Laboratory Investigation of Sand-Geosynthetic Interface Friction Parameters Using Cost-Effective Vertical Pullout Apparatus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Vertical Pullout Test Apparatus

2.2. Pullout Test Philosophy

- Fvp = peak vertical pullout force,

- B = width of the geotextile sample, and,

- Le = length of the geotextile embedded in soil.

2.3. Direct Shear Test

3. Results

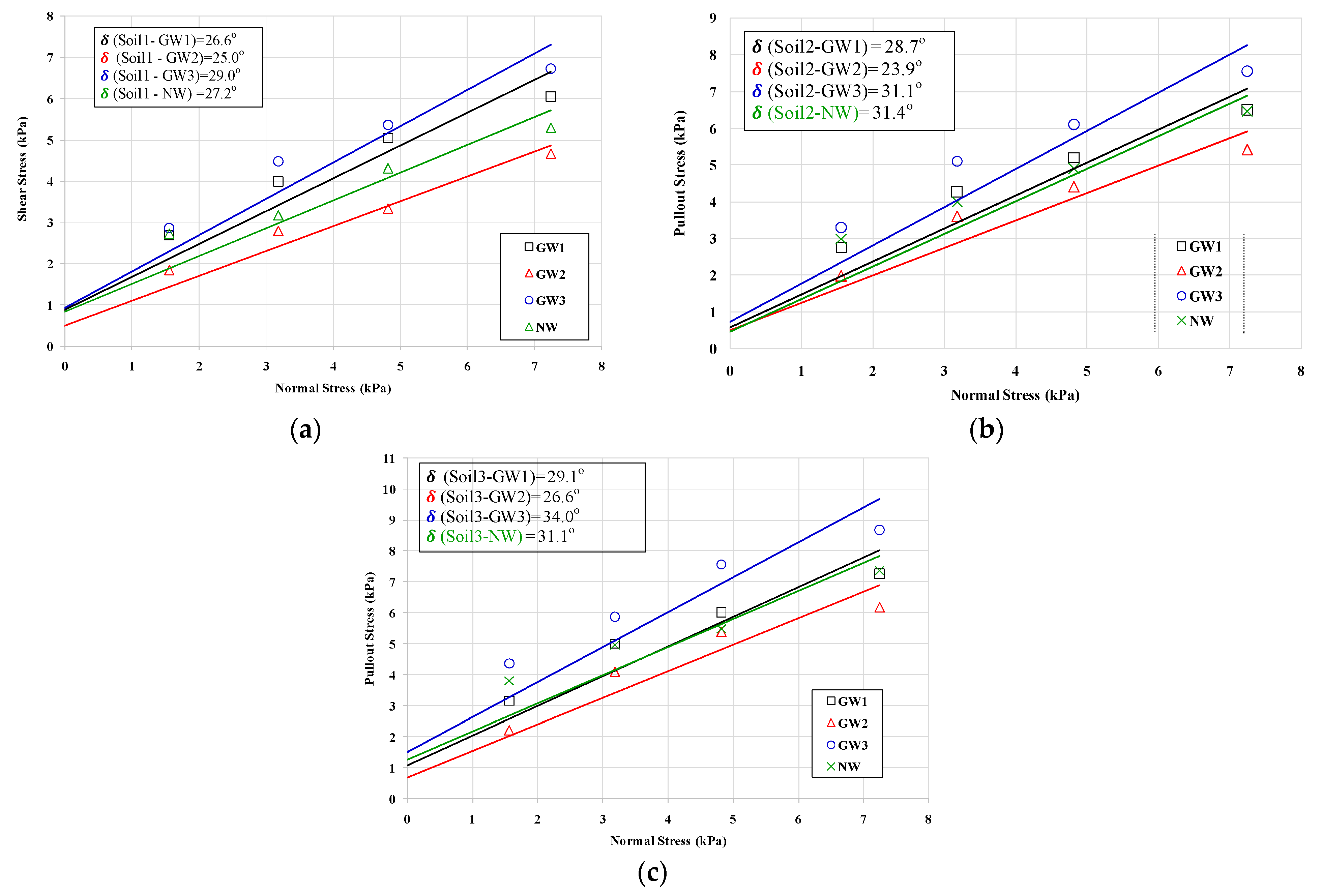

VPT Results

4. Discussion

4.1. Comparison of VPT and Direct Shear Test

4.2. Interface Efficiency

5. Conclusions

- The interaction of the sand-geotextile interface can be described by a linear failure envelope with interface efficiency ranging from 0.67~0.97.

- The sand-geotextile behavior depends on the type of geotextile and its surface characteristics. The interface efficiency of NW is 3~22% higher than the woven geotextile which is due to the rough surface of the non-woven geotextile.

- Modified direct shear test and vertical pullout test indicated that particle size has a marked influence on interface friction parameters. Interface friction angle increased by 1.6~4.8 degrees and friction coefficient values increased by 6.5~19.3% from Soil1 to Soil 3, respectively for the same geosynthetic reinforcement.

- VPT test yields a friction angle, i.e., 9~19% smaller as compared to the friction angles obtained by the modified direct shear test owing to the fact that the actual stiffness of the geotextile is incorporated in the VPT, meanwhile, the stiffness of the geotextile is increased by mounting it on a wooden box. Thus, VPT presents a more conservative and safe design parameter for geotextile interfacial strength.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, K.-H.; Yalew, W.M.; Nguyen, M.D. Behavior of Geotextile-Reinforced Clay with a Coarse Material Sandwich Technique under Unconsolidated-Undrained Triaxial Compression. Int. J. Géoméch. 2016, 16, 4015083. [Google Scholar] [CrossRef]

