1. Introduction

The environmental situation on our planet has become critical, atmospheric emissions are now unsustainable, and global warming has been relentless for more than a century. For this reason, countries’ environmental policies have included programs aimed at reducing CO

2 emissions into the atmosphere and a drastic reduction in resources from nonrenewable sources [

1]. In this context, construction plays a key role, which is why a change in mentality is needed. In the past decades, environmental problems have become globalized, and the social and economic forces behind them have undergone profound globalization. Indeed, human beings have faced precarious environmental conditions throughout their history. However, environmental-type instances have become more evident and common due to the processes of industrialization and urbanization [

2].

Environmental issues, especially those related to climate change induced by human activities, continue to have an important place within the global political agenda. The environment makes available resources that are necessary for human life in addition to the natural resources that are used by industrial-type activities. From that perspective, the environment acts as a repository, providing the basic sustenance for human societies [

3]. The resources that are made available are both renewable and nonrenewable types. Consequently, when there is overuse of the latter it is possible to have a shortage of the former as well, as can happen with fossil fuels. In addition, in the process of consuming resources, humans produce waste products. From this point of view, the environment serves as a repository for waste, either through its absorption or its recycling into other substances that are useful or at least cause less harm. When wastes turn out to exceed the capacity of the environment to absorb them, it results in environmental problems, namely pollution and scarcity of resources [

4].

To reduce waste generation, it is necessary to adopt policies to reuse and recycle resources. Reuse and recycling are the cornerstones of the waste hierarchy and represent the deep essence of the circular economy, being able to return environmental and economic benefits [

5]. In the transformation processes of raw materials that lead to the creation of finished supply chain products, production residues are obtained that can be destined for disposal as waste or for recovery. In the case of recovery, through appropriate treatments, the waste returns to being considered a resource to be used in defined production processes to make new products [

6]. The material, in this case, is given the name of a second raw material, that is, a new raw material derived from waste recovery or recycling. Agro-food residues are an important source of waste if not properly treated. Fibers extracted from the processing of some crops can be recovered and used as raw materials to produce building materials [

7]. From the cultivation of corn, for example, a plant fiber is extracted that can be used for a variety of purposes. Yılmaz [

8] studied the characteristics of corn stem fibers from a mechanical point of view. The author extracted corn stem fibers by means of water maceration, alkalinization, and enzymatic procedures. Maceration in water restored maximum breaking strength and breaking toughness. The enzymatic treatment, while resulting in a reduction in breaking toughness and elongation in the fibers, returned increased initial moduli and breaking toughness in the alkalized fibers. Sari et al. [

9] examined the effects of varying concentrations of NaOH on the chemical, physical, and mechanical properties of corn stem fibers. The study revealed that the treatment removed hemicellulose and lignin from the fibers and reduced moisture content, resulting in significant improvements in the fibers’ chemical, physical, and mechanical properties. Youssef et al. [

10] have produced, by casting and compression molding, a composite material using corn stem fibers and recycled low-density polyethylene (R-LDPE). The final product was evaluated to determine its mechanical properties by assessing the relationship between fiber loading and moduli, tensile strength, and hardness. The results showed that as fiber loading increased, moduli and tensile strength also increased, but hardness decreased. Ibrahim et al. [

11] used corn stem fiber as a reinforcing filler to produce a biodegradable composite on a thermoplastic corn starch matrix. The study showed that the use of stem fiber improved the mechanical and thermal performance of the composite films. A reduction in the density and moisture content of the films was measured, and a lower resistance to biodegradation was also found.

Noise is a key component of environmental pollution, and it can affect the quality of life in urban and suburban environments [

12]. Therefore, the attention of researchers has focused over time on finding materials that can contribute to the insulation and soundproofing of domestic environments [

13]. Soundproofing interventions aim to minimize the transmission of noise between two environments and reduce the acoustic energy that propagates through the air from a disturbing environment to a receiving environment [

14]. Sound-absorbing measures, on the other hand, aim to control the reflection of sound on the walls of a room and thus adapt the propagation of sound within a room to suit one’s needs. In the construction of new buildings, as well as in the renovation of existing ones, it becomes crucial to use materials with acoustic properties to ensure acoustic comfort in buildings [

15]. The choice of materials with acoustic properties derived from plant waste can make an important contribution to environmental sustainability. Several researchers have measured the acoustic properties of fibers derived from plant waste from corn cultivation. Lyu et al. [

16] have produced a composite material from corn stem fibers immersed in a polylactic acid-based matrix. The composite was made through a hot mixing and pressing process, and panels with micro-cracks, air cavities, and linen felt were prepared from the resulting material. The results show optimal acoustic performance at high frequencies. As the panel thickness increases, the peak of the SAC increases, and the frequency shift moves towards lower frequencies. Sari et al. [

17] studied the sound-absorbing features of material made from an unsaturated polyester matrix and corn stem fibers. The authors showed that as the fiber content increases, acoustic performance improves at low frequencies. At high frequencies, the sound-absorption performance depends on the disposition of the fibers in the composite. Tang et al. [

18] used untreated corn stem simply washed with distilled water and then air-dried. The authors produced specimens by arranging several layers of fibers and measuring acoustic performance: Increasing the layers did not return an improvement in sound absorption, while it shifted the peak toward lower frequencies. Instead, increasing the cavity back to the absorbing panel may increase the absorption coefficient at low frequencies. Kaamin et al. [

19] produced sound-absorbing panels by filling egg carton containers with corn stem fibers. The authors measured the SAC with the impedance tube and found good acoustic performance at medium frequencies (1000 Hz). Berliandika et al. [

20] studied the sound-absorbing performance of a composite made from corn stem fiber immersed in a latex adhesive-based matrix. The authors treated the fiber by immersing it in a 5 percent sodium hydroxide (NaOH)-based solution for two hours. The results of SAC measurements by an impedance tube showed that the composite with untreated fiber had better sound absorption performance than the treated fiber. In addition, the authors tested the panels by arranging a cavity, finding that, in this case, the SAC shifts toward low frequencies depending on the stiffness of the composite layer by increasing the viscous damping effect.

