Mechanical Properties of Woven Fabrics Containing Elastane Fibers

Abstract

1. Introduction

2. Materials and Methods

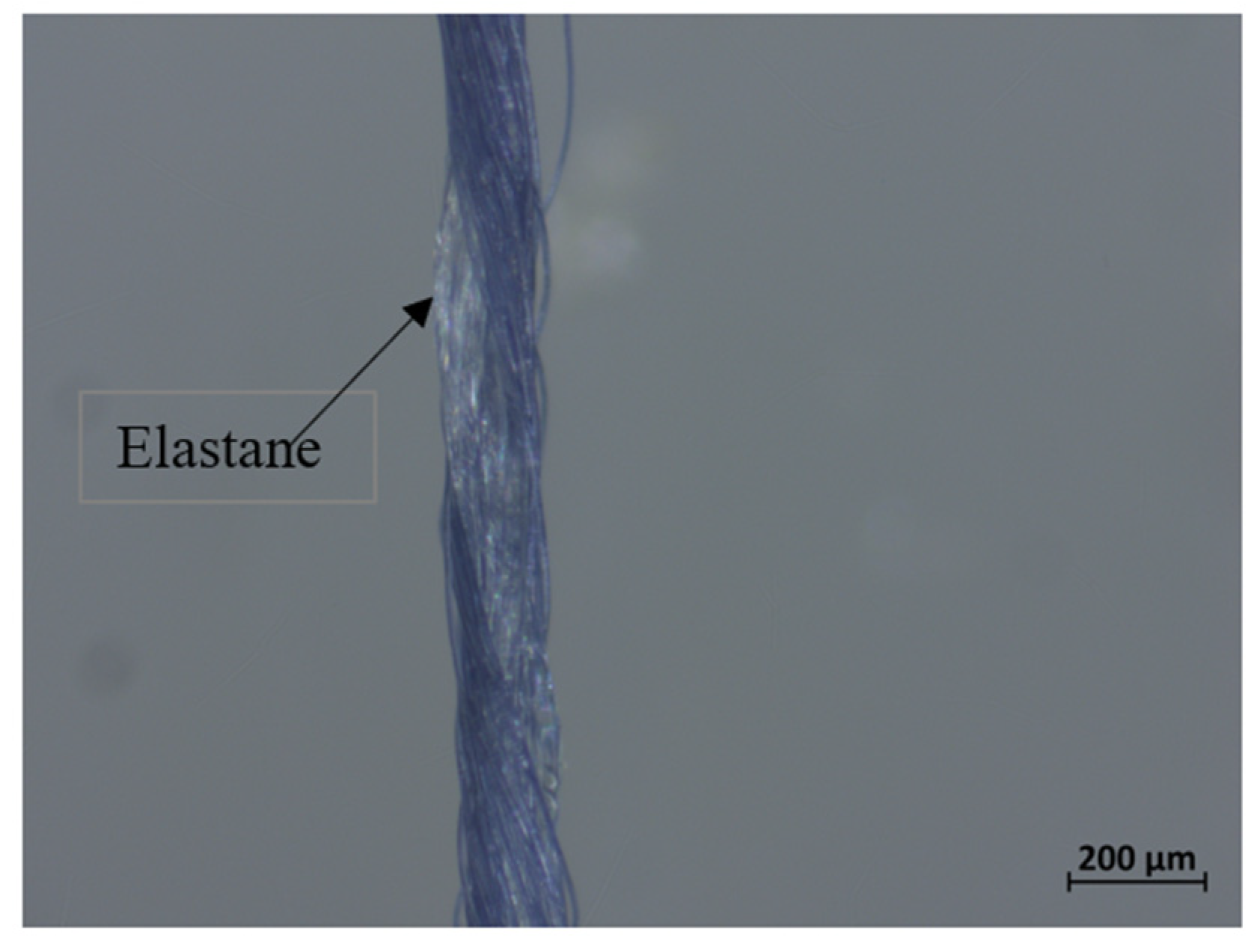

2.1. Materials

2.2. Methods

3. Results

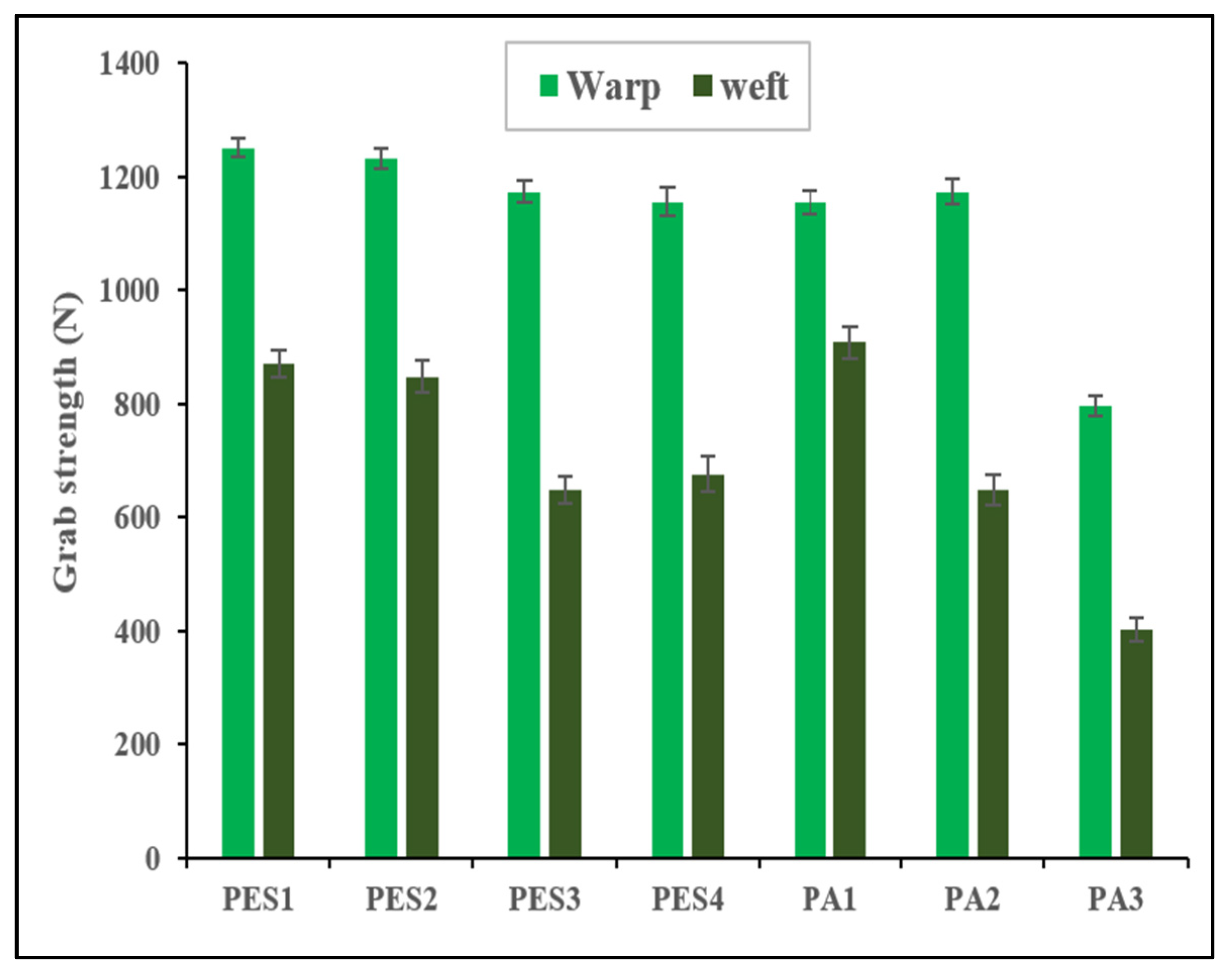

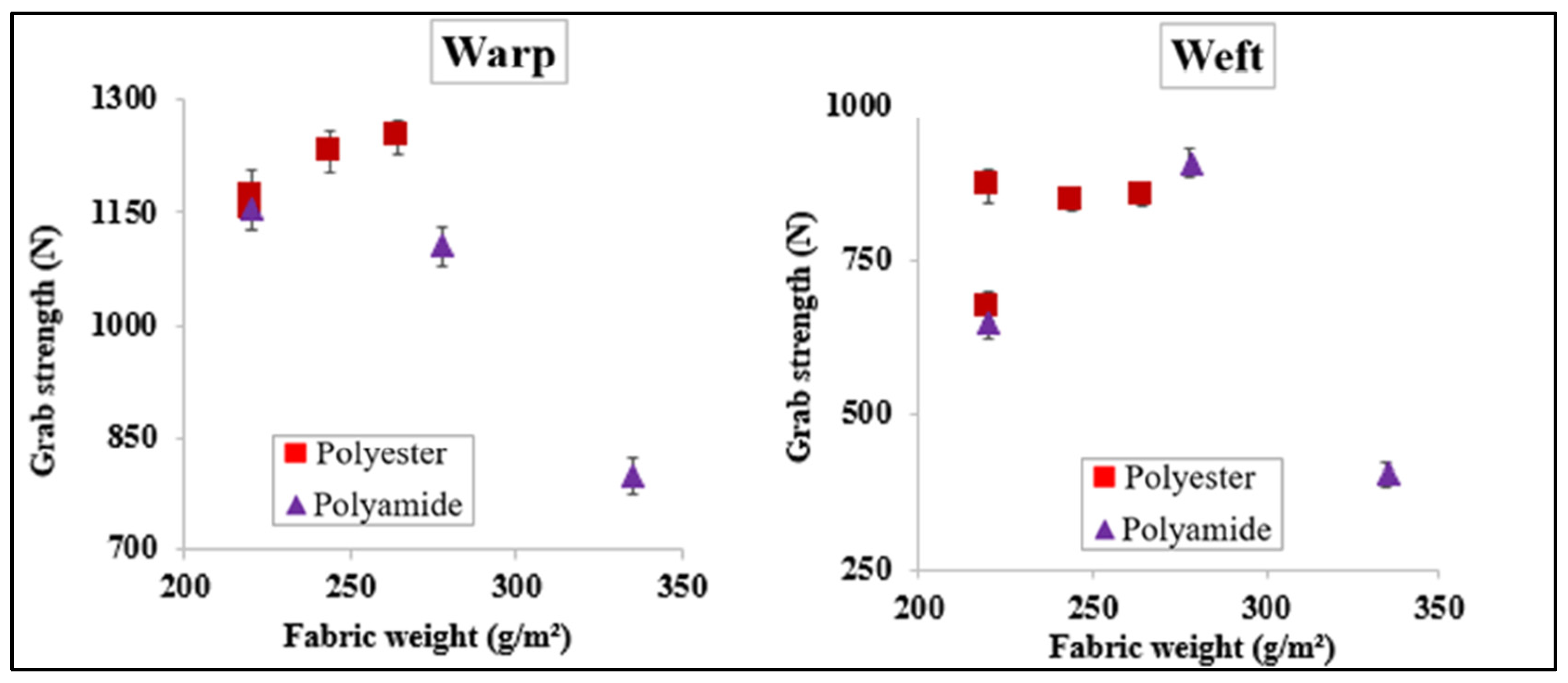

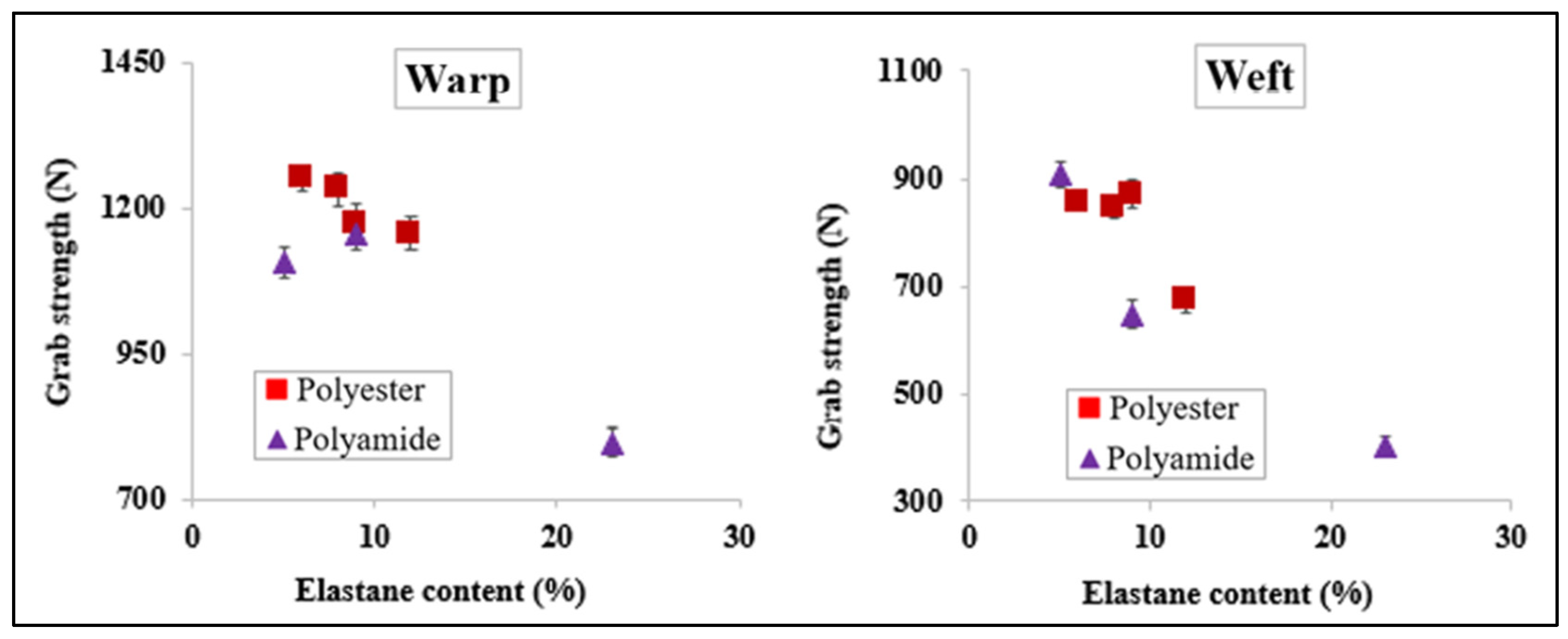