- Bhandari, A.; Han, J. Investigation of geotextile–soil interaction under a cyclic vertical load using the discrete element method. Geotext. Geomembr. 2010, 28, 33–43. [Google Scholar] [CrossRef]

- Reddy, Y.R.; Reddy, T.R.P. Stabilization of Soil by using Waste Fiber Materials. Int. J. Adv. Tech. Innov. Res. 2016, 8, 2963–2966. [Google Scholar]

- Cen, W.-J.; Wang, H.; Sun, Y.-J. Laboratory Investigation of Shear Behavior of High-Density Polyethylene Geomembrane Interfaces. Polymers 2018, 10, 734. [Google Scholar] [CrossRef] [PubMed]

- Yetimoglu, T.; Salbas, O. A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext. Geomembr. 2003, 21, 103–110. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, J.; Li, Z. Shear behaviour of a geogrid-reinforced coarse-grained soil based on large-scale triaxial tests. Geotext. Geomembr. 2014, 42, 312–328. [Google Scholar] [CrossRef]

- Tang, L.; Cong, S.; Ling, X.; Lu, J.; Elgamal, A. Numerical study on ground improvement for liquefaction mitigation using stone columns encased with geosynthetics. Geotext. Geomembr. 2015, 43, 190–195. [Google Scholar] [CrossRef]

- Consoli, N.C.; Vendruscolo, M.A.; Fonini, A.; Rosa, F.D. Fiber reinforcement effects on sand considering a wide cementation range. Geotext. Geomembr. 2009, 27, 196–203. [Google Scholar] [CrossRef]

- Dai, Z.-H.; Guo, W.-D.; Zheng, G.-X.; Ou, Y.; Chen, Y.-J. Moso Bamboo Soil-Nailed Wall and its 3D Nonlinear Numerical Analysis. Int. J. Géoméch. 2016, 16, 4016012. [Google Scholar] [CrossRef]

- Chen, M.; Shen, S.-L.; Arulrajah, A.; Wu, H.-N.; Hou, D.-W.; Xu, Y.-S. Laboratory evaluation on the effectiveness of polypropylene fibers on the strength of fiber-reinforced and cement-stabilized Shanghai soft clay. Geotext. Geomembr. 2015, 43, 515–523. [Google Scholar] [CrossRef]

