Mechanical Performances of Natural Textiles for Eco-Friendly Composite Materials: A Comparative Assessment

Highlights

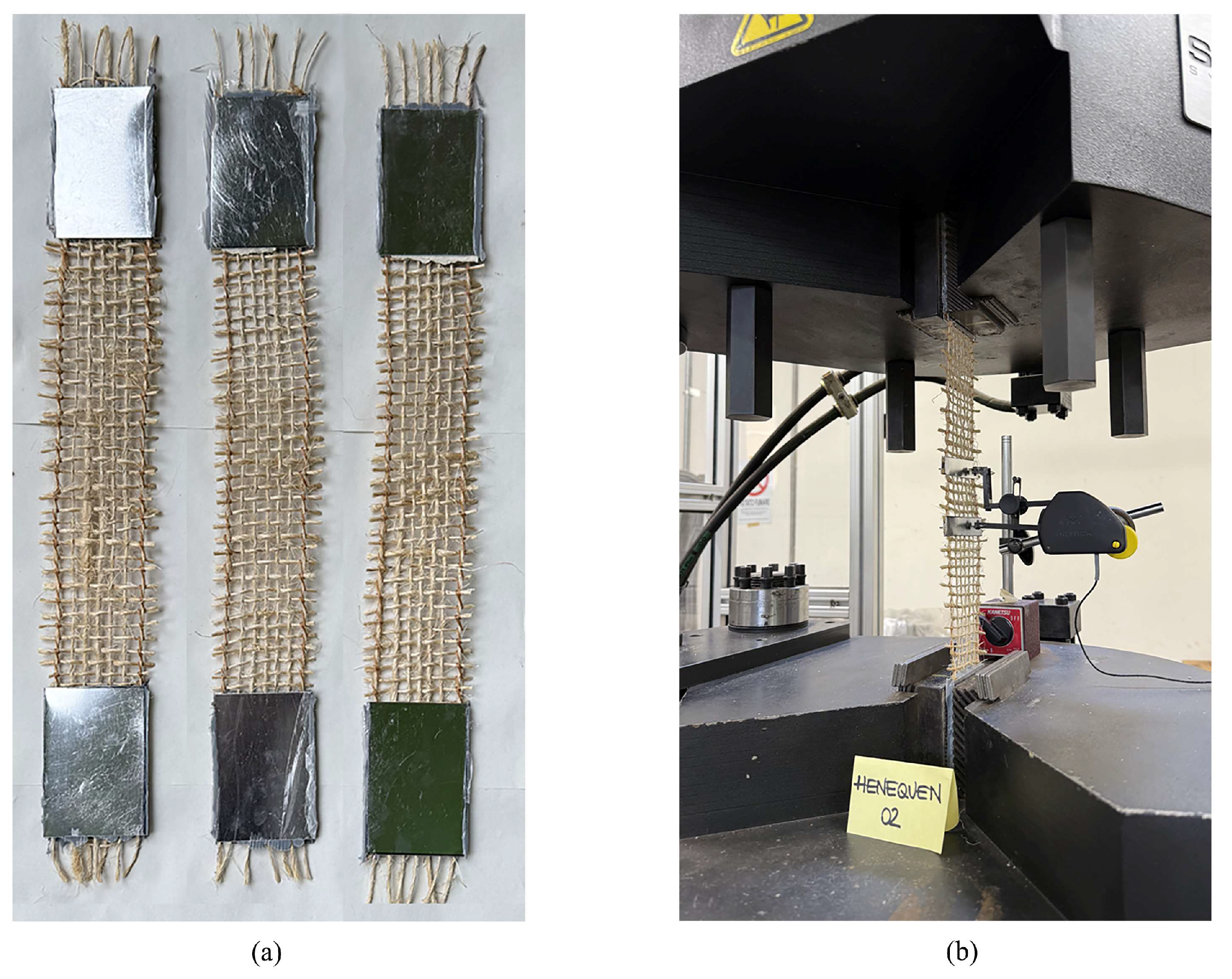

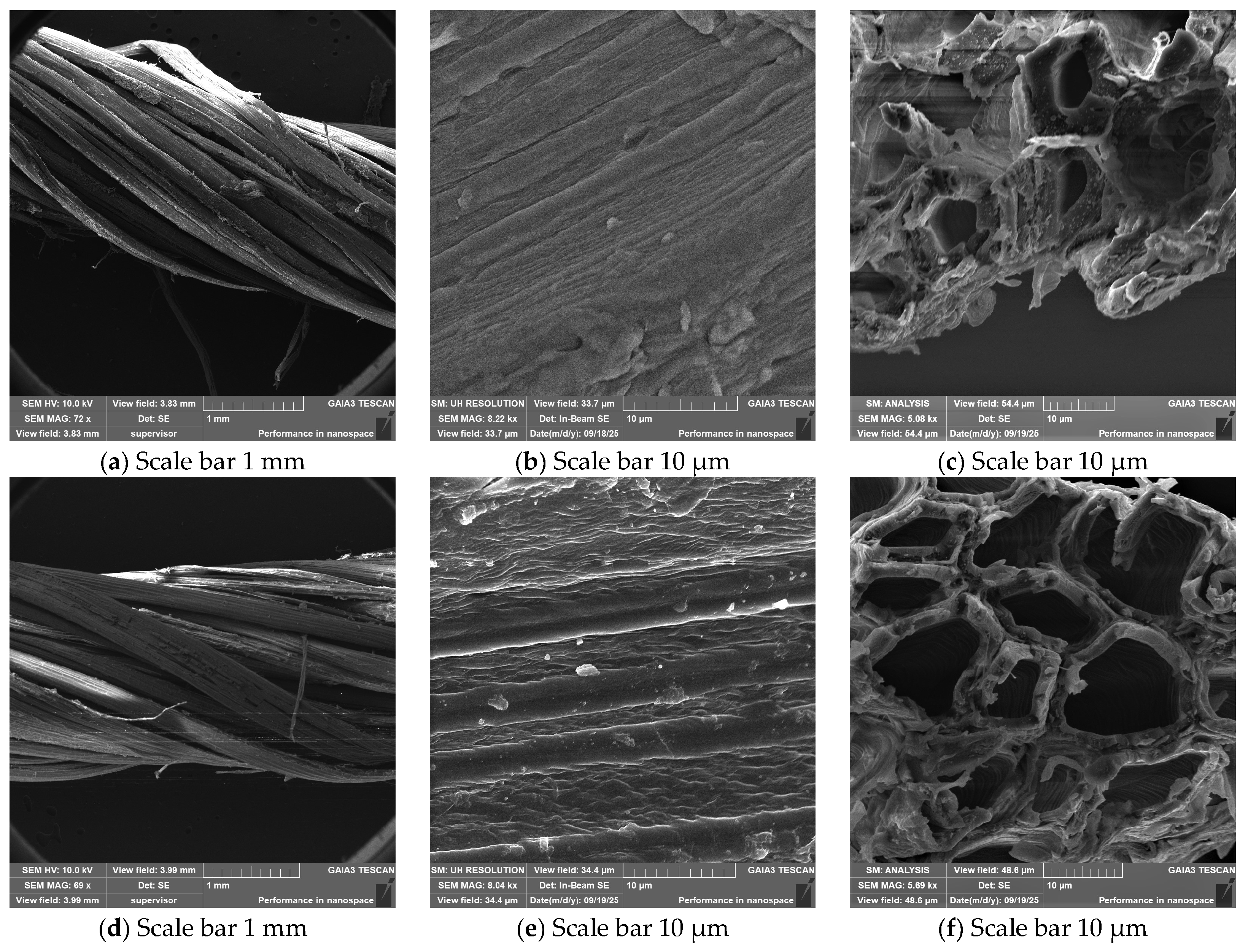

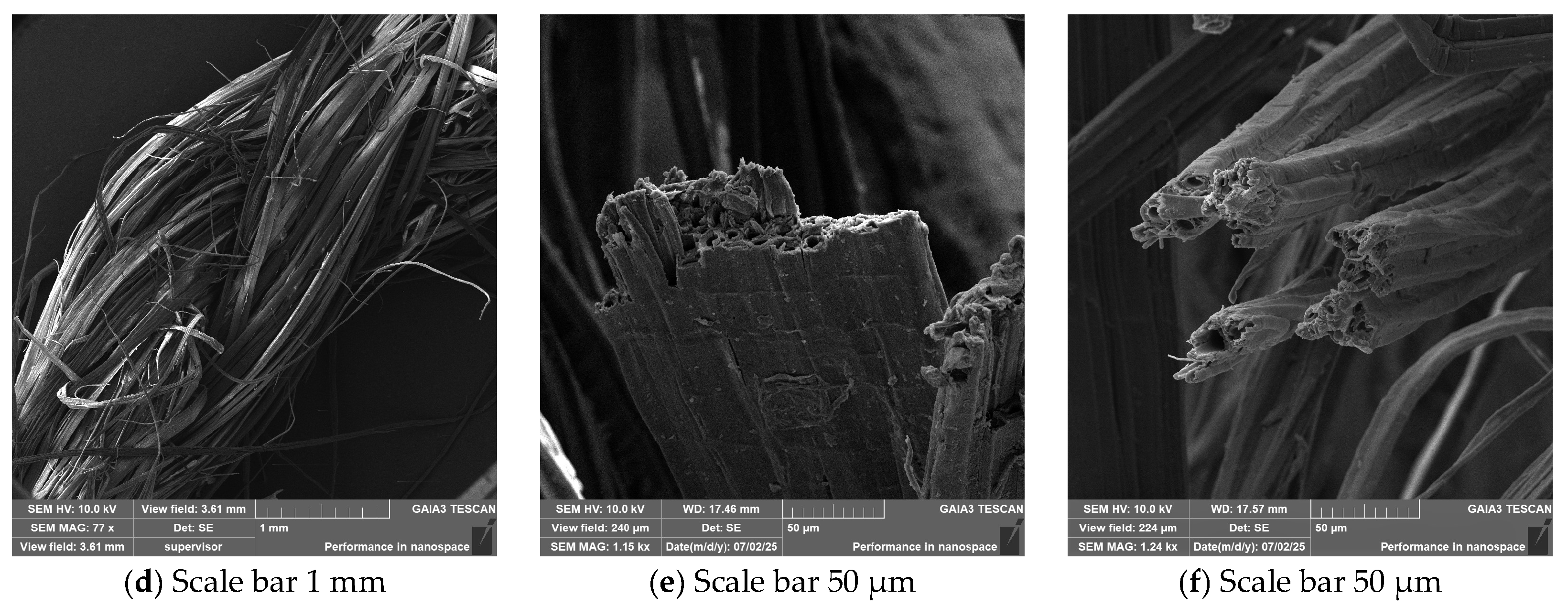

- The mechanical properties of ten different natural textiles were compared after an all-natural protective treatment referred to as “hornification” process.

- Hornification-induced changes in the fiber morphology were found by using a Scanning Electron Microscope (SEM).

- After 1 to 5 hornification cycles, some fibers like banana, henequen, coir and sisal increased their strength.

- The results of this study represent a promising starting point for future evaluations regarding the integration of natural fibers in innovative and fully sustainable composite materials.

Abstract

1. Introduction

2. Materials and Methods

2.1. Hornification Process

2.2. Tensile Tests

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J.A. Fiber-Reinforced Polymer Composites in Strengthening Reinforced Concrete Structures: A Critical Review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Khodadadi, N.; Roghani, H.; Harati, E.; Mirdarsoltany, M.; De Caso, F.; Nanni, A. Fiber-Reinforced Polymer (FRP) in Concrete: A Comprehensive Survey. Constr. Build. Mater. 2024, 432, 136634. [Google Scholar] [CrossRef]

- Minafò, G.; Cucchiara, C.; Monaco, A.; La Mendola, L. Effect of FRP Strengthening on the Flexural Behaviour of Calcarenite Masonry Walls. Bull. Earthq. Eng. 2017, 15, 3777–3795. [Google Scholar] [CrossRef]

- Sandoli, A.; Ferracuti, B.; Calderoni, B. FRP-confined tuff masonry columns: Regular and irregular stone arrangement. Compos. Part B Eng. 2019, 162, 621–630. [Google Scholar] [CrossRef]

