Carbon Fibers from Wet-Spun Cellulose-Lignin Precursors Using the Cold Alkali Process

Abstract

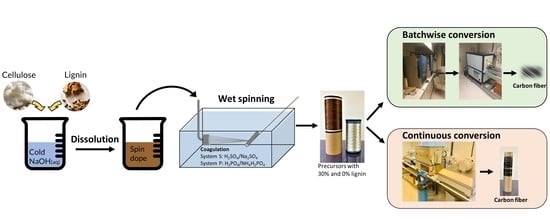

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Spin Dopes

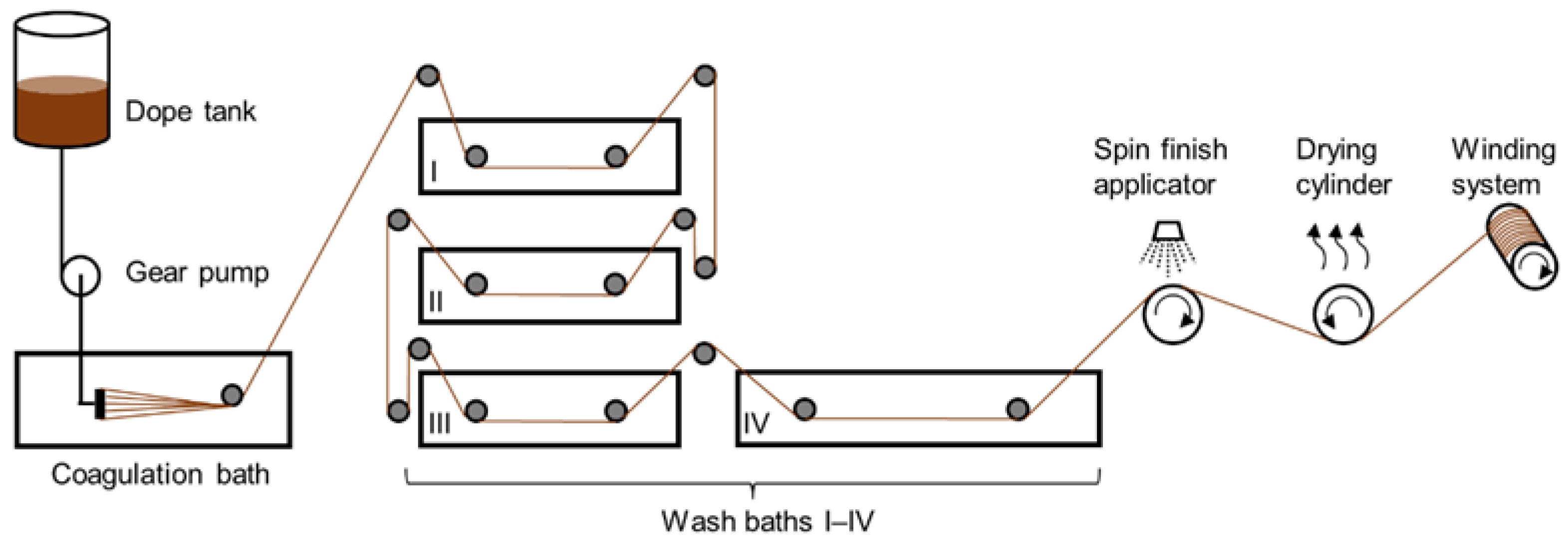

2.3. Wet Spinning

2.4. Stabilization and Carbonization

2.4.1. Batchwise Conversion

2.4.2. Continuous Conversion

