Highlights

What are the main findings?

- Bio-based materials significantly improve thermal insulation compared to conventional concrete. Banana fiber, straw, and Typha Australis demonstrated the best thermal performance.

- These materials reduced cooling energy demand by up to 31.71%, with banana-based concrete achieving the highest savings.

- Thermal simulations using COMSOL 6.2 and TRNSYS 16 confirmed their ability to delay and attenuate heat transfer, improving indoor comfort in hot desert climates.

- Concrete showed higher thermal inertia but lower insulation effectiveness, whereas bio-based composites (especially straw and Typha) provided better thermal attenuation.

What are the implications of these findings?

- The results support sustainable construction by encouraging the use of low-carbon, energy-efficient materials in hot climates.

- Incorporating bio-based materials can substantially lower cooling energy demand and CO2 emissions, reducing the building sector’s environmental footprint.

- Many of these materials are locally available, offering opportunities for local sourcing, job creation, and circular economy initiatives.

- Despite remaining challenges (scalability, durability, regulation), the findings call for greater investment in research, standardization, and real-world application of bio-based solutions.

Abstract

This study investigates the thermal and energy performance of various bio-based materials, including Typha Australis, straw, banana fiber, Alfa fiber, peanut shells, and VSS (a blend of wood pulp, cotton, flax, and hemp), in comparison to conventional concrete. A combined approach integrating numerical simulations and experimental analyses was employed to ensure robust and comprehensive insights. COMSOL Multiphysics was utilized for detailed thermal modeling of wall assemblies, while TRNSYS enabled dynamic simulations to evaluate the impact of these materials on overall cooling energy demand. The results demonstrate that bio-based materials offer significantly improved thermal insulation, reducing air conditioning needs by over 30% relative to concrete, with banana fiber exhibiting the highest performance. This study underscores the need for industrial-scale optimization, supportive regulatory frameworks, and real-world implementation to promote broader adoption. Despite their strong potential, challenges remain, particularly regarding cost-effectiveness, durability, and market penetration. Ultimately, this research advocates for a transition toward more sustainable and environmentally conscious construction practices, aligning with efforts to reduce CO2 emissions and enhance building energy efficiency.

1. Introduction

The building sector is responsible for a significant share of global energy consumption and greenhouse gas emissions, accounting for approximately 40% of total energy use and nearly 30% of CO2 emissions worldwide [1]. In the context of climate change and dwindling natural resources, it is essential to rethink construction practices and prioritize materials that are both environmentally sustainable and high-performing.

Bio-based materials have emerged as viable alternatives to conventional construction materials, primarily due to their low environmental impact and excellent thermal and hygrothermal properties [2]. Sourced from renewable resources such as wood, hemp, straw, and other plant-based fibers, these materials help reduce the carbon footprint of the construction industry [3]. In addition to offering thermal performance equal to or even better than that of traditional materials, they also enhance indoor comfort and improve building durability [4]. This study focuses on bio-based materials naturally available in West Africa, particularly in Mauritania, where extreme heat and arid conditions require effective and sustainable insulation strategies.

The thermal performance of insulation materials plays a key role in improving building energy efficiency. Among various bio-based materials, fiber-reinforced composites such as those made with hemp, flax, or coconut have demonstrated high efficiency due to their low thermal conductivity and their ability to regulate moisture [5]. Recent research has shown that incorporating natural fibers into bio-based mortars and concretes can improve both insulation capacity and mechanical strength [6].

Insulation panels made from plant fibers and hemp-clay bricks offer very good thermal performance and contribute to indoor comfort by regulating humidity [7]. These materials also help reduce thermal bridging and improve heat transfer management within walls [8]. Moreover, the integration of phase change materials (PCMs) into bio-based building systems is a promising solution for reducing heating and cooling needs [9].

Other recent innovations include bio-based polymers and nanocellulose aerogels. These materials have extremely low thermal conductivity and are lightweight, making them suitable for passive and energy-efficient buildings [10,11].

To better understand and optimize the performance of these materials, numerical tools such as COMSOL Multiphysics and TRNSYS are increasingly used [12]. These tools make it possible to analyze heat transfer through building envelopes and to predict energy performance in various climatic conditions. For instance, simulations have shown how the thermal conductivity of materials affects heat loss through floor slabs [13]. In addition, CFD studies on airflow in urban areas support better passive heating and ventilation strategies [14]. Recent models also include coupled heat and moisture transfer, providing a more realistic assessment of material performance [15]. Nevertheless, experimental validation remains a challenge, and it is crucial to ensure the accuracy of numerical predictions to encourage broader adoption of bio-based materials.

Despite their many advantages, bio-based materials are still rarely used at large scale. One reason is the lack of quantitative data on their thermal and energy performance. Most studies emphasize the need for advanced modeling and comparison with conventional materials. This raises a key research question: how can bio-based materials be optimized to improve thermal insulation while maintaining structural and economic viability?

Several recent initiatives are addressing these challenges. For example, rapeseed concrete, a bio-concrete made from rapeseed straw, has shown potential for both structural and insulating applications [16]. Similarly, research into natural fibers for thermal and acoustic insulation is opening up new opportunities for multifunctional construction materials [17].

The future of bio-based construction depends on an integrated approach combining experimental testing, numerical modeling, and industrial production. These developments will support a shift towards more sustainable, resilient, and low-carbon construction practices aligned with global energy and climate targets [18].

This study aims to assess the thermal performance of selected bio-based materials using a combined approach that includes both experimental data and numerical simulations. Two modeling tools are used: COMSOL Multiphysics, which simulates transient heat transfer through different wall materials to evaluate thermal inertia and attenuation capacity, and TRNSYS, which analyzes the energy performance of a full-scale building under real climatic conditions by integrating these materials into its envelope. The goal is to identify the most effective materials in terms of thermal insulation and energy savings. Although mechanical strength is not tested directly, it is considered based on literature values to ensure the suitability of these materials for load-bearing and bioclimatic buildings.

The expected outcomes of this research will help develop strategies for optimizing bio-based insulation materials based on thermal conductivity and heat storage capacity. Special attention is given to Typha Australis, straw, and banana fiber, which have shown strong potential for reducing heat transfer and improving indoor comfort. A comparison with conventional concrete is also carried out to quantify the possible energy savings when substituting traditional materials with bio-based alternatives.

This work contributes to the broader objective of promoting the use of local natural resources for ecological and climate-adapted construction. It supports the development of low-energy buildings and helps reduce the environmental impact of the building sector.

2. Materials and Methods

2.1. Materials

The selection of bio-based materials was based on several criteria: local availability, low carbon footprint, thermal and mechanical properties ensuring that they meet the minimum requirements for load-bearing use as defined by RILEM classifications, and compatibility with the extreme climatic conditions of Atar, Mauritania. The selected materials include the following:

- -

- Typha Australis: A fibrous wetland plant widely found in West Africa. Its fibers are primarily composed of cellulose and lignin, and its porous internal structure contributes to low thermal conductivity. These properties make Typha a highly effective natural insulator, traditionally used in vernacular architecture in the region [19].

- -

- Straw: A readily available agricultural byproduct with well-documented thermal performance. Its low cost and accessibility make it a practical insulation material in many rural contexts.

- -

- Banana fiber: Another agricultural residue with strong insulation potential. Its fibrous nature and lightweight structure enhance its thermal performance.

- -

- Alfa: A plant historically used in local construction. It offers a balance of thermal performance and availability, making it suitable for both traditional and modern applications.

- -

- Peanut shells and VSS: VSS refers to a composite mix of wood pulp, cotton, flax, and hemp. Both peanut shells and VSS are used as alternative insulating components that contribute to improving the thermal inertia of building envelopes.

The main thermal and mechanical characteristics of these bio-based composites are summarized in Table 1:

Table 1.

Summary of bio-based materials studied.

2.2. Methodology

2.2.1. Site Selection and Meteorological Data

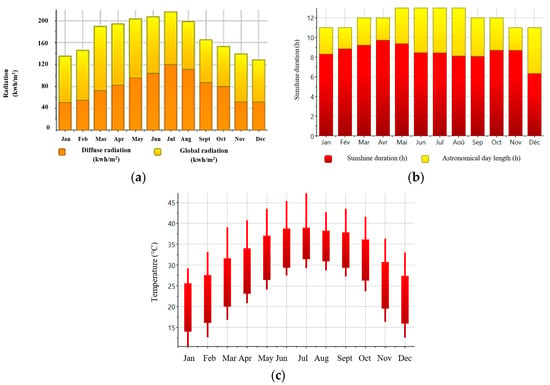

The simulations were carried out for Atar, Mauritania, a location characterized by a hot desert clitamate typical of the Sahara region. This area experiences high temperatures throughout the year, along with pronounced seasonal variations.

