Abstract

Currently, natural fibers attract the attention of researchers and builders in the construction industry as they are eco-friendly, cost-effective, lightweight, and renewable resources. The inclusion of natural fibers in the concrete and mortar will contribute to solving the environmental problems associated with dumping or burning them and improve the properties and durability of concrete and mortar. Similar to other natural fibers, Date Palm Fibers (DPF) have been receiving more attention as construction materials. This paper presents a review on the properties of DPF and its effects on the physical, mechanical, and thermal properties of concrete and mortar as well as the processing of DPF and mix design. DPFs can be used in concrete and mortar to improve their properties. However, some of the properties could be reduced. Even though the conducted studies and investigations are promising, it is still not enough to introduce DPF concrete and mortar to the construction industry’s applications.

1. Introduction

Cement-based materials (i.e., concrete and mortar) are widely used nowadays in construction industry. With all-new technologies and scientific research efforts, cement-based materials could now be produced with ultra-high compressive strength [1]. Cement-based materials are brittle and become more brittle as their compressive strength increases. Thus, to overcome this drawback, the scientific community has introduced a wide range of manufactured fibers that could enhance the ductility and tensile resistance of cement-based materials [2,3,4,5,6]. Concerning climate issues such as global warming, manufacturing processes in factories and the construction industry are becoming a serious threat to environmental stabilization [7,8,9,10,11].

Natural fibers are an alternative environmentally attractive, cost-effective, and renewable solution for reinforcing and improving the properties of cement-based materials [12,13,14,15]. Jute, sisal, coir, pineapple, hemp, kelp, bamboo, bagasse, coconut, and ramie are some examples of natural fibers. Studies on utilizing natural fibers as inclusion in concrete and mortar showed promising results. For example, the flexural strength of mortar containing kelp, coconut, and jute fibers increases up to 28%, 24%, and 16%, respectively, as compared to the control mortar [14]. Mortar containing coconut fibers could be used to improve the thermal insulation in low-income buildings for low-income people, saving up to 16% of annual energy costs [16]. Fly ash-based alkali-activate containing treated hemp fibers with sodium hydroxide showed an improvement in compressive strength mortar, as the sodium hydroxide leads to separation of fiber bundles [17]. Similar to other natural fibers, Date Palm Fiber (DPF) has attracted the attention of researchers as reinforcing fibers in cement-based materials. However, even though the conducted studies and investigations are promising, it is still not enough to introduce DPF concrete and mortar to the construction industry’s applications. Researchers have investigated the effects of DPF on concrete and mortar properties. Their results showed that the properties of concrete and mortar could be improved when DPF is incorporated into mixtures. However, some properties could be reduced.