2.5. Characterization

3. Results and Discussion

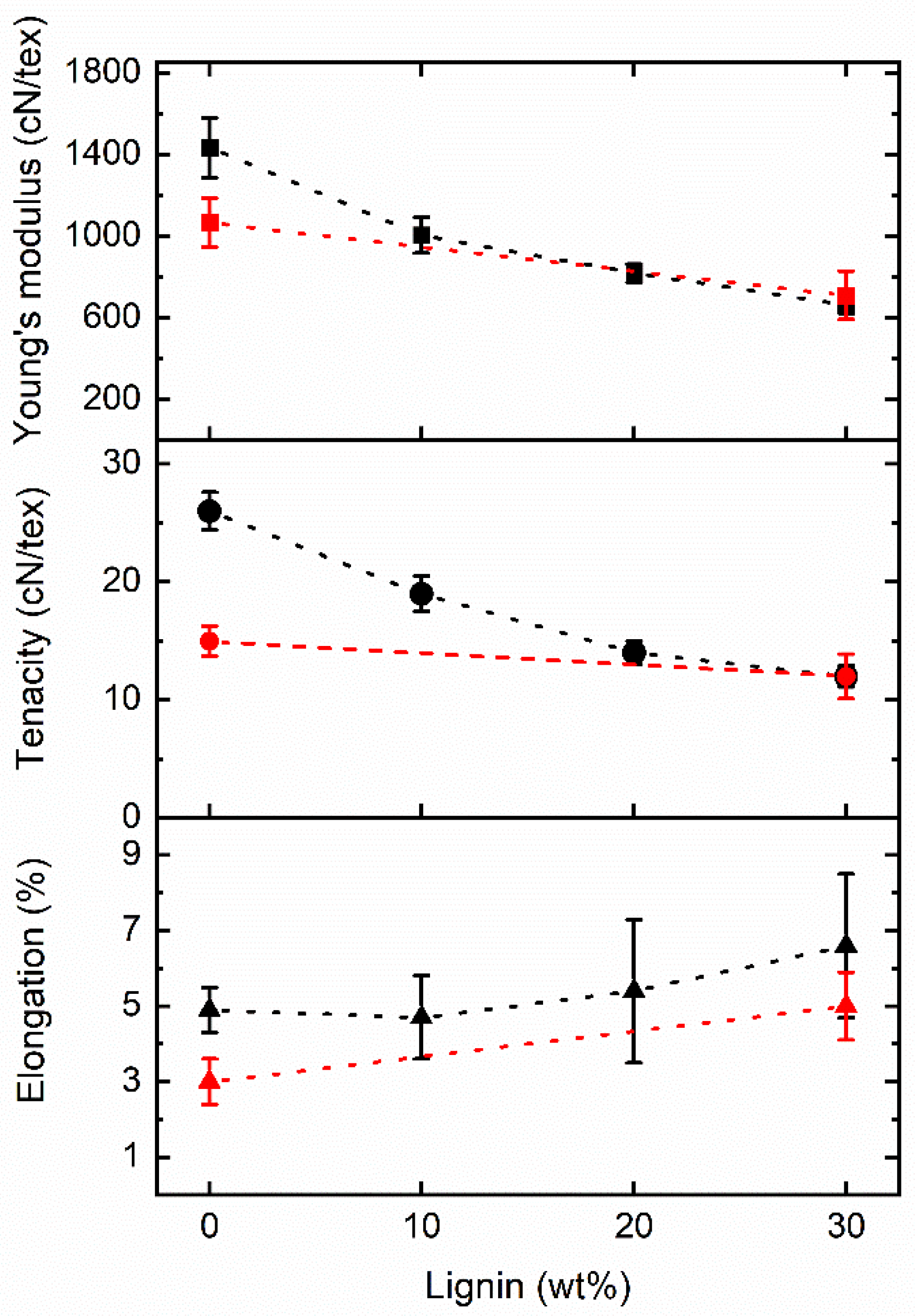

3.1. Properties of Precursors

3.1.1. Morphology

3.1.2. Tensile Properties

3.1.3. Precursor Structure

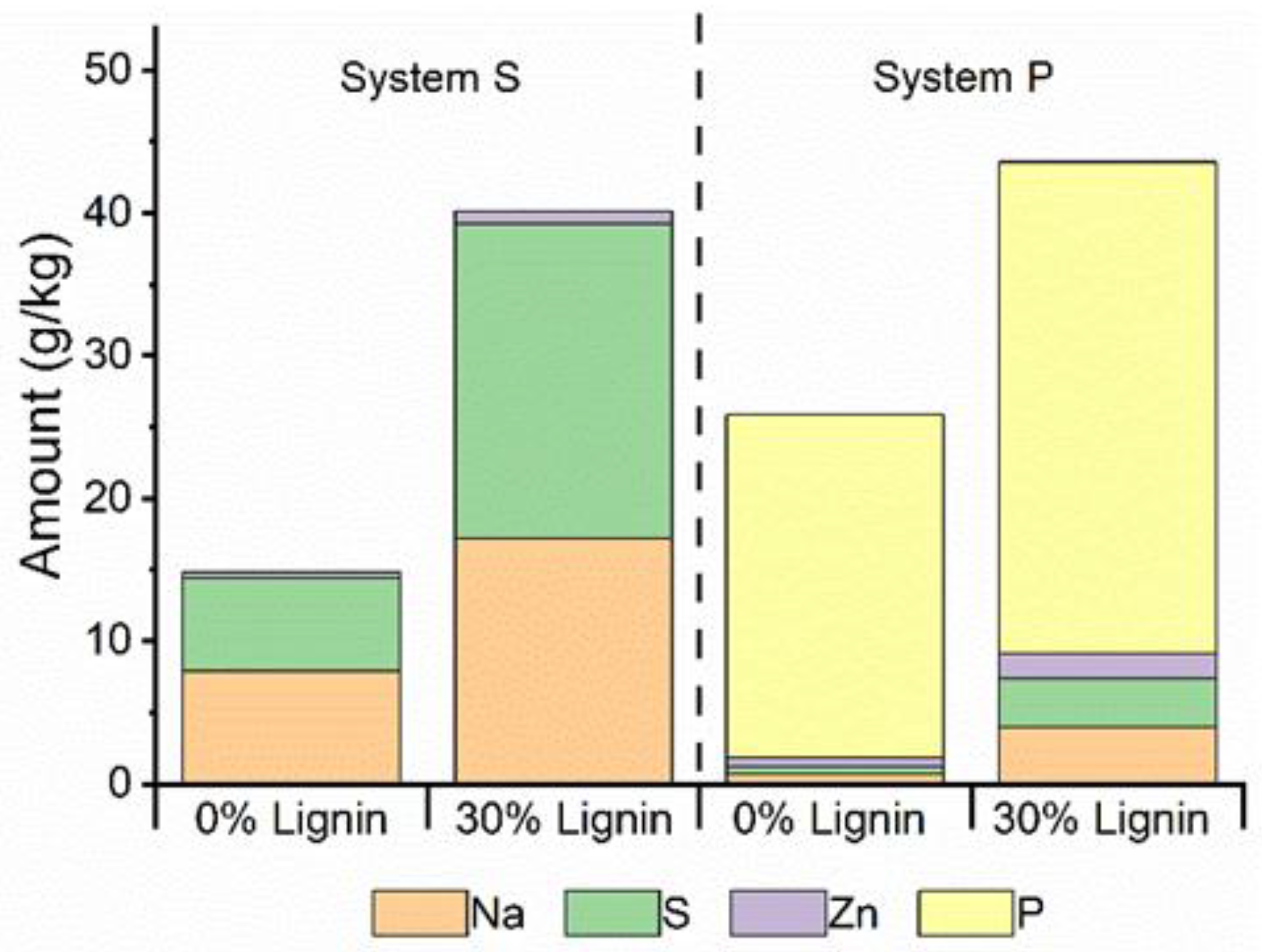

3.1.4. Composition of Inorganic Elements in the Precursors

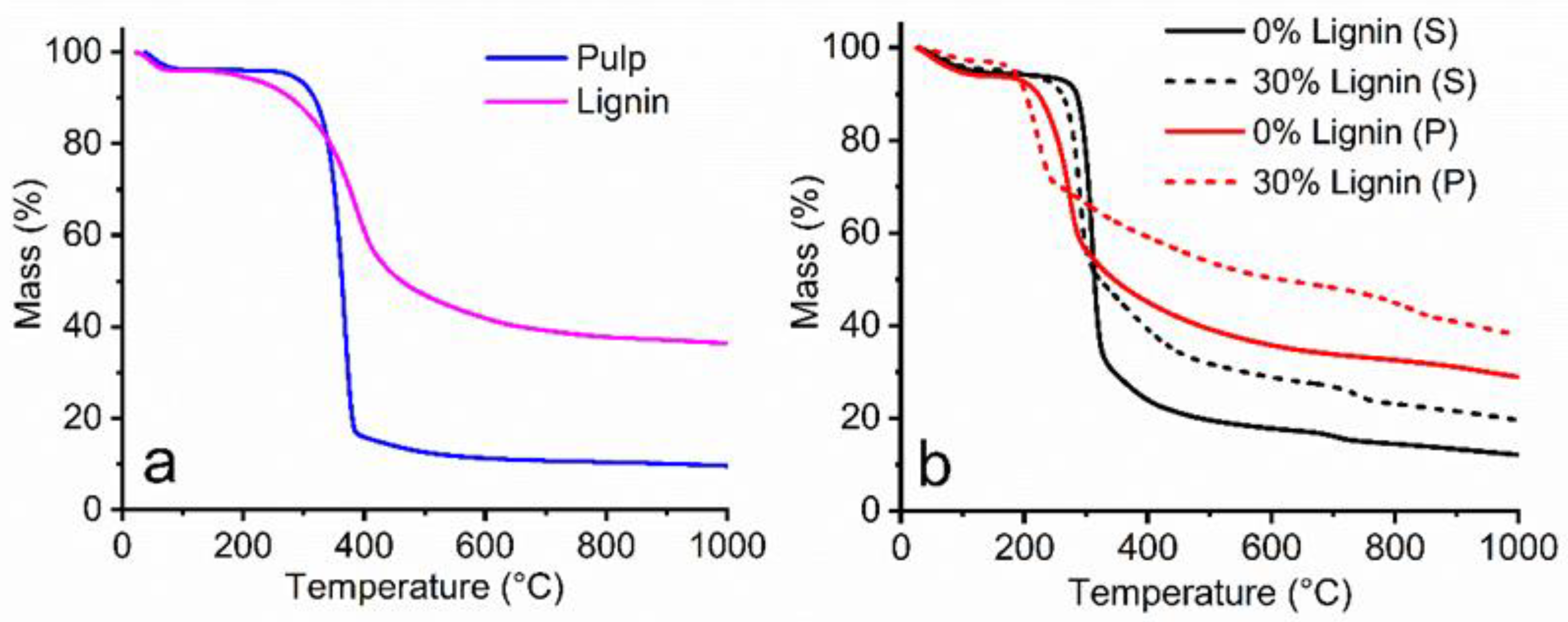

3.1.5. Thermal Properties

