Abstract

Combining different types of fibers inside a concrete mixture was revealed to improve the strength properties of cementitious matrices by monitoring crack initiation and propagation. The contribution of hybrid fibers needs to be thoroughly investigated, taking into consideration a variety of parameters such as fibers type and content. In this paper, the impact of integrating hybrid steel-polypropylene fibers on the mechanical properties of the concrete mixture was investigated. Hybrid fiber-reinforced high-strength concrete mixtures were tested for compressive strength, tensile strength, and flexural strength. According to the results of the experiments, the addition of hybrid fibers to the concrete mixture improved the mechanical properties significantly, more than adding just one type of fiber for specimens exposed to room temperature. Using hybrid fibers in the concrete mixture increased compressive, tensile, and flexural strength by approximately 50%, 53%, and 46%, respectively, over just using one type of fiber. Furthermore, results showed that including hybrid fibers into the concrete mixture increased residual compressive strength for specimens exposed to high temperatures. When exposed to temperatures of 200 °C, 400 °C, and 600 °C, the hybrid fiber reinforced concrete specimens maintained 87%, 65%, and 42% of their initial compressive strength, respectively. In comparison, the control specimens, which were devoid of fibers, would be unable to tolerate temperatures beyond 200 °C, and an explosive thermal spalling occurred during the heating process.

1. Introduction

In the construction industry, concrete is a broadly involved material, which is due to its multiple uses and applications. In recent years, the review and utilization of high-strength concrete (HSC) has been extending as a result of the extraordinary need to implement structures that can resist high stresses as such bridges, dams, tunnels, high rises, and wide span structures, etc., as using high strength concrete in the construction gives more applications and improves performance when compared with normal strength concrete.

The growing demand for high-strength concrete (HSC) has led to a significant increase in cement consumption, causing serious environmental issues [1]. In contrast, the use of high-strength concrete ultimately leads to an increase in the cost of construction as a result of the need to use specific materials and additives to increase the strength, as well as specialized curing methods [2,3]. Therefore, different research has been focused on realizing the manufacture of high-strength concrete (HSC) at the lowest possible cost [4].

Adding fibers to the concrete mix improves the strength and the behavior of concrete by delaying the initiation of cracks and controlling its propagation [5,6,7,8]. The commonly used fibers in the concrete mixture are mainly steel fibers (SF), carbon fibers (CF), and polymer fibers (PF). Steel fiber is considered the most popular, as it can effectively increase the tensile and compressive strength of the hardened concrete more than other types of fibers [9]. Despite this, the use of polypropylene fiber has proven its efficiency in improving the mechanical properties of hardened concrete and its use in many applications [10,11,12,13,14]. Polypropylene fiber has attracted the interest of many researchers due to its low cost and high resistance to shrinking and roughness [14,15]. Several earlier investigations on the addition of polypropylene fiber to concrete mixtures revealed that the type and content of fibers has a substantial impact on the mechanical properties of concrete [10,11,16].

The effect of adding hybrid steel-polypropylene fiber on the mechanical behavior of hardened concrete has been investigated in previous studies [17,18,19,20]. Sivakumar et al. [21] investigated the effect of adding hybrid fiber of 1.5% as a replacement percentage of cement weight in an HSC mixture. Different steel–polypropylene fiber volume content was added in various concrete mixtures such as 1.2–0.3%, 1.05–0.45%, and 0.9–0.6% as a replacement percentage of cement weight. It could be observed from the investigation that the inclusion of hybrid steel-polypropylene fiber leads to improved compressive and tensile strength, as well as enhanced ductile properties. The optimum compressive strength was obtained for a mixture that has 1.2% steel fiber and 0.3% polypropylene fiber as a replacement percentage of cement weight. Furthermore, Rajarajeshwari et al. [22] investigated the effect of adding hybrid fibers on the mechanical properties of the concrete mixture. The studied key parameters were compressive and splitting tensile strength. A hybrid fiber reinforced concrete has been formed by adding steel fiber and polypropylene fiber with 1%, and 0.036% volume content as a replacement of cement weight, to the concrete mixture, respectively. It was observed from the results that the compressive strength after 14 and 28 days, increased by 14.30% and 17.11% when compared to the control specimen, respectively. In addition, adding 1% of steel fiber increased the compressive strength more than by adding 0.036% of polypropylene fiber. On the other hand, adding hybrid steel–polypropylene fiber led to a significant increase in the compressive strength of the tested concrete specimens compared with mono fibers. Additionally, the splitting tensile strength of concrete specimens with hybrid fibers increased by 53% compared to the control specimen. Another study had been conducted by Yusof et al. [23] to investigate the mechanical properties of hybrid fiber reinforced concrete (HFRC). The length and volume content of the steel fiber were the major parameters investigated. Results showed that the optimum compressive strength was obtained in a concrete mixture with a 1.5% volume fraction of steel fiber (30% long fibers and 70% short fibers). Furthermore, as compared to the performance of concrete with long steel fiber, adding short steel fiber increased compressive strength. The results revealed that HFRC had the highest splitting tensile strength at a volume fraction of 1.5 percent, with 70 percent long fiber and 30 percent short fiber. It was also discovered that increasing the percentage of fiber in the concrete mixture reduces the workability of the mixture. Zhang et al. [24] investigated the effect of curing conditions, steel fiber ratio and reactive powder ratio on the behavior of the concrete mix.. Zhong C. et al. [25] investigated the effect of integrating hybrid steel-polypropylene fibers into concrete mixtures on mechanical characteristics. The addition of hybrid fibers to the concrete mixture boosted compressive and tensile strength more than by just adding polypropylene fiber, according to the findings. 0.15% polypropylene fiber and 1.75% steel fiber were found to be the ideal fiber content for hybrid polypropylene-steel fiber concrete. Ali B. et al. [26] studied the effects of steel fiber addition on the mechanical behavior of high-strength concrete. Furthermore, the effect of combining steel fiber with micro-silica in concrete mixtures has been explored. The results showed that steel fiber has a significant effect on compressive strength only at low volume content. A high-volume content of steel fiber reduces compressive strength. The addition of micro-silica to steel fiber improves not only the strength properties but also the interaction between the fibers and the cementitious composite. The largest compressive strength gain was 20%, with a steel fiber content of 0.5% and micro-silica content of 10%, while the maximum tensile strength increases were 60% with a steel fiber content of 1% and micro-silica content of 10%. A Sharma et al. [27] analyzed the effects of incorporating hybrid lead-steel fibers on the mechanical properties of concrete. The results clearly demonstrated that the hybrid fibers significantly improved the mechanical properties of the concrete mixture. The use of hybrid fibers in the concrete mixture increased compressive, tensile, and flexural strength by approximately 16%, 38%, and 39%, respectively, over plain concrete.