3.1. Grab Strength

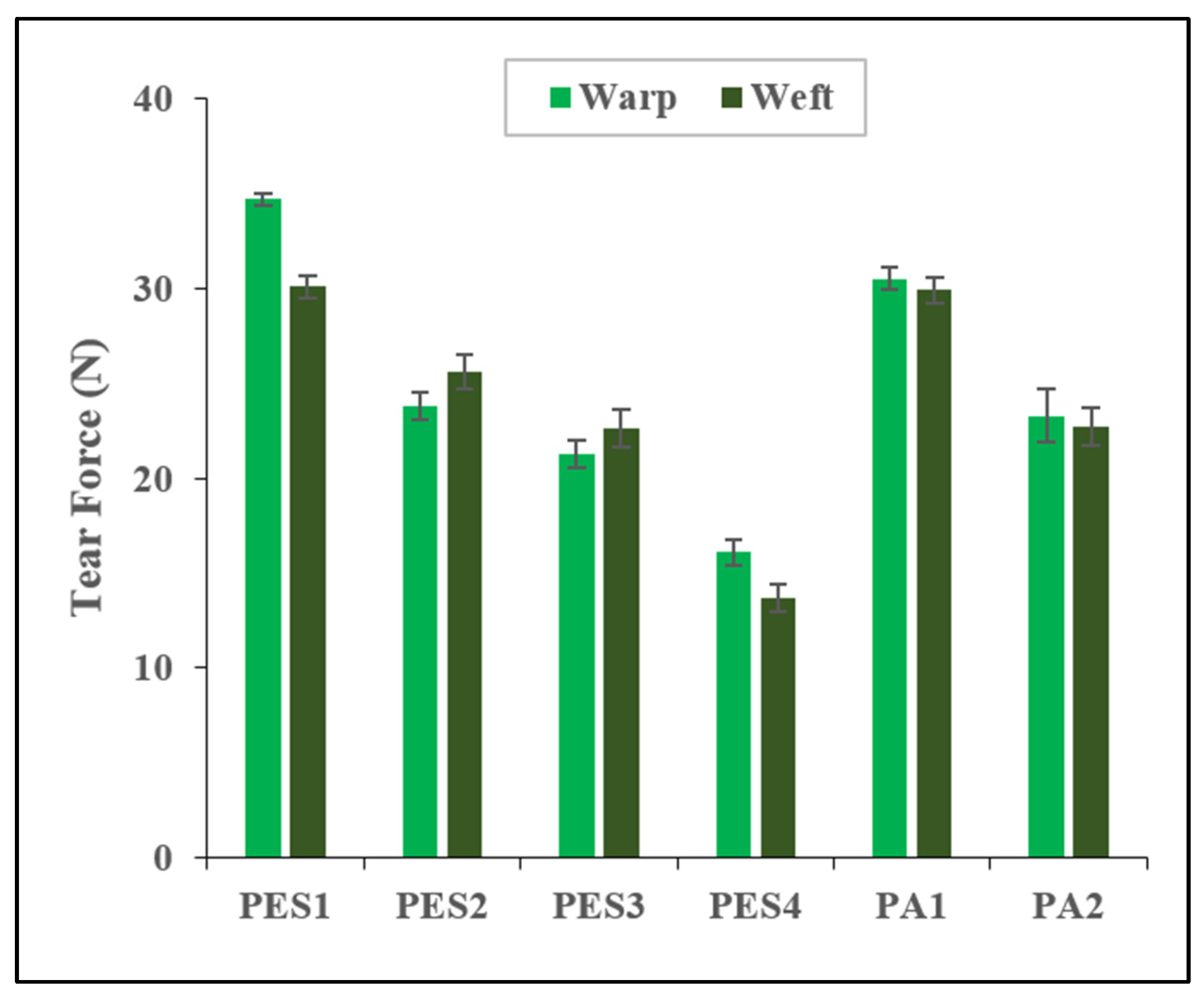

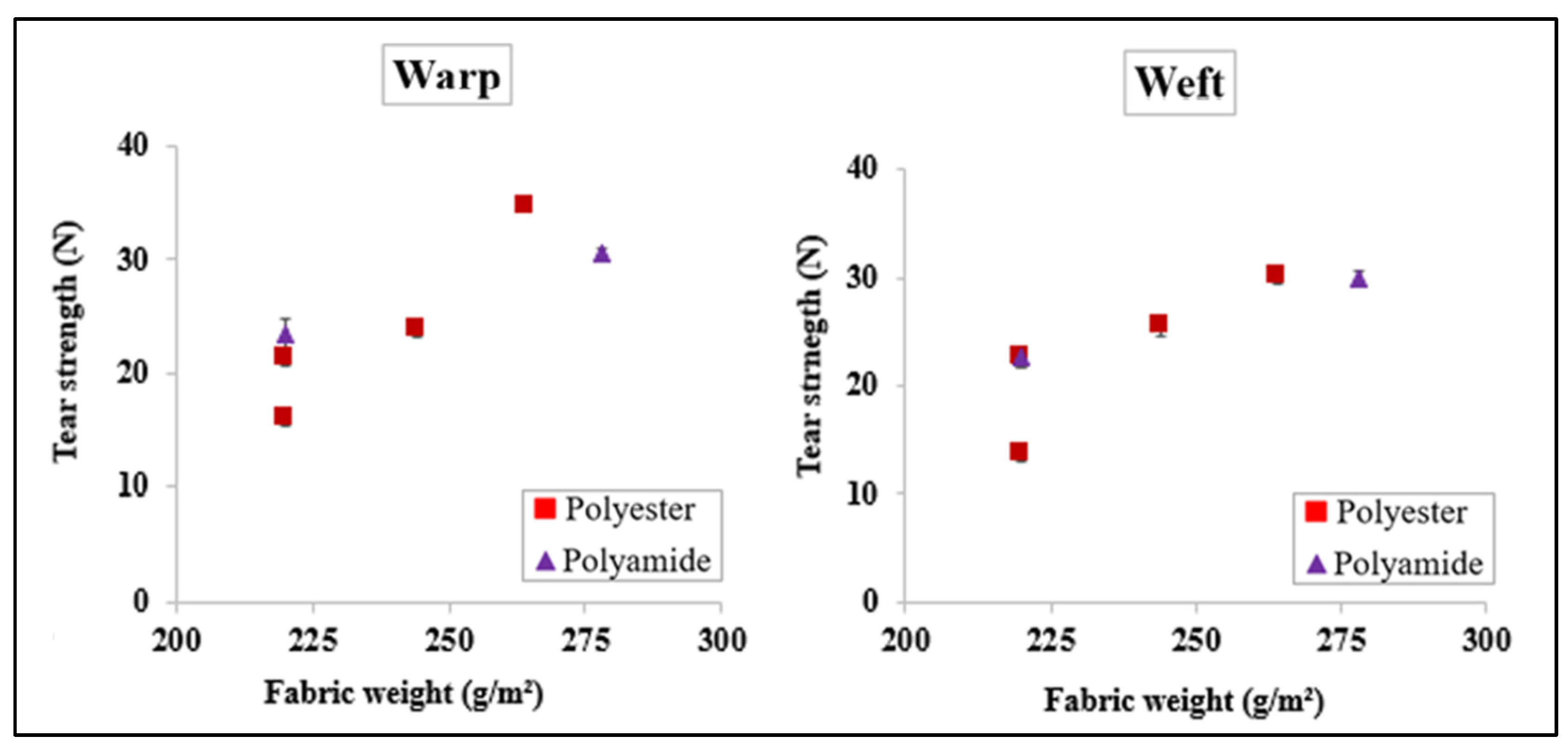

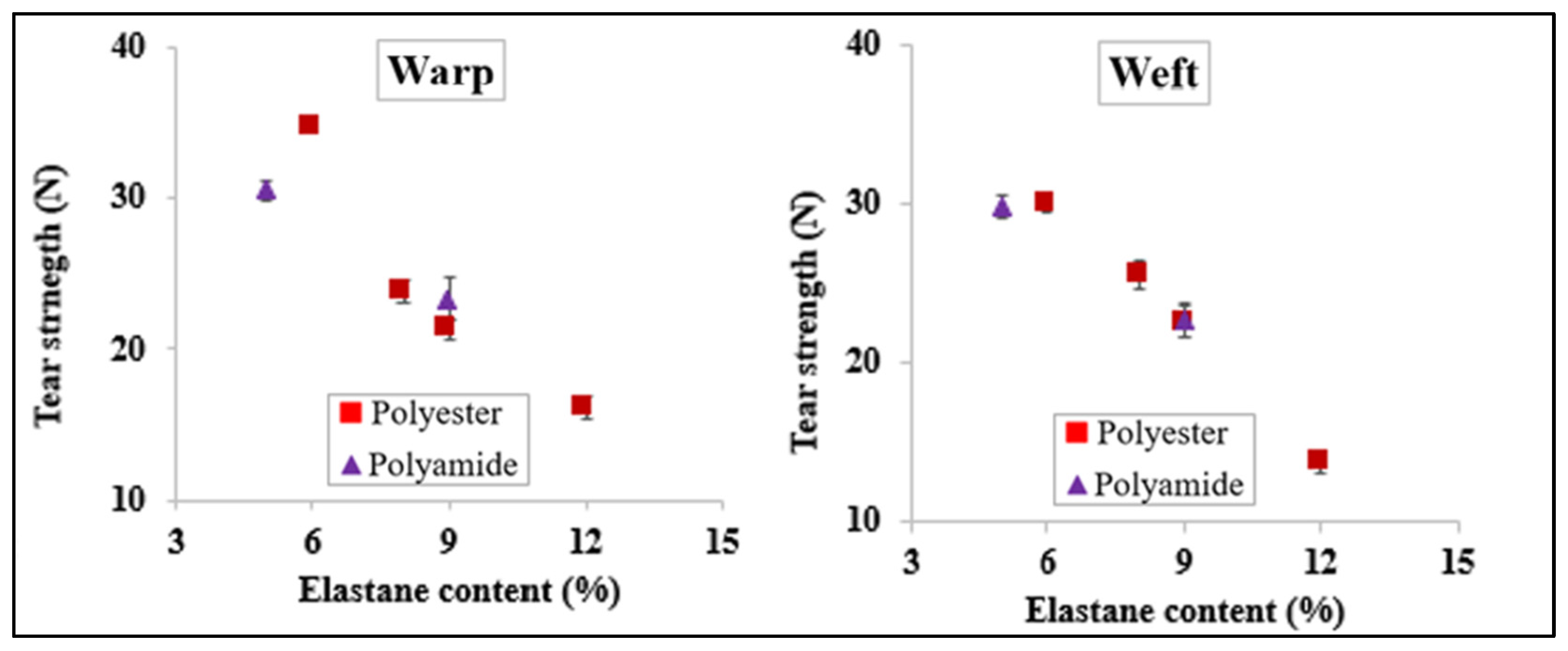

3.2. Tear Strength

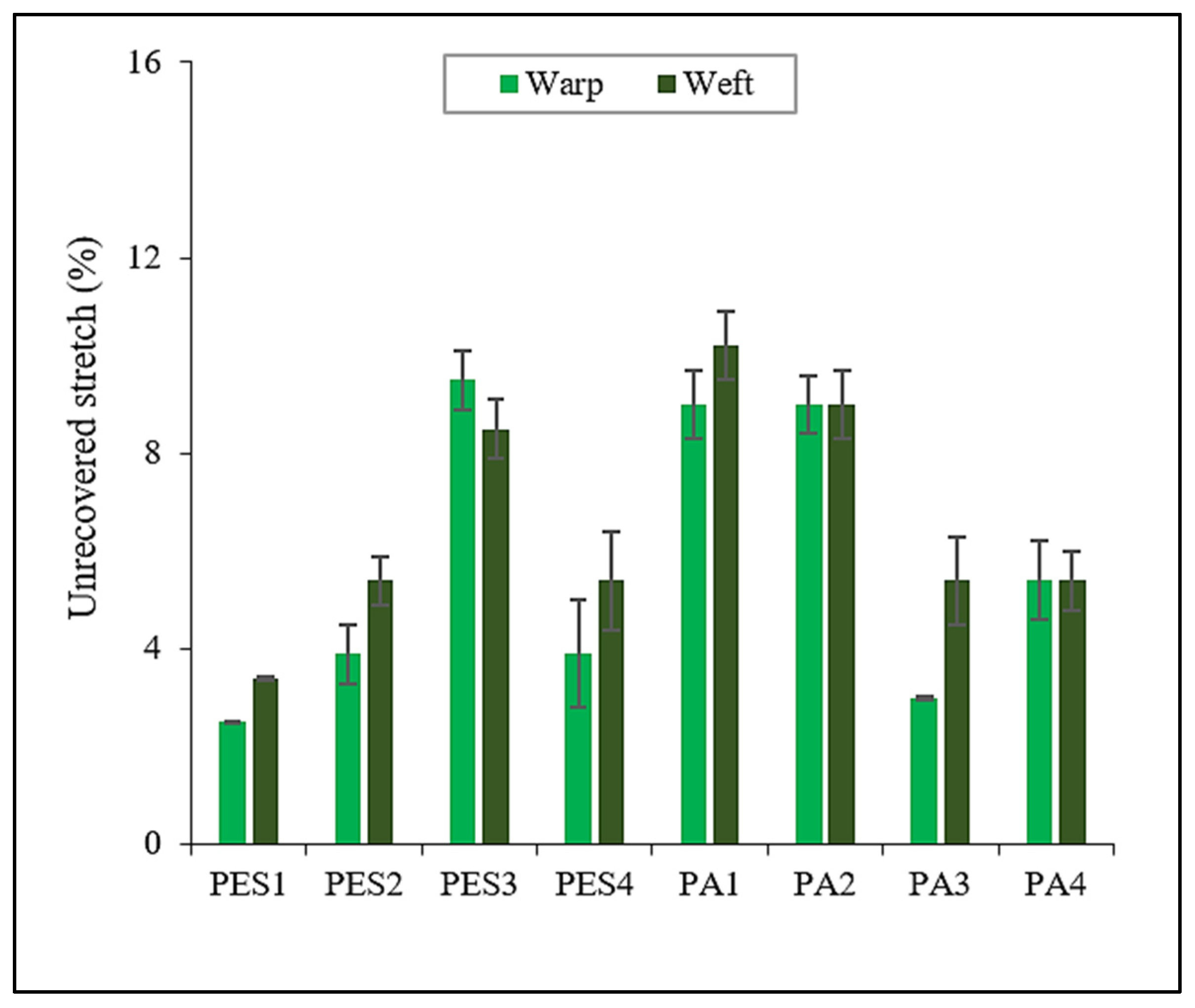

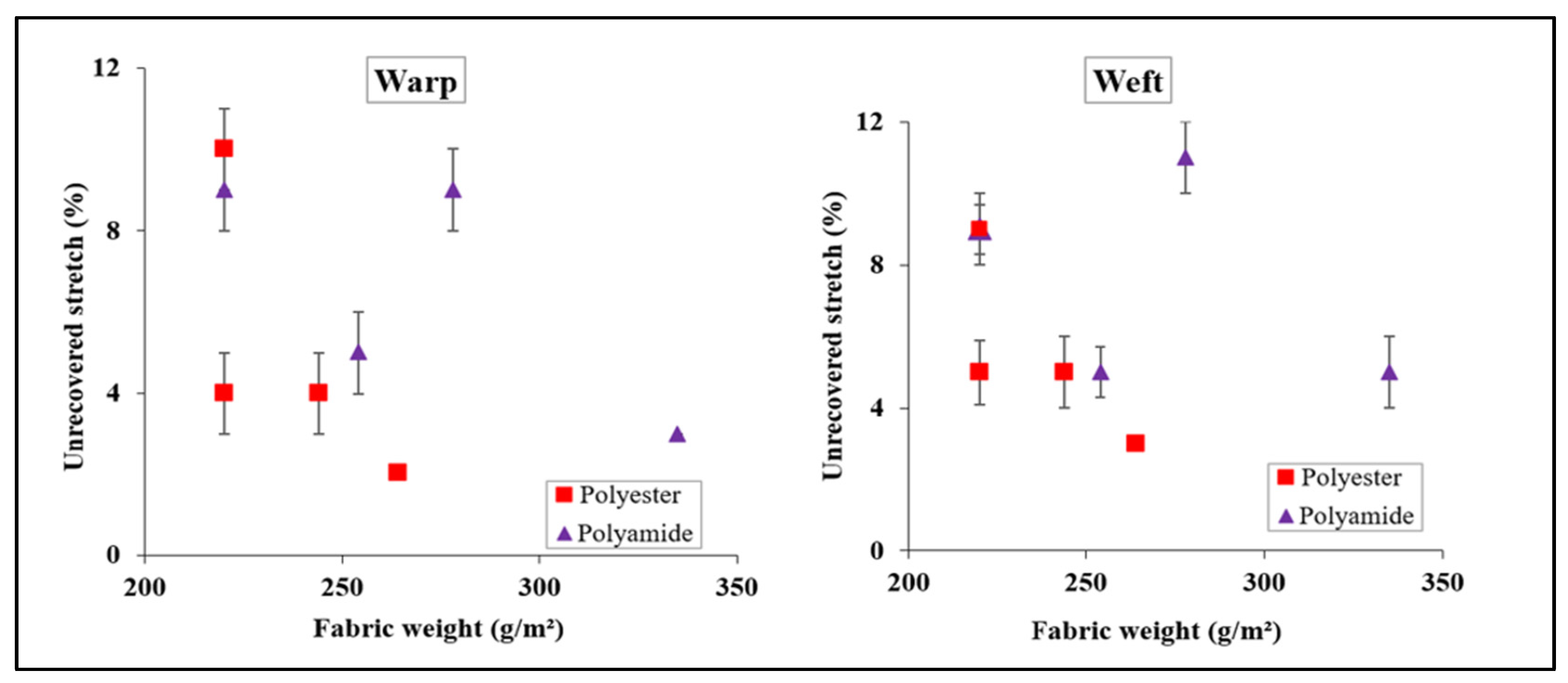

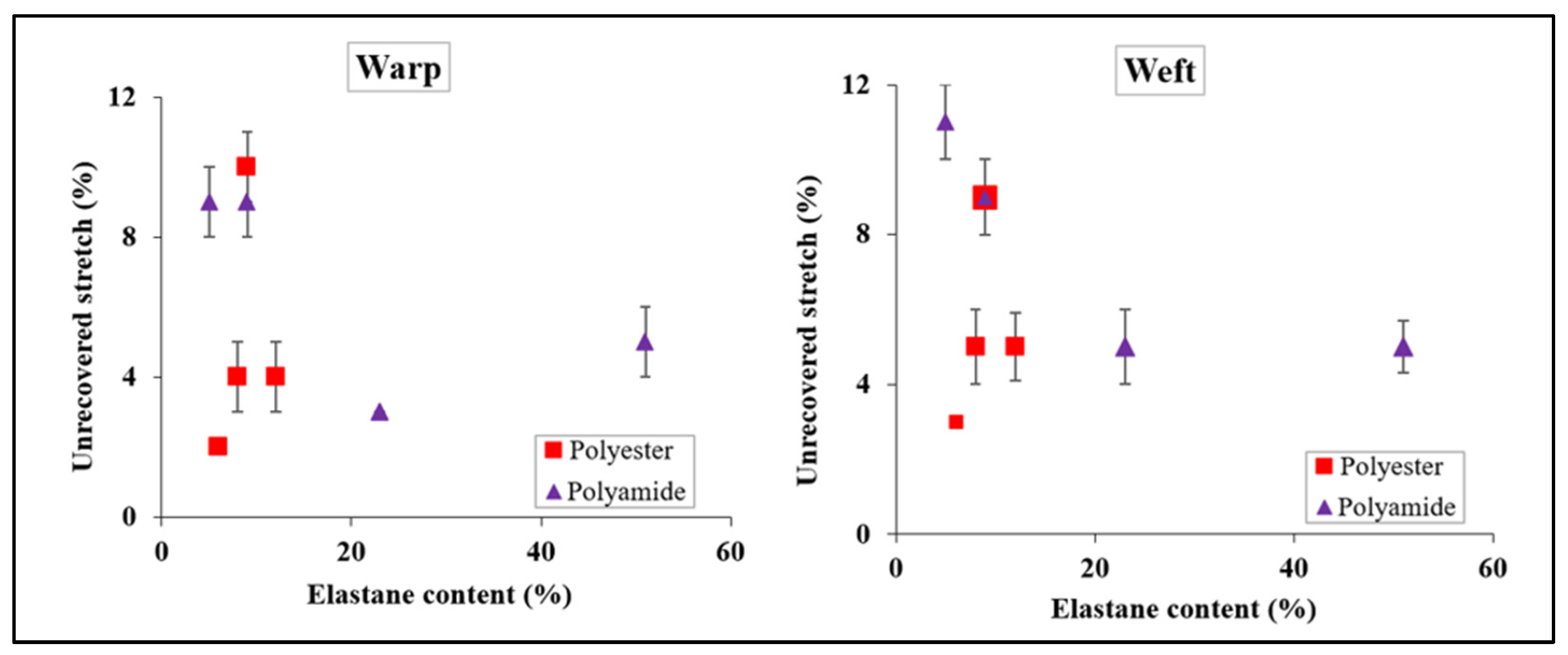