3.2. CFs from Precursors Spun with System S

3.2.1. Tensile Properties

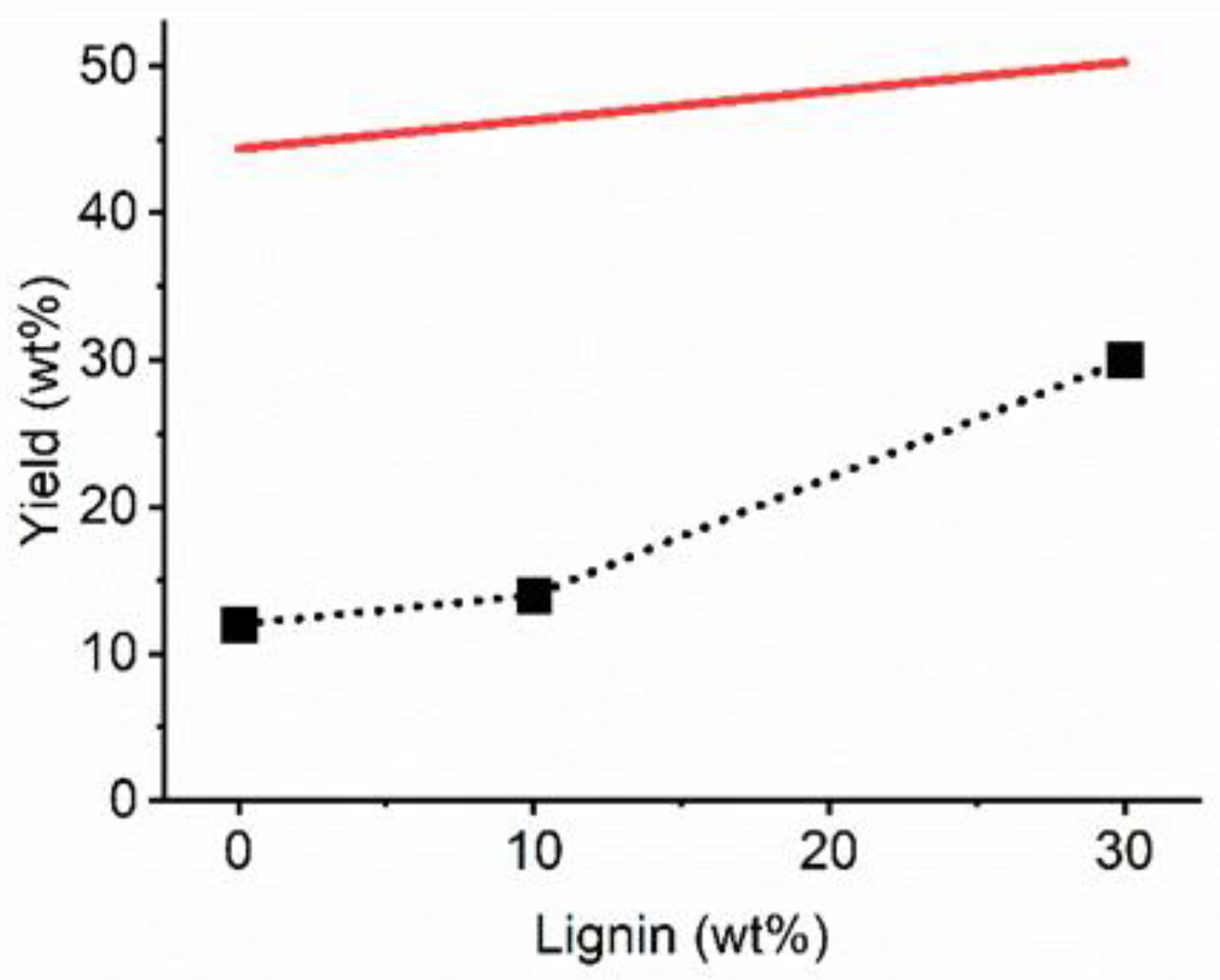

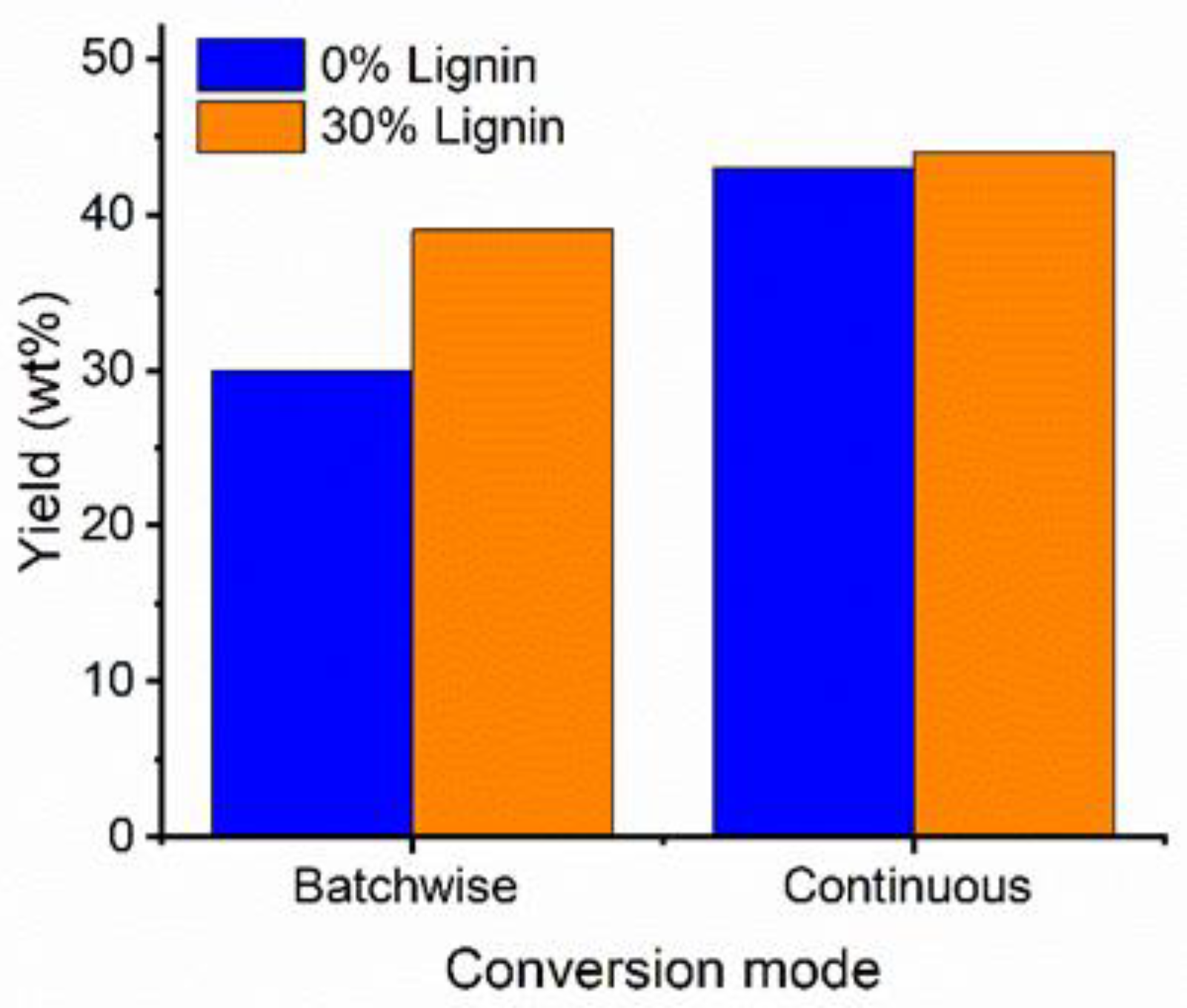

3.2.2. Gravimetric Yield

3.2.3. Morphology

3.3. CFs from Precursors Spun with System P

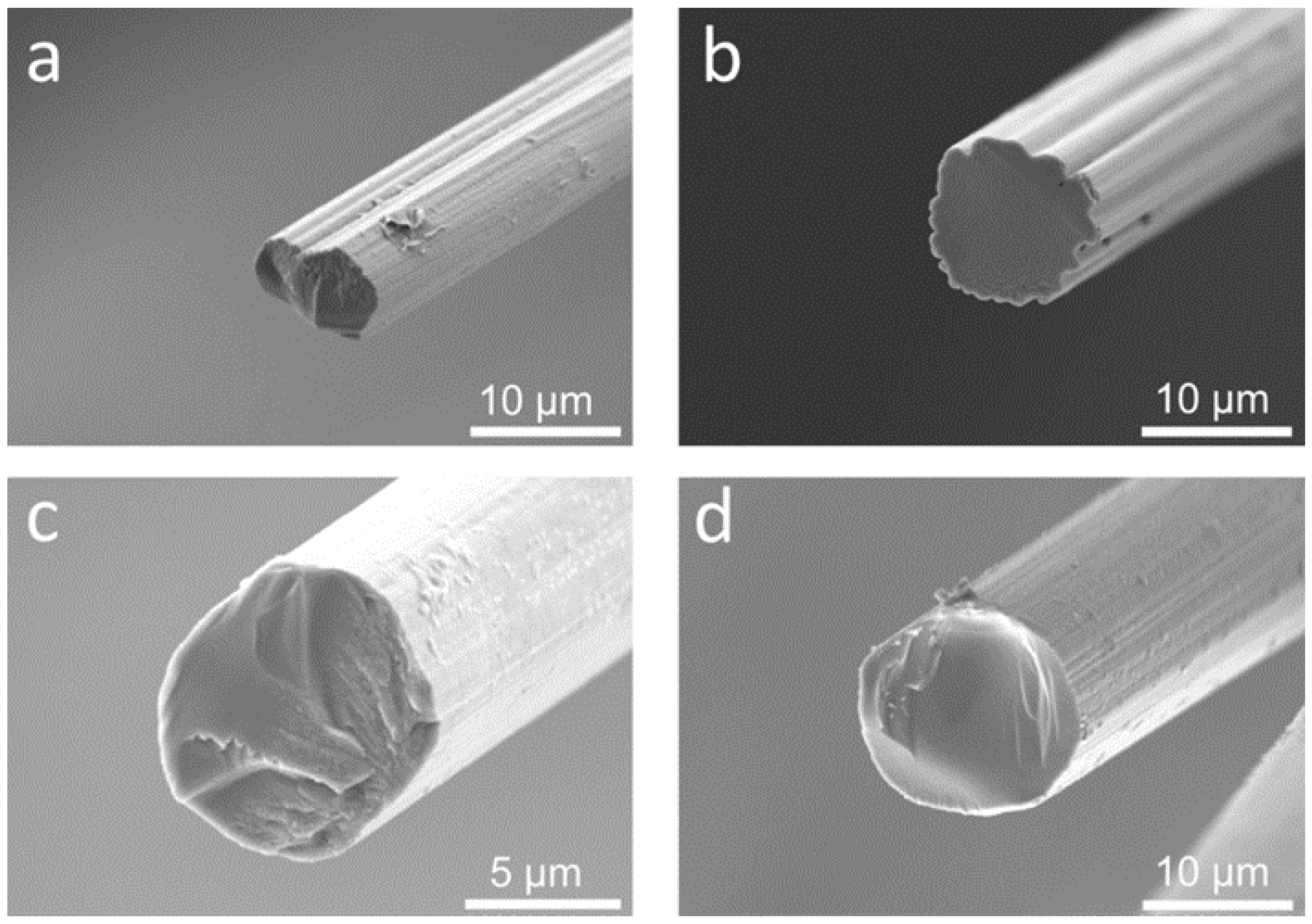

3.3.1. Morphology

3.3.2. Gravimetric Yield

3.3.3. Tensile Properties

3.3.4. Structure of CFs

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bahl, O.; Shen, Z.; Lavin, J.G.; Ross, R.A. Manufacture of Carbon Fibers. In Carbon Fibers; Donnet, J.-B., Wang, T.K., Peng, J.C.M., Rebouillat, S., Eds.; Marcel Dekker Inc.: New York, NY, USA, 1998; Volume 3, pp. 1–85. [Google Scholar]

- Huang, X. Fabrication and Properties of Carbon Fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Newcomb, B.A. Processing, structure, and properties of carbon fibers. Compos. Part A Appl. Sci. Manuf. 2016, 91, 262–282. [Google Scholar] [CrossRef]

- Composites World. Carbon Fiber 2014 Conference Report. Available online: https://www.compositesworld.com/articles/carbon-fiber-2014-conference-report (accessed on 14 November 2018).