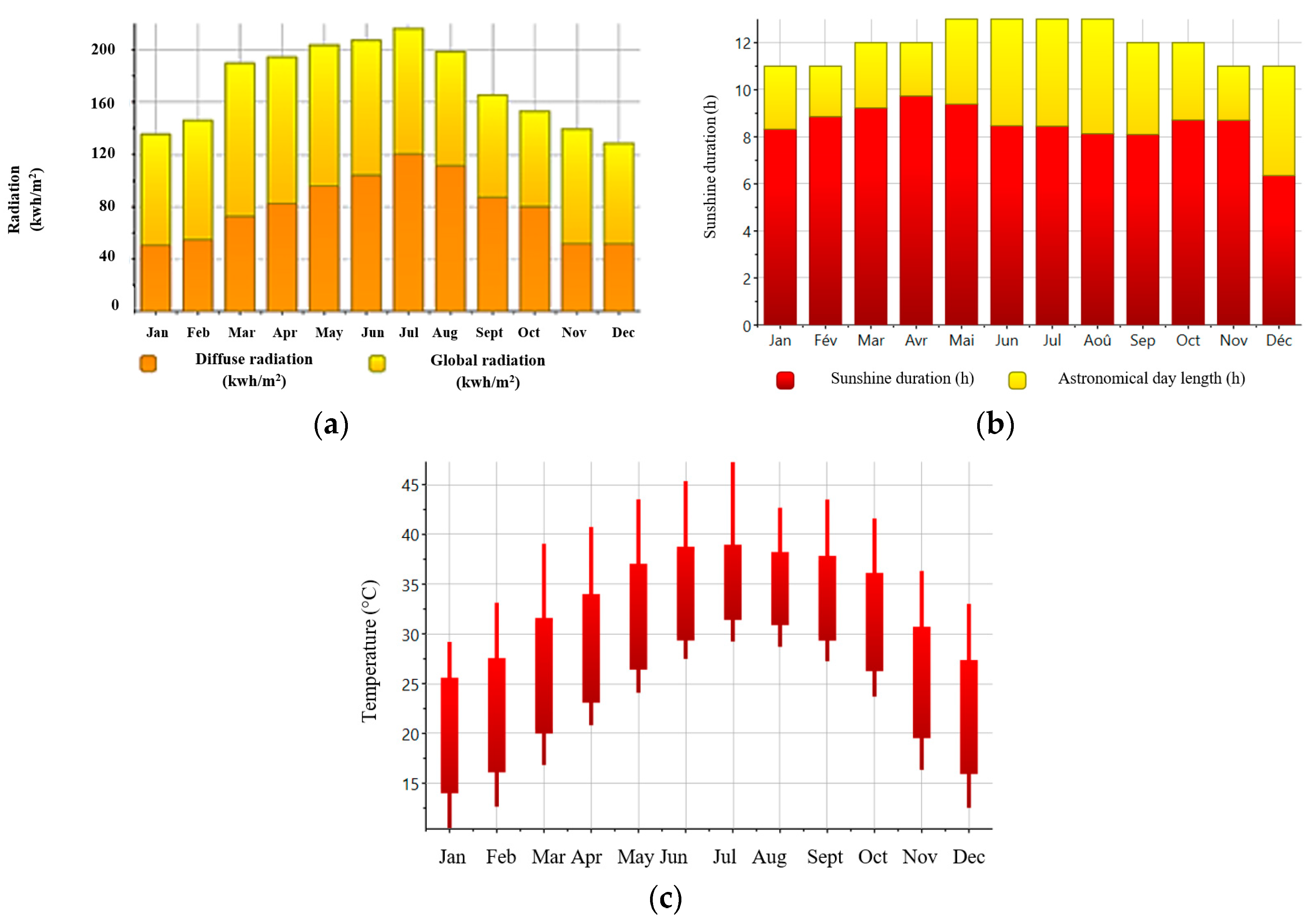

Meteorological data were obtained using the Meteonorm software 8 (Figure 1). Key climate parameters such as annual solar radiation and average daily sunshine duration (approximately 9 h) were considered. Peak diffuse solar radiation reaches up to 120 kWh/m2 in July.

Figure 1.

Climatic conditions in Atar (Mauritania) based on Meteonorm: annual temperature and solar radiation data used as simulation inputs. (a) Solar radiation; (b) Sunshine duration; (c) Temperature.

Temperature fluctuations in this region range from around 12 °C during winter nights to as high as 48 °C in summer, highlighting the importance of optimizing thermal comfort and minimizing building energy consumption through effective insulation strategies.

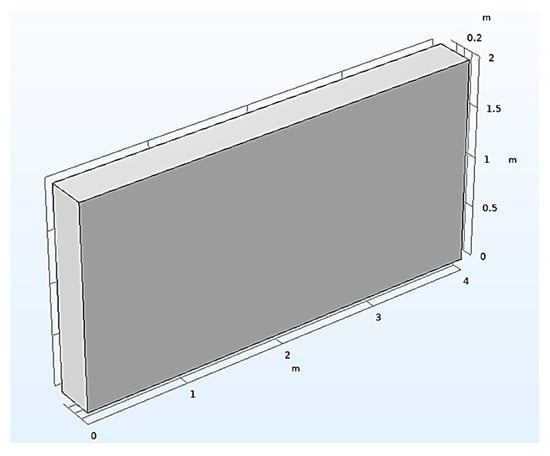

2.2.2. Numerical Simulation with COMSOL Multiphysics

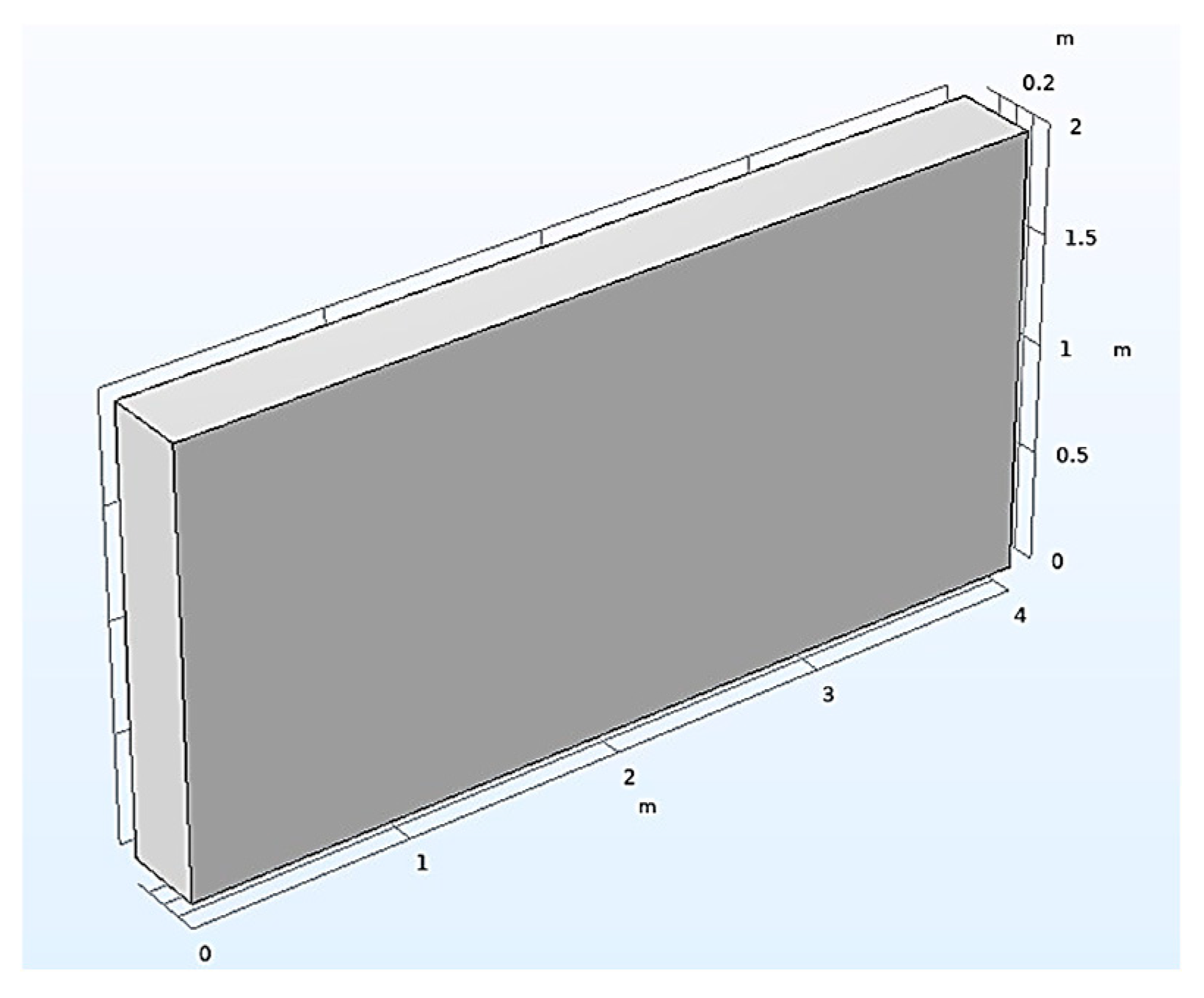

An initial series of simulations was performed using COMSOL Multiphysics to analyze heat transfer through a wall constructed from bio-based materials (Figure 2). The modeled wall had dimensions of 4 m in length, 2.5 m in height, and 0.38 m in thickness. The thermophysical properties of each material were integrated into the model based on experimental and literature data.

Figure 2.

Studied wall.

To replicate realistic thermal loading, a sinusoidal temperature variation was applied to the wall’s exterior surface, following the equation:

T(t) = 305 + 17 × sin (2 × pi × F × t − π/2)

In this expression, T(t) represents the temperature at a given time t over a 24 h cycle, with the maximum temperature occurring at midday (12 h). This idealized thermal profile allows for a consistent and controlled comparison of the thermal behavior of different materials under identical conditions.

Although this simplified sinusoidal model does not account for the full complexity of real climatic fluctuations, it provides a useful baseline for evaluating the thermal inertia and attenuation capacity of each material. To reflect actual weather variability, real meteorological data were incorporated into the TRNSYS simulations described later.

2.2.3. Dynamic Simulation with TRNSYS

To evaluate the influence of bio-based materials on the overall energy performance of a building, a dynamic thermal simulation was carried out using the TRNSYS software 16. This simulation tool accounts for transient heat transfer phenomena and enables the prediction of a building’s thermal behavior under real climatic conditions.

The TRNSYS model was developed according to the following structure:

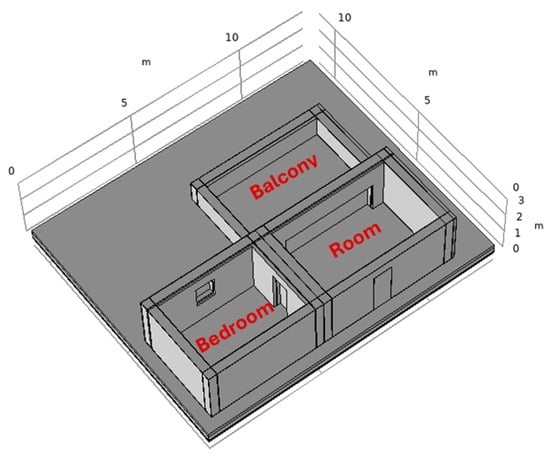

- -

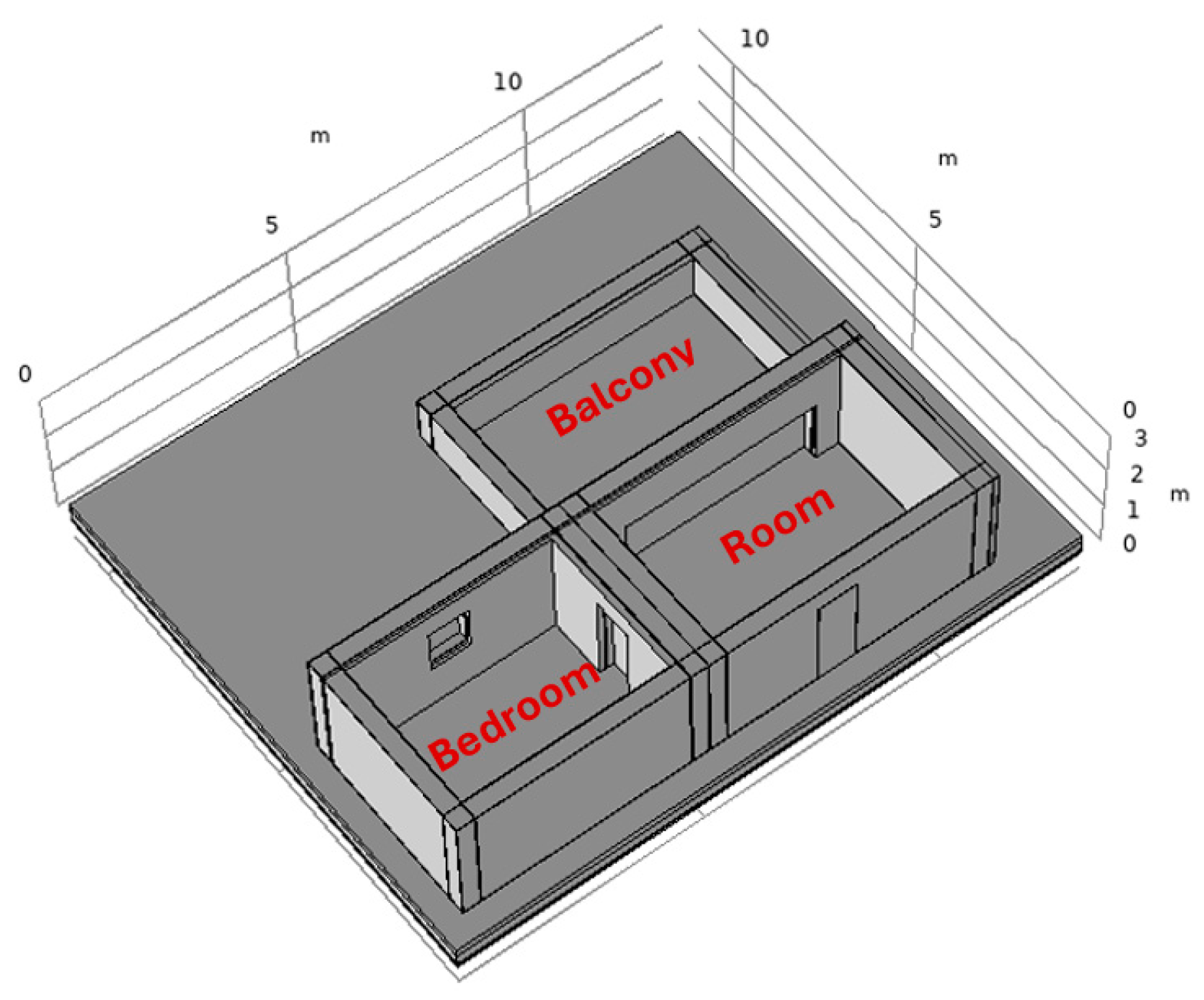

- Building definition: The simulated building is a simplified residential unit composed of a bedroom (including two computers to simulate internal heat gains), a living room with an open kitchen, and a balcony. Secondary spaces such as the kitchen and bathroom were excluded from the model due to their limited influence on the building’s overall thermal dynamics (Figure 3).

Figure 3. Three-dimensional building.

Figure 3. Three-dimensional building.

- -

- Opening configurations and usage scenarios: Natural ventilation was implemented through openings that ensured an air renewal rate of 1 volume per hour. The indoor temperature setpoint was maintained at 22 °C in all occupied spaces, as indicated in the usage schedule (Table 2).

Table 2. Usage Scenario.

Table 2. Usage Scenario.

The characteristics of all openings, including windows, French windows, and doors, were clearly defined in terms of material, surface area, and thermal transmittance (U-value), as shown in Table 3.

Table 3.

Characteristics of windows, French windows and doors.

- -

- Wall composition: A reference building initially composed of conventional materials such as concrete, plaster, and mortar was used for the baseline simulation. In subsequent simulations, the concrete in the walls and roof was replaced with various bio-based composites to evaluate their thermal performance.

Table 4 presents the thermophysical properties of the selected materials used in the COMSOL simulations. These properties include thermal conductivity, specific heat capacity, and density.

Table 4.

Wall composition.

The thermophysical properties of materials play a critical role in dynamic thermal simulations. These parameters are essential for accurately predicting the thermal behavior and energy performance of the building. Table 5 summarizes the thermophysical properties of all materials used in this study.

Table 5.

Thermophysical properties of the elements.

This combined approach using COMSOL and TRNSYS enables a comprehensive analysis of the thermal performance of bio-based materials. It addresses both the heat transfer through insulating walls and the overall energy efficiency of the building.

3. Results and Discussion

3.1. Heat Transfer Analysis Using COMSOL

3.1.1. Comparative Evaluation of Thermal Response of Materials

The thermal efficiency of construction materials plays a key role in energy management and indoor comfort. Several studies, including those by Al-Homoud [25] and Zhou et al. [26], have shown that bio-based materials offer superior thermal performance compared to conventional materials such as concrete. More recent research, including work by Rotini et al. [27], Panyakaew et al. [28], Sbirrazzuoli et al. [29], and Huang et al. [30], further confirms the advantages of plant fibers and bio-based composites in enhancing thermal insulation and reducing environmental impact.