3.3. Unrecovered Stretch

4. Discussion

4.1. Effect of Fabric Characteristics on the Grab Strength

4.1.1. Effect of Fabric Weight

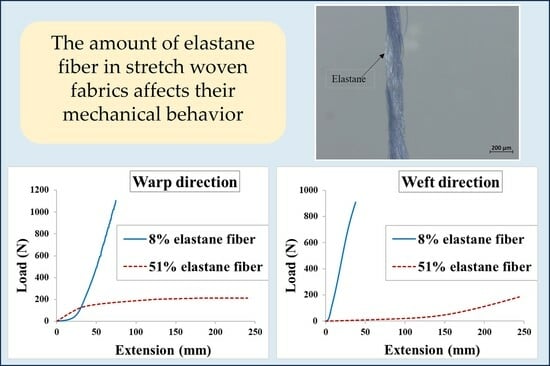

4.1.2. Effect of Elastane Fiber Content

4.2. Effect of Fabric Characteristics on the Tear Strength

4.2.1. Effect of Fabric Weight

4.2.2. Effect of Elastane Fiber Content

4.3. Effect of Fabric Characteristics on the Unrecovered Stretch

4.3.1. Effect of Fabric Weight

4.3.2. Effect of Elastane Fiber Content

4.4. Fabric Selection

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hossain, M.M.; Datta, E.; Rahman, S. A review on different factors of woven fabric strength. Sci. Res. 2016, 4, 88–97. [Google Scholar] [CrossRef]

- Jahan, I. Effect of fabric structure on the mechanical properties of woven fabrics. Adv. Res. Text. Eng. 2017, 2, 1011–1018. [Google Scholar] [CrossRef]

- Choudhary, A.K.; Bansal, S. Influences of elastane content, aesthetic finishes and fabric weight on mechanical and comfort properties of denim fabric. Text. Eng. Fash. Technol. 2018, 4, 36–42. [Google Scholar]

- Kim, H. Mechanical properties and garment formability of PET/Elastane stretch fabric. J. Korean Soc. Cloth. 2017, 41, 1098–1108. [Google Scholar] [CrossRef]

