Tension Lap Splices in Recycled-Aggregate Concrete Strengthened with Steel–Polyolefin Fibers

Abstract

1. Introduction

Research Significance

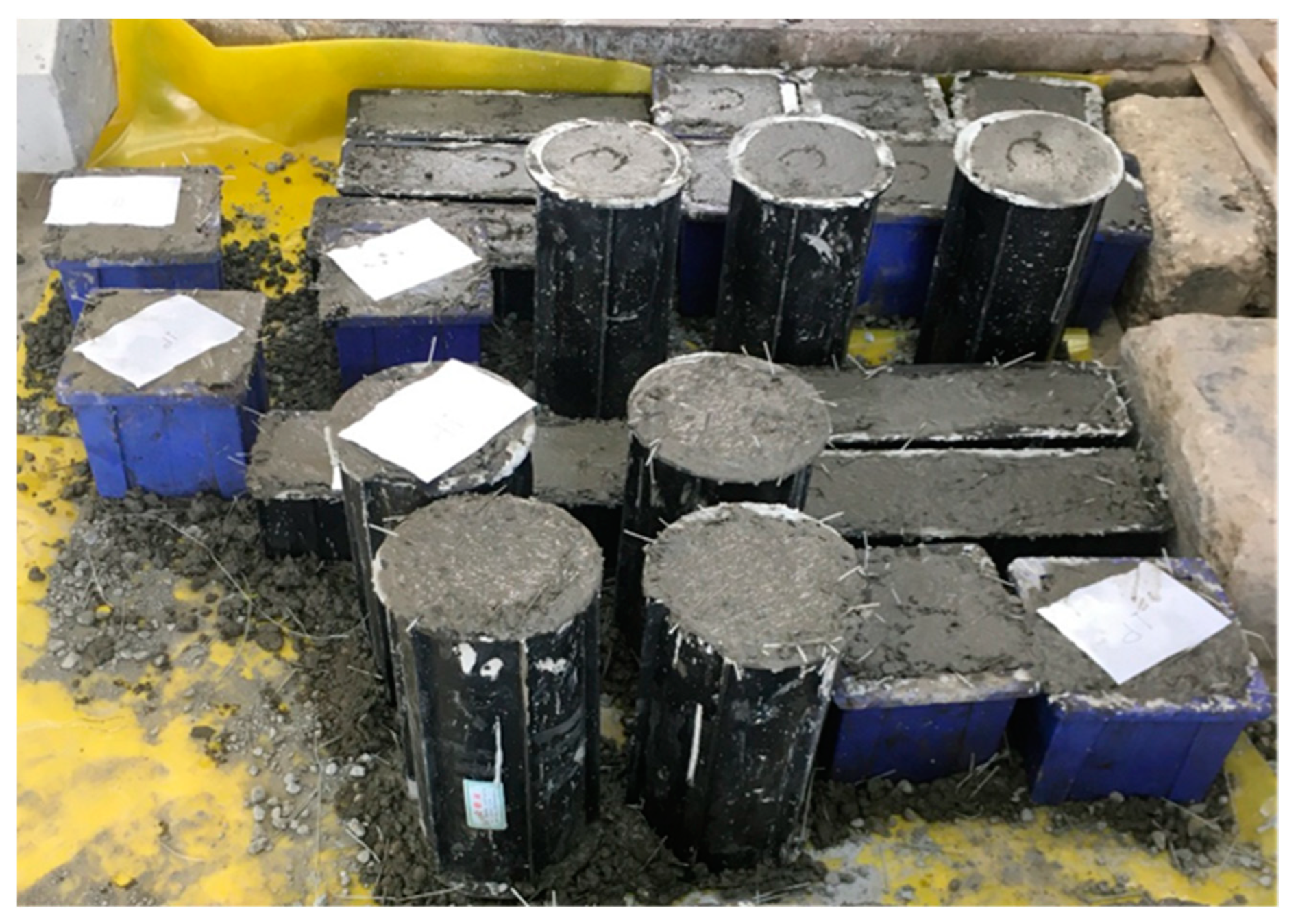

2. Experimental Program

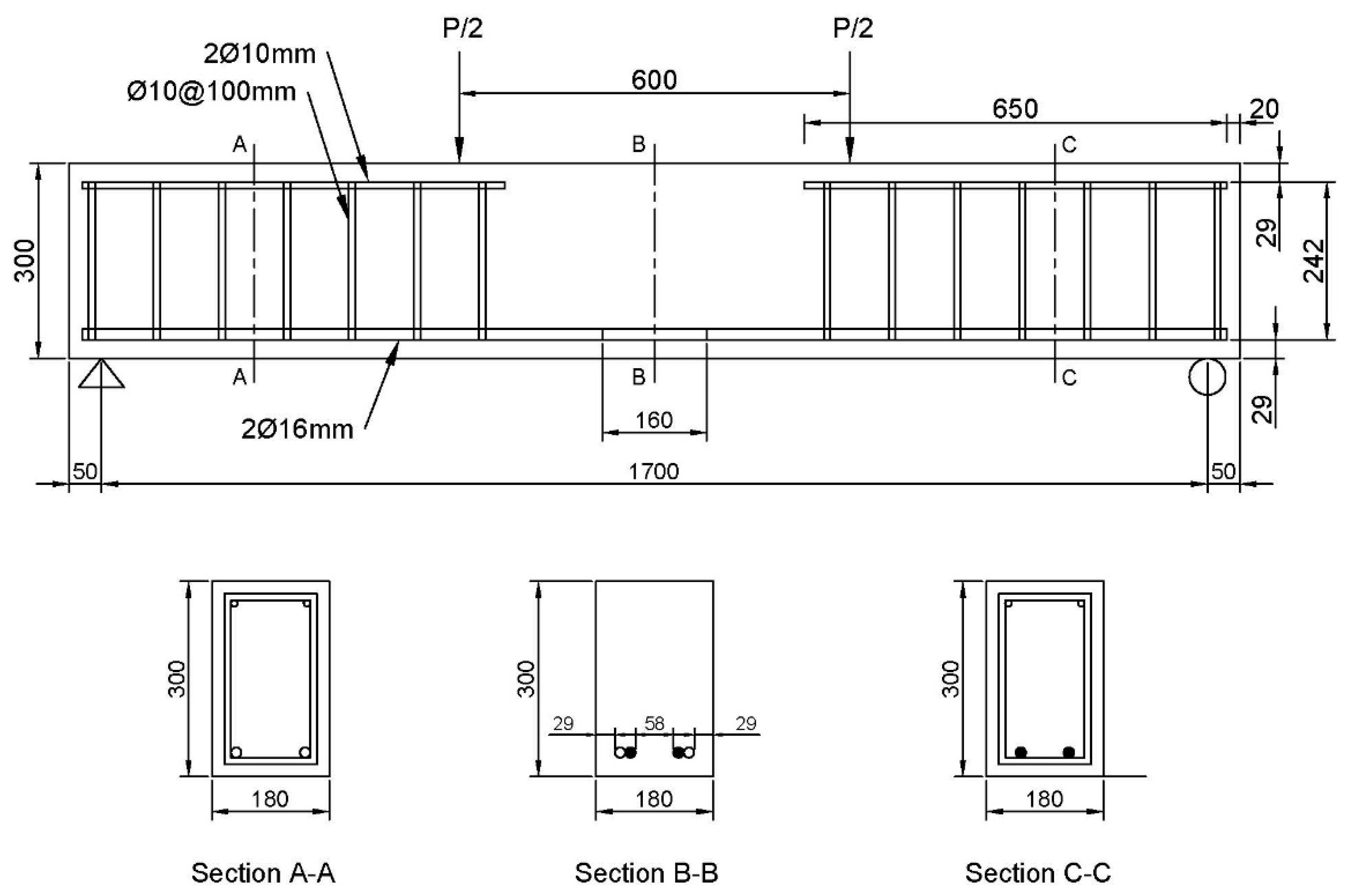

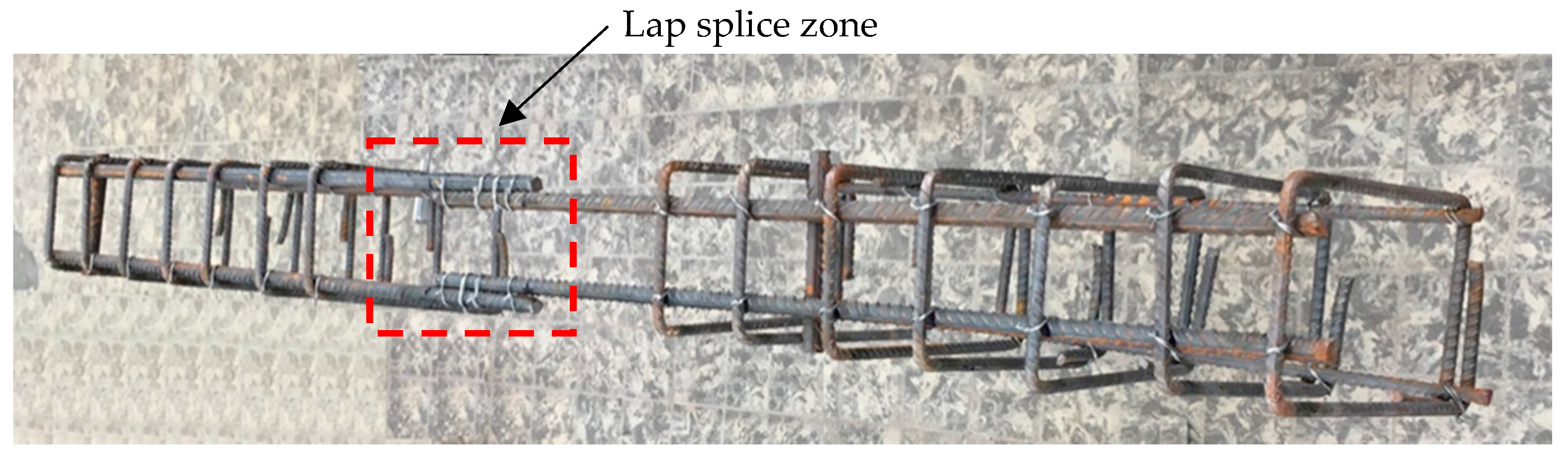

3. Specimens Details

4. Materials

4.1. Steel Reinforcement (Rebar)

4.2. Fibers

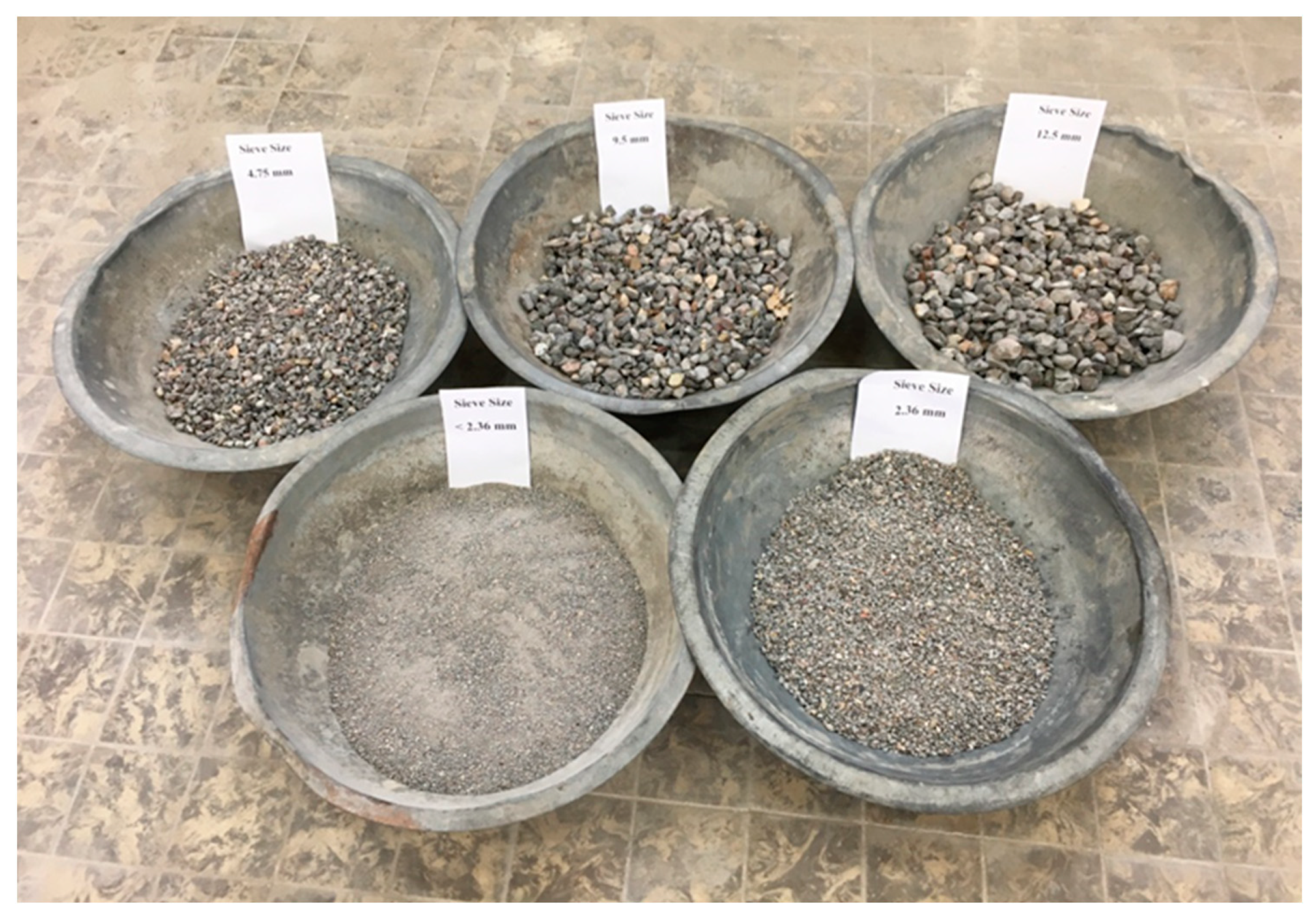

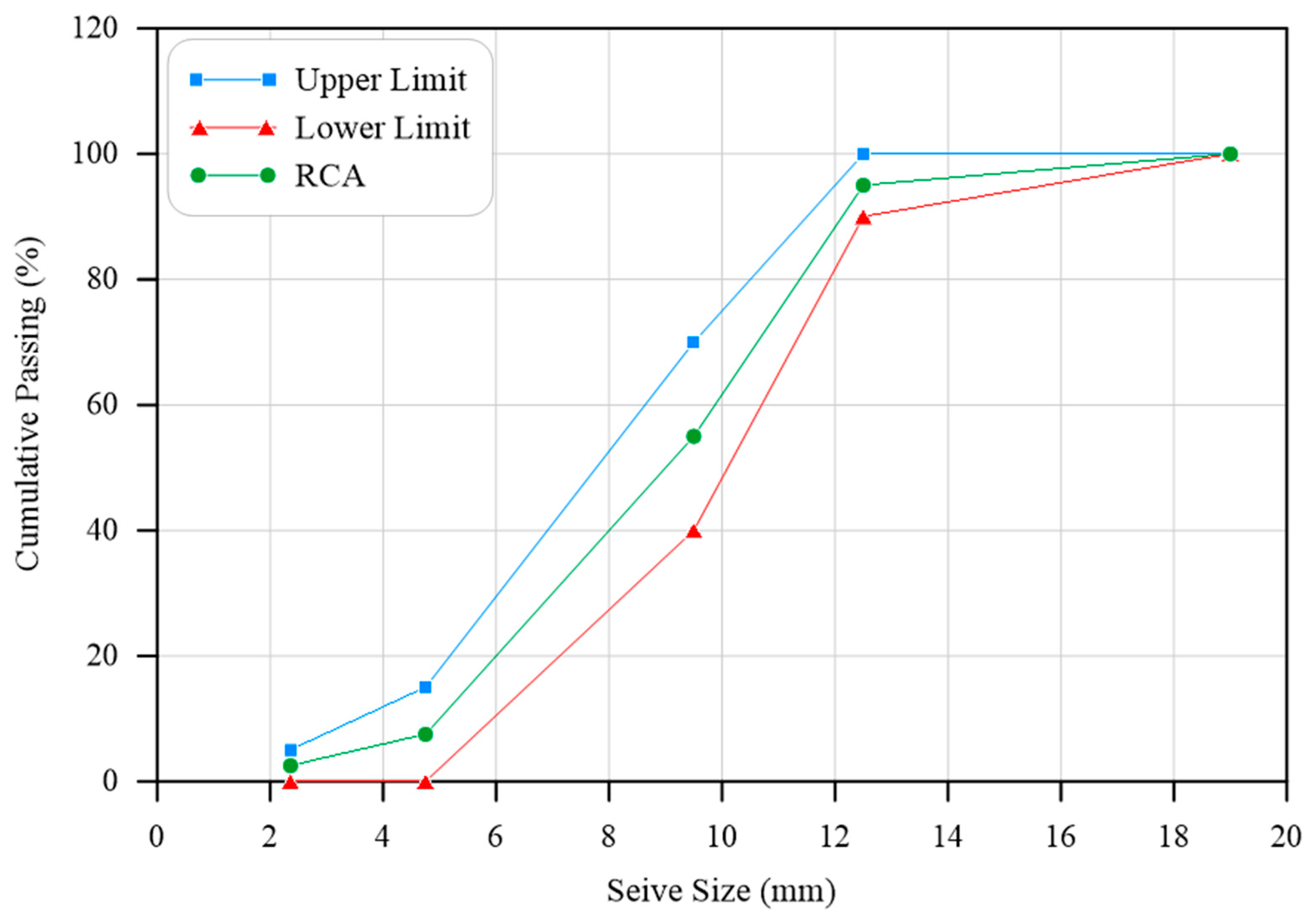

4.3. Concrete

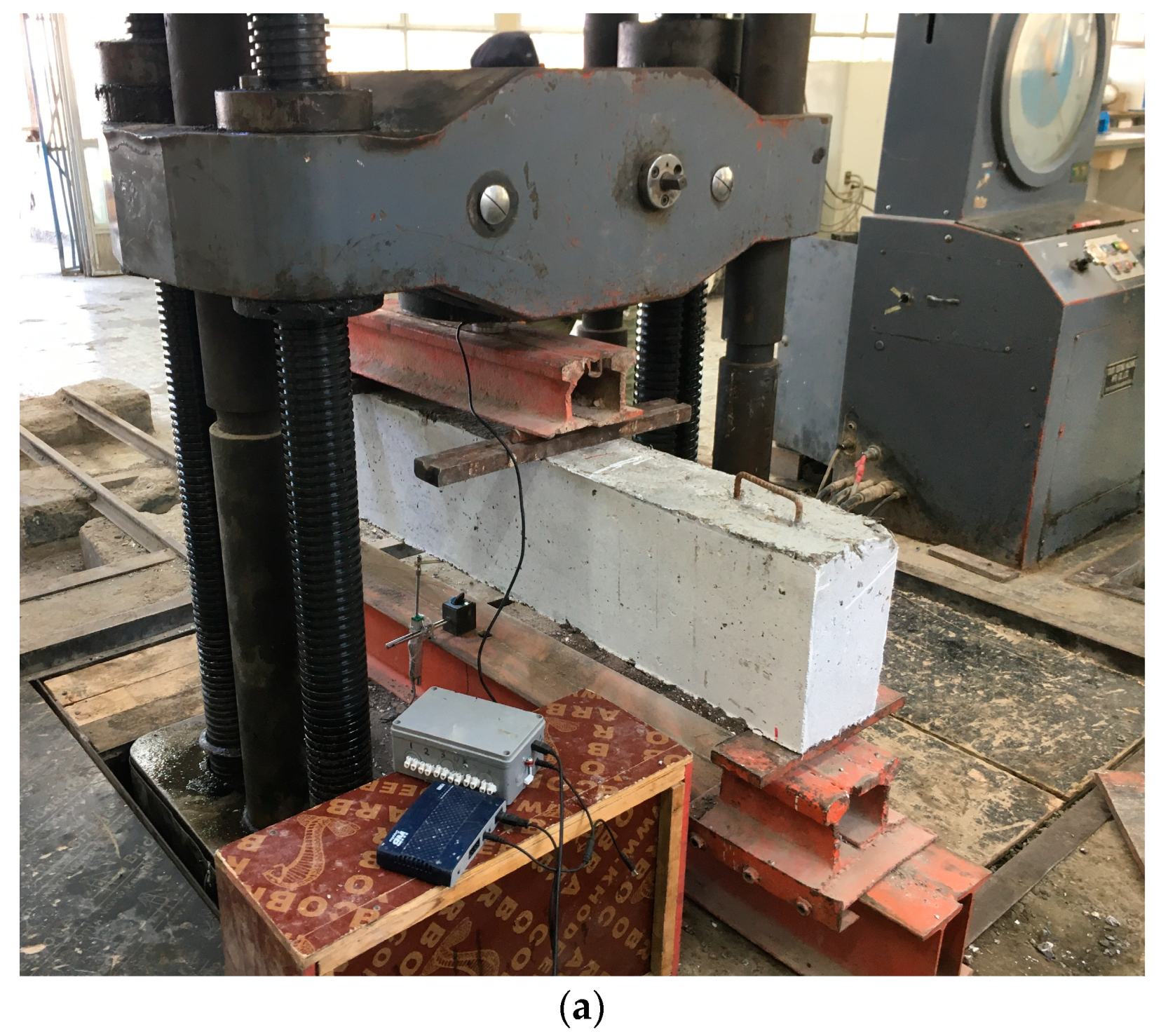

5. Test Setup

6. Results and Discussions

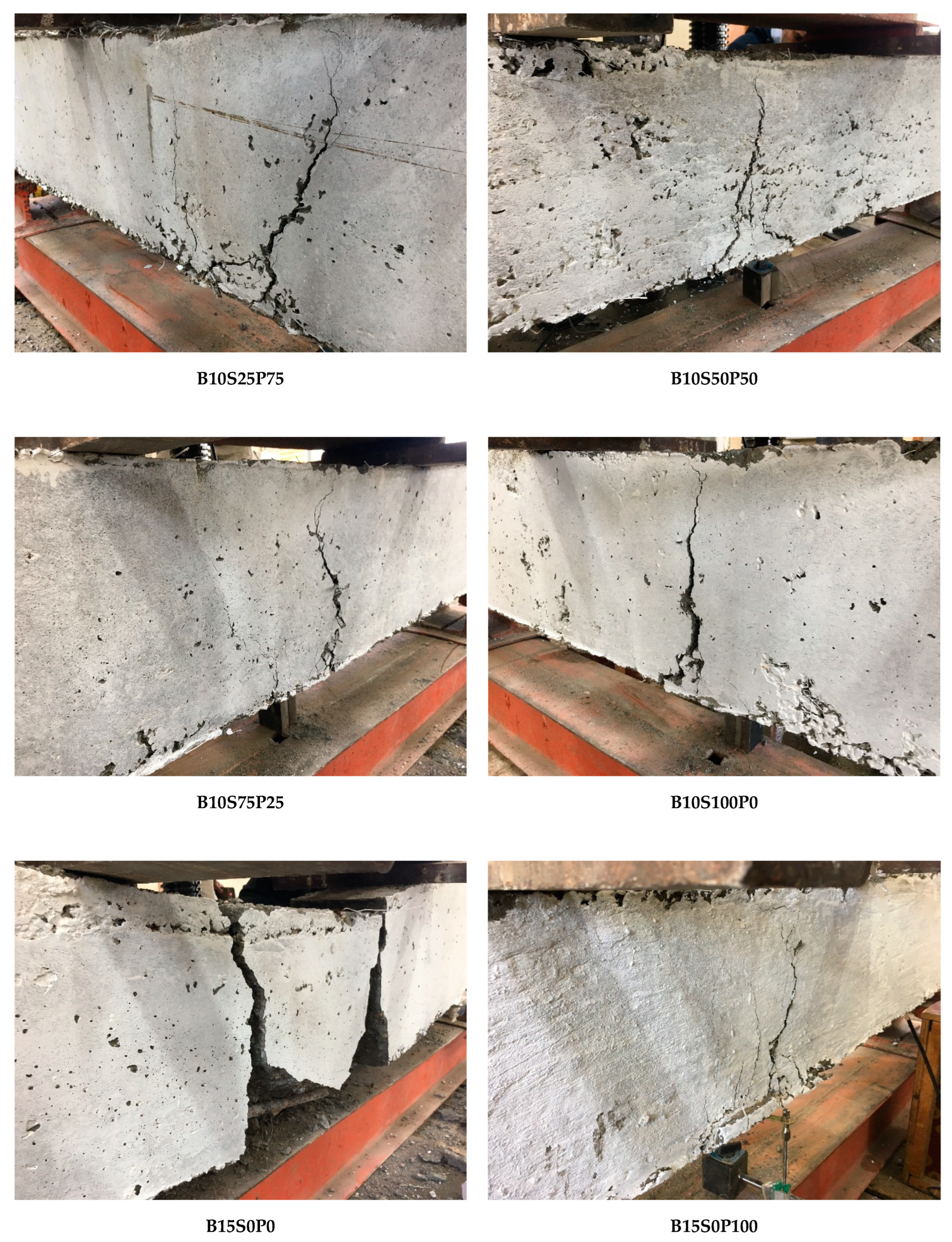

6.1. General Behavior and Failure Mode

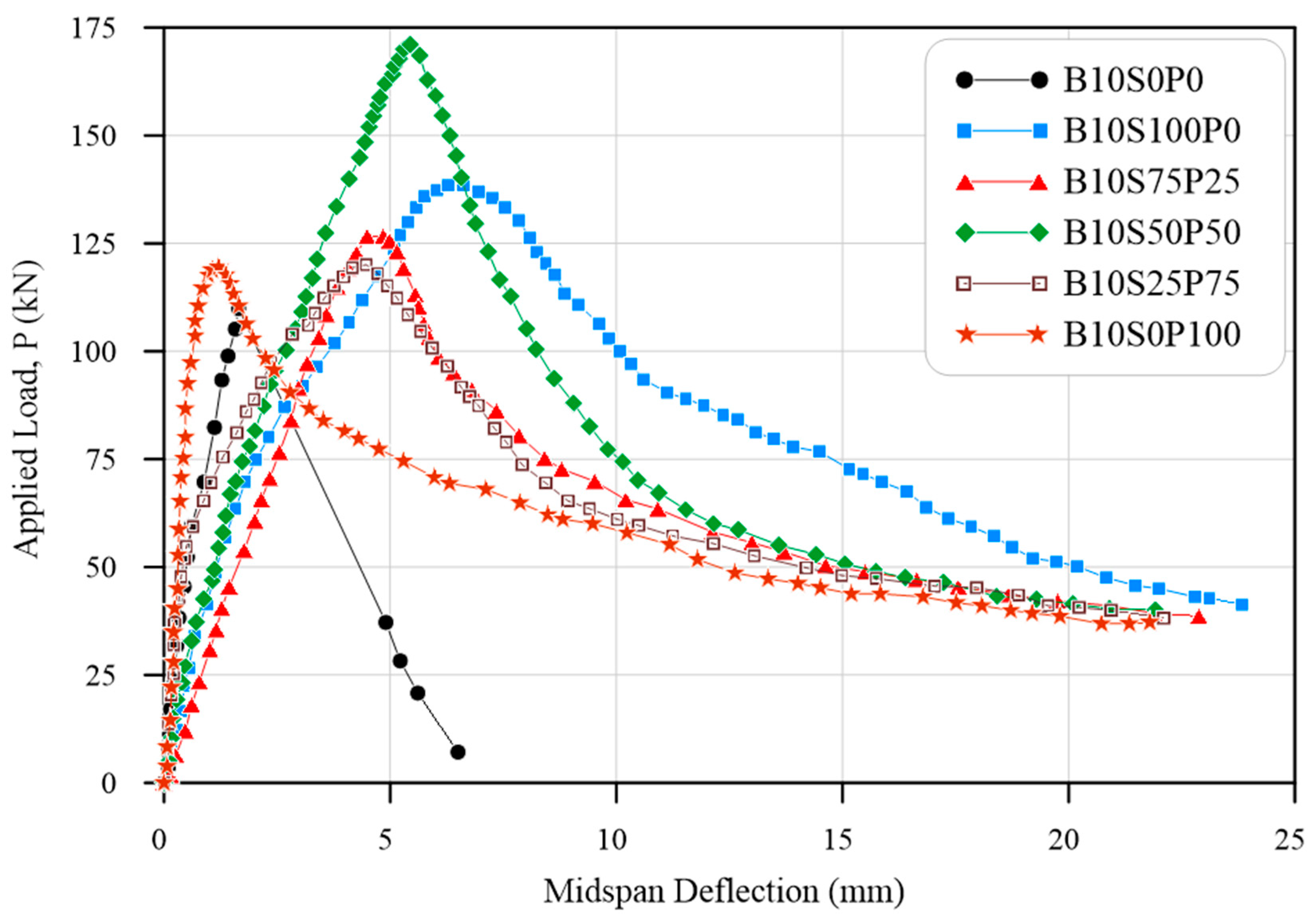

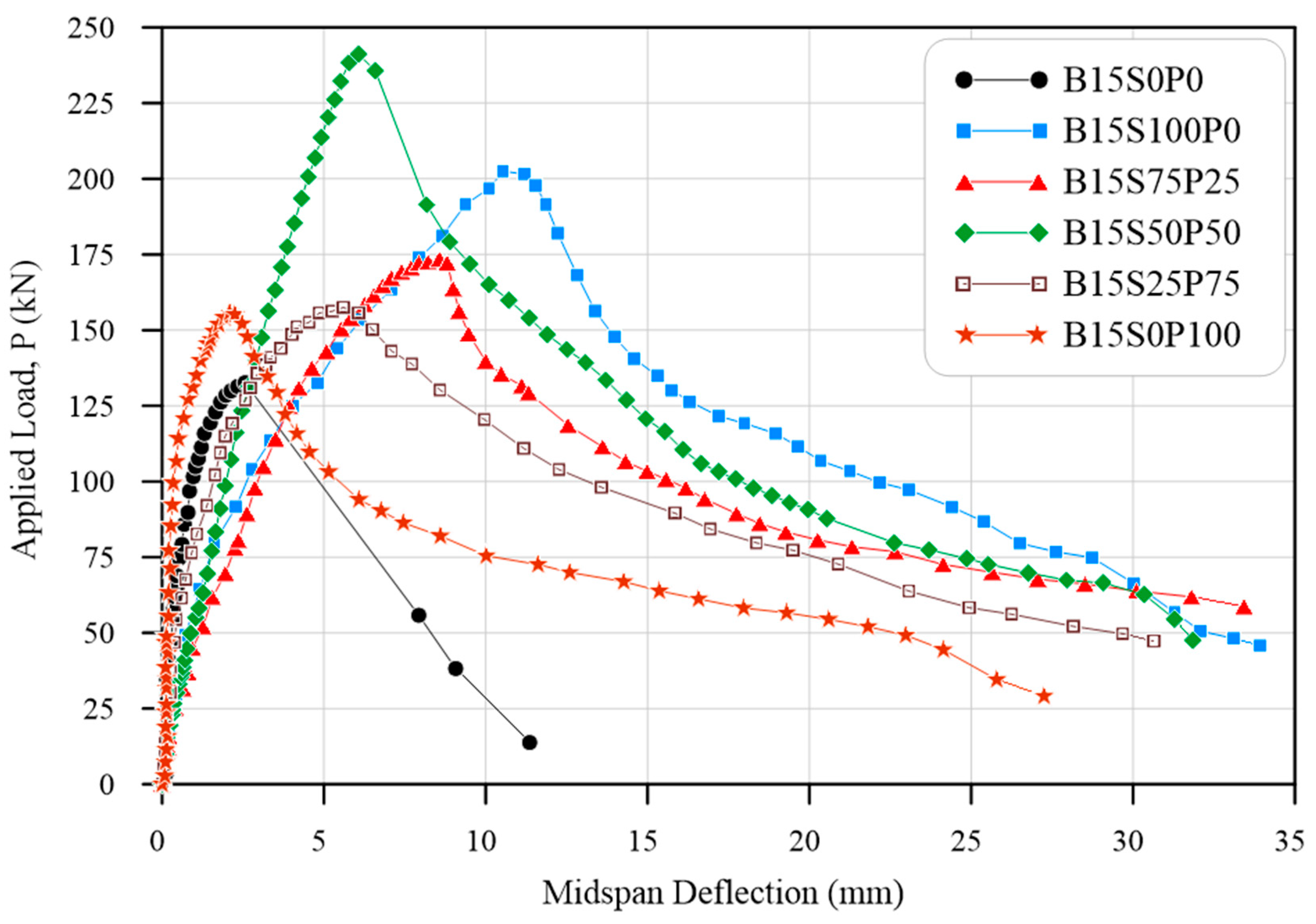

6.2. Load-Deflection Behavior

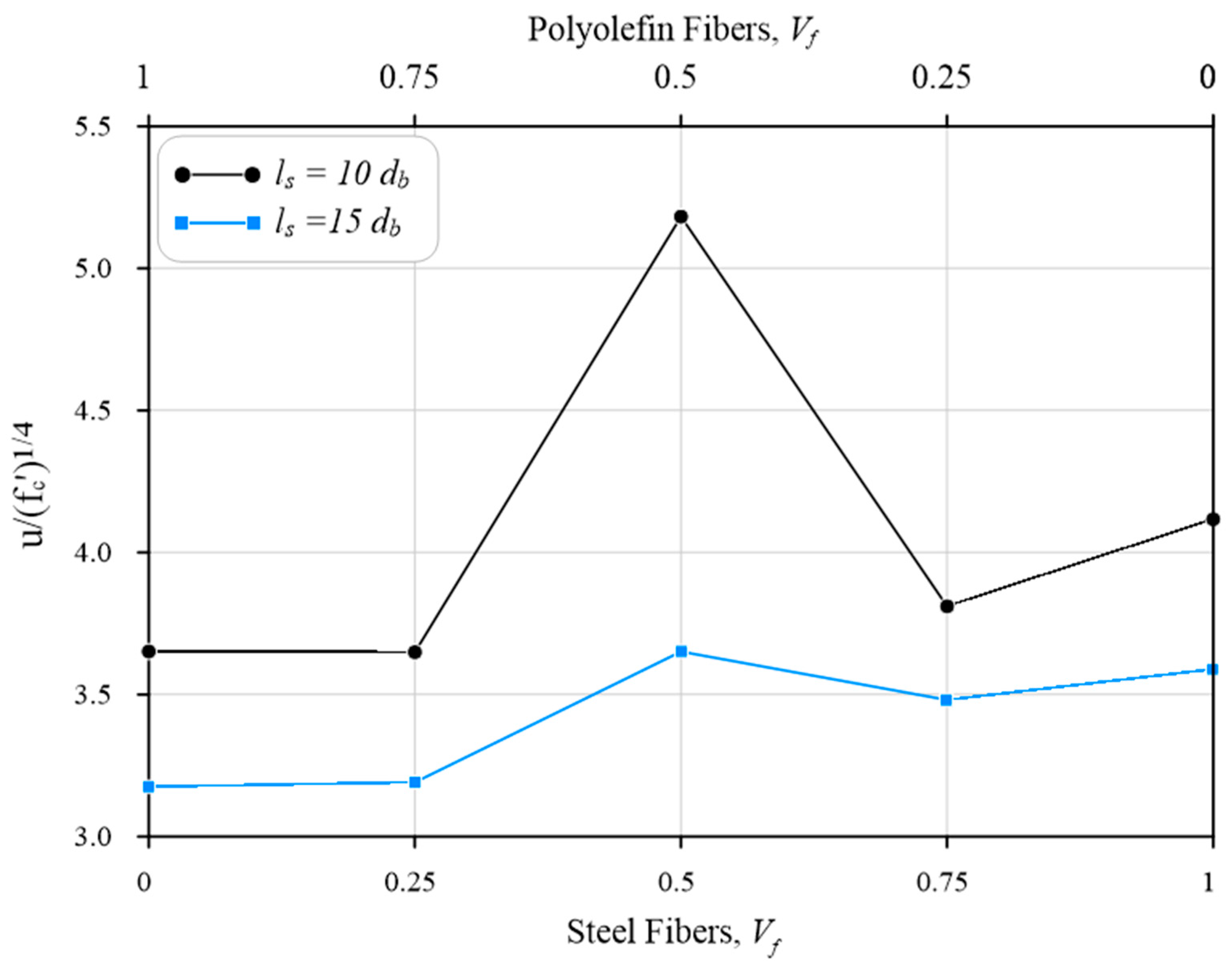

6.3. Bond Strength

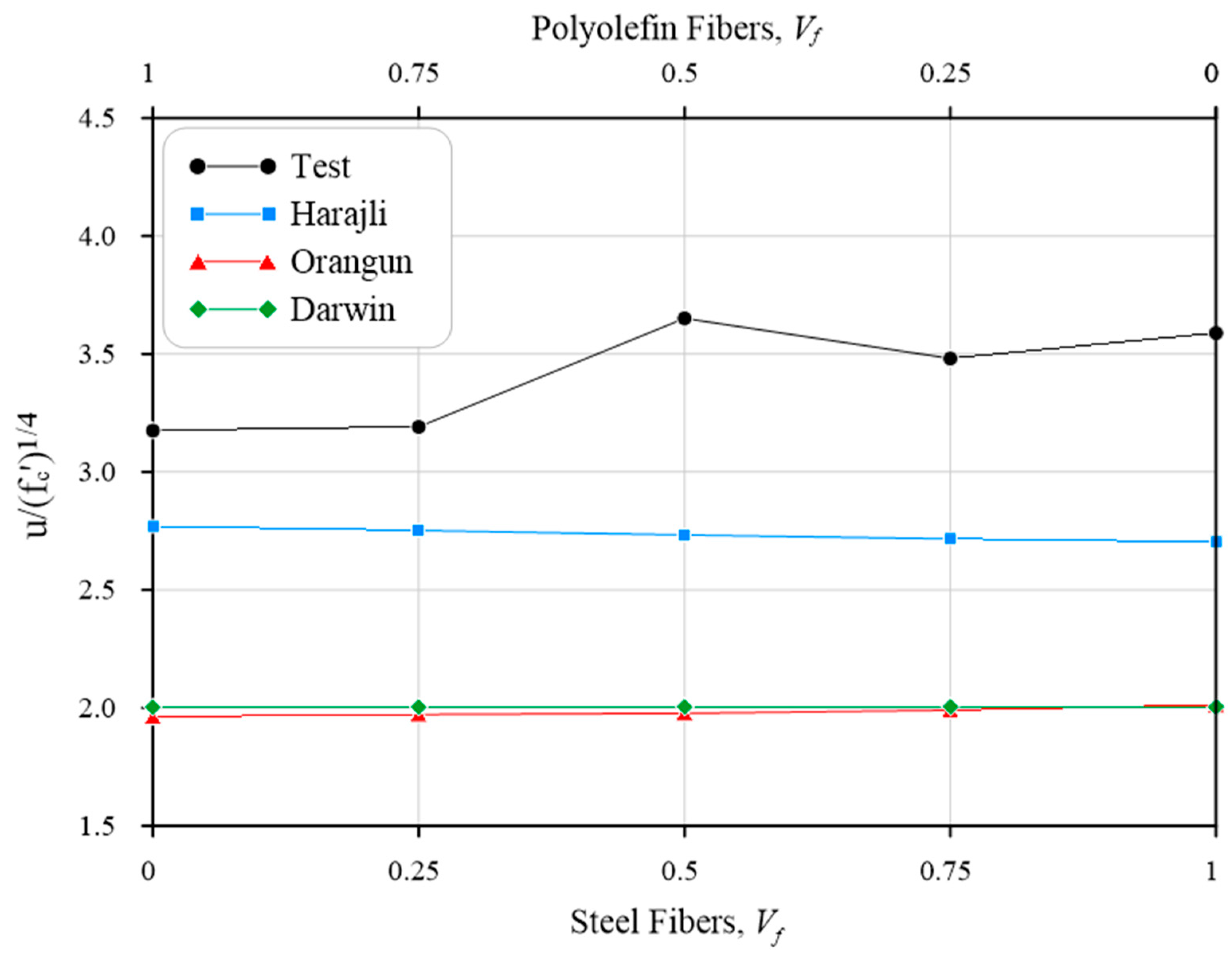

6.4. Comparison between Theoretical and Experimental Results

7. Conclusions

- The failure mode observed for all fiber-reinforced recycled-aggregate (FR-RA) concrete specimens was splitting. All specimens showed fundamentally similar cracking behavior regardless of the type and relative ratio of steel–polyolefin fibers.

