Industrial Hemp as Precursor for Sustainable Bioproducts: Recent Trends and Prospects

Abstract

1. Introduction

2. Hemp Overview

2.1. Cultivation

2.2. Components, Composition, and Properties

2.2.1. Hemp Fibers

2.2.2. Hemp Seeds

2.2.3. Hemp Shives

2.2.4. Hemp Hurds

2.3. Processing

2.4. Hemp Waste Generation in North America

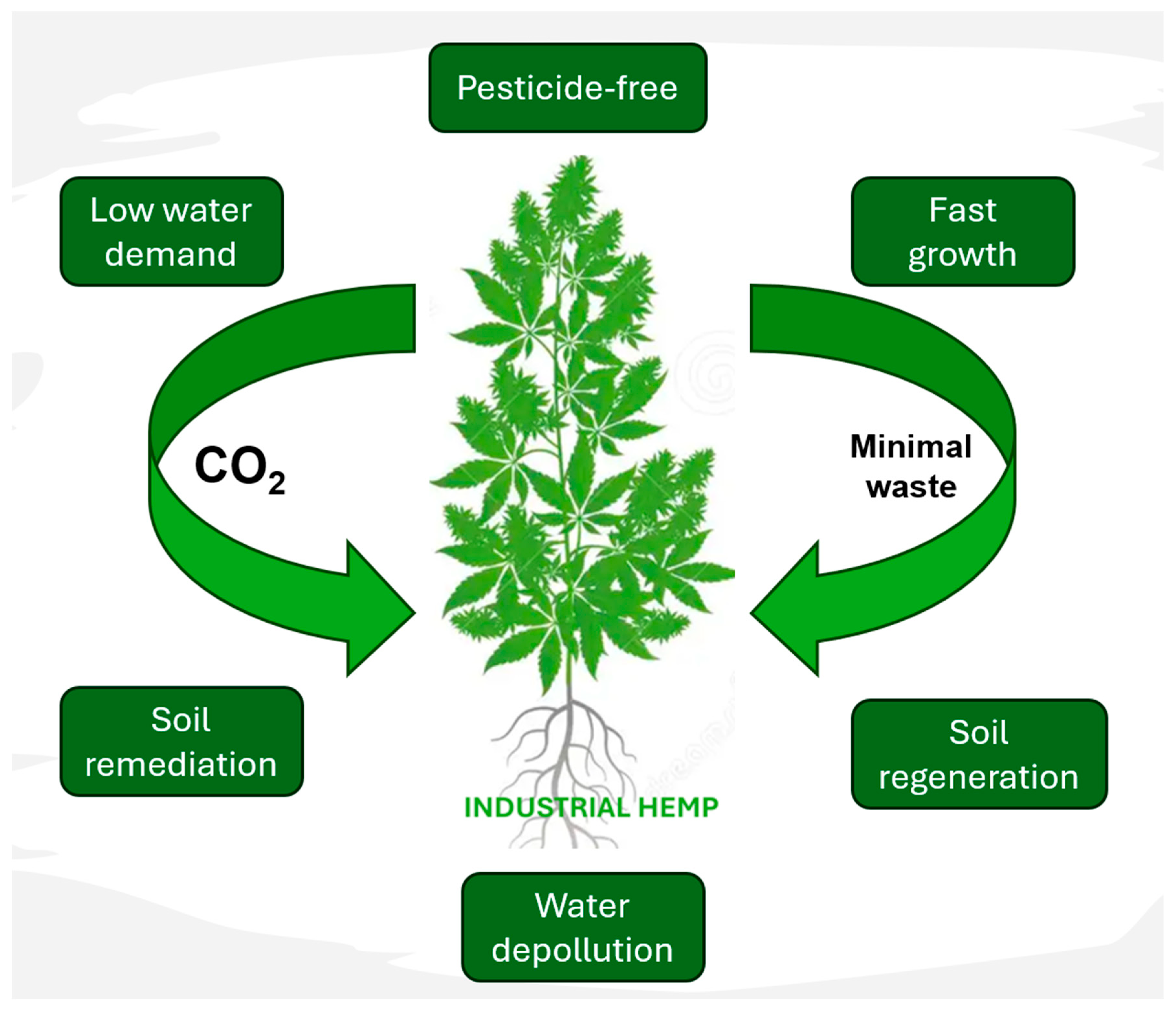

3. Hemp as a Sustainable Crop

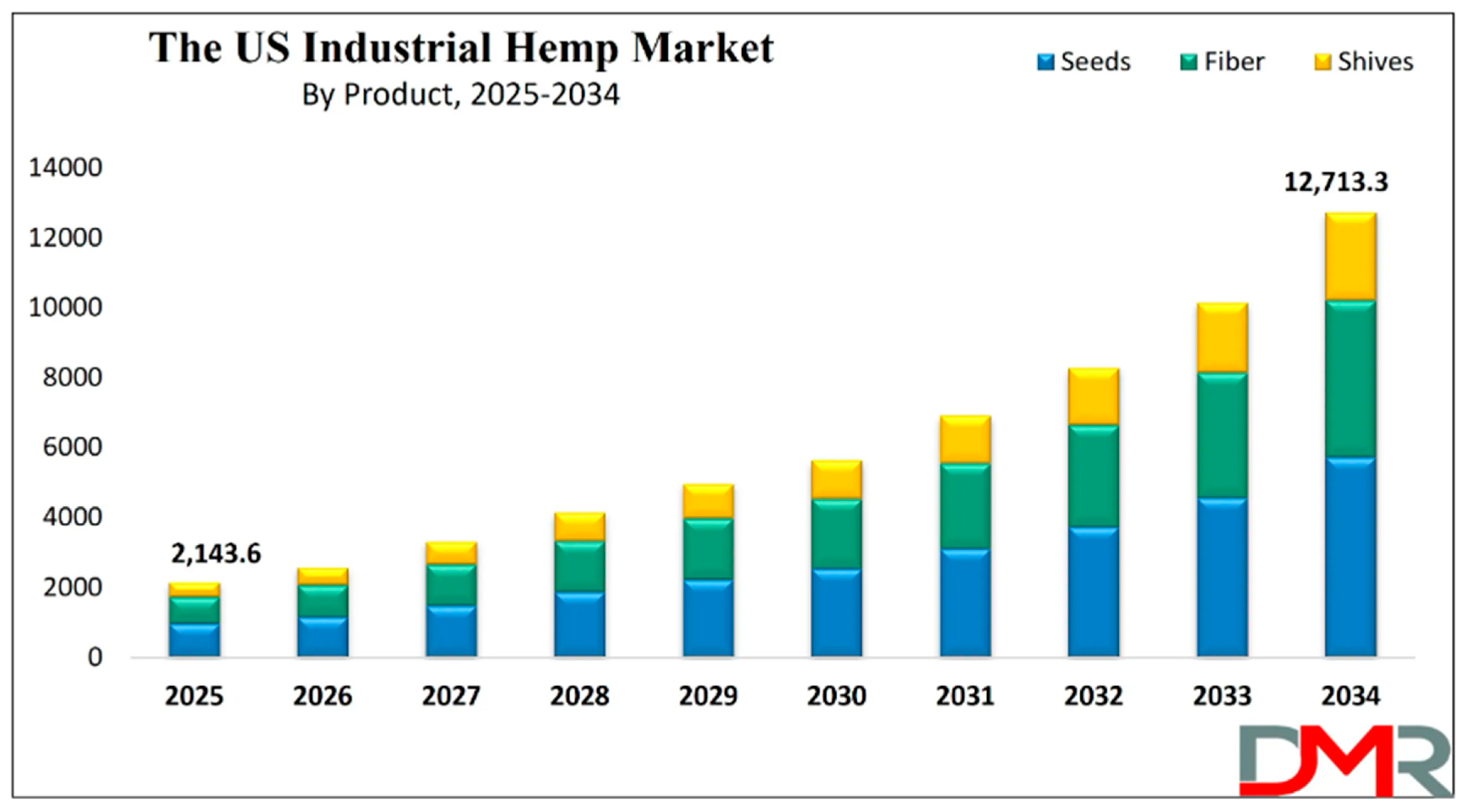

3.1. Economic Sustainability

3.2. Environmental Sustainability

3.3. Social Sustainability

4. Hemp Bioproduct Application in Textiles

4.1. Hemp in Spinning, Weaving, and Finishing

4.2. Hemp in Geotextiles

4.3. Hemp in Insulation

5. Hemp in Bio-Based Composites

5.1. Automotive Applications

5.2. Construction Applications

5.3. Packaging Applications

6. Hemp in Carbon Materials

7. Emerging and Prospective Use of Waste Hemp as Raw Material for Sustainable Bioproducts

8. Future Outlook, Barriers, and Recommendations

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ripple, W.J.; Smith, P.; Haberl, H.; Montzka, S.A.; McAlpine, C.; Boucher, D.H. Ruminants, Climate Change and Climate Policy. Nat. Clim. Change 2014, 4, 2–5. [Google Scholar] [CrossRef]

