Biopolymer Coatings as Alternative to Modified Atmosphere Packaging for Shelf Life Extension of Minimally Processed Apples

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Film Forming Solutions

2.2. Coating Application

2.3. Respiration Rate Measurement

2.4. Packaging, Storage Condition and Shelf Life Evaluation

2.4.1. Headspace Gas Analysis

2.4.2. Moisture Content, Color and pH

2.4.3. Mechanical Properties

2.4.4. Antioxidant Capacity

2.4.5. Experimental Design and Data Analysis

3. Results and Discussions

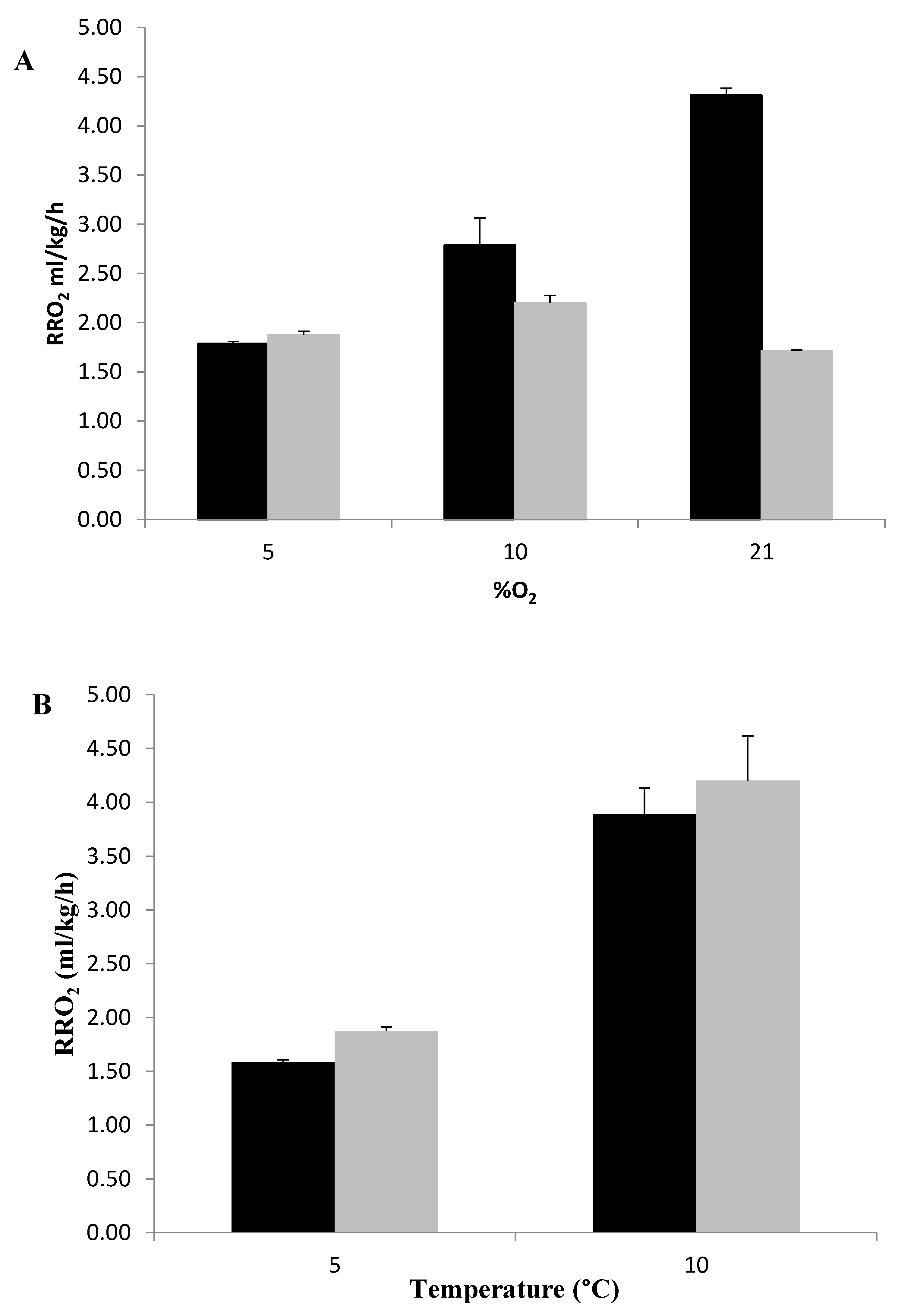

3.1. Respiration Rate Measurement

3.2. Shelf Life Evaluation

