Influence of Different Surfactants on Carbon Fiber Dispersion and the Mechanical Performance of Smart Piezoresistive Cementitious Composites

Abstract

:1. Introduction

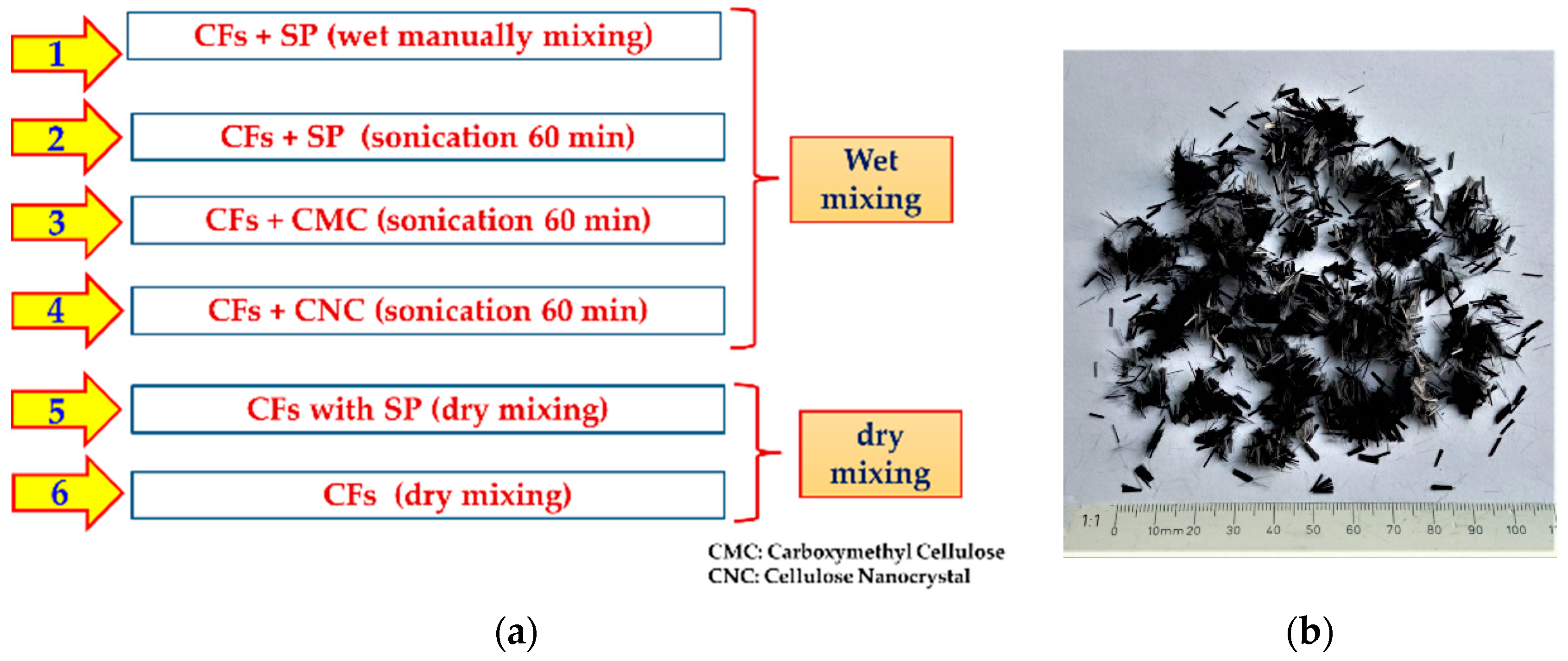

2. Materials and Methods

3. Experimental Section

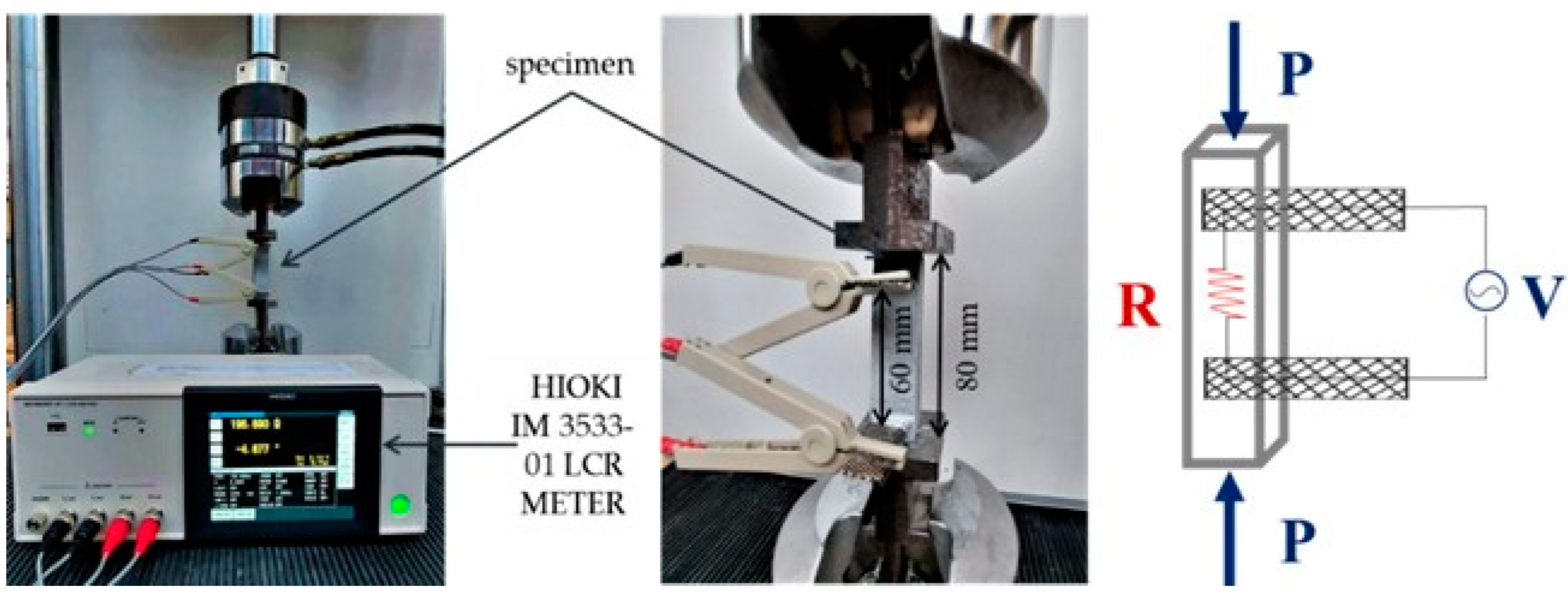

3.1. Mechanical Testing Procedure

3.2. Self-Sensing Experimental Procedure

4. Results