- Kadla, J.; Kubo, S.; Venditti, R.; Gilbert, R.; Compere, A.; Griffith, W. Lignin-based carbon fibers for composite fiber applications. Carbon 2002, 40, 2913–2920. [Google Scholar] [CrossRef]

- Gellerstedt, G. Softwood kraft lignin: Raw material for the future. Ind. Crop Prod. 2015, 77, 845–854. [Google Scholar] [CrossRef]

- Morgan, P. Carbon Fibers and Their Composites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Dumanlı, A.G.; Windle, A.H. Carbon fibres from cellulosic precursors: A review. J. Mater. Sci. 2012, 47, 4236–4250. [Google Scholar] [CrossRef]

- Baker, D.A.; Rials, T.G. Recent advances in low-cost carbon fiber manufacture from lignin. J. Appl. Polym. Sci. 2013, 130, 713–728. [Google Scholar] [CrossRef]

- Braun, J.; Holtman, K.; Kadla, J. Lignin-based carbon fibers: Oxidative thermostabilization of kraft lignin. Carbon 2005, 43, 385–394. [Google Scholar] [CrossRef]

- Baker, D.A.; Gallego, N.C.; Baker, F.S. On the characterization and spinning of an organic-purified lignin toward the manufacture of low-cost carbon fiber. J. Appl. Polym. Sci. 2012, 124, 227–234. [Google Scholar] [CrossRef]

- Uraki, Y.; Kubo, S.; Nigo, N.; Sano, Y.; Sasaya, T. Preparation of Carbon Fibers from Organosolv Lignin Obtained by Aqueous Acetic Acid Pulping. Holzforschung 1995, 49, 343–350. [Google Scholar] [CrossRef]

- Mainka, H.; Hilfert, L.; Busse, S.; Edelmann, F.; Haak, E.; Herrmann, A.S. Characterization of the major reactions during conversion of lignin to carbon fiber. J. Mater. Res. Technol. 2015, 4, 377–391. [Google Scholar] [CrossRef]

- Norberg, I.; Nordström, Y.; Drougge, R.; Gellerstedt, G.; Sjöholm, E. A new method for stabilizing softwood kraft lignin fibers for carbon fiber production. J. Appl. Polym. Sci. 2012, 128, 3824–3830. [Google Scholar] [CrossRef]

- Nordström, Y.; Norberg, I.; Sjöholm, E.; Drougge, R. A new softening agent for melt spinning of softwood kraft lignin. J. Appl. Polym. Sci. 2012, 129, 1274–1279. [Google Scholar] [CrossRef]

- Kleinhans, H.; Salmén, L. Development of lignin carbon fibers: Evaluation of the carbonization process. J. Appl. Polym. Sci. 2016, 133, 43965. [Google Scholar] [CrossRef]

- Ma, Y.; Asaadi, S.; Johansson, L.-S.; Ahvenainen, P.; Reza, M.; Alekhina, M.; Rautkari, A.-P.L.; Michud, A.; Hauru, L.; Hummel, M.; et al. High-Strength Composite Fibers from Cellulose-Lignin Blends Regenerated from Ionic Liquid Solution. ChemSusChem 2015, 8, 4030–4039. [Google Scholar] [CrossRef]

- Olsson, C.; Sjöholm, E.; Reimann, A. Carbon fibres from precursors produced by dry-jet wet-spinning of kraft lignin blended with kraft pulps. Holzforschung 2017, 71, 275–283. [Google Scholar] [CrossRef]

- Bengtsson, A.; Bengtsson, J.; Olsson, C.; Sedin, M.; Jedvert, K.; Theliander, H.; Sjöholm, E. Improved yield of carbon fibres from cellulose and kraft lignin. Holzforschung 2018, 72, 1007–1016. [Google Scholar] [CrossRef]

- Svenningsson, L.; Bengtsson, J.; Jedvert, K.; Schlemmer, W.; Theliander, H.; Evenäs, L. Disassociated molecular orientation distributions of a composite cellulose–lignin carbon fiber precursor: A study by rotor synchronized NMR spectroscopy and X-ray scattering. Carbohydr. Polym. 2020, 254, 117293. [Google Scholar] [CrossRef]

- Vincent, S.R.; Prado, R.; Kuzmina, O.; Potter, K.; Bhardwaj, J.; Wanasekara, N.D.; Harniman, R.L.; Koutsomitopoulou, A.; Eichhorn, S.J.; Welton, T.; et al. Regenerated Cellulose and Willow Lignin Blends as Potential Renewable Precursors for Carbon Fibers. ACS Sustain. Chem. Eng. 2018, 6, 5903–5910. [Google Scholar] [CrossRef]

- Byrne, N.; De Silva, R.; Ma, Y.; Sixta, H.; Hummel, M. Enhanced stabilization of cellulose-lignin hybrid filaments for carbon fiber production. Cellulose 2017, 25, 723–733. [Google Scholar] [CrossRef]

- Bengtsson, A.; Bengtsson, J.; Sedin, M.; Sjöholm, E. Carbon Fibers from Lignin-Cellulose Precursors: Effect of Stabilization Conditions. ACS Sustain. Chem. Eng. 2019, 7, 8440–8448. [Google Scholar] [CrossRef]

- Trogen, M.; Le, N.-D.; Sawada, D.; Guizani, C.; Lourençon, T.V.; Pitkänen, L.; Sixta, H.; Shah, R.; O’Neill, H.; Balakshin, M.; et al. Cellulose-lignin composite fibres as precursors for carbon fibres. Part 1—Manufacturing and properties of precursor fibres. Carbohydr. Polym. 2020, 252, 117133. [Google Scholar] [CrossRef] [PubMed]

- Mai, N.L.; Ahn, K.; Koo, Y.-M. Methods for recovery of ionic liquids—A review. Process Biochem. 2014, 49, 872–881. [Google Scholar] [CrossRef]