When exposed to fire or elevated heat, the mechanical properties of fiber-reinforced concrete can be severely affected. It can be one of the most serious risks for different concrete structures. Many researchers found that a severe deterioration of the concrete and explosive spalling occurred when exposed to a high level of temperature [28,29,30]. Consequently, the concrete deteriorates due to severe physical and chemical changes [31,32]. The lack of voids, which may relieve the constant pressure build-up caused by evaporable water vaporization, could result in major deterioration or possibly the spalling of the concrete. Previous studies indicated that the use of fibers such as polypropylene and steel can provide adequate fire protection on concrete structures, reducing the risk of degradation and spalling [33,34]. However, polypropylene fiber may have little or even a detrimental influence on the residual performance of heated concrete [35].

J Bosnjak et al. [36] observed the effect of high temperatures on the mechanical and physical properties of high-strength concrete with and without fibers. The inclusion of steel-polypropylene fibers in the concrete mixture increased residual compressive strength for specimens exposed to high temperatures up to 600 °C according to the results. Utilizing hybrid fibers or single fibers, on the other hand, was ineffective in improving the compressive strength of concrete mixtures exposed to high temperatures above 600 °C. The tensile and flexural strength of hybrid fibers and single fiber reinforced concrete specimens increased significantly more than normal concrete at all temperatures. Bangi et al. [37] investigated the impact of hybrid propylene, polyvinyl alcohol, and steel fiber on the mechanical properties of concrete mixtures at high temperatures in 2012. The diameters and lengths of fibers were the main studied parameters. Pore pressure studies in fiber reinforced HSC (FRHSC) exposed to high temperatures revealed that the inclusion of fibers, regardless of type, considerably reduced pore pressure. When compared to polyvinyl alcohol fibers, polypropylene fiber was more effective in preventing maximum pore pressure increase, while steel fiber had a minor effect. Longer fibers of 12 mm in length with a smaller diameter of 18 mm performed better than shorter fibers of 6 mm in length with bigger diameters of 28 mm and 40 mm.

Previous studies have mainly focused on incorporating individual polypropylene fibers or steel fibers into concrete mixtures and investigating the impact on mechanical behavior, while the impact of hybrid fibers on the mechanical behavior of fiber-reinforced concrete is less well understood, especially when the mixture is exposed to high temperatures. One type of fiber can be added to improve only a part of the mechanical characteristics while reducing others [38,39]. To mitigate the weaknesses of such characteristics, combining two types of fibers can help. Thus, in the current study, the impact of integrating hybrid steel-polypropylene fibers on the mechanical properties of the concrete mixture was investigated. Various hybrid fiber-reinforced high-strength concrete mixtures were tested for compressive strength, tensile strength, and flexural strength. In addition, the effect of temperature on the mechanical properties was investigated and the concrete mixes were subjected to different levels of temperature. The results of this study are beneficial in determining the volume content of steel fibers and polypropylene fibers for the optimum mechanical behavior of hybrid fibers reinforced with high strength concrete that is exposed to high temperatures.

2. Experimental Program

The experimental investigation was conducted to obtain the mechanical properties of hybrid-fibers high-strength concrete mixtures (flexural, tensile strength, and compressive strength) that were exposed to various temperatures (Supplementary Materials).

2.1. Description of Specimens

The performed experimental work consisted of eleven hybrid-fibers high-strength concrete mixtures with different contents of steel and polypropylene fibers, divided into three groups, and one ordinary concrete mixture with 0% steel and polypropylene fiber content. Group one consisted of four hybrid-fibers and high-strength concrete mixtures that were exposed to room temperature and tested for compressive strength, tensile strength, and flexural strength. The steel fiber content in group one was constant with 7% as a replacement percentage of cement weight, and polypropylene fiber content varied at 0%, 0.3%, 0.45%, and 0.6%. Group two consisted of four more hybrid-fibers high-strength concrete mixtures that were also exposed to room temperatures and tested for compressive strength, tensile strength, and flexural strength. The polypropylene fiber content in group two was constant at 0.45% as a replacement percentage of cement weight, and steel fiber content varied as 0%, 4%, 7%, and 10%. Finally, group three consisted of three fiber-reinforced high-strength concrete mixtures that were exposed to high temperatures and tested for compressive strength. The first mixture in group three was made with hybrid steel-polypropylene fibers, while the second and third mixtures were made with only steel fibers and only polypropylene fibers, respectively. The impact of using hybrid or single fibers in concrete mixtures exposed to high temperatures was studied. Steel fiber has a length of 35 mm and a rectangular cross-section of (1 mm × 4 mm). Polypropylene fiber has a length of 20 mm and a diameter of 0.04 mm. Figure 1 shows the shape of steel and polypropylene fibers used in all mixtures.

Figure 1.

Shape of (a) polypropylene fiber and (b) steel fiber.

2.2. Preparation of Specimens

The following steps were taken during the mixing procedure: To have a satisfactory dispersion, ingredients included fine sand, crushed granite, cement, and silica fume, which were dry mixed in a mechanical dry mixer for 2–3 min. Next, around three-quarters of the superplasticizer and all of the water were mixed thoroughly before being put into the dry mixture. Following wet mixing for 5 min, the steel fiber and polypropylene fiber were slowly thrown into the mixture by hand and mixed thoroughly for another 3 min, once the liquid had reached the desired fluidity and viscosity. Lastly, the residual superplasticizer was added, and mixing was continued until a good flowability was produced. Table 1 shows the weight-based quantities required for one cubic meter of fresh concrete for each admixture. For example, for the specimen identification system (M0.45/7), 0.45 represents the ratio of polypropylene fiber to cement weight, and seven represents the ratio of steel fiber to cement weight.

Table 1.

Mix Properties.

The fresh concrete was placed in 50 mm layers into the molds of the various specimens. It then had to be compacted manually in order to remove all of the air from the mix. The specimens were removed after 24 h and left under water until the test time. For groups one and two, the specimens consisted of:

- six cube specimens (150 mm × 150 mm × 150 mm) for each concrete mixture. Three cubes were tested after 14 days, while another three cubes were tested after 28 days to obtain the compressive strength.

- Three cylindrical specimens (150 mm. diameter and 300 mm. height) for each concrete mixture. Cylinders were tested after 28 days to determine the splitting tensile strength of concrete.