2. Properties of DPF

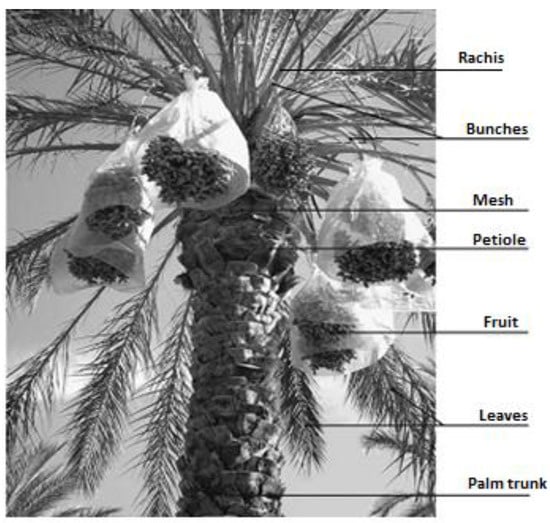

Date palm (Phoenix dactylifera L.) is one of the high growing varieties, where the covered area is almost increased twice from 2000 to 2020. Date palm is commonly planted for a variety of uses [18]. For example, in hot arid areas, such as the middle east and north Africa, the date palm is considered the most important source of life necessities [19]. According to [20], date palms were used for 360 purposes of life. Date palm is widely cultivated in 94 countries with about 11.8 million hectares, mostly in Asia (8.18 million ha.), Africa (1.66 million ha.), and South America (1.01 million ha.) [21]. For example, date palm trees cover 72% of the permanent crops area in Saudi Arabia [22], with a covered area of 117,157 ha. and more than 28.5 million date palm trees. Algeria has 17.8 million date palms [19], with an estimated waste of 1.2 million tons of petioles, 0.41 million tons of leaves, and 0.3 million tons of bunches [23]. Overall, the date palm waste, generated from seasonal pruning and trimming can be estimated at an average of 35 kg per tree [24]. Thus, million tons of waste materials could be produced and dumped in landfills causing environmental and fire hazards. Figure 1 shows the date palm tree parts. Mesh fibers (also called trunk fibers, or surface fibers), leaves, bunches, rachis, and petioles are some attractive date palm fibers that have been investigated as construction and building materials. For example, petioles, bunches, and rachis of date palm were investigated as inclusion in mortars [25,26].

Figure 1.

Date palm aerial parts [23].

The chemical composition and structure of DPF fibers could be affected by climate exposure, age, and the degradation process [27]. Water is considered the main chemical component of a living date palm tree. However, as a dry cell, date palm cell walls consist mainly of cellulose, hemicellulose, and lignin, and with a lower amount of extractives, protein, starch, and inorganics [27]. The composition of DPF fibers shown in Table 1 varies depending on their type either mesh fibers or leaves. The structure of the date palm plant at the cellular level is similar to other agricultural fibers such as Bamboo and Coir [28].

Table 1.

Chemical composition of DPF.

Mesh fibers surrounding trunks were investigated as addition to mortar by different researchers [1,19,31,32,33,34]. Kriker et al. [35] studied four types of date palm mesh fibers. The mesh fibers were extracted from the tree and manually separated into individual fibers of 0.2–0.8 mm diameter. With different lengths of fibers (i.e., 100 mm, 60 mm, and 20 mm), and with different moisture contents (i.e., dry and wet conditions), Kriker et al. [35] tested the mechanical properties of the mesh fibers. They concluded that with shorter fibers, the tensile strength and modulus of elasticity increase while elongation decreases. However, the difference in the moisture content of DPF fibers has a marginal effect on the wet fibers. Kriker et al. [33], tested DPF mesh fibers pretreated with alkalis, namely calcium hydroxide Ca(OH)2 and sodium hydroxide Na(OH) to study the effects of alkalis on the mechanical properties of DPF. They concluded that the pretreated DPF fibers lose their tensile strength and elongation up to 30% and 40% for DPF fibers treated with Ca(OH)2, and 24% and 35% for DPF fibers treated with Na(OH), respectively. In addition, they concluded that the reduction in the tensile strength and elongation of the pretreated DPF fibers become higher with longer immersion time and smaller diameter. With the fact that the concrete and mortar are alkaline environments, DPF fibers may lose their strength with aging and hence, affecting the strength and durability of the concrete and mortar. The mechanical properties of DPF fibers are summarized in Table 2.

Table 2.

Mechanical properties of DPF compared to other agricultural fibers.

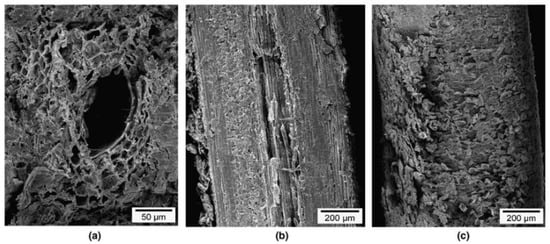

The physical properties of DPF were investigated by [1,32,34,35,37] and summarized in Table 3. Kriker et al. [35] conducted a scanning electron micrograph test on DPF mesh fiber as shown in Figure 2. As Figure 2a,b shows, the DPF mesh has a small canal with huge numbers of little pores. This confirms the porosity structure of the DPF mesh, which explains its ultra-high absorption capacity. It was concluded that DPF fibers can absorb up to 3 times their dry weight [26,29]. It has been proven that many factors can affect the absorption behavior of natural fibers such as the size of fibers, chemical composition, specific surface, and time of exposure to water [26,38,39,40]. For the longitudinal view of the DPF mesh (Figure 2c), the irregularity of the surface with the absence of filaments could allow for good bonding with the concrete matrix. it is worth mentioning that even though the bonding between fibers and matrix is very important to be understood. However, there are no published studies yet that explain the mechanism of this bonding.

