Coconut-Fiber Composite Concrete: Assessment of Mechanical Performance and Environmental Benefits

Abstract

1. Introduction

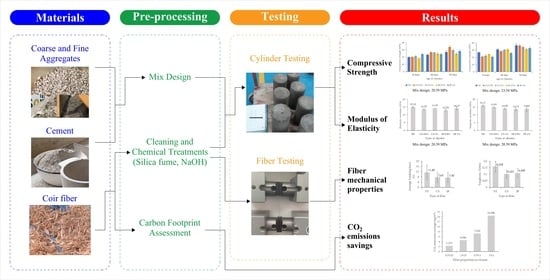

2. Materials and Methods

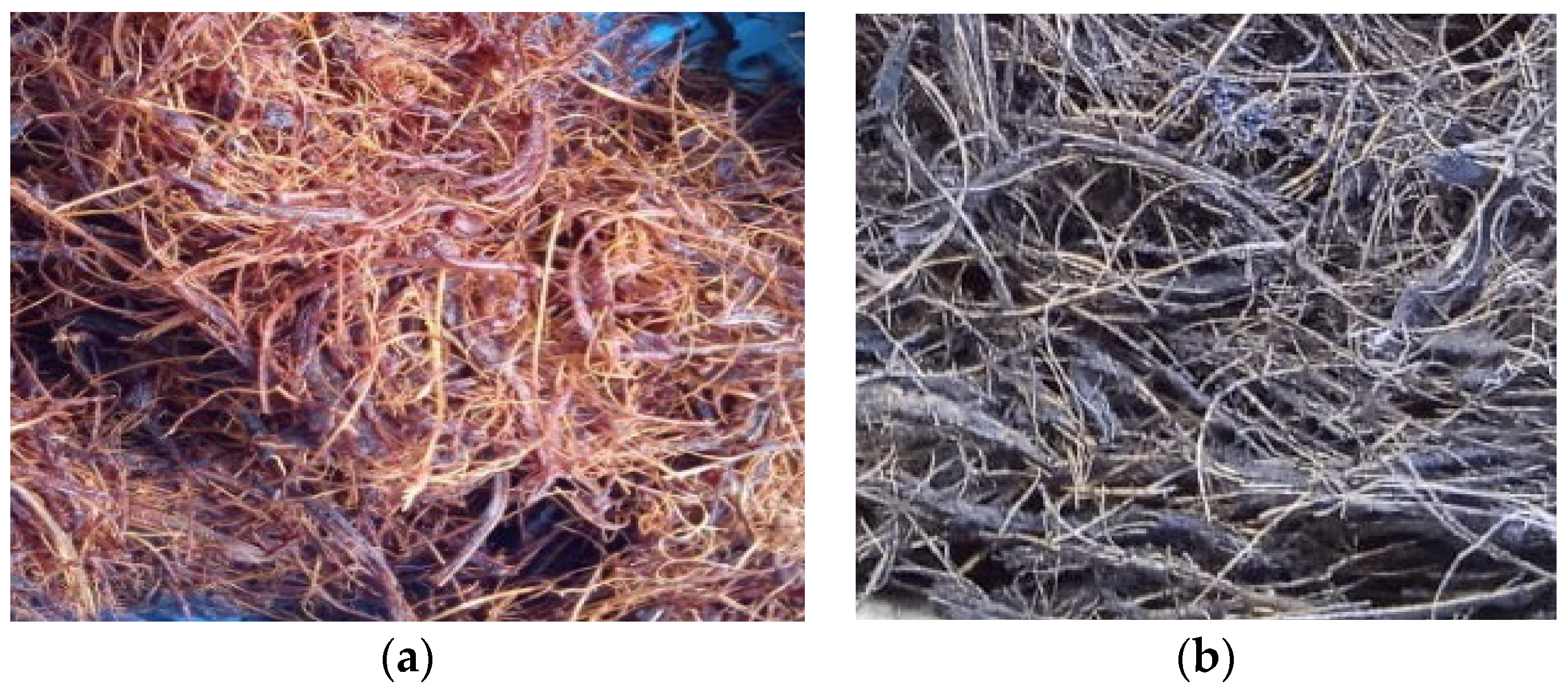

2.1. Materials

2.2. Specimen Preparation and Testing

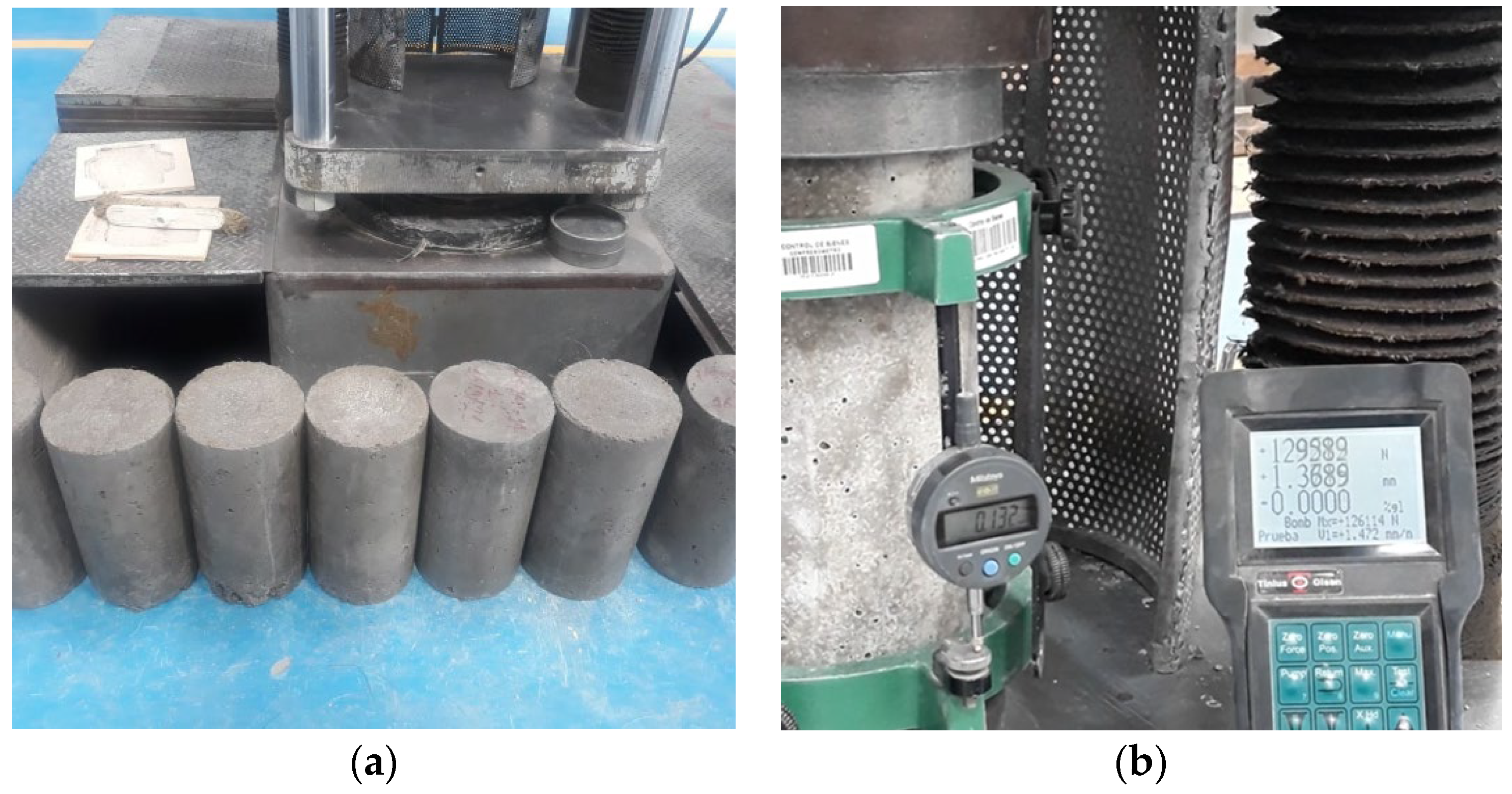

2.3. Determination of Compressive Strength and Modulus of Elasticity

2.4. Carbon-Footprint Determination

3. Results and Discussion

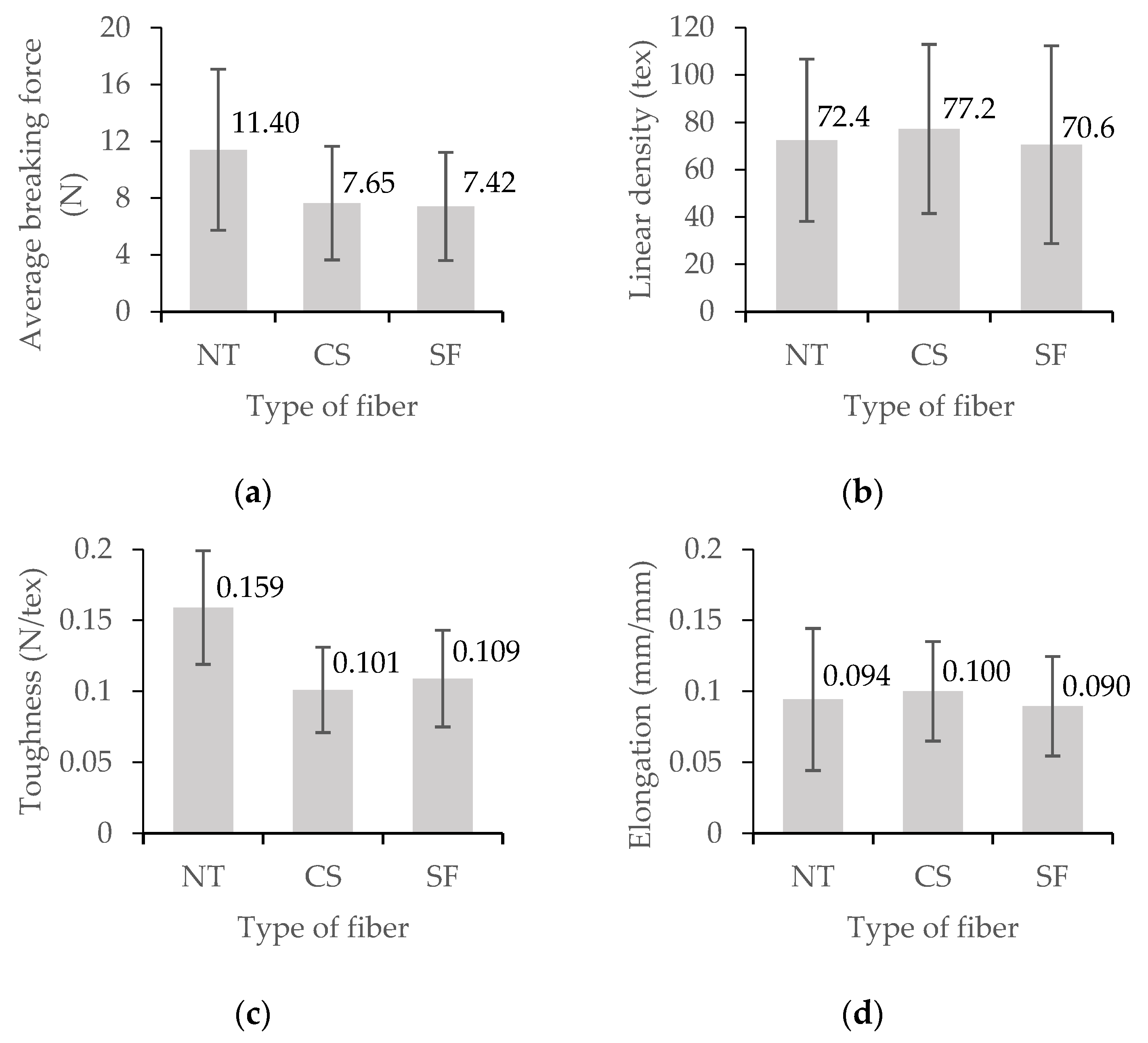

3.1. Physical and Mechanical Characteristics of the Fiber

3.2. Composite Concrete Density

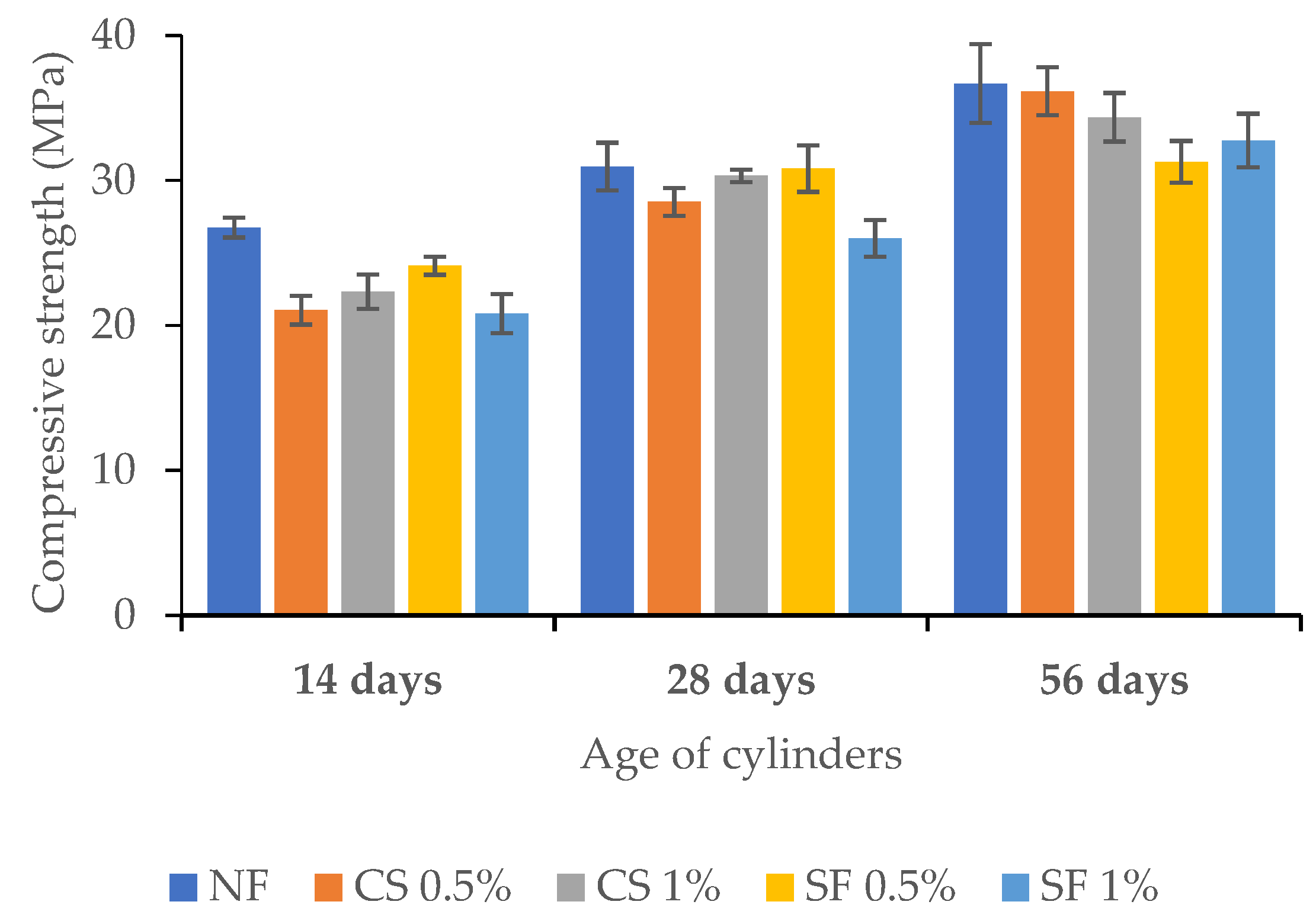

3.3. Compressive Strength

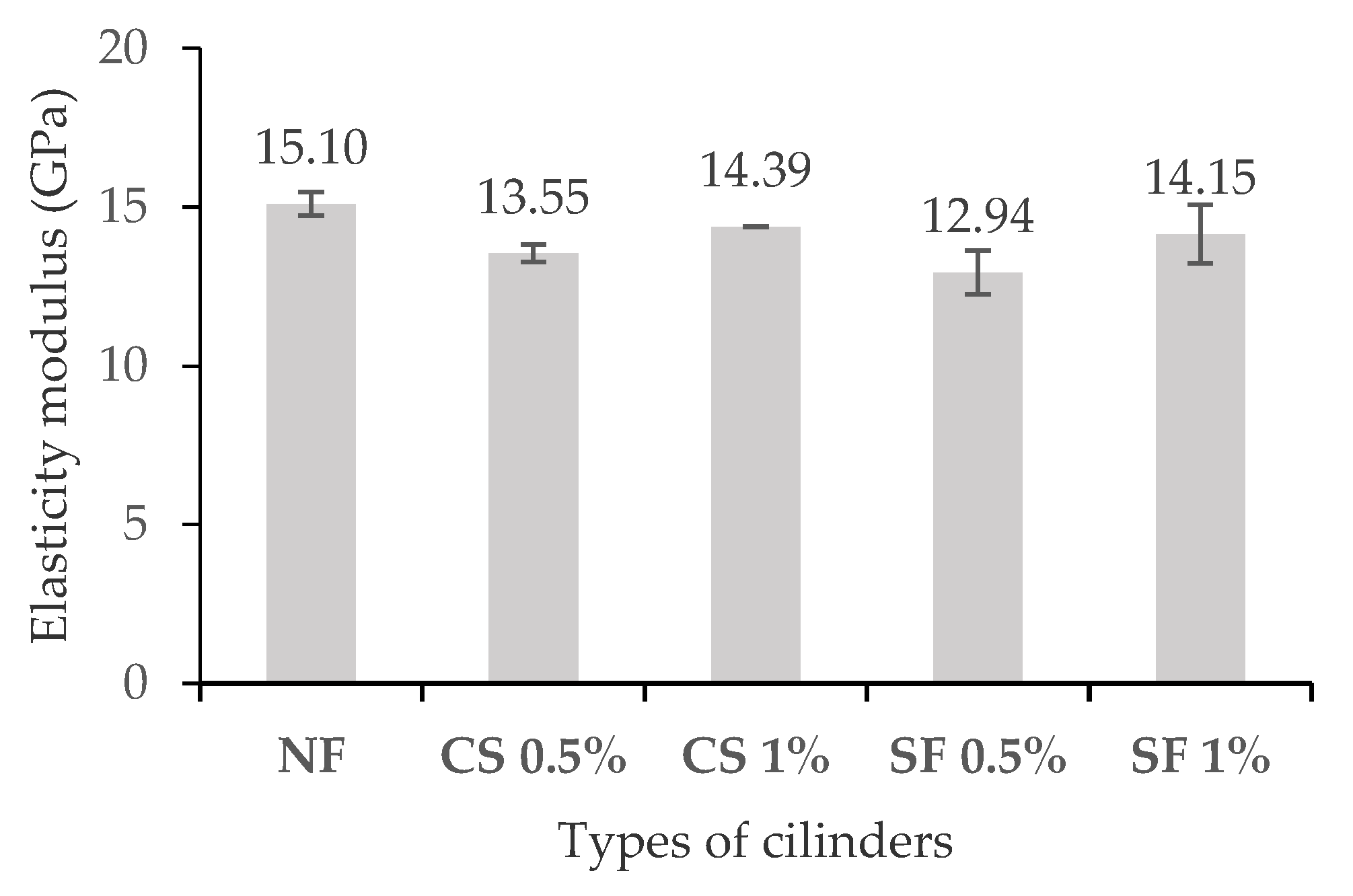

3.4. Modulus of Elasticity

