Investigating the Mechanical Performance on Static and Shock Wave Loading of Aramid Fiber-Reinforced Concrete

Abstract

:1. Introduction

2. Materials

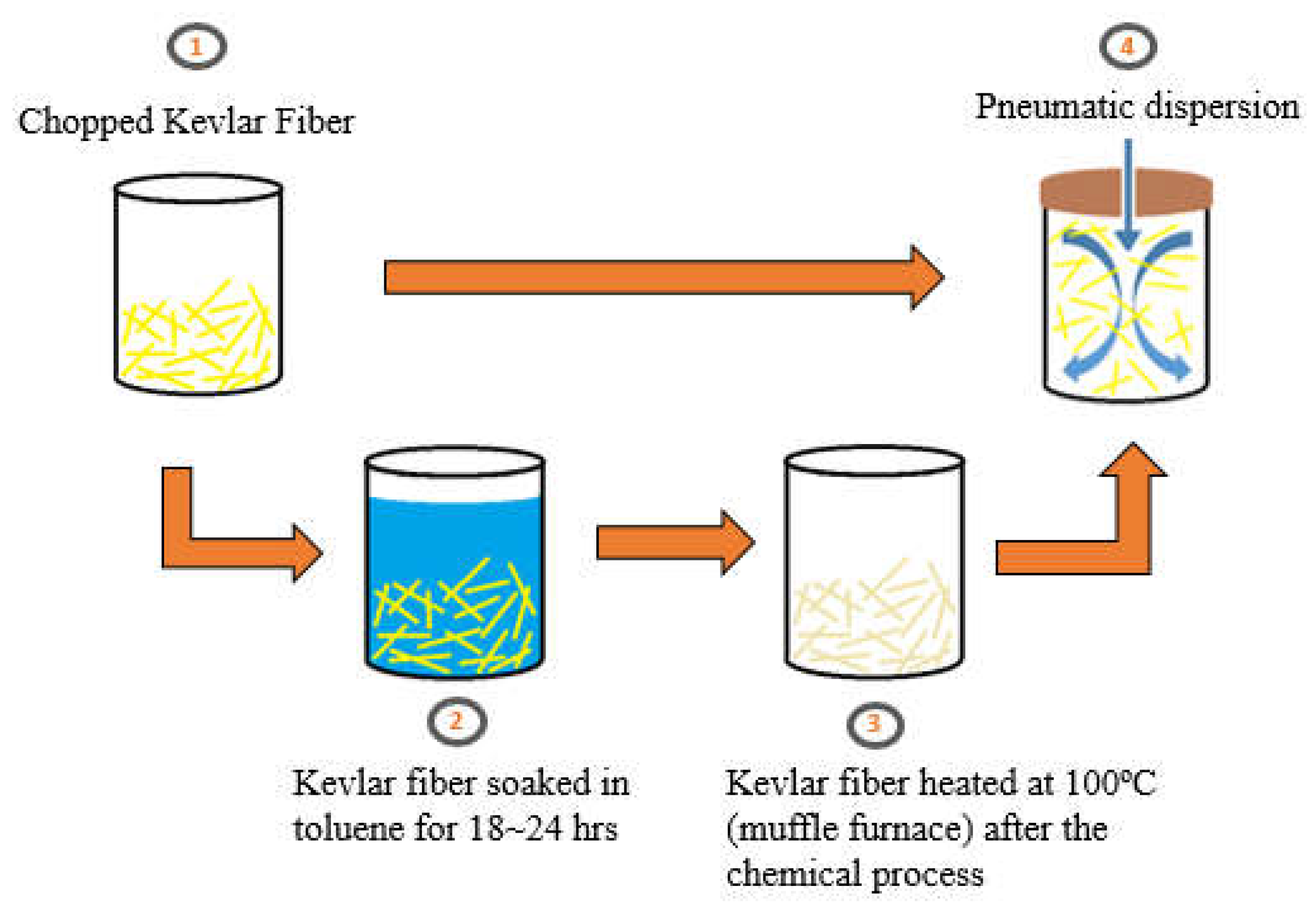

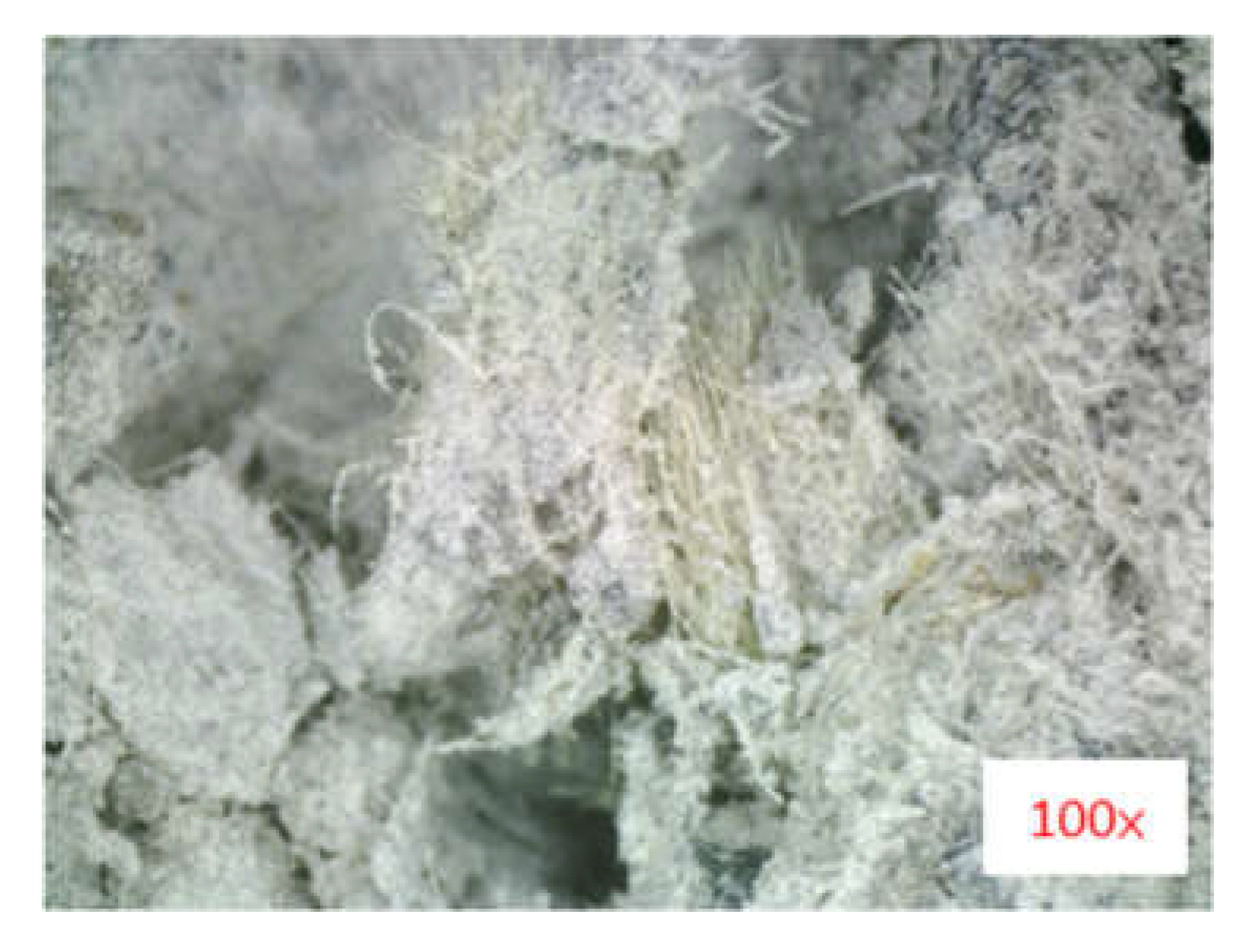

2.1. Kevlar Fiber (KF)

2.2. Cement and Aggregate

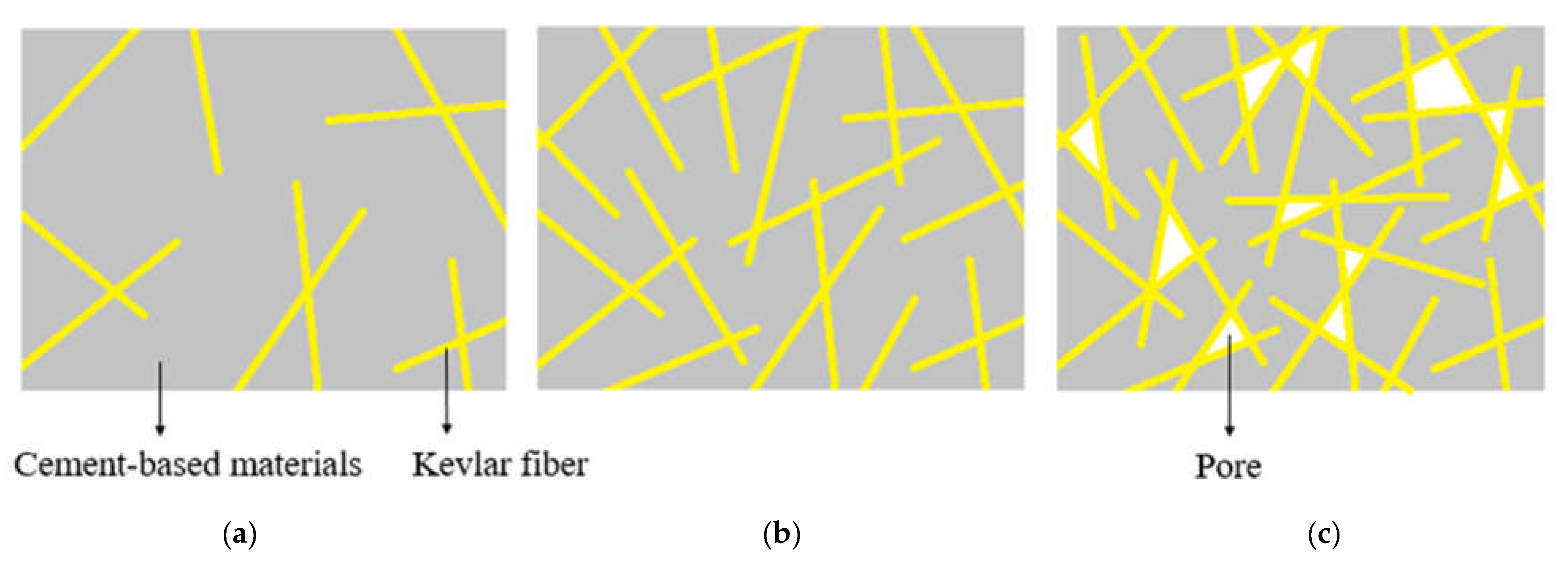

2.3. Kevlar Fiber-Reinforced Concrete (KFRC)