Table 3.

Physical properties of DPF compared to other agricultural fibers.

Figure 2.

SEM of DPF mesh, (a) transversal section; (b) longitudinal section; (c) longitudinal view [35].

3. Properties of Concrete and Mortar with DPF Fibers

DPF concrete and mortar behave differently from the conventional mortar. Some of the characteristics of DPF concrete and mortar that they are lightweight, have low density, better absorption rate, and have low thermal conductivity. Table 4 summarizes the standard codes and methods used for testing the DPF concretes and mortars in previous studies. The various properties of DPF concrete and mortar are discussed further in the sub-sections below.

Table 4.

Summary of standard codes and methods used for testing DPF concrete/mortar.

3.1. Mixing Method

The DPF fibers are usually collected from date palm farms and then cleaned, dried, manually separated, and cut to desired lengths. The separation of the date palm mesh fibers could be easily facilitated by immersing them in the water. Figure 3 shows the date palm mesh fibers after pulling them off from the tree.

Figure 3.

Date Palm Mesh Fibers.

The content and size of DPF fibers play a very important role in the concrete and mortar. Therefore, researchers have investigated such effects on the concrete and mortar by testing different contents of fibers starting from 1% to 60% by volume, and different lengths of fibers starting from 3 mm to 100 mm [1,19,26,34,37,38,41,43,44]. In fact, when the content of DPF increases, the water demand is also increased due to the high DPF absorption capacity [35]. Thus, to minimize the water absorption of DPF fibers in the mixture, the DPF fibers are submerged in water before adding them to the mixture [34,35,41]. According to [37], the sand was first mixed with DPF fibers and the cement to ensure the equal distribution of the fibers among the mixture before gradually adding the mixing water. The mixing process is usually carried out slowly to avoid the probability of fibers clumping [34,41]. Table 5 shows some examples of the mixing proportions of concretes and mortars containing DPF fibers.

Table 5.

Mix proportions of mortars and concretes containing DPF fibers.

3.2. Density

The use of DPF fibers as inclusion to the mortar and concrete leads to lowering of the density since they are lighter, porous, and generate voids in the matrix. Vantadori et al. [1], concluded that a slight decrease ranging from 1% to 8% can be noticed in the density due to changing the content of DPF mesh fibers from 2% to 10% by volume, respectively. Bamaga [37] tested the density of mortar containing DPF leaves; the results showed an insignificant decrease in the density as a function of the length and content. However, for large volumes of DPF inclusion, a significant reduction in the density could be observed. Several researchers [19,26,38,45] tested mortars containing high volumes of DPF mesh fibers. For example, the results showed that the density of mortars decreases up to 16% and 39% corresponding mortars containing 21% to 51% of DPF mesh fibers, respectively [31]. The lower density of DPF mortar leads to lighter construction materials with very favorable thermal properties which are very welcomed in green and smart construction. Table 6 shows some physical, mechanical, and thermal properties of concretes and mortars containing DPF fibers.

Table 6.

Physical, mechanical, and thermal properties of concretes and mortars containing DPF fibers.

3.3. Porosity and Water Absorption

As mentioned earlier, the DPF fibers have a porous structure, and thus, the mortars containing them are expected to have more voids and pores. Kareche et al. [45] investigated the porosity and water absorption of three mortars containing 5%, 10%, and 15% by weight DPF fibers. The DPF fibers used were composite of petiole and rachis with a maximum length of 50 mm and 3 mm diameter. As a function of DPF content, the porosity and water absorption of mortars increase up to 24% and 25%, respectively, for mortar containing 15% of DPF fibers, as compared to the control mortar. This behavior could be attributed to the fiber porosity and the inter-particle spaces created between fibers and into the matrix [46]. Similar results were reported by [37], and the results showed that the water absorption of mortars is proportional to the length and content of DPF leave fibers. For example, the water absorption of mortars containing 1% and 3% by weight of DPF leaves (with 50 mm length) increased by 26.95% and 74.06%, respectively, as compared to the control mortar. However, this behavior of mortars containing DPF fibers could be reversed by using alkali pre-treatment DPF fibers. Ozerkan et al. [43], conducted water absorption tests for mortars containing Ca(OH)2 pretreated DPF leave fibers with a length of 100 mm and width of 0.7–4 mm. The authors concluded that the mortars containing the pretreated DPF leaves behaved differently as compared to untreated DPF fibers. For example, the mortar containing 2% by weight of the pretreated DPF leaves showed a reduction of 32% for water absorption as compared to the mortar containing 0.5% by weight. Such results are explained by the effects of the alkali pretreatment that reduces the water absorption capacity of DPF leaves by removing hemicellulose and lignin or by imparting hydrophobicity. The water absorption rate of DPF mortar was studied by [37]. The results showed an extremely lower water absorption rate for mortars containing fibers with lengths of 10 mm and 20 mm. This behavior could be explained by the ability of DPF fibers to retain some of the mixing water inside their pores due to their high absorption capacity.