- The effect of fibers on the ultimate load capacity of the beam specimen with ls = 15 db was higher than that of ls = 10 db. In the case of ls = 15 db, the increase in the ultimate load capacity of the FRC beam specimens ranged between 8% and 53% in comparison to that of the plain beam specimen. However, in the case of ls = 15 db, it ranged between 17% and 79%.

- The maximum increase in the bond strength of reinforcing bars embedded in FR-RA concrete was when a ratio of steel–polyolefin of 50–50% was used. In this ratio of fibers, the bond ratio was about 1.53 for the case of ls = 10 db; however, it was about 1.34 for the case of ls = 15 db.

- In general, the effect of fibers on the bond strength in the case of ls = 15 db was more than that of ls = 10 db except for the ratio of steel–polyolefin of 50–50%.

- The ductility of the FR-RA concrete was substantially improved for all the cases of various relative ratios of steel and polyolefin fibers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Variable | Definition |

| Ab | area of rebars |

| c | the smallest of concrete bottom cover, side cover, or half the clear distance between the bars |

| cb | concrete bottom cover |

| cso | concrete side cover |

| csi | half the clear spacing between the bars |

| cm | the largest value of bottom cover and the smallest of side cover or half the clear distance between the bars + 6.0 mm |

| db | nominal diameter of rebar |

| df | diameter of fiber |

| compressive strength of concrete | |

| fs | stress in the rebar at failure |

| lf | length of fiber |

| ls | lap splice length |

| u | bond strength |

| Vf | volume fraction of fibers |

References

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled Aggregate from C&D Waste & Its Use in Concrete—A Breakthrough towards Sustainability in Construction Sector: A Review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Oikonomou, N.D. Recycled Concrete Aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Poon, C. Recent Studies on Mechanical Properties of Recycled Aggregate Concrete in China-A Review. Sci. China Technol. Sci. 2012, 55, 1463–1480. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A Critical Review and Assessment for Usage of Recycled Aggregate as Sustainable Construction Material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Kazmi, S.M.S.; Munir, M.J.; Park, C. Properties Enhancement of Recycled Aggregate Concrete through Pretreatment of Coarse Aggregates—Comparative Assessment of Assorted Techniques. J. Clean. Prod. 2018, 191, 339–349. [Google Scholar] [CrossRef]

- Australian Government. Productivity Commission, Waste Management: Productivity Commission Draft Report; Australian Government: Canberra, Australia, 2006.

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of Amount of Recycled Coarse Aggregates and Production Process on Properties of Recycled Aggregate Concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Chakradhara Rao, M.; Bhattacharyya, S.K.; Barai, S.V. Influence of Field Recycled Coarse Aggregate on Properties of Concrete. Mater. Struct. Mater. Constr. 2011, 44, 205–220. [Google Scholar] [CrossRef]

- Ajdukiewicz, A.; Kliszczewicz, A. Influence of Recycled Aggregates on Mechanical Properties of HS/HPC. Cem. Concr. Compos. 2002, 24, 269–279. [Google Scholar] [CrossRef]

- Choi, H.; Choi, H.; Lim, M.; Inoue, M.; Kitagaki, R.; Noguchi, T. Evaluation on the Mechanical Performance of Low-Quality Recycled Aggregate through Interface Enhancement between Cement Matrix and Coarse Aggregate by Surface Modification Technology. Int. J. Concr. Struct. Mater. 2016, 10, 87–97. [Google Scholar] [CrossRef]

- Li, J.; Xiao, H.; Zhou, Y. Influence of Coating Recycled Aggregate Surface with Pozzolanic Powder on Properties of Recycled Aggregate Concrete. Constr. Build. Mater. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Katz, A. Properties of Concrete Made with Recycled Aggregate from Partially Hydrated Old Concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Nokken, M. Compressive Behavior of Steel Fiber Reinforced Recycled Coarse Aggregate Concrete Designed with Equivalent Cubic Compressive Strength. Constr. Build. Mater. 2017, 141, 235–244. [Google Scholar] [CrossRef]

- Carneiro, J.A.; Lima, P.R.L.; Leite, M.B.; Toledo Filho, R.D. Compressive Stress-Strain Behavior of Steel Fiber Reinforced-Recycled Aggregate Concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Akça, K.I.R.; Çakir, Ö.; Ipek, M. Properties of Polypropylene Fiber Reinforced Concrete Using Recycled Aggregates. Constr. Build. Mater. 2015, 98, 620–630. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Li, C.; Zhao, J.; Cheng, S. Mechanical Properties of Fully Recycled Aggregate Concrete Reinforced with Steel Fiber and Polypropylene Fiber. Materials 2024, 17, 1156. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.; Yao, Y.; Wu, B.; Zhang, W.; He, W.; Fu, Y. The Impact Resistance and Mechanical Properties of Recycled Aggregate Concrete with Hooked-End and Crimped Steel Fiber. Materials 2022, 15, 7029. [Google Scholar] [CrossRef]

- Arslan, M.E. Effects of Basalt and Glass Chopped Fibers Addition on Fracture Energy and Mechanical Properties of Ordinary Concrete: CMOD Measurement. Constr. Build. Mater. 2016, 114, 383–391. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Riella, J.; Chung, D.; Collister, T.; Combe, M.; Sivakugan, N. Comparative Evaluation of Virgin and Recycled Polypropylene Fibre Reinforced Concrete. Constr. Build. Mater. 2016, 114, 134–141. [Google Scholar] [CrossRef]