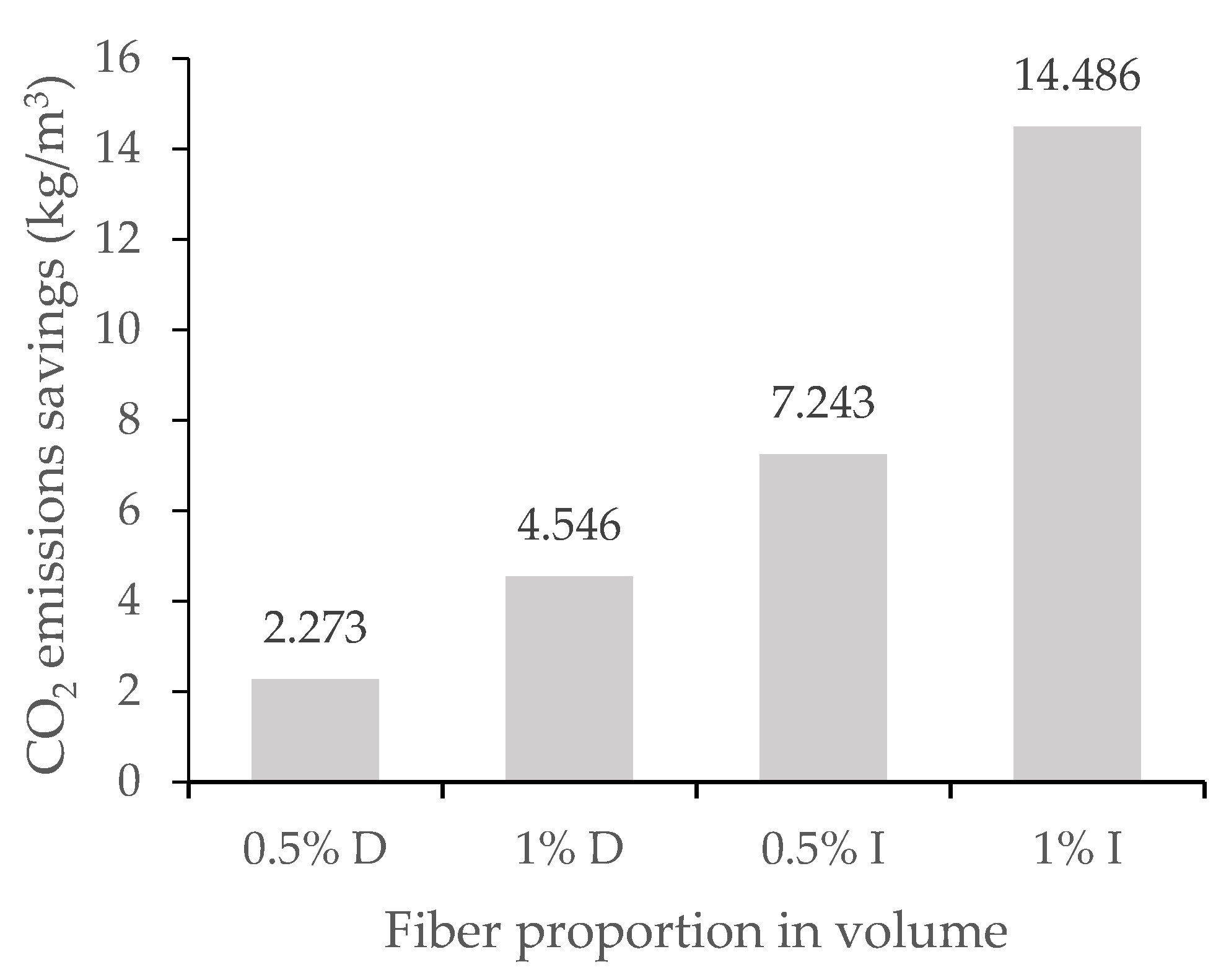

3.5. CO2-Emission Savings

4. Conclusions

- The best results were obtained for concrete cylinders made with a design strength of 20.59 MPa, including a 0.5% volume fraction of NaOH-treated fibers, which slightly exceeded that of fiber-free concrete. Mostly, increasing the fiber volume fraction and design compressive strength led to a major disadvantage in compressive strength and modulus of elasticity of composite concrete, compared with fiber-free concrete.

- Concrete density was not significantly affected by the volume fractions used in this research. More coconut fiber would be needed in the concrete mix to achieve lower densities.

