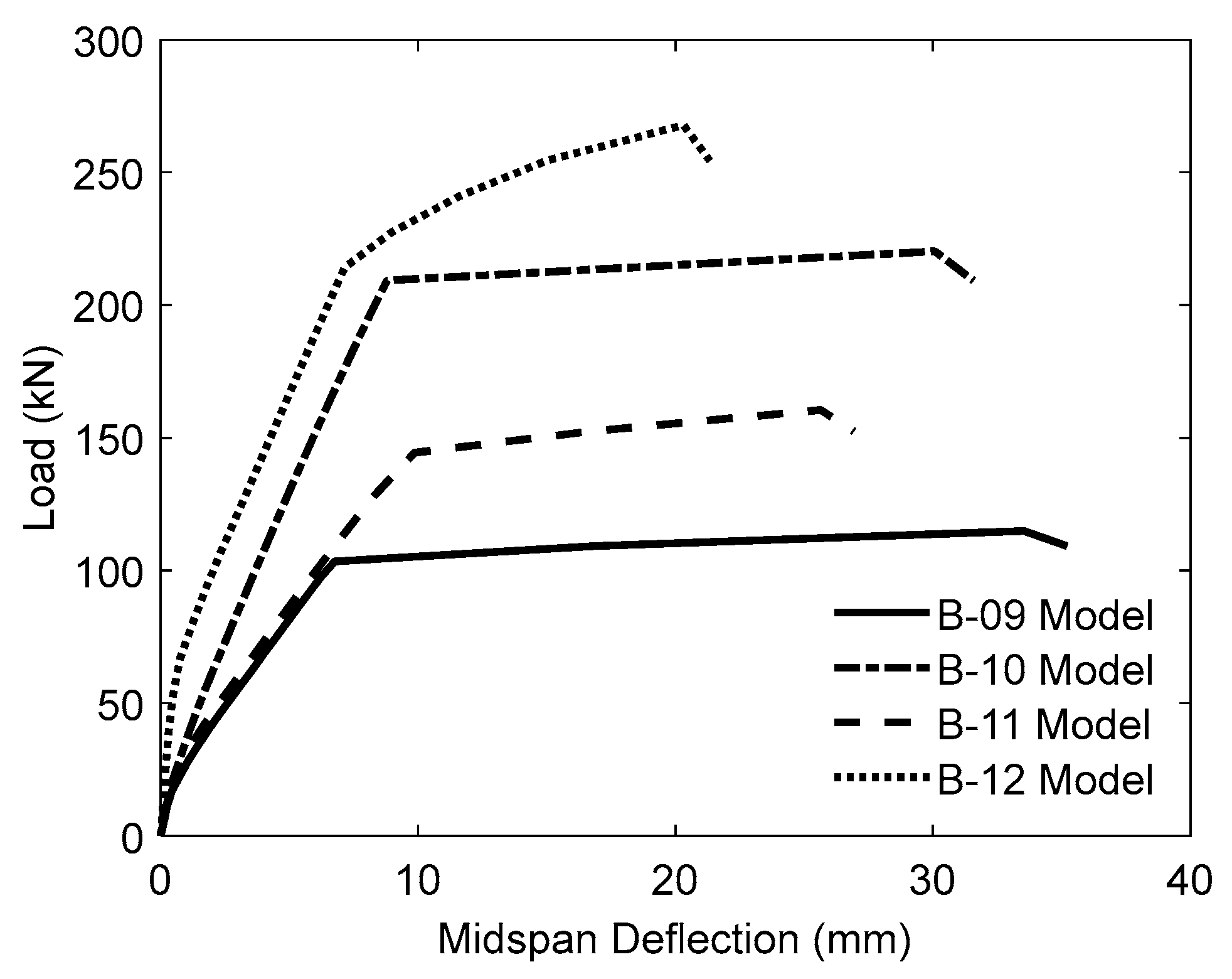

4.3.3. Effect of Steel Reinforcement Ratio

5. Conclusions

- Flexural strengthening of RC T-beams with bonded SWRs proved to be effective, as demonstrated by the increase in crack initiation, yield, and ultimate loads. Although the mode of failure remained flexural for both the strengthened and unstrengthened specimens, the strengthened beam exhibited higher load capacities at each stage of failure, highlighting the contribution of bonded SWRs in enhancing structural performance.

