Abstract

Unlike the recycling of particleboards, the recycling of medium-density fiberboards (MDF) is not a widespread industrial practice, and currently, most waste MDF panels are landfilled or incinerated after the end of their life cycle. Therefore, it is of great importance to develop cost-effective methods for MDF recycling. The extraction of resins used for bonding the panels, mostly urea–formaldehyde (UF) resins, is carried out mainly with hydrolysis. Hydrothermal hydrolysis is a more environmentally friendly and cheaper recycling technique compared to acid hydrolysis and allows obtaining a high yield of recycled fibers. The aim of this research work was to investigate and evaluate the effect of hydrolysis regime applied on its efficiency and on the properties of the recycled MDF fibers. For this purpose, thermal hydrolysis was carried out in an autoclave with saturated steam as a heat carrier. The main novelty of the research is the preliminary preparation of the recyclable MDF in samples with dimensions close to those of pulp chips. The effect of hydrolysis regime characteristics, i.e., process time and temperature on the properties of recycled MDF wood fibers, was studied. The hydrolysis temperatures used were 121 °C (saturated steam pressure of 0.2 MPa) and 134 °C (saturated steam pressure of 0.3 MPa); for each temperature, three durations were applied—30, 45, and 60 min. After hydrolysis, the resulting fiber fraction was refined using a hammer mill. The fractional and elemental composition of the recycled fibers obtained were evaluated. The hemicellulose content after each hydrolysis treatment was also determined. The chemical oxygen demand (COD) was defined as an indicator of wastewater contamination and as an indirect indicator of the quantitative yield of the process. The results revealed no significant changes in the elemental composition of the recycled fibers, and the hydrolysis regimes used showed no decrease in pentosan content. The recycled MDF fibers exhibited similar fiber morphology and fractional composition, being shorter than fibers from industrial pulp. The increased temperature and time of hydrolysis resulted in a significant increase in COD values. Based on the obtained results, with a view to the slightest contamination of wastewater (as determined by COD), the most promising hydrolysis regime was at a temperature of 121 °C and a time of 30 min. It should be emphasized that for a confirmation of this statement, the properties of MDF panels fabricated with fibers recycled in different regimes should be subsequently investigated.

1. Introduction

The growing demand for wood and wood-based materials, including medium-density fiberboards (MDF), has led to significantly increased wood harvesting and accelerated deforestation in many world regions [1]. A solution to this problem should be sought by optimizing the use of the available natural resources, searching for alternative lignocellulosic raw materials, and promoting the more effective reuse, recycling, and upcycling of wood and wood-based materials [2,3,4,5]. The increased use of recycled wood and wood-based composite materials in a variety of end uses is a viable approach to supporting the woodworking and furniture industries’ ongoing green transition to a circular and biobased economy, reducing their reliance on petroleum-derived products and lowering the industrial carbon footprint [6,7].

MDF production is one of the developing industries with a steady growth rate. The world production of MDF in 2021 was estimated to be 105 million m3 [1]. It should be emphasized that the life cycle of manufactured MDF panels is from 4 to 50 years [8]. According to the findings reported by the same research, 25% of the MDF panels end their life cycle within one year, and within 10 years, this percentage increased to 80% [8]. Consequently, this is associated with the greatly increased accumulation of waste MDF panels and difficulties in their disposal [9]. It is well known that 1 m3 of MDF is produced from 1.6 to 2.0 m3 of wood [10]. Therefore, even with just one recycling cycle of the panels, more than 168 million m3 of wood raw material can be saved. Another major problem regarding the increased amounts of waste MDF panels is associated with their disposal at landfills [11]. The landfilling of MDF panels is prohibited in Germany and other EU countries, and considering the recent environmental legislation encouraging the “cascading use” of wood resources, material recycling should always be considered before incineration for energy recovery [12,13,14].

While particleboard recycling is a relatively common production practice [15], some difficulties are encountered in MDF recycling [16,17]. Recycling wood-based panels can be carried out with or without extracting the incorporated resins, and recycling without removing the resins results in increased formaldehyde emission from the panels. When this recycling technique is used for manufacturing particleboards, the resulting particles are most commonly used as a filler in the panels’ core layer [18].

Waste MDF recycling can be carried out with or without resin extraction. The use of steam-based or hydrothermal recycling methods allows for the hydrolysis of urea–formaldehyde (UF) resins, which are the predominant thermoset synthetic resins used by the European wood-based panel industry manufacturers [19,20,21].

In addition to the increased formaldehyde emission, recycling without resin extraction is characterized by a significant decrease in fiber slenderness [22,23]. These are often bundles of cut and shortened fibers [24,25]. The amount of recycled fibers used in the panels is drastically reduced, and expensive formaldehyde scavengers must be incorporated into the manufacturing process [26,27].

Therefore, efforts regarding MDF recycling methods have focused primarily on resin extraction [28,29,30,31]. UF resin has no resistance to hydrolysis [31,32,33]. Hydrolysis can be thermal [34], thermochemical in an acidic solution [35], or hydrolysis by electrolysis [36].