3. Experimental Methods

3.1. Slump Test

3.2. Compressive Test

3.3. Three-Point Bending Test

3.4. Impact Test

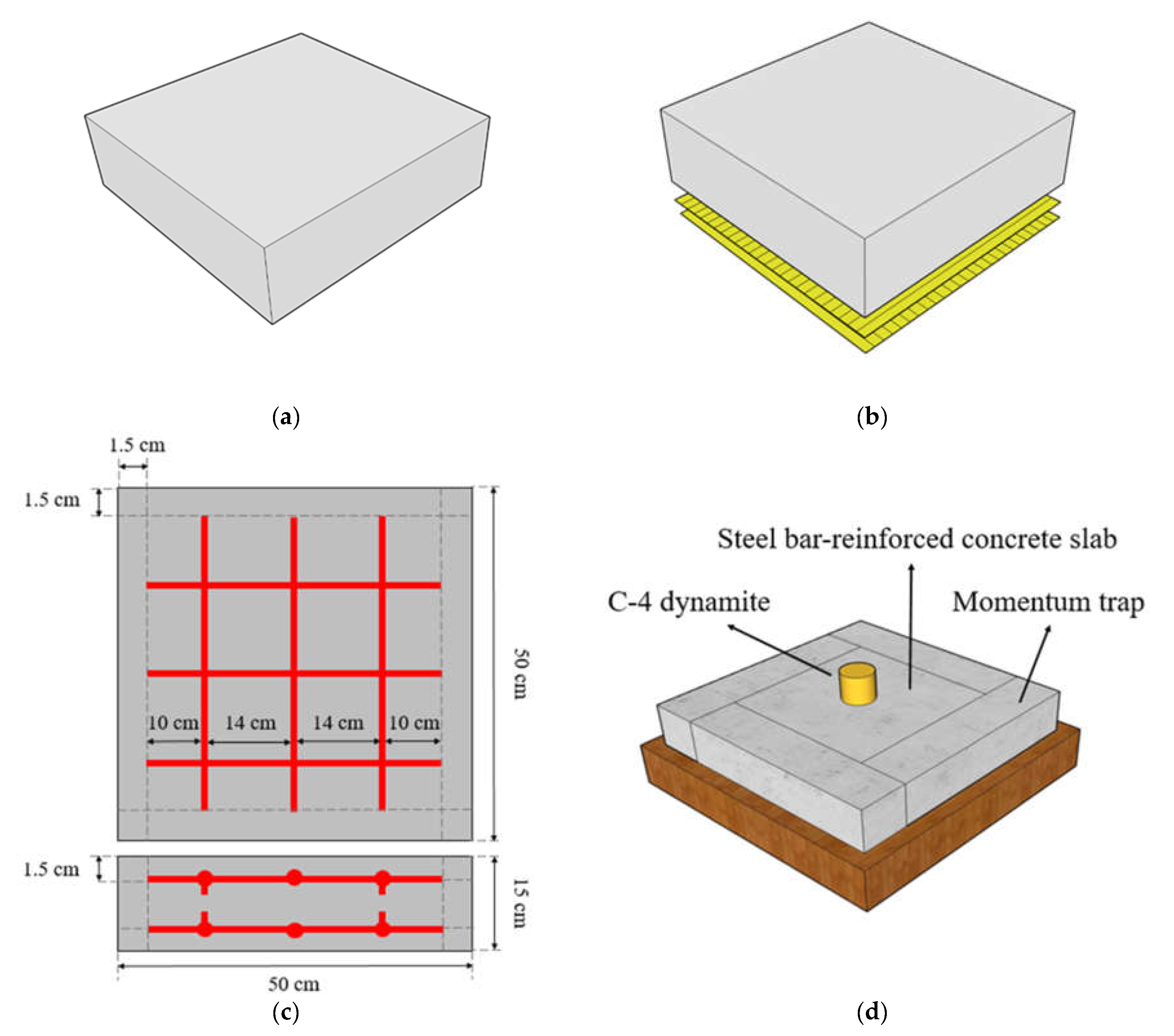

3.5. Shock Wave Test

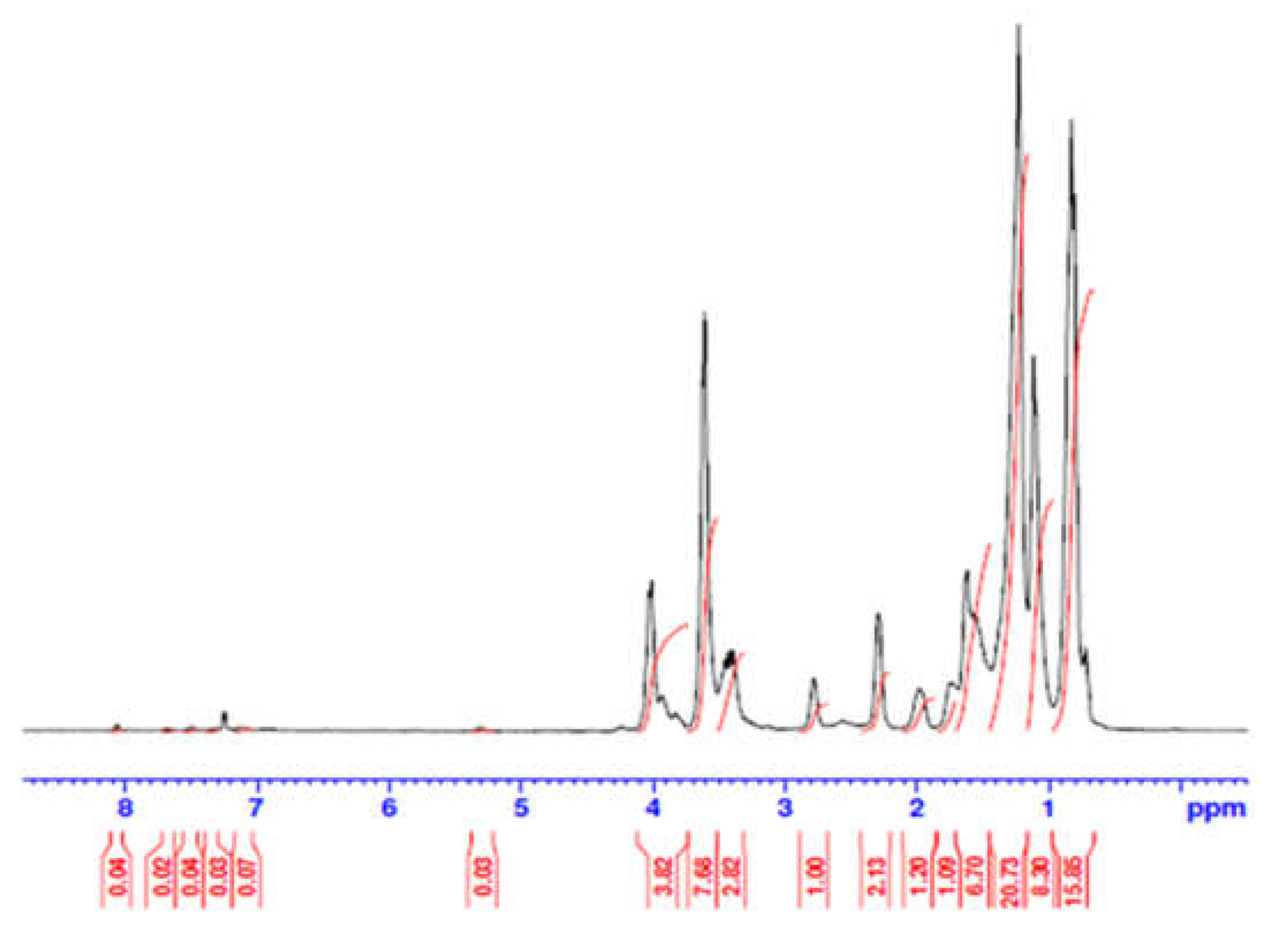

3.6. NMR Spectroscopy Analysis

4. Results and Discussions

4.1. Slump Test Results

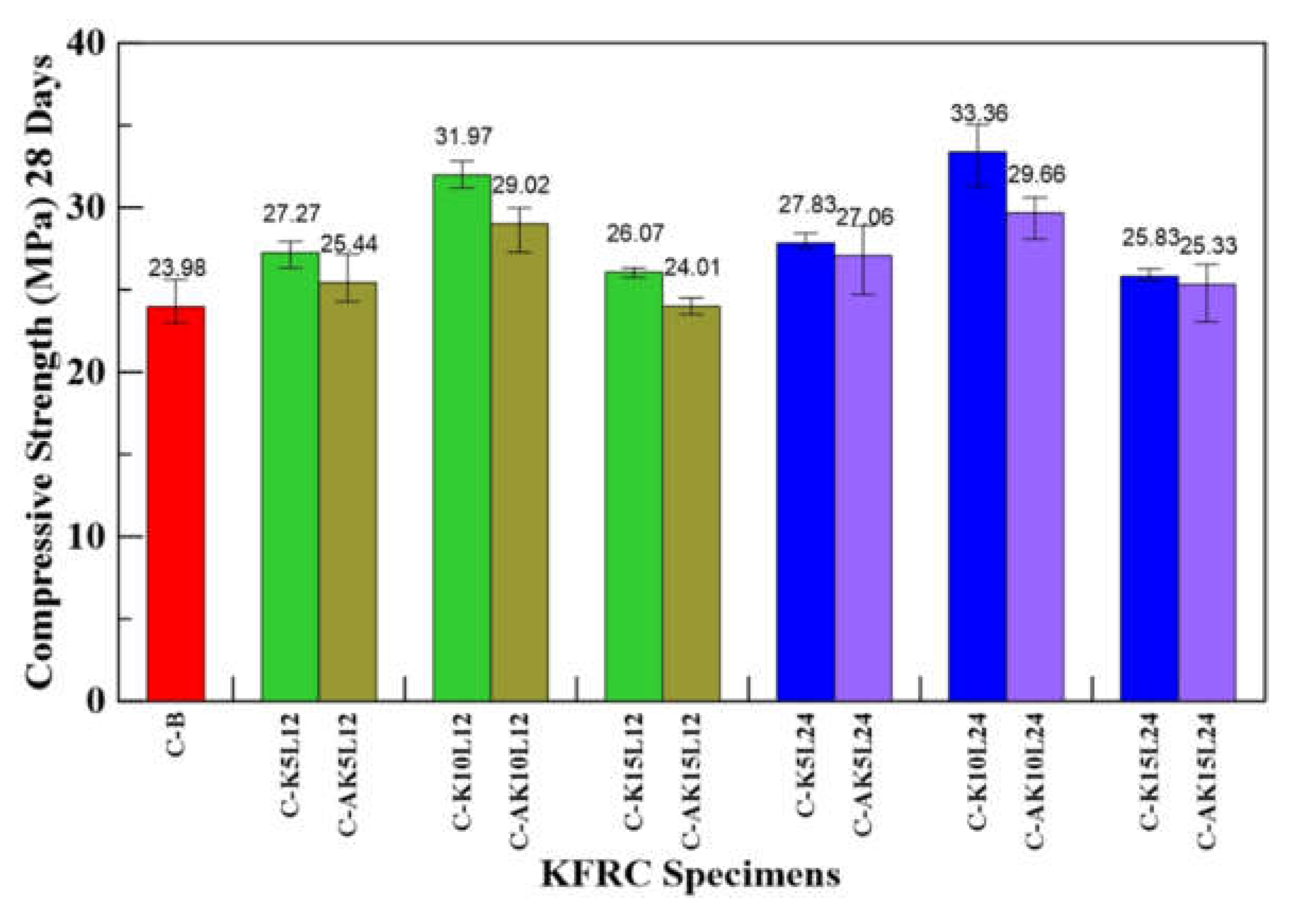

4.2. Compression Test Results