- Three beam specimens (150 mm × 150 mm × 700 mm) for each concrete mixture. Beams were tested after 28 days to determine the flexural strength of concrete.

- For group three, the specimens consisted of:

- twelve cube specimens (150 mm × 150 mm × 150 mm) for each concrete mixture. After 28 days, the compressive strength of three standard-cured specimens exposed to various temperatures (room temperature, 200 °C, 400 °C, and 600 °C) was determined.

All tests were carried out in accordance with Egyptian standards.

2.3. Test Setup

2.3.1. Compression Test

Cubes are subjected to increasing compressive loads until they fail for compressive strength. Cubes were weighed and positioned centrally between the two compression plates, with the moving head’s center vertically above the specimen’s center. The load was applied to the specimens and raised at a relatively constant level until there was no longer any more load that could be tolerated.

2.3.2. Splitting Tensile Test

The split cylinder test is performed on cylinder specimens placed on their side and loaded in compression along their length. The stresses along the diameter are of nearly uniform tension and perpendicular to the loading plan.

2.3.3. Flexure Test

The bending test is performed on beam specimens to get the flexure tensile strength. Concrete beam specimens are loaded up to failure. The specimens were installed as a simple beam with two hinged and roller supports at the end of the span and a vertical load at the mid-span. The distance between the applied load and support was 300 mm.

2.3.4. Heating Procedure

Concrete specimens were heated to varying temperatures of 200 °C, 400 °C, and 600 °C in an electrical furnace. The temperature was fixed for 30 min after attaining the appropriate raised temperature with a heating rate of 2 °C/min, then the furnace was shut off. The specimens were retrieved and tested once the furnace had dropped to normal temperature.

3. Results

3.1. Compressive Strength of Hybrid Steel-Polypropylene Fiber Reinforced High Strength Concrete

3.1.1. Compressive Strength for Specimens Exposed to Room Temperature

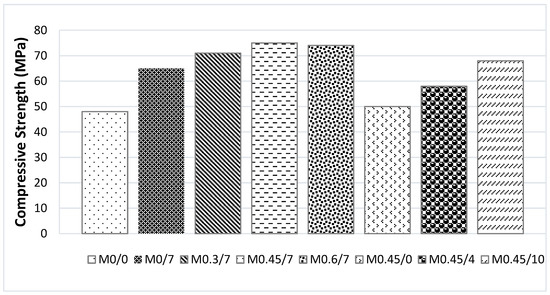

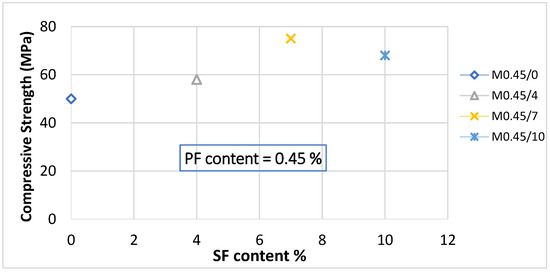

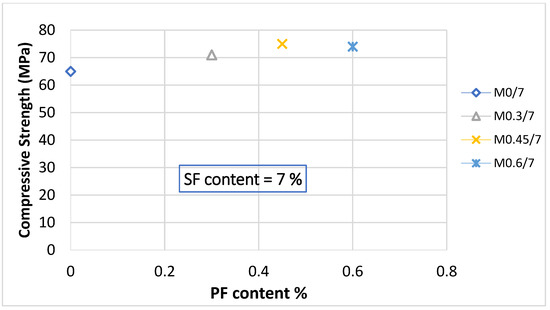

The 28 day compressive strength for specimens in group 1 that contain a constant steel fiber volume content of 7% showed an enhancement of 35%, 48%, 56%, and 54%, compared to control specimen M0/0 when polypropylene fiber content was 0%, 0.3%, 0.45%, and 0.6%, respectively. When polypropylene fiber volume content was constant at 0.45%, the 28-day compressive strength for specimens in group 2 exhibited improvements of 4%, 21%, 56%, and 41%, when steel fiber content was 0%, 4%, 7%, and 10%, respectively, compared to control specimen M0/0. Figure 2 illustrates the maximum compressive strength of concrete specimens exposed to room temperature.

Figure 2.

Compressive strength for all concrete specimens under ambient conditions.

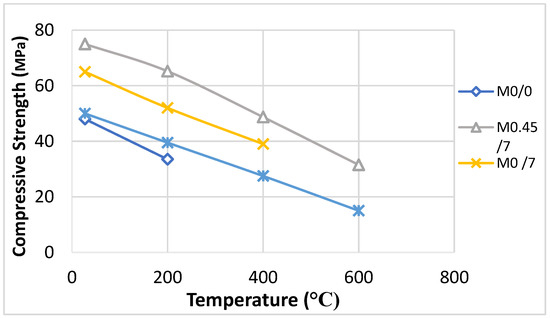

3.1.2. Compressive Strength for Specimens Exposed to High Temperatures

Concrete specimens were tested for compressive strength at temperatures ranging from room temperature to 600 °C. The comparative residual compressive strength of all specimens was determined by the ratio between the strength of heated specimens and the equivalent control specimens to explore the behavior of concrete specimens at high temperatures. When exposed to a temperature of 200 °C, the residual compressive strength of the control specimen (M0/0), hybrid fiber reinforced concrete specimen (M0.45/7), steel fiber reinforced concrete specimen (M0/7), and polypropylene fiber reinforced concrete specimen (M0.45/0) were 70%, 87%, 80%, and 79%, respectively. And compared to the control specimen, the residual compressive strength increased by 24% for the hybrid fiber reinforced concrete specimen. When exposed to a temperature of 400 °C, brittle explosive failure was observed for the control specimen during the heating process. On the other hand, hybrid fiber reinforced concrete specimen (M0.45/7), steel fiber reinforced concrete specimen (M0/7), and polypropylene fiber reinforced concrete specimen (M0.45/0) maintained 65%, 60%, and 55% of their original compressive strength. In contrast, they could keep 42%, 39%, and 30% of their original compressive strength when exposed to a temperature of 600 °C, respectively.