Acid hydrolysis significantly accelerates the overall process, with treatment times ranging from 1 to 5 min [35,37]. However, this type of treatment increases the costs of the process due to the use of chemical reagents and the need for wastewater treatment. Recycling by electrolysis has demonstrated the best performance in terms of reduced process time and satisfactory properties of the recycled fibers obtained. However, the main drawback of this method is connected with the significantly increased process costs. As a result, the thermochemical hydrolysis of UF resin is emerging as the most promising recycling treatment suitable for industrial applications. A significant amount of research has been conducted in this regard, with the overall process time ranging from 30 to 150 min [25,38]. In the study carried out by Moezzipour et al. [39], it was found that with an increase in the hydrolysis temperature above 125 °C, a significant decrease in the hemicellulose content in recycled fibers was determined, compared to natural (virgin) fibers. It should be emphasized that the processing time was relatively long—150 min. This same study found that at a treatment temperature of 105 °C, the resulting panels produced from the recycled fibers exhibited deteriorated mechanical properties in comparison with MDF panels manufactured from natural wood fibers. Therefore, a temperature of about 125 °C can be defined as the optimal value for conducting hydrolysis treatment.

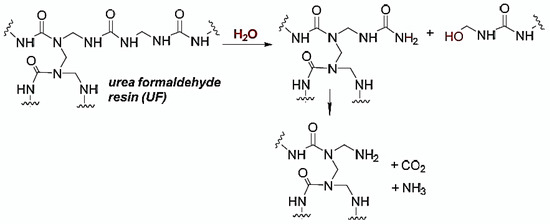

The use of hydrolysis is possible only with UF resins. When melamine–formaldehyde resins are present in the adhesive system, they will remain in the composition since they have a degradation temperature above that of wood [40]. In hydrolysis, the secondary products are NH3, HCN, and HNCO (Figure 1) [40,41,42]. Therefore, if such products are present in the fibers, this indicates a hydrolysis process.

Figure 1.

Hydrolysis of urea–formaldehyde resin [40].

The total time required for the hydrolysis process is also directly proportional to the size of the recyclable material. From a technological standpoint, it would be preferable if the recycled material had dimensions similar to pulp chips. This would allow the recyclable material to be included directly in the production flow after hydrolysis [41]. Other potential uses for recycled MDF fibers include the manufacture of wood polymer composites [42,43], the isolation of cellulose nanocrystals [44], the production of biogas and bio-oil [45,46], packaging [47,48,49], and so on.

This research work aimed to investigate and evaluate the effect of two different hydrolysis regimes applied on their efficiency and on the properties of the recycled MDF fibers.

2. Materials and Methods

For the study, conventional MDF panels, produced by Kronospan Bulgaria EOOD (Veliko Tarnovo, Bulgaria), were recycled, and industrial pulp from the same factory was supplied for comparative analysis. The pulp was produced via the thermomechanical Asplund method using a Defibrator L56 (Valmet, Stockholm, Sweden). The preheating during refining was carried out at a steam pressure of 12 atm (188 °C) for 3 min.

The commercial MDF was produced from mixed-wood raw materials—40% hardwoods (beech and Turkish oak) and 60% softwoods (spruce and pine). The density of the commercial MDF panels was 780 kg.m−3. UF resin with a molar ratio of 1.00 was used as a binder. The adhesive system contained 4% melamine based on the dry resin. Wax (paraffin emulsion) was used as a waterproof substance. The resin content relative to dry fibers was 8%, and the paraffin content was 1%.

MDF panels were processed into samples with dimensions similar to those of pulp chips—approximately 10 mm wide, 20 mm long, and 8 mm thick (Figure 2).

Figure 2.

MDF samples before hydrolysis.

The samples were treated in a TS 14 B+ autoclave (Cixi Tonsor Medical Instrument Co., Ltd., Ningbo, China). Following previous studies on recycling waste MDF panels, the temperatures used were 121 °C and 134 °C. Saturated steam with corresponding pressure of 0.2 MPa and 0.3 MPa was used as the heat carrier in thermal hydrolysis [39]. The effect of three processing times (30, 45, and 60 min) of thermal hydrolysis of the MDF samples on the properties of the recycled fibers was investigated. The selected process parameters are consistent with the study carried out by Moezzipour, B. et al. [39]. Other studies in the field show that at lower hydrolysis temperatures and similar process times, formaldehyde emissions in MDF panels fabricated with recycled fibers significantly increase [34]. That could be seen as circumstantial evidence of the incomplete disintegration of UF resins to amino compounds. On the other hand, when temperatures increase, the depolymerization of hemicelluloses and the formation of significant amounts of pentosans in the recycled fibers begin [14].

The characteristics of recycled fibers (RF) were compared to those of fibers from industrial pulp (FIP). The experimental plan used to perform the hydrolysis of MDF panels is presented in Table 1.