3.4. Compressive and Flexural Strength

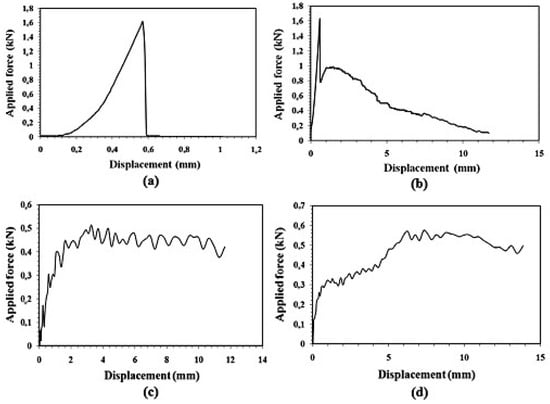

Compressive strength is a key property for construction materials. All other properties could be related to the compressive strength. The performance of date palm concrete and mortar can vary as a function of the size and content of DPF fibers. According to [31], in contrast with other vegetal fibers, DPF mesh has very interesting effects on the failure mode of the mortar (Figure 4), where a ductile behavior can be observed as compared to the brittle behavior of DPF-free mortar. The ductility of DPF mortar increases with the increase of DPF content. Such behavior is mainly related to the ability of DPF fibers to bond and convey the stresses across the crack surfaces [41].

Figure 4.

Flexural load displacement of DPF mortar: (a) control specimen; (b) specimen with 21% DPF; (c) specimen with 35% DPF; (d) specimen with 51% DPF [31].

The compressive and flexural strengths decrease with DPF content increase [26,31,33,35,41,43]. For example, a decrease up to 82.5% and 63% in compressive strength and flexural strength, respectively, for mortars containing 51% by volume of DPF mesh fibers [31]. The reduction is due to (a) the increase of porosity with the DPF content, caused by the inclusion of air during mixing and casting, limited wettability of fibers, and low ability of fibers to compact [31,41,47], and (b) the fact that DPFs lose their durability and strength due to calcium hydroxide releasing during the hydration process [33]. However, with a small inclusion of 0.5% by weight in the mortar, a marginal improvement in the compressive strength and flexural strength could be observed [43]. Such improvement could be attributed to the high compaction between the fibers and the cement matrix that is likely be achieved leading to good homogeneity [43,48]. However, there are no solid conclusions confirming that the mentioned improvements are statistically significant. Kriker et al. [35] presented proof that the compressive strength and flexural strength can be negatively affected if the DPF concretes are cured in hot dry environments. The effects of DPF length on compressive strength were studied by [25,35,37]. They concluded that concrete and mortar reinforced with shorter DPF fibers yield higher compressive strength.