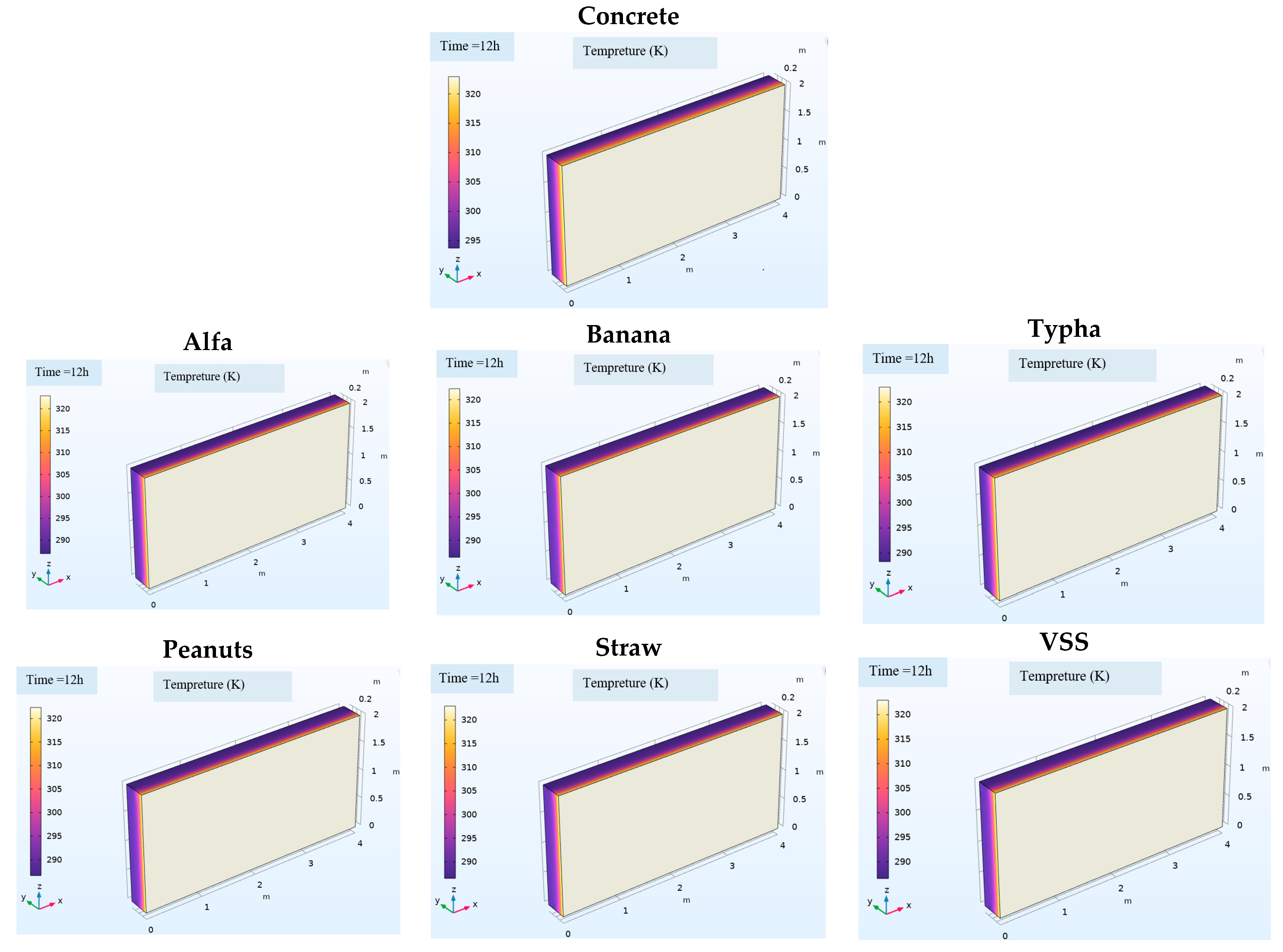

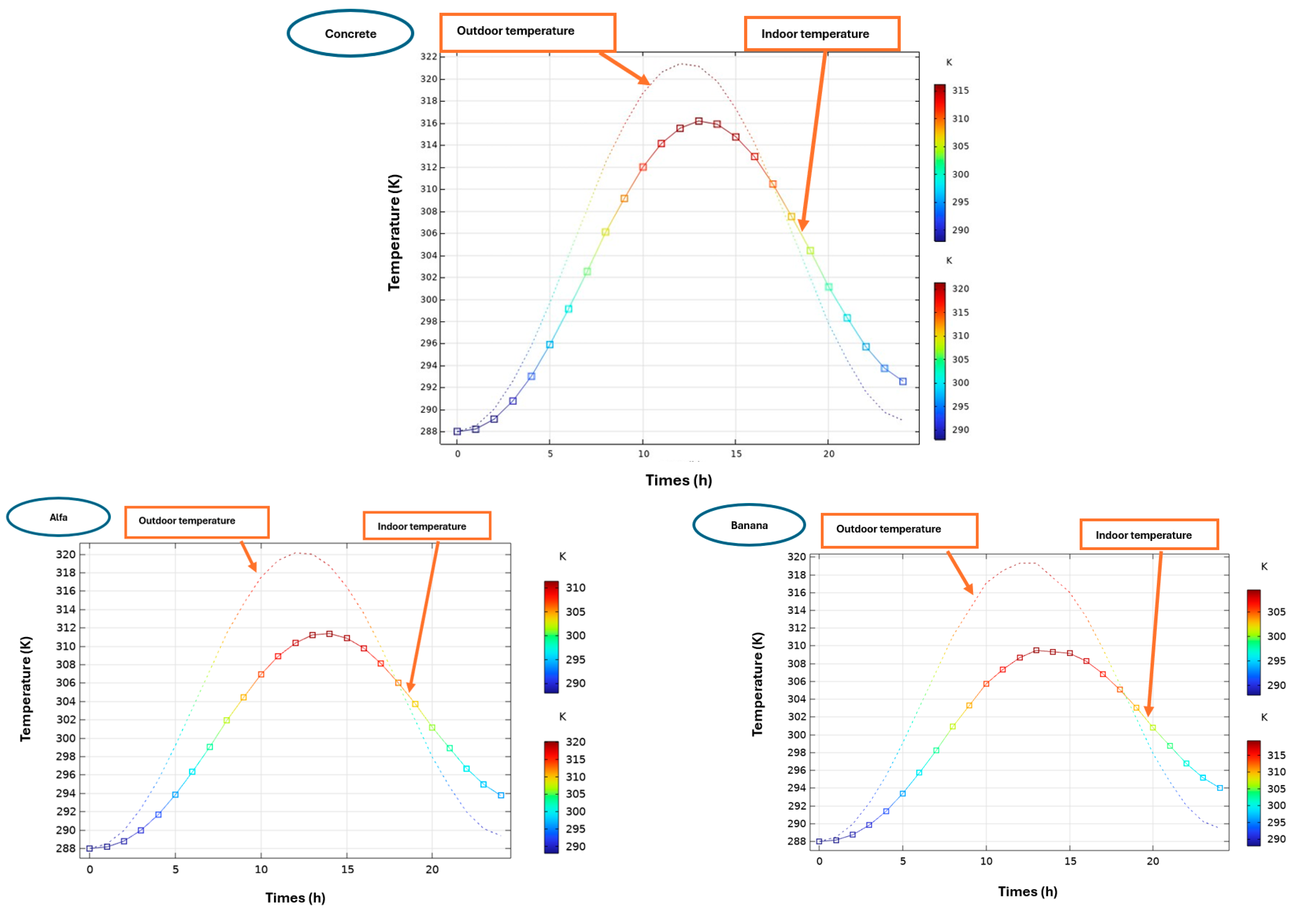

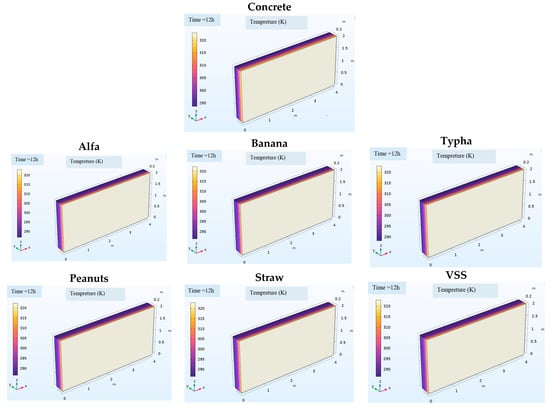

This discussion focuses on three main aspects of material behavior: the speed of thermal stabilization, insulation capacity, and heat storage. Figure 4 presents the results of heat transfer simulations conducted at 12:00 p.m. for each material.

Figure 4.

Heat transfer in a wall at 12:00 p.m.

Although the temperature curves appear similar, differences in peak timing and amplitude clearly reveal the influence of each material’s thermal inertia.

- Thermal Stabilization and Thermal Inertia

Concrete exhibits high thermal inertia, which means it can absorb and store a considerable amount of heat before releasing it gradually. According to Al-Homoud [25], this property is particularly beneficial in climates with large temperature fluctuations, as it helps to moderate thermal variations over time. However, when compared to bio-based materials such as Typha Australis or straw, concrete tends to transfer heat more rapidly into the interior of a building.

In contrast, bio-based materials like Alfa, banana fiber, and peanut shells display stronger thermal attenuation. This effect is illustrated in Figure 4, where the internal surface temperatures of walls made from these materials are lower and more stable than those observed with concrete. This indicates better thermal damping capacity. These results are consistent with the findings of Zhou et al. [26], who demonstrated that natural fibers reduce heat transfer due to their porous structure. More recent studies [31,32,33] have also emphasized the ability of certain agro-based materials to regulate both heat and moisture, contributing to improved indoor thermal comfort.

- b.

- Thermal Insulation Capacity and Heat Storage

The thermal insulation capacity of a material defines its ability to resist heat transfer, whereas heat storage refers to the material’s capacity to absorb and retain heat before releasing it gradually.

Among the materials studied, VSS, straw, and Typha Australis demonstrated the most effective thermal attenuation. As shown in Table 6, these materials exhibit the lowest internal temperature amplitude and the longest time lag, confirming their superior ability to delay and smooth heat flow through the wall. These results are in line with the findings of Asdrubali et al. [34], who showed that low-density materials with a cellular structure are particularly efficient in limiting heat transfer.

Table 6.

Thermal storage capacity of materials.

In contrast, concrete offers higher heat storage capacity but performs less effectively in terms of insulation. This observation is consistent with the work of Elfordy et al. [35], who highlighted the high thermal conductivity of mineral-based materials.

It is also worth noting that most bio-based materials have relatively low thermal inertia. As a result, they do not retain heat significantly, which makes them more suitable for applications where a strong thermal barrier is needed without heat accumulation [36,37,38]. These results are supported by studies on natural insulation materials, which highlight their ability to reduce energy demand for both heating and cooling [37].

Although hourly temperature curves are not shown for every time step in this manuscript, the analysis presented in Table 6 is based on the full dataset generated by COMSOL simulations.

The thermal amplitude and time lag values are derived from COMSOL simulation results. The qualitative descriptors used (low, medium, high) represent a comparative interpretation of these parameters across all tested materials.

Based on these findings, several recommendations can be proposed depending on the intended application:

- -

- For optimal thermal insulation, the most effective materials are VSS, straw, and Typha Australis.

- -

- For a balance between heat storage and insulation, Alfa, banana fiber, and peanut shells offer suitable performance.

- -

- For applications requiring high thermal inertia, concrete remains the preferred choice.

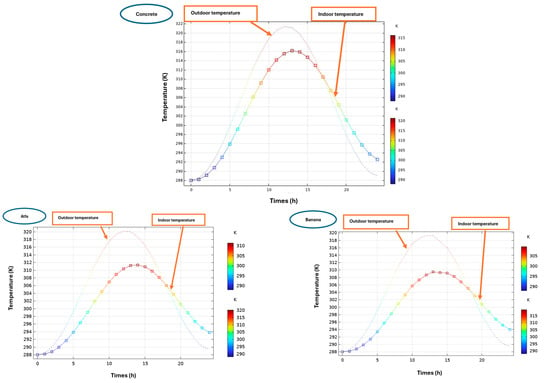

3.1.2. Temporal Evolution of Wall Temperatures

As illustrated in Figure 5, the temperature difference between the inner and outer surfaces of the wall indicates that each material responds differently to oscillating thermal conditions. Conventional materials like concrete exhibit high thermal inertia, which allows them to store heat and release it gradually over time [25]. In contrast, bio-based materials such as straw, Typha Australis, and VSS show a greater capacity for thermal attenuation, confirming their effectiveness as insulating materials [26].

Figure 5.

Temperature evolution in the wall.

In the figures, continuous lines represent the input temperatures, while dashed lines correspond to the output (internal surface) temperatures. As observed in Figure 4, materials like straw and banana fiber result in slightly lower peak internal surface temperatures compared to concrete. Although the differences are modest, they highlight the superior thermal damping behavior of bio-based materials, which helps delay and reduce indoor temperature peaks under dynamic thermal loads.

The results indicate that concrete transfers heat more gradually due to its high thermal inertia, whereas bio-based materials significantly reduce heat transmission. Among the materials tested, Typha Australis and straw exhibit the strongest thermal attenuation, with VSS also showing excellent performance. These observations are consistent with the findings of Panyakaew and Fotios [28], as well as with more recent studies that have explored the use of other natural fibers, such as coconut, bagasse, and hemp, to improve thermal performance [29,30].

- a.

- Heat Storage Capacity and Applications

- -

- High thermal inertia materials (such as concrete and Alfa) are suitable for climates where gradual heat regulation is needed. Their ability to absorb and slowly release heat helps stabilize indoor temperatures over time.

- -

- Low thermal inertia materials (including banana fiber, peanut shells, straw, Typha Australis, and VSS) respond more rapidly to temperature fluctuations. This quick response is advantageous in hot climates, as it helps to limit indoor temperature increases by reducing the transmission of external heat [33,34,35,36,37,38].

- b.

- Implications and Material Selection

Based on these results, several recommendations can be made:

- -

- For optimal thermal insulation, Typha Australis, straw, and VSS are the most effective materials, as they efficiently block heat transfer and minimize thermal conduction.

- -

- For a balance between heat storage and insulation, Alfa, banana fiber, and peanut shells represent intermediate solutions.

- -

- For applications requiring high thermal inertia, concrete remains more suitable, particularly in massive buildings where thermal stabilization is essential.

The analysis of temperature profiles confirms that bio-based materials significantly outperform concrete in terms of thermal insulation. Typha Australis and straw, in particular, stand out as promising alternatives for bioclimatic building design, helping to reduce reliance on air conditioning and heating systems. Further studies that incorporate real-world simulation conditions would be beneficial to refine these findings and evaluate their long-term performance [32,33].

This study highlights the potential of bio-based materials as sustainable alternatives to conventional insulation products. The results are consistent with existing literature and support the growing interest in natural materials for energy-efficient building applications. Additional research, especially focused on hygrothermal behavior and in situ testing, would provide deeper insights into the full impact of these materials on thermal comfort and structural durability.