- Barros, J.A.O.; Cunha, V.M.C.F.; Ribeiro, A.F.; Antunes, J.A.B. Post-Cracking Behaviour of Steel Fibre Reinforced Concrete. Mater. Struct. Mater. Constr. 2005, 38, 47–56. [Google Scholar] [CrossRef]

- Buratti, N.; Mazzotti, C.; Savoia, M. Post-Cracking Behaviour of Steel and Macro-Synthetic Fibre-Reinforced Concretes. Constr. Build. Mater. 2011, 25, 2713–2722. [Google Scholar] [CrossRef]

- Banthia, N.; Sappakittipakorn, M. Toughness Enhancement in Steel Fiber Reinforced Concrete through Fiber Hybridization. Cem. Concr. Res. 2007, 37, 1366–1372. [Google Scholar] [CrossRef]

- Lee, C.J.; Salas Montoya, A.; Moon, H.; Kim, H.; Chung, C.-W. The Influence of the Hybridization of Steel and Polyolefin Fiber on the Mechanical Properties of Base Concrete Designed for Marine Shotcreting Purposes. Appl. Sci. 2021, 11, 9456. [Google Scholar] [CrossRef]

- Guo, Q.; Wang, H.; Gao, Y.; Jiao, Y.; Liu, F.; Dong, Z. Investigation of the Low-Temperature Properties and Cracking Resistance of Fiber-Reinforced Asphalt Concrete Using the DIC Technique. Eng. Fract. Mech. 2020, 229, 106951. [Google Scholar] [CrossRef]

- Mpalaskas, A.C.; Matikas, T.E.; Aggelis, D.G.; Alver, N. Acoustic Emission for Evaluating the Reinforcement Effectiveness in Steel Fiber Reinforced Concrete. Appl. Sci. 2021, 11, 3850. [Google Scholar] [CrossRef]

- Voutetaki, M.E.; Naoum, M.C.; Papadopoulos, N.A.; Chalioris, C.E. Cracking Diagnosis in Fiber-Reinforced Concrete with Synthetic Fibers Using Piezoelectric Transducers. Fibers 2022, 10, 5. [Google Scholar] [CrossRef]

- Xiao, J.; Falkner, H. Bond Behaviour between Recycled Aggregate Concrete and Steel Rebars. Constr. Build. Mater. 2007, 21, 395–401. [Google Scholar] [CrossRef]

- Choi, H.B.; Kang, K.I. Bond Behaviour of Deformed Bars Embedded in RAC. Mag. Concr. Res. 2008, 60, 399–410. [Google Scholar] [CrossRef]

- ACI Committee. Bond and Development of Straight Reinforcing Bars in Tension. ACI 408R-03; American Concrete Institute: Farmington Hills, MI, USA, 2003; pp. 48–49. [Google Scholar]

- Guoliang, B.A.I.; Shuhai, W.U.; Xiaowen, L.I. Investigation of Bond-Slip Behavior between Recycled Concrete and Steel Bars under Pull-out Test. In Proceedings of the 2nd International Conference on Waste Engineering and Management-ICWEM 2010, Shanghai, China, 13–15 October 2010; pp. 628–637. [Google Scholar]

- Butler, L.; West, J.S.; Tighe, S.L. The Effect of Recycled Concrete Aggregate Properties on the Bond Strength between RCA Concrete and Steel Reinforcement. Cem. Concr. Res. 2011, 41, 1037–1049. [Google Scholar] [CrossRef]

- Kim, Y.; Sim, J.; Park, C. Mechanical Properties of Recycled Aggregate Concrete with Deformed Steel Re-Bar. J. Mar. Sci. Technol. 2012, 20, 5. [Google Scholar] [CrossRef]

- Morohashi, N.; Sakurada, T.; Yanagibashi, K. Bond Splitting Strength of High-Quality Recycled Coarse Aggregate Concrete Beams. J. Asian Archit. Build. Eng. 2007, 6, 331–337. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirements for Structural Concrete and Commentary (ACI 318M-19); Concrete Institute: Farmington Hills, MI, USA, 2019; Volume 552. [Google Scholar]

- Wu, Z.; Khayat, K.H.; Shi, C. How Do Fiber Shape and Matrix Composition Affect Fiber Pullout Behavior and Flexural Properties of UHPC? Cem. Concr. Compos. 2018, 90, 193–201. [Google Scholar] [CrossRef]

- ASTM C 33-18; Designation: C33/C33M—18 Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2018.

- Darwin, D.; Zuo, J.; Tholen, M.L.; Idun, E.K. Development Length Criteria for Conventional and High Relative Rib Area Reinforcing Bars. ACI Struct. J. 1996, 93, 347–359. [Google Scholar]

- Orangun, C.O.; Jirsa, J.O.; Breen, J.E. The Strength of Anchor Bars: A Reevaluation of Test Data on Development Length and Splices; Research Report No. 154-3F; Center for Highway Research, University of Texas at Austin: Austin, TX, USA, 1975; p. 78. [Google Scholar]

- Orangun, C.O.; Jirsa, J.O.; Breen, J.E. Reevaluation of Test Data on Development Length and Splices. In International Concrete Abstracts Portal; ACI Journal: Farmington Hills, MI, USA, 1977; Volume 74, pp. 114–122. [Google Scholar] [CrossRef]

- Darwin, D.; Lutz, L.A.; Zuo, J. Recommended Provisions and Commentary on Development and Lap Splice Lengths for Deformed Reinforcing Bars in Tension. ACI Struct. J. 2005, 102, 892–900. [Google Scholar] [CrossRef][Green Version]

- Harajli, M.H. Bond Behavior in Steel Fiber-Reinforced Concrete Zones under Static and Cyclic Loading: Experimental Evaluations and Analytical Modeling. J. Mater. Civ. Eng. 2010, 22, 674–686. [Google Scholar] [CrossRef]

| Group No. | Specimen ID | Lap Splice Length | Steel Fiber Percentage (%) | Polyolefin Fiber Percentage (%) |

|---|---|---|---|---|

| 1 | B10S0P0 | 10 | 0 | 0 |

| B10S100P0 | 10 | 100 | 0 | |

| B10S75P25 | 10 | 75 | 25 | |

| B10S50P50 | 10 | 50 | 50 | |

| B10S25P75 | 10 | 25 | 75 | |

| B10S0P100 | 10 | 0 | 100 | |

| 2 | B15S0P0 | 15 | 0 | 0 |

| B15S100P0 | 15 | 100 | 0 | |

| B15S75P25 | 15 | 75 | 25 | |

| B15S50P50 | 15 | 50 | 50 | |

| B15S25P75 | 15 | 25 | 75 | |

| B15S0P100 | 15 | 0 | 100 |

| Rebar Diameter (mm) | Yield Strength (MPa) | Ultimate Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 10 | 470 | 620 | 11.3 |

| 16 | 522 | 695 | 10.2 |

| Fiber Types | Length (mm) | Diameter (mm) | Aspect Ratio |

|---|---|---|---|

| Hooked-end steel | 35 | 0.55 | 63.6 |

| Macro-polyolefin | 60 | 0.84 | 71.4 |

| Cement (kg/m3) | Sand (kg/m3) | RCA (kg/m3) | Water (kg/m3) | Superplasticizer (kg/m3) | w/c |

|---|---|---|---|---|---|

| 405 | 608 | 1135 | 182 | 4.05 | 0.42 |

| Physical Properties | Test Result | Limits of ASTM C150-04 | |

|---|---|---|---|

| Specific surface area (Blaine method) (m2/kg) | 312 | Not less than 280 | |

| Setting time (Vicat method) (min) | Initial setting | 126 | More than 45 |

| Final setting | 321 | Less than 375 | |

| Compressive strength (MPa) | 3 days | 13.8 | More than 12 |

| 7 days | 23.4 | More than 19 | |

| Oxide Composition | % By Weight | Limits of ASTM C150-04 |

|---|---|---|

| Lime (CaO) | 62.3 | --- |

| MgO | 2.04 | 6.0 (max) |

| Fe2O3 | 4.09 | --- |

| SO3 | 2.10 | --- |

| C3A | 2.81 | 3.0 (max) |

| C4AF | 14.2 | 25.0 (max) |

| Loss on ignition | 2.42 | 3.0 (max) |

| Insoluble residue | 0.59 | 0.75 (max) |

| Mix No. | Steel Fiber Ratio (%) | Polyolefin Fiber Ratio (%) | Compressive Strength, fcu (MPa) | Compressive Strength, (MPa) | Tensile Strength, fct (MPa) | Flexural Strength, ft (MPa) |