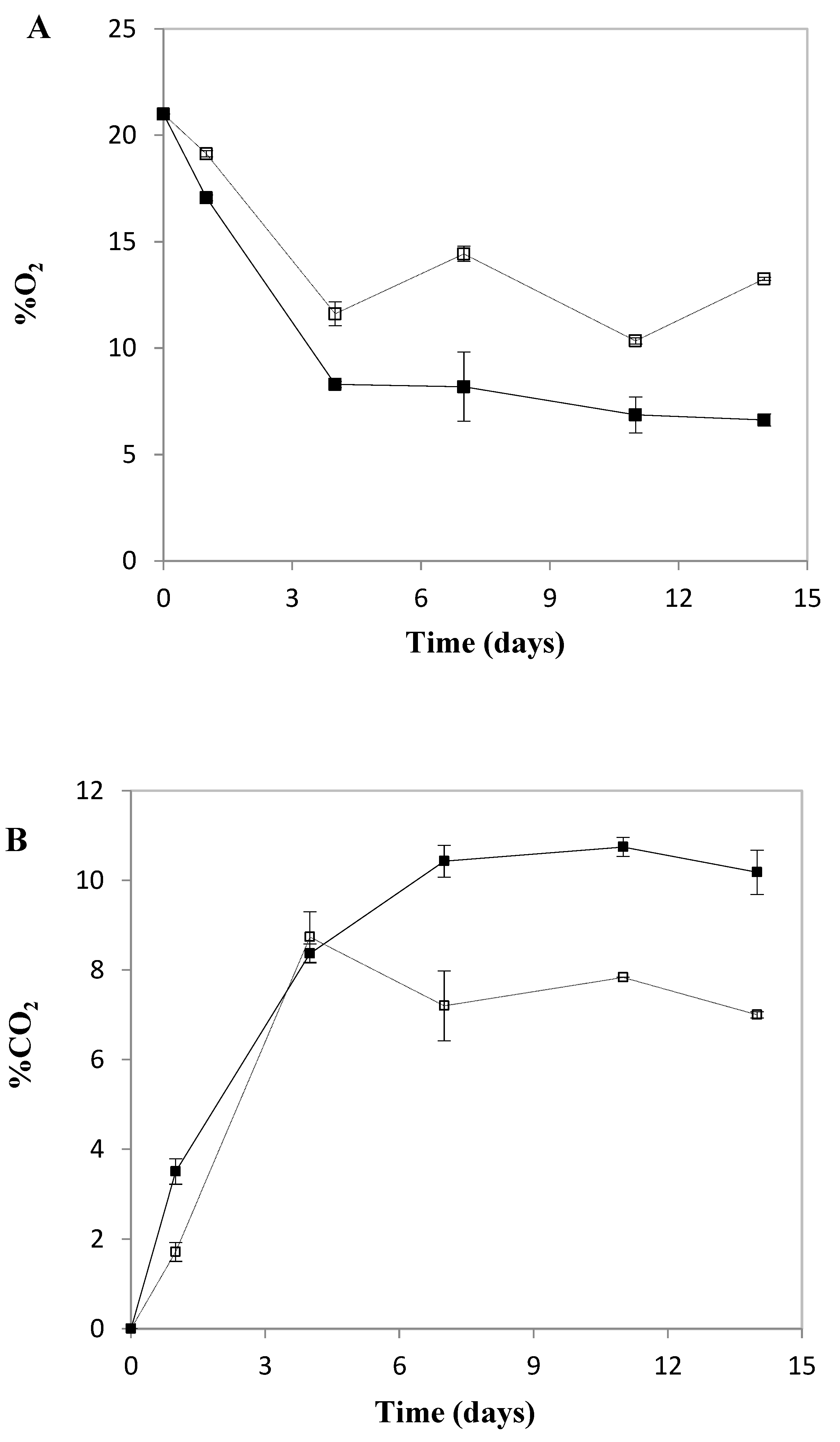

3.2.1. Headspace Gas Analysis

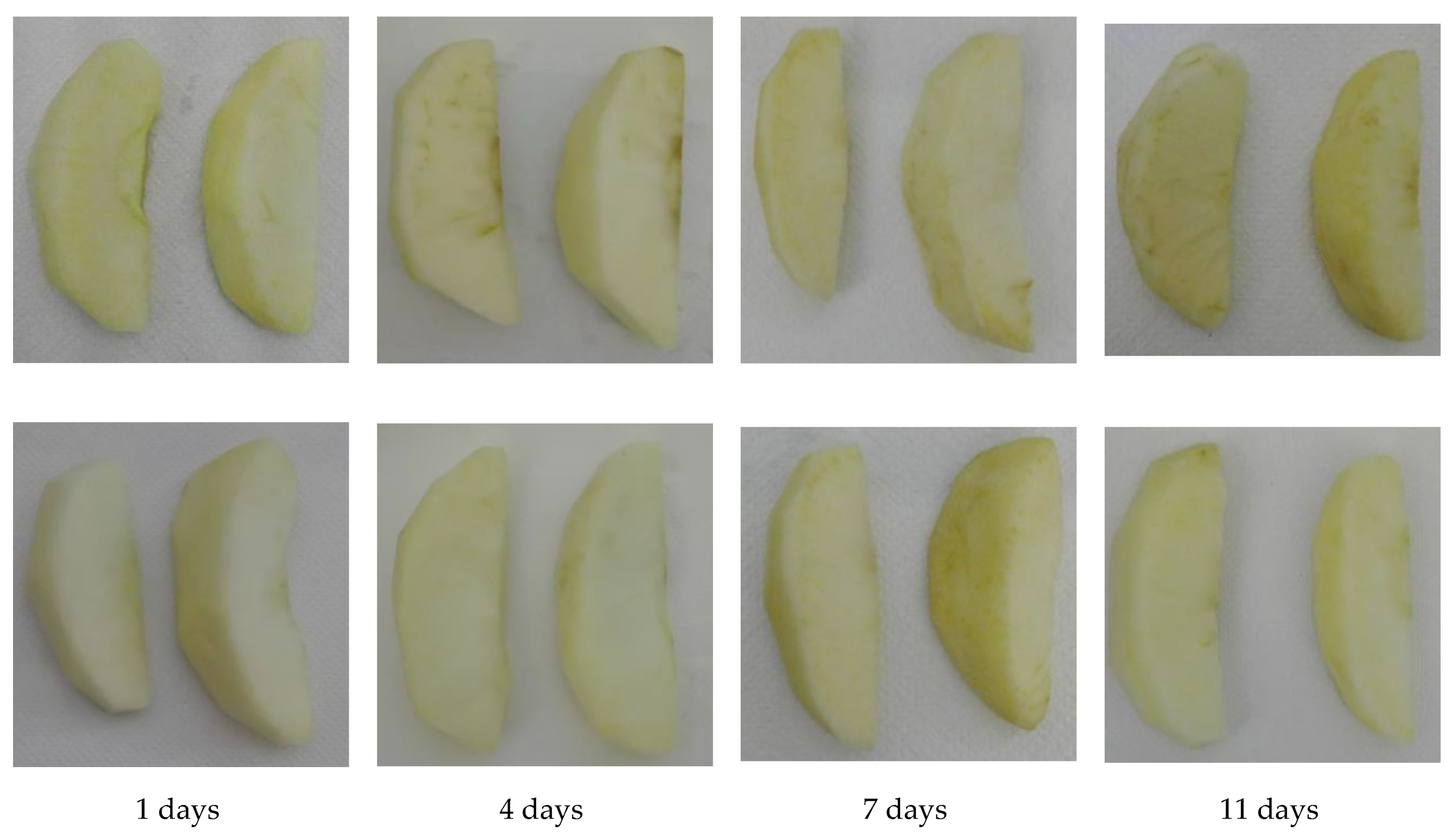

3.2.2. Moisture Content, Color and pH

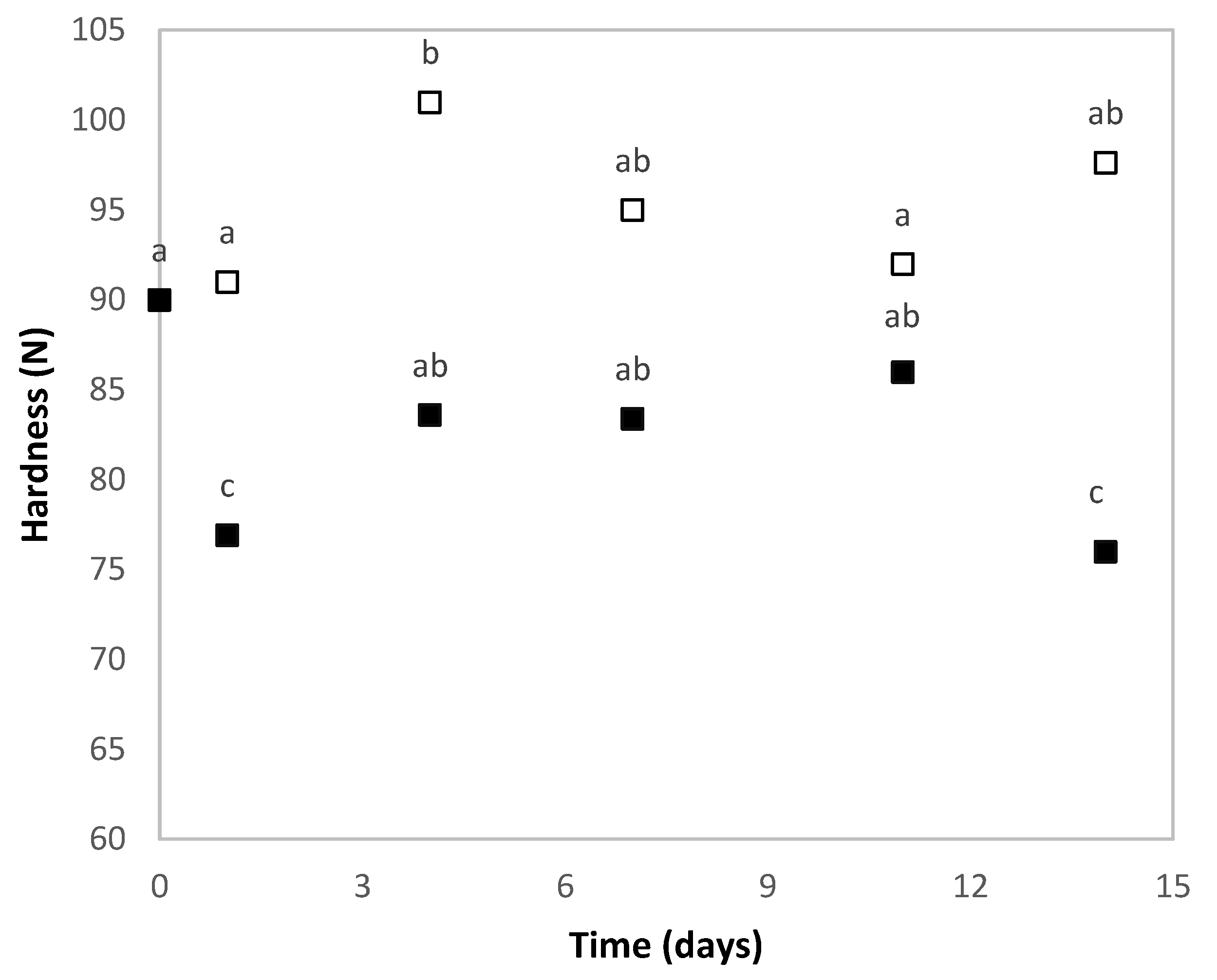

3.2.3. Mechanical Properties

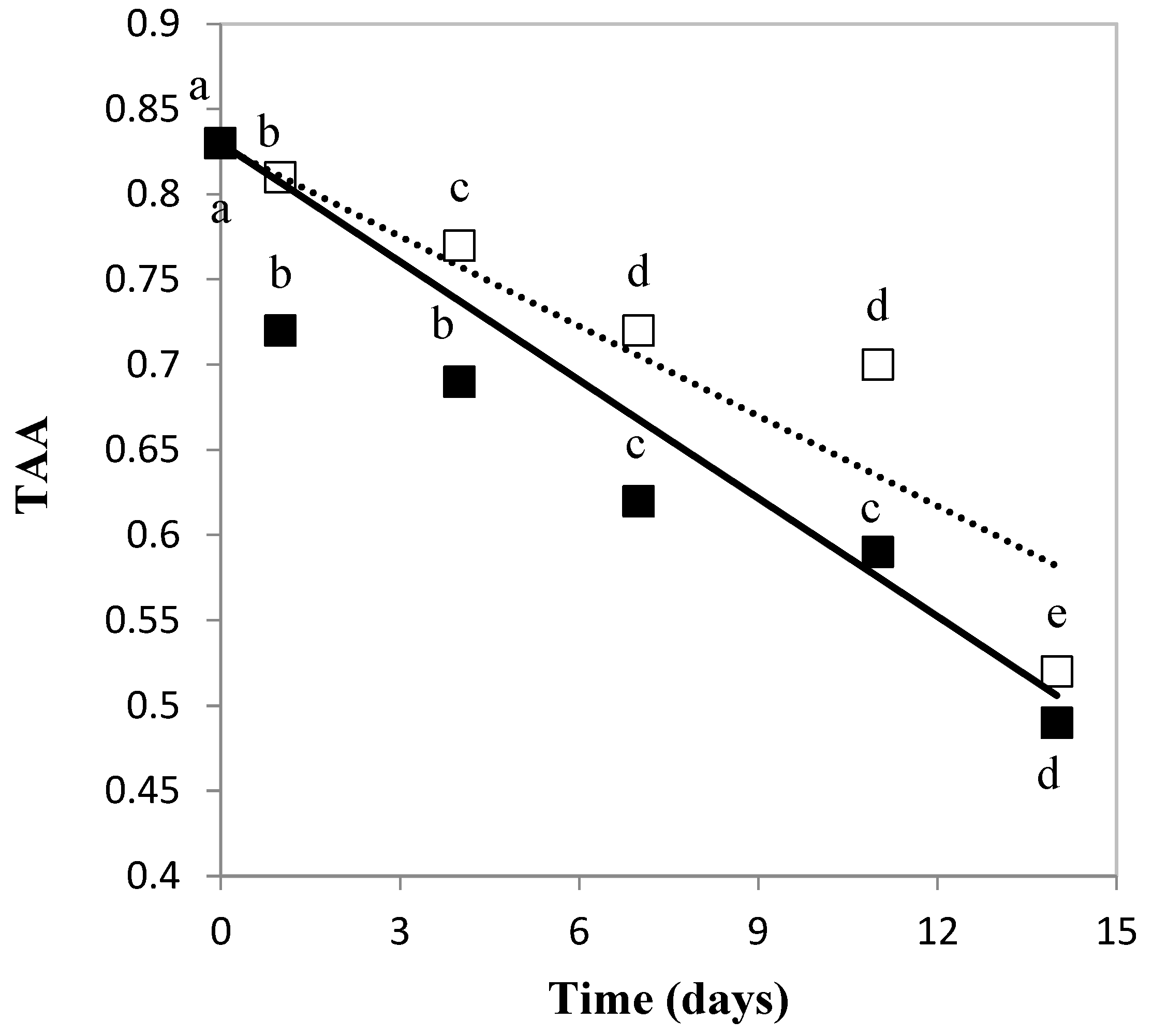

3.2.4. Antioxidant Capacity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bazzano, L.A. Dietary Intake of Fruit and Vegetables and Risk of Diabetes Mellitus and Cardiovascular Diseases; FAO/WHO Workshop on Fruit & Vegetables for Health: Kobe, Japan, 2004. [Google Scholar]