- The strengthened beam exhibited increased stiffness due to the additional reinforcement, which restricted crack initiation and propagation; however, this also led to a decrease in ductility by limiting its deformation capacity.

- The energy absorption capacity of the strengthened beam improved compared to the control beam, primarily due to delayed crack formation, increased stiffness, and enhanced yield and ultimate loads.

- The steel strain values in the strengthened beam were consistently lower than those in the control beam at the same load levels, indicating improved load distribution. This reduction in strain suggests that the bonded FC-SWRs effectively transferred tensile stresses.

- The analytical models successfully simulated the flexural behavior of the RC T-beam specimens, with and without bonded FC-SWRs, demonstrating good agreement with experimental results.

- The increase in load-carrying capacity was directly proportional to the increase in FC-SWR diameter, confirming a size-dependent strengthening effect.

- The use of bonded FC-SWRs with a higher modulus of elasticity reduced ductility, highlighting the trade-off between strength enhancement and deformation capacity.

- The effectiveness of bonded FC-SWRs was more prominent in under-reinforced beams, which showed greater flexural strength gains than over-reinforced specimens.

- Despite offering valuable insights, this study is limited by the small number of specimens. Future work should involve a broader test matrix to improve statistical validity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RC | Reinforced concrete |

| FRP | Fiber-reinforced polymer |

| NSM | Near-surface mounted |

| CFRP | Carbon fiber-reinforced polymer |

| HSC | High-strength concrete |

| SWR | Steel wire rope |

| FC-SWR | Fiber-core steel wire rope |

| LVDT | Linear Variable Differential Transducers |

| R2K | Response-2000 |

| MCFT | Modified Compression Field Theory |

References

- Turki, A.Y.; Al-Farttoosi, M.H. Flexural Strength of damaged RC beams repaired with carbon fiber-reinforced polymer (CFRP) using different techniques. Fibers 2023, 11, 61. [Google Scholar] [CrossRef]

- Rizwan, M.; Ahmad, N.; Khan, A.N. Seismic performance of RC frame having low strength concrete: Experimental and numerical studies. Earth Struct. 2019, 17, 75–89. [Google Scholar]

- Pei, Q.; Cai, B.; Xue, Z.; Ding, Y.; Cui, D.; Guo, Y. Study on mechanical properties of corroded concrete columns strengthened with SMA wires. PLoS ONE 2023, 18, e0276280. [Google Scholar] [CrossRef] [PubMed]

- Pei, Q.; Zhong, Y.; Wang, B.; Qi, P.; Xue, Z.; Cui, D.; Ding, Y.; Cai, B. Performance of SRC unequal-depth beam-column irregular joint in NPP under progressive collapse. Structures 2024, 70, 107593. [Google Scholar] [CrossRef]

- Al-Mosawe, D.; Neves, L.; Owen, J. Reliability analysis of deteriorated post-tensioned concrete bridges: The case study of Ynys-y-Gwas bridge in UK. Structures 2022, 41, 242–259. [Google Scholar] [CrossRef]

- Jiang, X.; Cao, D.Q.; Qiang, X.H.; Xu, C.L. Study on fatigue performance of steel bridge welded joints considering initial defects. J. Constr. Steel Res. 2024, 212, 108309. [Google Scholar] [CrossRef]

- Franco, N.; Biscaia, H.; Chastre, C. Experimental and numerical analyses of flexurally-strengthened concrete T-beams with stainless steel. Eng. Struct. 2018, 172, 981–996. [Google Scholar] [CrossRef]

- Tehrani, B.N.; Mostofinejad, D.; Hosseini, S.H. Experimental and analytical study on flexural strengthening of RC beams via prestressed EBROG CFRP plates. Eng. Struct. 2019, 197, 109395. [Google Scholar] [CrossRef]