3.5. Thermal Conductivity

Thermal conductivity is one of the important properties of construction materials. It has been proven that palm date fibers (DPF) could be classified among the best construction materials in terms of thermal insulation [19,25,26,31,38,49,50]. Boumhaout et al. [31] conducted experimental works to investigate the thermo-mechanical properties of mortar containing DPF. Mesh fibers with lengths of 20 mm to 50 mm and a diameter of 0.7 mm were used. DPFs were found to have very interesting thermo-physical properties that could classify them as heat-insulating materials. Six mortar mixtures with different DPF ratios were used. DPF inclusions of 21%, 27%, 31%, 35%, 48% and 51% by volume were used. Thermal conductivity, diffusivity, and effusivity of DPF mortar were improved up to 70%, 52%, and 56% respectively, for mortar with 51% PDF inclusion, as compared to the control specimen. This result can be attributed to the matrix porosity of DPF mortar, the inclusion of air, and the lower thermal conductivity of DPF fibers. Similar results were obtained by [38], where a reduction in the thermal conductivity up to 75% is observed for 51% DPF inclusion. Moreover, Boukhattem et al. [38], concluded that the thermal conductivity of DPF mortar increases as a function of the volumetric water content due to the fact that the thermal conductivity of water is greater than the one of air. Mortars containing composite DPF fibers of petiole and rachis showed a reduction in the thermal conductivity up to almost 80% for DPF inclusion of 30% [26]. These authors noticed that with DPF inclusion of less than 15%, the shorter size of fibers (with a length of 3 mm) has significant effects on the thermal conductivity. However, for larger DPF inclusions (more than 15%), these effects become negligible. This is due to the difficulty of aligning and packing the shorter fibers as compared to the larger ones [51].

4. Conclusions

From the above discussion, it can be concluded that DPF fibers have very good properties that make them an ideal candidate for construction materials. The reviewed literature shows that DPF concrete and mortar have the potential to positively affect the environment by eliminating the date palm waste hazards and improving the properties and behavior of concrete and mortar. The inclusion of DPF fibers in concrete and mortar produces lower density, lower thermal conductivity, higher ductility, and good environmental credentials. However, it is obvious that the compressive strength and flexural strength of DPF concrete and mortar have been substantially reduced. Therefore, the author suggests that DPF concrete and mortar containing chemical and mineral admixtures may be investigated to reduce the effects of DPF on mechanical properties. In addition, other forms of construction elements such as concrete blocks and bricks containing DPF fibers may be explored and studied.

Funding

This research received no external funding.

Conflicts of Interest

The author declares no conflict of interest.

References

- Vantadori, S.; Carpinteri, A.; Zanichelli, A. Lightweight construction materials: Mortar reinforced with date-palm mesh fibres. Theor. Appl. Fract. Mech. 2019, 100, 39–45. [Google Scholar] [CrossRef]

- Li, Y.; Deng, Y.G. Mechanical properties and corrosion resistance of high performance fiber-reinforced concrete with steel or amorphous alloy fibers. Mater. Res. Express 2021, 8, 095201. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, Q.; Cheng, M. Study on mechanical properties and air-void structure characteristics of hybrid fiber fly ash concrete under sulfate attack. Mater. Res. Express 2021, 8, 105504. [Google Scholar] [CrossRef]

- Abuzaid, E.K.M. Behavior and Strength of Steel-Carbon-Plastic Hybrid Fiber Reinforced Concrete Beams. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 022061. [Google Scholar] [CrossRef]

- Farooq, M.; Banthia, N. Strain-hardening fiber reinforced polymer concrete with a low carbon footprint. Constr. Build. Mater. 2022, 314, 125705. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Liu, M.Y.J. Contribution of acrylic fibre addition and ground granulated blast furnace slag on the properties of lightweight concrete. Constr. Build. Mater. 2015, 95, 686–695. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Yuan, H.; Zillante, G.; Wang, J. Cross-regional mobility of construction and demolition waste in Australia: An exploratory study. Resour. Conserv. Recycl. 2020, 156, 104710. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current sustainable trends of using waste materials in concrete—A decade review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Ali, M.B.; Saidur, R.; Hossain, M.S. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Anand, S.; Vrat, P.; Dahiya, R.P. Application of a system dynamics approach for assessment and mitigation of CO2 emissions from the cement industry. J. Environ. Manag. 2006, 79, 383–398. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; de Coninck, H.; Loos, M.; Meyer, L. IPCC Special Report on Carbon Dioxide Capture and Storage—Summary for Policymakers of the Intergovernmental Panel on Climate Change. Assessment; Cambridge University Press: New York, NY, USA, 2005. [Google Scholar]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Constr. Build. Mater. 2021, 297, 123759. [Google Scholar] [CrossRef]