4.2.1. Single-Length KFRC

4.2.2. Mix-Proportion KFRC

4.3. Three-Point Bending Test Results

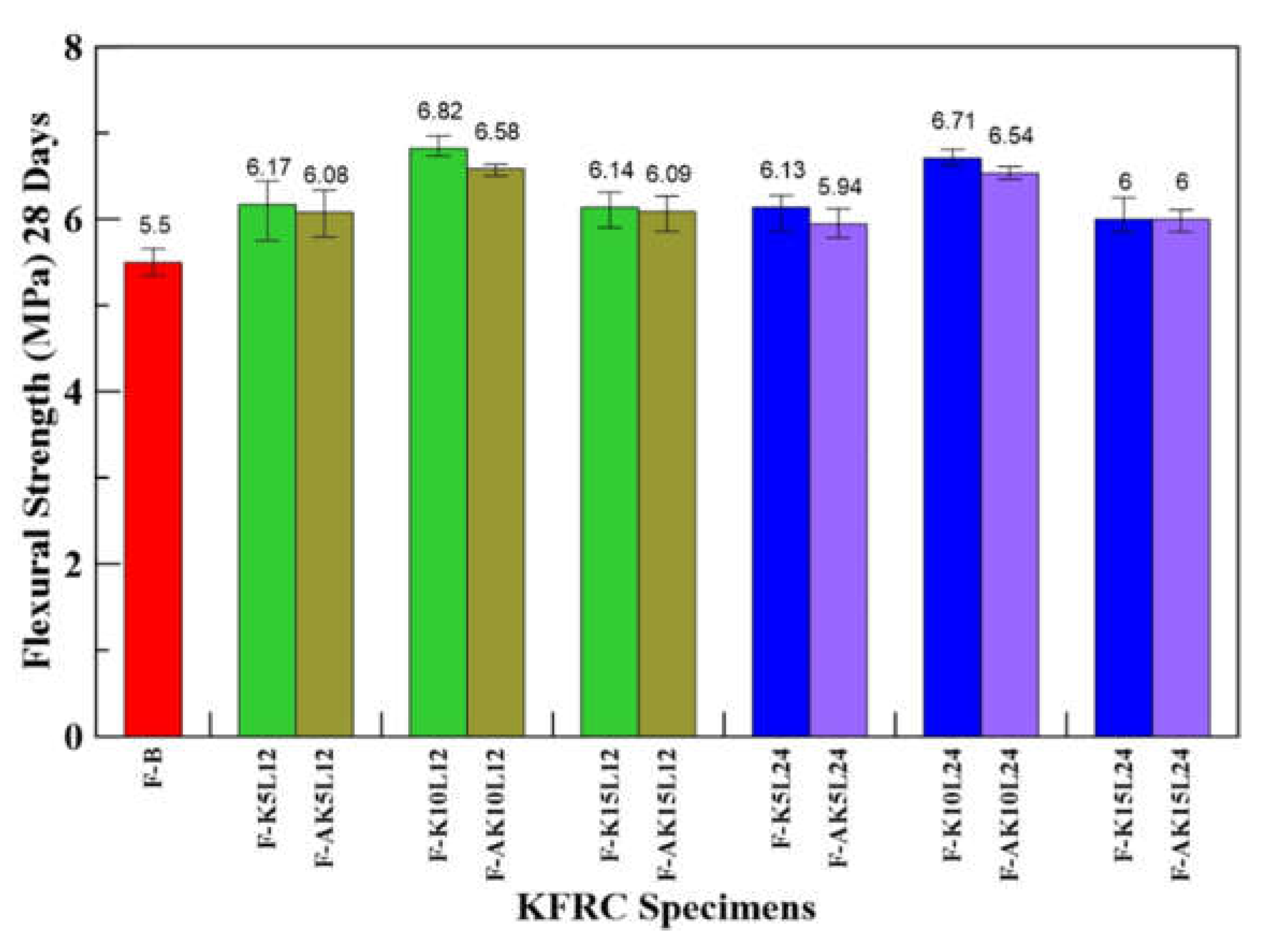

4.3.1. Single-Length KFRC

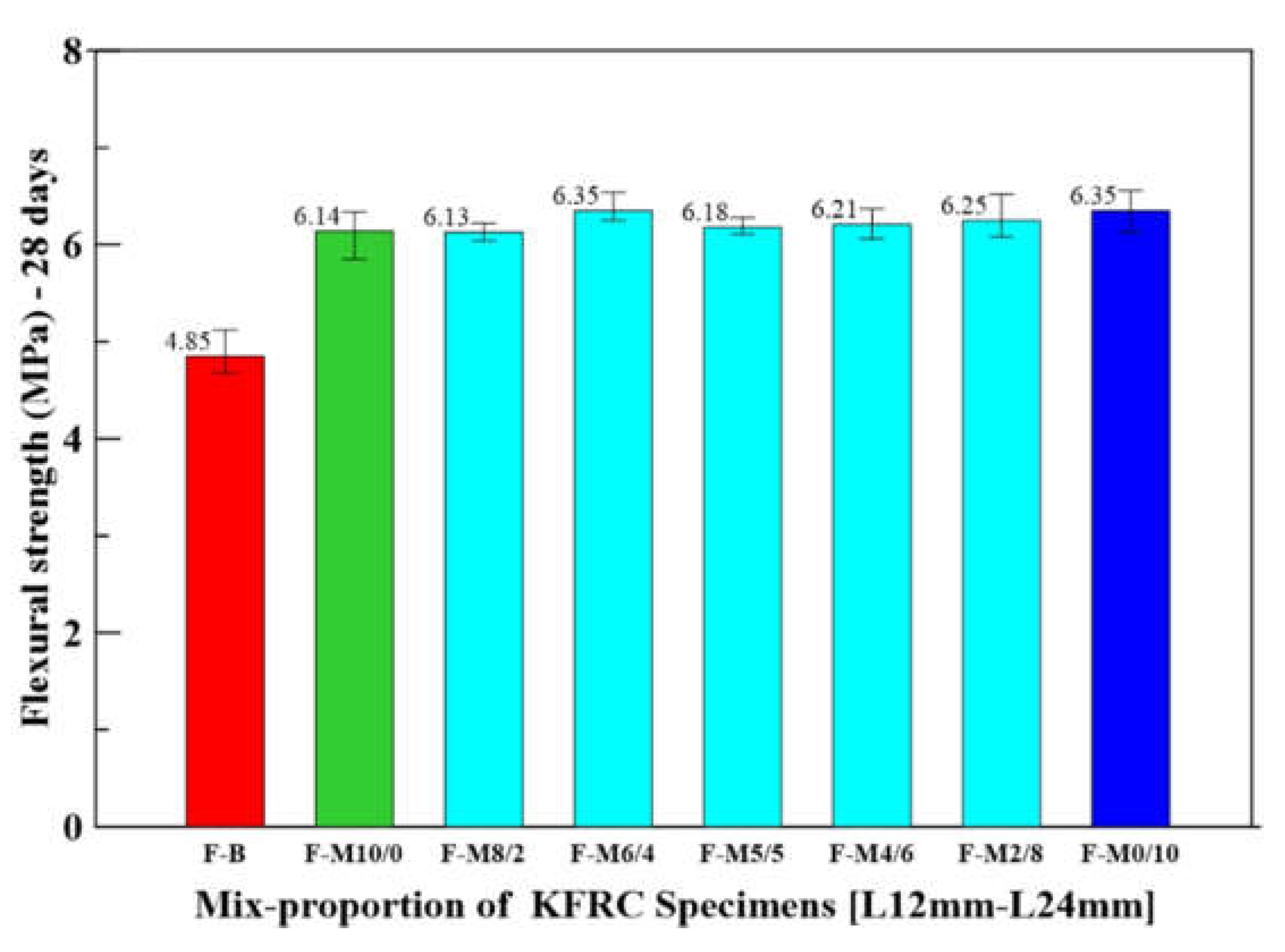

4.3.2. Mix-Proportion KFRC

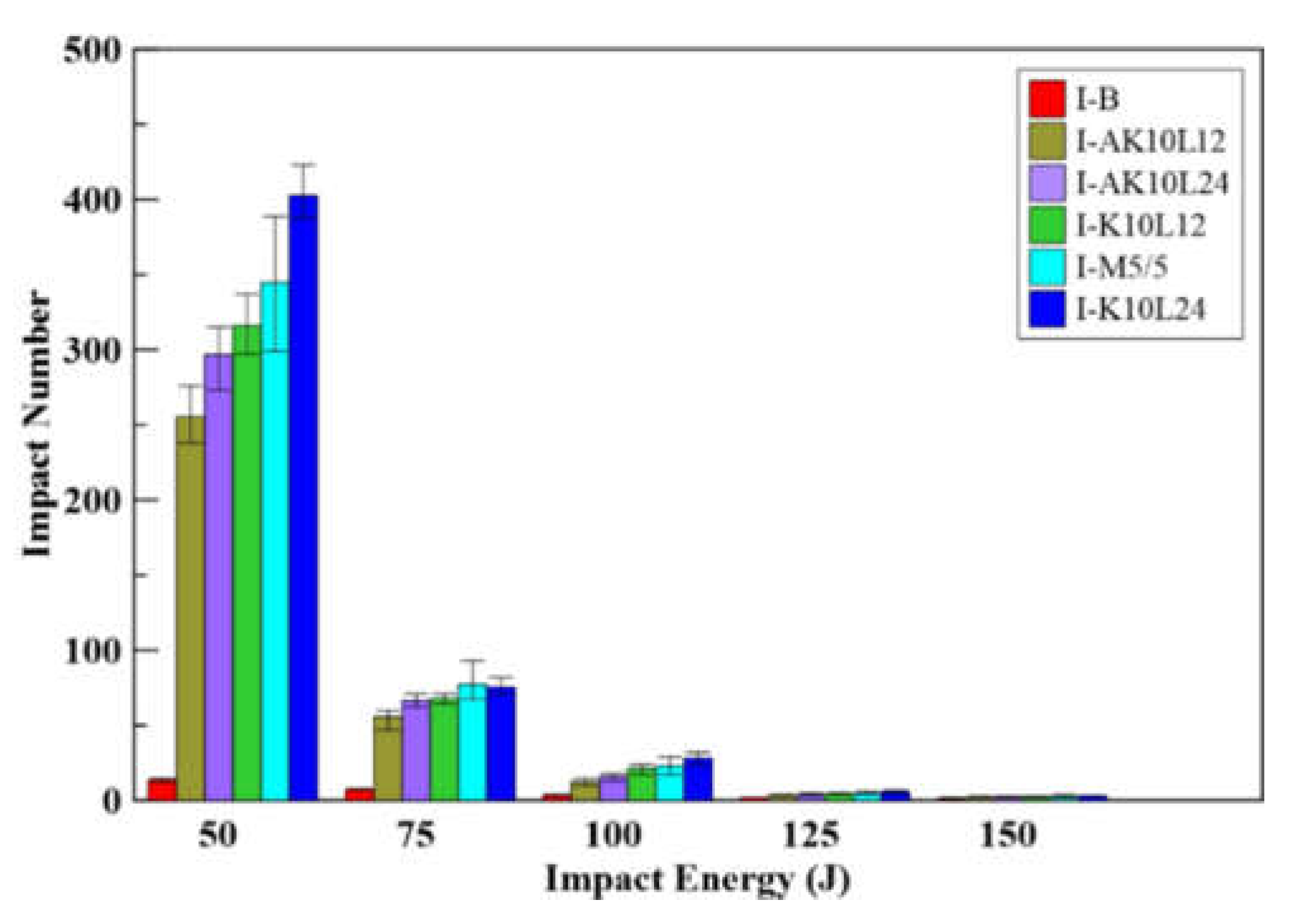

4.4. Impact Test Results

4.5. Shock Wave Explosion Test Validation

5. Conclusions

- Evidence that 10‰ KF was the more optimal weight ratio than 5‰ and 15‰ KF can be found in the static mechanical test results, as it produced higher increments in both compressive strength and flexural strength. Moreover, this finding was evident in all combinations (fiber lengths and types).

- Mix-proportion KFRC specimens did not exhibit enhanced effects on the compressive and flexural strength when compared with single-length KFRC specimens; however, within the mix-proportion KFRC test group, the static mechanical strength increased, as the ratio of longer-piece fiber increased.

- KF could improve the impact resistance of concrete, and KFRC specimens with single-length 24 mm KF content demonstrated the strongest impact resistance.