- The mechanic properties of the fibers were similar among the CS and SF fibers. We observed a reduction in their features compared with the NT fibers, except for elongation and linear density, for which CS fibers achieved better performance.

- In all cases, the dosages of composite concrete with fibers exceeded the expected compressive strengths of 20.59 and 23.54 MPa, demonstrating the feasibility of adding 0.5% and 1% fibers and maintaining admissible mechanical properties.

- Emission savings of up to 4.54 kg CO2 were observed, considering only the contribution of the fibers and up to 14.49 kg CO2 per cubic meter of concrete, considering the non-incineration of all components of the original husk, with the addition of 1% of fibers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Readily implementable techniques can cut annual CO2 emissions from the production of concrete by over 20%. Environ. Res. Lett. 2016, 11, 074029. [Google Scholar] [CrossRef]

- Koo, B.M.; Kim, J.H.J.; Kim, S.B.; Mun, S. Material and Structural Performance Evaluations of Hwangtoh Admixtures and Recycled PET Fiber-Added Eco-Friendly Concrete for CO2 Emission Reduction. Materials 2014, 7, 5959–5981. [Google Scholar] [CrossRef] [PubMed]

- Bostanci, S.C.; Limbachiya, M.; Kew, H. Use of recycled aggregates for low carbon and cost effective concrete construction. J. Clean. Prod. 2018, 189, 176–196. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Abutaha, F.; Alqedra, M.A.; Nayaka, R.R. Assessment on engineering properties and CO2 emissions of recycled aggregate concrete incorporating waste products as supplements to Portland cement. J. Clean. Prod. 2018, 203, 822–835. [Google Scholar] [CrossRef]

- Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Carbon dioxide sequestration of fly ash alkaline-based mortars containing recycled aggregates and reinforced by hemp fibers: Mechanical properties and numerical simulation with a finite element method. Carbon Dioxide Sequestration Cem. Constr. Mater. 2018, 373–391. [Google Scholar]

- Sai, P.P.; Murali, K.; Purnachandra Sai, P.; Murali, K.; Sravan Kumar, G. Study on Properties of Natural Fibre Reinforced Concrete Made with Coconut Shells and Coir Fibre. Artic. Int. J. Civ. Eng. Technol. 2018, 9, 416–422. [Google Scholar]

- Zhou, C.; Shi, S.Q.; Chen, Z.; Cai, L.; Smith, L. Comparative environmental life cycle assessment of fiber reinforced cement panel between kenaf and glass fibers. J. Clean. Prod. 2018, 200, 196–204. [Google Scholar] [CrossRef]

- Sera, E.E.; Robles-Austriaco, L.; Pama, R.P. Natural Fibers as Reinforcement. J. Ferrocem. 1990, 20, 109–124. [Google Scholar]

- Vilela, J. Sensibilización Sobre La Importancia Del Manejo De Desechos De Estopa De Cocotero Frente Al Cambio Climático. Caso De Estudio Manglar De La Remacam, En Las Comunidades Pampanal De Bolívar Y Tambillo. Periodo 2015–2019. Master’s Thesis, FLACSO Ecuador, Quito, Ecuador, 2020. [Google Scholar]