- Holden, N.M.; Neill, A.M.; Stout, J.C.; O’Brien, D.; Morris, M.A. Biocircularity: A Framework to Define Sustainable, Circular Bioeconomy. Circ. Econ. Sustain. 2023, 3, 77–91. [Google Scholar] [CrossRef]

- Ripple, W.J.; Wolf, C.; Newsome, T.M.; Galetti, M.; Alamgir, M.; Crist, E.; Mahmoud, M.I.; Laurance, W.F. 15,364 scientist signatories from 184 countries, World Scientists’ Warning to Humanity: A Second Notice. BioScience 2017, 67, 1026–1028. [Google Scholar] [CrossRef]

- Muscat, A.; de Olde, E.M.; Ripoll-Bosch, R.; Van Zanten, H.H.E.; Metze, T.A.P.; Termeer, C.J.A.M.; van Ittersum, M.K.; de Boer, I.J.M. Principles, drivers and opportunities of a circular bioeconomy. Nat. Food 2021, 2, 561–566. [Google Scholar] [CrossRef]

- Yang, L.; Wang, X.C.; Dai, M.; Chen, B.; Qiao, Y.; Deng, H.; Zhang, D.; Zhang, Y.; Villas Bôas de Almeida, C.M.; Chiu, A.S.F.; et al. Shifting from Fossil-Based Economy to Bio-Based Economy: Status Quo, Challenges, and Prospects. Energy 2021, 228, 120533. [Google Scholar] [CrossRef]

- Martins, F.; Felgueiras, C.; Smitkova, M.; Caetano, N. Analysis of Fossil Fuel Energy Consumption and Environmental Impacts in European Countries. Energies 2019, 12, 964. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Message from the Executive Director; United Nations Environment Programme: Nairobi, Kenya, 2025. [Google Scholar]

- Cahill, A.E.; Aiello-Lammens, M.E.; Caitlin Fisher-Reid, M.; Hua, X.; Karanewsky, C.J.; Ryu, H.Y.; Sbeglia, G.C.; Spagnolo, F.; Waldron, J.B.; Warsi, O.; et al. How Does Climate Change Cause Extinction? Proc. R. Soc. B Biol. Sci. 2013, 280, 1890. [Google Scholar] [CrossRef]

- Dubey, S. Addressing the Ecological Sustainability through Bio-Economy—A Comprehensive Review. J. Pharmaceutical. Biol. Sci. 2024, 2, 95–99. [Google Scholar] [CrossRef]

- Hiloidhari, M.; Sharno, M.A.; Baruah, D.C.; Bezbaruah, A.N. Green and Sustainable Biomass Supply Chain for Environmental, Social and Economic Benefits. Biomass Bioenergy 2023, 175, 106893. [Google Scholar] [CrossRef]

- Korosuo, A.; Borzacchiello, M.T.; Giuntoli, J.; Lasarte, L.; M’barek, R.; Mubareka, S.B.; Camia, A. Trends in the EU Bioeconomy-Update 2024; Publications Office of the European Union: Luxembourg City, Luxembourg, 2024. [Google Scholar]

- US Department of Energy; US Department of Agriculture. Final_Billionton_Vision_Report2; US Department of Agriculture: Washington, DC, USA, 2005.

- Langholtz, M.H.; Stokes, B.J.; Eaton, L.M. 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy; US Forest Service Research and Development: Washington, DC, USA, 2016.

- Department of Energy, U.; Langholtz, M.H. 2023 Billion-Ton Report: An Assessment of U.S. Renewable Carbon Resources; US Forest Service Research and Development: Washington, DC, USA, 2023.

- Golden, J.S.; Handfield, R.; Daystar, J.; Pires, S. An Economic Impact Analysis of the US Biobased Products Industry; USDA: Washington, DC, USA, 2024.

- USDA. Service National Hemp Report. In National Agricultural Statistics Service; USDA: Washington, DC, USA, 2023; pp. 1–17. [Google Scholar]

- National Hemp Report; National Agricultural Statistics Science: Washington, DC, USA, 2022.

- Böttcher, H.; Liste, V.; Fyson, C. Options for Multilateral Initiatives to Close the Global 2030 Climate Ambition and Action Gap—Policy Field Forest Protection; IAEA: Vienna, Austria, 2021. [Google Scholar]

- Pietrzykowski, M.; Woś, B.; Tylek, P.; Kwaśniewski, D.; Juliszewski, T.; Walczyk, J.; Likus-Cieślik, J.; Ochał, W.; Tabor, S. Carbon Sink Potential and Allocation in Above- and below-Ground Biomass in Willow Coppice. J. Res. 2021, 32, 349–354. [Google Scholar] [CrossRef]

- European Union. Hemp Production in the EU. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en/ (accessed on 20 July 2025).

- Moliterni, V.M.C.; Pojić, M.; Tiwari, B. Industrial Hemp By-Product Valorization. Ind. Hemp Food Nutraceutical Appl. 2022, 301–340. [Google Scholar] [CrossRef]

- Edyta, M.; Piotr, P.; Marcin, D.; Marta, K.; Kamila, B. Comparison of Papermaking Potential of Wood and Hemp Cellulose Pulps. For. Wood Technol. 2015, 91, 134–137. [Google Scholar]

- Danielewicz, D.; Surma-Ślusarska, B. Processing of Industrial Hemp into Papermaking Pulps Intended for Bleaching. Fibres Text. East. Eur. 2010, 18, 110. [Google Scholar]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a Potential Raw Material toward a Sustainable World: A Review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef]

- Chabbert, B.; Kurek, B.; Beherec, O. Physiology and Botany of Industrial Hemp. In Hemp: Industrial Production and Uses; Bouloc, P., Allegret, S., Arnaud, L., Eds.; CABI: Paris, France, 2013; pp. 27–47. [Google Scholar] [CrossRef]

- Hemp Benchmarks. A Growing Problem: What Is to Be Done with the Millions of Tons of Hemp Waste? Available online: https://www.hempbenchmarks.com/hemp-market-insider/hemp-waste/ (accessed on 18 July 2025).