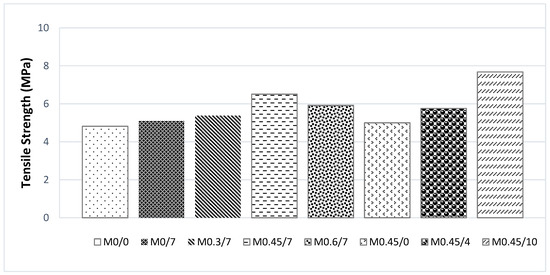

3.2. Tensile Strength of Hybrid Steel-Polypropylene Fiber Reinforced High Strength Concrete Exposed to Room Temperature

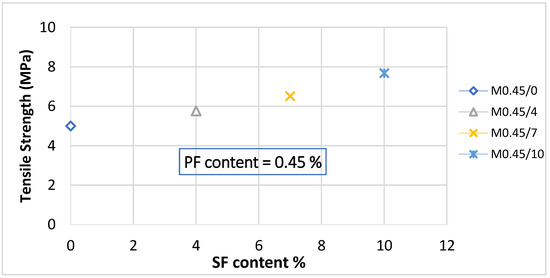

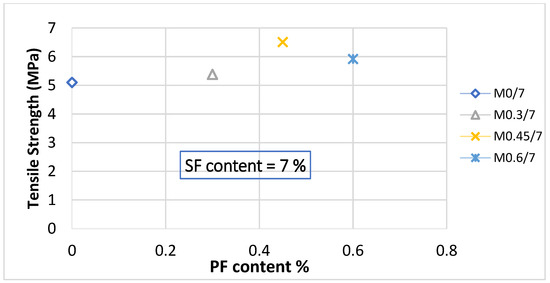

At a constant polypropylene fiber volume content of 0.45%, the tensile strength showed an enhancement of 4%, 20%, 35%, and 59% compared to control specimen M0/0 when steel fiber content was 0%, 4%, 7%, and 10%, respectively. Additionally, the tensile strength at constant steel fiber volume content of 7%, showed an enhancement of 6%, 12%, 35%, and 23%, compared to control specimen M0/0 when polypropylene fiber content was 0%, 0.3%, 0.45%, and 0.6%, respectively. Figure 3 shows the tensile strength of concrete specimens exposed to room temperature.

Figure 3.

Tensile strength for all concrete specimens under ambient conditions.

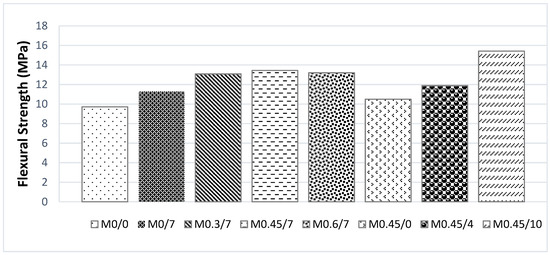

3.3. Flexural Strength of Hybrid Steel-Polypropylene Fiber Reinforced High Strength Concrete Exposed to Room Temperature

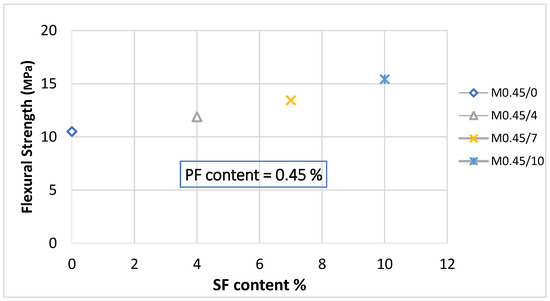

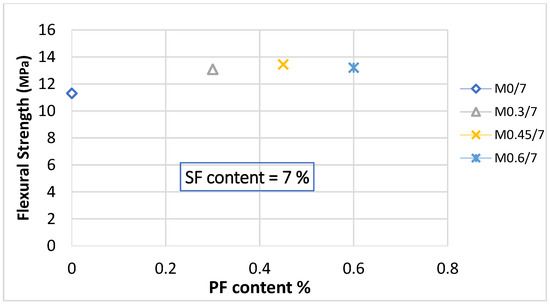

At a constant polypropylene fiber volume content of 0.45%, the flexural strength showed an enhancement of 8%, 22%, 38%, and 58%, compared to control specimen M0/0 when steel fiber content was 0%, 4%, 7%, and 10%, respectively. On the other hand, flexural strength at a constant steel fiber volume content of 7%, increased by 16%, 34%, 38%, and 35% when polypropylene fiber content was 0%, 0.3%, 0.45%, and 0.6%, respectively, compared to control specimen M0/0. Figure 4 shows the flexural strength of concrete specimens exposed to room temperature. In summary, utilizing hybrid steel-polypropylene fibers in the concrete mixture increased compressive, tensile, and flexural strength by 50%, 53%, and 46%, respectively, overusing only one type of fibers under ambient conditions.

Figure 4.

Flexural strength for all concrete specimens under ambient conditions.

4. Discussions

4.1. Compressive Failure Modes

4.1.1. Compressive Failure Modes for Specimens Exposed to Room Temperature

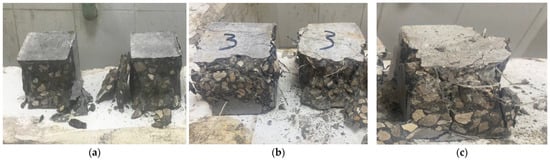

During the compression process, Vertical fine cracks had initiated on the surface of the control specimen parallel to the load direction. As the load increased, the cracks continued to spread and widen further. At failure load, explosive brittle failure was observed due to the local crushing of concrete. The inclusion of hybrid or single fibers had no impact on the failure mode, as all specimens including the control one showed the same failure mode as shown in Figure 5. However, the cracks in the specimens containing hybrid fibers or individual fibers are considerably smaller and thinner when compared to the cracks in the control specimen, indicating the role of fibers in preventing the opening and expansion of micro and macro cracks. Furthermore, the inclusion of fibers improved the plastic properties of concrete specimens as the period between the first crack and failure load increased, resulting in enhanced ductility.

Figure 5.

Compressive failure modes for specimens exposed to room temperature for (a) Control specimens, (b) Hybrid fiber reinforced concrete specimens, (c) Mono fiber reinforced concrete specimens.