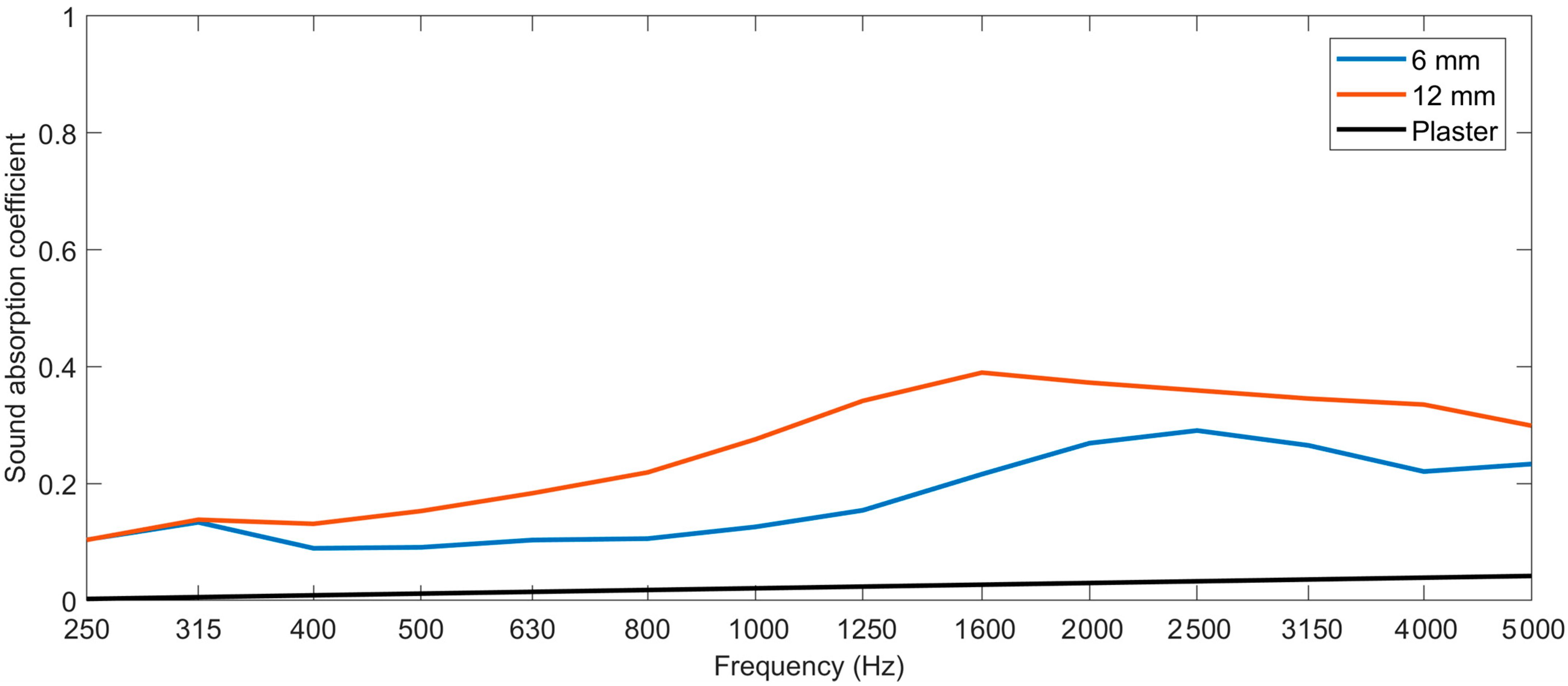

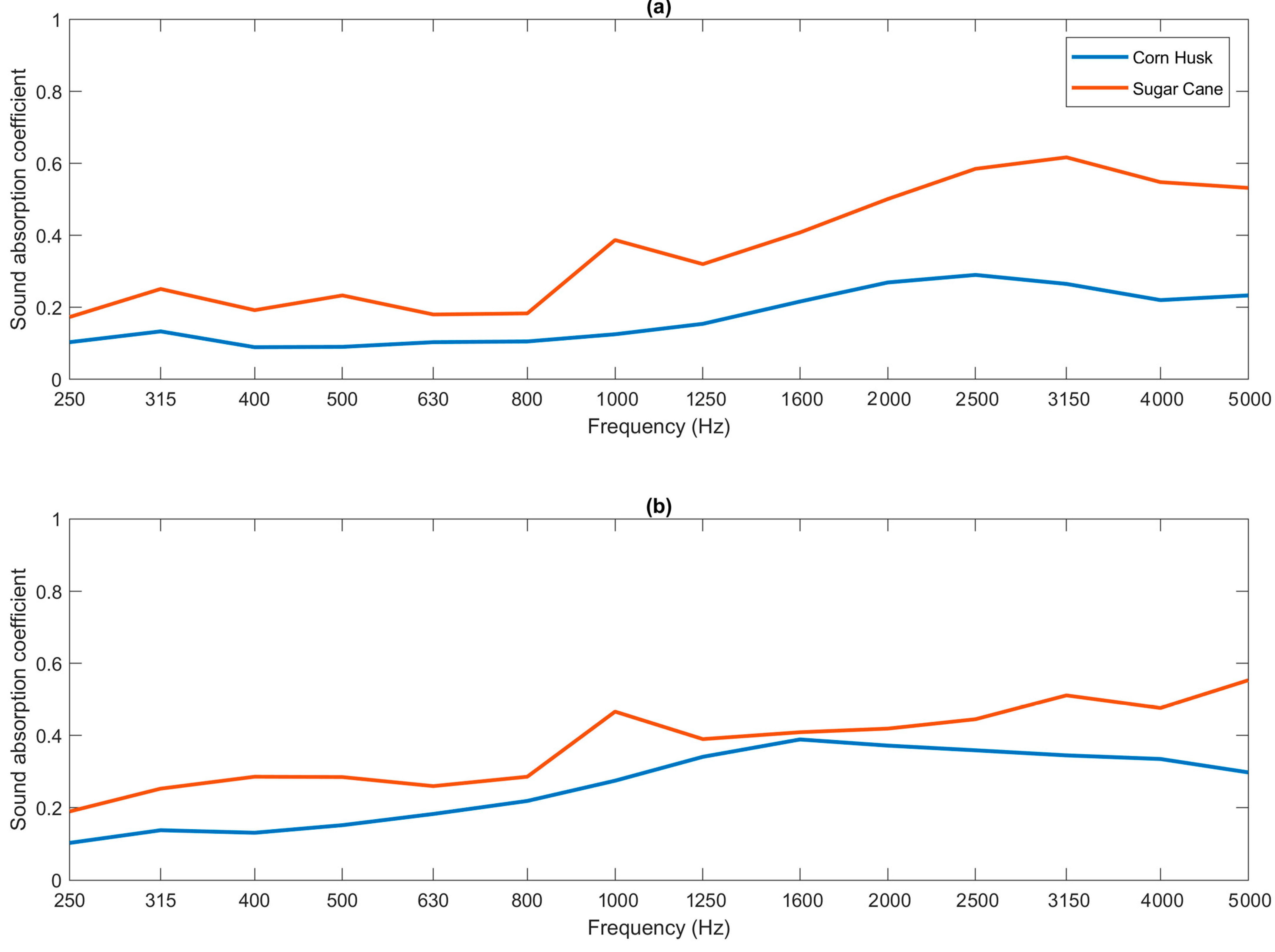

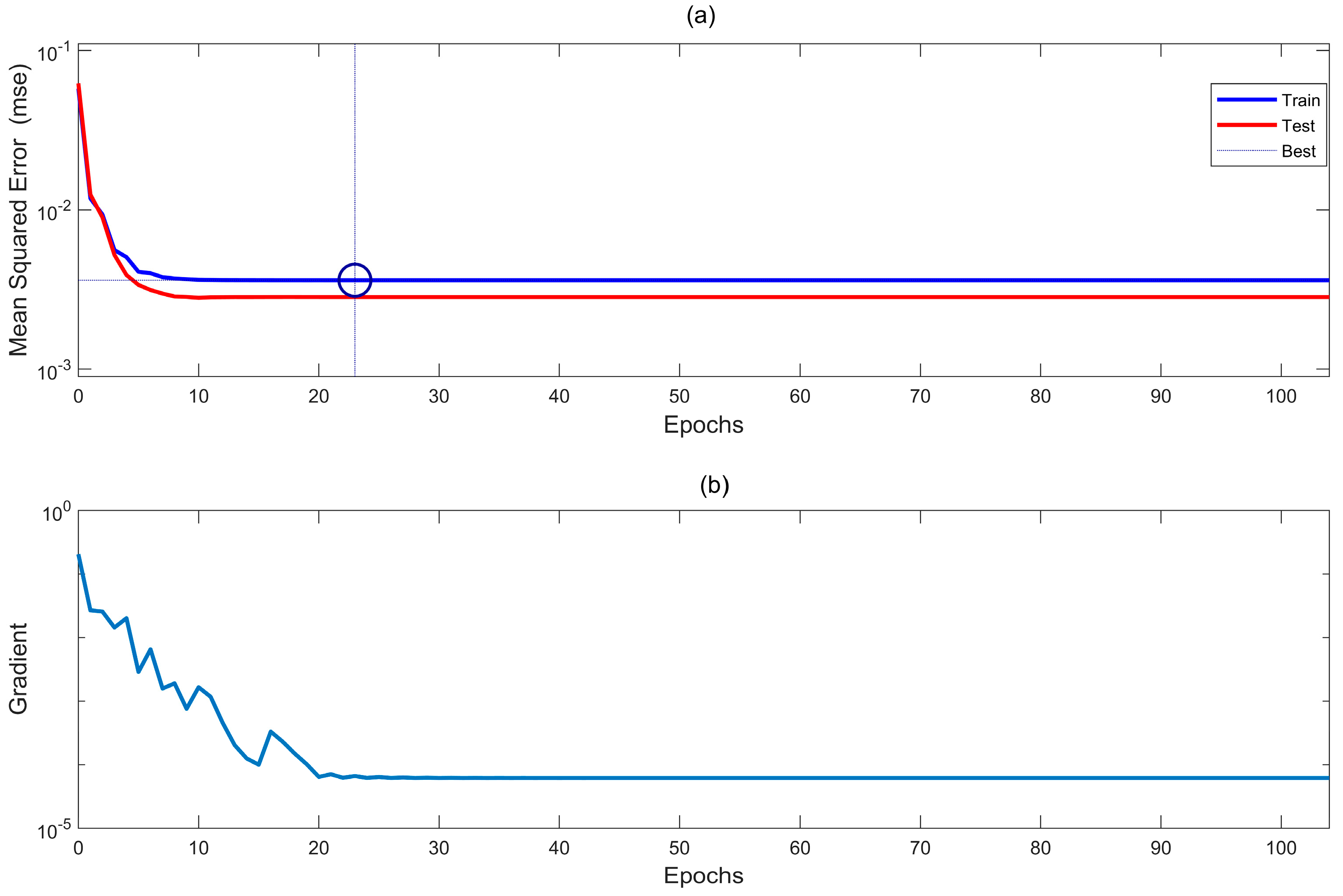

In this work, the absorption characteristics of a composite produced with the fiber extracted from corn cultivation waste were characterized. First, sound absorption coefficient (SAC) measurement campaigns were prepared as prescribed by UNE-EN ISO 10534-2 [