Table 1.

Experimental plan of MDF hydrolysis.

Following the UF resin hydrolysis protocol, the samples were refined using a laboratory hammer mill (prototype, University of Forestry, Sofia, Bulgaria).

The choice of refiner type was in line with the findings reported by Lubis et al. [37]. In their study, the authors discovered that using a hammer mill resulted in significantly less cutting of the fibers than using a disc refiner. The hammer mill used had a through action with eighteen plates and a rotation frequency of 8500 min−1. The sieve used had a diameter of 500 mm and a hole size of 8 mm. The selection of the respective sieve was made to allow even the longest bundles of wood fibers to pass through without unwanted fiber cutting.

To achieve the aim of the study, namely establishing the effect of the hydrolysis regime on the properties of fibers obtained from recycling medium-density fiberboards, the following analyses were carried out: elemental analysis of carbon (C), nitrogen (N), and hydrogen (H); analysis of the fractional composition of recycled and industrial pulp fibers; determination of pentosans; analyses of Chemical Oxygen Demand (COD) values of wastewater; FTIR analysis; microscopic analysis; and hierarchical cluster analysis. The elemental analysis was carried out to establish possible changes in the elemental composition of the recycled fibers, as well as the residual content of UF resin, demonstrated by the nitrogen content (an element contained in wood up to 0.1%). The fractional composition of recycled and industrial pulp fibers was analyzed to establish the difference in the lengths of these two types of fibers. The last indicator is of considerable importance for forming bonds between the fibers in producing MDF panels. The determination of pentosans aims to establish possible changes in the chemical structure of the fibers as a result of hydrolysis. COD analysis was conducted to establish the wastewater contamination and as an indirect indicator of the changes in the recycled fibers. FTIR analysis was performed with a view to a comparative characteristic of the functional groups in the recycled fibers and those from the industrial pulp. The microscopic analysis establishes the differences in pulp from recycled and natural fibers. The hierarchical cluster analysis was conducted to comprehensively analyze the similarities and differences between recycled fibers and those from the industrial pulp.

Elemental Analyzer Euro EA 3000 (HEKAtech, Wegberg, Germany) was utilized to carry out the elemental analysis of carbon (C), nitrogen (N), and hydrogen (H) elements. The number of pentosans was evaluated using the T 223 cm-01 standard method [50].

Chemical Oxygen Demand (COD) was also determined. A DR 2800 photo-spectrometer (Hach Lange GmbH, Düsseldorf, Germany) was used for this purpose.

The fractional composition of recycled waste MDF fibers was determined by using a laboratory sieve analyzer (MLW, Leipzig, Germany) equipped with ten sieves.

Fourier-transform infrared spectroscopy (FTIR) analysis was performed using Varian 600-IR (Palo Alto, CA, USA). For this purpose, 1 g of dehydrated recycled and natural fibers was used.

A microscopic analysis of the recycled and natural fibers was also conducted using a light microscope Carl Zeiss AG, Oberkochen, Germany.

Hierarchical cluster analysis was carried out using IBM SPSS Statistics 18 software (2010). The Ward method was applied in the analysis, using squared Euclidean distance intervals.

3. Results and Discussion

Figure 3 shows the MDF samples after hydrolysis.

Figure 3.

MDF samples after thermal hydrolysis.

The curves in the MDF samples most possibly result from the destruction of adhesive bonds, the release of internal stresses in the material and, of course, the absorbed moisture during steaming, leading to additional deformations.

Table 2 displays the results obtained for the elemental composition of recycled MDF fibers.

Table 2.

Elemental composition of recycled MDF fibers at different hydrolysis temperatures and times.

The results in Table 2 show that the applied hydrolysis regimes, process times ranging from 30 to 60 min, and temperatures ranging from 121 to 134 °C had no effect on the elemental composition of the recycled fibers in practice. Other studies on the nitrogen content of natural fibers have yielded results ranging from 0.07% [51] to 0.1% [37].

The nitrogen content of UF resin is known to be from 30% to 32% [14,35,37]. The recycled fibers obtained in the present study had a nitrogen content varying from 3.68% to 3.94%. Therefore, the residual products of UF resin in the composition of the fibers were 10–11%. With the selected hydrolysis regimes, 100% of the binder components remained in the recycled fibers. Lubis et al. [34] found that only 33.5% of the UF resin components were present in recycled fibers after performing acid hydrolysis. Another study [39] corroborated these findings. In general, residual UF resin products, primarily amino groups, result in lower formaldehyde emissions from panels made from recycled fibers [52].

Table 3 shows the pentosan content of recycled and industrial pulp fibers.

Table 3.

Content of pentosans in the recycled and industrial pulp fibers.