|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 36.41 | 30.34 | 2.68 | 16.13 |

| 2 | 100 | 0 | 41.45 | 34.54 | 4.30 | 23.80 |

| 3 | 75 | 25 | 39.66 | 33.05 | 3.89 | 23.28 |

| 4 | 50 | 50 | 38.69 | 32.24 | 4.86 | 25.54 |

| 5 | 25 | 75 | 38.26 | 31.88 | 3.75 | 21.69 |

| 6 | 0 | 100 | 37.48 | 31.23 | 3.47 | 17.93 |

| Group No. | Specimen ID | Concrete Strength, (MPa) | Ultimate Load, Pu (kN) | Midspan Deflection at Pu (mm) | Steel Stress, fs (MPa) | Bond Strength, utest (MPa) | utest/ | Bond Ratio | Failure Mode |

|---|---|---|---|---|---|---|---|---|---|

| 1 | B10S0P0 | 30.34 | 109.90 | 1.65 | 317.83 | 7.95 | 3.39 | 1.00 | SP |

| B10S100P0 | 34.54 | 138.45 | 6.29 | 399.21 | 9.98 | 4.12 | 1.22 | SP | |

| B10S75P25 | 33.05 | 126.62 | 4.49 | 365.45 | 9.14 | 3.81 | 1.13 | SP | |

| B10S50P50 | 32.24 | 171.03 | 5.44 | 493.92 | 12.35 | 5.18 | 1.53 | SP | |

| B10S25P75 | 31.88 | 120.07 | 4.47 | 346.83 | 8.67 | 3.65 | 1.08 | SP | |

| B10S0P100 | 31.23 | 119.47 | 1.21 | 345.28 | 8.63 | 3.65 | 1.08 | SP | |

| 2 | B15S0P0 | 30.34 | 132.64 | 2.56 | 383.58 | 6.39 | 2.72 | 1.00 | SP |

| B15S100P0 | 34.54 | 202.52 | 10.53 | 522.00 * | 8.70 | 3.59 | 1.32 | SP + Y | |

| B15S75P25 | 33.05 | 173.49 | 8.57 | 500.75 | 8.35 | 3.48 | 1.28 | SP | |

| B15S50P50 | 32.24 | 241.11 | 6.07 | 522.00 * | 8.70 | 3.65 | 1.34 | SP + Y | |

| B15S25P75 | 31.88 | 157.49 | 5.60 | 454.93 | 7.58 | 3.19 | 1.17 | SP | |

| B15S0P100 | 31.23 | 155.83 | 2.09 | 450.35 | 7.51 | 3.18 | 1.17 | SP |

| Group No. | Specimen ID | Concrete Strength, (MPa) | Ultimate Load, Pu (kN) | Normalized Load Ratio | Test and Calculated Bond Stress, u (MPa) | Normalized Bond Stress, | ucalc/utest | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test | Orangun | Darwin | Harajli | Test | Orangun | Darwin | Harajli | Orangun | Darwin | Harajli | ||||||

| 1 | B10S0P0 | 30.34 | 109.90 | 46.83 | 1.00 | 7.95 | 5.33 | 5.81 | 5.81 | 3.39 | 2.27 | 2.47 | 2.47 | 0.67 | 0.73 | 0.73 |

| B10S100P0 | 34.54 | 138.45 | 57.11 | 1.22 | 9.98 | 5.69 | 6.00 | 7.69 | 4.12 | 2.35 | 2.47 | 3.17 | 0.57 | 0.60 | 0.77 | |

| B10S75P25 | 33.05 | 126.62 | 52.81 | 1.13 | 9.14 | 5.57 | 5.93 | 7.64 | 3.81 | 2.32 | 2.47 | 3.19 | 0.61 | 0.65 | 0.84 | |

| B10S50P50 | 32.24 | 171.03 | 71.78 | 1.53 | 12.35 | 5.50 | 5.89 | 7.63 | 5.18 | 2.31 | 2.47 | 3.20 | 0.45 | 0.48 | 0.62 | |

| B10S25P75 | 31.88 | 120.07 | 50.53 | 1.08 | 8.67 | 5.47 | 5.88 | 7.66 | 3.65 | 2.30 | 2.47 | 3.22 | 0.63 | 0.68 | 0.88 | |

| B10S0P100 | 31.23 | 119.47 | 50.54 | 1.08 | 8.63 | 5.41 | 5.85 | 7.66 | 3.65 | 2.29 | 2.47 | 3.24 | 0.63 | 0.68 | 0.89 | |

| 2 | B15S0P0 | 30.34 | 132.64 | 56.52 | 1.00 | 6.39 | 4.57 | 4.70 | 4.70 | 2.72 | 1.95 | 2.00 | 2.00 | 0.71 | 0.74 | 0.74 |

| B15S100P0 | 34.54 | 202.52 | 83.54 | 1.48 | 8.70 | 4.88 | 4.86 | 6.55 | 3.59 | 2.01 | 2.00 | 2.70 | 0.56 | 0.56 | 0.75 | |

| B15S75P25 | 33.05 | 173.49 | 72.36 | 1.28 | 8.35 | 4.77 | 4.80 | 6.51 | 3.48 | 1.99 | 2.00 | 2.72 | 0.57 | 0.58 | 0.78 | |

| B15S50P50 | 32.24 | 241.11 | 101.19 | 1.79 | 8.70 | 4.71 | 4.77 | 6.51 | 3.65 | 1.98 | 2.00 | 2.73 | 0.54 | 0.55 | 0.75 | |

| B15S25P75 | 31.88 | 157.49 | 66.28 | 1.17 | 7.58 | 4.69 | 4.76 | 6.54 | 3.19 | 1.97 | 2.00 | 2.75 | 0.62 | 0.63 | 0.86 | |

| B15S0P100 | 31.23 | 155.83 | 65.92 | 1.17 | 7.51 | 4.64 | 4.74 | 6.55 | 3.18 | 1.96 | 2.00 | 2.77 | 0.62 | 0.63 | 0.87 | |

| Mean | 0.60 | 0.62 | 0.79 | |||||||||||||

| SD | 0.07 | 0.08 | 0.08 | |||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Hussein, A.; Majeed, F.H.; Naser, K.Z. Tension Lap Splices in Recycled-Aggregate Concrete Strengthened with Steel–Polyolefin Fibers. Fibers 2024, 12, 60. https://doi.org/10.3390/fib12080060

Al-Hussein A, Majeed FH, Naser KZ. Tension Lap Splices in Recycled-Aggregate Concrete Strengthened with Steel–Polyolefin Fibers. Fibers. 2024; 12(8):60. https://doi.org/10.3390/fib12080060

Chicago/Turabian StyleAl-Hussein, Abdullah, Fareed H. Majeed, and Kadhim Z. Naser. 2024. "Tension Lap Splices in Recycled-Aggregate Concrete Strengthened with Steel–Polyolefin Fibers" Fibers 12, no. 8: 60. https://doi.org/10.3390/fib12080060

APA StyleAl-Hussein, A., Majeed, F. H., & Naser, K. Z. (2024). Tension Lap Splices in Recycled-Aggregate Concrete Strengthened with Steel–Polyolefin Fibers. Fibers, 12(8), 60. https://doi.org/10.3390/fib12080060