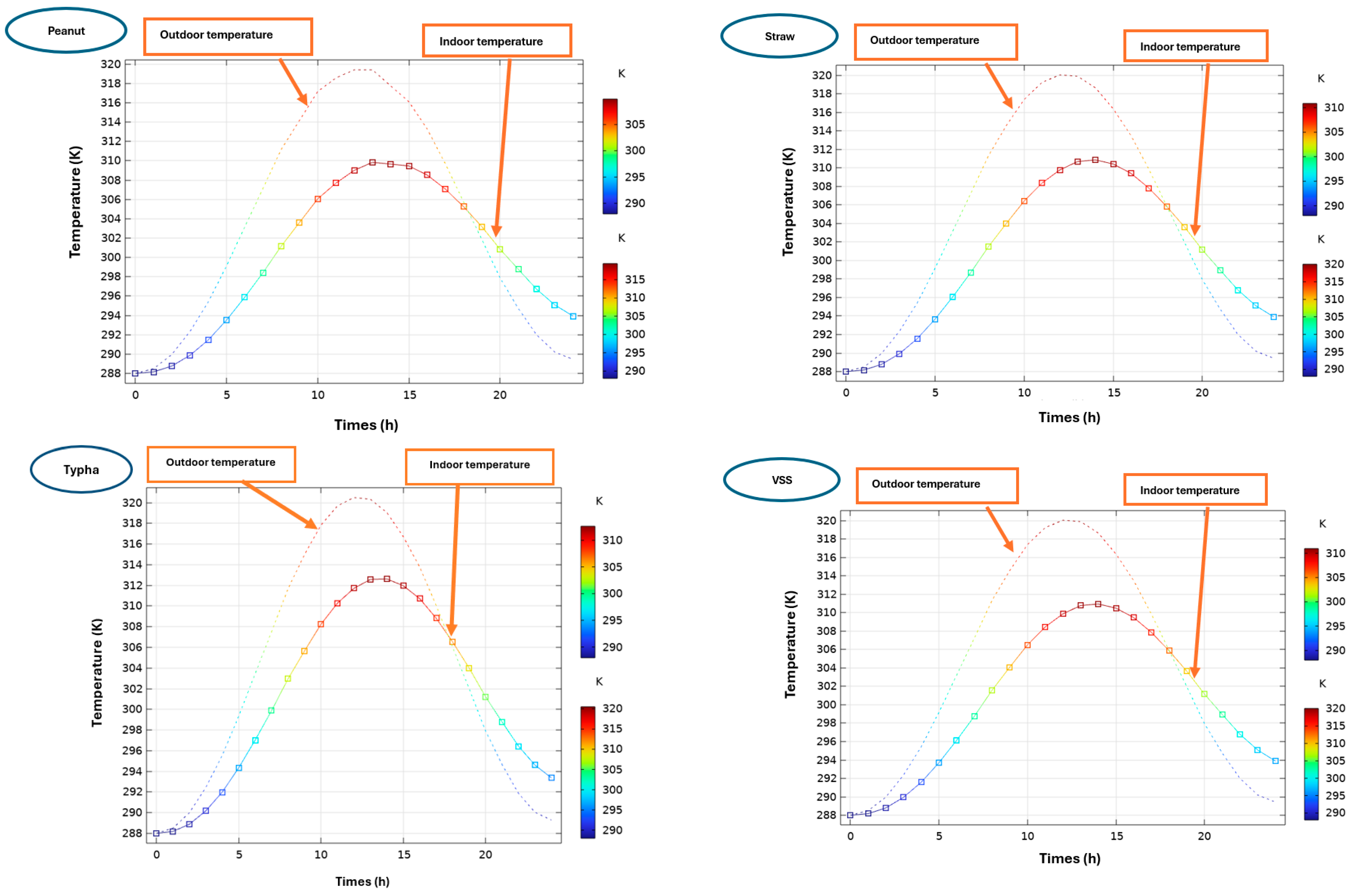

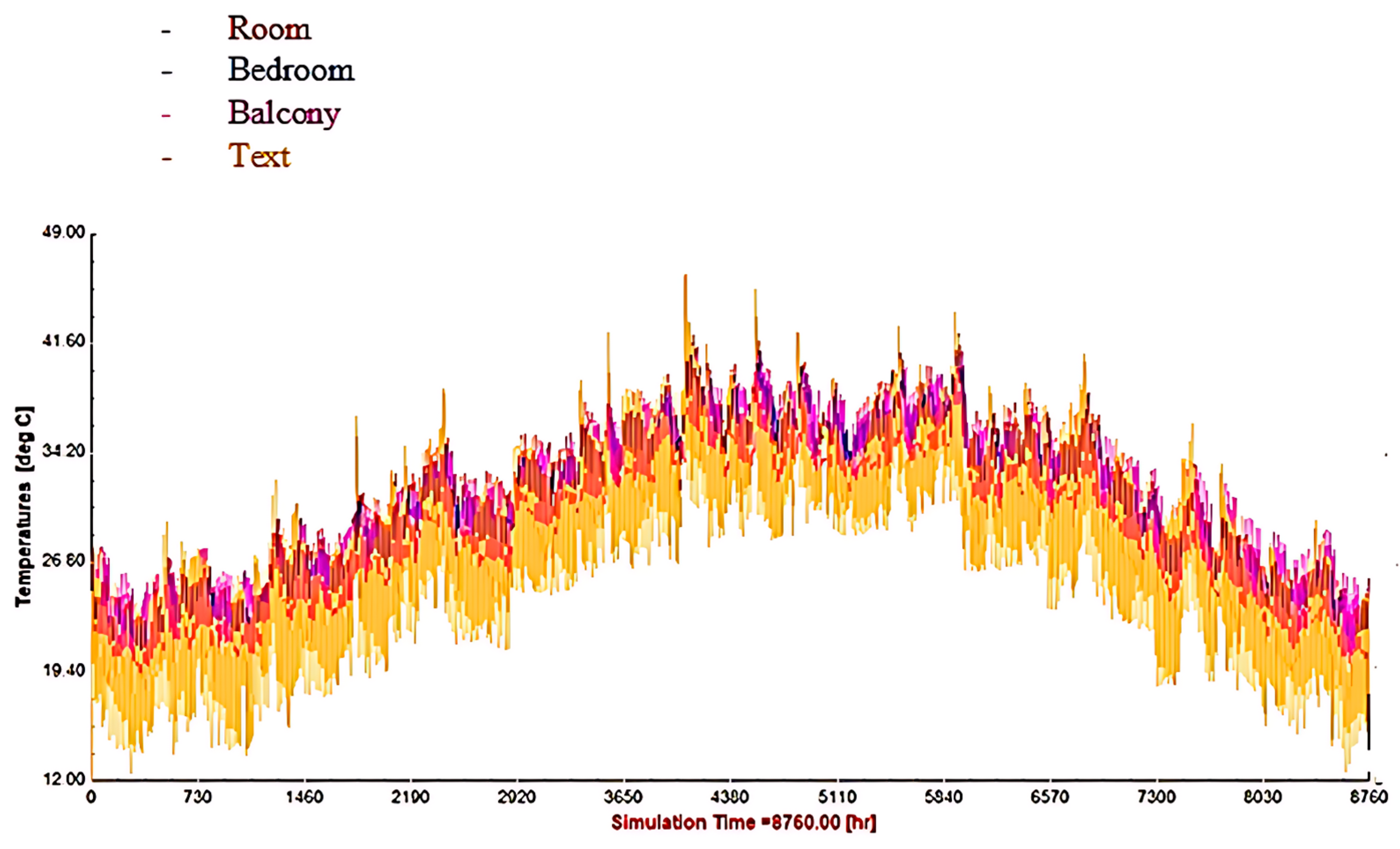

3.2. Energy Performance Analysis

This section presents the results of the energy performance analysis of buildings constructed with different materials, with a particular focus on the impact of using bio-based materials as substitutes for conventional concrete. Several recent studies have demonstrated the effectiveness of bio-based materials in reducing building energy consumption [39,40]. These materials typically have low thermal conductivity and reduced thermal inertia, which contributes to improved overall thermal efficiency in buildings [41,42].

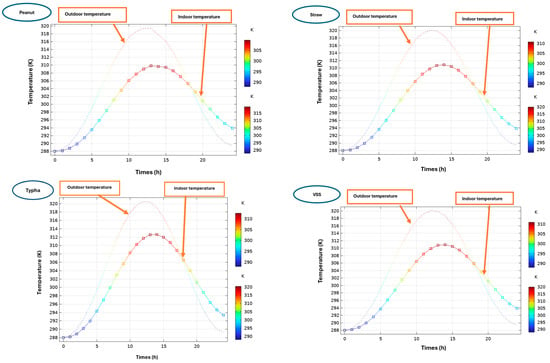

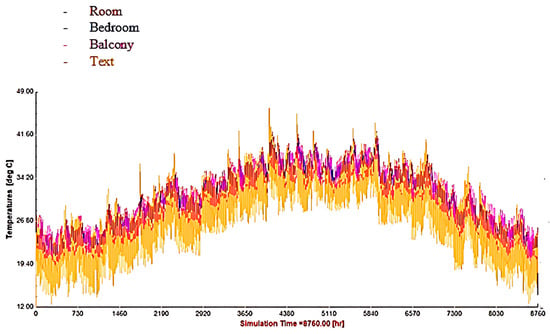

3.2.1. Variation in Outdoor and Indoor Temperatures

Ambient temperature fluctuations remain consistent across all simulations, providing a useful reference for analyzing indoor temperature variations. These two variables are closely related: an increase in outdoor temperature generally leads to a corresponding rise in indoor temperature, although the extent of this effect depends on the thermal properties of the construction materials.

This relationship has been explored by Rode et al. [38] and more recently by Abou-Chakra et al. [43], who emphasized the role of material choice in regulating indoor temperature dynamics. The figure below illustrates the annual variation in both outdoor and indoor temperatures when a temperature setpoint is applied.

In Atar, the outdoor temperature ranges from 12 °C in winter to 48 °C in summer, reflecting the extreme climatic conditions of the study site (see Figure 1). Given the intensity of these temperatures, a mechanical cooling system is required. Accordingly, a setpoint temperature of 22 °C was applied, in line with the occupancy scenarios described in Table 2.

Figure 6 presents the following conditions:

Figure 6.

Temperature variation with and without temperature setpoint.

- -

- When the building is unoccupied or when the outdoor temperature is below 22 °C, the indoor temperature remains stable without activating the cooling system.

- -

- When the temperature exceeds 22 °C and the building is occupied, the indoor temperature is actively maintained at 22 °C.

Recent studies, including those by Ba et al. [19] and Ahmed et al. [44], have shown that bio-based materials such as Typha Australis and other plant fibers are highly effective in regulating both thermal and hygrometric conditions. These materials help mitigate temperature fluctuations and reduce reliance on active cooling and heating systems.

Additional research [29,45,46] confirms that bio-based materials significantly reduce indoor thermal peaks. Their natural fiber composition and cellular microstructure improve thermal attenuation, often outperforming conventional materials in hot climates.