- Song, H.; Liu, J.; He, K.; Ahmad, W. A comprehensive overview of jute fiber reinforced cementitious composites. Case Stud. Constr. Mater. 2021, 15, e00724. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Quiñones-Bolaños, E.; Gómez-Oviedo, M.; Mouthon-Bello, J.; Sierra-Vitola, L.; Berardi, U.; Bustillo-Lecompte, C. Potential use of coconut fibre modified mortars to enhance thermal comfort in low-income housing. J. Environ. Manag. 2021, 277, 111503. [Google Scholar] [CrossRef]

- Poletanovic, B.; Janotka, I.; Janek, M.; Bacuvcik, M.; Merta, I. Influence of the NaOH-treated hemp fibres on the properties of fly-ash based alkali-activated mortars prior and after wet/dry cycles. Constr. Build. Mater. 2021, 309, 125072. [Google Scholar] [CrossRef]

- Abdullah, H.M.; Abdul Latif, M.H.; Attiya, H.G. Characterization and determination of lignin in different types of Iraqi phoenix date palm pruning woods. Int. J. Biol. Macromol. 2013, 61, 340–346. [Google Scholar] [CrossRef]

- Belakroum, R.; Gherfi, A.; Kadja, M.; Maalouf, C.; Lachi, M.; El Wakil, N.; Mai, T. Design and properties of a new sustainable construction material based on date palm fibers and lime. Constr. Build. Mater. 2018, 184, 330–343. [Google Scholar] [CrossRef]

- Nixon, R.W. The date palm—“Tree of Life” in the subtropical deserts. Econ. Bot. 1951, 5, 274–301. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Global Forest Resources Assessment 2020 Main Report; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2020. [Google Scholar] [CrossRef]

- Al-Fuhaid, K.M. The Famous Date Varieties in the Kingdom of Saudi Arabia, 1st ed.; Ministry of Higher Education: Riyadh, Saudi Arabia, 2006.

- Agoudjil, B.; Benchabane, A.; Boudenne, A.; Ibos, L.; Fois, M. Renewable materials to reduce building heat loss: Characterization of date palm wood. Energy Build. 2011, 43, 491–497. [Google Scholar] [CrossRef]

- El-Juhany, L.I. Surveying of lignocellulosic agricultural residues in some major cities of Saudi Arabia. Res. Bull. 2001, 1, 5–23. [Google Scholar]

- Chikhi, M. Young’s modulus and thermophysical performances of bio-sourced materials based on date palm fibers. Energy Build. 2016, 129, 589–597. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Lewin, M. Handbook of Fiber Chemistry, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Saadaoui, N.; Rouilly, A.; Fares, K.; Rigal, L. Characterization of date palm lignocellulosic by-products and self-bonded composite materials obtained thereof. Mater. Des. 2013, 50, 302–308. [Google Scholar] [CrossRef]

- Bourmaud, A.; Dhakal, H.; Habrant, A.; Padovani, J.; Siniscalco, D.; Ramage, M.H.; Beaugrand, J.; Shah, D.U. Exploring the potential of waste leaf sheath date palm fibres for composite reinforcement through a structural and mechanical analysis. Compos. Part A Appl. Sci. Manuf. 2017, 103, 292–303. [Google Scholar] [CrossRef] [Green Version]

- Boumhaout, M.; Boukhattem, L.; Hamdi, H.; Benhamou, B.; Ait Nouh, F. Thermomechanical characterization of a bio-composite building material: Mortar reinforced with date palm fibers mesh. Constr. Build. Mater. 2017, 135, 241–250. [Google Scholar] [CrossRef]

- Taallah, B.; Guettala, A.; Guettala, S.; Kriker, A. Mechanical properties and hygroscopicity behavior of compressed earth block filled by date palm fibers. Constr. Build. Mater. 2014, 59, 161–168. [Google Scholar] [CrossRef]

- Kriker, A.; Bali, A.; Debicki, G.; Bouziane, M.; Chabannet, M. Durability of date palm fibres and their use as reinforcement in hot dry climates. Cem. Concr. Compos. 2008, 30, 639–648. [Google Scholar] [CrossRef]