- Määttänen, M.; Gunnarsson, M.; Wedin, H.; Stibing, S.; Olsson, C.; Köhnke, T.; Asikainen, S.; Vehviläinen, M.; Harlin, A. Pre-treatments of pre-consumer cotton-based textile waste for production of textile fibres in the cold NaOH(aq) and cellulose carbamate processes. Cellulose 2021, 28, 3869–3886. [Google Scholar] [CrossRef]

- Vehviläinen, M.; Kamppuri, T.; Rom, M.; Janicki, J.; Ciechańska, D.; Grönqvist, S.; Siika-Aho, M.; Christoffersson, K.E.; Nousiainen, P. Effect of wet spinning parameters on the properties of novel cellulosic fibres. Cellulose 2008, 15, 671–680. [Google Scholar] [CrossRef]

- Brännvall, E.; Walter, K. Process modifications to obtain a prehydrolysis kraft dissolving pulp with low limiting pulp viscosity. Nord. Pulp Pap. Res. J. 2020, 35, 332–341. [Google Scholar] [CrossRef]

- Bengtsson, A.; Bengtsson, J.; Jedvert, K.; Kakkonen, M.; Tanhuanpää, O.; Brännvall, E.; Sedin, M. Continuous Stabilization and Carbonization of a Lignin–Cellulose Precursor to Carbon Fiber. ACS Omega 2022, 7, 16793–16802. [Google Scholar] [CrossRef]

- Langan, P.; Nishiyama, A.Y.; Chanzy, H. X-ray Structure of Mercerized Cellulose II at 1 Å Resolution. Biomacromolecules 2001, 2, 410–416. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2013, 21, 885–896. [Google Scholar] [CrossRef]

- Costa, C.; Medronho, B.; Eivazi, A.; Svanedal, I.; Lindman, B.; Edlund, H.; Norgren, M. Lignin enhances cellulose dissolution in cold alkali. Carbohydr. Polym. 2021, 274, 118661. [Google Scholar] [CrossRef]

- Mao, Y.; Zhang, L.; Cai, J.; Zhou, J.; Kondo, T. Effects of Coagulation Conditions on Properties of Multifilament Fibers Based on Dissolution of Cellulose in NaOH/Urea Aqueous Solution. Ind. Eng. Chem. Res. 2008, 47, 8676–8683. [Google Scholar] [CrossRef]

- Budtova, T.; Navard, P. Cellulose in NaOH–water based solvents: A review. Cellulose 2015, 23, 5–55. [Google Scholar] [CrossRef]

- Hagman, J.; Gentile, L.; Jessen, C.M.; Behrens, M.; Bergqvist, K.-E.; Olsson, U. On the dissolution state of cellulose in cold alkali solutions. Cellulose 2017, 24, 2003–2015. [Google Scholar] [CrossRef]

- Le, N.-D.; Trogen, M.; Varley, R.J.; Hummel, M.; Byrne, N. Chemically Accelerated Stabilization of a Cellulose–Lignin Precursor as a Route to High Yield Carbon Fiber Production. Biomacromolecules 2022, 23, 839–846. [Google Scholar] [CrossRef]

- Protz, R.; Lehmann, A.; Ganster, J.; Fink, H.-P. Solubility and spinnability of cellulose-lignin blends in aqueous NMMO. Carbohydr. Polym. 2020, 251, 117027. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Dawelbeit, A.; Deng, Y.; Lang, Y.; Yu, M. Structure and properties of regenerated cellulose fibers from aqueous NaOH/thiourea/urea solution. Cellulose 2017, 24, 4123–4137. [Google Scholar] [CrossRef]

- Cui, S.; Zhang, Y.; Liu, C.; Lou, S.; Zhang, Y.; Wang, H. The influence of the multi-level structure under high drawing on the preparation of high strength Lyocell fiber. Cellulose 2022, 29, 751–762. [Google Scholar] [CrossRef]

- Enengl, C.; Lone, S.A.; Unterweger, C.; Fürst, C. Screening of spinning oils for melt-spun lignin-based carbon fiber precursors. J. Appl. Polym. Sci. 2022, 139, 52134. [Google Scholar] [CrossRef]

- Spörl, J.M.; Beyer, R.; Abels, F.; Cwik, T.; Müller, A.; Hermanutz, F.; Buchmeiser, M.R. Cellulose-Derived Carbon Fibers with Improved Carbon Yield and Mechanical Properties. Macromol. Mater. Eng. 2017, 302, 1700195. [Google Scholar] [CrossRef]

- Jones, F.; Tran, H.; Lindberg, D.; Zhao, L.; Hupa, M. Thermal Stability of Zinc Compounds. Energy Fuels 2013, 27, 5663–5669. [Google Scholar] [CrossRef]

- Puziy, A.M.; Poddubnaya, O.I.; Martínez-Alonso, A.; Suárez-García, F.; Tascón, J.M. Surface chemistry of phosphorus-containing carbons of lignocellulosic origin. Carbon 2005, 43, 2857–2868. [Google Scholar] [CrossRef]

- Chen, X.; Wu, H. Transformation and release of phosphorus during rice bran pyrolysis: Effect of reactor configurations under various conditions. Fuel 2019, 255, 115755. [Google Scholar] [CrossRef]

- Olsson, E.O.L.; Glarborg, P.; Leion, H.; Dam-Johansen, K.; Wu, H. Release of P from Pyrolysis, Combustion, and Gasification of Biomass—A Model Compound Study. Energy Fuels 2021, 35, 15817–15830. [Google Scholar] [CrossRef]