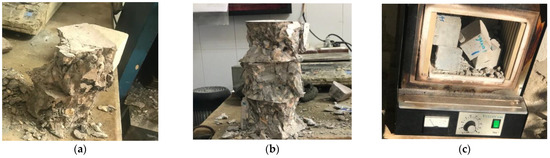

4.1.2. Compressive Failure Modes for Specimens Exposed to High Temperatures

Concrete specimens were tested for compression once the furnace had dropped to normal temperature. The process of thermal deterioration in concrete starts from the heating process and continues until the temperature reaches ambient level. Thermal cracking due to mechanical actions and hydration decomposition occurs during this process. The thermal cracks increase as the heating level rises, and the progressive increase in pore pressure more rapidly meets or exceeds the strength, eventually breaking up the concrete. This explains why the control specimens, which were devoid of fibers, would be unable to tolerate temperatures beyond 200 °C, where an explosive thermal spalling occurred suddenly during the heating process as shown in Figure 6c. Concrete specimens containing individual or hybrid fibers, on the other hand, did not experience explosive thermal spalling during the heating process and could withstand temperatures up to 600 °C. This reflects the effect of fibers in enhancing the hydration process and subsequently delaying the cracking process and improving the bonding strength between the aggregates and the surrounded paste.

Figure 6.

Compressive failure modes for specimens exposed to temperatures up to 600 °C for (a) Mono fiber reinforced concrete specimens, (b) Hybrid fiber reinforced concrete specimens, (c) Control Specimens.

As shown in Figure 6, The failure modes were explosive brittle failures in all of the tested concrete specimens under compression tests at all temperatures (room temperature, 200 °C, 400 °C, and 600 °C). However, the number of cracks increased and expanded more in the concrete specimens whenever they were exposed to a higher temperature. Numerous wide cracks were visibly noticed in the hybrid and single fiber reinforced concrete specimens heated to 600 °C, as well as severe damage with more pieces, as illustrated in Figure 3. Cement hydration ingredients break down quickly as the temperature rises, causing quite severe thermal cracks including within the cementitious matrix and surrounding aggregate or fibers, which likely led to explosive spalling. This could explain why specimens exposed to temperatures up to 600 °C during the compression test experienced rapid explosive spalling with more fragments.

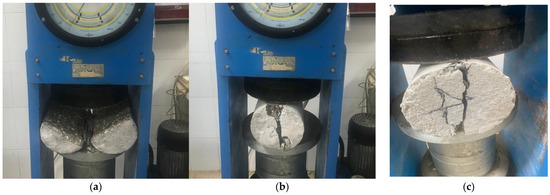

4.2. Tensile Failure Modes

The tensile failure modes for the tested concrete specimens exposed to room temperature are shown in Figure 7. The failure pattern for control specimens was brittle, as shown in Figure 7a, as they completely split in half due to a wide vertical fracture in the middle of the cross-section. Micro-cracks first appeared in the critical zone, which is located in the middle of the cross-section. As the load increased, the cracks started to expand vertically and widen until the failure occurred. The presence of fibers in the concrete mixture prevented brittle failure and improved the tensile strength. This is owing to the fiber’s capability to inhibit micro and macro cracks from opening and expanding, as well as the continuity of crack development and dissemination at various levels of stress. Subsequently, adding fibers to the concrete mixture improves bonding strength and avoids brittle failure. As shown in Figure 7a,b, the failure modes for individual or hybrid fiber reinforced concrete specimens were typical bonding failures where the tensile stress exceeded the bonding stress between fibers and the composite. A wide vertical fracture was found at failure load for individual or hybrid fiber reinforced concrete specimens without full splitting.

Figure 7.

Typical tensile failure modes at room temperature for (a) Control specimen, (b) Hybrid fiber reinforced concrete specimens, (c) Mono fiber reinforced concrete specimens.

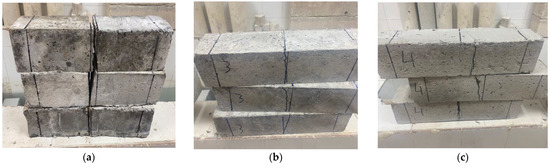

4.3. Flexural Failure Modes

The flexural failure modes for the tested concrete specimens exposed to room temperature are shown in Figure 8. Vertical micro-cracks first appeared in the location of maximum tensile stress, which is the mid-span for beam specimens. As the loading increased, these cracks began to extend vertically and expand until the failure occurred. The failure pattern for control specimens was a brittle failure with total splitting into two halves due to a wide vertical crack at the mid-span, as shown in Figure 8a. Specimens with individual fibers or hybrid fibers had failed when the tensile stress exceeded the bonding stress between fibers and the composite (bonding failure) without full splitting at the critical zone, as shown in Figure 8a,b. This indicates that fiber-reinforced concrete specimens behaved similarly under both the splitting tensile and bending tests.

Figure 8.

Typical flexural failure modes at room temperature (a) Control specimen, (b) Hybrid fiber reinforced concrete specimens, (c) Mono fiber reinforced concrete specimens.

4.4. Compressive Strength of Hybrid Steel-Polypropylene Fiber Reinforced High Strength Concrete

4.4.1. Effect of Fiber on Compressive Strength under Ambient Conditions

The addition of individual polypropylene fibers had no noticeable effect on compressive strength because of the existence of many fibers, resulting in inappropriate compaction and extra voids. The inclusion of individual steel fibers results in substantial improvement in compressive strength as they bridge the cracks, ultimately enhancing the composite’s strength. The addition of hybrid fibers to the concrete mixture improved the compressive strength significantly, more than adding just one type of fiber. The reason for this increase in strength is that the integration of hybrid steel-polypropylene fibers prevents the formation of multiscale cracks in concrete at different stress levels. Polypropylene fibers with a low modulus of elasticity greatly improve concrete compressive behavior by limiting the formation of microcracks at low levels of stress. Polypropylene fibers cannot bear the loads at high levels of stress, whereas steel fibers with a high modulus of elasticity incorporated in the cementitious materials improve the compressive behavior by preventing the growth of macro-cracks at high levels of stress. The largest compressive strength was observed for specimen M0.45/7, which contains a steel fiber content of 7 % and a polypropylene fiber content of 0.45 %. There had also been a decrement in the compressive strength when the fiber volume content exceeded the optimum. This result was supported by prior findings that increasing the amount of fiber added to a relatively large volume had a detrimental impact on compressive strength [8,9,40,41]. This is because the cement matrix is being replaced by a larger volume content of fibers which decreases mechanical and durability properties. Figure 9 and Figure 10 illustrate the effect of steel fiber content and polypropylene fiber content on compressive strength, respectively.

Figure 9.

Effect of steel fiber content on compressive strength under ambient conditions.

Figure 10.

Effect of polypropylene fiber content on compressive strength under ambient conditions.

4.4.2. Effect of High Temperatures on the Residual Compressive Strength for All Concrete Specimens

According to the findings, the presence of fibers in the concrete mixture increased the residual compressive strength when exposed to temperatures up to 600 °C. The capacity of the vapor to escape through the tiny openings generated within the mixture by melting fibers could explain this improvement [42].