- Obeng, G.Y.; Amoah, D.Y.; Opoku, R.; Sekyere, C.K.K.; Adjei, E.A.; Mensah, E. Coconut Wastes as Bioresource for Sustainable Energy: Quantifying Wastes, Calorific Values and Emissions in Ghana. Energies 2020, 13, 2178. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G. Natural Fiber Composites; CRC Press: Boca Raton, FL, USA, 2016; Volume 4, ISBN 9781482239010. [Google Scholar]

- da Silva, E.J.; Marques, M.L.; Velasco, F.G.; Fornari Junior, C.; Luzardo, F.M.; Tashima, M.M. A new treatment for coconut fibers to improve the properties of cement-based composites—Combined effect of natural latex/pozzolanic materials. Sustain. Mater. Technol. 2017, 12, 44–51. [Google Scholar] [CrossRef]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic treatment of natural fibers and their composites—A review. J. Ind. Text. 2016, 47, 2153–2183. [Google Scholar] [CrossRef]

- Sudhakaran Pillai, M.; Sivaraja, M.; Kandasamy, S. Effect of silica fume surface treatment on natural fibres in resisting chloride resistance in concrete. Mater. Sci. Res. India 2010, 7, 209–214. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Yousef, R.A.; Abduljabbar, H.A.; Sufian, M.; Alyousef, R.; et al. Effect of Coconut Fiber Length and Content on Properties of High Strength Concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef]

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- ASTM C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- ASTM C138/C138M; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM C566; Standard Test Method for Total Evaporable Moisture Content of Aggregate by Drying. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM C188; Standard Test Method for Density of Hydraulic Cement. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM C187; Standard Test Method for Amount of Water Required for Normal Consistency of Hydraulic Cement Paste. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- ACI 544.1R-96; (Reapproved 2009) State-of-the-art report on fiber reinforced concrete. American Concrete Institute: Farmington Hills, MI, USA, 1997.

- Karthikeyan, A.; Balamurugan, K.; Kalpana, A. The effect of sodium hydroxide treatment and fiber length on the tensile property of coir fiber-reinforced epoxy composites. Sci. Eng. Compos. Mater. 2014, 21, 315–321. [Google Scholar] [CrossRef]

- Vivek, S.S.; Prabalini, C. Experimental and microstructure study on coconut fibre reinforced self compacting concrete (CFRSCC). Asian J. Civ. Eng. 2020, 22, 111–123. [Google Scholar] [CrossRef]

- ASTM D2256; Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- ACI 211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1991; ISBN 9780870310171.

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- ASTM C469; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- Puentes, L.H.; Joya, E. Reconocimiento de Características, Obtención y Utilización de la Estopa de Coco; Artesanías De Colombia S.A.: Bogotá, Colombia, 2005; pp. 1–68. [Google Scholar]

- Puspaningrum, T.; Haris, Y.H.; Sailah, I.; Yani, M.; Indrasti, N.S. Physical and mechanical properties of binderless medium density fiberboard (MDF) from coconut fiber. IOP Conf. Ser. Earth Environ. Sci. 2020, 472, 1–9. [Google Scholar] [CrossRef]

- Encinas Soto, K.K. Determinación Del Mecanismo De Hidrólisis Ácida De Hemicelulosa De Cenchrus Ciliaris. Master’s Thesis, Universidad de Sonora, Hermosillo, Mexico, 2016. [Google Scholar]

- Monteiro, S.N.; Margem, F.M.; Guimarães Santafé Júnior, H.P.; de Souza Martins, L.B.; Oliveira, M.P. Correlation between the Diameter and the Density of Coir Fiber Using the Weibull Statistic Methodology. Mater. Sci. Forum 2014, 775–776, 266–271. [Google Scholar]

- Zhang, W.; Lilargem Rocha, D.; Urbano Durlo Tambara Júnior, L.; Teixeira Marvila, M.; Cristina Pereira, E.; Souza, D.; Rangel Garcez de Azevedo, A. A Review of the Use of Natural Fibers in Cement Composites: Concepts, Applications and Brazilian History. Polymers 2022, 14, 2043. [Google Scholar]

- MA Ismail, D. Compressive and Tensile Strength of Natural Fibre-reinforced Cement base Composites. Coll. Eng. Univ. Mosul 2007, 15, 42–51. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Huang, L.; Kasal, B. Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr. Build. Mater. 2016, 112, 168–182. [Google Scholar] [CrossRef]