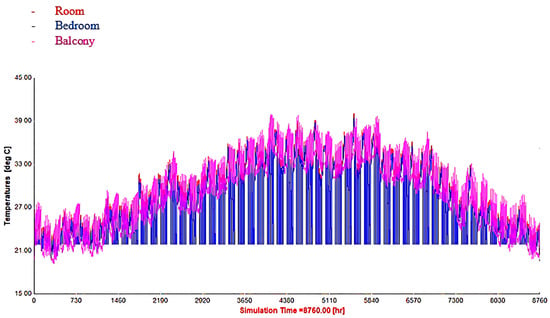

3.2.2. Energy Performance in Buildings

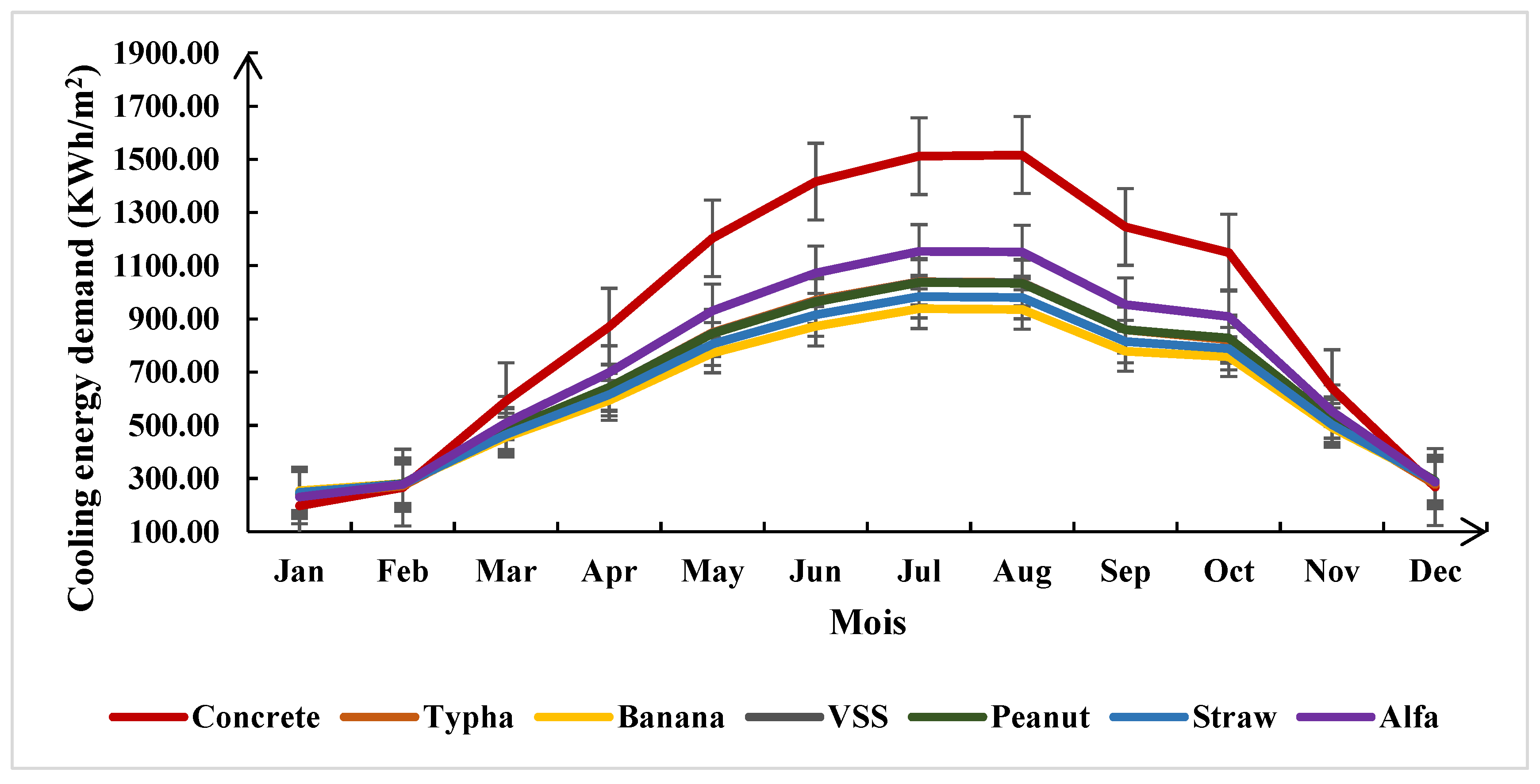

- Variation in energy demand according to wall type

Figure 7 shows the impact of using bio-based materials as substitutes for conventional concrete on the building’s cooling energy demand. It can be observed that buildings constructed with conventional concrete display the highest energy consumption, indicating that more energy is required to maintain a comfortable indoor temperature. This is due to the low thermal insulation capacity of concrete, which allows substantial heat transfer into the interior and increases the cooling load [25].

Figure 7.

Variation in energy demand.

In comparison, the curves representing buildings made with bio-based concrete, such as Typha, banana fiber, straw, Alfa, PSFA, and VSS, show a clear reduction in cooling demand. The energy consumption follows a seasonal pattern, with a noticeable peak during the summer months (June, July, and August) and lower values in winter (December and January).

The energy consumption results are based on simulations of a realistic residential building, using climate data from Atar obtained through Meteonorm. These findings are consistent with those of Ba et al. [19], who showed that natural fiber insulation panels significantly reduce energy demand. Other recent studies, such as those by Łapka et al. [40] and Bourbia et al. [41], also confirm that bio-based materials enhance thermal comfort and reduce reliance on active heating and cooling systems.

Among the bio-based materials analyzed, Typha-based concrete demonstrates strong performance in reducing energy consumption, although its values remain slightly higher than those of other bio-based options [11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46]. Materials such as banana fiber, PSFA (peanut shells), VSS, and straw exhibit similar and notably lower energy consumption levels compared to conventional concrete. Cooling requirements are highest during the summer months (June to August), reaching a peak, and gradually decrease in winter, reflecting the seasonal variation of outdoor temperatures [29].

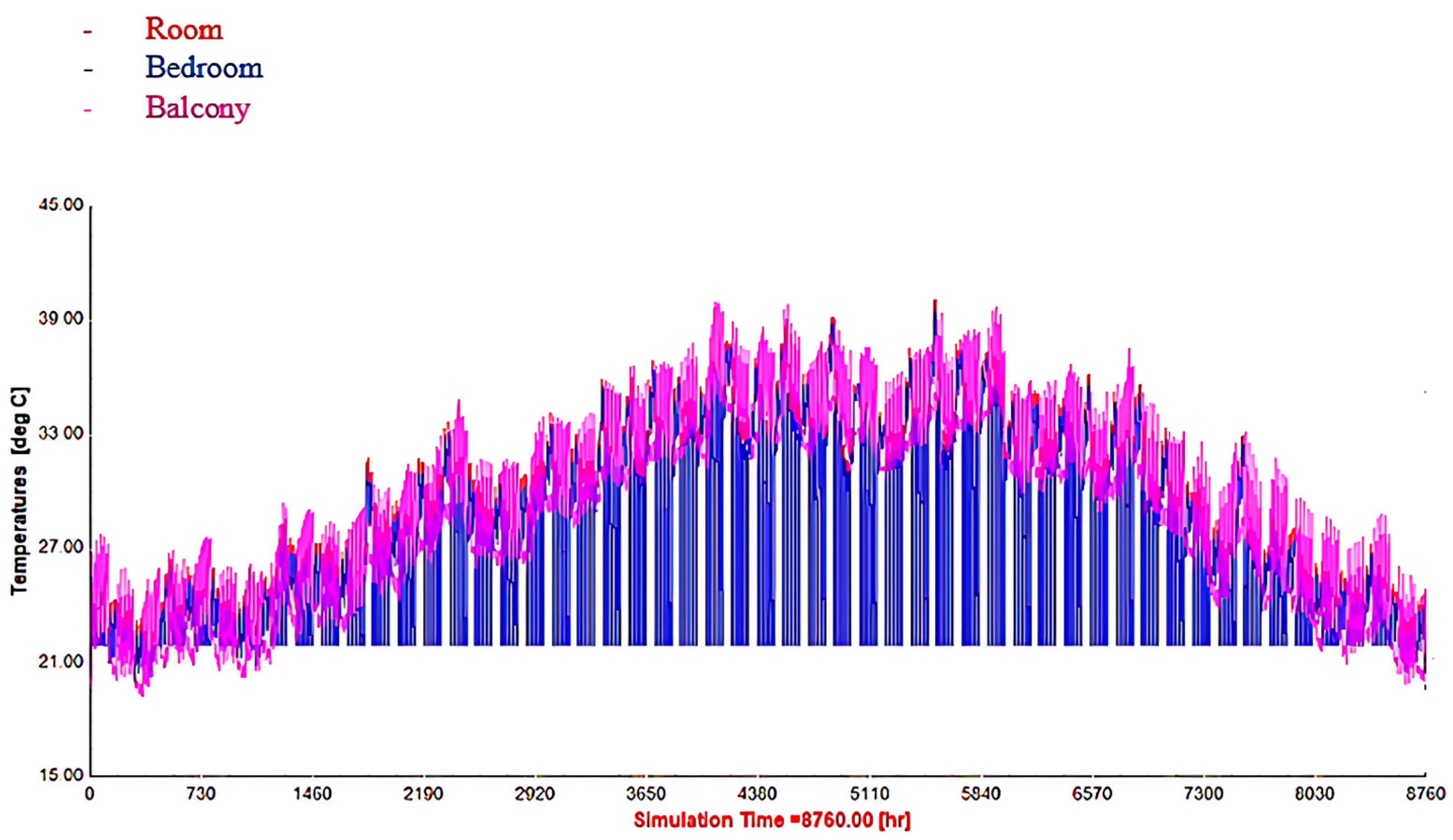

- b.