- Alecci, V.; Galassi, S.; Mistretta, F.; Stipo, G.; De Stefano, M. Stability Assessment of Masonry Arches Reinforced with Fiber-Reinforced Composite Materials Under Large Deformation. Lect. Notes Civ. Eng. 2024, 437, 737–746. [Google Scholar] [CrossRef]

- Di Tommaso, A.; Focacci, F.; Micelli, F. Strengthening Historical Masonry with FRP or FRCM: Trends in Design Approach. In Key Engineering Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2017; Volume 747 KEM, pp. 166–173. [Google Scholar]

- Bertolesi, E.; Torres, B.; Adam, J.M.; Calderón, P.A.; Moragues, J.J. Effectiveness of Textile Reinforced Mortar (TRM) Materials for the Repair of Full-Scale Timbrel Masonry Cross Vaults. Eng. Struct. 2020, 220, 110978. [Google Scholar] [CrossRef]

- Kariou, F.; Triantafyllou, S.; Bournas, D. TRM strengthening of masonry arches: An experimental investigation on the effect of strengthening layout and textile fibre material. Compos. Part B Eng. 2019, 173, 106765. [Google Scholar] [CrossRef]

- Zampieri, P.; Gonzalez-Libreros, J.; Simoncello, N.; Pellegrino, C. Strengthening of Masonry Arches with FRCM Composites: A Review. Key Eng. Mater. 2019, 817, 251–258. [Google Scholar] [CrossRef]

- Alecci, V.; De Stefano, M.; Galassi, S.; Luciano, R.; Pugliese, D.; Stipo, G. Influence of Different Mortar Matrices on the Effectiveness of FRCM Composites for Confining Masonry Columns. J. Test. Eval. 2023, 51, 735–750. [Google Scholar] [CrossRef]

- Alecci, V.; De Stefano, M.; Galassi, S.; Magos, R.; Stipo, G. Confinement of Masonry Columns with Natural Lime-Based Mortar Composite: An Experimental Investigation. Sustainability 2021, 13, 13742. [Google Scholar] [CrossRef]