In the applied hydrolysis regimes, no change in pentosan content was observed. In other words, these regimes did not affect the primary chemical composition of wood. In the study by Moezzipour et al. [39], however, a 12% reduction in hemicellulose content was reported. The procedures described in the study were carried out for 150 min at temperatures ranging from 105 °C to 150 °C. By comparing the results of these studies, it is possible to conclude that decreasing the dimensions of the material subjected to hydrolysis allows for a shorter hydrolysis time, preserving the chemical structure of the wood fibers. The thickness of the samples in the previous study was approximately 16 mm, whereas it was approximately 8 mm in the current case.

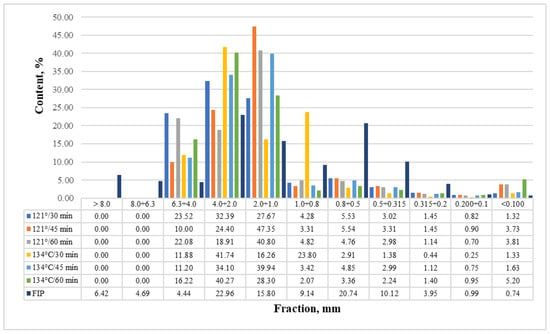

Data on the fractional composition of the recycled and fibers from industrial pulp are presented in Figure 4. As a result of the research on the fractional composition of the recycled fibers, it was found that their main fractions were from 4.0 mm to 1.0 mm. No significant difference in this distribution was observed for the studied hydrolysis regimes. In the analysis of the smallest fraction, below 100 μm, an increase in its amount was found when the hydrolysis time was increased from 30 to 60 min. The hydrolysis performed at a temperature of 134 °C for 60 min produced the most significant waste fraction. The share of the small fraction in this regime was nearly five times greater than in the fibers obtained at the hydrolysis temperature of 121 °C and a processing time of 30 min.

Figure 4.

Fractional composition of recycled and industrial pulp fibers.

The fibers from industrial pulp contained 11.11% fibers with a length greater than 6.3 mm, according to the comparison of recycled and natural fibers. After recycling MDF panels, no fibers of this length were found. This is consistent with previous research, which found fiber length reductions of up to 30% after recycling [18]. Natural fibers have a significantly more uniform distribution among the individual fractions, according to the current study.

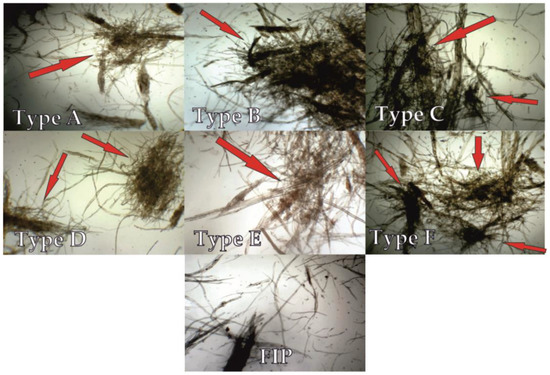

According to the microscopic analysis (Figure 5), the uneven distribution and increased coarse fractions in recycled fibers were caused primarily by unseparated bundles of short fibers of spherical or irregular shape.

Figure 5.

Microscopic images (×32) of recycled (Type A to Type F) and industrial pulp fibers.

The microscopic images clearly show the presence of such formations (indicated by arrows in the Figure 5) in the pulp of recycled fibers and their absence in the industrial pulp. The direct consequence of the participation of such structures, with small slenderness, is a deterioration of the properties of panels that could be produced from such pulp, which might be attributed to the small slenderness of the structures and the difficulty in forming both adhesive and cohesive bonds between them. It should be emphasized that the formation of such structures in the recycled pulp is not affected by the hydrolysis regime, and they were present in the pulp obtained in all regimes used. Therefore, increasing the process time and temperature of hydrolysis would not positively affect this characteristic of the recycled fiber mass.

The COD of the wastewater from the different hydrolysis regimes was also studied. The results obtained are presented in Table 4.

Table 4.

The COD values of wastewater from different hydrolysis regimes.

With increasing temperature and processing time, an increase in COD by 64.31% was observed. That shows that the aggravation of the parameters of the hydrolysis regime led to a significant increase in the pollution of the wastewater and a decrease in the quantitative yield. Because the hemicellulose content of the recycled wood fibers did not change, the increase in contamination should be due to the release of water-soluble extracts from the panels. Temperature was found to have the greatest influence on COD values of the two factors studied (temperature and processing time). For example, at 121 °C, the increase in COD with increasing the processing time from 30 to 60 min was 5.1%, while at 134 °C, the increase was 17.6%. Increasing the hydrolysis temperature from 121 to 134 °C resulted in an increase in COD value from 40% to 57%. The removal of nitrogen-containing UF resins from recycled MDF may be responsible for rising COD values [53,54]. The significant effect of temperature and the significantly weaker influence of the hydrolysis time on COD values was also confirmed by the conducted ANOVA (Table 5).

Table 5.

ANOVA for the significance of hydrolysis temperature and time on COD values.