- Tioua, T.; Kriker, A.; Barluenga, G.; Palomar, I. Influence of date palm fiber and shrinkage reducing admixture on self-compacting concrete performance at early age in hot-dry environment. Constr. Build. Mater. 2017, 154, 721–733. [Google Scholar] [CrossRef]

- Kriker, A.; Debicki, G.; Bali, A.; Khenfer, M.M.; Chabannet, M. Mechanical properties of date palm fibres and concrete reinforced with date palm fibres in hot-dry climate. Cem. Concr. Compos. 2005, 27, 554–564. [Google Scholar] [CrossRef]

- Abani, S.; Hafsi, F.; Kriker, A.; Bali, A. Valorisation of Date Palm Fibres in Sahara Constructions. Energy Procedia 2015, 74, 289–293. [Google Scholar] [CrossRef] [Green Version]

- Bamaga, S.O. Physical and mechanical properties of mortars containing date palm fibers. Mater. Res. Express 2022, 9, 015102. [Google Scholar] [CrossRef]

- Boukhattem, L.; Boumhaout, M.; Hamdi, H.; Benhamou, B.; Ait Nouh, F. Moisture content influence on the thermal conductivity of insulating building materials made from date palm fibers mesh. Constr. Build. Mater. 2017, 148, 811–823. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Effects of processing method and fiber size on the structure and properties of wood-plastic composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 80–85. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Benaimeche, O.; Carpinteri, A.; Mellas, M.; Ronchei, C.; Scorza, D.; Vantadori, S. The influence of date palm mesh fibre reinforcement on flexural and fracture behaviour of a cement-based mortar. Compos. Part B Eng. 2018, 152, 292–299. [Google Scholar] [CrossRef] [Green Version]

- Zanichelli, A.; Carpinteri, A.; Fortese, G.; Ronchei, C.; Scorza, D.; Vantadori, S. Contribution of date-palm fibres reinforcement to mortar fracture toughness. Procedia Struct. Integr. 2018, 13, 542–547. [Google Scholar] [CrossRef]

- Ozerkan, N.G.; Ahsan, B.; Mansour, S.; Iyengar, S.R. Mechanical performance and durability of treated palm fiber reinforced mortars. Int. J. Sustain. Built Environ. 2013, 2, 131–142. [Google Scholar] [CrossRef] [Green Version]

- Chennouf, N.; Agoudjil, B.; Boudenne, A.; Benzarti, K.; Bouras, F. Hygrothermal characterization of a new bio-based construction material: Concrete reinforced with date palm fibers. Constr. Build. Mater. 2018, 192, 348–356. [Google Scholar] [CrossRef]

- Kareche, A.; Agoudjil, B.; Haba, B.; Boudenne, A. Study on the Durability of New Construction Materials Based on Mortar Reinforced with Date Palm Fibers Wastes. Waste Biomass Valoriz. 2020, 11, 3801–3809. [Google Scholar] [CrossRef]

- Haba, B.; Agoudjil, B.; Boudenne, A.; Benzarti, K. Hygric properties and thermal conductivity of a new insulation material for building based on date palm concrete. Constr. Build. Mater. 2017, 154, 963–971. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- MA Ismail, D. Compressive and Tensile Strength of Natural Fibre-reinforced Cement base Composites. AL-Rafdain Eng. J. (AREJ) 2007, 15, 42–51. [Google Scholar] [CrossRef]

- Braiek, A.; Karkri, M.; Adili, A.; Ibos, L.; Ben Nasrallah, S. Estimation of the thermophysical properties of date palm fibers/gypsum composite for use as insulating materials in building. Energy Build. 2017, 140, 268–279. [Google Scholar] [CrossRef]

- Chennouf, N.; Agoudjil, B.; Alioua, T.; Boudenne, A.; Benzarti, K. Experimental investigation on hygrothermal performance of a bio-based wall made of cement mortar filled with date palm fibers. Energy Build. 2019, 202, 109413. [Google Scholar] [CrossRef]

- Khedari, J.; Suttisonk, B.; Pratinthong, N.; Hirunlabh, J. New lightweight composite construction materials with low thermal conductivity. Cem. Concr. Compos. 2001, 23, 65–70. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).