21]. In addition, to expand the study into unexplored domains, the experimental measurement procedure was compared with a simulative analysis. The simulative study was conducted by adopting a data-driven approach. The simulation was performed by exploiting the data collected in the measurement campaigns and obtaining automatic knowledge extraction using Machine Learning-based algorithms. The potential of corn stem fibers extracted from corn crop waste (corn stem fibers) as a reinforcement material to produce a plaster matrix composite was analyzed. To make the panels, corn stem fibers were mixed with the plaster-based binder in a ratio of one to three by weight, respectively. Specimens of two thicknesses, 6 and 12 mm, were prepared. Then, the SAC was measured, and subsequently, the findings of the measurement procedures were compared with the results obtained with a simulation model centered on ANN.

The structure of the article is as follows:

Section 2 covers the materials and methods used in this study, including the techniques for preparing samples from corn cultivation waste. Then, the methodologies adopted for the measurement of SAC using the impedance tube technique are presented. Next, the technologies adopted to set up the ANN-based simulation model are illustrated. In

Section 3, the results obtained from the ANN-based simulation model are compared and discussed, and in the final section, the overall results of the work are summarized, and potential real-world applications of the developed technology are discussed.

2. Materials and Methods

2.1. Characterization of Corn Cultivation

Corn is a raw material derived from the cultivation of herbaceous plants of the grass family (of the Maydeae type, species Zea mays) which is used in various forms for animal and human sustenance and energy production. Corn is native to Central America, with grain production amounting to around 1,150,000,000 tons (about 195,000,000 hectares) to date, according to official world data supplied by the Food and Agriculture Organization of the United Nations (FAO) [

22], and in recent years, corn is the most widely grown grain in the world. Almost a quarter of the world’s grain production distribution is located between the U.S., China, Brazil, and Mexico. Corn cultivation can produce significant amounts of agri-food residues throughout the supply chain, which are of interest in other industrial processes and depend on the purpose of cultivation and the type of processing involved [

23]. In recent years, there has been an increase in the use of corn cultivation waste for artisanal purposes through its processing into fibers, which can become an important resource in support of environmental sustainability policies. These natural fibers have gained importance in the world market in recent years as their demand has increased in industrialized countries, replacing synthetic ones in various applications [

24].

The purpose of this work is to study the acoustic characterization of fiber obtained from the corn stem, through the development of creating sound-absorbing panels for environmentally sustainable architecture. Thus, the focus of the use of this material will be sound absorption, generally in enclosed spaces. The use of natural materials can facilitate the replacement of synthetic materials, which require industrial development. The focus is on the use of corn cane fibers, which are obtained from the stem of the same plant [

25]. Given the large production of this crop in Ecuador, no problems are expected for the commercial production of the acoustic panels that can be obtained, since it is grown in large quantities, especially in the Andean areas of the country.

In recent years, natural fibers have been considered raw materials to produce sound-absorbing panels at a reduced cost compared to synthetic materials. These fibers generally have good acoustic, thermal, and insulating properties. In addition, they do not cause adverse health effects and are available in large quantities as a residual product of other industrial processes [

26,

27].

The best areas for growing and harvesting corn, based on their climate, are the Andean regions, Central America, and Mexico, where great genetic diversity has been observed. Corn is one of the most significant crops within the Andean areas because of the area devoted to its cultivation, making it one of the largest production and food systems for people. In the Ecuadorian highlands, corn cultivation is one of the main drivers of the economy, due to the large amount of area dedicated to its cultivation, which generates production reserved mainly for the food sector. The most widely cultivated corn in the mountainous region of Ecuador is the yellow floury type found in Carchi, Imbabura, and Pichincha. White floury corn is grown in the central Sierra zone, especially in Tungurahua, Chimborazo, and Bolívar, and corn called Zhima or white amorochado is grown in the southern Sierra zone such as Cañar and Azuay. Currently, 29 varieties of corn have been identified in Ecuador, of which 17 are grown in the highlands.