- Sabzi, J.; Esfahania, M.R.; Ozbakkaloglu, T.; Farahic, B. Effect of concrete strength and longitudinal reinforcement arrangement on the performance of reinforced concrete beams strengthened using EBR and EBROG methods. Eng. Struct. 2020, 205, 110072. [Google Scholar] [CrossRef]

- Moshiri, N.; Czaderski, C.; Mostofinejad, B.; Motavalli, M. Bond resistance of prestressed CFRP strips attached to concrete by using EBR and EBROG strengthening methods. Constr. Build. Mater. 2021, 266, 121209. [Google Scholar] [CrossRef]

- Nugroho, L.; Haryanto, Y.; Hu, H.-T.; Hsiao, F.-P.; Pamudji, G.; Setiajdi, B.H.; Hsu, C.-N.; Weng, P.-W.; Lin, C.-C. Prestressed concrete T-beams strengthened with near-surface mounted carbon-fiber-reinforced polymer rods under monotonic loading: A finite element analysis. Eng 2025, 6, 36. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Stress–strain model for FRP-confined concrete under cyclic axial compression. Eng. Struct. 2009, 31, 308–321. [Google Scholar]

- Hui, C.; Li, Y.; Zhao, Z.; Hai, R. Behavior of concrete-filled GFRP tube columns under cyclic axial compression. Constr. Build. Mater. 2021, 294, 123566. [Google Scholar]

- Lin, C.T.; Wu, Y.H.; Chin, W.H.; Lin, M.L. Performance of CFRP-strengthened RC beams subjected to repeated loads. J. Chin. Inst. Eng. 2014, 37, 1007–1017. [Google Scholar]

- Lee, D.H.; Han, J.S.; LaFave, J.M. Shear strength of reinforced concrete beams strengthened in shear using externally-bonded FRP composites. Compos. Struct. 2017, 173, 177–187. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Shannaq, A. Using textile reinforced mortar modified with carbon nano tubes to improve flexural performance of RC beams. Compos. Struct. 2018, 200, 127–134. [Google Scholar] [CrossRef]

- Karayannis, C.G. Golias, Full scale tests of RC joints with minor to moderate seismic damage repaired using CFRP sheets. Earthq. Struct. 2018, 15, 617–627. [Google Scholar]

- Liao, J.; Zeng, J.-J.; Zhuge, Y.; Ma, G.; Zhang, L. FRP-confined concrete columns with a stress reduction-recovery behavior: A state-of-the-art review, design recommendations and model assessments. Compos. Struct. 2023, 321, 117313. [Google Scholar] [CrossRef]

- Spinella, N.; Colajanni, P.; Recupero, A.; Tondolo, F. Ultimate shear of RC beams with corroded stirrups and strengthened with FRP. Buildings 2019, 9, 34. [Google Scholar] [CrossRef]

- Abdallah, M.; Al Mahmoud, F.; Khelil, A.; Mercier, J.; Almassri, B. Assessment of the flexural behavior of continuous RC beams strengthened with NSM-FRP bars, experimental and analytical Study. Compos. Struct. 2020, 242, 112127. [Google Scholar]

- Giese, A.C.H.; Giese, D.N.; Dutra, V.F.P.; Filho, L.C.P.D.S. Flexural behavior of reinforced concrete beams strengthened with textile reinforced mortar. J. Build. Eng. 2021, 33, 101873. [Google Scholar] [CrossRef]

- Haryanto, Y.; Wariyatno, N.G.; Hsiao, F.-P.; Hu, H.-T.; Han, A.L.; Nugroho, L.; Hartono, H. RC T-beams with flexural strengthening in the negative moment region under different configurations of NSM CFRP rods. Eng. Fail. Anal. 2025, 173, 109458. [Google Scholar] [CrossRef]

- Han, A.L.; Hu, H.-T.; Gan, B.S.; Hsiao, F.-P.; Haryanto, Y. Carbon fiber-reinforced polymer rod embedment depth influence on concrete strengthening. Arab. J. Sci. Eng. 2022, 47, 12685–12695. [Google Scholar]