- Cheng, Y.M.; Choi, Y.K.; Yeung, A.T.; Tham, L.G.; Au, S.K.; Wei, W.B.; Chen, J. New soil nail material—Pilot study of grouted GFRP pipe nails in Korea and Hong Kong. J. Mater. Civil Eng. 2009, 21, 93–102. [Google Scholar] [CrossRef]

- Cheng, Y.; Au, S.; Pearson, A.; Li, N. An innovative Geonail system for soft ground stabilization. Soils Found. 2013, 53, 282–298. [Google Scholar] [CrossRef]

- Cheng, Y.; Au, S.; Yeung, A.T. Laboratory and field evaluation of several types of soil nails for different geological conditions. Can. Geotech. J. 2015, 53, 634–645. [Google Scholar] [CrossRef]

- Anubhav; Basudhar, P.K. Interface Behavior of Woven Geotextile with Rounded and Angular Particle Sand. J. Mater. Civ. Eng. 2013, 25, 1970–1974. [Google Scholar] [CrossRef]

- Markou, I.N. Direct Shear Testing of Sand—Geotextile Interfaces. In Advances in Reinforced Soil Structures, GeoMEast, 2017. Sustainable Civil Infrastructures; Shukla, S., Guler, E., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Tuna, S.; Altun, S. Mechanical behavior of sand-geotextile interface. Sci. Iran. 2012, 19, 1044–1051. [Google Scholar] [CrossRef]

- Abdi, M.R.; Gonbad, M.S.S. Studying the effect of roughness on soil-geotextile interaction in direct shear test. J. Eng. Geol. 2018, 12, 1–30. [Google Scholar]

- Hsieh, C.W.; Chen, G.H.; Wu, J.H. The shear behavior obtained from the direct shear and pullout tests for different poor graded soil-geosynthetic systems. J. GeoEng. 2011, 6, 15–26. [Google Scholar]

- ASTM D5261-10; Standard Test Method for Measuring Mass per Unit Area of Geotextiles. ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 23 April 2020).

- ASTM D4595-17; Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method. ASTM International: West Conshohocken, PA, USA, 2017. Available online: www.astm.org (accessed on 30 June 2020).

- ASTM D5199-12; Standard Test Method for Measuring the Nominal Thickness of Geosynthetics. ASTM International,: West Conshohocken, PA, USA, 2019. Available online: www.astm.org (accessed on 15 April 2020).

- Shukla, R.P.; Parihar, N.S.; Gupta, A.K. The effect of geotextile on low plastic sandy clay. In Proceedings of the 6th Asian Regional Conference on Geosynthetics—Geosynthetics for Infrastructure Development, New Delhi, India, 8–11 November 2016; pp. 251–259. [Google Scholar]

- Rehman, Z.U.; Zhang, G. Shear coupling effect of monotonic and cyclic behavior of the interface between steel and gravel. Can. Geotech. J. 2019, 56, 876–884. [Google Scholar] [CrossRef]

- ASTM D 5321-12; Standard Test Method for Determining the Shear Strength of Soil-Geosynthetic and Geosynthetic-Geosynthetic Interfaces by Direct Shear. ASTM International: West Conshohocken, PA, USA, 2017. Available online: www.astm.org (accessed on 15 May 2020).