- The explosion damage of the KFRC slabs was less than that in benchmark RC slabs, as seen in the external damage evaluation. The external damage evaluation provides a clearer understanding that the explosion damage of the KFRC slabs was less than that in benchmark RC slabs. Therefore, KFRC can effectively enhance the shock wave resistance; in addition, attaching KFRP to the rear side of the slab could prevent the development of spalling on KFRC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Dong, H. Preparation and performance analysis of polypropylene fiber-reinforced concrete composite. Asia-Pac. J. Chem. Eng. 2020, 15, e2445. [Google Scholar] [CrossRef]

- Singh, N.K.; Rai, B. Assessment of synergetic effect on microscopic and mechanical properties of steel-polypropylene hybrid fiber reinforced concrete. Struct. Concr. 2021, 22, 516–534. [Google Scholar] [CrossRef]

- Sdiri, A.; Kammoun, S.; Daoud, A. Numerical modeling of the interaction between reinforcement and concrete at early age—A comparison between glass fiber reinforced polymer and steel rebars. Struct. Concr. 2021, 22, 168–182. [Google Scholar] [CrossRef]

- Torrijos, M.C.; Giaccio, G.; Zerbino, R. Glass macrofiber self-compacting concrete: Fiber distribution and mechanical properties in thin walls and slabs. Struct. Concr. 2019, 20, 798–807. [Google Scholar] [CrossRef]

- Hu, X.; Guo, Y.; Lv, J.; Mao, J. The mechanical properties and chloride resistance of concrete reinforced with hybrid polypropylene and basalt fibres. Materials 2019, 12, 2371. [Google Scholar] [CrossRef]

- Yang, L.; Xie, H.; Fang, S.; Huang, C.; Yang, A.; Chao, Y.J. Experimental study on mechanical properties and damage mechanism of basalt fiber reinforced concrete under uniaxial compression. Structures 2021, 31, 330–340. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Düzgün, O.A.; Gül, R.; Aydin, A.C. Effect of steel fibers on the mechanical properties of natural lightweight aggregate concrete. Mater. Lett. 2005, 59, 3357–3363. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Köksal, F.; Altun, F.; Yiğit, İ.; Şahin, Y. Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater. 2008, 22, 1874–1880. [Google Scholar] [CrossRef]

- Naraganti, S.R.; Pannem, R.M.R.; Putta, J. Impact resistance of hybrid fibre reinforced concrete containing sisal fibres. Ain Shams Eng. J. 2019, 10, 297–305. [Google Scholar] [CrossRef]

- Li, Y.-F.; Wang, H.-F.; Syu, J.-Y.; Kadagathur Ramanathan, G.; Tsai, Y.-K.; Lok, M.-H. mechanical properties of aramid/carbon hybrid fiber-reinforced concrete. Materials 2021, 14, 5881. [Google Scholar] [CrossRef]

- García, D.; Vegas, I.; Cacho, I. Mechanical recycling of GFRP waste as short-fiber reinforcements in microconcrete. Constr. Build. Mater. 2014, 64, 293–300. [Google Scholar] [CrossRef]

- Ail, B.; Qureshi, L.A.; Khan, S.U. Flexural behavior of glass fiber-reinforced recycled aggregate concrete and its impact on the cost and carbon footprint of concrete pavement. J. Clean. Prod. 2021, 262, 120820. [Google Scholar]

- Rodin III, H.; Nassiri, S.; Englund, K.; Fakron, O.; Li, H. Recycled glass fiber reinforced polymer composites incorporated in mortar for improved mechanical performance. Constr. Build. Mater. 2018, 187, 738–751. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R. The impact resistance and mechanical properties of reinforced self-compacting concrete with recycled glass fibre reinforced polymers. J. Clean. Prod. 2016, 124, 312–324. [Google Scholar] [CrossRef]

- Ogi, K.; Shinoda, T.; Makoto, M. Strength in concrete reinforced with recycled CFRP pieces. Compos. Part A Appl. Sci. Manuf. 2005, 36, 893–902. [Google Scholar] [CrossRef]

- Guo, Z.; Zhuang, C.; Li, Z.; Chen, Y. Mechanical properties of carbon fiber reinforced concrete (CFRC) after exposure to high temperatures. Compos. Struct. 2021, 256, 113072. [Google Scholar] [CrossRef]

- Xiong, C.; Li, Q.; Lan, T.; Li, H.; Long, W.; Xing, F. Sustainable use of recycled carbon fiber reinforced polymer and crumb rubber in concrete: Mechanical properties and ecological evaluation. J. Clean. Prod. 2021, 279, 123624. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. The impact resistance and mechanical properties of self-compacting concrete reinforced with recycled CFRP pieces. Compos. Part B Eng. 2016, 92, 360–376. [Google Scholar] [CrossRef]

- Nguyen, H.; Fujii, T.; Okubo, K.; Carvelli, V. Cement mortar reinforced with recycled carbon fiber and CFRP waste. In Proceedings of the ECCM17-17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Erdem, S.; Hanbay, S.; Blankson, M.A. Self-sensing damage assessment and image-based surface crack quantification of carbon nanofiber reinforced concrete. Constr. Build. Mater. 2017, 134, 520–529. [Google Scholar] [CrossRef]

- Safiuddin, M.; Yakhlaf, M.; Soudki, K.A. Key mechanical properties and microstructure of carbon fibre reinforced self-consolidating concrete. Constr. Build. Mater. 2018, 164, 477–488. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Zhang, C.; Wang, Y.; Yu, X.; Ou, J. Reinforcement effect and mechanism of carbon fibers to mechanical and electrically conductive properties of cement-based materials. Constr. Build. Mater. 2016, 125, 479–489. [Google Scholar] [CrossRef]

- De Souza Abreu, F.; Ribeiro, C.C.; Da Silva Pinto, J.D.; Nsumbu, T.M.; Buono, V.T.L. Influence of adding discontinuous and dispersed carbon fiber waste on concrete performance. J. Clean. Prod. 2020, 273, 122920. [Google Scholar] [CrossRef]

- Li, Y.-F.; Yang, T.-H.; Kuo, C.-Y.; Tsai, Y.-K. A Study on improving the mechanical performance of carbon-fiber-reinforced cement. Materials 2019, 12, 2715. [Google Scholar] [CrossRef]

- Li, Y.-F.; Lee, K.-F.; Kadagathur Ramanathan, G.; Cheng, T.-W.; Huang, C.-H.; Tsai, Y.-K. static and dynamic performances of chopped carbon-fiber-reinforced mortar and concrete incorporated with disparate lengths. Materials 2021, 14, 972. [Google Scholar] [CrossRef]

- Hambach, M.; Möller, H.; Neumann, T.; Volkmer, D. Portland cement paste with aligned carbon fibers exhibiting exceptionally high flexural strength (>100 MPa). Cem. Concr. Res. 2016, 89, 80–86. [Google Scholar] [CrossRef]

- Wang, C.; Li, K.-Z.; Li, H.-J.; Jiao, G.-S.; Lu, J.; Hou, D.-S. Effect of carbon fiber dispersion on the mechanical properties of carbon-fiber-reinforced cement-based composites. Mater. Sci. Eng. A 2008, 487, 52–57. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, J.; Ai, T.; Jiang, W.; Zhao, P. Quantitative evaluation of carbon fiber dispersion in cement based composites. Constr. Build. Mater. 2014, 68, 26–30. [Google Scholar] [CrossRef]

- Talikoti, R.S.; Kandekar, S.B. Strength and durability study of concrete structures using aramid-fiber-reinforced polymer. Fibers 2019, 7, 11. [Google Scholar] [CrossRef] [Green Version]

- Dhanesh, S.; Kumar, K.S.; Maruthur, P.; Rejumon, R.; Usmanasha, G.S. Experimental investigation of strength of Aramid kelvar and chopped carbon reinforced concrete beam. Mater. Today Proc. 2021, 45, 1269–1273. [Google Scholar] [CrossRef]

- Teijin. An Outstanding Para-Aramid Combining Unique Properties. Available online: https://www.teijinaramid.com/wp-content/uploads/2018/10/Product-brochure-Technora.pdf (accessed on 12 July 2022).