- Ogunbode, E.B.; Egba, E.I.; Olaiju, O.A.; Elnafaty, A.S.; Kawywa, S.A. Microstructure and Mechanical Properties of Green Concrete Composites Containing Coir Fibre. Chem. Eng. Trans. 2017, 61, 1879–1884. [Google Scholar]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

| Ref. | Property | Unit | Coarse Aggregate | Fine Aggregate |

|---|---|---|---|---|

| [17] | Nominal maximum size | mm | 19.05 | - |

| [17] | Fineness modulus | - | - | 2.76 |

| [18,19] | Density (oven dried) | g/cm3 | 1.89 | 2.19 |

| [18,19] | Density (saturated surface dry) | g/cm3 | 2.35 | 2.23 |

| [18,19] | Absorption | % | 2.00 | 2.07 |

| [20] | Dry compacted density | g/cm3 | 1.49 | - |

| [21] | Moisture content | % | 2.72 | 2.66 |

| Ref. | Property | Unit | Value |

|---|---|---|---|

| [22] | Density | g/cm3 | 2.68 |

| [23] | Normal consistency (moisture) | % | 23 |

| Property | Unit | Value |

|---|---|---|

| Density (saturated surface dry) | g/cm3 | 0.582 |

| Absorption | % | 145.5 |

| Code | Design f’c (MPa) | Cement | Fine Aggregate/ Cement | Coarse Aggregate/ Cement | Water/ Cement |

|---|---|---|---|---|---|

| M1 | 20.59 | 1 | 2.07 | 1.66 | 0.57 |

| M2 | 23.54 | 1 | 1.77 | 1.36 | 0.50 |

| Component | C (%) | Mass in Husk (%) | C Husk (%) | Mass in Fiber (%) | C Fiber (%) |

|---|---|---|---|---|---|

| Pectin | 37.11 | 19.26 | 7.15 | 3.17 | 1.17 |

| Cellulose | 44.44 | 28.47 | 12.65 | 45.85 | 20.37 |

| Hemi-cellulose | 45.17 | 11.49 | 5.19 | 0.26 | 0.12 |

| Lignin | 63.4 | 39.5 | 25.04 | 48.38 | 30.67 |

| Total | 50.03 | 52.34 |

| Mixture | 14 Days | 28 Days | 56 Days |

|---|---|---|---|

| NF | 20.01 (0.69) | 23.26 (1.64) | 26.91 (2.71) |

| CS 0.5% | 20.09 (0.99) | 26.58 (0.96) | 34.15 (1.65) |

| CS 1% | 21.19 (1.19) | 26.38 (0.42) | 29.79 (1.68) |

| SF 0.5% | 18.49 (0.62) | 24.75 (1.60) | 24.60 (1.43) |

| SF 1% | 24.16 (1.35) | 24.19 (1.27) | 28.42 (1.85) |

| Mixture | 14 Days | 28 Days | 56 Days |

|---|---|---|---|

| NF | 26.75 (0.64) | 30.97 (1.52) | 36.69 (1.84) |

| CS 0.5% | 21.05 (2.98) | 28.52 (3.12) | 36.15 (1.81) |

| CS 1% | 22.32 (1.06) | 30.32 (1.11) | 34.36 (2.30) |

| SF 0.5% | 24.11 (0.96) | 30.82 (0.95) | 31.29 (3.49) |

| SF 1% | 20.82 (1.31) | 26.01 (1.38) | 32.75 (2.24) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vélez, E.; Rodríguez, R.; Yanchapanta Gómez, N.B.; Mora, E.D.; Hernández, L.; Albuja-Sánchez, J.; Calvo, M.I. Coconut-Fiber Composite Concrete: Assessment of Mechanical Performance and Environmental Benefits. Fibers 2022, 10, 96. https://doi.org/10.3390/fib10110096

Vélez E, Rodríguez R, Yanchapanta Gómez NB, Mora ED, Hernández L, Albuja-Sánchez J, Calvo MI. Coconut-Fiber Composite Concrete: Assessment of Mechanical Performance and Environmental Benefits. Fibers. 2022; 10(11):96. https://doi.org/10.3390/fib10110096

Chicago/Turabian StyleVélez, Emilio, Ricardo Rodríguez, Nicolay Bernardo Yanchapanta Gómez, Edgar David Mora, Luis Hernández, Jorge Albuja-Sánchez, and María Inés Calvo. 2022. "Coconut-Fiber Composite Concrete: Assessment of Mechanical Performance and Environmental Benefits" Fibers 10, no. 11: 96. https://doi.org/10.3390/fib10110096

APA StyleVélez, E., Rodríguez, R., Yanchapanta Gómez, N. B., Mora, E. D., Hernández, L., Albuja-Sánchez, J., & Calvo, M. I. (2022). Coconut-Fiber Composite Concrete: Assessment of Mechanical Performance and Environmental Benefits. Fibers, 10(11), 96. https://doi.org/10.3390/fib10110096