- Haryanto, Y.; Hsiao, F.-P.; Hu, H.-T.; Han, A.L.; Chua, A.W.; Salim, F.; Nugroho, L. Structural behavior of negative moment region NSM-CFRP strengthened RC T-beams with various embedment depth under monotonic and cyclic loading. Compos. Struct. 2022, 301, 116214. [Google Scholar]

- Haryanto, Y.; Hermanto, N.I.S.; Hsiao, F.-P.; Hu, H.-T.; Han, A.L.; Nugroho, L.; Salim, F. Predicting the behavior of RC T-beams strengthened with NSM-CFRP rods in the negative moment region: A finite element approach for low cyclic loading. E3S Web Conf. 2023, 464, 06001. [Google Scholar]

- Nugroho, L.; Haryanto, Y.; Hu, H.-T.; Han, A.L.; Hsiao, F.-P.; Lin, C.-C.; Weng, P.-W.; Widiastuti, E.P. NSM-CFRP rods with varied embedment depths for strengthening RC T-beams in the negative moment region: Investigation on high cyclic response. Compos. Struct. 2024, 331, 117891. [Google Scholar]

- Emara, M.; Salem, M.A.; Mohamed, H.A.; Shehab, H.A.; El-Zohairy, A. Shear strengthening of reinforced concrete beams using engineered cementitious composites and carbon fiber-reinforced polymer sheets. Fibers 2023, 11, 98. [Google Scholar] [CrossRef]

- Mussa, M.H.; Mutalib, A.A.; Hao, H. Experimental and numerical study of carbon fibre-reinforced polymer-strengthened reinforced concrete beams under static and impact loads. Fibers 2024, 12, 63. [Google Scholar] [CrossRef]

- Alasmari, H.A.; Sharaky, I.A.; Elamary, A.S.; El-Zohairy, A. Rehabilitation and strengthening of damaged reinforced concrete beams using carbon fiber-reinforced polymer laminates and high-strength concrete integrating recycled tire steel fiber. Fibers 2025, 13, 10. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Almusallam, T.H.; Alsayed, S.H.; Al-Salloum, Y.A. Flexural strengthening of RC beams using textile reinforced mortar—Experimental and numerical study. Compos. Struct. 2013, 97, 40–55. [Google Scholar]

- Ueda, T.; Dai, J. Interface bond between FRP sheets and concrete substrates: Properties, numerical modeling and roles in member behaviour. Prog. Struct. Eng. Mat. 2004, 7, 27–43. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.-C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Chang, X.-d.; Huang, H.-b.; Peng, Y.-x.; Li, S.-x. Friction, wear and residual strength properties of steel wire rope with different corrosion types. Wear 2020, 458–459, 203425. [Google Scholar] [CrossRef]

- Kim, S.Y.; Yang, K.H.; Byun, H.Y.; Ashour, A.F. Tests of reinforced concrete beams strengthened with wire rope units. Eng. Struct. 2007, 29, 2711–2722. [Google Scholar] [CrossRef]

- Yang, K.H.; Ashour, A.F. Tests of reinforced concrete short columns laterally strengthened with wire rope units and steel elements. Mag. Concr. Res. 2007, 59, 547–557. [Google Scholar] [CrossRef]

- Yang, K.H.; Ashour, A.F.; Lee, E.T. Axial behavior of reinforced concrete short columns strengthened with wire rope and T-shaped steel plate units. Mag. Concr. Res. 2009, 61, 143–154. [Google Scholar] [CrossRef]

- Yang, K.H.; Byun, H.Y.; Ashour, A.F. Shear strengthening of continuous reinforced concrete T-beams using wire rope units. Eng. Struct. 2009, 31, 1154–1165. [Google Scholar] [CrossRef]

- Yang, K.H.; Joo, D.B.; Sim, J.I.; Kang, J.H. In-plane seismic performance of unreinforced masonry walls strengthened with unbonded prestressed wire rope units. Eng. Struct. 2012, 45, 449–459. [Google Scholar] [CrossRef]