2.2. Preparation of Specimens

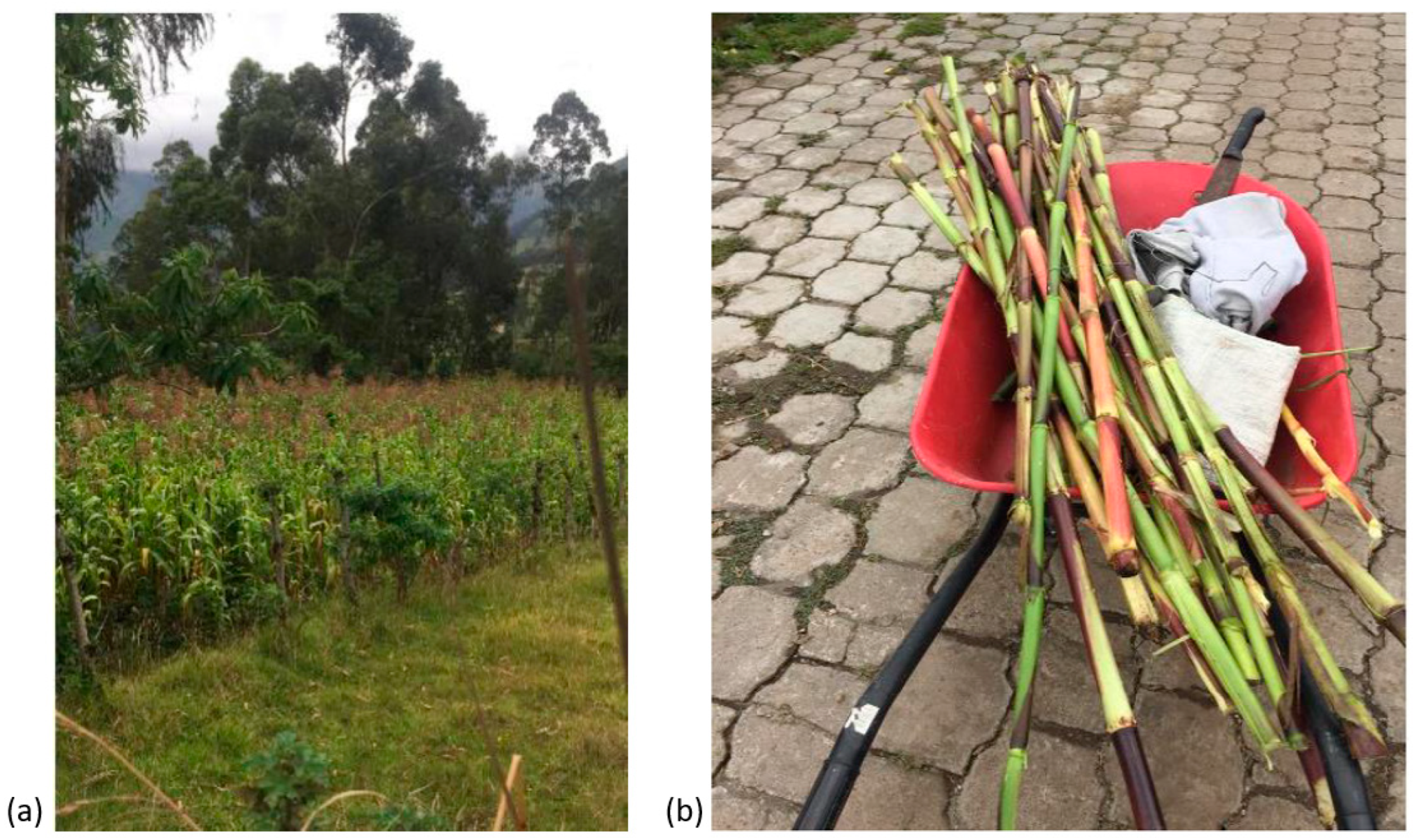

Corn cane of the “Chaucho mejorado” type, with the following characteristics, was used for the preparation of the specimens: yellow kernel, floury texture, low height (1.20–1.40 m), resistant to plant inclination and bending, early, good kernel quality. This corn variety is mainly grown in temperate areas such as Imbabura Province (González Suárez Sector) for food production (

Figure 1a). However, it is possible to exploit the waste from its cultivation to produce, for example, soundproofing panels using its fiber and bark.

Harvesting takes place in April during the ripening stage. Light green and purple stems were chosen, formed by a hard, compact woody layer with a cylindrical base that was simple, straight, strong, and gnarled (8–38 knots). During the collection of this material, internodes measuring 15 to 20 cm and a general plant height of 1 to 3 m were also evident. The material has a crop cycle of 125 to 210 days from sowing to maturity. Sample analysis was carried out before harvesting the stems which was used to assess and status of the corn plants. This analysis was aimed at determining the degree of maturity to continue with the fiber crushing and drying process. As a result, it was revealed that not all stems were in the same state of maturity, so stems ranging from 2 to 2.5 cm in diameter had to be selected. Once the plants were selected, a quantity of 56 stems was collected over two consecutive days (

Figure 1b).