- Kaur, G.; Kander, R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability 2023, 15, 6457. [Google Scholar] [CrossRef]

- Dölle, K. Reinventing Hemp as Bio Fiber Material for Industrial Applications: Past, Present and the Future. Adv. Res. 2024, 25, 98–112. [Google Scholar] [CrossRef]

- Enarevba, D.R.; Haapala, K.R. The Emerging Hemp Industry: A Review of Industrial Hemp Materials and Product Manufacturing. AgriEngineering 2024, 6, 2891–2925. [Google Scholar] [CrossRef]

- Basak, M.; Broadway, M.; Lewis, J.; Starkey, H.; Bloomquist, M.; Peszlen, I.; Davis, J.; Lucia, L.A.; Pal, L. A Critical Review of Industrial Fiber Hemp Anatomy, Agronomic Practices, and Valorization into Sustainable Bioproducts. Bioresources 2025, 20, 5030–5070. [Google Scholar] [CrossRef]

- Ranalli, P.; Venturi, G. Hemp as a Raw Material for Industrial Applications. Euphytica 2004, 140, 1–6. [Google Scholar] [CrossRef]

- Rupasinghe, H.P.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial Hemp (Cannabis sativa subsp. sativa) as an Emerging Source for Value-Added Functional Food Ingredients and Nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef]

- Liu, M.; Fernando, D.; Daniel, G.; Madsen, B.; Meyer, A.S.; Ale, M.T.; Thygesen, A. Effect of Harvest Time and Field Retting Duration on the Chemical Composition, Morphology and Mechanical Properties of Hemp Fibers. Ind. Crops Prod. 2015, 69, 29–39. [Google Scholar] [CrossRef]

- Müssig, J. Industrial Applications of Natural Fibres: Structure, Properties and Technical Applications. Ind. Appl. Nat. Fibres Struct. Prop. Tech. Appl. 2010, 538, 9780470660324. [Google Scholar] [CrossRef]

- Booth, I.; Goodman, A.M.; Grishanov, S.A.; Harwood, R.J. A Mechanical Investigation of the Retting Process in Dew-Retted Hemp (Cannabis sativa). Ann. Appl. Biol. 2004, 145, 51–58. [Google Scholar] [CrossRef]

- Zimniewska, M. Hemp Fibre Properties and Processing Target Textile: A Review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef]

- Gedik, G.; Avinc, O. Hemp Fiber as a Sustainable Raw Material Source for Textile Industry: Can We Use Its Potential for More Eco-Friendly Production? In Sustainability in the Textile and Apparel Industries. Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer: Cham, Switzerland, 2020; pp. 87–109. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp Fiber and Its Composites—A Review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Toonen, M.A.J.; Maliepaard, C.; Reijmers, T.H.; Van Der Voet, H.; Mastebroek, H.D.; Van Den Broeck, H.C.; Ebskamp, M.J.M.; Kessler, W.; Kessler, R.W. Predicting the Chemical Composition of Fibre and Core Fraction of Hemp (Cannabis sativa L.). Euphytica 2004, 140, 39–45. [Google Scholar] [CrossRef]

- Dimension Market Research U.S. Industrial Hemp Market by Product (Seeds, Fiber, and Shives), by Source, by Application—Industry Outlook, Key Companies (GenCanna, IND HEMP, Victory Hemp Foods, and Others), Trends and Forecast 2025–2034. Available online: https://dimensionmarketresearch.com/report/us-industrial-hemp-market/ (accessed on 28 September 2025).

- Ona, G.; Balant, M.; Bouso, J.C.; Gras, A.; Valles, J.; Vitales, D.; Garnatje, T. The Use of Cannabis sativa L. for Pest Control: From the Ethnobotanical Knowledge to a Systematic Review of Experimental Studies. Cannabis Cannabinoid Res. 2022, 7, 365–387. [Google Scholar] [CrossRef] [PubMed]

- Visković, J.; Zheljazkov, V.D.; Sikora, V.; Noller, J.; Latković, D.; Ocamb, C.M.; Koren, A. Industrial Hemp (Cannabis sativa L.) Agronomy and Utilization: A Review. Agronomy 2023, 13, 931. [Google Scholar] [CrossRef]

- Ranalli, P. Paoli Ranolli Advances in Hemp Research. In Advances in Hemp Research, 1st ed.; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar] [CrossRef]

- Ely, K.; Podder, S.; Reiss, M.; Fike, J. Industrial Hemp as a Crop for a Sustainable Agriculture. In Cannabis/Hemp for Sustainable Agriculture and Materials; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–28. [Google Scholar] [CrossRef]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp Fibers: An Overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef]

- Bambach, M.R. Direct Comparison of the Structural Compression Characteristics of Natural and Synthetic Fiber-Epoxy Composites: Flax, Jute, Hemp, Glass and Carbon Fibers. Fibers 2020, 8, 62. [Google Scholar] [CrossRef]

- Dahal, R.K.; Acharya, B.; Dutta, A. Mechanical, Thermal, and Acoustic Properties of Hemp and Biocomposite Materials: A Review. J. Compos. Sci. 2022, 6, 373. [Google Scholar] [CrossRef]

- Iucolano, F.; Boccarusso, L.; Langella, A. Hemp as Eco-Friendly Substitute of Glass Fibres for Gypsum Reinforcement: Impact and Flexural Behaviour. Compos. B Eng. 2019, 175, 107073. [Google Scholar] [CrossRef]

- Musio, S.; Müssig, J.; Amaducci, S. Optimizing Hemp Fiber Production for High Performance Composite Applications. Front. Plant Sci. 2018, 871, 1702. [Google Scholar] [CrossRef]

- Callaway, J.C. Hempseed as a Nutritional Resource: An Overview. Euphytica 2004, 140, 65–72. [Google Scholar] [CrossRef]

- House, J.D.; Neufeld, J.; Leson, G. Evaluating the Quality of Protein from Hemp Seed (Cannabis sativa L.) Products Through the Use of the Protein Digestibility-Corrected Amino Acid Score Method. J. Agric. Food Chem. 2010, 58, 11801–11807. [Google Scholar] [CrossRef]

- Sapino, S.; Carlotti, M.E.; Gallarate, M. Hemp-Seed and Olive Oils: Their Stability against Oxidation and Use in O/W Emulsions. Int. J. Cosmet. Sci. 2005, 27, 353. [Google Scholar] [CrossRef]

- Vonapartis, E.; Aubin, M.P.; Seguin, P.; Mustafa, A.F.; Charron, J.B. Seed Composition of Ten Industrial Hemp Cultivars Approved for Production in Canada. J. Food Compos. Anal. 2015, 39, 8–12. [Google Scholar] [CrossRef]

- Toptaş, Y.; Yavuz, B.; Aksoğan Korkmaz, A.; Önal, Y. Sustainable Approach to Dye Adsorption: Hemp-Based Activated Carbon as an Effective Adsorbent. Int. J. Environ. Anal. Chem. 2024, 1–26. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Applications of Hemp in Textiles, Paper Industry, Insulation and Building Materials, Horticulture, Animal Nutrition, Food and Beverages, Nutraceuticals, Cosmetics and Hygiene, Medicine, Agrochemistry, Energy Production and Environment: A Review. Environ. Chem. Lett. 2020, 18, 1451–1476. [Google Scholar] [CrossRef]

- Li, S.Y.; Stuart, J.D.; Li, Y.; Parnas, R.S. The Feasibility of Converting Cannabis sativa L. Oil into Biodiesel. Bioresour. Technol. 2010, 101, 8457–8460. [Google Scholar] [CrossRef] [PubMed]

- Russo, E.B. Taming THC: Potential Cannabis Synergy and Phytocannabinoid-Terpenoid Entourage Effects. Br. J. Pharmacol. 2011, 163, 1344–1364. [Google Scholar] [CrossRef]

- Yano, H.; Fu, W. Hemp: A Sustainable Plant with High Industrial Value in Food Processing. Foods 2023, 12, 651. [Google Scholar] [CrossRef]

- Arnaud, L.; Gourlay, E. Experimental Study of Parameters Influencing Mechanical Properties of Hemp Concretes. Constr. Build. Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Amaducci, S.; Scordia, D.; Liu, F.H.; Zhang, Q.; Guo, H.; Testa, G.; Cosentino, S.L. Key Cultivation Techniques for Hemp in Europe and China. Ind. Crops Prod. 2015, 68, 2–16. [Google Scholar] [CrossRef]

- Prade, T.; Svensson, S.E.; Andersson, A.; Mattsson, J.E. Biomass and Energy Yield of Industrial Hemp Grown for Biogas and Solid Fuel. Biomass Bioenergy 2011, 35, 3040–3049. [Google Scholar] [CrossRef]

- Ewurum, N.; McDonald, A.G. Lignin Reinforcement in Polybutylene Succinate Copolymers. Polymers 2025, 17, 194. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yu, Z.; McDonald, A.G. Effect of Different Reinforcing Fillers on Properties, Interfacial Compatibility and Weatherability of Wood-Plastic Composites. J. Bionic Eng. 2019, 16, 337–353. [Google Scholar] [CrossRef]