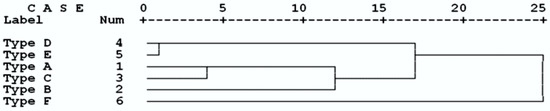

The cluster analysis (based on COD, the contents of pentosans, and elements) revealed that fiber Type F was clustered as a separate group (Figure 6). Although the processing time had a slight effect—comparable with the result of random disturbances—at the lower of the two temperatures studied, the combination of the influence of the two factors, temperature and process time, significantly increased the heat quantity. This cumulative effect substantially changed the COD values of the wastewater of recycled fibers type F (temperature 134° C and process time of 60 min). It should be emphasized that the caused wastewater contamination is not necessarily related to the hydrolysis of UF resin but may also be due to the release of water-soluble extracts from the wood. In any case, this contamination would make the MDF panels’ recycling processes more expensive.

Figure 6.

Cluster analysis for the different fiber types.

It should be said that all three fiber types at the temperature of 121 °C were clustered under the same category, illustrating somewhat similar effects of the temperature on the overall properties of the fibers produced. The two fiber types D and E were also clustered closely, showing the decisive impact of temperature on the properties of recycled fibers obtained.

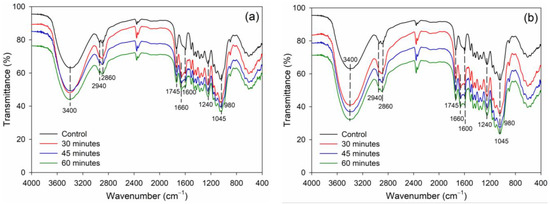

The alteration of functional groups of MDF panels after hydrolysis at different times was observed using FTIR analysis (Figure 7). The FTIR spectra clearly displayed the absence of the primary amide group, comprising the C=O and C–N bonds in UF resins, at 1660 cm−1 from UF resins in the control MDF fibers. However, the primary amide group of UF resins in MDF after hydrolysis was detected at 1660 cm−1. The amount of cured UF resins in MDF did not decrease much when extending the hydrolysis time, and the amide group in MDF fibers decreased slightly with extended hydrolysis time. The peaks at 1600 and 1510 cm−1 belonged to the C=O and C–N stretching of secondary amides from the UF resins, respectively. In addition, higher hydrolysis temperatures and longer times resulted in broader –OH groups at 3400 cm−1 originating from water. No alterations were found in the recycled MDF fibers after hydrolysis, such as 2940 cm−1, 2860 cm−1, 1732 cm−1, 1157 cm−1, and 1105 cm−1, which belonged to the intramolecular hydrogen bonds, C–O–C and –OH vibrations of cellulose and hemicellulose, respectively [53,54].

Figure 7.

Functional groups analysis of recycled MDF fibers after hydrolysis at different temperatures and times: (a) 121 °C, (b) 134 °C.

4. Conclusions

According to the research findings, the hydrolysis treatments at the selected temperatures and times did not result in a significant extraction of the incorporated UF resin, but instead in destroying the resin’s components. The number of pentosans in the recycled MDF fibers obtained at the different hydrolysis regimes remained constant throughout the process, and their concentrations were comparable to those found in natural fibers. As a result, the chosen regimes, which included temperatures ranging from 121 °C to 134 °C and processing times varying from 30 to 60 min, effectively preserved the chemical composition of wood fibers at the material’s dimensions subjected to hydrolysis. That leads to the conclusion that integrating the resulting recycled fibers into a general manufacturing flow would be more accessible when combined with natural fibers refined using thermomechanical processes. The fractional composition of the recycled fibers produced at different hydrolysis regimes was also studied, and no significant differences were determined between them. Markedly, the length of recycled fibers was always shorter than that of natural fibers. The presence of structures (bundles) of irregular shape and small slenderness was determined, which could significantly deteriorate the properties of the panels produced using recycled fibers. In addition, it was discovered that the COD values increased significantly with processing time and, more importantly, with processing temperature, i.e., greater wastewater pollution and decreased quantitative yield were determined. The extraction of water-soluble extracts from recyclable panels should account for the decrease in quantitative yield. As the main conclusion and novelty of the study, it can be stated that in the preliminary preparation of the MDF boards with dimensions similar to those of pulp chips, it is not recommended to increase the hydrolysis temperature above 121 °C or the processing time above 30 min. However, this should be further confirmed by studying the properties of MDF panels produced with fibers recycled at different hydrolysis regimes.

Despite the presented hydrolysis treatments for recycling waste MDF panels, there are numerous technical limitations that prevent their widespread application in industrial practice. Future research in the field of recycling waste wood composites is therefore required in order to achieve optimal processing parameters.

Author Contributions

Conceptualization, V.S. and P.A.; methodology, V.S., C.P., P.A., M.A.R.L., S.H.L. and H.R.T.; investigation, C.P., M.T. and S.P.; resources, P.A. and V.S.; writing—original draft preparation, V.S., P.A., C.P., M.A.R.L., S.H.L. and H.R.T.; writing—review and editing, P.A., M.A.R.L., S.H.L. and H.R.T.; visualization, V.S., M.A.R.L. and H.R.T.; supervision, V.S. and P.A.; project administration, V.S. and P.A.; funding acquisition, V.S. and P.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.