- Ferretti, F.; Khatiwada, S.; Incerti, A.; Giacomin, G.; Tomaro, F.; De Martino, V.; Mazzotti, C. Structural Strengthening of Masonry Elements by Reinforced Repointing Combined with FRCM and CRM. Procedia Struct. Integr. 2023, 44, 2254–2261. [Google Scholar] [CrossRef]

- Alecci, V.; Fagone, M.; Galassi, S.; Rotunno, T.; Stipo, G.; De Stefano, M. Experimental Shear Behaviour of Masonry Walls Reinforced with FRCM. Eng. Struct. 2024, 315, 118425. [Google Scholar] [CrossRef]

- Santandrea, M.; Daissè, G.; Mazzotti, C.; Carloni, C. An Investigation of the Debonding Mechanism between FRCM Composites and a Masonry Substrate. Key Eng. Mater. 2017, 747, 382–389. [Google Scholar] [CrossRef]

- D’Antino, T.; Carloni, C.; Sneed, L.H.; Pellegrino, C. Matrix-Fiber Bond Behavior in PBO FRCM Composites: A Fracture Mechanics Approach. Eng. Fract. Mech. 2014, 117, 94–111. [Google Scholar] [CrossRef]

- Dalalbashi, A.; Ghiassi, B.; Oliveira, D.; Freitas, A. Effect of test setup on the fiber-to-mortar pull-out response in TRM composites: Experimental and analytical modeling. Compos. Part B 2018, 143, 250–268. [Google Scholar] [CrossRef]

- Calabrese, A.S.; D’Antino, T.; Colombi, P. Experimental and Analytical Investigation of PBO FRCM-Concrete Bond Behavior Using Direct and Indirect Shear Test Set-Ups. Compos. Struct. 2021, 267, 113672. [Google Scholar] [CrossRef]

- De Santis, S.; Carozzi, F.; de Felice, G.; Poggi, C. Test methods for Textile Reinforced Mortar systems. Compos. Part B 2017, 127, 121–132. [Google Scholar] [CrossRef]

- Kumar, S.; Manna, A.; Dang, R. A Review on Applications of Natural Fiber-Reinforced Composites (NFRCs). In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 50, pp. 1632–1636. [Google Scholar]

- Codispoti, R.; Oliveira, D.V.; Olivito, R.S.; Lourenço, P.B.; Fangueiro, R. Mechanical Performance of Natural Fiber-Reinforced Composites for the Strengthening of Masonry. Compos. B Eng. 2015, 77, 74–83. [Google Scholar] [CrossRef]

- Mercedes, L.; Gil, L.; Bernat-Maso, E. Mechanical Performance of Vegetal Fabric Reinforced Cementitious Matrix (FRCM) Composites. Constr. Build. Mater. 2018, 175, 161–173. [Google Scholar] [CrossRef]

- Asprone, D.; Durante, M.; Prota, A.; Manfredi, G. Potential of Structural Pozzolanic Matrix-Hemp Fiber Grid Composites. Constr. Build. Mater. 2011, 25, 2867–2874. [Google Scholar] [CrossRef]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Tolêdo Filho, R.D. Tensile Behavior of Flax Textile Reinforced Lime-Mortar: Influence of Reinforcement Amount and Textile Impregnation. Cem. Concr. Compos. 2021, 119, 103984. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Toledo Filho, R.D.; de Silva, F.A.; Mechtcherine, V.; Butler, M.; Hempel, S. The Effect of Accelerated Aging on the Interface of Jute Textile Reinforced Concrete. Cem. Concr. Compos. 2016, 74, 7–15. [Google Scholar] [CrossRef]

- Lima, P.R.L.; Santos, M.; Camilloto, P.; Souza Cruz, R. Effect of Surface Biopolymeric Treatment on Sisal Fiber Properties and Fiber-Cement Bond. J. Eng. Fibers Fabr. 2017, 12, 155892501701200207. [Google Scholar] [CrossRef]

- Abdollahiparsa, H.; Shahmirzaloo, A.; Teuffel, P.; Blok, R. A Review of Recent Developments in Structural Applications of Natural Fiber-Reinforced Composites (NFRCs). Compos. Adv. Mater. 2023, 32, 263498332211475. [Google Scholar] [CrossRef]

- Laverde, V.; Marin, A.; Benjumea, J.M.; Rincón Ortiz, M. Use of Vegetable Fibers as Reinforcements in Cement-Matrix Composite Materials: A Review. Constr. Build. Mater. 2022, 340, 127729. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Silva, F.D.A.; Lima, P.R.L.; Toledo Filho, R.D. Effect of Fiber Treatments on the Sisal Fiber Properties and Fiber-Matrix Bond in Cement Based Systems. Constr. Build. Mater. 2015, 101, 730–740. [Google Scholar] [CrossRef]

- Zugenmaier, P. Crystalline Cellulose and Derivatives: Characterization and Structures. In Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Mai, Y.W.; Hakeem, M.I.; Cotterell, B. Effects of Water and Bleaching on the Mechanical Properties of Cellulose Fibre Cements. J. Mater. Sci. 1983, 18, 2156–2162. [Google Scholar] [CrossRef]

- Coutts, R.S.P. Flax Fibres as a Reinforcement in Cement Mortars. Int. J. Cem. Compos. Lightweight Concr. 1983, 5, 257–262. [Google Scholar] [CrossRef]

- Rocha Ferreira, S.; Rodrigues Sena Neto, A.; de Andrade Silva, F.; Gomes de Souza, F.; Dias Toledo Filho, R. The Influence of Carboxylated Styrene Butadiene Rubber Coating on the Mechanical Performance of Vegetable Fibers and on Their Interface with a Cement Matrix. Constr. Build. Mater. 2020, 262, 120770. [Google Scholar] [CrossRef]

- Abbass, A.; Oliveira, D.V.; Lourenço, P.B.; Paiva, M.C. Multi-Scale Experimental Investigation on the Structural Behaviour of Novel Nanocomposite/Natural Textile-Reinforced Mortars. Constr. Build. Mater. 2024, 444, 137798. [Google Scholar] [CrossRef]

- Abbass, A.; Paiva, M.C.; Oliveira, D.V.; Lourenço, P.B.; Fangueiro, R. Graphene/Polyurethane Nanocomposite Coatings—Enhancing the Mechanical Properties and Environmental Resistance of Natural Fibers for Masonry Retrofitting. Compos. Part A Appl. Sci. Manuf. 2023, 166, 107379. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Durante, M.; Zinno, A.; Balsamo, A.; Prota, A. Structural Behaviour of Masonry Panels Strengthened with an Innovative Hemp Fibre Composite Grid. Constr. Build. Mater. 2015, 100, 111–121. [Google Scholar] [CrossRef]