- Li, K.; Wei, Y.; Li, Y.; Li, Z.; Zhu, J. Flexural behavior of reinforced concrete beams strengthened with high-strength stainless steel wire rope meshes reinforced ECC. Constr. Build. Mater. 2013, 362, 129627. [Google Scholar] [CrossRef]

- Wu, G.; Wu, Z.S.; Jiang, J.B.; Tian, Y.; Zhang, M. Experimental study of RC beams strengthened with distributed prestressed high-strength steel wire rope. Mag. Concr. Res. 2010, 62, 253–265. [Google Scholar] [CrossRef]

- Wu, G.; Wu, Z.S.; Wei, Y.; Jiang, J.B.; Cui, Y. Flexural strengthening of RC beams using distributed prestressed high strength steel wire rope: Theoretical analysis. Struct. Infrastruct. Eng. 2014, 10, 160–174. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, Y.F. Compression behavior of concrete columns confined by high strength steel wire. Constr. Build. Mater. 2014, 54, 443–453. [Google Scholar] [CrossRef]

- JGJ/T 325-2014; Technical Specification for Strengthening Concrete Structures with Prestressed High Strength Steel Wire Ropes. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2014. (In Chinese)

- Haryanto, Y.; Gan, B.S.; Widyaningrum, A.; Wariyatno, N.G.; Fadli, A. On the performance of steel wire rope as the external strengthening of RC beams with different end-anchor type. J. Teknol. 2018, 80, 145–154. [Google Scholar] [CrossRef]

- Haryanto, Y.; Han, A.L.; Hu, H.-T.; Hsiao, F.-P.; Hidayat, B.A.; Widyaningrum, A. Enhancement of flexural performance of RC beams with steel wire rope by external strengthening technique. J. Chin. Inst. Eng. 2021, 44, 193–203. [Google Scholar] [CrossRef]

- Sudibyo, G.H.; Haryanto, Y.; Hsiao, F.-P.; Hu, H.-T.; Nugroho, L.; Pamudji, G.; Widyaningrum, A.; Nugroho, P.S. Three-dimensional finite element analysis of externally strengthened RC bemas in flexure with SWR. Lect. Notes Civ. Eng. 2025, 625, 267–275. [Google Scholar]

- Li, X.; Wu, G.; Popal, M.S.; Jiang, J. Experimental and numerical study of hollow core slabs strengthened with mounted steel bars and prestressed steel wire ropes. Constr. Build. Mater. 2018, 188, 456–469. [Google Scholar] [CrossRef]

- Miao, W.; Guo, Z.-X.; Ye, Y.; Basha, S.H.; Liu, X.-J. Flexural behavior of stone slabs strengthened with prestressed NSM steel wire ropes. Eng. Struct. 2020, 222, 111046. [Google Scholar] [CrossRef]

- Haryanto, Y.; Sudibyo, G.H.; Nugroho, L.; Hu, H.-T.; Han, A.L.; Hsiao, F.-P.; Widyaningrum, A.; Susetyo, Y. Flexural performance of the negative moment region in bonded steel-wire-rope-strengthened reinforced concrete T-beams at different prestressing levels. Adv. Struct. Eng. 2024, 27, 2338–2358. [Google Scholar] [CrossRef]

- ACI Committee 318; Building Code Requirements for Structural Concrete and Commentary (ACI 318-19). American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Morais, M.; Burgoyne, C. Energy Dissipation in Sections Prestressed with FRP Tendons. In Proceedings of the International Conference on Composites in Construction (CCC 2001), Porto, Portugal, 10–12 October 2001; Lisse: Exton, PA, USA; pp. 421–426. [Google Scholar]

- Li, C.; Aoude, H. Effect of UHPC jacketing on the shear and flexural behaviour of high-strength concrete beams. Structures 2023, 51, 1972–1996. [Google Scholar] [CrossRef]