- Pannu, S.; Jamdigni, R.; Behera, B.K. Influence of weave design on shrinkage potential of stretch fabric. J. Manag. Rev. 2019, 7, 1025–1035. [Google Scholar]

- Kaynak, H.K. Optimization of stretch and recovery properties of woven stretch fabrics. Text. Res. J. 2017, 87, 582–592. [Google Scholar] [CrossRef]

- Sacevicienė, V.; Masteikaitė, V.; Klevaitytė, R.; Audzevičiūtė, I. Influence of the elastane Fibre on the woven fabric structural mobility. Mater. Sci. 2011, 17, 413–416. [Google Scholar] [CrossRef][Green Version]

- Eryuruk, S.H. The effects of elastane and finishing processes on the performance properties of denim fabrics. Int. J. Cloth. Sci. 2019, 31, 243–258. [Google Scholar] [CrossRef]

- Tsai, I.D.; Cassidy, C.; Cassidy, T.; Shen, J. The influence of woven stretch fabric properties on garment design and pattern construction. Meas. Cont. 2002, 24, 3–14. [Google Scholar] [CrossRef]

- Varghese, N.; Thilagavathi, G. Development of woven stretch fabric for comfortably fitting blouses and analysis of fit. Int. J. Fash. Des. 2013, 6, 53–62. [Google Scholar] [CrossRef]

- Ertas, O.G.; Zervent, B.U.; Celik, N. Analyzing the effect of the elastane-containing dual-core weft yarn density on the denim fabric performance properties. J. Text. Inst. 2016, 107, 116–126. [Google Scholar] [CrossRef]

- AL-ansary, M.A.R. Effect of spandex ratio on the properties of woven fabrics made of cotton / spandex spun yarns. J. Am. Sci. 2011, 7, 63–67. [Google Scholar]

- Mourad, M.M.; Elshakankery, M.H.; Alsaid, A.A. Physical and stretch properties of woven cotton fabrics containing different rates of elastane. J. Am. Sci. 2012, 8, 567–572. [Google Scholar]

- Qadir, B.; Hussain, T.; Malik, M. Effect of Elastane Denier and Draft Ratio of Core-Spun Cotton Weft Yarns on the Mechanical Properties of Woven Fabrics. J. Eng. Fibers Fabr. 2014, 9, 23–31. [Google Scholar] [CrossRef]

- Kumar, S.; Chatterjee, K.; Padhye, R.; Nayak, R. Designing and developing denim fabrics: Part 1- study of the effect of fabric parameters on the fabric characteristics of women’s wear. J. Text. Sci. Eng. 2016, 6, 4. [Google Scholar] [CrossRef]

- Hill, B.J.; Mcllhager, R.; Harper, C.M. Weaving of three-dimensional fabrics to perform construction: Part I, use of texturized glass yarns. J. Text. Inst. 1995, 86, 96–103. [Google Scholar] [CrossRef]

- Kumpikaite, E.; Varnaite-Zuravliova, S.; Tautkute-Stankuviene, I.; Laureckiene, G. Comparison of mechanical and end-use properties of grey and dyed cellulose and cellulose/protein woven fabrics. Material 2021, 14, 2860. [Google Scholar] [CrossRef]

- Stig, F.; Halstrom, S. Effect of crimp and textile architecture on the stiffness and strength of composites with 3D reinforcement. J. Adv. Mater. Sci. Eng. 2019, 2019, 8439530. [Google Scholar] [CrossRef]

- Karmakar, S.R. Heat setting—Chapter 8. In Textile Science and Technology; Elsevier: Amsterdam, The Netherlands, 1999; Volume 12, pp. 259–278. [Google Scholar] [CrossRef]

- ASTM D 5034; Standard Test Method for Breaking Strength and Elongation of Textile Fabrics. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D 1424-09; Standard Test Method for Tearing Strength of Fabrics by Falling Pendulum (Elmendorf-Type). ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D 4964-96; Standard Test Method for Tension and Elongation of Elastic Fabrics (Constant-Rate-of-Extension Type Tensile Testing Machine). ASTM International: West Conshohocken, PA, USA, 2016.

- CAN/CGSB-4.2 No. 6-M89/ISO 7211/2; Woven Fabrics Construction Method of Analysis Part Two: Determination of Number of Threads per Unit Length. Canadian General Standards Board (CGSB): Ottawa, ON, Canada, 1989.

- CAN/CGSB-4.2, No. 5.1; Determination of Number of Fabric Weight. Canadian General Standards Board (CGSB): Ottawa, ON, Canada, 2004.

- ASTM D 1777-96; Standard Test Method for Thickness of Textile Materials. ASTM International: West Conshohocken, PA, USA, 2019.

- Sun, F.; Seyen, A.M.; Gupta, B.S. A generalized model for predicting load-extension properties of woven fabrics. Text. Res. J. 1997, 67, 866–874. [Google Scholar] [CrossRef]

- Chan, C.K.; Jiang, X.Y.; Liew, K.L.; Chan, L.K.; Wong, W.K.; Lau, M.P. Evaluation of mechanical properties of uniform fabrics in garment manufacturing. J. Mater. Process. Technol. 2006, 174, 183–189. [Google Scholar] [CrossRef]

- Shaw, V.P.; Mukhopadhyay, A. Reliability analysis of stretchable workwear fabric under abrasive damage: Influence of stretch yarn composition. J. Nat. Fibers 2021, 20, 2134262. [Google Scholar] [CrossRef]

- Gorjanc, D.S.; Bukosek, V. The behavior of elastane yarn during stretching. Fibres Text. East. Eur. 2008, 16, 63–68. [Google Scholar]

- Milanka, D.N.; Mihailovic, T.V. Investigation of fabric deformation under different loading conditions. Int. J. Cloth. Sci. 1996, 8, 9–16. [Google Scholar]

- Su, C.-I.; Maa, M.-C.; Yang, H.-I. Structure and performance of elastic core-spun yarn. Text. Res. J. 2004, 74, 607–610. [Google Scholar] [CrossRef]

- Klevaitytė, R.; Masteikaitė, V. Anisotropy of woven fabric deformation after stretching. Fibres Text. East. Eur. 2006, 16, 52–56. [Google Scholar]

- Nosraty, H.; Jeddi, A.A.A.; Avanaki, M.J. Fatigue behavior of filament warp yarns under cyclic loads during weaving process. Text. Res. J. 2009, 79, 154–165. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Deakin, C.H. Physical and Mechanical Testing of Textiles; Woodhead Publishing: Cambridge, UK, 2008; pp. 90–124. [Google Scholar]