- Rolle, R.S.; Chism, G.W. Physiological consequences of minimally processed fruits and vegetables. J. Food Qual. 1987, 10, 157–177. [Google Scholar] [CrossRef]

- Torrieri, E.; Langella, A.; Cavella, S.; Masi, P. Valutazione dei fenomeni di degradazione di mele fresche tagliate (Malus Communis Mill.) conservate in atmosfera protettiva. In Ricerche ed Innovazioni Nell’industria Alimentare, 6th ed.; Chirotti Editori: Pinerolo, Italy, 2003. [Google Scholar]

- Torrieri, E.; Di Monaco, R.; Cavella, S.; Masi, P. Fresh-cut Annurca apples: Acceptability study and shelf life determination. J. Sens. Stud. 2008, 23, 195–203. [Google Scholar] [CrossRef]

- Rojas-Grau, M.A.; Sobrino-Lopez, A.; Tapia, M.S.; Martin-Belloso, O. Browning inhibition in fresh-cut Fuji apple slices by natural antibrowning agents. J. Food Sci. 2006, 71, 59–65. [Google Scholar] [CrossRef]

- Ioannou, I.; Ghoul, M. Prevention of enzymatic browning in fruit and vegetables. Eur. Sci. J. ESJ 2013, 9, 30. [Google Scholar]

- Watada, A.E.; Qi, L. Quality of fresh-cut produce. Postharvest Biol. Technol. 1999, 15, 201–205. [Google Scholar] [CrossRef]

- Laurilia, E.; Kervinen, R.; Ahvenainen, R. The inhibition of enzymatic browning in minimally processed vegetables and fruits. Review article. Postharvest News Informat. 1998, 9, 53N–66N. [Google Scholar]