Acknowledgments

This research was supported by the project No. HИC-Б-1215/04.2022 “Properties and application of innovative biocomposite materials in furniture manufacturing” carried out at the University of Forestry, Sofia, Bulgaria. The authors would also like to thank (i) Kronospan Bulgaria EOOD for supplying the industrial MDF panels.

Conflicts of Interest

The authors declare no conflict of interest.

References

- FAO Stat. Forestry Production and Trade. Available online: https://www.fao.org/faostat/en/#data/FO (accessed on 10 October 2021).

- Lykidis, C.; Grigoriou, A. Hydrothermal recycling of waste and performance of the recycled wooden particleboards. Waste Manag. 2008, 28, 57–63. [Google Scholar] [CrossRef]

- Wan, H.; Wang, X.-M.; Barry, A.; Shen, J. Recycling wood composite panels: Characterizing recycled materials. Bioresources 2014, 9, 7554–7565. [Google Scholar] [CrossRef]

- Hagel, S.; Joy, J.; Cicala, G.; Saake, B. Recycling of Waste MDF by Steam Refining: Evaluation of Fiber and Paper Strength Properties. Waste Biomass Valorization 2021, 2, 5701–5713. [Google Scholar] [CrossRef]

- Antov, P.; Lee, S.H.; Lubis, M.A.R.; Kristak, L.; Réh, R. Advanced Eco-Friendly Wood-Based Composites II. Forests 2023, 14, 826. [Google Scholar] [CrossRef]

- Kharazipour, A.; Kües, U. Recycling of Wood Composites and Solid Wood Products. In Wood Production, Wood Technology, and Biotechnological Impacts; Universitätsverlag Göttingen: Göttingen, Germany, 2007; pp. 509–533. [Google Scholar]

- Antov, P.; Savov, V. Possibilities for Manufacturing Eco-friendly Medium Density Fiberboards from Recycled Fibers—A Review. In Proceedings of the 30th International Conference on Wood Science and Technology—ICWST 2019 “Implementation of Wood Science in Woodworking Sector” & 70th Anniversary of Drvna industrija Journal, Zagreb, Croatia, 12–13 December 2019; pp. 18–24. [Google Scholar]

- Irle, M.; Privat, F.; Couret, L.; Belloncle, C.; Déroubaix, G.; Bonnin, E.; Cathala, B. Advanced recycling of post-consumer solid wood and MDF. Wood Mat. Sci. Eng. 2018, 11, 1–5. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Manohar, S.Y.; Laksana, R.P.B.; Fatriasari, W.; Ismayati, M.; Falah, F.; Solihat, N.N.; Sari, F.P.; Hidayat, W. The Removal of Cured Urea-Formaldehyde Adhesive Towards Sustainable Medium Density Fiberboard Production: A Review. J. Silva Lestari 2021, 9, 23–44. [Google Scholar] [CrossRef]

- Kim, M.H.; Song, H.B. Analysis of the Global Warming Potential for Wood Waste Recycling Systems. J. Clean. Prod. 2014, 69, 199–207. [Google Scholar] [CrossRef]

- Irle, M.; Barbu, M.C. Wood-Based Panels Technology. In Wood-Based Panels: An Introduction for Specialists; Thoemen, H., Irle, M., Šernek, M., Eds.; Brunel University Press: London, UK, 2010; Available online: http://www.cost.eu/media/publications/10-35-Wood-Based-Panels-An-Introductionfor-Specialists (accessed on 10 January 2022).

- Garcia, C.A.; Hora, G. State-of-the-art of waste wood supply chain in Germany and selected European countries. Waste Manag. 2017, 70, 189–197. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives, OJ L 312, 22.11.2008; The European Parliament and the Council of the European Union: London, UK, 2008; pp. 3–30. [Google Scholar]

- Hagel, S.; Saake, B. Fractionation of Waste MDF by Steam Refining. Molecules 2020, 25, 2165. [Google Scholar] [CrossRef]

- Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from Recycled Wood. Forests 2020, 11, 1166. [Google Scholar] [CrossRef]

- Michanicki, A. Recovery of Fibers and Particles from Wood-Based Products. In Proceedings of the Forest Products Society Conference on Use of Recycled Wood and Paper in Building Applications; Forest Products Society: LaGrange, GA, USA, 1997. [Google Scholar]

- Mitchell, A.; Stevens, G. A Life Cycle Assessment of Closed Loop MDF Recycling Using the Microrelease Process to Produce Recycled Wood Fiber from MDF Waste; Final report of WRAP project MDD005; WRAP: Banbury, UK, 2009; pp. 1–50. ISBN 1-84405-417-9. [Google Scholar]