- Momeni, S.; Safder, M.; Khondoker, M.A.H.; Elias, A.L. Valorization of Hemp Hurds as Bio-Sourced Additives in Pla-Based Biocomposites. Polymer 2021, 13, 3786. [Google Scholar] [CrossRef]

- Siouta, L.; Apostolopoulou, M.; Bakolas, A. Natural Fibers in Composite Materials for Sustainable Building: A State-of-the-Art Review on Treated Hemp Fibers and Hurds in Mortars. Sustainability 2024, 16, 10368. [Google Scholar] [CrossRef]

- Assirelli, A.; Fischetti, E.; Scarfone, A.; Santangelo, E.; Carnevale, M.; Paris, E.; Palma, A.; Gallucci, F. Characterization of Hemp Hurd-Derived Biochar for Potential Agricultural Applications. Agronomy 2025, 15, 2136. [Google Scholar] [CrossRef]

- Zhao, J.; Xu, Y.; Wang, W.; Griffin, J.; Roozeboom, K.; Wang, D. Bioconversion of Industrial Hemp Biomass for Bioethanol Production: A Review. Fuel 2020, 281, 118725. [Google Scholar] [CrossRef]

- Brazdausks, P.; Puke, M.; Rizhikovs, J.; Pubule, J. Evaluation of Cellulose Content in Hemp Shives after Salt Catalyzed Hydrolysis. Energy Procedia 2017, 128, 297–301. [Google Scholar] [CrossRef]

- Müssig, J.; Beaugrand, J. Decortication and Separation of Wet or Dry Hemp Stems—What Difference Does It Make? Ind. Crops Prod. 2025, 223, 119965. [Google Scholar] [CrossRef]

- Duque Schumacher, A.G.; Pequito, S.; Pazour, J. Industrial Hemp Fiber: A Sustainable and Economical Alternative to Cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Amir, S. Hemp as a Biomass Crop. 2023. Available online: https://www.biomassconnect.org/technical-articles/hemp-as-a-biomass-crop/# (accessed on 15 July 2025).

- 9Fiber. Processing Cannabis + Hemp Waste into Industrial and Textile Products. 2021. Available online: https://recycleark.org/wp-content/uploads/2019/10/Processing-Cannabis-Hemp-Waste-Into-Industrial-and-Textile-Products.pdf (accessed on 10 July 2025).

- Carol Kahn. 9fiber: The Invisible Industry Innovation for a Cleaner World. Available online: https://greenlivingmag.com/9fiber-the-invisible-industry-innovation-for-a-cleaner-world/ (accessed on 12 June 2025).

- Mahmood, A.B.; Runciman, J.; Badr, M.; Al-Badrawi, Y.; Hudson, D. Hemp Waste Classification Using Convolutional Neural Networks. In Proceedings of the Canadian Conference on Electrical and Computer Engineering, Vancouver, QC, Canada, 26–29 May 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024; pp. 871–875. [Google Scholar]

- Mark, T.; Will, S. Economic Issues and Perspectives for Industrial Hemp; University of Kentucky: Lexington, KT, USA, 2019; pp. 107–118. ISBN 9780891186328. [Google Scholar]

- Victoria State Government. Industrial-Hemp-Update; Victoria State Government: Melbourne, VIC, Australia, 2020.

- Moscariello, C.; Matassa, S.; Esposito, G.; Papirio, S. From Residue to Resource: The Multifaceted Environmental and Bioeconomy Potential of Industrial Hemp (Cannabis sativa L.). Resour. Conserv. Recycl. 2021, 175, 1865. [Google Scholar] [CrossRef]

- Mark, T.; Shepherd, J.; Olson, D.; Snell, W.; Proper, S.; Thornsbury, S. Economic Viability of Industrial Hemp in the United States: A Review of State Pilot Programs United States Department of Agriculture; US Department of Agriculture: Washington, DC, USA, 2020.

- Giddings, B.; Hopwood, B.; O’Brien, G. Environment, Economy and Society: Fitting Them Together into Sustainable Development. Sustain. Dev. 2002, 10, 187–196. [Google Scholar] [CrossRef]

- Silva, G.S.; Rosenbach, M. Climate Change and Dermatology: An Introduction to a Special Topic, for This Special Issue. Int. J. Womens Dermatol. 2021, 7, 3–7. [Google Scholar] [CrossRef]

- Gill, A.R.; Loveys, B.R.; Cavagnaro, T.R.; Burton, R.A. The Potential of Industrial Hemp (Cannabis sativa L.) as an Emerging Drought Resistant Fibre Crop. Plant Soil. 2023, 493, 7–16. [Google Scholar] [CrossRef]

- National hemp Association Industrial Hemp. A Sustainable and Versatile Crop for Climate-Smart Agriculture and Economic Development. Available online: https://nationalhempassociation.org/industrial-hemp-a-sustainable-and-versatile-crop-for-climate-smart-agriculture-and-economic-development/ (accessed on 14 July 2025).

- The Future of Hemp-Based Products in India. Available online: https://thetrost.com/blogs/blogs/the-future-of-hemp-based-products-in-india (accessed on 15 July 2025).

- Yarn Development from Industrial Hemp: A Technical White Paper Introduction and Overview. Available online: https://indhemp.com/wp-content/uploads/2025/05/UTF-8Yarn-Development-from-Industrial-HempFINAL5-2-2025.pdf (accessed on 13 July 2025).

- Muhit, I.B.; Omairey, E.L.; Pashakolaie, V.G. A Holistic Sustainability Overview of Hemp as Building and Highway Construction Materials. Build. Environ. 2024, 256, 111470. [Google Scholar] [CrossRef]

- Catarino, M.L.; Sampaio, F.; Gonçalves, A.L. Sustainable Wet Processing Technologies for the Textile Industry: A Comprehensive Review. Sustainability 2025, 17, 3041. [Google Scholar] [CrossRef]

- Pizzicato, B.; Pacifico, S.; Cayuela, D.; Mijas, G.; Riba-Moliner, M. Advancements in Sustainable Natural Dyes for Textile Applications: A Review. Molecules 2023, 28, 5954. [Google Scholar] [CrossRef]

- Prasad, V.V.B.; Ishwarya, M.V.S.; Jayakrishnan, P.; Sathyan, D.; Muthukumar, S. Applications of Natural Geotextile in Geotechnical Engineering. Mater. Today Proc. 2023, 1–8. [Google Scholar] [CrossRef]

- Wu, H.; Yao, C.; Li, C.; Miao, M.; Zhong, Y.; Lu, Y.; Liu, T. Review of Application and Innovation of Geotextiles in Geotechnical Engineering. Materials 2020, 13, 1774. [Google Scholar] [CrossRef] [PubMed]

- Langley, K.D.; Kim, Y.K. Manufacturing Nonwovens and Other Products Using Recycled Fibers Containing Spandex. Recycl. Text. A Vol. Woodhead Publ. Ser. Text. 2006, 34, 137–164. [Google Scholar] [CrossRef]

- Kaur, N.; Kumar, A.; Malik, T.; Girdhar, M.; Singh, M.; Singh, R.; Tariq, M.; Mohan, A. Herbicide Use and Weed Management Strategies in Hemp Cultivation. J. Cannabis Res. 2025, 7, 1–25. [Google Scholar] [CrossRef]

- Placido, D.F.; Lee, C.C. Potential of Industrial Hemp for Phytoremediation of Heavy Metals. Plants 2022, 11, 595. [Google Scholar] [CrossRef] [PubMed]

- Fiedler, T.; Pedersen, J. Evaluating the Thermal Conductivity of Hemp-Based Insulation. Materials 2025, 18, 1723. [Google Scholar] [CrossRef] [PubMed]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel Insulation for Building Applications: A State-of-the-Art Review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- McLaggan, M.S.; Hadden, R.M.; Gillie, M. Flammability Assessment of Phase Change Material Wall Lining and Insulation Materials with Different Weight Fractions. Energy Build. 2017, 153, 439–447. [Google Scholar] [CrossRef]