- King, A.D., Jr.; Bolin, H.R. Physiological and microbiological storage stability of minimally processed fruits and vegetables. Food Technol. 1989, 43, 132. [Google Scholar]

- Torrieri, E.; Di Monaco, R.; Cavella, S.; Masi, P. Determinazione della Shelf-Life della mela annurca confezionata in atmosfera protettiva. Ingred. Alim. 2009, 1, 15–20. [Google Scholar]

- Gonzalez-Aguilar, G.A.; Valenzuela-Soto, E.; Lizardi-Mendoza, J.; Goycoolea, F.; Martinez-Tellez, M.A.; Villegas-Ochoa, M.A.; Monroy-Garcia, I.N.; Ayala-Zavala, J.F. Effect of chitosan coating in preventing deterioration and preserving the quality of fresh-cut papaya ‘Maradol’. J. Sci. Food Agric. 2009, 89, 15–23. [Google Scholar] [CrossRef]

- Porta, R.; Rossi-Marquez, G.; Mariniello, L.; Sorrentino, A.; Giosafatto, C.V.L.; Marilena Esposito, M.; Di Pierro, P. Edible Coating as Packaging Strategy to Extend the Shelf-life of Fresh-Cut fruits and vegetables. J. Biotechnol. Biomater. 2013, 3, 1–3. [Google Scholar] [CrossRef]

- Yousuf, B.; Qadri, O.S.; Srivastava, A.K. Recent developments in shelf-life extension of fresh-cut fruits and vegetables by application of different edible coatings: A review. LWT Food Sci. Techol. 2018, 89, 198–209. [Google Scholar] [CrossRef]