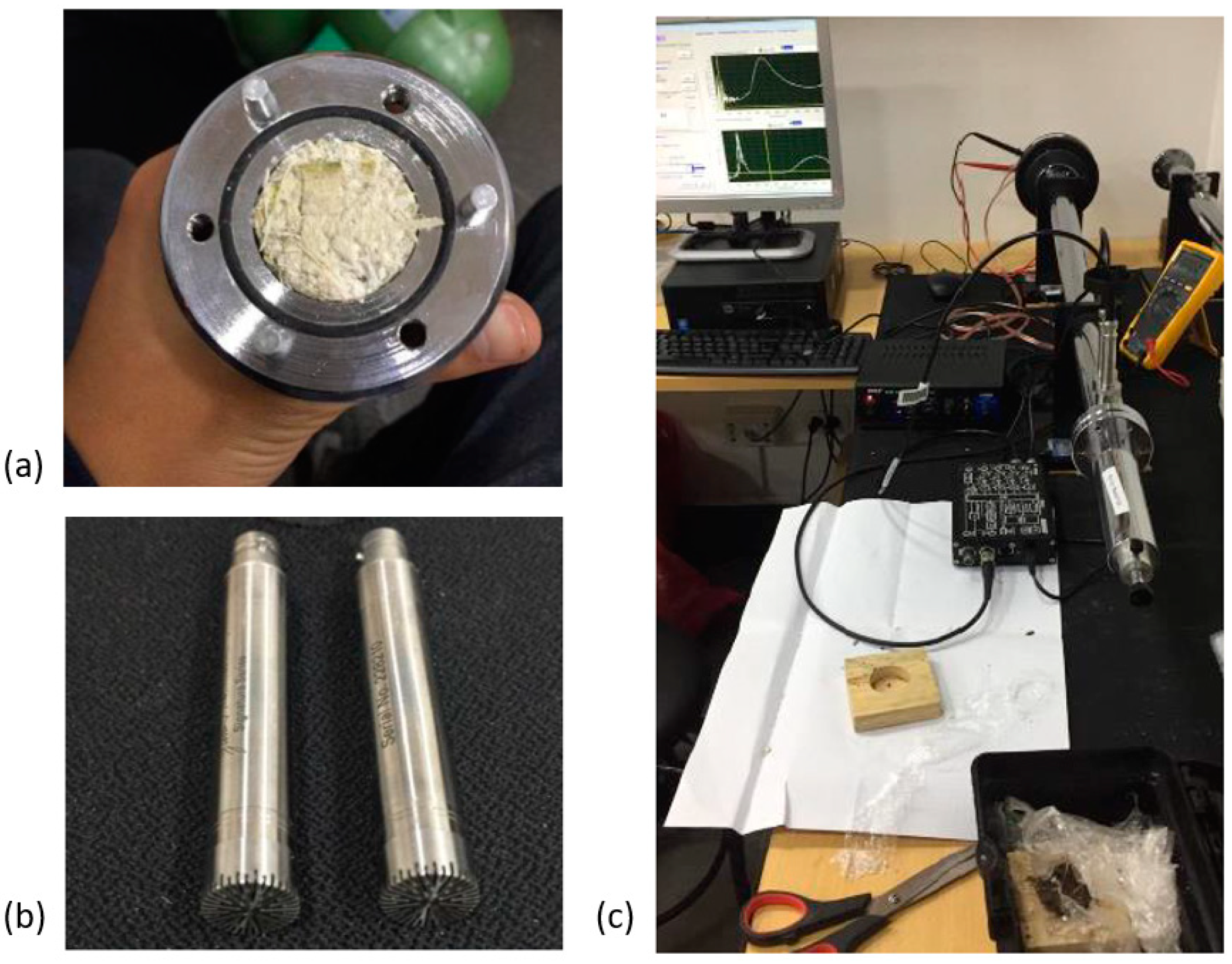

Next, the stem was separated from the root, leaves, flowers, and fruits, which were not needed for this procedure. The treatment explained below was carried out on all selected plants (

Figure 2a). With the stems obtained, the crushing step was consecutively carried out, that is, the stems were passed through an electric machine to extract the juice from the cane (

Figure 2b).

In this process, each of the stems was cut and divided into small parts so that they could fit into the machine and all the superfluous juice could be extracted from the plant so that only the bark and fiber were obtained. Then, the crushed fiber was placed outdoors for the drying stage for a period of two days (

Figure 2c).

One of the most important aspects to take into consideration when producing a sound-absorbing material consisting of fibers is its durability. In this case, it was possible to show that, through the drying phase at room temperature, the fiber of the corn stalk contracts to easily handled brittle filaments. Generally, this happens when it is allowed to dry from 6 months to 1 year.

To accelerate the drying process, artificial drying was performed in an oven [

28]. The fiber was then placed in an oven at a temperature of 60 °C for about 6 h, and then the weight loss in grams experienced by the fiber was evaluated. This was used to compare the drying status between weather-exposed fiber and oven-exposed fiber through a controlled procedure. The fibers used for the test had an initial weight of 95.5 g, while at the end of the drying process, they showed a reduction in weight at 91.2 g. Thus, a difference of 4.3 g from the initial weight was found, returning a percentage reduction of 4.5 percent.

The use of a binder such as plaster helped to increase the durability of the fibrous material and the functionality of the panel. The selection of this type of binder has two key advantages: first, it is an easily accessible material, and second, it allows this composition to be developed manually.

Use of gypsum, due to its low production cost, aesthetic finish, and installation, is one of the most widely used resources for interior finishes, cladding, and walls in buildings. The behavior of this material with the addition of fibers, both natural and artificial, has been studied for several years. Gypsum needs firing earlier than when it is mixed with water, and once mixed, it hardens. Gypsum is a natural stone with the chemical formula CaSO4 × 2H2O (calcium sulfate dihydrate), which treated at temperatures between 120 °C and 1000 °C, loses the water of crystallization, changing its composition and chemical formula, which becomes CaSO4 × 1/2H2O (calcium sulfate hemihydrate). Different types of gypsum are produced by treating the mined material at different temperatures. Gypsum is a material that changes its behavior in contact with water. In the hydration phase, gypsum is mixed with water, and calcium sulfate dihydrate returns. In this phase, gypsum is gradually added to the water until the mixture reaches saturation. The amount of water in the hydration phase conditions the mechanical behavior of the product, which generally reduces its strength with more water. Later, in the curing phase, the material hardens by losing its plasticity and forming a three-dimensional coagulated structure where Diberot crystals are joined by weak Van del Waals forces of molecular cohesion. The hydration process of gypsum yields a porous crystalline product composed of small, randomly oriented needle-shaped crystallites and larger particles. The mechanical properties of the hardened plaster are mainly determined by the closely interconnected crystalline structure and the remaining porosity of the material.

The plaster used in this study is the fine-grained plaster of type C6 finishes according to the EN 13279-1 standard (

Table 1).

Plaster has limitations in its use due to its permeability and brittleness, so for some time, researchers have been trying to improve its characteristics by producing plaster-based composites with the addition of reinforcement. From the combination of a brittle matrix and an elastic reinforcement, it is possible to obtain a composite with improved mechanical and acoustic characteristics.