- Roffael, E.; Athanassiadou, E.; Mantanis, G. Recycling of Particle and Fiberboards Using the Extruder Technique. In Proceedings of the 2nd Conference on Environmental Protection in the Wood Industry, Goettingen, Germany, 9 March 2002; pp. 56–65. [Google Scholar]

- Franke, R.; Roffael, E. Zum recycling von span- und MDFplatten. Holz als Roh- und Werkstoff 1998, 56, 79–82. [Google Scholar] [CrossRef]

- Pizzi, A.; Papadopoulos, A.N.; Policardi, F. Wood composites and their polymer binders. Polymers 2020, 12, 1115. [Google Scholar] [CrossRef]

- Mantanis, G.I.; Athanassiadou, E.T.; Barbu, M.C.; Wijnendaele, K. Adhesive systems used in the European particleboard, MDF and OSB industries. Wood Mater. Sci. Eng. 2018, 13, 104–116. [Google Scholar] [CrossRef]

- Hwang, C.Y.; Hse, C.Y.; Shupe, T.F. Effects of recycled fiber on the properties of fiberboard panels. Forest Prod. J. 2005, 55, 61–64. [Google Scholar]

- Ahmadi, M.; Moezzipour, B. Thermal Stability of Wood Fibers Produced from Recycled Medium Density Fiberboards. Drvna Ind. 2019, 70, 149–155. [Google Scholar] [CrossRef]

- Roffael, E.; Behn, C.; Schneider, T.; Krug, D. Bonding of recycled fibers with urea-formaldehyde resins. Int. Wood Prod. J. 2016, 7, 36–45. [Google Scholar] [CrossRef]

- Nuryawan, A.; Risnasari, I.; Pohan, A.P.; Husna, A.U.; Nasution, T.I.; Banurea, R.; Hartini, K.S. Properties of fiberboard (F.B.s) and recycle fiberboard (rFBs) and analysis of their wastage after recycling. IOP Conf. Ser. Mater. Sci. Eng. 2020, 935, 012060. [Google Scholar] [CrossRef]

- Mantanis, G.I.; Athanassiadou, E.; Nakos, P.; Coutinho, A. A New Process for Recycling Waste Fiberboards. In Proceedings of the 38th International Wood Composites Symposium, Washington, DC, USA, 5–8 April 2004; pp. 119–122. [Google Scholar]

- Kristak, L.; Antov, P.; Bekhta, P.; Lubis, M.A.R.; Iswanto, A.H.; Reh, R.; Sedliacik, J.; Savov, V.; Taghiayri, H.; Papadopoulos, A.N.; et al. Recent Progress in Ultra-Low Formaldehyde Emitting Adhesive Systems and Formaldehyde Scavengers in Wood-Based Panels: A Review. Wood Mater. Sci. Eng. 2023, 18, 763–782. [Google Scholar] [CrossRef]

- Grigsby, W.J.; Carpenter, J.E.P.; Sargent, R. Investigating the extent of urea formaldehyde resin cure in medium density fiberboard: Resin extractability and fiber effects. J. Wood Chem. Technol. 2014, 34, 225–238. [Google Scholar] [CrossRef]

- Grigsby, W.J.; Thumm, A.; Carpenter, J.E.P.; Hati, N. Investigating the extent of urea formaldehyde resin cure in medium density fiberboard: Characterization of extractable resin components. Int. J. Adhes. Adhes. 2014, 50, 50–56. [Google Scholar] [CrossRef]

- Ormondroyd, G.A.; Elias, R.M.; Curling, S.F. MDF Recovery: Recycled MDF Technologies for Routed and Laminated Applications. In Proceedings of the Conference: COST Action FP1303, Sofia, Bulgaria, 28 February 2017. [Google Scholar]

- Chuang, I.; Maciel, E. NMR Study of the Stabilities of Urea-Formaldehyde Resin Components Toward Hydrolytic Treatments. J. App. Pol. Sci. 1994, 52, 1637–1651. [Google Scholar] [CrossRef]

- Dunky, M. Urea–formaldehyde (UF) adhesive resins for wood. Int. J. Adhes. Adhes. 1998, 18, 95–107. [Google Scholar] [CrossRef]

- Abdullah, Z.A.; Park, B.D. Hydrolytic Stability of Cured UF Resins Modified by Additives. J. App. Pol. Sci. 2009, 114, 1011–1017. [Google Scholar] [CrossRef]

- Bütün Buschalsky, F.Y.; Mai, C. Repeated thermo-hydrolytic disintegration of medium density fiberboards (MDF) for the production of new MDF. Eur. J. Wood Prod. 2021, 79, 1451–1459. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Park, B.D. Analysis of the hydrolysates from cured and uncured urea-formaldehyde (UF) resins with two F/U mole ratios. Holzforschung 2018, 72, 759–768. [Google Scholar] [CrossRef]