- Kong, L.; Liu, H.; Cao, W.; Xu, L. PAN fiber diameter effect on the structure of PAN-based carbon fibers. Fibers Polym. 2014, 15, 2480–2488. [Google Scholar] [CrossRef]

- Vocht, M.P.; Ota, A.; Frank, E.; Hermanutz, F.; Buchmeiser, M.R. Preparation of Cellulose-Derived Carbon Fibers Using a New Reduced-Pressure Stabilization Method. Ind. Eng. Chem. Res. 2022, 61, 5191–5201. [Google Scholar] [CrossRef]

- Belenkov, E. Formation of Graphite Structure in Carbon Crystallites. Inorg. Mater. 2001, 37, 928–934. [Google Scholar] [CrossRef]

- Sagues, W.; Jain, A.; Brown, D.; Aggarwal, S.; Suarez, A.; Kollman, M.; Park, S.; Argyropoulos, D.S. Are lignin-derived carbon fibers graphitic enough? Green Chem. 2019, 21, 4253–4265. [Google Scholar] [CrossRef]

- Breitenbach, S.; Unterweger, C.; Lumetzberger, A.; Duchoslav, J.; Stifter, D.; Hassel, A.W.; Fürst, C. Viscose-based porous carbon fibers: Improving yield and porosity through optimization of the carbonization process by design of experiment. J. Porous Mater. 2021, 28, 727–739. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Moon, H.; Zarrabeitia, M.; Frank, E.; Böse, O.; Enterría, M.; Saurel, D.; Hasa, I.; Passerini, S. Assessing the Reactivity of Hard Carbon Anodes: Linking Material Properties with Electrochemical Response Upon Sodium- and Lithium-Ion Storage. Batter. Supercaps 2021, 4, 960–977. [Google Scholar] [CrossRef]

| System | Coagulation Bath Composition | Number of Spinneret Holes | Wash Sequence | Spin Finish Application |

|---|---|---|---|---|

| S | 10 wt% H2SO4 + 15 wt% Na2SO4 | 100 | I–IV | In bath IV |

| P | 12 wt% H3PO4 + 10 wt% NH4H2PO4 | 300 | II + IV | Applicator |

| Coagulation System | Cellulose Conc. (wt%) | Lignin Conc. (wt%) | Cellulose/Lignin (wt/wt) | Titer (dtex) |

|---|---|---|---|---|

| S | 5.5 | 0 | 100/0 | 2.0 |

| S | 5.5 | 0.6 | 90/10 | 3.3 |

| S | 5.5 | 1.4 | 80/20 | 9.5 |

| S | 4.5 | 1.9 | 70/30 | 6.0 |

| P | 5.5 | 0 | 100/0 | 3.3 |

| P | 4.5 | 1.9 | 70/30 | 3.0 |

| Precursor | Xc (%) | fc (%) |

|---|---|---|

| Lyocell (ref.) | 45.4 | 95.6 |

| 0% Lignin, System S | 40.2 | 92.3 |

| 30% Lignin, System S | 29.8 | 88.1 |

| 0% Lignin, System P | 40.6 | 88.1 |

| 30% Lignin, System P | 28.5 | 85.7 |

| Conversion Mode | Precursor | Ea (GPa) | La (nm) | Lc (nm) | d002 (nm) | fc (%) |

|---|---|---|---|---|---|---|

| Batchwise | 0% L (S) | 77 | 2.03 | 2.14 | 0.36 | 86.1 |

| 0% L (P) | 55 | 2.47 | 1.88 | 0.35 | 84.5 | |

| 30% L (P) | 53 | 2.28 | 1.78 | 0.37 | 84.5 | |

| Continuous | 0% L (P) b | 46 | 2.63 | 1.89 | 0.36 | 82.4 |

| 0% L (P) c | 35 | 2.55 | 1.89 | 0.36 | 76.7 | |

| 30% L (P) c | 33 | 2.72 | 1.91 | 0.35 | 75.6 |

| Conversion Mode | Precursor | Ea (GPa) | ID/IG |

|---|---|---|---|

| Batchwise | 0% L (S) | 77 | 1.63 |

| 0% L (P) | 55 | 1.58 | |

| 30% L (P) | 53 | 1.59 | |

| Continuous | 0% L (P) b | 46 | 1.46 |

| 0% L (P) c | 35 | 1.46 | |

| 30% L (P) c | 33 | 1.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bengtsson, A.; Landmér, A.; Norberg, L.; Yu, S.; Ek, M.; Brännvall, E.; Sedin, M. Carbon Fibers from Wet-Spun Cellulose-Lignin Precursors Using the Cold Alkali Process. Fibers 2022, 10, 108. https://doi.org/10.3390/fib10120108

Bengtsson A, Landmér A, Norberg L, Yu S, Ek M, Brännvall E, Sedin M. Carbon Fibers from Wet-Spun Cellulose-Lignin Precursors Using the Cold Alkali Process. Fibers. 2022; 10(12):108. https://doi.org/10.3390/fib10120108

Chicago/Turabian StyleBengtsson, Andreas, Alice Landmér, Lars Norberg, Shun Yu, Monica Ek, Elisabet Brännvall, and Maria Sedin. 2022. "Carbon Fibers from Wet-Spun Cellulose-Lignin Precursors Using the Cold Alkali Process" Fibers 10, no. 12: 108. https://doi.org/10.3390/fib10120108

APA StyleBengtsson, A., Landmér, A., Norberg, L., Yu, S., Ek, M., Brännvall, E., & Sedin, M. (2022). Carbon Fibers from Wet-Spun Cellulose-Lignin Precursors Using the Cold Alkali Process. Fibers, 10(12), 108. https://doi.org/10.3390/fib10120108