- Singh, A.; Yadav, B.P. Sustainable Innovations and Future Prospects in Construction Material: A Review on Natural Fiber-Reinforced Cement Composites. Environ. Sci. Pollut. Res. 2024, 31, 62549–62587. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, S.R.; de Silva, F.A.; Lima, P.R.L.; Toledo Filho, R.D. Effect of Hornification on the Structure, Tensile Behavior and Fiber Matrix Bond of Sisal, Jute and Curauá Fiber Cement Based Composite Systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- de Silva, F.A.; Chawla, N.; Filho, R.D. de T. Tensile Behavior of High Performance Natural (Sisal) Fibers. Compos. Sci. Technol. 2008, 68, 3438–3443. [Google Scholar] [CrossRef]

- Charlet, K.; Baley, C.; Morvan, C.; Jernot, J.P.; Gomina, M.; Bréard, J. Characteristics of Hermès Flax Fibres as a Function of Their Location in the Stem and Properties of the Derived Unidirectional Composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1912–1921. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the Flax Fibres Tensile Behaviour and Analysis of the Tensile Stiffness Increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Kaith, B.S.; Mittal, H.; Jindal, R.; Maiti, M.; Kalia, S. Environment Benevolent Biodegradable Polymers: Synthesis, Biodegradability, and Applications. In Cellulose Fibers: Bio- and Nano-Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2011; pp. 425–451. [Google Scholar]

- Ren, G.; Yao, B.; Ren, M.; Gao, X. Utilization of Natural Sisal Fibers to Manufacture Eco-Friendly Ultra-High Performance Concrete with Low Autogenous Shrinkage. J. Clean. Prod. 2022, 332, 130105. [Google Scholar] [CrossRef]

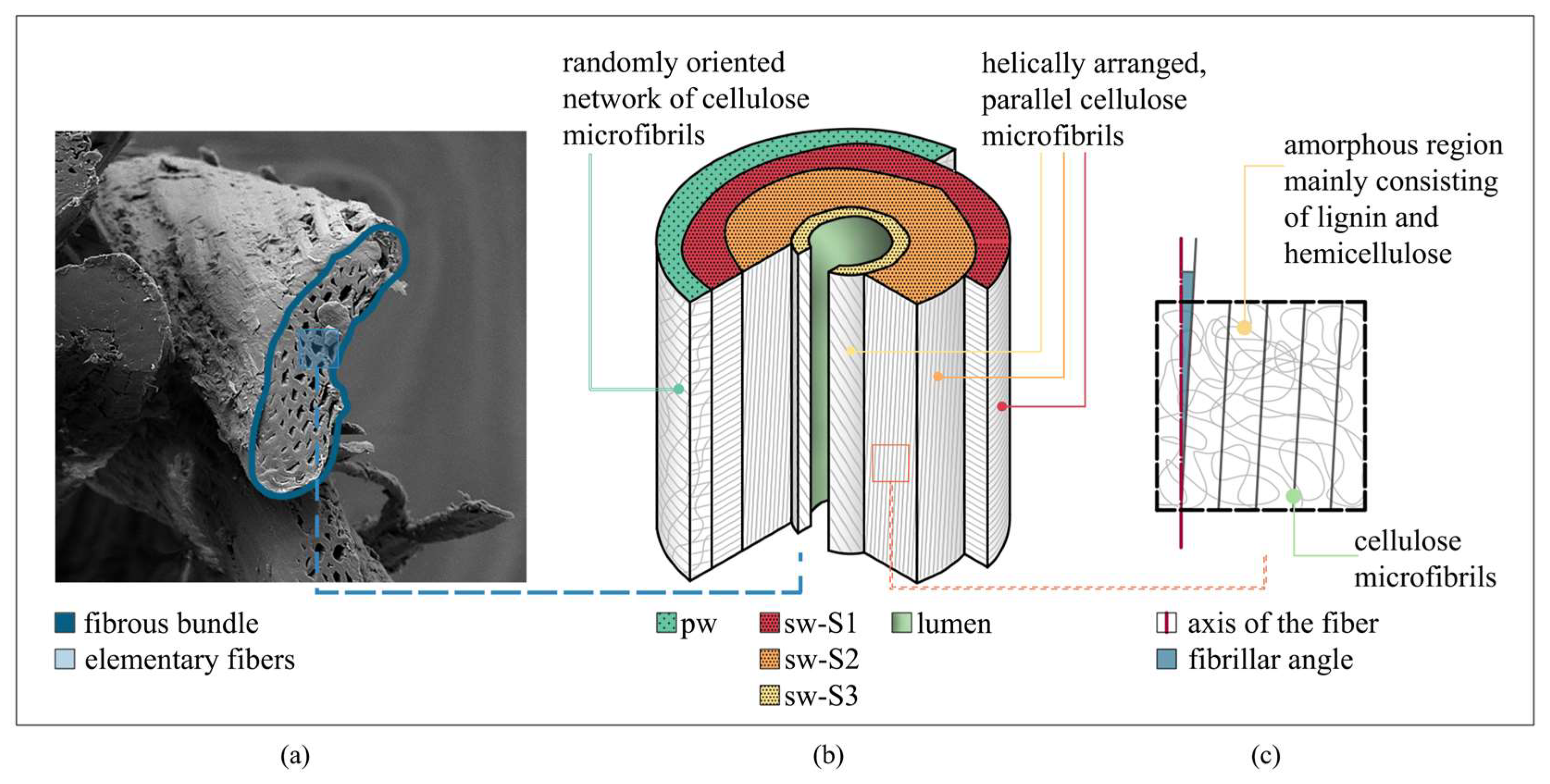

- Alves Fidelis, M.E.; Pereira, T.V.C.; Gomes, O.D.F.M.; De Andrade Silva, F.; Toledo Filho, R.D. The Effect of Fiber Morphology on the Tensile Strength of Natural Fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Lakshmi Narayana, V.; Bhaskara Rao, L. A Brief Review on the Effect of Alkali Treatment on Mechanical Properties of Various Natural Fiber Reinforced Polymer Composites. Mater. Today Proc. 2021, 44, 1988–1994. [Google Scholar] [CrossRef]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic Treatment of Natural Fibers and Their Composites—A Review. J. Ind. Text. 2018, 47, 2153–2183. [Google Scholar] [CrossRef]

- Han, S.O.; Jung, Y.M. Characterization of Henequen Natural Fiber by Using Two-Dimensional Correlation Spectroscopy. J. Mol. Struct. 2008, 883–884, 142–148. [Google Scholar] [CrossRef]

- Kharbanda, S.; Bhadury, T.; Gupta, G.; Fuloria, D.; Pati, P.R.; Mishra, V.K.; Sharma, A. Polymer Composites for Thermal Applications—A Review. Mater. Today Proc. 2021, 47, 2839–2845. [Google Scholar] [CrossRef]

- Majumder, A.; Stochino, F.; Farina, I.; Valdes, M.; Fraternali, F.; Martinelli, E. Physical and Mechanical Characteristics of Raw Jute Fibers, Threads and Diatons. Constr. Build. Mater. 2022, 326, 126903. [Google Scholar] [CrossRef]

- ACI PRC-549.6R-20; Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) and Steel-Reinforced Grout (SRG) Systems for Repair and Strengthening Masonry Structures. ACI Committee 549: Farmington Hills, MI, USA, 2020; ISBN 9781641951203.

- CNR-DT 200R1/2013; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures. National Research Council: Roma, Italy, 2013.