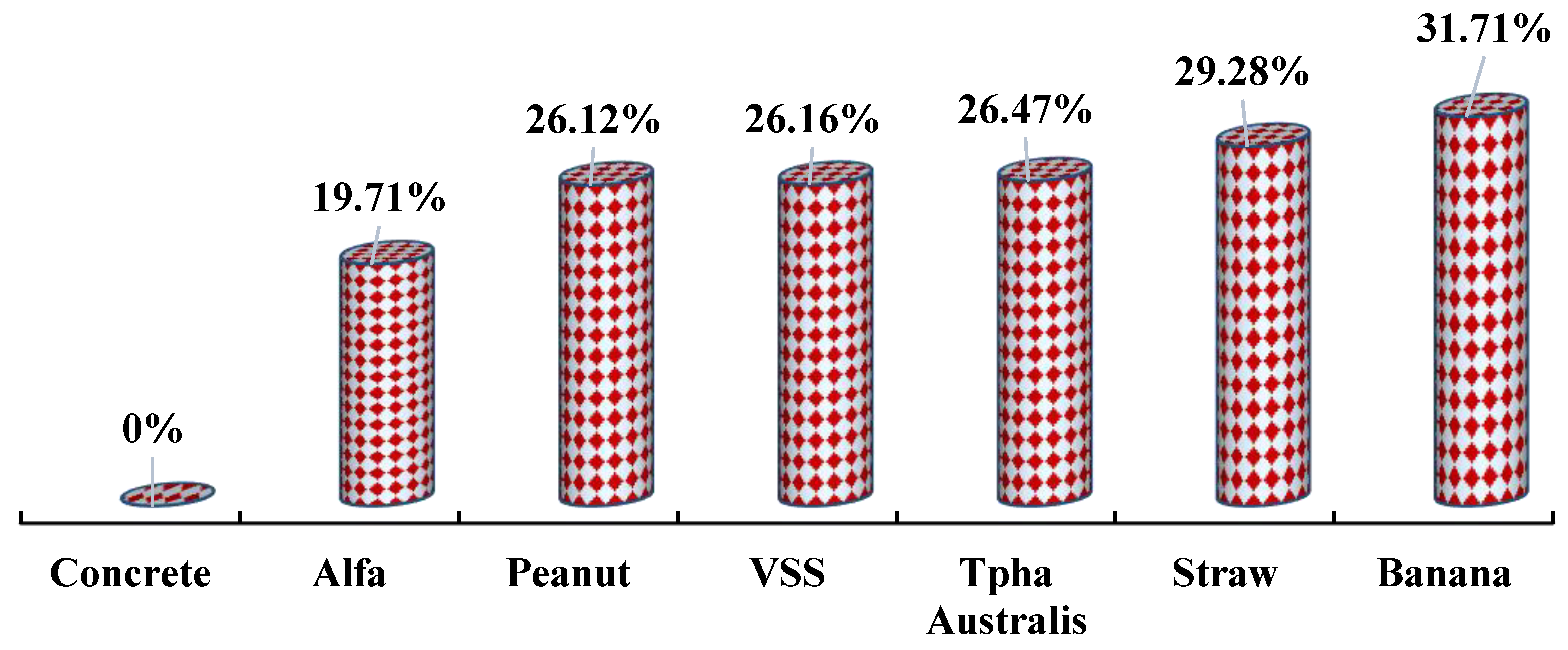

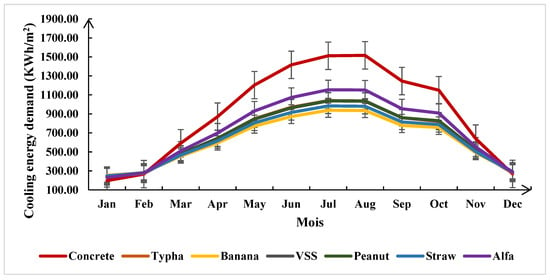

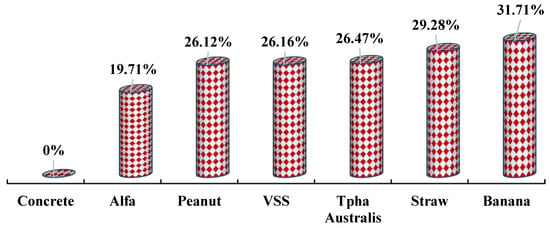

- Energy demand reduction rate

Figure 8 shows the energy demand reduction rate in cooling for different types of bio-based concretes, compared to conventional concrete, which serves as the reference (with a reduction rate of 0%). This graph emphasizes the positive impact of bio-based materials on improving building energy efficiency.

Figure 8.

Energy demand reduction rate.

Among the materials tested, banana concrete demonstrates the best performance, with a 31.71% reduction in cooling demand compared to conventional concrete. This supports the findings of Jahangir et al. [45] and Abou-Chakra et al. [43]. The observed performance can be explained by the following thermal properties of the materials:

- -

- Low thermal conductivity (W/mK): As shown in several studies [20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44], materials with low thermal conductivity, such as banana (0.25 W/mK), straw (0.3 W/mK), and Typha (0.39 W/mK), effectively reduce heat transfer from the exterior, thus minimizing the thermal load of the building.

- -

- High thermal capacity (J/kgK): A material’s thermal capacity plays a key role in regulating indoor temperature fluctuations. For example, banana fiber (1204.81 J/kgK) is particularly effective at reducing peak cooling consumption [42,43,44].

- -

- Density and thermal inertia: Lighter materials, such as straw and banana, trap air more effectively and form a stronger thermal barrier [45,46,47].

This figure further confirms that incorporating bio-based materials into building construction significantly reduces cooling energy demand. Banana and straw concretes show the best performance, while Alfa, though beneficial, proves to be the least efficient among the bio-based materials tested. These results provide strong support for the use of bio-based materials in the development of energy-efficient and environmentally friendly buildings [41].

These results are based on building-scale dynamic simulations using TRNSYS. The cooling energy demand for concrete walls served as a reference. Compared to this baseline, the use of banana, straw, and Typha-based composites reduced the cooling energy demand by 31.71%, 29.28%, and 26.47%, respectively. These results confirm the superior thermal performance of bio-based materials in hot climates.

- c.

- Recommendations

- -

- Industrial optimization: Promote large-scale production of bio-based materials to reduce manufacturing costs and facilitate broader adoption.

- -

- Regulatory framework: Establish relevant standards to ensure the durability, safety, and performance of these materials in construction.

- -

- Real-world testing: Conduct performance testing of bio-based materials in various climatic conditions and architectural contexts to validate their effectiveness and long-term viability.

4. Conclusions

This study on the thermal performance of bio-based materials underscores their significant potential as sustainable alternatives to conventional building insulation materials. By combining numerical simulations with experimental validation, we have shown that these materials offer enhanced energy efficiency, improved thermal regulation, and a reduced environmental impact.

The results confirm that the biocomposites studied, especially those based on Typha, straw, and banana fibers, exhibit outstanding thermal performance. Typha and straw have maximum temperatures of 305 K (32 °C) and 306 K (33 °C), respectively, compared to 322 K (49 °C) for conventional concrete, demonstrating superior thermal mitigation. Additionally, these materials contribute to a marked reduction in building energy consumption. Specifically, banana-based bio-concrete reduced cooling demand by 31.71%, while straw and Typha reduced it by 29.28% and 26.47%, respectively, compared to traditional concrete.

Integrating these materials into the construction sector would significantly decrease heating and cooling demands, leading to a substantial reduction in both energy consumption and CO2 emissions. However, challenges remain concerning their industrialization and large-scale adoption. Variability in bio-based material properties, their durability, and production costs require further research to optimize their implementation. Additional studies on hygrothermal behavior, mechanical resistance, and compatibility with other building components are essential to improve their competitiveness in the market.

Looking ahead, advancing manufacturing processes and incorporating innovative materials such as bio-based polymers and nanocellulose aerogels will open new possibilities for maximizing efficiency. Furthermore, improved regulation and increased awareness among industry stakeholders will promote wider adoption of bio-based solutions, accelerating the shift toward more sustainable construction practices.

The rise of bio-based materials presents a significant opportunity for developing resilient, comfortable, and eco-responsible infrastructure. In the face of climate challenges, integrating these materials into construction represents a crucial step toward buildings with low energy footprints, contributing to more than a 30% reduction in energy demand in hot climates, in line with sustainable development goals.

Although this study focused on thermal performance under ideal conditions, future research should investigate the long-term behavior of bio-based materials, including their hygroscopic properties, biodegradability, and resistance to aging. These factors can significantly impact their durability and thermal efficiency in real-world environments.

Author Contributions

Conceptualization, L.B. and A.T.; methodology, L.B., A.T., T.T.N. and P.P.; software, L.B., A.T., T.T.N. and P.P.; validation, L.B., I.E.A., C.S.E.K., A.T., T.T.N. and P.P.; formal analysis, L.B., I.E.A., C.S.E.K., A.T., T.T.N. and P.P.; data curation, L.B., A.T., T.T.N., P.P., I.E.A. and C.S.E.K.; writing—original draft preparation, L.B.; writing—review and editing, L.B., A.T., T.T.N., P.P., I.E.A. and C.S.E.K.; visualization, L.B., A.T., T.T.N., P.P., I.E.A. and C.S.E.K.; supervision, A.T., T.T.N., P.P., I.E.A. and C.S.E.K.; project administration, A.T., T.T.N., P.P., I.E.A. and C.S.E.K. All authors have read and agreed to the published version of the manuscript.

Funding

There is no funding for this work.

Data Availability Statement

All data generated or analyzed during this study are included in the article. Additional information is available from the corresponding author upon reasonable request.

Conflicts of Interest

Authors declare no conflict of interest.

References

- Chipade, A.M.; Vispute, P.P.; Sonawane, S.K.; Sasane, N.B.; Jadhav, M.; Nerlekar, T. Construction Materials for Sustainable Environment in Residential Buildings. J. Mines Met. Fuels 2025, 73, 45–58. [Google Scholar] [CrossRef]

- Dipasquale, L.; Giuffrida, G.; Jorquera Silva, N.; Pulselli, R.M.; Caponetto, R. Sustainable Design of a Tiny House: Using a Life Cycle Assessment Approach to Compare the Environmental Performance of Industrial and Earth-Based Building Systems. Buildings 2025, 15, 491. [Google Scholar] [CrossRef]

- Figueiredo, A.; Vela, G.; Ascensão, G.; Vettorazzi, E.; Vicente, R.; Oliveira, M. Development of an innovative biocomposite using coconut fibres and bio-based binder for thermal and acoustic aplications in buildings. J. Clean. Prod. 2025, 491, 144834. [Google Scholar] [CrossRef]

- Borodinecs, A.; Jacnevs, V.; Ákos, L.; Gendelis, S. Hygrothermal Performance of Well-Insulated Wood-Frame Walls in Baltic Climatic Conditions. Case Stud. Therm. Eng. 2025, 42, 103402. [Google Scholar] [CrossRef]

- Bernat-Masó, E.; Martínez, B.; Mendizábal, V.; Gil, L. Thermal Performance and Durability of Hemp Shiv and Recycled Cardboard Fibers. In Advances in Bio-Based Materials for Construction and Energy Efficiency; Elsevier: Amsterdam, The Netherlands, 2025; Volume 18, p. 2345. [Google Scholar]

- Dlimi, M.; Bouazaoui, K.; Kadiri, I.; Agounoun, R. Thermal Performance and Cost Efficiency of Hemp Filled Bricks. In Advances in Bio-Based Materials for Construction and Energy Efficiency; Elsevier: Amsterdam, The Netherlands, 2025; Volume 44, pp. 323–341. [Google Scholar]

- Es-sakali, N.; Charai, M.; Laasri, I.A.; Kaitouni, S.I.; Mghazli, M.O.; Cherkaoui, M. Thermal Performance of Hemp Clay Walls. In Advances in Bio-Based Materials for Construction and Energy Efficiency; Elsevier: Amsterdam, The Netherlands, 2025; Volume 44, pp. 89–106. [Google Scholar]

- Bevilacqua, P.; Bruno, R.; Arcuri, N. Performance of Dry-Assembled Wooden Walls with Bio-PCM. In Advances in Bio-Based Materials for Construction and Energy Efficiency; Elsevier: Amsterdam, The Netherlands, 2025; Volume 44, pp. 67–85. [Google Scholar]

- Alvarez-Rodriguez, M.; Lopez-Arias, M.; Velay-Lizancos, M.; Alonso-Martinez, M. Impact of the Phase Change Material (PCM) Integration on the Mortar’s Thermal Inertia: The Role of the Aggregates and PCM Types. Constr. Build. Mater. 2025, 470, 140642. [Google Scholar] [CrossRef]