- De Meersman, G.; Van Den Bossche, N.; Janssens, A. Long Term Durability of Vacuum Insulation Panels: Determination of the Sd-Value of MF-2 Foils. Energy Procedia 2015, 78, 1574–1580. [Google Scholar] [CrossRef]

- Griffith, B.T.; Arasteh, D. Gas-Filled Panels: A Thermally Improved Building Insulation. In Proceedings of the ASHRAE/DOE/BTECC Conference, Clearwater Beach, FL, USA, 7 December 1992; American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 1992; pp. 1–13. [Google Scholar]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative Analysis of Building Insulation Material Properties and Performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Pundiene, I.; Vitola, L.; Pranckeviciene, J.; Bajare, D. Hemp Shive-Based Bio-Composites Bounded by Potato Starch Binder: The Roles of Aggregate Particle Size and Aspect Ratio. J. Ecol. Eng. 2022, 23, 220–234. [Google Scholar] [CrossRef] [PubMed]

- Schmehl, M.; Müssig, J.; Schönfeld, U.; Buttlar, H.B. Life Cycle Assessment on a Bus Body Component Based on Hemp Fiber and PTP®. J. Polym. Environ. 2008, 16, 51–60. [Google Scholar] [CrossRef]

- Delhomme, F.; Hajimohammadi, A.; Almeida, A.; Jiang, C.; Moreau, D.; Gan, Y.; Wang, X.; Castel, A. Physical Properties of Australian Hurd Used as Aggregate for Hemp Concrete. Mater. Today Commun. 2020, 24, 100986. [Google Scholar] [CrossRef]

- Sarika, P.R.; Nancarrow, P.; Khansaheb, A.; Ibrahim, T. Progress in Bio-Based Phenolic Foams: Synthesis, Properties, and Applications. ChemBioEng Rev. 2021, 8, 612–632. [Google Scholar] [CrossRef]

- Zeng, X.; Deng, K.; Wang, Y.; Yan, G.; Zhao, C. Field Investigation and Numerical Analysis of Damage to a High-Pier Long-Span Continuous Rigid Frame Bridge in the 2008 Wenchuan Earthquake. J. Earthq. Eng. 2022, 26, 5204–5220. [Google Scholar] [CrossRef]

- Zhao, J.R.; Zheng, R.; Tang, J.; Sun, H.J.; Wang, J. A Mini-Review on Building Insulation Materials from Perspective of Plastic Pollution: Current Issues and Natural Fibres as a Possible Solution. J. Hazard. Mater. 2022, 438, 129449. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A Comprehensive Review of Natural Fibers and Their Composites: An Eco-Friendly Alternative to Conventional Materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Denault, J. Natural Fiber Composites in the Automotive Industry. Mater. Sci. 2009, 126, 22–27. [Google Scholar]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural Fibres: Can They Replace Glass in Fibre Reinforced Plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Marcus Fairs. Hemp “More Effective than Trees” at Sequestering Carbon Says Cambridge ResearcherHemp “More Effective than Trees” at Sequestering Carbon Says Cambridge Researcher. Available online: https://www.dezeen.com/2021/06/30/carbon-sequestering-hemp-darshil-shah-interview/ (accessed on 14 July 2025).

- Shanmugam, V.; Mensah, R.A.; Försth, M.; Sas, G.; Restás, Á.; Addy, C.; Xu, Q.; Jiang, L.; Neisiany, R.E.; Singha, S.; et al. Circular economy in biocomposite development: State-of-the-art, challenges and emerging trends. Compos. C Open Access 2021, 5, 100138. [Google Scholar] [CrossRef]

- Vink, E.T.H.; Davies, S. Life Cycle Inventory and Impact Assessment Data for 2014 Ingeo® Polylactide Production. Ind. Biotechnol. 2015, 11, 167–180. [Google Scholar] [CrossRef]

- Thakur, A.; Musioł, M.; Duale, K.; Kowalczuk, M. Exploring the Future of Polyhydroxyalkanoate Composites with Organic Fillers: A Review of Challenges and Opportunities. Polymers 2024, 16, 1768. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B.; Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B. Applications of Natural Fibers and Its Composites: An Overview. Nat. Resour. 2016, 7, 108–114. [Google Scholar] [CrossRef]

- Shelly, D.; Lee, S.Y.; Park, S.J. Hemp Fiber and Its Bio-Composites: A Comprehensive Review Part I—Characteristics and Processing. Adv. Compos. Hybrid Mater. 2025, 8, 1–47. [Google Scholar] [CrossRef]

- Varma, M.; Chandran, S. Surface Treatment of Natural Fibers for Enhancing Interfacial Adhesion and Mechanical Properties in Biocomposites—A Comprehensive Review. Compos. Interfaces 2025, 2025, 2498795. [Google Scholar] [CrossRef]

- Niemelä, T.; Kellomäki, M. Bioactive Glass and Biodegradable Polymer Composites. Bioact. Glas. Mater. Prop. Appl. 2011, 21, 227–245. [Google Scholar] [CrossRef]

- Lee, E.C.; Flanigan, C.M.; Williams, K.A.; Mielewski, D.F.; Houston, D.Q. Hemp Fiber Reinforced Sheet Molding Compounds for Automotive Applications; Ford Motor Company: Dearborn, MI, USA, 2022; pp. 1–12. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress Report on Natural Fiber Reinforced Composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.P.J.; Virk, A.S.; Hall, W. A Review of Bast Fibres and Their Composites. Part 1—Fibres as Reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- Mphuthi, B.R.; Thabede, P.M.; Modise, J.S.; Xaba, T.; Shooto, N.D. Adsorption of Cadmium and Methylene Blue Using Highly Porous Carbon from Hemp Seeds. Appl. Sci. 2023, 13, 9659. [Google Scholar] [CrossRef]

- Allegret, S. The History of Hemp. Hemp Ind. Prod. Uses 2013, 11, 4–26. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Compos. 2015, 62, 97–105. [Google Scholar] [CrossRef]

- Jothilingam, M.; Paul, P. Study on Strength and Microstructure of Hempcrete. Proc. AIP Conf. Proc. 2019, 2117, 020028. [Google Scholar] [CrossRef]

- Elfordy, S.; Lucas, F.; Tancret, F.; Scudeller, Y.; Goudet, L. Mechanical and Thermal Properties of Lime and Hemp Concrete (“Hempcrete”) Manufactured by a Projection Process. Constr. Build. Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- Binega Yemesegen, E.; Memari, A.M. A Review of Experimental Studies on Cob, Hempcrete, and Bamboo Components and the Call for Transition towards Sustainable Home Building with 3D Printing. Constr. Build. Mater. 2023, 399, 132603. [Google Scholar] [CrossRef]

- Niyigena, C.; Amziane, S.; Chateauneuf, A.; Arnaud, L.; Bessette, L.; Collet, F.; Lanos, C.; Escadeillas, G.; Lawrence, M.; Magniont, C.; et al. Variability of the Mechanical Properties of Hemp Concrete. Mater. Today Commun. 2016, 7, 122–133. [Google Scholar] [CrossRef]

- Demir, İ.; Doğan, C. Physical and Mechanical Properties of Hempcrete. Open Waste Manag. J. 2020, 13, 26–34. [Google Scholar] [CrossRef]

- Steyn, K.; de Villiers, W.; Babafemi, A.J. A Comprehensive Review of Hempcrete as a Sustainable Building Material. Innov. Infrastruct. Solut. 2025, 10, 97. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.R.; Singh, L.P. A Review of the Properties of Hemp Concrete for Green Building Applications. J. Clean Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel Sustainable Hemp-Based Composites for Application in the Building Industry: Physical, Thermal and Mechanical Characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Arrigoni, A.; Pelosato, R.; Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life Cycle Assessment of Natural Building Materials: The Role of Carbonation, Mixture Components and Transport in the Environmental Impacts of Hempcrete Blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Ip, K.; Miller, A. Life Cycle Greenhouse Gas Emissions of Hemp-Lime Wall Constructions in the UK. Resour. Conserv. Recycl. 2012, 69, 1–9. [Google Scholar] [CrossRef]