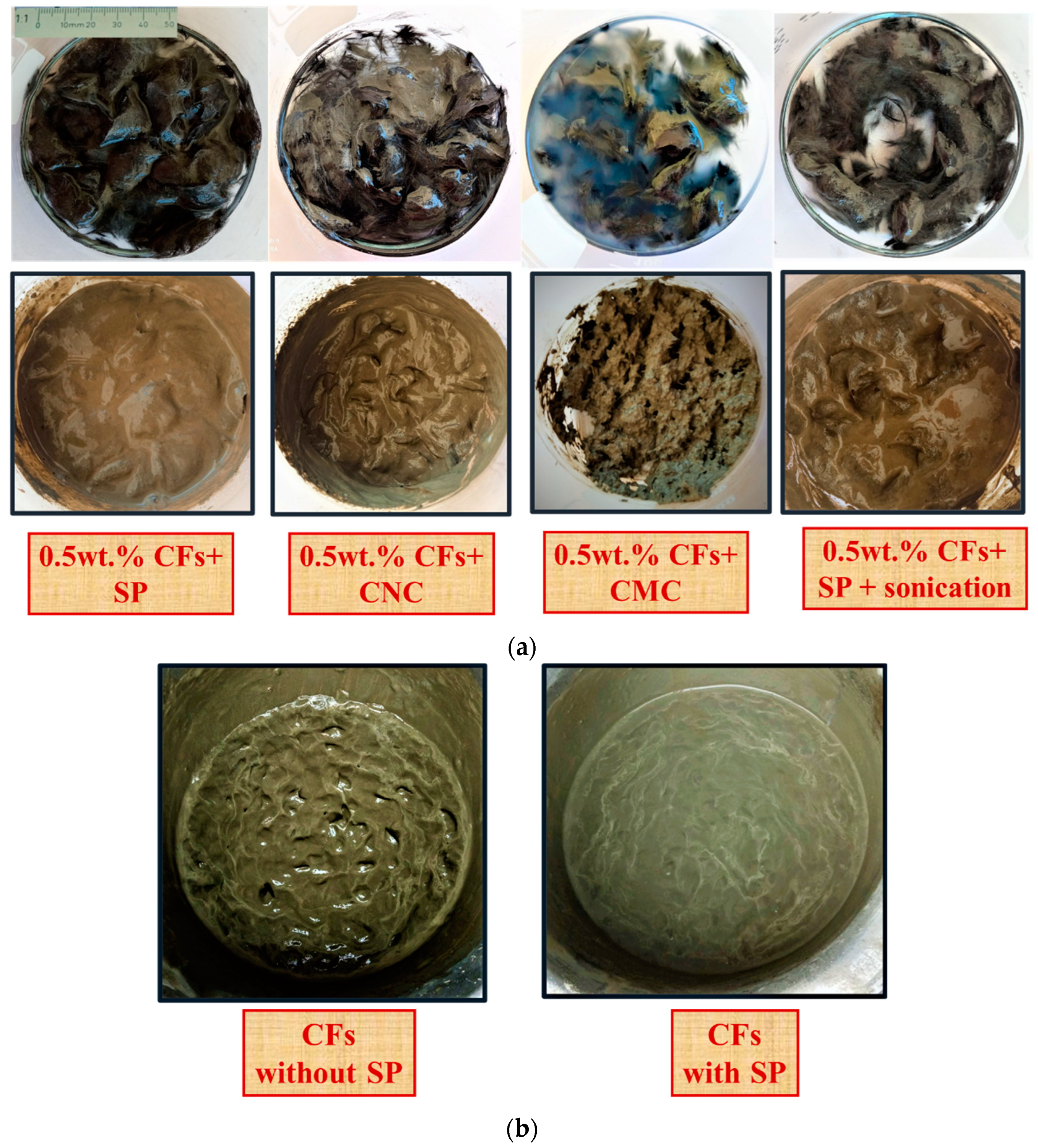

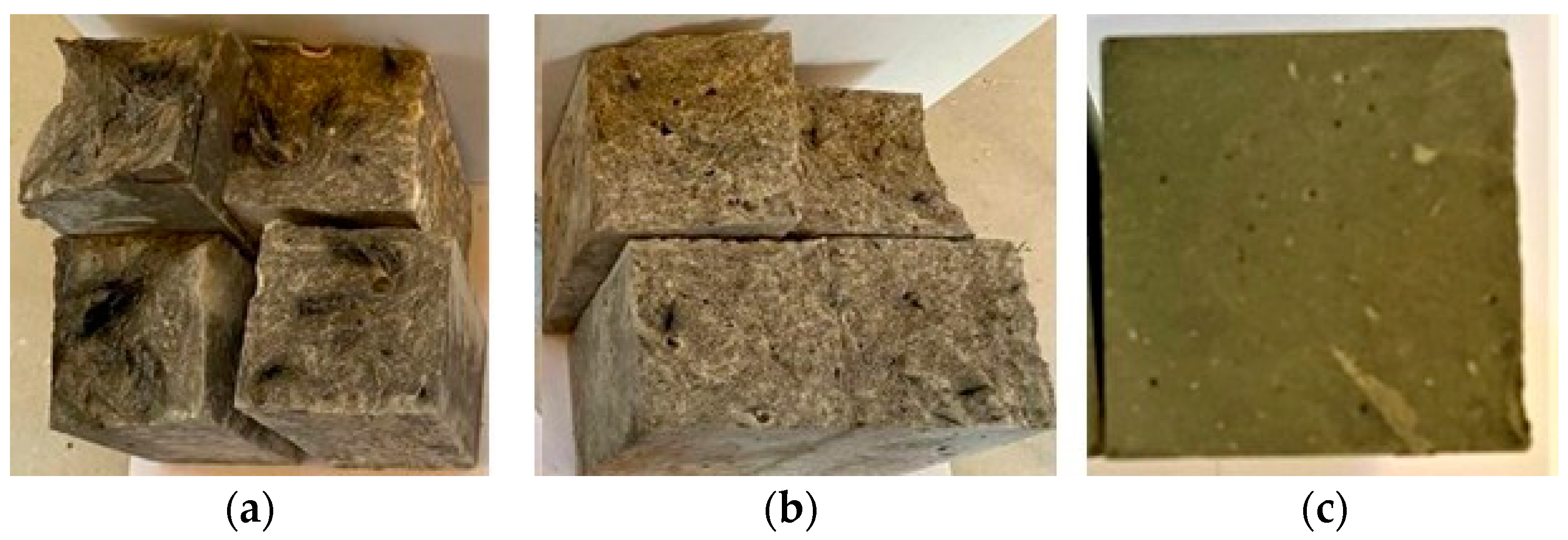

4.1. Dispersion of Microscale CFs

4.2. Self-Sensing Response of Micro Modified Cement Pastes

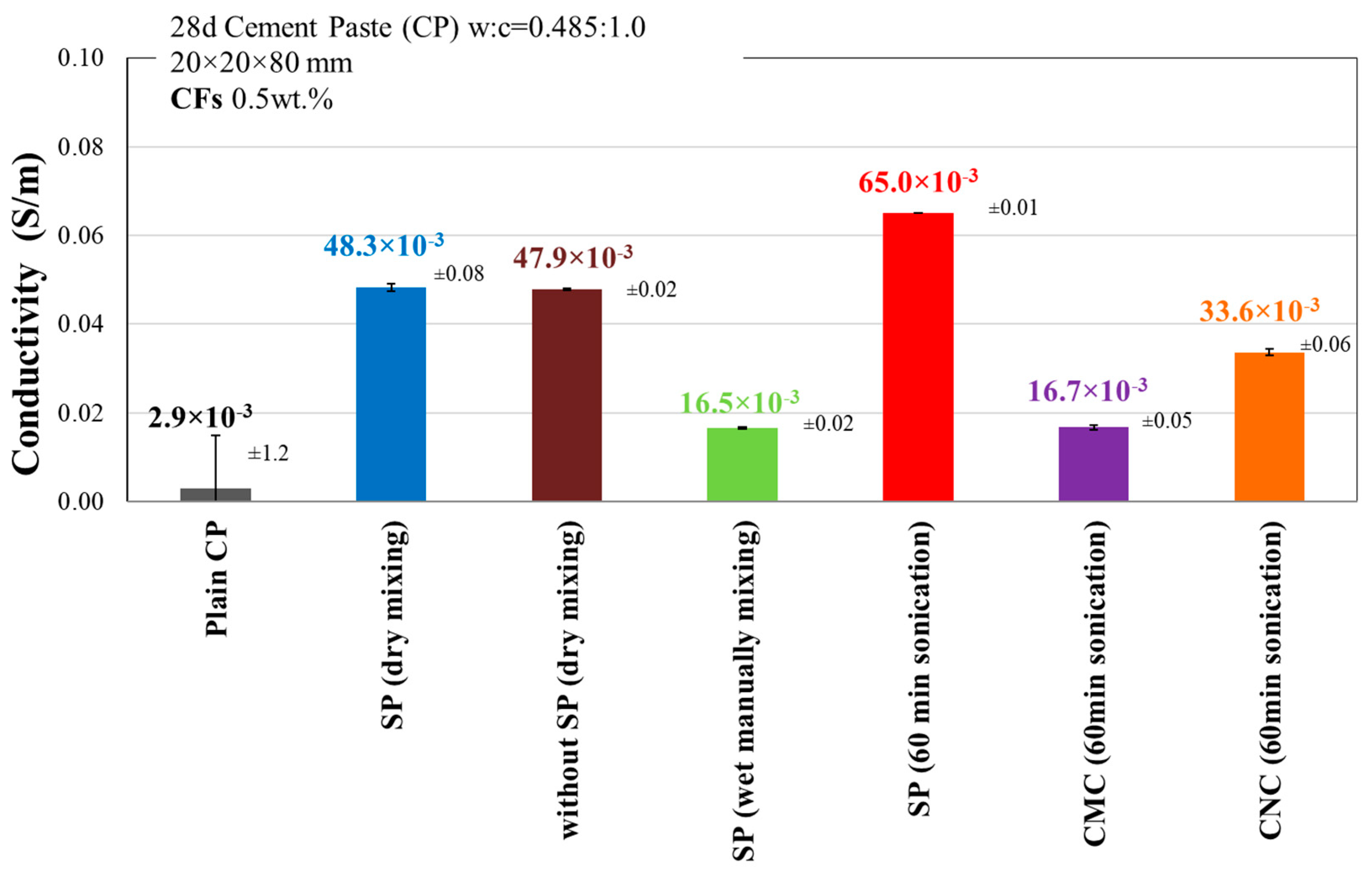

4.2.1. Electrical Conductivity Properties

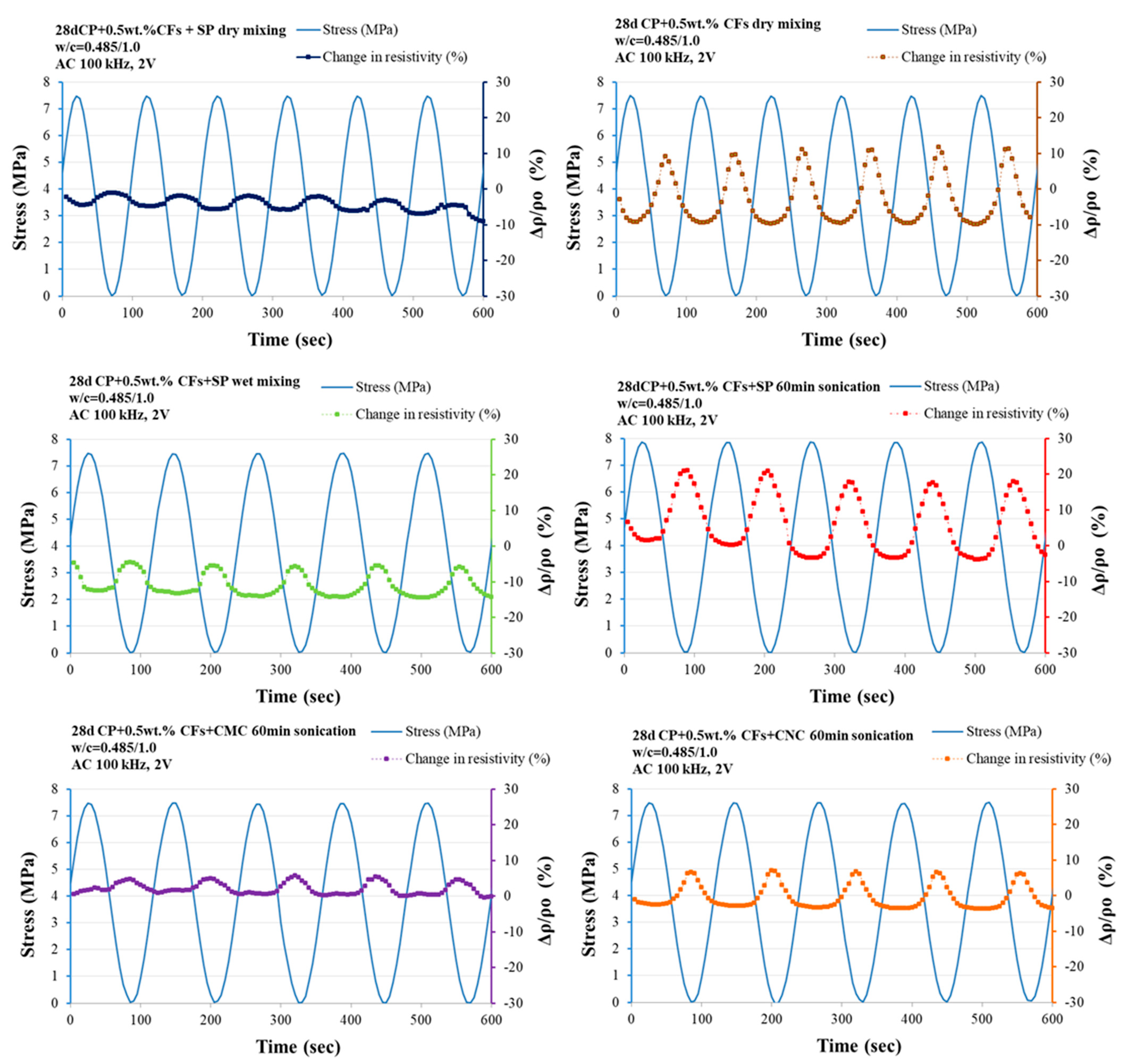

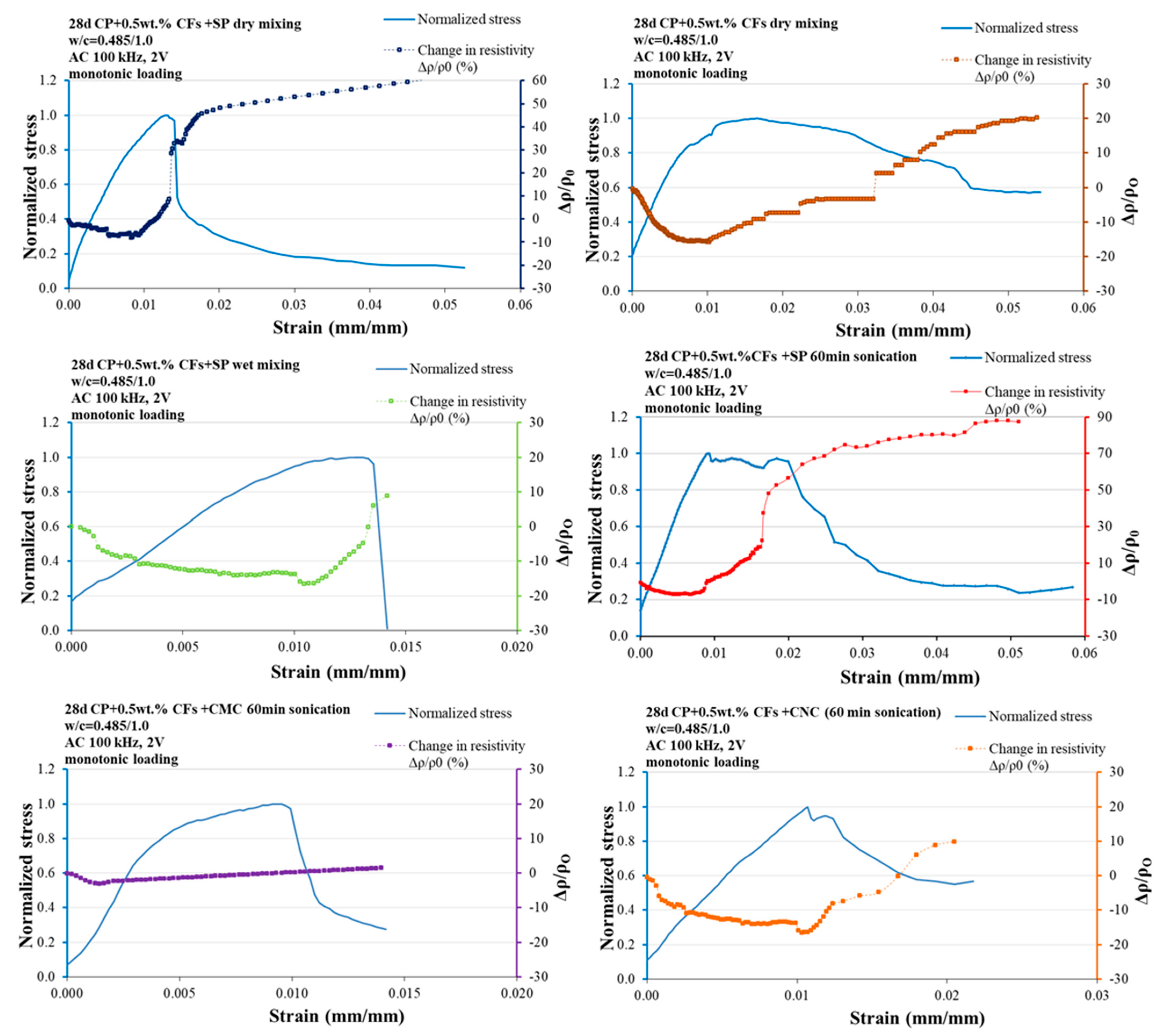

4.2.2. Self-Sensing Ability of CF Modified Cement Pastes