Beginning with the dried fibers that were exposed to room temperature, each of the dried stems was cut and crushed to a size of about 5 mm × 5 mm.

Next, all the cut fiber was collected to perform sieving, using a metal sieve, through which the residue was filtered and then assembled with the plaster-based binder. This technique was repeated several times until the required amount was obtained to make all the specimens needed for measurements. For the plaster-based binder to act, a percentage of water was incorporated, relative to the amount of the binder, so that their particles could be compacted and could adhere to the fiber (

Table 2 shows the mixing water rate of each of the samples).

Next, specimens were assembled in wooden molds with circular holes (35 mm in diameter) to allow SAC measurements in the impedance tube. Specimens with thicknesses of 6 and 12 mm of corn stem fibers composite material were assembled (

Figure 3).

Table 3 shows the weight percentage of each of the assembled composites.

2.3. SAC measurement Using Impedance Tube

The present work studies the possibility of making sound-absorbing panels based on corn stem fibers. The methodology involves the use of a binder that allows the fibers to join and mix, such as plaster. The acoustic properties of the composite material were measured through tests based on the ISO 10534-2 standard [

21] carried out with an impedance tube. The standard allows for the calculation of SAC from the measurement of the surface impedance of the material under normal incidence by exploiting an impedance tube. The measurements should be conducted by taking a normalized approach so that the performance of different materials can be compared. The instrumentation used in this study is an ACUPRO Spectronics impedance tube that allows for the measurement of SAC in a specific range frequency (50 Hz–5700 Hz). The tube dimensions consist of a 34.9 mm inner diameter, a 41.3 mm outer diameter, and a 1200 mm length (

Figure 4c).

The acquisition system is equipped with a JBL 2426J speaker that emits a 150-dB white signal that is captured by two microphones (

Figure 4b) and sent to the ACUPRO software. The software makes 150 surface impedance measurements and calculates the SAC from the average of the measurements. SACs were calculated in a 250 Hz to 5000 Hz frequency range using 1/3-octave bands. The specimens were placed inside the impedance tube (

Figure 4a), and to normalize any irregularities in the material, five measurements of the same specimen were made, performing a pro-vine relocation for each measurement.

2.4. SAC modelling Using ANN

Machine Learning (ML) is a field of computer science that studies systems and algorithms capable of learning directly from data without having been programmed in advance [

29,

30,

31]. Data scientists use ML algorithms to identify patterns within their data that provide them with interesting insights to support strategic decisions of various kinds. ML bases its operation on two different methodologies depending on whether labeled examples are used (supervised learning [

32]) or data are provided without any label (unsupervised learning [

33]). In this case, having the SAC measures properly labeled, the approach we will take is supervised learning.

Let us now turn our attention to the format of the output in order to distinguish classification algorithms from regression algorithms. Classification algorithms are used when the desired output is a discrete label, that is, it can take one among a set of predetermined values. Regression algorithms, on the other hand, are used to predict continuous outputs. This means that the answer to the originally posed question is represented by a quantity that does not fall within a set of possibilities but can be determined with greater flexibility.

ANNs are adaptive systems, capable of changing their structure in terms of nodes and interconnections based on both internal and external inputs. Artificial neural networks attempt to simulate the functioning of biological neural networks and their component parts [

34]. Neural networks are based on the simulation of appropriately connected artificial neurons, which receive stimuli as input and process them accordingly. The simplest case involves individual inputs being multiplied by an appropriate value, called a “weight”, and the outcome is then summed. When this sum exceeds a specific threshold, the output of the neuron is activated. Note that the distribution of weight values varies according to the input significance: a valuable input assumes high weight, unlike a less valuable one that assumes a lower value [

35].