- Arnaud, L.; Boyeux, B.; Hustache, Y. Hemp and the Construction Industry. Hemp Ind. Prod. Uses 2013, 32, 239–259. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Wang, X. Compressive and Flexural Properties of Hemp Fiber Reinforced Concrete. Fibers Polym. 2004, 5, 187–197. [Google Scholar] [CrossRef]

- Jellen, A.C.; Memari, A.M. State-of-the-Art Review of Hempcrete for Residential Building Construction. Designs 2025, 9, 44. [Google Scholar] [CrossRef]

- Asghari, N.; Memari, A.M. State of the Art Review of Attributes and Mechanical Properties of Hempcrete. Biomass 2024, 4, 65–91. [Google Scholar] [CrossRef]

- Tong, W.; Memari, A.M. State of the Art Review on Hempcrete as a Sustainable Substitute for Traditional Construction Materials for Home Building. Buildings 2025, 15, 1988. [Google Scholar] [CrossRef]

- Collet, F.; Pretot, S. Thermal Conductivity of Hemp Concretes: Variation with Formulation, Density and Water Content. Constr. Build. Mater. 2014, 65, 612–619. [Google Scholar] [CrossRef]

- What Is Composite Cladding & How Is It Used?|Trex. Available online: https://www.trex.com/deck-ideas/what-is-composite-cladding-how-is-it-used/ (accessed on 21 July 2025).

- Saingam, P.; Hussain, Q.; Sua-iam, G.; Nawaz, A.; Ejaz, A. Hemp Fiber-Reinforced Polymers Composite Jacketing Technique for Sustainable and Environment-Friendly Concrete. Polymers 2024, 16, 1774. [Google Scholar] [CrossRef]

- Hemp as a Raw Material for Packaging—PAPACKS Fiber Cast Packaging. Available online: https://www.papacks.com/en/molded-fiber-production-2/hemp-as-a-packaging-raw-material/ (accessed on 21 July 2025).

- Su, Y.; Yang, B.; Liu, J.; Sun, B.; Cao, C.; Zou, X.; Lutes, R.; He, Z. Prospects for Replacement of Some Plastics in Packaging with Lignocellulose Materials: A Brief Review. Bioresources 2018, 13, 4550–4576. [Google Scholar] [CrossRef]

- Debnath, M.; Sarder, R.; Pal, L.; Hubbe, M.A. Molded Pulp Products for Sustainable Packaging: Production Rate Challenges and Product Opportunities. Bioresources 2022, 17, 3810–3870. [Google Scholar] [CrossRef]

- Das, R.; Panda, A.K.; Mohanty, S. Enhancing Barrier and Antioxidant Properties of Cellulose-Based Films for Packaging. ACS Appl. Nano Mater. 2024, 7, 1456–1470. [Google Scholar] [CrossRef]

- Bharath, H.S.; Bonthu, D.; Prabhakar, P.; Doddamani, M. 3D Printed Lightweight Composite Foams. arXiv 2020, arXiv:2004.12471. [Google Scholar] [CrossRef]

- Promhuad, K.; Srisa, A.; San, H.; Laorenza, Y.; Wongphan, P.; Sodsai, J.; Tansin, K.; Phromphen, P.; Chartvivatpornchai, N.; Ngoenchai, P.; et al. Applications of Hemp Polymers and Extracts in Food, Textile and Packaging: A Review. Polymers 2022, 14, 4274. [Google Scholar] [CrossRef]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a Circular Economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef]

- He, H.; Zhang, R.; Zhang, P.; Wang, P.; Chen, N.; Qian, B.; Zhang, L.; Yu, J.; Dai, B. Functional Carbon from Nature: Biomass-Derived Carbon Materials and the Recent Progress of Their Applications. Adv. Sci. 2023, 10, 2205557. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Lipka, S.M.; Swartz, C.; Williams, D.; Yang, F. Hemp-Derived Activated Carbons for Supercapacitors. Carbon. N. Y. 2016, 103, 181–192. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, R.; Li, M.; Zhao, Z. Hydrothermal Preparation of Highly Porous Carbon Spheres from Hemp (Cannabis sativa L.) Stem Hemicellulose for Use in Energy-Related Applications. Ind. Crops Prod. 2015, 65, 216–226. [Google Scholar] [CrossRef]

- Gunasekaran, S.S.; Badhulika, S. High-Performance Solid-State Supercapacitor Based on Sustainable Synthesis of Meso-Macro Porous Carbon Derived from Hemp Fibres via CO2 Activation. J. Energy Storage 2021, 41, 102997. [Google Scholar] [CrossRef]

- Wang, P.; Gong, Z.; Ye, K.; Gao, Y.; Zhu, K.; Yan, J.; Wang, G.; Cao, D. N-Rich Biomass Carbon Derived from Hemp as a Full Carbon-Based Potassium Ion Hybrid Capacitor Anode. Appl. Surf. Sci. 2021, 553, 149569. [Google Scholar] [CrossRef]

- Guan, Z.; Guan, Z.; Li, Z.; Liu, J.; Yu, K. Characterization and Preparation of Nano-Porous Carbon Derived from Hemp Stems as Anode for Lithium-Ion Batteries. Nanoscale Res. Lett. 2019, 14, 338. [Google Scholar] [CrossRef]

- Antorán, D.; Alvira, D.; Peker, M.E.; Malón, H.; Irusta, S.; Sebastián, V.; Manyà, J.J. Waste Hemp Hurd as a Sustainable Precursor for Affordable and High-Rate Hard Carbon-Based Anodes in Sodium-Ion Batteries. Energy Fuels 2023, 37, 9650–9661. [Google Scholar] [CrossRef]

- Morin-Crini, N.; Loiacono, S.; Placet, V.; Torri, G.; Bradu, C.; Kostić, M.; Cosentino, C.; Chanet, G.; Martel, B.; Lichtfouse, E.; et al. Hemp-Based Adsorbents for Sequestration of Metals: A Review. Environ. Chem. Lett. 2019, 17, 393–408. [Google Scholar] [CrossRef]

- Dizbay-Onat, M.; Vaidya, U.K.; Balanay, J.A.G.; Lungu, C.T. Preparation and Characterization of Flax, Hemp and Sisal Fiber-Derived Mesoporous Activated Carbon Adsorbents. Adsorpt. Sci. Technol. 2018, 36, 441–457. [Google Scholar] [CrossRef]

- Tang, C.; Ni, Z.; Xu, C.; Luo, Y.; Cai, X.; Gao, Q.; Fang, Y.; Zhong, G.; Qiu, R.; Zhang, S. Enhanced Adsorption of Organic Pollutants Using N-Doped Porous Carbon Derived from Hemp Stems: Insights into the Mechanism. Sep. Purif. Technol. 2024, 333, 125878. [Google Scholar] [CrossRef]

- Sieracka, D.; Frankowski, J.; Wacławek, S.; Czekała, W. Hemp Biomass as a Raw Material for Sustainable Development. Appl. Sci. 2023, 13, 9733. [Google Scholar] [CrossRef]

- Brar, K.K.; Raheja, Y.; Chadha, B.S.; Magdouli, S.; Brar, S.K.; Yang, Y.H.; Bhatia, S.K.; Koubaa, A. A Paradigm Shift towards Production of Sustainable Bioenergy and Advanced Products from Cannabis/Hemp Biomass in Canada. Biomass Convers. Biorefinery 2022, 14, 1. [Google Scholar] [CrossRef]

- Cabral, E.M.; Zhu, X.; Garcia-Vaquero, M.; Pérez-Vila, S.; Tang, J.; Gómez-Mascaraque, L.G.; Poojary, M.M.; Curtin, J.; Tiwari, B.K. Recovery of Protein from Industrial Hemp Waste (Cannabis sativa L.) Using High-Pressure Processing and Ultrasound Technologies. Foods 2023, 12, 2883. [Google Scholar] [CrossRef]