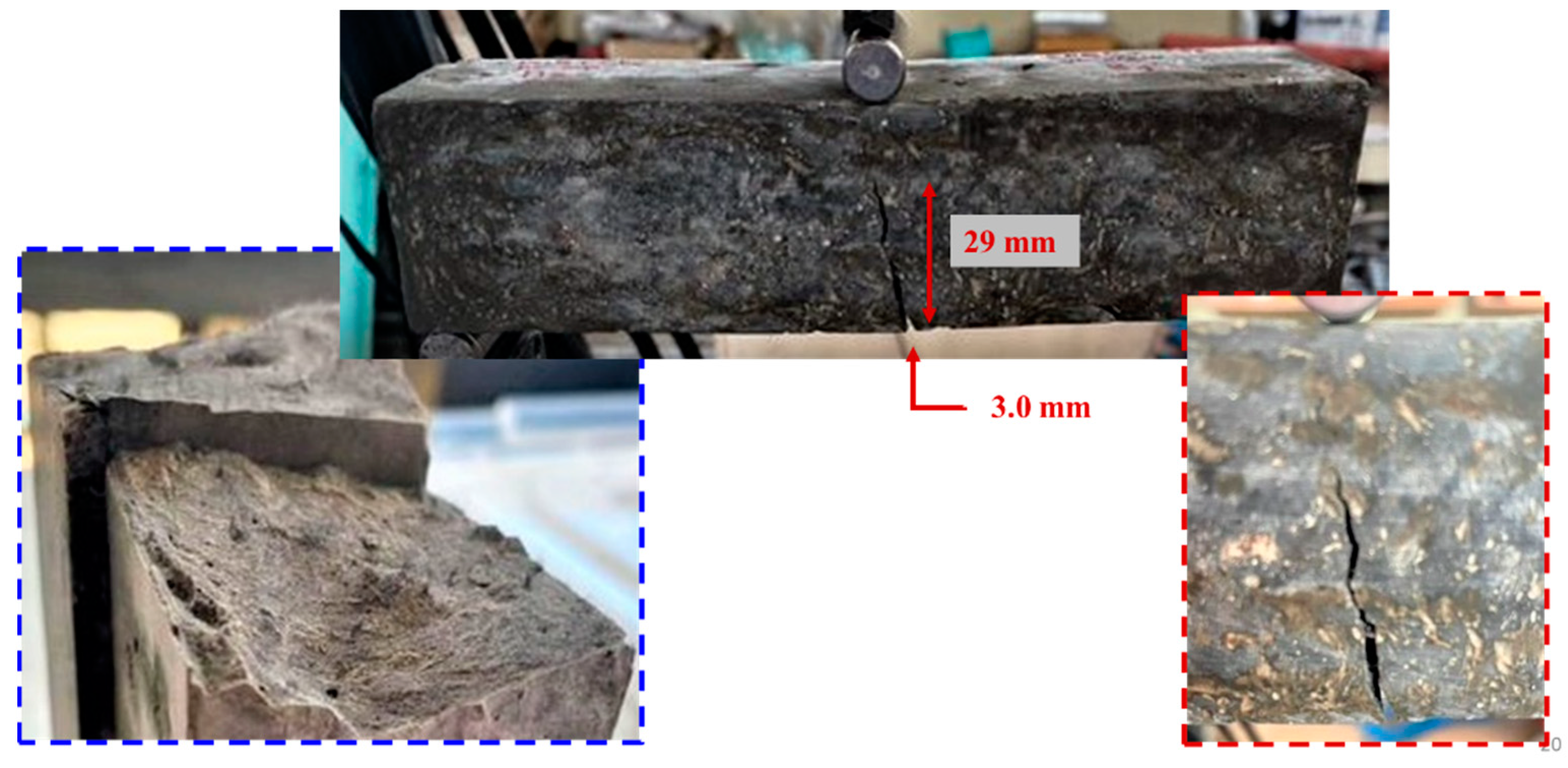

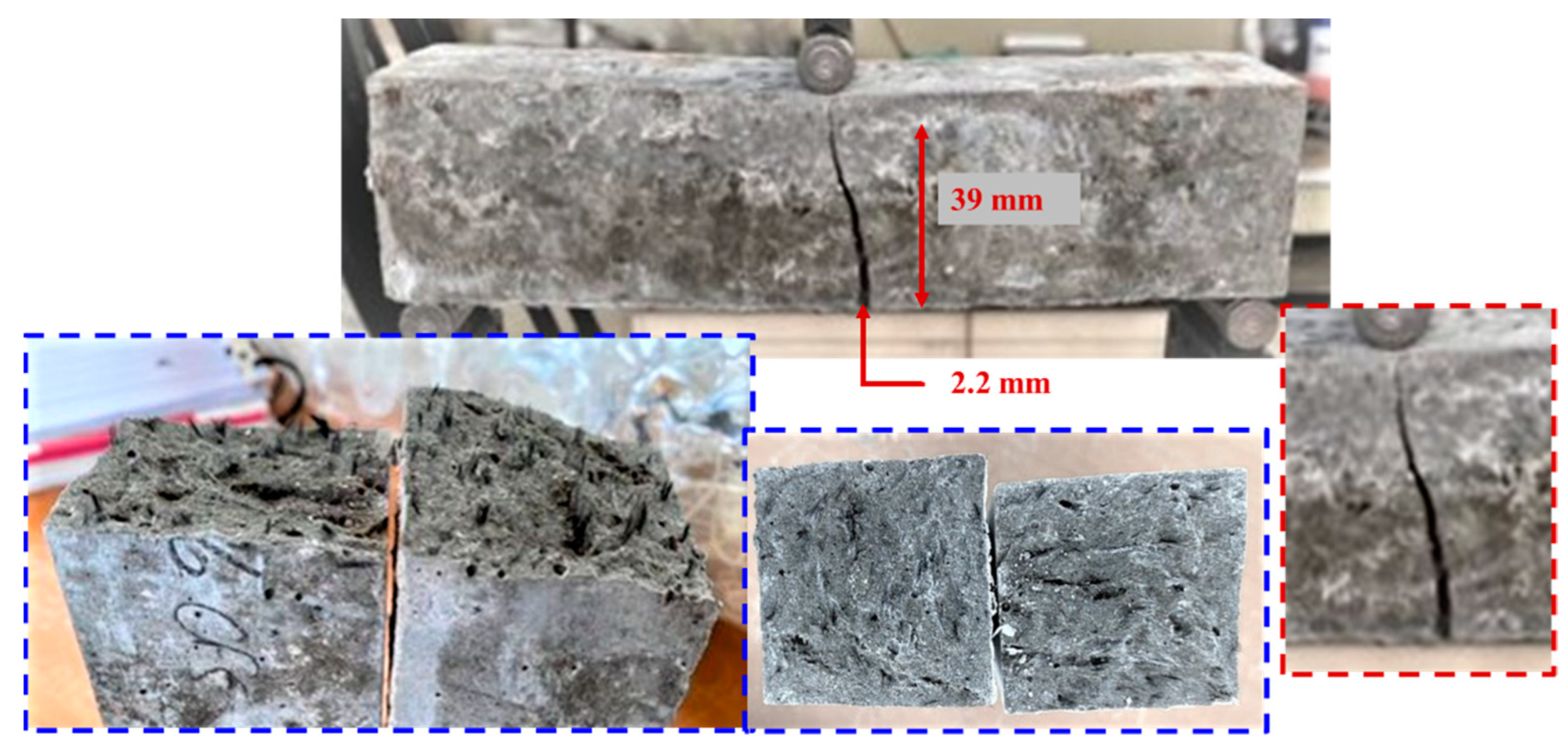

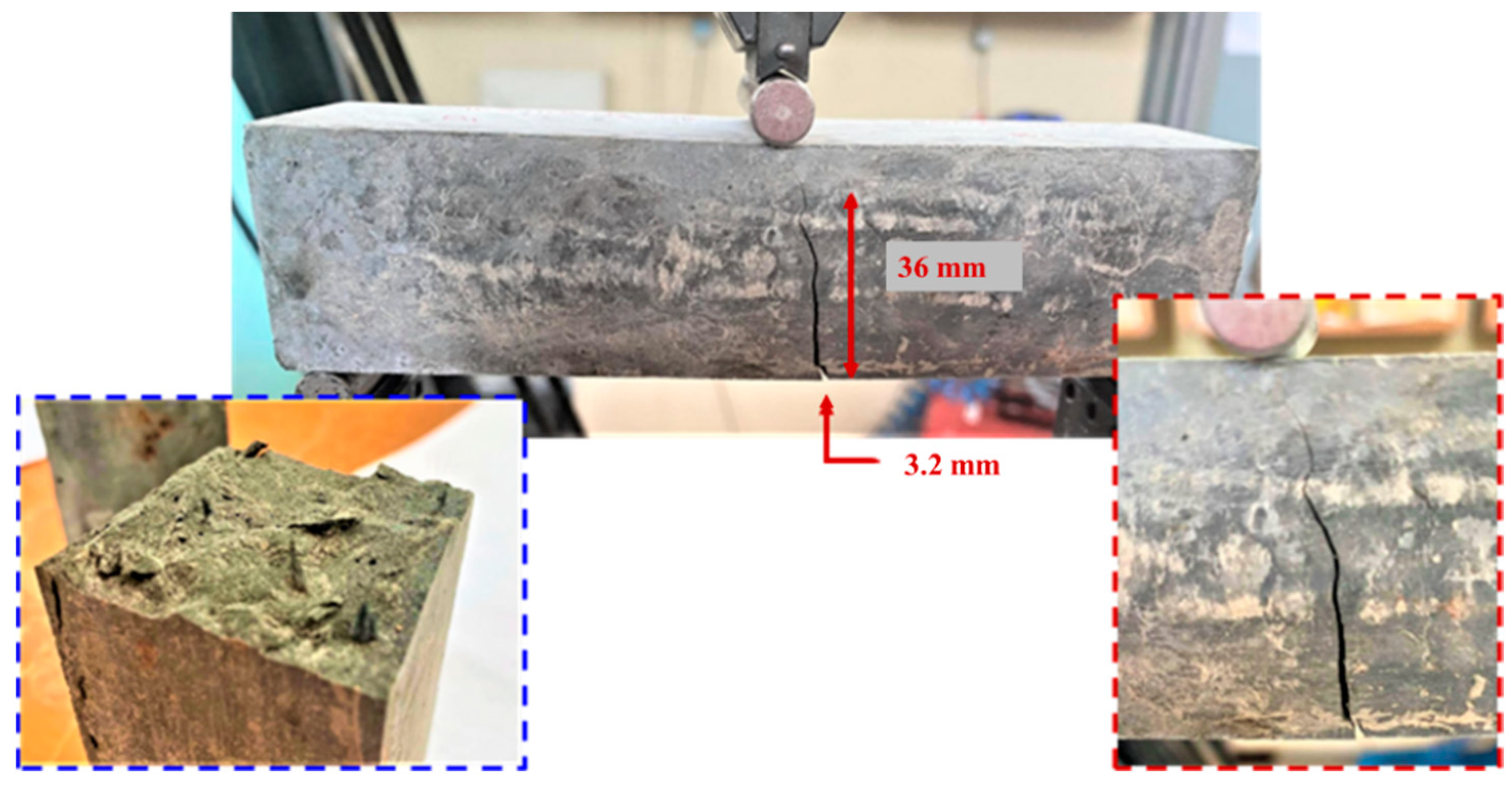

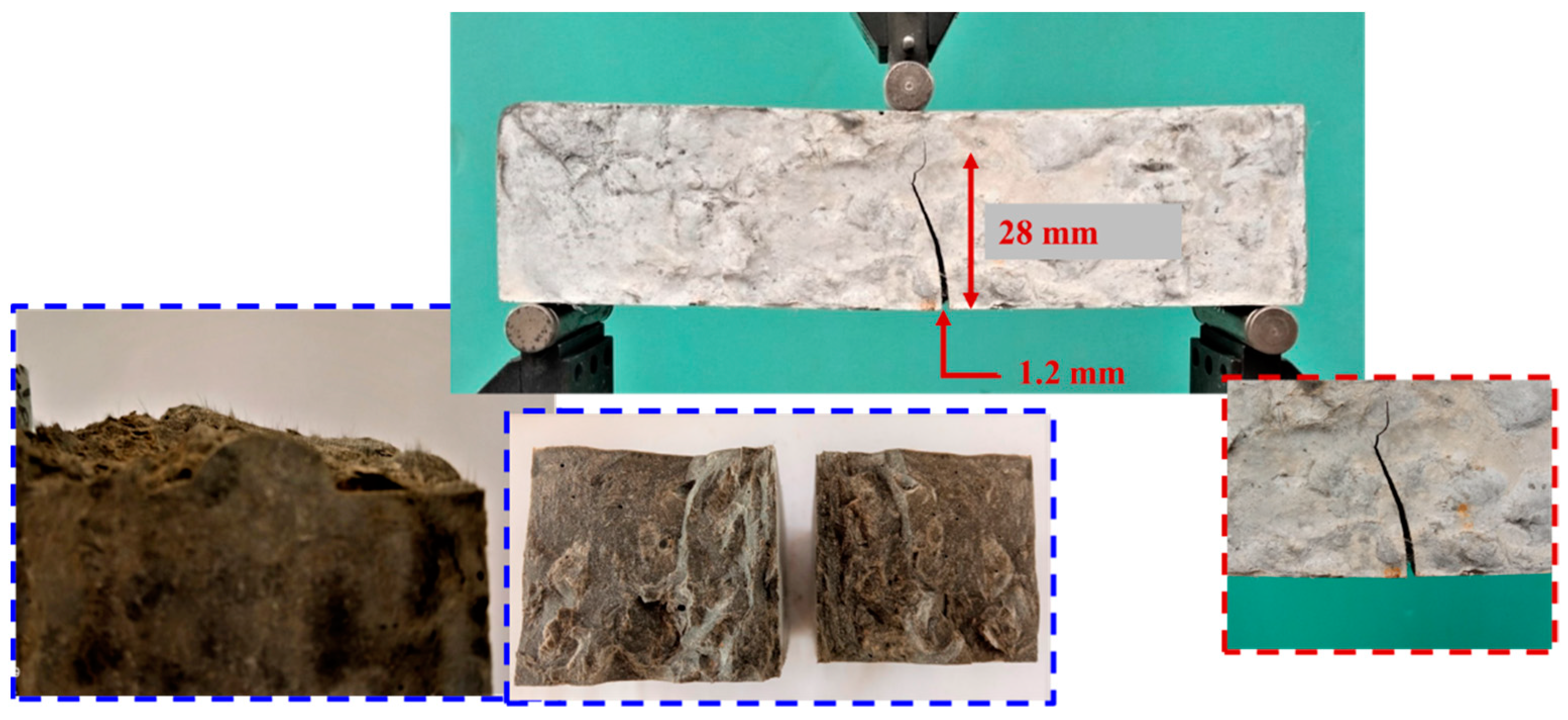

4.3. Failure Mode of Cracking Propagation after the Three-Point Bending Test

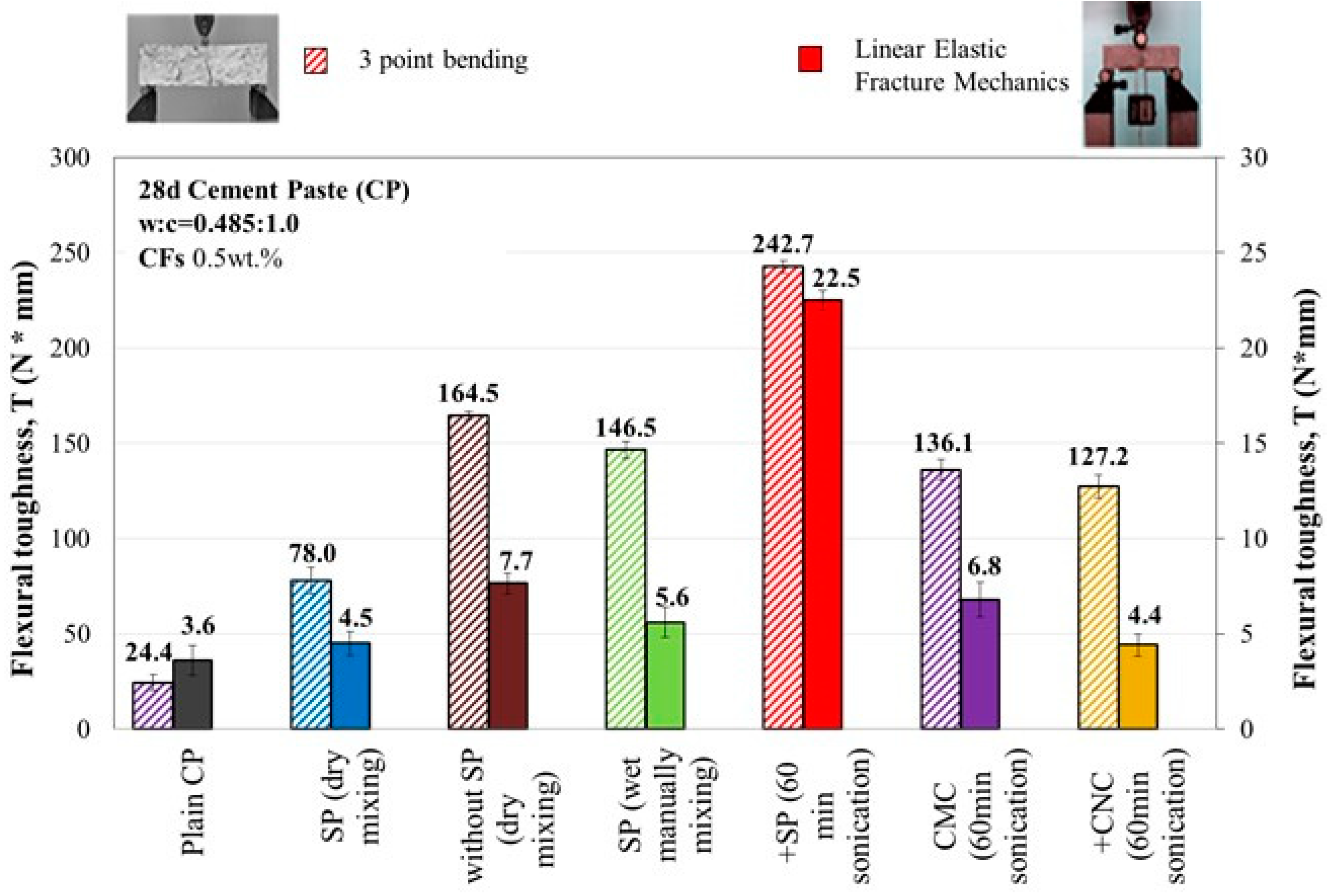

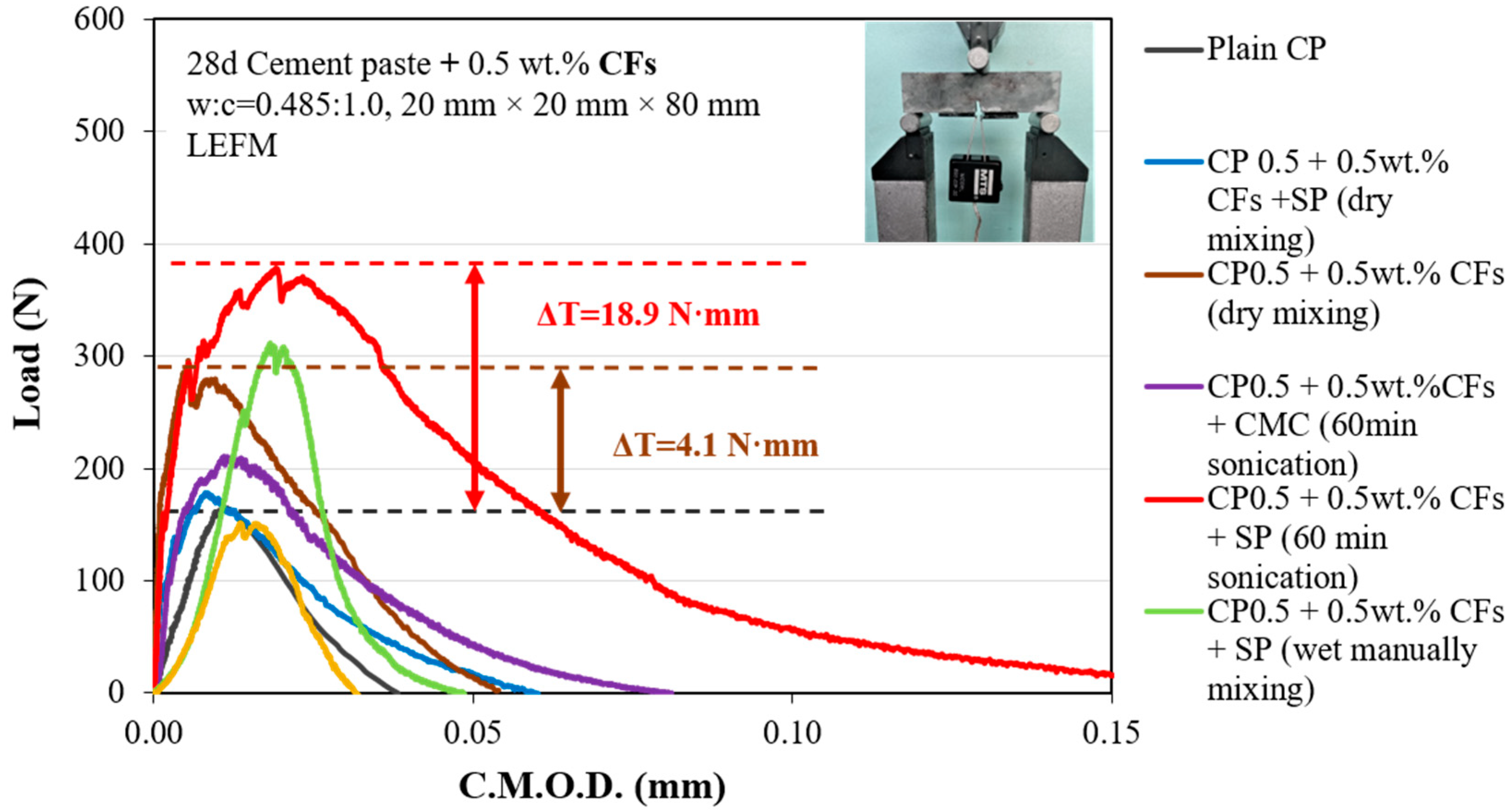

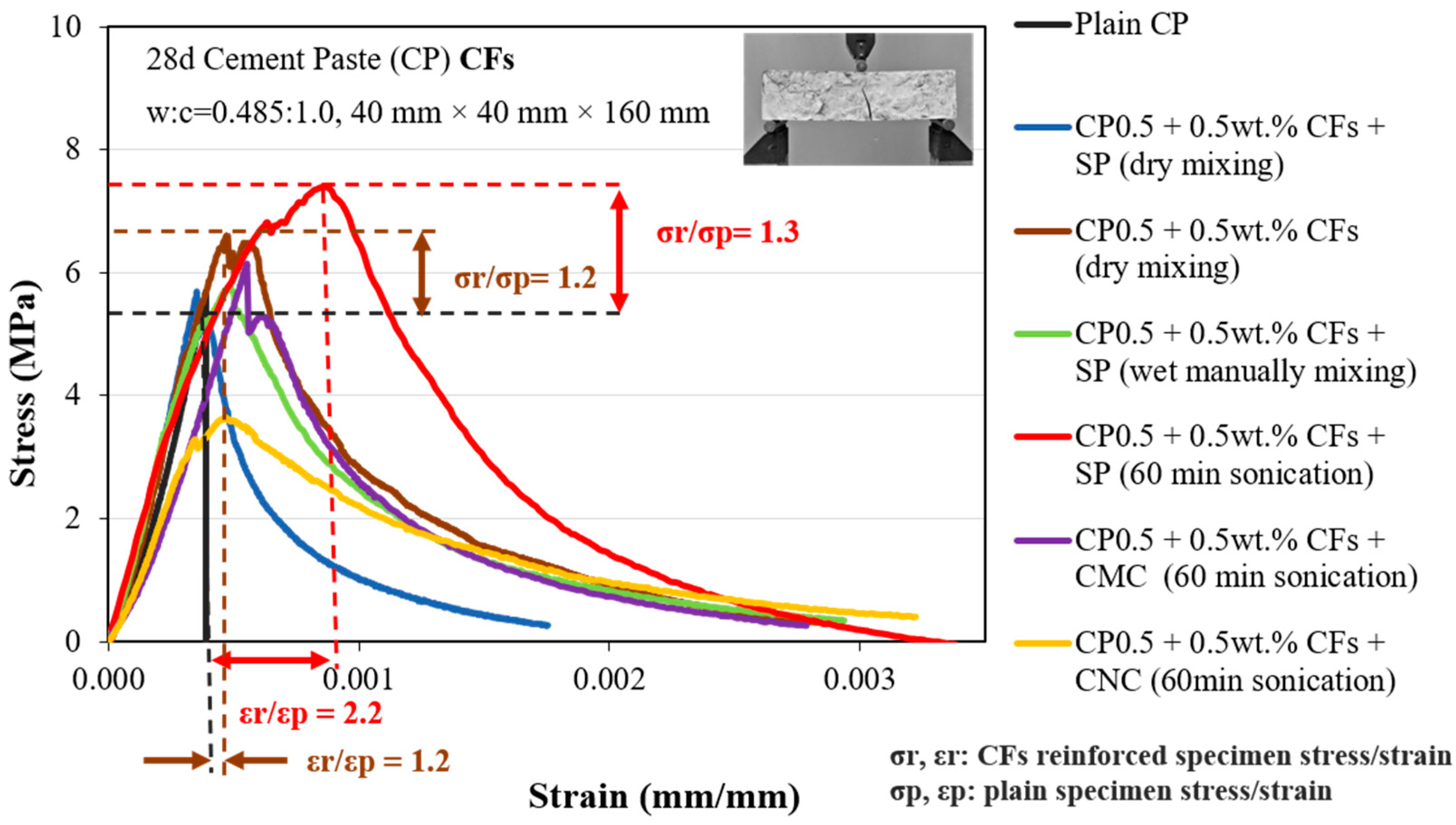