- Seo, M.H.; Realff, M.L.; Pan, N.; Boyce, M.; Schwartz, P.; Backer, S. Mechanical properties of fabric woven from yarns produced by different spinning technologies: Yarn failure in woven fabrics. Text. Res. J. 1993, 63, 123–134. [Google Scholar] [CrossRef]

- Pan, N.; Yoon, M.-Y. Behavior of yarn pullout from woven fabrics: Theoretical and experimental. Text. Res. J. 1992, 63, 629–637. [Google Scholar]

- Ferdons, N.; Rahman, S.; Kabir, R.B.; Ahmed, A.F. A comparative study on tensile strength of different weave structures. Sci. Res. Eng. Technol. 2014, 3, 1307–1313. [Google Scholar]

- Aseyah, A.; Jeddi, A.A. Modelling the creep behavior of plain-woven fabrics constructed from textured polyester yarn. Text. Res. J. 2000, 90, 642–650. [Google Scholar] [CrossRef]

- Elrys, S.M.M.E.; El-Habiby, F.F.; Eldeeb, A.S.; El-Hossiny, A.M.; Elkhalek, R.A. Influence of core yarn structure and yarn count on yarn elastic properties. Text. Res. J. 2022, 92, 3534–3544. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Yeung, K.W.; Miao, M.H.; Yao, M. Fabric bagging: Stress distribution in isotropic and anisotropic fabrics. J. Text. Inst. 2000, 91, 563–576. [Google Scholar] [CrossRef]

- Mebrate, M.; Gessesse, N.; Zinabu, N. Effect of loom tension on mechanical properties of plain-woven cotton fabrics. J. Nat. Fibres 2020, 19, 1443–1448. [Google Scholar] [CrossRef]

- Nassif, G.A.A. Effect of weave structure and weft density on the physical and mechanical properties of micro polyester woven fabrics. Life Sci. J. 2012, 9, 413–416. [Google Scholar]

- Eltahan, E. Structural parameters affecting tear strength of the fabric tents. Alex. Eng. J. 2018, 57, 97–105. [Google Scholar] [CrossRef]

- Almetwally, A.A.; Mourad, M.M. Effect of spandex drawing ratio and weave structure on the physical and properties of cotton/spandex fabrics. J. Text. Inst. 2014, 105, 235–245. [Google Scholar] [CrossRef]

- Quye, A. Factors influencing the stability of man-made fibers: A retrospective view for historical textiles. Polym. Degrad. Stab. 2014, 107, 210–218. [Google Scholar] [CrossRef]

- Singha, K. Analysis of spandex/cotton elastomeric properties: Spinning and applications. Int. J. Compos. Mater. 2012, 2, 11–16. [Google Scholar] [CrossRef]

- ASTM D 7019; Standard Performance Specification for Brassiere, Slip, Lingerie and Underwear Fabrics. ASTM International: West Conshohocken, PA, USA, 2020.

- Fabric and Apparel Performance Testing Protocol; Kate Spade & Company: New York, NY, USA, 2018; 23p.

- McGhee, D.E.; Steele, J.R.; Zealey, W.J.; Takacs, G.J. Bra-breast forces generated in women with large breasts while standing and during treadmill running: Implications for sports bra design. Appl. Ergon. 2013, 144, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Hoque, M.d.S.; Degenstein, L.; Dolez, P.I. Innovations in woven textiles. In Sustainable Innovations in the Textile Industry; Paul, R., Gries, T., Eds.; Elsevier: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2024. [Google Scholar]

- Dolez, P.I.; Marsha, S.; McQueen, R.H. Fibers and Textiles for Personal Protective Equipment: Review of Recent Progress and Perspectives on Future Developments. Textiles 2022, 2, 349–381. [Google Scholar] [CrossRef]

| Fabric | Fabric Composition * | Fabric Structure | Direction of Elastane Fiber | Fabric Weight (g/m2) | Fabric Count (yarn/cm) | Thickness (mm) | |

|---|---|---|---|---|---|---|---|

| Warp | Weft | ||||||

| PES1 | 94% PET–6% ES | 1/2 basket weave | Weft | 264 | 20 | 44 | 0.53 |

| PES2 | 92% PET–8% ES | 1/2 basket weave | Warp and weft | 244 | 30 | 56 | 0.58 |

| PES3 | 91% PET–9% ES | 2/2 twill | Warp and weft | 220 | 46 | 34 | 0.84 |

| PES4 | 88% PET–12% ES | 2/1 twill | Warp and weft | 220 | 44 | 34 | 0.56 |

| PA1 | 95% PA–5% ES | 1/2 basket weave | Weft | 278 | 20 | 44 | 0.52 |

| PA2 | 91% PA–9% ES | 2/2 twill | Warp and weft | 220 | 50 | 34 | 0.56 |

| PA3 | 77% PA–23% ES | 1/2 basket weave | Weft | 335 | 28 | 38 | 0.81 |

| PA4 | 49% PA–51% ES | Dooby weave | Warp and weft | 254 | 39 | 39 | 0.66 |

| Fabric | Force at 30% Extension (N) | |

|---|---|---|

| Warp | Weft | |

| PES1 | 24 | 18 |

| PES2 | 11 | 12 |

| PES3 | 76 | 81 |

| PES4 | 54 | 56 |

| PA1 | 408 | 373 |

| PA2 | 73 | 79 |

| PA3 | 12 | 13 |

| PA4 | 10 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolaji, J.T.; Dolez, P.I. Mechanical Properties of Woven Fabrics Containing Elastane Fibers. Fibers 2024, 12, 30. https://doi.org/10.3390/fib12040030

Bolaji JT, Dolez PI. Mechanical Properties of Woven Fabrics Containing Elastane Fibers. Fibers. 2024; 12(4):30. https://doi.org/10.3390/fib12040030

Chicago/Turabian StyleBolaji, Josephine T., and Patricia I. Dolez. 2024. "Mechanical Properties of Woven Fabrics Containing Elastane Fibers" Fibers 12, no. 4: 30. https://doi.org/10.3390/fib12040030

APA StyleBolaji, J. T., & Dolez, P. I. (2024). Mechanical Properties of Woven Fabrics Containing Elastane Fibers. Fibers, 12(4), 30. https://doi.org/10.3390/fib12040030