Concrete specimens containing individual or hybrid steel-polypropylene fibers were able to withstand temperatures up to 600 °C, whereas the control specimens, which were devoid of fibers, would be unable to tolerate temperatures beyond 200 °C. An explosive thermal spalling occurred during the heating process, as the presence of fibers inside the concrete mixture enhanced the hydration process and subsequently delayed the cracking process and improved the bonding strength between the aggregates and the surrounded paste. Increasing the exposure temperature to 600° C reduced the compressive strength of the fiber concrete specimens significantly. This decrease could be attributed to the breakdown of the bonding strength between the aggregates and the surrounding paste and the significant decomposing of the hydration processes [43]. Figure 11 represents the effect of high temperatures on the residual compressive strength of all concrete specimens.

Figure 11.

Effect of high temperatures on the residual compressive strength of all concrete specimens.

4.5. Tensile Strength of Hybrid Steel-Polypropylene Fiber Reinforced High Strength Concrete Exposed to Room Temperature

When hybrid fibers were added to a concrete mix, the tensile strength improved much more than when only one type of fiber was used. This is due to the hybrid fiber’s ability to prevent the opening and expansion of micro and macro cracks, as well as the continuity of crack development and dissemination at various levels of stress. Prior findings that polypropylene fibers in the concrete bridged microcracks at the failure region and increased peak-stress supported this result. The steel fibers in the concrete prevent the spread of macro-cracks [25,26,41,44,45]. The largest tensile strength was observed for specimen M0.45/10, which contains a steel fiber content of 10% and polypropylene fiber content of 0.45%. The results revealed that increasing the polypropylene fiber concentration above 0.45% reduced the concrete specimens’ tensile strength. This is due to the inclusion of many fibers, which causes improper compaction and additional voids. Figure 12 and Figure 13 illustrate the effect of steel fiber content and polypropylene fiber content on tensile strength.

Figure 12.

Effect of steel fiber content on tensile strength under ambient conditions.

Figure 13.

Effect of polypropylene fiber content on tensile strength under ambient conditions.

4.6. Flexural Strength of Hybrid Steel-Polypropylene Fiber Reinforced High Strength Concrete Exposed to Room Temperature

The presence of hybrid steel-polypropylene fibers improved the flexural strength of fiber-reinforced concrete specimens more than the inclusion of only one type of fiber. As previously stated, this is due to the hybrid fiber’s ability to prevent the opening and expansion of micro and macro cracks at various stress levels, as polypropylene fibers with a low modulus of elasticity greatly improve concrete flexural behavior by limiting the formation of microcracks at low-stress levels, and steel fibers with a high modulus of elasticity incorporated in cementitious materials improve flexural behavior by preventing the growth of microcracks. The largest flexural strength was observed for specimen M0.45/10, which contains a steel fiber content of 10% and a polypropylene fiber content of 0.45%. The same was true with tensile strength, as increasing the polypropylene fiber concentration above 0.45% reduced the flexural strength of the concrete specimens. Figure 14 and Figure 15 illustrate the effect of steel fiber content and polypropylene fiber content on tensile strength, respectively. These findings will help advance future applications [46,47,48,49,50,51,52,53,54,55,56].

Figure 14.

Effect of steel fiber content on flexural strength under ambient conditions.

Figure 15.

Effect of polypropylene fiber content on flexural strength under ambient conditions.

5. Conclusions

The purpose of this work was to investigate the behavior of hybrid steel-polypropylene fiber reinforced high strength concrete exposed to room and high temperatures up to 600 °C. The experimental study of this work can lead to the following reasonable conclusions:

- Adding hybrid steel-polypropylene fibers to concrete mixtures exposed to the room or high temperatures up to 600 °C considerably improved compressive strength, tensile strength, and flexural strength, compared to adding just one type of fiber.

- The largest compressive strength gain was 56%, with steel fiber replacing 7% of the cement and polypropylene fiber replacing 0.45%, while the maximum tensile and flexural strength increases were 59% and 58%, respectively, with a cement replacement rate of 10% steel fiber and 0.45% polypropylene fiber when compared to control specimen under ambient conditions.

- Increasing the hybrid steel-polypropylene fibers’ concentration over the optimum reduced the compressive, tensile, and flexural strength of the concrete specimens due to the inclusion of numerous fibers, which resulted in poor compaction and more voids, lowering the bonding strength.

- During the compression test, the presence of hybrid fibers in concrete specimens exposed to room or high temperatures was insufficient to prevent brittle explosive spalling failure, which occurred in control specimens as well. However, during the splitting tensile and bending test, the presence of fibers prevented the brittle sudden failure and full splitting of concrete specimens, as they failed when the tensile stress exceeded the bonding stress between fibers and the composite (bonding failure) without complete separation in the critical zone.

- Concrete specimens containing individual or hybrid steel-polypropylene fibers were able to withstand temperatures up to 600 °C, whereas the control specimens, which were devoid of fibers, would be unable to tolerate temperatures beyond 200 °C and an explosive thermal spalling occurred during the heating process, as the presence of fibers inside the concrete mixture enhances the hydration process and subsequently delays the cracking process and improves the bonding strength between the aggregates and the surrounding paste.

- Increasing the exposure temperature to 600 °C considerably decreased the compressive strength of the fiber-reinforced concrete specimens due to the breakdown of the bonding strength between the aggregates and the surrounding paste, as well as the severe decomposition of the hydration process.

- When exposed to temperatures of 200 °C, 400 °C, and 600 °C, the hybrid fiber reinforced concrete specimens maintained 87%, 65%, and 42% of their initial compressive strength, respectively.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/fib10060053/s1.

Author Contributions

Conceptualization, A.D.; methodology, M.T.; software, A.A.; validation, A.E.-s.; resources, A.E.-s. and M.T.; Data curation, A.E.-s. and M.T.; writing—original draft preparation, A.A.; writing—review and editing, A.D.; supervision, A.D.; project administration, M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data produced from the study are included in the manuscript.