4.4. Effect of Micro-Scale Fiber Incorporation on the Energy Absorption Capability

5. Conclusions

- (1)

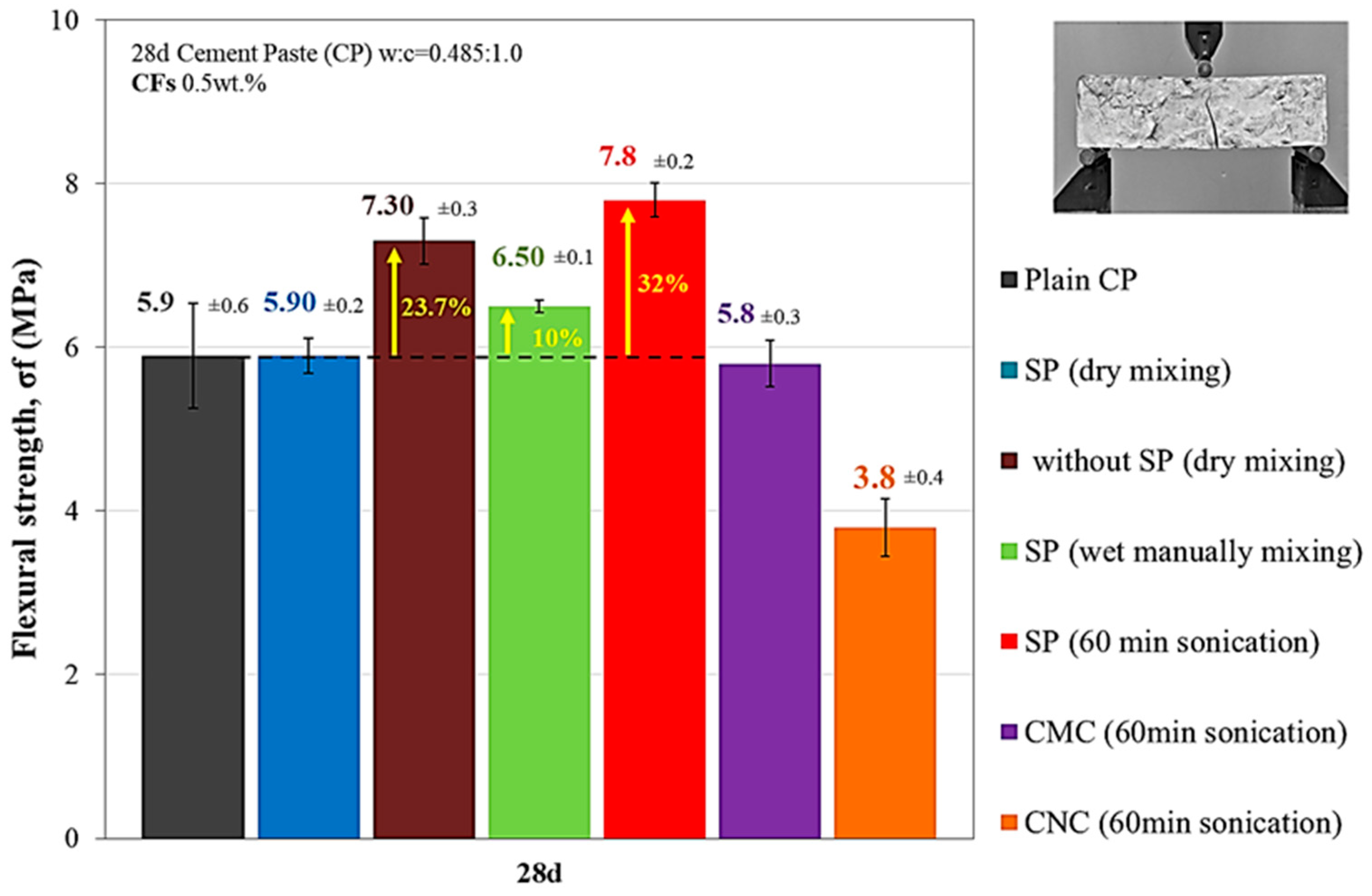

- Among the three kinds of dispersants, SP is superior for improving the fiber dispersion, so its effect is also addressed. Therefore, it was demonstrated that SP could be characterized as the most efficient admixture for giving high tensile and compressive strength.

- (2)

- The 60 min ultrasonic vibration of SP dispersant treatment can significantly improve the fiber dispersion in the solution and can be further upgrade the mechanical performance. The compressive and flexural strength of CFRC increases due to the carbon micro-fiber dispersion, presenting a strengthening effect on CFRC. As the strength is significantly affected by the matrix defects, it is not valid for the evaluation of the fiber dispersion.

- (3)

- The compressive strength increased by 10.4% with the method of dry mixing without SP, while with the wet method of SP addition and simple agitation with a manual stirrer by 8.6%. The flexural strength increased by 32% with the wet method of adding SP using 60 min sonication and by 24% with the method of dry mixing of CFs without SP.