- Moezzipour, B.; Abdolkhani, A.; Doost-hoseini, K.; Ramazani, S.A.A.; Tarmian, A.S. Practical properties and formaldehyde emission of medium density fiberboards (MDFs) recycled by electrical method. Eur. J. Wood Wood Prod. 2018, 76, 1287–1294. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Hong, M.K.; Park, B.D.; Lee, S.M. Effects of recycled fiber content on the properties of medium density fiberboard. Eur. J. Wood Wood Prod. 2018, 76, 1515–1526. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Y.; Wu, Y.; Wan, H. Hydrolysis and recycling of urea formaldehyde resin residues. J. Hazard. Mater. 2018, 355, 96–103. [Google Scholar] [CrossRef] [PubMed]

- Moezzipour, B.; Ahmadi, M.; Abdolkhani, A.; Doosthoseini, K. Chemical changes of wood fibers after hydrothermal recycling of MDF waste. J. Ind. Acad. Wood Sci. 2017, 14, 133–138. [Google Scholar] [CrossRef]

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers 2021, 13, 1752. [Google Scholar] [CrossRef] [PubMed]

- Girods, P.; Dufour, A.; Rogaume, Y.; Rogaume, C.; Zoulalian, A. Pyrolysis of Wood Waste Containing Urea-Formaldehyde and Melamine-Formaldehyde Resins. J. Anal. Appl. Pyrolysis 2008, 81, 113–120. [Google Scholar] [CrossRef]

- Bütün, F.Y.; Sauerbier, P.; Militz, H.; Mai, C. The effect of fiberboard (MDF) disintegration technique on wood polymer composites (WPC) produced with recovered wood particles. Compos. A Appl. Sci. Manuf. 2019, 118, 312–316. [Google Scholar] [CrossRef]

- Bütün, F.Y.; Mayer, A.K.; Ostendorf, K.; Gröne, O.-E.Z.; Krause, K.C.; Schöpper, C.; Mertens, O.; Krause, A.; Mai, C. Recovering fibers from fiberboards for wood polymer composites production. Int. Wood Prod. J. 2018, 52, 42–49. [Google Scholar] [CrossRef]

- Couret, L.; Irle, M.; Belloncle, C.; Cathala, B. Extraction and characterization of cellulose nanocrystals from post-consumerwood fiberboard waste. Cellulose 2017, 24, 2125–2137. [Google Scholar] [CrossRef]

- Park, Y.-K.; Park, K.-S.; Park, S.H. Fast pyrolysis of medium density fiberboard using a fluidized bed reactor. Appl. Chem. Eng. 2013, 24, 672–675. [Google Scholar] [CrossRef]

- Han, T.U.; Kim, Y.-M.; Watanabe, C.; Teramae, N.; Park, Y.-K.; Kim, S.; Lee, Y. Analytical pyrolysis properties of waste medium-density fiberboard and particle board. J. Ind. Eng. Chem. 2015, 32, 345–352. [Google Scholar] [CrossRef]

- Dominic, C.; Östlund, S.; Buffington, J.; Masoud, M.M. Towards a conceptual sustainable packaging development model: A corrugated box case study. Package Technol. Sci. 2015, 28, 397–413. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, C.; Bokka, S.K.; He, Z.; Ni, Y. Molded fiber and pulp products as green and sustainable alternatives to plastics: A mini review. J. Biores. Bioprod. 2022, 7, 14–25. [Google Scholar] [CrossRef]

- Zhang, Y.; He, Z.B.; Xue, L.; Chu, D.M.; Mu, J. Influence of a Urea–Formaldehyde Resin Adhesive on Pyrolysis Characteristics and Volatiles Emission of Poplar Particleboard. RSC Adv. 2016, 6, 12850–12861. [Google Scholar] [CrossRef]

- Technical Association of the Pulp and Paper Industry. T 223 cm-01 Pentosans in Wood and Pulp; Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 2011. [Google Scholar]

- Cowling, E.B.; Merrill, W. Nitrogen in wood and its role in wood deterioration. Can. J. Bot. 2011, 44, 1539–1554. [Google Scholar] [CrossRef]

- Dazmiri, M.K.; Kiamahalleh, M.V.; Kiamahalleh, M.V.; Mansouri, H.R.; and Moazami, V. Revealing the Impacts of Recycled Urea–Formaldehyde Wastes on the Physical–Mechanical Properties of MDF. Eur. J. Wood Wood Prod. 2018, 77, 293–299. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Hong, M.K.; Park, B.D. Hydrolytic Removal of Cured Urea–Formaldehyde Resins in Medium-Density Fiberboard for Recycling. J. Wood Chem. Technol. 2018, 38, 1–14. [Google Scholar] [CrossRef]

- Hong, M.-K.; Lubis, M.A.R.; Park, B.-D.; Sohn, C.H.; Roh, J. Effects of surface laminate type and recycled fiber content on properties of three-layer medium density fiberboard. Wood Mater. Sci. Eng. 2020, 15, 163–171. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).