- Galus, S. Development of edible coating in the preservation of fruits and vegetables. In Polymers for Agri-Food Applications; Gutiérrez, T., Ed.; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Pacaphola, K.; Seraypheapc, K.; Aht-Ong, D. Development and application of nanofibrillated cellulose coating for shelf life extension of fresh-cut vegetable during postharvest storage. Carbohydr. Polym. 2019, 224, 115167. [Google Scholar] [CrossRef] [PubMed]

- Chena, H.; Sunb, Z.; Yang, H. Effect of carnauba wax-based coating containing glycerol monolaurate on the quality maintenance and shelf-life of Indian jujube (Zizyphus mauritiana Lamk.) fruit during storage. Sci. Hortic. 2019, 244, 157–164. [Google Scholar] [CrossRef]

- Patel, C.; Panigrahi, J. Starch glucose coating-induced postharvest shelf-life extension of cucumber. Food Chem. 2019, 288, 208–214. [Google Scholar] [CrossRef] [PubMed]

- Gundewadia, G.; Gaur Rudra, S.; Jyoti Sarkar, D.; Singh, D. Nanoemulsion based alginate organic coating for shelf life extension of okra. Food Packag. Shelf Life 2018, 18, 1–12. [Google Scholar] [CrossRef]

- Pan, S.Y.; Chen, C.H.; Lai, L.S. Effect of Tapioca Starch/Decolorized Hsian-Tsao Leaf Gum-Based Active Coatings on the of Fresh-Cut Apples. Food Bioprocess Technol. 2013, 6, 2059–2206. [Google Scholar] [CrossRef]

- Qi, H.; Hu, W.; Jiang, A.; Tian, M.; Li, Y. Extending shelf-life of Fresh-cut ‘Fuji’ apples with chitosan-coatings. Innov. Food Sci. Emerg. Technol. 2011, 12, 62–66. [Google Scholar] [CrossRef]

- Rojas-Grau, M.A.; Tapia, M.S.; Martin-Belloso, O. Using polysaccharide-based edible coatings to maintain quality of fresh-cut fuji apples. Food Sci. Technol. 2008, 41, 139–147. [Google Scholar] [CrossRef]

- Saba, M.K.; Sogvar, O.B. Combination of carboxymethyl cellulose-based coatings with calcium and ascorbic acid impacts in browning and quality of fresh-cut apples. LWT Food Sci. Technol. 2016, 66, 165–171. [Google Scholar] [CrossRef]

- Guerreiro, A.C.; Gago, C.M.L.; Faleiro, M.L.; Miguel, M.G.C.; Antunes, M.D.C. The effect of edible coatings on the nutritional quality of ‘Bravo de Esmolfe’ fresh-cut apple through shelf-life. LWT Food Sci. Technol. 2017, 75, 210–219. [Google Scholar] [CrossRef]

- Özdemir, K.S.; Gökmen, V. Effect of Chitosan-Ascorbic Acid Coatings on the Refrigerated Storage Stability of Fresh-Cut Apples. Coatings 2019, 9, 503. [Google Scholar] [CrossRef]

- Volpe, S.; Torrieri, E.; Cavella, S. Use of chitosan and chitosan-caseinate coating to prolong shelf life of minimally processed apples. Ital. J. Food Sci. 2018, 30, 30–35. [Google Scholar]

- Torrieri, E.; Perone, N.; Cavella, S.; Masi, P. Modelling the respiration rate of minimally processed broccoli (Brassica rapa var. sylvestris) for modified atmosphere package design. Int. J. Food Sci. Technol. 2010, 45, 2186–2193. [Google Scholar] [CrossRef]

- Moreira, M.R.; Cassani, L.; Martín-Belloso, O.; Soliva-Fortuny, R. Effects of polysaccharide-based edible coatings enriched with dietary fiber on quality attributes of fresh-cut apples. J. Food Sci. Technol. 2015, 52, 7795–7805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Galus, S.; Kadzińska, J. Food applications of emulsion-based edible films and coatings. Trends Food Sci. Technol. 2015, 45, 273–283. [Google Scholar] [CrossRef]