- CNR-DT 215/2018; Guidelines for the Design and Execution of Strengthening of Existing Structures Using FRCM Systems. National Research Council: Roma, Italy, 2018.

- EN ISO 1889:2009; Reinforcement Yarns—Determination of Linear Density. International Organization for Standardization (ISO): Geneva, Switzerland, 2009.

| Fibers | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Microfibrillar/Spiral Angle (Degree) |

|---|---|---|---|---|

| Banana | 64 | 20 | 5 | - |

| Hemp | 70–74.4 | 17.9–22.4 | 3.7–6 | 6.2 |

| Coir | 31–42 | 10–20 | 40–46 | - |

| Cotton | 82.7–95 | 2–5.7 | 0.7–1.6 | - |

| Henequen | 75–77 | 4–8 | 13–14 | - |

| Jute | 61–74.4 | 13.6–20.4 | 12–13 | 8.0 |

| Flax | 70–73 | 18–20.6 | 2–2.2 | 10.0 |

| Ramie | 68–76.2 | 13–16.7 | 0.6–1 | 7.5 |

| Raffia | 53 | 13 | 24 | - |

| Sisal | 60.5–78 | 10–25.7 | 8.0–12.1 | 20 |

| Fibers | Plants | Origin | Diameter (mm) | Weight (g/m) | Density (g/cm3) |

|---|---|---|---|---|---|

| Banana | Musa textilis | India | 1 0.09 (0.092) | 0.67 0.31 (0.467) | 1.35 0.13 (0.096) |

| Hemp | Cannabis sativa | Spain | 2 0.19 (0.094) | 2.30 0.33 (0.142) | 1.32 0.06 (0.049) |

| Coir | Cocos nucifera | Sri Lanka | 3 0.31 (0.101) | 4.17 0.28 (0.068) | 1.2 0.08 (0.067) |

| Cotton | Gossypium | India | 3 0.19 (0.061) | 2.50 0.16 (0.062) | 1.55 0.05 (0.032) |

| Henequen | Agave fourcroydes | Mexico | 2 0.24 (0.121) | 1.38 0.33 (0.237) | 1.45 0.11 (0.079) |

| Jute | Corchorus capsularis | Bangladesh | 3 0.29 (0.099) | 1.67 0.16 (0.098) | 1.37 0.04 (0.029) |

| Flax | Linum usitatissimum | Netherlands | 2 0.34 (0.166) | 0.76 0.08 (0.101) | 1.44 0.07 (0.049) |

| Ramie | Girardina diversifolia | Nepal | 1 0.33 (0.330) | 0.49 0.08 (0.165) | 1.35 0.04 (0.031) |

| Raffia | Raphia farinifera | Madagascar | 2.5 0.19 (0.077) | 0.60 0.09 (0.146) | 0.75 0.02 (0.026) |

| Sisal | Agave sisalana | Brazil | 2.5 0.40 (0.159) | 2.67 0.06 (0.023) | 1.45 0.04 (0.027) |

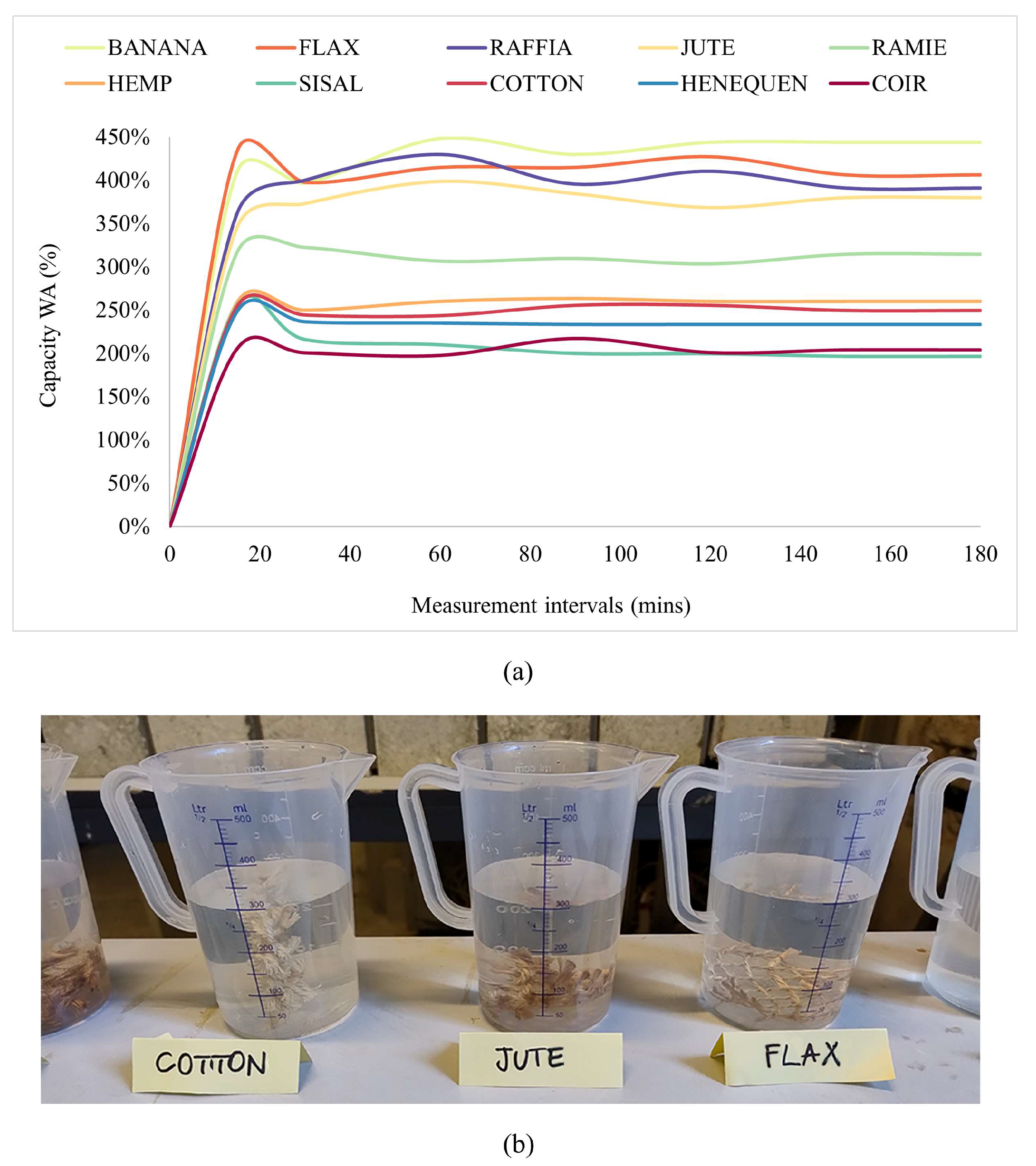

| Fibers | Wdry0 [g] | Wwetmax [g] | Wwet180 [g] | Maximum Absorption Time [min] | Absorption Capacity WA [%] |