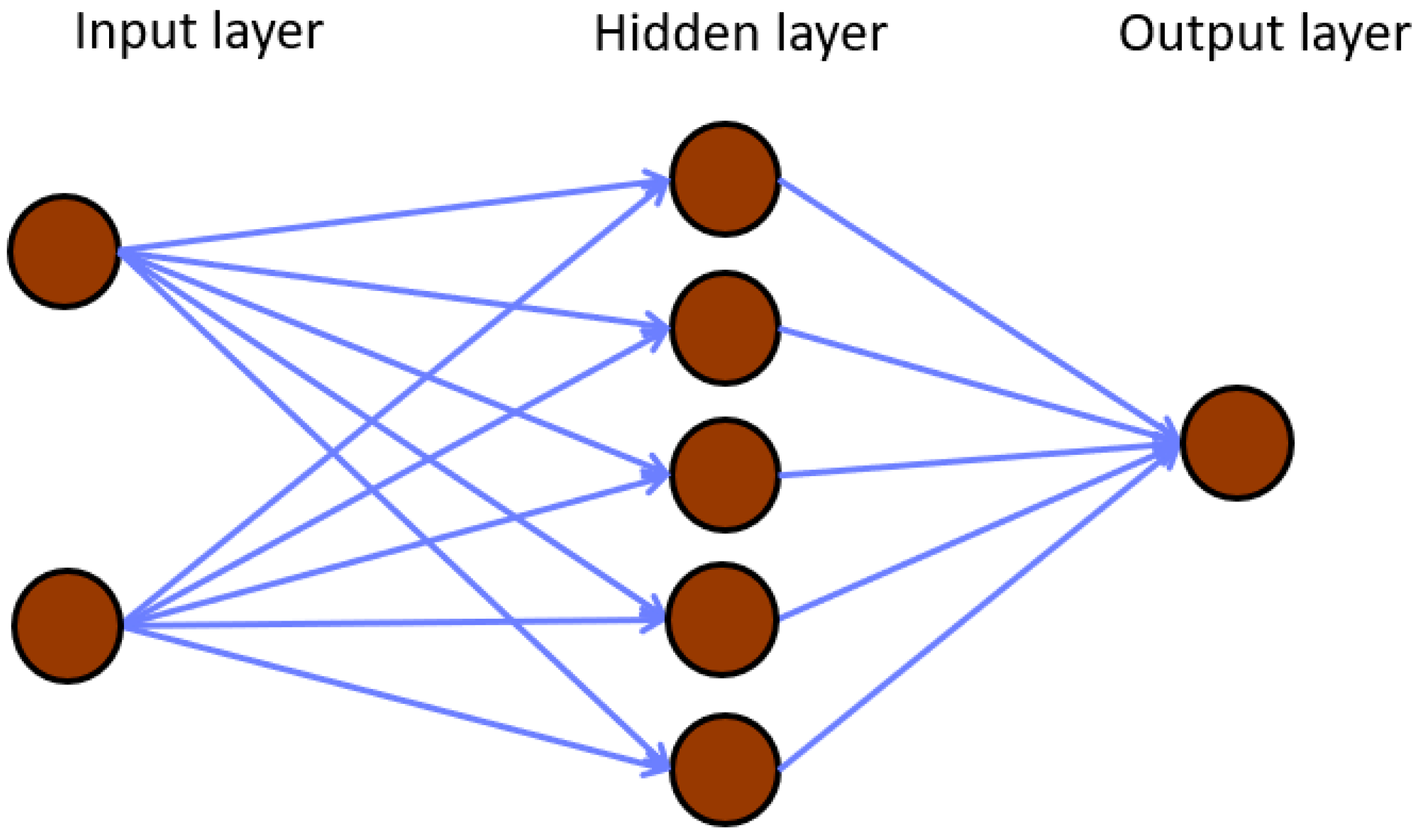

The multilayer perceptron (MLP) is an artificial neural network model composed of multiple perceptrons [

36]. It consists of an input layer, which receives the signal; an output layer, which makes a prediction or decides regarding the input; and an arbitrary number of hidden layers, the real computational engine of the network (

Figure 5). Each neuron in one layer is connected to all neurons in the previous layer. For that reason, such a network is also called Fully Connected [

37]. In a (simple) neural network, the category to which MPL belongs, it is, therefore, possible to identify three components [

38]:

The input layer is responsible for receiving and processing input signals, adapting them to the requirements of the neurons in the network;

The hidden layer which oversees the actual processing. The hidden layers can be more than one; the greater the number, the smarter the neural network will be;

The output layer collects the processing results from the hidden layer and adapts them to the needs of the next layer-block of the neural network.

Figure 5.

ANN architecture scheme.

Figure 5.

ANN architecture scheme.

Each layer of the neural network contains one or more artificial neurons, which in turn possess one or more input communication pathways, so-called dendrites [

39]. In the basic artificial neuron model, a set of adaptive parameters known as weights are used to multiply the neuron’s inputs. The sum of these weighted inputs is referred to as the linear combination of the inputs (Equation (1)) [

40].

Here,

xi = input;

wn = weights;

b = bias;

y = output.

Once the linear combination is calculated, the neuron takes the linear combination and submits it to an activation function, which, together with the linear combination, determines the neuron’s output. As a result, the learning phase within the network takes place when the weights are adjusted to produce the correct outputs. The neural networks are often very large, with some containing hundreds of billions of weights, making optimization of all of them a challenging task that requires high computing power [

41].

In feed-forward networks, each neuron at one level receives input only from neurons at earlier levels and can propagate only to neurons at later levels [

42]. Thus, no self-connections or connections with neurons of the same level are possible. The main functionality of the neuron is therefore to propagate the signal through the network, with a flow of information from inputs to outputs [

43]. In such a system, the current output depends solely and exclusively on the current input; therefore, in essence, the network has no memory of inputs that occurred at earlier times [

44].

One limitation proposed historically by the scientific community concerns the supposed unfathomability of the final product. Indeed, it has been pointed out by several quarters that once an ANN has been trained, it is no longer possible to understand its exact operation and, consequently, risks losing control of one’s product [

45,

46]. Today, it is possible to have an advanced broad understanding of the role of the various layers of the network and often of specific areas of each layer. To gain this understanding, the most effective strategy is to cast the network in reverse, entering the output and retracing the calculation until finding the exact input that would have generated that output [

47]. This approach, combined with the ability to input not only the final output of the network but also intermediate outputs on each layer of the network, makes it possible to reconstruct the reasoning pattern of the network and identify the role of the various areas [

48].

ANNs require substantial computing power. One solution is to distribute computations among several processors and perform those computations simultaneously. When training neural networks, the main ways to achieve this are model parallelism, which involves distributing the neural network among several processors, and data parallelism, which involves distributing training examples over several processors and processing updates to the neural network in parallel [

49]. Although pattern parallelism allows training neural networks larger than a single processor can support, it usually requires adapting the model architecture to the available hardware. In contrast, data parallelism is model-independent and applicable to any neural network architecture. It is the simplest and most widely used technique for parallelizing neural network training [

50].

The size of the available input data is another critical issue in ANN training. The amount of data required depends on many factors, such as the complexity of the problem. The unknown function that relates the input variables to the output variable takes a major weight in the choice of sample size [

51]. However, it is also important to consider the complexity of the learning algorithm. In fact, the algorithm used to inductively learn the unknown underlying mapping function from specific examples becomes crucial in estimating the sufficient sample size to be used. It is necessary to have data sufficiently representative of the problem we are addressing. In addition, the data must be independent and identically distributed. We must have sufficient data to reasonably capture the relationships that may exist between both input features and output features [

52].