- Lopes, R.; Freitas, M.; Andrade, T.; Moita, W.; Carvalho, D.; Montenegro, I.; Moura, C.F.H.; Lopes, M.M.A.; De Miranda, A. Chitosan coating with trans-cinnamaldehyde improves structural integrity and antioxidant metabolism of fresh-cut melon. Postharvest Biol. Technol. 2016, 113, 29–39. [Google Scholar]

- Rico, D.; Martin-Diana, A.B.; Barat, J.M.; Barry-Ryan, C. Extending and Measuring the Quality of Fresh-Cut Fruit and Vegetables: A Review. Trends Food Sci. Technol. 2007, 18, 373–386. [Google Scholar] [CrossRef]

| Sample | IQ | Time (Days) | |||||

|---|---|---|---|---|---|---|---|

| 0 | 1 | 4 | 7 | 11 | 14 | ||

| control | L* | 80.6 ± 0.5a | 75.7 ± 0.5b | 75.6 ± 0.4b | 75.8 ± 0.6c | 75.8 ± 0.2bc | 73.5 ± 0.5d |

| a* | −4.4 ± 0.2a | −5.0 ± 0.1ab | −5.3 ± 0.5a | −4.53 ± 0.03bc | −4.3 ± 0.5c | −3.3 ± 0.1d | |

| b* | 14.8 ± 0.1a | 17.8 ± 0.3b | 17.61 ± 0.09b | 18.0 ± 1.5b | 18.6 ± 0.5b | 17.7 ± 0.7b | |

| ΔE | 0 ± 0a | 5.6 ± 0.2b | 5.5 ± 0.5b | 6.8 ± 0.1c | 6.3 ± 0.2bc | 7.8 ± 0.1d | |

| pH | 3.12 ± 0.01a | 3.21 ± 0.01a | 4.47 ± 0.05b | 4.8 ± 0.1c | 5.01 ± 0.02d | 5.06 ± 0.07d | |

| coating | L* | 80.2 ± 0.1a | 78.7 ± 0.3b * | 78.5 ± 0.3bc * | 78.2 ± 0.8bcd * | 77.2 ± 0.3cd * | 76.7 ± 1.4d * |

| a* | −4.3 ± 0.2a | −4.8 ± 0.2a | −4.3 ± 0.5ab | −3.8 ± 0.5bc | −3.76 ± 0.07bc | −3.6 ± 0.4d | |

| b* | 15.5 ± 0.3a | 16.9 ± 0.8b | 18 ± 1bc | 19 ± 1bcd | 20.2 ± 0.5cd * | 22.7 ± 0.6d * | |

| ΔE | 0 ± 0a | 2.4 ± 0.9b * | 3 ± 1b * | 4 ± 1c * | 5.8 ± 0.4c | 8 ± 1d | |

| pH | 3.54 ± 0.02a | 3.96 ± 0.06b * | 4.08 ± 0.08b * | 4.21 ± 0.06c * | 4.6 ± 0.2d * | 4.94 ± 0.04e | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Volpe, S.; Cavella, S.; Torrieri, E. Biopolymer Coatings as Alternative to Modified Atmosphere Packaging for Shelf Life Extension of Minimally Processed Apples. Coatings 2019, 9, 569. https://doi.org/10.3390/coatings9090569

Volpe S, Cavella S, Torrieri E. Biopolymer Coatings as Alternative to Modified Atmosphere Packaging for Shelf Life Extension of Minimally Processed Apples. Coatings. 2019; 9(9):569. https://doi.org/10.3390/coatings9090569

Chicago/Turabian StyleVolpe, Stefania, Silvana Cavella, and Elena Torrieri. 2019. "Biopolymer Coatings as Alternative to Modified Atmosphere Packaging for Shelf Life Extension of Minimally Processed Apples" Coatings 9, no. 9: 569. https://doi.org/10.3390/coatings9090569