- Obaydullah, M.; Jumaat, M.Z.; Alengaram, U.J.; Darain, K.M.U.; Huda, M.N.; Hosen, M.A. Prestressing of NSM steel strands to enhance the structural performance of prestressed concrete beams. Constr. Build. Mater. 2016, 129, 289–301. [Google Scholar] [CrossRef]

- Hosen, M.A.; Jumaat, M.Z.; Alengaram, U.J.; Sulong, H.N.R. CFRP strips for enhancing flexural performance of RC beams by SNSM strengthening technique. Constr. Build. Mater. 2018, 165, 28–44. [Google Scholar] [CrossRef]

- Rasheed, H.A.; Harrison, R.R.; Peterman, R.J.; Alkhrdaji, T. Ductile strengthening using externally bonded and near surface mounted composite systems. Compos. Struct. 2010, 92, 2379–2390. [Google Scholar] [CrossRef]

- Qeshta, I.M.I.; Shafigh, P.; Jumaat, M.Z.; Abdulla, A.I.; Ibrahim, Z.; Alengaram, U.J. The use of wire mesh-epoxy composite for enhancing the flexural performance of concrete beams. Mater. Des. 2014, 60, 250–259. [Google Scholar] [CrossRef]

- Bentz, E.C. Sectional Analysis of Reinforced Concrete Members. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2000. [Google Scholar]

- Lam, N.; Wilson, J.; Lumantarna, E. Force-deformation behavior modelling of cracked reinforced concrete by EXCEL spreadsheets. Comput. Concr. 2011, 8, 43–57. [Google Scholar] [CrossRef]

- Metwally, I.M. Evaluate the capability and accuracy of Response-2000 program in prediction of the shear capacities of reinforced and prestressed concrete members. HBRC J. 2012, 8, 99–106. [Google Scholar] [CrossRef]

- Suryanto, B.; Morgan, R.; Han, A.L. Predicting the response of shear-critical reinforced concrete beams using Response-2000 and SNI 2847:2013. Civ. Eng. Dimens. 2016, 8, 16–24. [Google Scholar]

- Huang, Z.; Tu, Y.; Meng, S.; Bagge, N.; Nilimaa, J.; Blanksvärd, T. Validation of a numerical method for predicting shear deformation of reinforced concrete beams. Eng. Struct. 2019, 197, 109367. [Google Scholar] [CrossRef]

- Popovics, S. 1973. Numerical approach to the complete stress-strain curve of concrete. Cem. Concr. Res. 1973, 3, 582–599. [Google Scholar] [CrossRef]

- Porasz, A. An Investigation of the Stress-Strain Characteristics of High Strength Concrete in Shear. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 1989. [Google Scholar]

- Seckin, M. Hysteretic Behavior of Cast-in-Place Exterior Beam-Column Sub-Assemblies. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 1981. [Google Scholar]

- Menegotto, M.; Pinto, P.E. Method of Analysis for Cyclically Loaded Reinforced Concrete Plane Frames Including Changes in Geometry and Non-Elastic Behavior of Elements Under Combined Normal Force and Bending. In Proceedings of the IABSE Symposium on Resistance and Ultimate Deform Ability of Structures Acted on by Well Defined Repeated Loads; International Association of Bridge and Structural Engineering (IABSE): Lisbon, Portugal, 1973; pp. 15–22. [Google Scholar]

- Collins, M.P.; Mitchell, D. Prestressed Concrete Structures; Englewood Cliffs, N.J.: Prentice-Hall, NJ, USA, 1991. [Google Scholar]

- Hawileh, R.A. Nonlinear finite element modeling of RC beams strengthened with NSM FRP rods. Constr. Build. Mater. 2012, 27, 461–471. [Google Scholar] [CrossRef]