| Property | Type/Value | ||

|---|---|---|---|

| Soil1 | Soil2 | Soil3 | |

| Effective Size, D10 (mm) | 0.09 | 0.16 | 0.17 |

| D50(mm) | 0.19 | 0.26 | 0.75 |

| D85 (mm) | 0.33 | 0.40 | 1.24 |

| Coefficient of uniformity, Cu | 2.67 | 1.75 | 2.94 |

| Coefficient of Curvature, Cc | 1.04 | 0.98 | 1.36 |

| Friction angle, ϕ (deg) | 34.4 | 37.2 | 42.9 |

| Specific Gravity, Gs | 2.67 | 2.67 | 2.66 |

| Maximum index density,γdmax (kN/m3) | 15.95 | 16.03 | 17.69 |

| emin | 0.63 | 0.64 | 0.47 |

| emax | 0.96 | 0.93 | 0.73 |

| Soil classification (USCS) | *SP | *SP | *SP |

| Material | Polymer | Mass/Unit Area | Thickness | Effective Opening Size | Ultimate Tensile Strength | Axial Strain at Failure |

|---|---|---|---|---|---|---|

| g/m2 | mm | mm | KN/m | % | ||

| GW1 | PP | 310 | 0.425 | 76.2 | 8.0 | |

| GW2 | PP | 190 | 0.20 | 24.0 | 6.8 | |

| GW3 | PET | 295 | 1.2 | 0.45 | 103.8 | 15.7 |

| NW | PET | 150 | 0.4 | -- | 3.3 | 42.5 |

| Interface Type | Interface Friction Angle, δ (°) | Interface Friction Coefficient (tanδ) | Interface Efficiency, Eϕ (tanδ/tanϕ) |

|---|---|---|---|

| Soil1-Soil1 | 34.4 | ||

| Soil1-GW1 | 31.7 | 0.618 | 0.90 |

| Soil1-GW2 | 31.0 | 0.601 | 0.88 |

| Soil1-GW3 | 32.9 | 0.647 | 0.94 |

| Soil1-NW | 33.5 | 0.662 | 0.97 |

| Soil2-Soil2 | 37.2 | ||

| Soil2-GW1 | 34.7 | 0.692 | 0.91 |

| Soil2-GW2 | 29.2 | 0.559 | 0.74 |

| Soil2-GW3 | 35.3 | 0.708 | 0.93 |

| Soil2-NW | 36.0 | 0.727 | 0.96 |

| Soil3-Soil3 | 42.9 | ||

| Soil3-GW1 | 35.5 | 0.713 | 0.77 |

| Soil3-GW2 | 32.6 | 0.640 | 0.69 |

| Soil3-GW3 | 37.2 | 0.759 | 0.82 |

| Soil3-NW | 38.3 | 0.790 | 0.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizwan, M.; Mujtaba, H.; Farooq, K.; Rehman, Z.U.; Ashiq, S.Z.; Kazmi, S.M.S.; Munir, M.J. Laboratory Investigation of Sand-Geosynthetic Interface Friction Parameters Using Cost-Effective Vertical Pullout Apparatus. Fibers 2022, 10, 84. https://doi.org/10.3390/fib10100084

Rizwan M, Mujtaba H, Farooq K, Rehman ZU, Ashiq SZ, Kazmi SMS, Munir MJ. Laboratory Investigation of Sand-Geosynthetic Interface Friction Parameters Using Cost-Effective Vertical Pullout Apparatus. Fibers. 2022; 10(10):84. https://doi.org/10.3390/fib10100084

Chicago/Turabian StyleRizwan, Malik, Hassan Mujtaba, Khalid Farooq, Zia Ur Rehman, Syed Zishan Ashiq, Syed Minhaj Saleem Kazmi, and Muhammad Junaid Munir. 2022. "Laboratory Investigation of Sand-Geosynthetic Interface Friction Parameters Using Cost-Effective Vertical Pullout Apparatus" Fibers 10, no. 10: 84. https://doi.org/10.3390/fib10100084

APA StyleRizwan, M., Mujtaba, H., Farooq, K., Rehman, Z. U., Ashiq, S. Z., Kazmi, S. M. S., & Munir, M. J. (2022). Laboratory Investigation of Sand-Geosynthetic Interface Friction Parameters Using Cost-Effective Vertical Pullout Apparatus. Fibers, 10(10), 84. https://doi.org/10.3390/fib10100084