Acknowledgments

The authors would like to acknowledge the contribution of VELOCIT company and EDARA company from Egypt for donating steel fiber and polypropylene fiber.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties, and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; El-Tawil, S.; Parra-Montesinos, G.J. Ultra-high-performance concrete and fiber reinforced concrete: Achieving strength and ductility without heat curing. Mater. Struct. 2012, 45, 309–324. [Google Scholar] [CrossRef]

- Chan, Y.W.; Chu, S.H. Effect of silica fume on SFbond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Wang, D.H.; Shi, C.J.; Wu, Z.M.; Xiao, J.F.; Huang, Z.Y.; Fang, Z. A review on ultra-high-performance concrete: Part II. Hydration, microstructure, and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined effect of silica fume and SF on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Nili, M.; Afroughsabet, V. The effects of silica fume and PF on the impact resistance and mechanical properties of concrete. Construct. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Xu, Z.; Hao, H.; Li, H.N. Experimental study of dynamic compressive properties of fibre reinforced concrete material with different fibres. Mater. Des. 2012, 33, 42–55. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Nagaraj, T.S.; Basavaraja, S.B. Reproportioning of steel fibre reinforced concrete mixes and their impact resistance. Cem. Concr. Res. 2005, 35, 2350–2359. [Google Scholar] [CrossRef]

- Xu, L.H.; Wu, F.H.; Chi, Y.; Cheng, P.; Zeng, Y.Q.; Chen, Q. Effects of coarse aggregate and steel fibre contents on mechanical properties of high-performance concrete. Constr. Build. Mater. 2019, 206, 97–110. [Google Scholar] [CrossRef]

- Alhozaimy, M.; Soroushian, P.; Mirza, F. Mechanical properties of polypropylene fiber reinforced concrete and the effects of pozzolanic materials. Cem. Concr. Compos. 1996, 18, 85–92. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.F. Effect of polypropylene fiber on durability of concrete composite containing fly ash and silica fume. Compos. B Eng. 2013, 45, 1587–1594. [Google Scholar] [CrossRef]

- Brandt, A.M.; Glinicki, M.A.; Potrzebowski, J. Application of FRC in construction of the underground railway track. Cem. Concr. Compos. 1996, 18, 305–312. [Google Scholar] [CrossRef]

- Sethunarayanan, R.; Chockalingam, S.; Ramanathan, R. Natural fiber reinforced concrete. Transport. Res. Rec. 1989, 1226, 57–60. [Google Scholar] [CrossRef] [Green Version]

- Toutanji, H.A. Properties of polypropylene fiber reinforced silica fume expansive-cement concrete, Construct. Build. Mater. 1999, 13, 171–177. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Impact resistance of fiber-reinforced concrete—A review. Cem. Concr. Compos. 2019, 104, 103389. [Google Scholar] [CrossRef]

- Aliabdo, A.A.E.; Abd-Elmoaty, A.E.M.; Hamdy, M. Effect of internal short fibers, steel reinforcement, and surface layer on impact and penetration resistance of concrete. Alex. Eng. J. 2013, 52, 407–417. [Google Scholar] [CrossRef] [Green Version]

- Chen, B.; Liu, J. Contribution of hybrid fibers on the properties of the high-strength lightweight concrete having good workability. Cem. Concr. Res. 2005, 35, 913–917. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Construct. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Qian, C.X.; Stroeven, P. Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Yao, W.; Li, J.; Wu, K. Mechanical properties of hybrid fiber-reinforced concrete at low fiber volume fraction. Cem. Concr. Res. 2003, 33, 27–30. [Google Scholar] [CrossRef]

- Sivakumar, V.; Karthik, K.; Jachin, S.B.; Xavier, C.A. Experimental investigation on strength properties of hybrid fibre reinforced high strength concrete. Mater. Today Proc. 2020, in press. [Google Scholar] [CrossRef]

- Rajarajeshwari, V.; Radha, K.; Aravind, N. Mechanical properties of hybrid fiber reinforced concrete for pavements. Int. J. Res. Eng. Technol. 2013, 2, 244–247. [Google Scholar] [CrossRef]

- Yusof, M.; Nor, N.; Zain, M.; Peng, N.; Sohaimi, R.; Zaidi, A. Mechanical properties of hybrid steel fibre reinforced concrete with different aspect ratio. Aust. J. Basic Appl. Sci. 2011, 5, 159–166. [Google Scholar]

- Zhang, Y.; Wu, B.; Wang, J.; Liu, M.; Zhang, X. Reactive Powder Concrete Mix Ratio and Steel Fiber Content Optimization under Different Curing Conditions. Materials 2019, 12, 3615. [Google Scholar] [CrossRef] [Green Version]

- Zhong, C.; Liu, M.; Zhang, Y.; Wang, J.; Liang, D.; Chang, L. Study on Mechanical Properties of Hybrid Polypropylene-Steel Fiber RPC and Computational Method of Fiber Content. Materials 2020, 13, 2243. [Google Scholar] [CrossRef]

- Ali, B.; Kurda, R.; Herki, B.; Alyousef, R.; Mustafa, R.; Mohammed, A.; Raza, A.; Ahmed, H.; Fayyaz Ul-Haq, M. Effect of Varying Steel Fiber Content on Strength and Permeability Characteristics of High Strength Concrete with Micro Silica. Materials 2020, 13, 5739. [Google Scholar] [CrossRef]

- Sharma, A.; Reddy, G.R.; Varshney, L.; Kumar, H.B.; Vaze, K.K.; Ghosh, A.K.; Kushwaha, H.S.; Krishnamoorthy, T.S. Experimental investigations on mechanical and radiation shielding properties of hybrid lead-steel fiber reinforced concrete. Nucl. Eng. Des. 2009, 239, 1180–1185. [Google Scholar] [CrossRef]

- Horiguchi, T.; Sugawara, T.; Saeki, N. Fire Resistance of Hybrid Fibre Reinforced High Strength Concrete. RILEM Publ. PRO 2004, 39, 303–310. [Google Scholar]

- Phan, L.T.; Carino, N.J. Effects of Testing Conditions and Mixture Proportions on Behaviour of High-Strength Concrete Exposed to High Temperature. ACI Mater. J. 2002, 99, 54–66. [Google Scholar]

- Suhaendi, S.L.; Horiguchi, T. Explosive Spalling Mitigation Mechanism of Fibre Reinforced High Strength Concrete under High Temperature Condition. In Proceedings of the International FIB Workshop on Fire Design of Concrete Structure from Materials Modelling to Structural Performance, Coimbra, Portugal, 8–9 November 2007; University of Coimbra: Coimbra, Portugal; pp. 189–197. [Google Scholar]

- Heikal, M. Effect of Temperature on The Physico-Mechanical and Mineralogical Properties of HomraPozzolanic Cement Pastes. Cem. Concr. Res. 2000, 30, 1835–1839. [Google Scholar] [CrossRef]