- (4)

- The modulus of elasticity of CFRC is improved significantly by almost 6% by the addition of CFs adding SP and using 60 min sonication compared to the plain specimen and all other methods.

- (5)

- The addition of CMC and CNC with fiber is the least advantageous, leading to a deterioration of the compressive strength; also, the reduction in flexural strength and the modulus of elasticity is significant.

- (6)

- The dry-mixed specimen exhibits an improved piezoresistive performance and better linear variation of sensitivity. It constitutes an adequate strain and crack sensor and is also the most economical method compared to the rest mixing methods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reza, F.; Batson, G.B.; Yamamuro, J.A.; Lee, J.S. Resistance changes during compression of carbon fiber cement compo-sites. J. Mater. Civ. Eng. 2003, 15, 476–483. [Google Scholar] [CrossRef] [Green Version]

- Cao, J.; Chung, D.D.L. Carbon fiber reinforced cement mortar improved by using acrylic dispersion as an admixture. Cem. Concr. Res. 2001, 31, 1633–1637. [Google Scholar] [CrossRef]

- Chen, P.W.; Fu, X.; Chung, D.D.L. Microstructural and mechanical effects of latex, methylcellulose, and silica fume on carbon fiber reinforced cement. Mater. J. 1997, 94, 147–155. [Google Scholar]

- Wang, H.; Gao, X.; Wang, R. The influence of rheological parameters of cement paste on the dispersion of carbon nanofibers and self-sensing performance. Constr. Build. Mater. 2017, 134, 673–683. [Google Scholar] [CrossRef]

- Alanazi, H.; Alharbi, Y.R.; Abadel, A.A.; Elalaoui, O. Effect of edge oxidized graphene oxide on micro and macro mechanical properties and microstructure of cement paste. Int. J. Mater. Res. 2022, 113, 271–277. [Google Scholar] [CrossRef]

- Al Qader, H.; Jasim, A.M.; Salim, H.; Xing, Y.; Stalla, D. Enhanced Mechanical and Durability Properties of Cement Mortar by Using Alumina Nanocoating on Carbon Nanofibers. Materials 2022, 15, 2768. [Google Scholar] [CrossRef]

- Brown, L.; Stephens, C.S.; Allison, P.G.; Sanchez, F. Effect of Carbon Nanofiber Clustering on the Micromechanical Properties of a Cement Paste. Nanomaterials 2022, 12, 223. [Google Scholar] [CrossRef]

- Wang, C.; Li, K.Z.; Li, H.J.; Jiao, G.S.; Lu, J.; Hou, D.S. Effect of carbon fiber dispersion on the mechanical properties of carbon fiber-reinforced cement-based composites. Mater. Sci. Eng. A 2008, 487, 52–57. [Google Scholar] [CrossRef]

- Sanchez, F.; Ince, C. Microstructure and macroscopic properties of hybrid carbon nanofiber/silica fume cement composites. Compos. Sci. Technol. 2009, 69, 1310–1318. [Google Scholar] [CrossRef]

- Chung, D.D. Dispersion of short fibers in cement. J. Mater. Civ. Eng. 2005, 17, 379–383. [Google Scholar] [CrossRef]

- Chuang, W.; Geng-sheng, J.; Bing-liang, L.; Lei, P.; Ying, F.; Ni, G.; Ke-zhi, L. Dispersion of carbon fibers and conductivity of carbon fiber-reinforced cement-based composites. Ceram. Int. 2017, 43, 15122–15132. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Batis, G.; Danoglidis, P.; Zacharopoulou, A.K.; Zacharopoulou, E.K.; Falara, M.G.; Shah, S.P. Effect of CNT and CNF loading and count on the corrosion resistance, conductivity and mechanical properties of nanomodified OPC mortars. Constr. Build. Mater. 2017, 147, 48–57. [Google Scholar] [CrossRef]

- Toutanji, H.; McNeil, S.; Bayasi, Z. Chloride permeability and impact resistance of polypropylene-fiber-reinforced silica fume concrete. Cem. Concr. Res. 1998, 28, 961–968. [Google Scholar] [CrossRef]

- EFNARC (European Federation of National Associations Representing for Concrete). Specification and Guidelines for Self-Compacting Concrete. European 29 Federation of National Associations Representing Producers and Applicators of Specialist 30 Building Products for Concrete (EFNARC), 32:31. 2005. Available online: http://www.efnarc.org/pdf/SCCGuidelinesMay2005.pdf (accessed on 1 May 2005).

- Gull, I.; Tantray, M. Effect of Super Plasticizers on Fresh and Hardened State Properties of Short Carbon Fiber Reinforced Electrically Conductive Concrete. Int. J. Recent Technol. Eng. 2020, 8. [Google Scholar] [CrossRef]

- Ivorra, S.; Garcés, P.; Catalá, G.; Andión, L.G.; Zornoza, E. Effect of silica fume particle size on mechanical proper-ties of short carbon fiber reinforced concrete. Mater. Des. 2010, 31, 1553–1558. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D. Seebeck effect in carbon fiber-reinforced cement. Cem. Concr. Res. 1999, 29, 1989–1993. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D. Carbon fiber-reinforced cement as a thermistor. Cem. Concr. Res. 1999, 29, 961–965. [Google Scholar] [CrossRef]

- Endo, M.; Kim, Y.A.; Ezaka, M.; Osada, K.; Yanagisawa, T.; Hayashi, T.; Terrones, M.; Dresselhaus, M.S. Selective and efficient impregnation of metal nanoparticles on cup-stacked-type carbon nanofibers. Nano Lett. 2003, 3, 723–726. [Google Scholar] [CrossRef]

- Ismagilov, Z.R.; Shalagina, A.E.; Podyacheva, O.Y.; Ischenko, A.V.; Kibis, L.S.; Boronin, A.I.; Chesalov, Y.A.; Kochubey, D.I.; Romanenko, A.I.; Anikeeva, O.B.; et al. Structure and electrical conductivity of nitrogen-doped carbon nanofibers. Carbon 2009, 47, 1922–1929. [Google Scholar] [CrossRef]

- Safiuddin; Yakhlaf, M.; Soudki, K. Key mechanical properties and microstructure of carbon fibre reinforced self-consolidating concrete. Constr. Build. Mater. 2018, 164, 477–488. [Google Scholar] [CrossRef]

- Voutetaki, M.E.; Papadopoulos, N.A.; Angeli, G.M.; Providakis, C.P. Investigation of a new experimental method for damage assessment of RC beams failing in shear using piezoelectric transducers. Eng. Struct. 2016, 114, 226–240. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Kytinou, V.K.; Voutetaki, M.E.; Karayannis, C.G. Flexural Damage Diagnosis in Reinforced Concrete Beams Using a Wireless Admittance Monitoring System—Tests and Finite Element Analysis. Sensors 2021, 21, 679. [Google Scholar] [CrossRef] [PubMed]

- Voutetaki, M.E.; Providakis, C.P.; Chalioris, C.E. FRP debonding prevention of strengthened concrete members un-der dynamic load using smart piezoelectric materials (PZT). In Proceedings of the 15th European Conference on Composite Materials: Composites at Venice, ECCM 2012, Venice, Italy, 24–28 June 2012; p. 106145. [Google Scholar]

- Chen, P.W.; Chung, D.D.L. Concrete reinforced with up to 0.2 vol% of short carbon fibres. Composites 1993, 24, 33–52. [Google Scholar] [CrossRef]

- Cholker, A.K.; Tantray, M.A. Micro carbon fiber based concrete as a strain-damage sensing material. Mater. Today Proc. 2019, 19, 152–157. [Google Scholar] [CrossRef]

- Giraud, I.; Franceschi-Messant, S.; Perez, E.; Lacabanne, C.; Dantras, E. Preparation of aqueous dispersion of thermoplastic sizing agent for carbon fiber by emulsion/solvent evaporation. Appl. Surf. Sci. 2013, 266, 94–99. [Google Scholar] [CrossRef] [Green Version]

- Cholker, A.K.; Kavyateja, B.V.; Reddy, P.N. Influence of Carbon Fibers on Strain and Damage Sensing of Self Compacting Concrete under External Applied Forces. Instrum. Mes. Métrologie 2019, 18, 559–565. [Google Scholar] [CrossRef]

- Pozegic, T.R.; Huntley, S.; Longana, M.L.; He, S.; Bandara, R.M.I.; King, S.G.; Hamerton, I. Improving Dispersion of Recycled Discontinuous Carbon Fibres to Increase Fibre Throughput in the HiPerDiF Process. Materials 2020, 13, 1544. [Google Scholar] [CrossRef] [Green Version]

- Han, B.; Zhang, K.; Yu, X.; Kwon, E.; Ou, J. Fabrication of Piezoresistive CNT/CNF Cementitious Composites with Superplasticizer as Dispersant. J. Mater. Civ. Eng. 2012, 24, 658–665. [Google Scholar] [CrossRef]

- Bentz, D.; Jensen, O.; Coats, A.; Glasser, F. Influence of silica fume on diffusivity in cement-based materials: I. Experimental and computer modeling studies on cement pastes. Cem. Concr. Res. 2000, 30, 953–962. [Google Scholar] [CrossRef]

- Chung, D.D.L. Review: Improving cement-based materials by using silica fume. J. Mater. Sci. 2002, 37, 673–682. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Konsta-Gdoutos, M.S.; Shah, S.P. Relationship between the carbon nanotube dispersion state, electrochemical impedance and capacitance and mechanical properties of percolative nanoreinforced OPC mortars. Carbon 2018, 145, 218–228. [Google Scholar] [CrossRef]