| Material | Section | fy,m (MPa) | εy,m (%) | fu,m (MPa) | εu,m (%) | E (MPa) |

|---|---|---|---|---|---|---|

| Steel reinforcement | Ø8 | 373.85 | 0.185 | 525.33 | 20.91 | 201,624 |

| Steel reinforcement | Ø12 | 394.60 | 0.211 | 614.26 | 14.55 | 187,596 |

| Steel reinforcement | Ø13 | 479.71 | 0.243 | 742.52 | 24.55 | 197,664 |

| Fiber-core steel wire rope | Ø10 | - | - | 743.73 | 2.85 | 35,725 |

| Beam ID | Load Capacity (kN) | Deflection (mm) | ||||

|---|---|---|---|---|---|---|

| Cracking | Yield | Ultimate | Cracking | Yield | Ultimate | |

| BC | 28.20 | 87.00 | 111.80 | 1.60 | 7.45 | 31.63 |

| BS | 39.60 | 109.8 | 192.80 | 1.98 | 8.02 | 40.65 |

| Specimen | Ductility Index | Initial Stiffness (N/mm) | Yield Stiffness (N/mm) | |||

|---|---|---|---|---|---|---|

| Value | Ratio | Value | Ratio | Value | Ratio | |

| BC | 5.40 | 1 | 17,625 | 1 | 10,051 | 1 |

| BS | 5.19 | 0.96 | 20,000 | 1.13 | 11,623 | 1.16 |

| Beam ID | Pu (kN) | Ratio Pu,Exp/Pu,Ana | |

|---|---|---|---|

| Experimental | Analytical | ||

| BC | 111.80 | 110.75 | 1.01 |

| BS | 192.80 | 174.80 | 1.10 |

| Model ID | FC-SWR Diameter (mm) | Pu (kN) | % Pu Increase Over Control Beam | δu (mm) |

|---|---|---|---|---|

| B-01 | - | 110.41 | - | 19.35 |

| B-02 | 6 | 137.84 | 25 | 35.04 |

| B-03 | 8 | 153.24 | 39 | 35.42 |

| B-04 | 10 | 165.83 | 50 | 31.60 |

| Model ID | FC-SWR Modulus of Elasticity (MPa) | Pu (kN) | δu (mm) | % Δu Decrease Over Control Beam |

|---|---|---|---|---|

| B-05 | - | 111.02 | 20.90 | - |

| B-06 | 100,000 | 159.38 | 18.89 | 10 |

| B-07 | 120,000 | 158.35 | 16.16 | 23 |

| B-08 | 200,000 | 152.84 | 11.05 | 47 |

| Model ID | Steel Reinforcement Ratio (%) | Pu (kN) | % Pu Increase Over Control Beam | δu (mm) |

|---|---|---|---|---|

| B-09 | 1.2 | 114.94 | - | 33.54 |

| B-10 | 2.7 | 220.27 | 25 | 30.07 |

| B-11 | 1.2 | 160.47 | 39 | 25.65 |

| B-12 | 2.7 | 267.77 | 50 | 20.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atmajayanti, A.T.; Haryanto, Y.; Hsiao, F.-P.; Hu, H.-T.; Nugroho, L. Effective Flexural Strengthening of Reinforced Concrete T-Beams Using Bonded Fiber-Core Steel Wire Ropes. Fibers 2025, 13, 53. https://doi.org/10.3390/fib13050053

Atmajayanti AT, Haryanto Y, Hsiao F-P, Hu H-T, Nugroho L. Effective Flexural Strengthening of Reinforced Concrete T-Beams Using Bonded Fiber-Core Steel Wire Ropes. Fibers. 2025; 13(5):53. https://doi.org/10.3390/fib13050053

Chicago/Turabian StyleAtmajayanti, Anggun Tri, Yanuar Haryanto, Fu-Pei Hsiao, Hsuan-Teh Hu, and Laurencius Nugroho. 2025. "Effective Flexural Strengthening of Reinforced Concrete T-Beams Using Bonded Fiber-Core Steel Wire Ropes" Fibers 13, no. 5: 53. https://doi.org/10.3390/fib13050053

APA StyleAtmajayanti, A. T., Haryanto, Y., Hsiao, F.-P., Hu, H.-T., & Nugroho, L. (2025). Effective Flexural Strengthening of Reinforced Concrete T-Beams Using Bonded Fiber-Core Steel Wire Ropes. Fibers, 13(5), 53. https://doi.org/10.3390/fib13050053