- Donati, L.; Casagrande Pierantoni, D.; Conti, A.; Calzoni, E.; Corte, L.; Santi, C.; Rosati, O.; Cardinali, G.; Emiliani, C. Water Extracts from Industrial Hemp Waste Inhibit the Adhesion and Development of Candida Biofilm and Showed Antioxidant Activity on HT-29 Colon Cancer Cells. Int. J. Mol. Sci. 2024, 25, 3979. [Google Scholar] [CrossRef] [PubMed]

- Tutek, K.; Masek, A. Hemp and Its Derivatives as a Universal Industrial Raw Material (with Particular Emphasis on the Polymer Industry)—A Review. Materials 2022, 15, 2565. [Google Scholar] [CrossRef]

- Yusuf, S.B.; Maughan, M.R.; McDonald, A.G. Carbonized Hemp Fiber for Use in Composites. Materials 2025, 18, 2509. [Google Scholar] [CrossRef]

- da Silveira, P.H.P.M.; dos Santos, M.C.C.; Chaves, Y.S.; Ribeiro, M.P.; Marchi, B.Z.; Monteiro, S.N.; Gomes, A.V.; Tapanes, N.d.L.C.O.; Pereira, P.S.d.C.; Bastos, D.C. Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content. Polymer 2023, 15, 3271. [Google Scholar] [CrossRef]

- Siddiqui, V.U.; Lahmdi, F.S.H.; Sapuan, S.M.; Azka, M.A.; Khan, A.; Yusuf, J.; Hasan, M.Z.; Habib, A.; Firdaus, A.H.M. Characterization of Mechanical, Thermal, and Morphological Properties for Long Hemp Fiber-Reinforced Green Epoxy Biocomposites. Polym. Compos. 2025, 46, 10128–10137. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymer 2021, 13, 3514. [Google Scholar] [CrossRef] [PubMed]

- Pulleti, S.S.; Singh, S.B. Development and Characterization of Hemp/Carbon and Hemp/Glass Hybrid and Novel Functionally Graded Hybrid Composites for Structural Applications. Polym. Compos. 2024, 45, 11178–11199. [Google Scholar] [CrossRef]

- Huzaifa, M.; Zahoor, S.; Akhtar, N.; Abdullah, M.H.; Sajjad, H.; Salah Uddin, K.; Kamran, A. Exploring Mechanical Properties of Eco-Friendly Hybrid Epoxy Composites Reinforced with Sisal, Hemp, and Glass Fibers. J. Mater. Res. Technol. 2024, 33, 2785–2793. [Google Scholar] [CrossRef]

- Chandgude, S.; Salunkhe, S. In State of Art: Mechanical Behavior of Natural Fiber-Based Hybrid Polymeric Composites for Application of Automobile Components. Polym. Compos. 2021, 42, 2678–2703. [Google Scholar] [CrossRef]

- Rajput, S.; Tyagi, V.; Sonika, T.; Nayak, R.; Verma, S.K. Waste-Derived Activated Carbon for Supercapacitors: Current Trends and Future Prospects. Energy Technol. 2025, 13, 2401977. [Google Scholar] [CrossRef]

- Klangvijit, K.; Bowornthommatadsana, K.; Phonyiem Reilly, M.; Uwanno, T.; Yordsri, V.; Obata, M.; Fujishige, M.; Takeuchi, K.; Wongwiriyapan, W. Optimizing Electrochemical Performance: A Study of Aqueous Electrolytes with Hemp-Derived Activated Carbon for Supercapacitors. ACS Omega 2025, 10, 6601–6614. [Google Scholar] [CrossRef]

- Liao, Q.; Wan, S.; Liu, Y.; Niu, X.; Zhang, D.; Li, H.; Wang, K. Hemp-Derived Hierarchically Porous Carbon Cathode Enabling High Energy Storage for Advanced Zinc-Ion Hybrid Capacitor. J. Energy Storage 2025, 115, 115975. [Google Scholar] [CrossRef]

- Tekin, B.; Topcu, Y. Novel Hemp Biomass-Derived Activated Carbon as Cathode Material for Aqueous Zinc-Ion Hybrid Supercapacitors: Synthesis, Characterization, and Electrochemical Performance. J. Energy Storage 2024, 77, 109879. [Google Scholar] [CrossRef]

- Aruchamy, K.; Dharmalingam, K.; Lee, C.W.; Mondal, D.; Sanna Kotrappanavar, N. Creating Ultrahigh Surface Area Functional Carbon from Biomass for High Performance Supercapacitor and Facile Removal of Emerging Pollutants. Chem. Eng. J. 2022, 427, 131477. [Google Scholar] [CrossRef]

- Arumugam, B.; Mayakrishnan, G.; Subburayan Manickavasagam, S.K.; Kim, S.C.; Vanaraj, R. An Overview of Active Electrode Materials for the Efficient High-Performance Supercapacitor Application. Crystals 2023, 13, 1118. [Google Scholar] [CrossRef]

- Crawford, M. Hemp Carbon Makes Supercapacitors Superfast. Available online: https://www.asme.org/topics-resources/content/hemp-carbon-makes-supercapacitors-superfast (accessed on 20 July 2025).

- Sert, S.; Gültekin, Ş.S.; Kaya, D.D.; Körlü, A. Development of Activated Carbon from Hemp Hurd for EMI Shielding and Supercapacitors via One-Step Microwave Pyrolysis without Inert Gas. Biomass Convers. Biorefinery 2025, 15, 16087–16106. [Google Scholar] [CrossRef]

- Minakshi, M.; Mujeeb, A.; Whale, J.; Evans, R.; Aughterson, R.; Shinde, P.A.; Ariga, K.; Shrestha, L.K. Synthesis of Porous Carbon Honeycomb Structures Derived from Hemp for Hybrid Supercapacitors with Improved Electrochemistry. Chempluschem 2024, 89, e202400408. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I. Hemp Fibres: Essentials, Composites or Nanocomposites and Technical Applications. Nano-Horiz. J. Nanosci. Nanotechnol. 2023, 2, 13835. [Google Scholar] [CrossRef] [PubMed]

- Echeverria Molina, M.I.; Malollari, K.G.; Komvopoulos, K. Design Challenges in Polymeric Scaffolds for Tissue Engineering. Front. Bioeng. Biotechnol. 2021, 9, 617141. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, F.; Mushtaq, B.; Ahmad, S.; Rasheed, A.; Nawab, Y. A Novel Composite of Hemp Fiber and Alginate Hydrogel for Wound Dressings. J. Polym. Environ. 2023, 31, 2294–2305. [Google Scholar] [CrossRef]

- David, C.; de Souza, J.F.; Silva, A.F.; Grazioli, G.; Barboza, A.S.; Lund, R.G.; Fajardo, A.R.; Moraes, R.R. Cannabidiol-Loaded Microparticles Embedded in a Porous Hydrogel Matrix for Biomedical Applications. J. Mater. Sci. Mater. Med. 2024, 35, 1–16. [Google Scholar] [CrossRef]

- Zimniewska, M.; Pawlaczyk, M.; Romanowska, B.; Gryszczyńska, A.; Kwiatkowska, E.; Przybylska, P. Bioactive Hemp Clothing Modified with Cannabidiol (CBD) Cannabis sativa L. Extract. Materials 2021, 14, 6031. [Google Scholar] [CrossRef]

- Grifoni, L.; Vanti, G.; Donato, R.; Sacco, C.; Bilia, A.R. Promising Nanocarriers to Enhance Solubility and Bioavailability of Cannabidiol for a Plethora of Therapeutic Opportunities. Molecules 2022, 27, 6070. [Google Scholar] [CrossRef]

- Solano-Orrala, D.; Silva-Cullishpuma, D.A.; Díaz-Cruces, E.; Gómez-López, V.M.; Toro-Mendoza, J.; Gomez d’Ayala, G.; Troconis, J.; Narváez-Muñoz, C.; Alexis, F.; Mercader-Ros, M.T.; et al. Exploring the Potential of Nonpsychoactive Cannabinoids in the Development of Materials for Biomedical and Sports Applications. ACS Appl. Bio Mater. 2024, 7, 8177–8202. [Google Scholar] [CrossRef] [PubMed]