|---|---|---|---|---|---|

| Banana | 0.64 | 3.51 | 3.48 | 60 | 448 |

| Hemp | 1.77 | 6.43 | 6.37 | 90 | 263 |

| Coir | 4.23 | 13.41 | 12.85 | 90 | 217 |

| Cotton | 2.51 | 8.92 | 8.77 | 90 | 255 |

| Henequen | 1.92 | 6.7 | 6.4 | 15 | 249 |

| Jute | 2.18 | 10.87 | 10.46 | 60 | 399 |

| Flax | 0.81 | 4.33 | 4.1 | 15 | 435 |

| Ramiè | 0.63 | 2.66 | 2.61 | 30 | 322 |

| Raffia | 0.67 | 3.55 | 3.29 | 60 | 430 |

| Sisal | 3.29 | 11.7 | 9.75 | 15 | 256 |

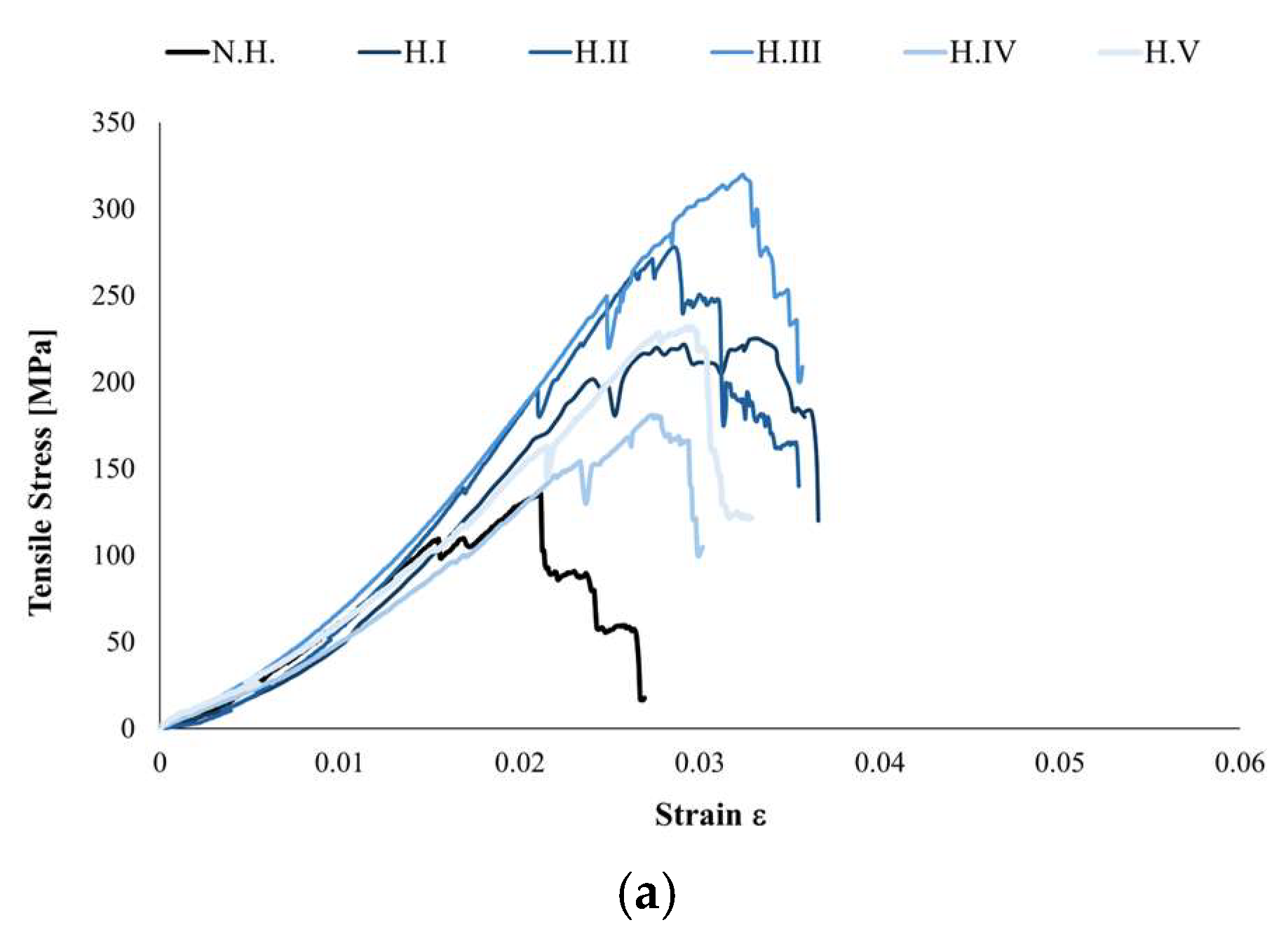

| Fibers | Cycles | Af | Fmax (N) | σt (MPa) | εu | E (GPa) |

|---|---|---|---|---|---|---|

| Banana | N.H. | 6.88 | 436 50.22 (0.12) | 63 7.30 (0.12) | 0.027 | 3.01 |

| Hemp | N.H. | 12.13 | 2079 164.42 (0.08) | 171 13.55 (0.08) | 0.035 | 6.48 |

| Coir | N.H. | 24.17 | 1866 184.41 (0.10) | 77 7.63 (0.10) | 0.158 | 0.78 |

| Cotton | N.H. | 11.23 | 1146 77.83 (0.07) | 102 6.93 (0.07) | 0.142 | 0.76 |

| Henequen | N.H. | 6.65 | 905 15.15 (0.02) | 136 2.28 (0.02) | 0.028 | 7.73 |

| Jute | N.H. | 8.47 | 1704 103.36 (0.06) | 201 12.20 (0.06) | 0.025 | 10.23 |

| Flax | N.H. | 3.88 | 886 97.94 (0.11) | 228 25.24 (0.11) | 0.022 | 13.24 |

| Ramiè | N.H. | 5.02 | 769 59.71 (0.08) | 153 11.89 (0.08) | 0.021 | 7.25 |

| Raffia | N.H. | 5.57 | 230 18.85 (0.08) | 41 3.38 (0.08) | 0.059 | 0.67 |

| Sisal | N.H. | 12.82 | 2515 238.42 (0.09) | 196 18.60 (0.09) | 0.035 | 6.31 |

| Fibers | Cycles | Fmax (N) | σt (MPa) | εu | E (GPa) |

|---|---|---|---|---|---|

| Banana | H.I | 467 28.05 (0.06) | 68 7.75 (0.06) | 0.030 | 2.43 |

| H.II | 568 25.00 (0.04) | 83 22.93 (0.04) | 0.042 | 2.77 | |

| H.III | 617 31.05 (0.05) | 90 24.86 (0.05) | 0.040 | 2.34 | |

| H.IV | 707 33.60 (0.05) | 103 9.28 (0.05) | 0.039 | 3.02 | |

| H.V | 363 22.61 (0.06) | 53 2.34 (0.06) | 0.067 | 1.06 | |

| Hemp | H.I | 1266 51.68 (0.04) | 104 4.25 (0.04) | 0.038 | 3.49 |

| H.II | 1216 109.34 (0.09) | 100 8.98 (0.09) | 0.059 | 3.06 | |

| H.III | 1551 133.84 (0.09) | 128 11.00 (0.09) | 0.050 | 2.21 | |

| H.IV | 1366 134.27 (0.10) | 113 11.03 (0.10) | 0.053 | 3.22 | |