- Liu, C. Thermal Insulating Lightweight Aerogels Based on Nanocellulose. In Advances in Bio-Based Materials for Construction and Energy Efficiency; Elsevier: Amsterdam, The Netherlands, 2025; Volume 44, pp. 157–176. [Google Scholar]

- Li, A.; Yang, Y.; Ren, Y.; Wu, W. Sustainable Lignocellulose Bio-Based Foam for Thermal Insulation. Ind. Crops Prod. 2024, 201, 117463. [Google Scholar]

- Lubguban, A.A.; Alguno, A.C.; Malaluan, R.M.; Dumancas, G.G. Foundations of Computational Thermo-Kinetics in RPUF. In Thermo-Kinetics of Rigid Polyurethane Foams; Springer: Singapore, 2025; Volume 1, pp. 1–24. [Google Scholar] [CrossRef]

- Bouraoui, W.; Laredj, N.; Maliki, M.; Missoum, H. Numerical Simulation of Heat Losses from a Slab-on-Ground Structure Using Comsol-Multiphysics. J. Mater. Eng. Struct. 2021, 8, 143–157. [Google Scholar]

- Andrić, I.; Pina, A.; Ferrão, P.; Fournier, J.; Lacarrière, B.; Le Corre, O. Assessing the Feasibility of Using the Heat Demand-Outdoor Temperature Function for a Long-Term District Heat Demand Forecast. Energy Procedia 2017, 139, 373–378. [Google Scholar] [CrossRef]

- Maliki, M.; Laredj, N.; Bendani, K.; Missoum, H. Two-Dimensional Transient Modeling of Energy and Mass Transfer in Porous Building Components Using COMSOL Multiphysics. J. Appl. Fluid Mech. 2017, 10, 319–328. [Google Scholar] [CrossRef]

- Obeid, M.H.; Douzane, O.; Dutra, L.F.; Promis, G.; Laidoudi, B.; Langlet, T. Mechanical and Thermal Properties of an Innovative Bio-Based Concrete. In Proceedings of the 15th International Conference on Bio-Based Building Materials (ICBBM 2023), Vienna, Austria, 21–23 June 2023. [Google Scholar] [CrossRef]

- Bhuvaneswari, V.; Devarajan, B.; Arulmurugan, B.; Mahendran, R.; Rajkumar, S.; Sharma, S.; Mausam, K.; Li, C.; Eldin, E.T. A Critical Review on Hygrothermal and Sound Absorption Behavior of Natural-Fiber-Reinforced Polymer Composites. Polymers 2022, 14, 4727. [Google Scholar] [CrossRef]

- Pawłosik, D.; Cebrat, K.; Brzezicki, M. Exploring Advancements in Bio-Based Composites for Thermal Insulation: A Systematic Review. Sustainability 2025, 17, 1143. [Google Scholar] [CrossRef]

- Ba, L.; Kane, C.S.E.; Darcherif, I.; Pliya, P.; Ngo, T.T.; Niang, I.; Haidara, F. Experimental and Numerical Investigation of Energy Performance of Building Using Biobased Materials for Sustainable Construction. Energy Effic. 2023, 16, 78. [Google Scholar] [CrossRef]

- Charai, M.; Mezrhab, A.; Moga, L.; Karkri, M. Hygrothermal, Mechanical and Durability Assessment of Vegetable Concrete Mixes Made with Alfa Fibers for Structural and Thermal Insulating Applications. Constr. Build. Mater. 2022, 335, 127518. [Google Scholar] [CrossRef]

- Salem, T.; Fois, M.; Omikrine-Metalssi, O.; Manuel, R.; Fen-Chong, T. Thermal and Mechanical Performances of Cement-Based Mortars Reinforced with Vegetable Synthetic Sponge Wastes and Silica Fume. Constr. Build. Mater. 2020, 264, 120213. [Google Scholar] [CrossRef]

- Horma, O.; Channouf, S.; El Hammouti, A.; El Hassani, S.; Miri, H.; Moussaoui, M.A.; Mezrhab, A. Enhancing Concrete Sustainability Using Crushed Peanut Shells: An Analysis of Thermophysical Properties, Durability, and Application Potential in Construction. J. Build. Eng. 2024, 90, 109434. [Google Scholar] [CrossRef]

- Alioui, A.; Idrissi Kaitouni, S.; Azalam, Y.; Al Armouzi, N.; Bendada, E.M.; Mabrouki, M. Effect of Straw Fibers Addition on Hygrothermal and Mechanical Properties of Carbon-Free Adobe Bricks: From Material to Building Scale in a Semi-Arid Climate. Build. Environ. 2024, 255, 111380. [Google Scholar] [CrossRef]

- Maaloufa, Y.; Mounir, S.; Ibnelhaj, S.; El Wardi, F.Z.; Souidi, A.; Dodo, Y.A.; Atigui, M.; Amazal, M.; Khabbazi, A.; Demrati, H.; et al. Thermo-Physical Potential of Recycled Banana Fibers for Improving the Thermal and Mechanical Properties of Biosourced Gypsum-Based Materials. J. Renew. Mater. 2024, 12, 844–867. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. Performance Characteristics and Practical Applications of Common Building Thermal Insulation Materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Zhou, T.; Zheng, X.; Li, S.; Wang, T. Review of Low-Carbon Building Materials and Their Applications in Civil Engineering. Energies 2021, 16, 1773. [Google Scholar] [CrossRef]

- Rotini, F.; Fiorineschi, L.; Conti, L.; Rossi, G. Investigating Polylactic Acid Foam–Plant Fiber Composites for Sound Absorption and Insulation. Sustainability 2024, 16, 6913. [Google Scholar] [CrossRef]

- Panyakaew, S.; Fotios, S. New Thermal Insulation Boards Made from Coconut Husk and Bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef]

- Sbirrazzuoli, N.; Quatrini, E.; Luda, M.P.; Camino, G. Development of Bio-Based Rigid Polyurethane Foams: Influence of Different Bio-Polyols and Flame Retardants on Thermal and Mechanical Properties. J. Clean. Prod. 2023, 418, 137971. [Google Scholar] [CrossRef]

- Huang, G. Prediction and Optimization of the Mechanical and Thermal Properties of Bio-Based Concrete: Analytical and Numerical Multi-Scale Approaches. Thèses HAL 2023. Available online: https://theses.hal.science/tel-04395834v1 (accessed on 8 March 2025).

- Kamali Moghaddam, M. Typha Leaves Fiber and Its Composites: A Review. J. Nat. Fibers 2022, 19, 4993–5007. [Google Scholar] [CrossRef]

- Koh, C.H.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. Investigation of Material Characteristics and Hygrothermal Performances of Different Bio-Based Insulation Composites. Constr. Build. Mater. 2022, 346, 128440. [Google Scholar] [CrossRef]

- Penazzato, L.; Illampas, R.; Oliveira, D.V. The Challenge of Integrating Seismic and Energy Retrofitting of Buildings: An Opportunity for Sustainable Materials? Sustainability 2024, 16, 3465. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Elfordy, S.; Lucas, F.; Tancret, F.; Scudeller, Y.; Goudet, L. Mechanical and Thermal Properties of Lime and Hemp Concrete (Hempcrete) Manufactured by a Projection Process. Constr. Build. Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- Shea, A.; Lawrence, M.; Walker, P. Hygrothermal Performance of an Experimental Hemp-Lime Building. Constr. Build. Mater. 2012, 36, 270–275. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Demirhan, C. Mechanical, thermal and acoustical characterizations of an insulation composite made of bio-based materials. Sustain. Cit. Soc. 2016, 22, 56–64. [Google Scholar] [CrossRef]

- Rode, C.; Peuhkuri, R.H.; Mortensen, L.H.; Hansen, K.K.; Time, B.; Gustavsen, A.; Ojanen, T. Moisture Buffering of Building Materials; Technical University of Denmark: Kongens Lyngby, Denmark, 2017. [Google Scholar]

- Boumlik, K.; Belarbi, R.; Ahachad, M.; Mahdaoui, M.; Radoine, H.; Krarti, M. Design Optimization of Energy-Efficient Residential Buildings in Morocco. Buildings 2024, 14, 3915. [Google Scholar] [CrossRef]

- Łapka, P.; Dietrich, F.; Furmański, P.; Sinka, M.; Sahmenko, G.; Bajare, D. Experimental and Numerical Estimation of Thermal Conductivity of Bio-Based Building Composite Materials with an Enhanced Thermal Capacity. J. Energy Storage 2024, 97, 112943. [Google Scholar] [CrossRef]

- Bourbia, S.; Kazeoui, H.; Belarbi, R. A Review on Recent Research on Bio-Based Building Materials and Their Applications. Mater. Renew. Sustain. Energy 2023, 12, 117–139. [Google Scholar] [CrossRef]

- Nasr, Y.; El Zakhem, H.; Hamami, A.E.A.; El Bachawati, M.; Belarbi, R. Comprehensive Review of Innovative Materials for Sustainable Buildings’ Energy Performance. Energies 2023, 16, 7440. [Google Scholar] [CrossRef]

- Abou-Chakra, A.; Latapie, S.R.; Sabathier, V. Bio-Based Building Materials: A Prediction of Insulating Properties for a Wide Range of Agricultural By-Products. J. Build. Eng. 2024, 86, 108867. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Ali, S.A.; Tarek, D.; Maafa, I.M.; Abutaleb, A.; Yousef, A.; Fahmy, M.K. Development of Bio-Based Lightweight and Thermally Insulated Bricks: Efficient Energy Performance, Thermal Comfort, and CO2 Emission of Residential Buildings in Hot Arid Climates. J. Build. Eng. 2024, 95, 107032. [Google Scholar]

- Jahangir, M.H.; Alimohamadi, R. A Comparative Evaluation on Energy Consumption of a Building Using Bio-Based and Paraffin-Based Phase Change Materials Integrated to External Building Envelop. Energy Rep. 2024, 11, 3914–3930. [Google Scholar] [CrossRef]

- Choi, J.Y.; Nam, J.; Yuk, H.; Yang, S.; Kim, S. Enhancing the Hygrothermal Performance of Corn Cob Residue-Based Eco-Friendly Building Materials Through Biochar and Microencapsulated Phase Change Material Incorporation. J. Build. Eng. 2024, 89, 109189. [Google Scholar] [CrossRef]

- Ba, L.; El Abbassi, I.; Ngo, T.-T.; Pliya, P.; Kane, C.S.E.; Darcherif, A.-M.; Ndongo, M. Experimental Investigation of Thermal and Mechanical Properties of Clay Reinforced with Typha australis: Influence of Length and Percentage of Fibers. Waste Biomass Valorization 2021, 12, 2617–2633. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).