- Fu, X.; Chung DD, L. Effects of silica fume, latex, methylcellulose, and carbon fibers on the thermal conductivity and specific heat of cement paste. Cem. Concr. Res. 1997, 27, 1799–1804. [Google Scholar] [CrossRef]

- Fu, X.; Lu, W.; Chung, D. Improving the bond strength between carbon fiber and cement by fiber surface treatment and polymer addition to cement mix. Cem. Concr. Res. 1996, 26, 1007–1012. [Google Scholar] [CrossRef]

- Chen, P.W.; Chung, D.D.L. Comparative study of concretes reinforced with carbon, polyethylene, and steel fibers and their improvement by latex addition. ACI Mater. J. 1996, 93, 129–133. [Google Scholar]

- Hou, J.; Chung, D. Effect of admixtures in concrete on the corrosion resistance of steel reinforced concrete. Corros. Sci. 2000, 42, 1489–1507. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D.D.L. Improving the bond strength of concrete to reinforcement by adding methylcellulose to concrete. ACI Mater. J. 1998, 95, 601–608. [Google Scholar]

- Xu, Y.; Chung, D. Effect of carbon fibers on the vibration-reduction ability of cement. Cem. Concr. Res. 1999, 29, 1107–1109. [Google Scholar] [CrossRef]

- Chen, P.-W.; Chung, D.D.L. Carbon Fiber Reinforced Concrete as an Electrical Contact Material for Smart Structures; SAMPE: Covina, CA, USA; Anaheim, CA, USA, 1993; pp. 2067–2076. [Google Scholar]

- Maria, F.; Athanasia, T.; Fani, G.; Anaxagoras, E. CNT amount and type: Crucial parameters in mechanical performance enhancement on cement paste nanocomposites. In Proceedings of the 2021 International Conference on Frontiers of Nanomaterials and Nanotechnology (NanoMT 2021), Singapore, 15–17 October 2021. [Google Scholar]

- Kim, Y.; McCoy, L.T.; Feit, C.; Mubarak, S.A.; Sharma, S.; Minko, S. Carboxymethyl Cellulose Enhanced Production of Cellulose Nanofibrils. Fibers 2021, 9, 57. [Google Scholar] [CrossRef]

- Trache, D.; Thakur, V.; Boukherroub, R. Cellulose Nanocrystals/Graphene Hybrids—A Promising New Class of Materials for Advanced Applications. Nanomaterials 2020, 10, 1523. [Google Scholar] [CrossRef]

- Antosik, A.K.; Wilpiszewska, K. Influence of cellulose fibers on physicochemical properties of biodegradable films based on polysaccharide derivatives. Open Agric. 2020, 5, 462–465. [Google Scholar] [CrossRef]

- Metaxa, Z.; Tolkou, A.; Efstathiou, S.; Rahdar, A.; Favvas, E.; Mitropoulos, A.; Kyzas, G. Nanomaterials in Cementitious Composites: An Update. Molecules 2021, 26, 1430. [Google Scholar] [CrossRef] [PubMed]

- Danoglidis, P.A.; Gdoutos, E.E.; Konsta-Gdoutos, M.S. Designing Carbon Nanotube and Nano-fiber-Polypropylene Hybrid Cementitious Composites with Improved Pre-and Post-Crack Load Carrying and Energy Absorption Capacity. Eng. Fract. Mech. 2022, 262, 108253. [Google Scholar] [CrossRef]

- Falara, M.G.; Konsta-Gdoutos, M.S.; Gdoutos, E.E. Enhanced Post-crack Load Carrying Capacity of Nano and Micro Scale Carbon Fiber Reinforced Mortars. In Proceedings of the International Conference on Theoretical, Applied and Experimental Mechanics, Corfu, Greece, 23–26 June 2019. [Google Scholar]

- Safiuddin; Abdel-Sayed, G.; Hearn, N. Flexural and Impact Behaviors of Mortar Composite Including Carbon Fibers. Materials 2022, 15, 1657. [Google Scholar] [CrossRef] [PubMed]

- Hunashyal, A.M.; Lohitha, S.J.; Quadri, S.S.; Banapurmath, N.R. Experimental investigation of the effect of car-bon nanotubes and carbon fibres on the behaviour of plain cement composite beams. IES J. Part A Civ. Struct. Eng. 2011, 4, 29–36. [Google Scholar] [CrossRef]

- Jamet, D.; Gettu, R.; Gopalaratnam, V.S.; Aguado, A. Toughness of Fiber-Reinforced High-Strength Concrete from Notched Beam Tests; ACI Special Publications 155: Testing of Fiber Reinforced Concrete; Special Publication: Tulsa, Oklahoma, 1995; Volume SP 155, pp. 23–40. [Google Scholar]

- Martinelli, E.; Pepe, M.; Fraternali, F. Meso-Scale Formulation of a Cracked-Hinge Model for Hybrid Fiber-Reinforced Cement Composites. Fibers 2020, 8, 56. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Boutsioukou, S.; Amenta, M.; Favvas, E.P.; Kourkoulis, S.K.; Alexopoulos, N.D. Dispersion of Multi-Walled Carbon Nanotubes into White Cement Mortars: The Effect of Concentration and Surfactants. Nanomaterials 2022, 12, 1031. [Google Scholar] [CrossRef]

- Barr, B.I.G.; Gettu, R.; Al-Oraimi, S.K.A.; Bryars, L.S. Toughness Measurement-The need to thing again. Cem. Concr. Compos. 1996, 18, 281–297. [Google Scholar] [CrossRef]

- Taylor, M.; Lydon, F.; Barr, B. Toughness measurements on steel fibre-reinforced high strength concrete. Cem. Concr. Compos. 1997, 19, 329–340. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Piezoresistivity-based strain sensing in carbon fiber reinforced cement. ACI Mater. J. 2007, 104, 171–179. [Google Scholar]

- ASTM C305-14 Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency; ASTM International: West Conshohocken, PA, USA, 1995.

- Akihama, S.; Suenaga, T.; Banno, T. Mechanical properties of carbon fibre reinforced cement composites. Int. J. Cem. Compos. Light. Concr. 1986, 8, 21–33. [Google Scholar] [CrossRef]

- Hambach, M.; Moller, H.; Neuman, T.; Volkmer, D. Portland cement paste with aligned carbon fibers exhibiting exceptionally high flexural strength (>100 MPa). Cem. Concr. Res. 2016, 89, 80–86. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Gdoutos, E.E.; Konsta-Gdoutos, M.S.; Danoglidis, P. Portland cement mortar nanocomposites at low carbon nanotube and carbon nanofiber content: A fracture mechanics experimental study. Cem. Concr. Compos. 2016, 70, 110–118. [Google Scholar] [CrossRef]

- Shah, S.P.; Swartz, S.E.; Ouyang, C. Fracture Mechanics of Concrete: Application of Fracture Mechanics to Concrete, Rock and Other Quasi-Brittle Materials; John Wiley and Sons: New York, NY, USA, 1995. [Google Scholar]

- Gdoutos, E.E. Fracture Mechanics: An Introduction, 2nd ed.; Springer Netherlands: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

| Carbon Content | Tensile Strength | Tensile Modulus | Strain at Failure | Density | Filament Diameter | Length | Electric Resistivity |

|---|---|---|---|---|---|---|---|

| (%) | (MPa) | (GPa) | (%) | (gr/cm3) | (μm) | (mm) | (Ω·cm) |

| 95 | 4900 | 230 | 2.1 | 1.8 | 7 | 6 | 1.6 × 10−3 |

| CP0.485+CFs 0.5 wt.% | Electrical Resistivity (Ohm·m) | Average Change in Resistivity Δρ/ρ0 (%) |

|---|---|---|

| SP (dry mixing) | 20.7 | 3.4 |

| Without SP (dry mixing) | 20.9 | 18.5 |

| SP (wet manually mixing) | 20.0 | 9.5 |

| SP (60 min sonication) | 15.4 | 20.2 |

| CMC (60 min sonication) | 59.8 | 3.4 |

| CNC (60 min sonication) | 29.7 | 8.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thomoglou, A.K.; Falara, M.G.; Gkountakou, F.I.; Elenas, A.; Chalioris, C.E. Influence of Different Surfactants on Carbon Fiber Dispersion and the Mechanical Performance of Smart Piezoresistive Cementitious Composites. Fibers 2022, 10, 49. https://doi.org/10.3390/fib10060049

Thomoglou AK, Falara MG, Gkountakou FI, Elenas A, Chalioris CE. Influence of Different Surfactants on Carbon Fiber Dispersion and the Mechanical Performance of Smart Piezoresistive Cementitious Composites. Fibers. 2022; 10(6):49. https://doi.org/10.3390/fib10060049

Chicago/Turabian StyleThomoglou, Athanasia K., Maria G. Falara, Fani I. Gkountakou, Anaxagoras Elenas, and Constantin E. Chalioris. 2022. "Influence of Different Surfactants on Carbon Fiber Dispersion and the Mechanical Performance of Smart Piezoresistive Cementitious Composites" Fibers 10, no. 6: 49. https://doi.org/10.3390/fib10060049

APA StyleThomoglou, A. K., Falara, M. G., Gkountakou, F. I., Elenas, A., & Chalioris, C. E. (2022). Influence of Different Surfactants on Carbon Fiber Dispersion and the Mechanical Performance of Smart Piezoresistive Cementitious Composites. Fibers, 10(6), 49. https://doi.org/10.3390/fib10060049