| H.V | 1227 94.69 (0.08) | 101 7.78 (0.08) | 0.080 | 2.42 | |

| Coir | H.I | 1783 153.19 (0.09) | 74 6.35 (0.09) | 0.197 | 0.67 |

| H.II | 1874 202.26 (0.11) | 78 8.39 (0.11) | 0.162 | 0.75 | |

| H.III | 1682 161.45 (0.10) | 70 6.70 (0.10) | 0.185 | 0.67 | |

| H.IV | 1450 147.50 (0.10) | 60 6.12 (0.10) | 0.196 | 0.50 | |

| H.V | 1774 192.92 (0.11) | 73 8.00 (0.11) | 0.167 | 0.68 | |

| Cotton | H.I | 936 74.05 (0.08) | 83 6.56 (0.08) | 0.173 | 0.67 |

| H.II | 414 31.05 (0.07) | 37 2.75 (0.07) | 0.180 | 0.39 | |

| H.III | 880 75.02 (0.09) | 78 6.65 (0.09) | 0.142 | 0.67 | |

| H.IV | 799 79.47 (0.10) | 71 7.05 (0.10) | 0.152 | 0.58 | |

| H.V | 1104 111.22 (0.10) | 98 9.86 (0.10) | 0.143 | 0.75 | |

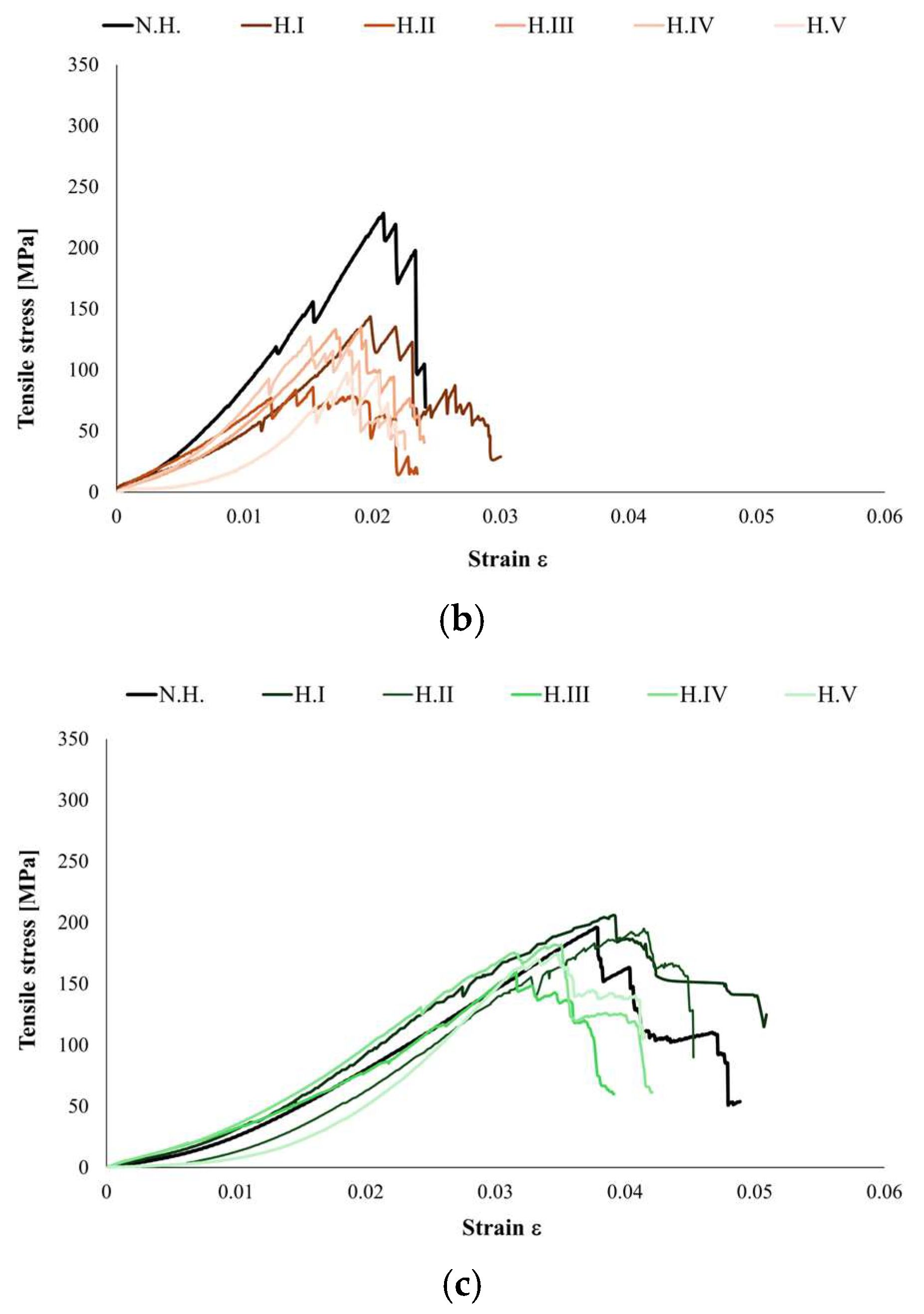

| Henequen | H.I | 1496 131.83 (0.09) | 225 19.82 (0.09) | 0.034 | 11.10 |

| H.II | 1849 111.80 (0.06) | 278 16.81 (0.06) | 0.028 | 11.82 | |

| H.III | 2128 130.37 (0.07) | 320 19.60 (0.07) | 0.032 | 11.76 | |

| H.IV | 1204 68.25 (0.06) | 181 10.26 (0.06) | 0.027 | 7.44 | |

| H.V | 1543 67.27 (0.04) | 232 10.12 (0.04) | 0.029 | 7.58 | |

| Jute | H.I | 659 64.21 (0.10) | 78 7.60 (0.10) | 0.044 | 2.98 |

| H.II | 549 54.84 (0.10) | 65 6.49 (0.10) | 0.045 | 1.89 | |

| H.III | 726 57.30 (0.08) | 86 6.78 (0.08) | 0.031 | 2.55 | |

| H.IV | 1134 98.15 (0.09) | 134 11.62 (0.09) | 0.043 | 3.56 | |

| H.V | 979 89.82 (0.09) | 116 10.63 (0.09) | 0.042 | 3.33 | |

| Flax | H.I | 555 47.26 (0.09) | 143 12.21 (0.09) | 0.019 | 6.92 |

| H.II | 334 36.54 (0.11) | 86 9.42 (0.11) | 0.015 | 6.02 | |

| H.III | 524 43.09 (0.08) | 135 11.11 (0.08) | 0.019 | 9.61 | |

| H.IV | 493 23.39 (0.05) | 127 6.03 (0.05) | 0.015 | 11.55 | |

| H.V | 376 16.15 (0.04) | 97 4.16 (0.04) | 0.018 | 8.03 | |

| Ramiè | H.I | 474 41.24 (0.09) | 94 8.18 (0.09) | 0.043 | 2.22 |

| H.II | 502 39.59 (0.08) | 100 7.86 (0.08) | 0.052 | 2.59 | |

| H.III | 420 37.03 (0.09) | 84 7.35 (0.09) | 0.054 | 2.65 | |

| H.IV | 494 44.91 (0.09) | 98 8.91 (0.09) | 0.060 | 4.56 | |

| H.V | 482 46.89 (0.10) | 96 9.30 (0.10) | 0.082 | 3.25 | |