- ACI-544.1R-96; Report on Fiber Reinforced Concrete, Reported by ACI Committee 544. America Concrete Institute: Farmington Hills, MI, USA, 2002.

- Ozen, M.; Demircan, G.; Kisa, M.; Acikgoz, A.; Ceyhan, G.; Işıker, Y. Thermal properties of surface-modified nano-Al2O3/kevlar fiber/epoxy composites. Mater. Chem. Phys. 2022, 278, 125689. [Google Scholar] [CrossRef]

- DuPont. Kevlar® Aramid Fiber Technical Guide. Available online: https://www.dupont.com/content/dam/dupont/amer/us/en/safety/public/documents/en/Kevlar_Technical_Guide_0319.pdf (accessed on 12 July 2022).

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM: West Conshohocken, PA, USA, 2018.

- De Figueiredo, A.D.; Ceccato, M.R. Workability analysis of steel fiber reinforced concrete using slump and Ve-Be test. Mater. Res. 2015, 18, 1284–1290. [Google Scholar] [CrossRef]

- ASTM C143/C143M−20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM C39/C39M-01; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM C293/C293M-16; Standard Test Method for Flexural Strength of Concrete. ASTM: West Conshohocken, PA, USA, 2016.

- ACI 544.2R-89; Measurement of Properties of Fiber Reinforced Concrete. America Concrete Institute: Farmington Hills, MI, USA, 1999; pp. 6–7.

- Barreca, S.; Bruno, M.; Oddo, L.; Orecchio, S. Preliminary study on analysis and removal of wax from a Carrara marble statue. Nat. Prod. Res. 2019, 33, 947–955. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

| Fiber | Carbon Fiber | Aramid Fiber | E-Glass Fiber | Steel Fiber | Polypropylene Fiber |

|---|---|---|---|---|---|

| Property | |||||

| Density (g/cm3) | 1.73−1.91 | 1.39−1.45 | 2.48−2.76 | 7.5−8.0 | 0.9–0.91 |

| Tensile strength (MPa) | 3300−6000 | 2700−3600 | 1500−3000 | <2600 | 140−700 |

| Elastic modulus (GPa) | 230−550 | 60−145 | 70−80 | 140−200 | 3−9 |

| Elongation (%) | 0.7−2.1 | 2.3−4.5 | 1.8−3.0 | <15 | 15 |

| Material Property | Value |

|---|---|

| Density (g/cm3) | 1.44 |

| Tensile strength (MPa) | 2920 |

| Specific strength (MPa·cm3/g) | 2030 |

| Elastic modulus (GPa) | 70 |

| Elongation (%) | 3.6 |

| Sieve | Sieve Size (mm) | Weight Retained (g) | Percent Retained (%) | Cumulative Percent Retained (%) |

|---|---|---|---|---|

| 3/2” | 37.5 | 0 | 0 | 0 |

| 3/4” | 19 | 742.6 | 22.5 | 22.5 |

| 3/8” | 9.5 | 1507.1 | 45.67 | 68.17 |

| No. 4 | 4.75 | 14.8 | 0.45 | 68.62 |

| No. 8 | 2.36 | 187.9 | 5.69 | 74.32 |

| No. 16 | 1.18 | 270.3 | 8.19 | 82.51 |

| No. 30 | 0.60 | 207.6 | 6.29 | 88.80 |

| No. 50 | 0.30 | 172.7 | 5.23 | 94.03 |

| No. 100 | 0.15 | 99.4 | 3.01 | 97.04 |

| Pan | - | 97.6 | 2.96 | - |

| Total | - | 3300.0 | 100 | 596 |

| Fineness modulus (F.M.) = 5.96 | ||||

| Experiment | Weight Ratio(‰) | Number of KFRC Specimens | Number of Benchmarks | Total | ||||

|---|---|---|---|---|---|---|---|---|

| Original KF | Sizing-Removed KF | Mix-Proportion | ||||||

| 12 mm | 24 mm | 12 mm | 24 mm | |||||

| Compressive test | 5 | 3 | 3 | 3 | 3 | 21 | 3 | 60 |

| 10 | 3 | 3 | 3 | 3 | ||||

| 15 | 3 | 3 | 3 | 3 | ||||

| Flexural test | 5 | 3 | 3 | 3 | 3 | 21 | 3 | 60 |

| 10 | 3 | 3 | 3 | 3 | ||||

| 15 | 3 | 3 | 3 | 3 | ||||

| Impact loading test | 10 * | 20 | 20 | 20 | 20 | 20 | 20 | 120 |

| Shock wave loading test | 10 * | 2 | 1 | 3 | ||||

| Fiber-to-Cement Weight Ratio (‰) | 0 | 5 | 10 | 15 |

| Slump (mm) | 230 | 120 | 70 | 15 |

| Specimen 1 | Compressive Strength (MPa) | Increment (%) | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | Average | ||

| C-B | 22.99 | 23.31 | 25.62 | 23.98 | - |

| C-K5L12 | 26.34 | 27.51 | 27.94 | 27.27 | 13.7 |

| C-K10L12 | 31.17 | 31.91 | 32.82 | 31.97 | 33.3 |

| C-K15L12 | 25.75 | 26.14 | 26.34 | 26.07 | 8.7 |

| C-K5L24 | 27.48 | 27.57 | 28.43 | 27.83 | 16.1 |

| C-K10L24 | 31.28 | 33.76 | 35.05 | 33.36 | 39.1 |

| C-K15L24 | 25.58 | 25.63 | 26.28 | 25.83 | 7.7 |

| C-AK5L12 | 24.27 | 24.88 | 27.17 | 25.44 | 6.1 |

| C-AK10L12 | 27.28 | 29.78 | 29.99 | 29.02 | 21.0 |

| C-AK15L12 | 23.52 | 23.99 | 24.52 | 24.01 | 0.1 |

| C-AK5L24 | 24.7 | 27.6 | 28.89 | 27.06 | 12.8 |

| C-AK10L24 | 28.08 | 30.3 | 30.6 | 29.66 | 23.7 |

| C-AK15L24 | 23.06 | 26.4 | 26.54 | 25.33 | 5.6 |

| Specimen 1 | Benchmark | Mix-Proportion KFRC (L12 mm/L24 mm) | ||||||

|---|---|---|---|---|---|---|---|---|

| C-B | C-M10/0 | C-M8/2 | C-M6/4 | C-M5/5 | C-M4/6 | C-M2/8 | C-M0/10 | |

| Compressive strength (MPa) | 22.99 | 31.40 | 29.79 | 32.92 | 31.41 | 33.96 | 31.90 | 31.18 |

| 23.31 | 31.34 | 30.37 | 30.41 | 32.38 | 32.52 | 35.12 | 32.13 | |

| 25.62 | 30.93 | 29.85 | 29.23 | 32.37 | 30.42 | 33.04 | 32.88 | |

| Average compressive strength (MPa) | 23.98 | 31.22 | 30.00 | 30.85 | 32.05 | 32.30 | 33.35 | 32.06 |