- Monou, P.K.; Mamaligka, A.M.; Tzimtzimis, E.K.; Tzetzis, D.; Vergkizi-Nikolakaki, S.; Vizirianakis, I.S.; Andriotis, E.G.; Eleftheriadis, G.K.; Fatouros, D.G. Fabrication and Preliminary In Vitro Evaluation of 3D-Printed Alginate Films with Cannabidiol (CBD) and Cannabigerol (CBG) Nanoparticles for Potential Wound-Healing Applications. Pharmaceutics 2022, 14, 1637. [Google Scholar] [CrossRef]

- Tongco, J.V. Physicochemical Properties of Delignified Hemp Fiber Cellulose Acetate (HFCA). Arab. J. Chem. Environ. Res. 2024, 11, 71–83. [Google Scholar]

- Chaudhary, B.; Winnard, T.; Oladipo, B.; Das, S.; Matos, H. Review of Fiber-Reinforced Composite Structures with Multifunctional Capabilities through Smart Textiles. Textiles 2024, 4, 391–416. [Google Scholar] [CrossRef]

- Fang, L.; Zhou, Y.; Huang, Q. Ionic Conductive Textiles for Wearable Technology. Adv. Mater. 2025, 13, 2502140. [Google Scholar] [CrossRef]

- Azhan, M.; Jabar, S.; Alam, M.A.; Khan, R.A. Sustainable Innovations: A Review of Bio-Based Materials and Bioplastics. In Proceedings of the 3rd International Conference on Advances in Concrete, Structural, and Geotechnical Engineering, Pilani, India, 2 July 2025; Springer: Singapore, 2025; Volume 1, pp. 223–257. [Google Scholar]

- Coppola, G.; Gaudio, M.T.; Lopresto, C.G.; Calabro, V.; Curcio, S.; Chakraborty, S. Bioplastic from Renewable Biomass: A Facile Solution for a Greener Environment. Earth Syst. Environ. 2021, 5, 231–251. [Google Scholar] [CrossRef]

- Stevulova, N.; Kidalova, L.; Junak, J.; Cigasova, J.; Terpakova, E. Effect of Hemp Shive Sizes on Mechanical Properties of Lightweight Fibrous Composites. Procedia Eng. 2012, 42, 496–500. [Google Scholar] [CrossRef]

- Hussain, A.; Calabria-Holley, J.; Lawrence, M.; Ansell, M.P.; Jiang, Y.; Schorr, D.; Blanchet, P. Development of Novel Building Composites Based on Hemp and Multi-Functional Silica Matrix. Compos. B Eng. 2019, 156, 266–273. [Google Scholar] [CrossRef]

- Islam, M.Z.; Sarker, M.E.; Rahman, M.M.; Islam, M.R.; Ahmed, A.T.M.F.; Mahmud, M.S.; Syduzzaman, M. Green Composites from Natural Fibers and Biopolymers: A Review on Processing, Properties, and Applications. J. Reinf. Plast. Compos. 2022, 41, 526–557. [Google Scholar] [CrossRef]

- Chatterjee, K.; Tabor, J.; Ghosh, T.K. Electrically Conductive Coatings for Fiber-Based E-Textiles. Fibers 2019, 7, 51. [Google Scholar] [CrossRef]

- Siddika, A.; Harmon, J. Reduced Graphene Oxide Coated Conductive Hemp Yarn for Wearable Electronic Textiles. In Proceedings of the International Textile and Apparel Association Annual Conference Proceedings, Cleveland, OH, USA, 31 December 2022; Iowa State University Digital Press: Ames, IA, USA, 2022; Volume 79. [Google Scholar]

- Tseghai, G.B.; Malengier, B.; Fante, K.A.; Nigusse, A.B.; Van Langenhove, L. Integration of Conductive Materials with Textile Structures, an Overview. Sensors 2020, 20, 6910. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Dong, K.; Wu, Z.; Wang, J.; Wang, Z.L. A Review on Emerging Biodegradable Polymers for Environmentally Benign Transient Electronic Skins. J. Mater. Sci. 2021, 56, 16765–16789. [Google Scholar] [CrossRef]

- Shin, J.W.; Chan Choe, J.; Lee, J.H.; Han, W.B.; Jang, T.M.; Ko, G.J.; Yang, S.M.; Kim, Y.G.; Joo, J.; Lim, B.H.; et al. Biologically Safe, Degradable Self-Destruction System for On-Demand, Programmable Transient Electronics. ACS Nano 2021, 15, 19310–19320. [Google Scholar] [CrossRef] [PubMed]

- Han, W.B.; Lee, H.; Shin, J.-W.; Hwang, S.-W.; Han, W.B.; Lee, J.H.; Shin, J.-W.; Hwang, S.-W. Advanced Materials and Systems for Biodegradable, Transient Electronics. Adv. Mater. 2020, 32, 2002211. [Google Scholar] [CrossRef]

- Jamshidi, R.; Taghavimehr, M.; Chen, Y.; Hashemi, N.; Montazami, R. Transient Electronics as Sustainable Systems: From Fundamentals to Applications. Adv. Sustain. Syst. 2022, 6, 2100057. [Google Scholar] [CrossRef]

- Kasuga, T.; Mizui, A.; Koga, H.; Nogi, M. Wirelessly Powered Sensing Fertilizer for Precision and Sustainable Agriculture. Adv. Sustain. Syst. 2024, 8, 2300314. [Google Scholar] [CrossRef]

- Sultan, R.; Skrifvars, M.; Khalili, P. 3D Printing of Polypropylene Reinforced with Hemp Fibers: Mechanical, Water Absorption and Morphological Properties. Heliyon 2024, 10, e26617. [Google Scholar] [CrossRef]

- Ceylan, İ.; Çakıcı Alp, N.; Aytaç, A. Sustainable 3D Printing with Alkali-Treated Hemp Fiber-Reinforced Polycarbonate Composites. Cellulose 2024, 31, 4477–4495. [Google Scholar] [CrossRef]

| Insulation Material | Thermal Conductivity (w/m·K) | Density (Kg/m3) | Specific Heat Capacity (KJ/Kg·K) | Thermal Resistance (m2·K/W) | Reference(s) |

|---|---|---|---|---|---|

| Aerogel | 0.01–0.02 | 70–150 | 1.05 | 1.8 | [94] |

| Phase change materials | 0.1–0.54 | 530–830 | 1.9–2.22 | - | [99] |

| Vacuum insulation panels | 0.02–0.008 | 150–300 | 0.8 | 4.4 | [92] |

| Gas-filled panels | 0.1–0.035 | 32–38 | - | 0.9–1.9 | [100] |

| Hemp hurd | 0.064–0.094 | 97–118.8 | 1.24–1.27 | 0.6 | [98,99,101] |

| Phenolic foam | 0.018–0.024 | 40–160 | 1.30–1.40 | 1.2–1.3 | [102,103,104] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yusuf, S.B.; Ewurum, N.; Appiah, H.; Tongco, J.V. Industrial Hemp as Precursor for Sustainable Bioproducts: Recent Trends and Prospects. Fibers 2025, 13, 155. https://doi.org/10.3390/fib13110155

Yusuf SB, Ewurum N, Appiah H, Tongco JV. Industrial Hemp as Precursor for Sustainable Bioproducts: Recent Trends and Prospects. Fibers. 2025; 13(11):155. https://doi.org/10.3390/fib13110155

Chicago/Turabian StyleYusuf, Sodiq Babatunde, Nnaemeka Ewurum, Harrison Appiah, and Jovale Vincent Tongco. 2025. "Industrial Hemp as Precursor for Sustainable Bioproducts: Recent Trends and Prospects" Fibers 13, no. 11: 155. https://doi.org/10.3390/fib13110155

APA StyleYusuf, S. B., Ewurum, N., Appiah, H., & Tongco, J. V. (2025). Industrial Hemp as Precursor for Sustainable Bioproducts: Recent Trends and Prospects. Fibers, 13(11), 155. https://doi.org/10.3390/fib13110155