| Raffia | H.I | 230 20.30 (0.09) | 41 3.62 (0.09) | 0.045 | 0.99 |

| H.II | 234 20.30 (0.11) | 42 3.62 (0.11) | 0.056 | 0.89 | |

| H.III | 247 21.63 (0.09) | 44 3.86 (0.09) | 0.052 | 0.82 | |

| H.IV | 252 23.00 (0.09) | 45 4.10 (0.09) | 0.062 | 0.77 | |

| H.V | 201 19.29 (0.10) | 36 3.44 (0.10) | 0.083 | 0.67 | |

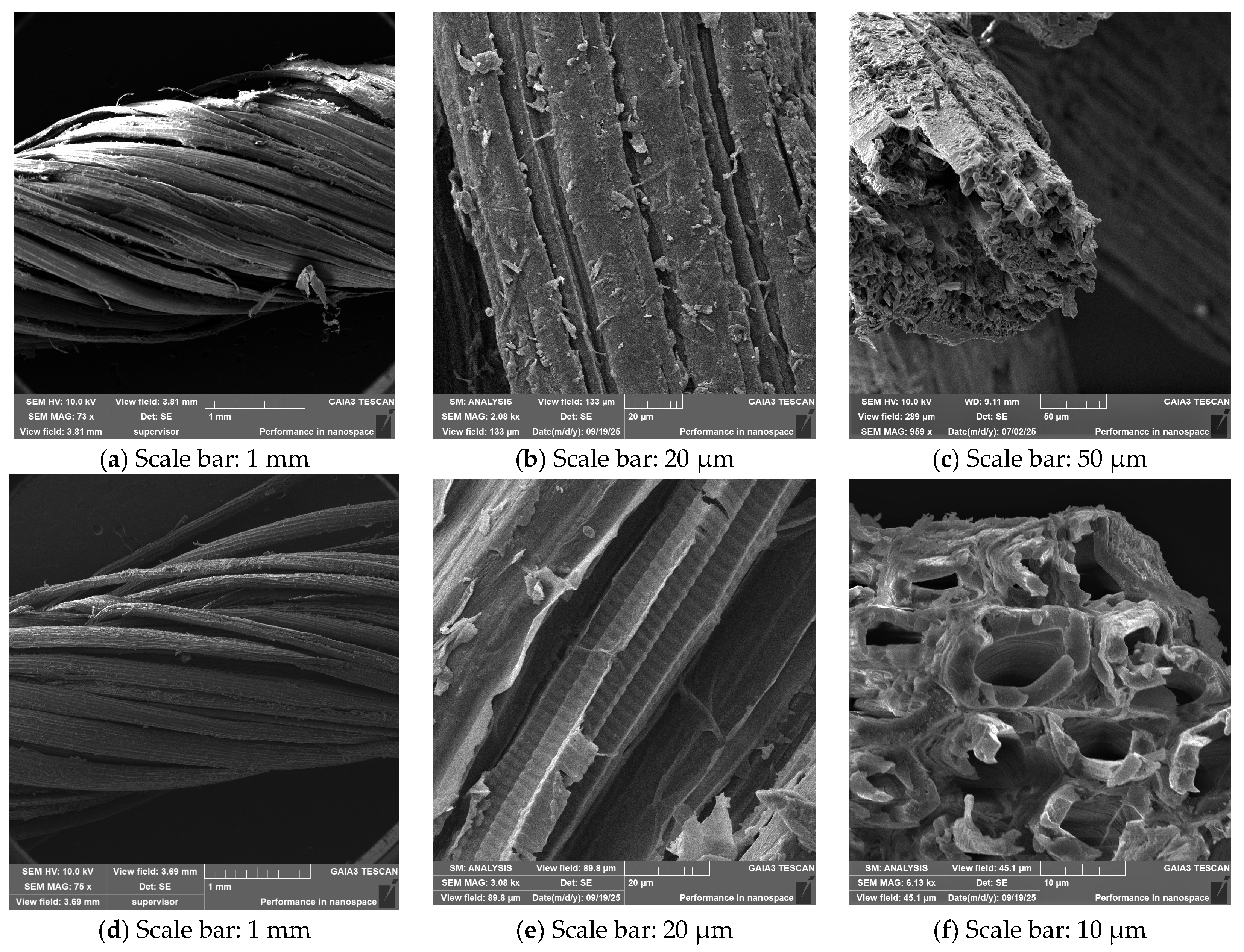

| Sisal | H.I | 2641 108.28 (0.04) | 206 8.45 (0.04) | 0.039 | 6.84 |

| H.II | 2500 274.16 (0.11) | 195 21.39 (0.11) | 0.041 | 6.94 | |

| H.III | 2064 148.22 (0.07) | 161 11.56 (0.07) | 0.031 | 4.69 | |

| H.IV | 2333 119.35 (0.05) | 182 9.31 (0.05) | 0.034 | 6.85 | |

| H.V | 2244 109.28 (0.05) | 175 8.52 (0.05) | 0.034 | 9.57 |

| SS | df | MS | F | p | VE (%) | |

|---|---|---|---|---|---|---|

| Fibers | 1.03 × 106 | 9 | 114,029 | 981.6 | <0.001 | 72 |

| Cycles | 39,855 | 5 | 7991 | 68.8 | <0.001 | 3 |

| Fibers × Cycles | 319,924 | 45 | 7109 | 61.2 | <0.001 | 23 |

| Residuals | 34,850 | 300 | 116 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stipo, G.; Alecci, V.; De Stefano, M.; Galassi, S.; Salvatici, M.C.; Satta, M.L. Mechanical Performances of Natural Textiles for Eco-Friendly Composite Materials: A Comparative Assessment. Fibers 2025, 13, 148. https://doi.org/10.3390/fib13110148

Stipo G, Alecci V, De Stefano M, Galassi S, Salvatici MC, Satta ML. Mechanical Performances of Natural Textiles for Eco-Friendly Composite Materials: A Comparative Assessment. Fibers. 2025; 13(11):148. https://doi.org/10.3390/fib13110148

Chicago/Turabian StyleStipo, Gianfranco, Valerio Alecci, Mario De Stefano, Stefano Galassi, Maria Cristina Salvatici, and Maria Luisa Satta. 2025. "Mechanical Performances of Natural Textiles for Eco-Friendly Composite Materials: A Comparative Assessment" Fibers 13, no. 11: 148. https://doi.org/10.3390/fib13110148

APA StyleStipo, G., Alecci, V., De Stefano, M., Galassi, S., Salvatici, M. C., & Satta, M. L. (2025). Mechanical Performances of Natural Textiles for Eco-Friendly Composite Materials: A Comparative Assessment. Fibers, 13(11), 148. https://doi.org/10.3390/fib13110148