| Increment (%) | - | 30 | 25 | 29 | 34 | 35 | 39 | 34 |

| Specimen | Flexural Strength (MPa) | Avg. Flexural Strength (MPa) | Increment (%) | ||

|---|---|---|---|---|---|

| F-B 1 | 5.12 | 4.76 | 4.68 | 4.85 | - |

| F-K5L12 | 5.75 | 6.31 | 6.44 | 6.17 | 27 |

| F-K10L12 | 6.73 | 6.76 | 6.97 | 6.82 | 41 |

| F-K15L12 | 5.9 | 6.19 | 6.31 | 6.14 | 27 |

| F-K5L24 | 5.87 | 6.26 | 6.28 | 6.13 | 26 |

| F-K10L24 | 6.62 | 6.69 | 6.81 | 6.71 | 38 |

| F-K15L24 | 5.85 | 5.9 | 6.25 | 6 | 24 |

| F-AK5L12 | 5.79 | 6.11 | 6.34 | 6.08 | 25 |

| F-AK10L12 | 6.5 | 6.61 | 6.64 | 6.58 | 36 |

| F-AK15L12 | 5.85 | 6.15 | 6.27 | 6.09 | 26 |

| F-AK5L24 | 5.78 | 5.93 | 6.12 | 5.94 | 23 |

| F-AK10L24 | 6.46 | 6.53 | 6.61 | 6.54 | 35 |

| F-AK15L24 | 6.03 | 6.11 | 5.85 | 6 | 24 |

| Specimen | Benchmark | KF Mix-Proportion (L12 mm/L24 mm) | ||||||

|---|---|---|---|---|---|---|---|---|

| F-B 1 | F-M10/0 | F-M8/2 | F-M6/4 | F-M5/5 | F-M4/6 | F-M2/8 | F-M0/10 | |

| Flexural strength (MPa) | 5.12 | 6.14 | 6.12 | 6.54 | 6.28 | 6.20 | 6.15 | 6.56 |

| 4.76 | 6.44 | 6.22 | 6.25 | 6.11 | 6.06 | 6.52 | 6.36 | |

| 4.68 | 5.95 | 6.04 | 6.26 | 6.15 | 6.37 | 6.08 | 6.13 | |

| Average flexural strength (MPa) | 4.85 | 6.24 | 6.13 | 6.35 | 6.18 | 6.21 | 6.25 | 6.35 |

| Increase percentage (%) | - | 29 | 26 | 31 | 27 | 28 | 29 | 31 |

| Specimen | Impact Energy (J) | Impact-Resistant Number | Increment (%) | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | Average | |||

| I-B 1 | 150 | 1 | 1 | 1 | 2 | 1.3 | - |

| 125 | 2 | 2 | 2 | 2 | 2.0 | - | |

| 100 | 3 | 4 | 4 | 4 | 3.8 | - | |

| 75 | 7 | 7 | 8 | 8 | 7.5 | - | |

| 50 | 12 | 14 | 14 | 15 | 13.8 | - | |

| I-AK10L12 1 | 150 | 2 | 2 | 2 | 3 | 2.3 | 80 |

| 125 | 3 | 3 | 4 | 4 | 3.5 | 75 | |

| 100 | 10 | 11 | 14 | 15 | 12.5 | 233 | |

| 75 | 47 | 56 | 59 | 60 | 55.5 | 640 | |

| 50 | 238 | 245 | 263 | 276 | 255.5 | 1758 | |

| I-AK10L24 1 | 150 | 2 | 2 | 3 | 3 | 2.5 | 100 |

| 125 | 3 | 4 | 4 | 5 | 4.0 | 100 | |

| 100 | 13 | 16 | 17 | 18 | 16.0 | 327 | |

| 75 | 62 | 66 | 67 | 71 | 66.5 | 787 | |

| 50 | 273 | 291 | 308 | 315 | 296.8 | 2058 | |

| I-K10L12 1 | 150 | 2 | 2 | 3 | 3 | 2.5 | 100 |

| 125 | 4 | 4 | 4 | 5 | 4.3 | 113 | |

| 100 | 17 | 21 | 22 | 24 | 21.0 | 460 | |

| 75 | 64 | 66 | 70 | 71 | 67.8 | 803 | |

| 50 | 297 | 312 | 318 | 337 | 316.0 | 2198 | |

| I-K10L24 1 | 150 | 3 | 3 | 3 | 3 | 3.0 | 140 |

| 125 | 5 | 5 | 6 | 7 | 5.8 | 188 | |

| 100 | 24 | 28 | 29 | 32 | 28.3 | 653 | |

| 75 | 71 | 72 | 77 | 82 | 75.5 | 907 | |

| 50 | 388 | 397 | 402 | 423 | 402.5 | 2827 | |

| I-M5/5 2 | 150 | 2 | 2 | 3 | 4 | 2.8 | 120 |

| 125 | 4 | 4 | 5 | 6 | 4.8 | 138 | |

| 100 | 17 | 22 | 24 | 29 | 23.0 | 513 | |

| 75 | 67 | 72 | 77 | 93 | 77.3 | 930 | |

| 50 | 299 | 334 | 356 | 389 | 344.5 | 2405 | |

| Specimen 1 | Slab Surface | Depth (cm) | Min. Diameter (cm) | Max. Diameter (cm) | Damaged Area (cm2) | Failure Type |

|---|---|---|---|---|---|---|

| SW-B | Front | - | 30 | 37 | 881 | Perforation and breaching |

| Rear | - | 34 | 47 | 1288 | ||

| SW-K10L24 | Front | - | 20 | 28 | 452 | Perforation and breaching |

| Rear | - | 25 | 40 | 830 | ||

| SW-K10L24-A | Front | 3.2 | 18 | 24 | 346 | Cratering |

| Rear (removing KFRP) | 5.6 | 20 | 37 | 638 | Spalling |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.-F.; Wang, H.-F.; Syu, J.-Y.; Ramanathan, G.K.; Tsai, Y.-K. Investigating the Mechanical Performance on Static and Shock Wave Loading of Aramid Fiber-Reinforced Concrete. Fibers 2022, 10, 82. https://doi.org/10.3390/fib10100082

Li Y-F, Wang H-F, Syu J-Y, Ramanathan GK, Tsai Y-K. Investigating the Mechanical Performance on Static and Shock Wave Loading of Aramid Fiber-Reinforced Concrete. Fibers. 2022; 10(10):82. https://doi.org/10.3390/fib10100082

Chicago/Turabian StyleLi, Yeou-Fong, Hsin-Fu Wang, Jin-Yuan Syu, Gobinathan Kadagathur Ramanathan, and Ying-Kuan Tsai. 2022. "Investigating the Mechanical Performance on Static and Shock Wave Loading of Aramid Fiber-Reinforced Concrete" Fibers 10, no. 10: 82. https://doi.org/10.3390/fib10100082

APA StyleLi, Y.-F., Wang, H.-F., Syu, J.-Y., Ramanathan, G. K., & Tsai, Y.-K. (2022). Investigating the Mechanical Performance on Static and Shock Wave Loading of Aramid Fiber-Reinforced Concrete. Fibers, 10(10), 82. https://doi.org/10.3390/fib10100082