- Xu, Y.; Wong, Y.L.; Poon, C.S.; Anson, M. Impact of High Temperature on PFA Concrete. Cem. Concr. Res. 2001, 31, 1065–1073. [Google Scholar] [CrossRef]

- Nishida, A.; Yamazaki, N. Study on the Properties of High Strength Concrete with Short Polypropylene Fibre for Spalling Resistance. In Proceedings of the International Conference on Concrete under Severe Conditions (CONSEC’95), Sapporo, Japan, 2–4 August 1995; pp. 1141–1150. [Google Scholar]

- Kalifa, P.; Chene, G.; Galle, C. High-Temperature Behaviour of HPC with Polypropylene Fibres from Spalling to Microstructure. Cem. Concr. Res. 2001, 31, 1487–1499. [Google Scholar] [CrossRef]

- Chan, Y.N.; Luo, X.; Sun, W. Compressive Strength and Pore Structure of High-Performance Concrete after Exposure to High Temperature up to 800 C. Cem. Concr. Res. 2000, 30, 247–251. [Google Scholar] [CrossRef]

- Bosnjak, J.; Sharma, A.; Grauf, K. Mechanical Properties of Concrete with Steel and Polypropylene Fibres at Elevated Temperatures. Fibers 2019, 7, 9. [Google Scholar] [CrossRef] [Green Version]

- Bangi, M.R.; Horiguchi, T. Effect of Fibre Type and Geometry on Maximum Pore Pressures in Fibre-Reinforced High Strength Concrete at Elevated Temperatures. Cem. Concr. Res. 2012, 42, 459–466. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Mahmoodi, M.J.; Safi, M. Effect of adding carbon nanotubes on the thermal conductivity of steel fiber-reinforced concrete. Compos. B Eng. 2019, 174, 106972. [Google Scholar] [CrossRef]

- Aydın, S.; Yazıcı, H.; Baradan, B. High-temperature resistance of normal strength and autoclaved high strength mortars incorporated polypropylene and SF. Constr. Build. Mater. 2008, 22, 504–512. [Google Scholar] [CrossRef]

- Hoang, A.L.; Fehling, E. Influence of steel fiber content and aspect ratio on the uniaxial tensile and compressive behavior of ultra-high-performance concrete. Constr. Build. Mater. 2017, 153, 790–806. [Google Scholar] [CrossRef]

- Koniki, S.; Prasad, D.R. Influence of hybrid fibres on strength and stress-strain behaviour of concrete under uni-axial stresses. Constr. Build. Mater. 2019, 207, 238–248. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Saleh, M.H. Thermal performance and fire resistance of nano clay modified cementitious materials. Constr. Build. Mater. 2018, 159, 213–219. [Google Scholar] [CrossRef]

- Zhang, L.W.; Kai, M.F.; Liew, K.M. Evaluation of microstructure and mechanical performance of CNT-reinforced cementitious composites at elevated temperatures. Compos. A Appl. Sci. Manuf. 2017, 95, 286–293. [Google Scholar] [CrossRef]

- Kazemi, S.; Lubell, A.S. Influence of specimen size and fiber content on mechanical properties of ultra-high-performance fiber-reinforced concrete. ACI Mater. J. 2012, 109, 675–684. [Google Scholar]

- Zhang, L.H.; Liu, J.Z.; Liu, J.P.; Zhang, Q.Q.; Han, F.Y. Effect of steel fiber on flexural toughness and fracture mechanics behavior of ultra-high-performance concrete with coarse aggregate. J. Mater. Civ. Eng. 2018, 30, 4018323. [Google Scholar] [CrossRef]

- Deifalla, A.; Zapris, A.; Chalioris, C. Multivariable Regression Strength Model for Steel Fiber-Reinforced Concrete Beams under Torsion. Materials 2021, 14, 3889. [Google Scholar] [CrossRef] [PubMed]

- Ashraf, M.; Akmal, U.; Khurram, N.; Aslam, F.; Deifalla, A. Impact Resistance of Rubber (SBR) Latex-Modified Fiber-Reinforced Concrete: The Role of Aggregate Size. Materials 2022, 15, 1283. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, H.; Ahmed, H.; Kurda, R.; Alyousef, R.; Deifalla, A. Heat-Induced Spalling of Concrete: A Review of the Influencing Factors and Their Importance to the Phenomenon. Materials 2022, 15, 1693. [Google Scholar] [CrossRef]

- Ali, B.; Fahad, M.; Ullah, S.; Ahmed, H.; Alyousef, R.; Deifalla, A. Development of Ductile and Durable High Strength Concrete (HSC) through Interactive Incorporation of Coir Waste and Silica Fume. Materials 2022, 15, 2616. [Google Scholar] [CrossRef]

- Ebid, A.; Deifalla, A. Using Artificial Intelligence Techniques to Predict Punching Shear Capacity of Lightweight Concrete Slabs. Materials 2022, 15, 2732. [Google Scholar] [CrossRef]

- Salem, N.; Deifalla, A. Evaluation of the Strength of Slab-Column Connections with FRPs Using Machine Learning Algorithms. Polymers 2022, 14, 1517. [Google Scholar] [CrossRef]

- Huang, S.; Wang, H.; Ahmad, W.; Ahmad, A.; Ivanovich Vatin, N.; Mohamed, A.; Deifalla, A.; Mehmood, I. Plastic Waste Management Strategies and Their Environmental Aspects: A Scientometric Analysis and Comprehensive Review. Int. J. Environ. Res. Public Health 2022, 19, 4556. [Google Scholar] [CrossRef]

- Alkhatib, S.; Deifalla, A. Punching Shear Strength of FRP-Reinforced Concrete Slabs without Shear Reinforcements: A Reliability Assessment. Polymers 2022, 14, 1743. [Google Scholar] [CrossRef] [PubMed]

- Deifalla, A.; Salem, N. A Machine Learning Model for Torsion Strength of Externally Bonded FRP-Reinforced Concrete Beams. Polymers 2022, 14, 1824. [Google Scholar] [CrossRef] [PubMed]

- Azam, R.; Riaz, M.; Farooq, M.; Ali, F.; Mohsan, M.; Deifalla, A.; Mohamed, A. Optimization-Based Economical Flexural Design of Singly Reinforced Concrete Beams: A Parametric Study. Materials 2022, 15, 3223. [Google Scholar] [CrossRef] [PubMed]

- Eurocode 2, Design of Concrete Structures; Part 1.2: Structural Fire Design; European Prestandard: Brussels, Belgium, 1995.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).