Formation of a Double-Layer Ultrafine Crystal Structure for High-Current Pulsed Electron Beam-Treated Al–20Si–5Mg Alloy

Abstract

1. Introduction

2. Experimental

2.1. Sample Preparation

2.2. HCPEB Treatment

2.3. Characterization

3. Results and Discussion

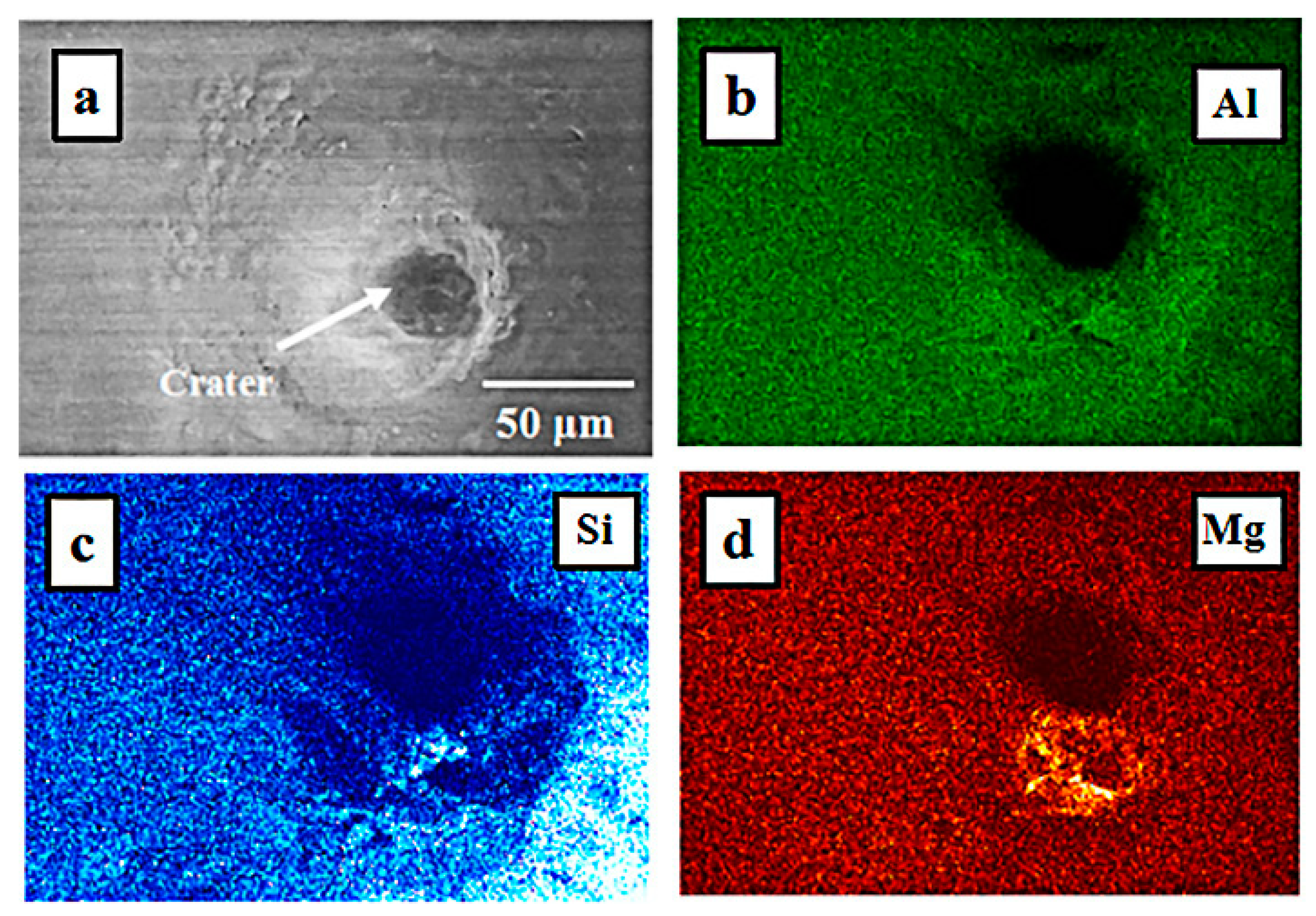

3.1. SEM Analysis of the Surface Morphology

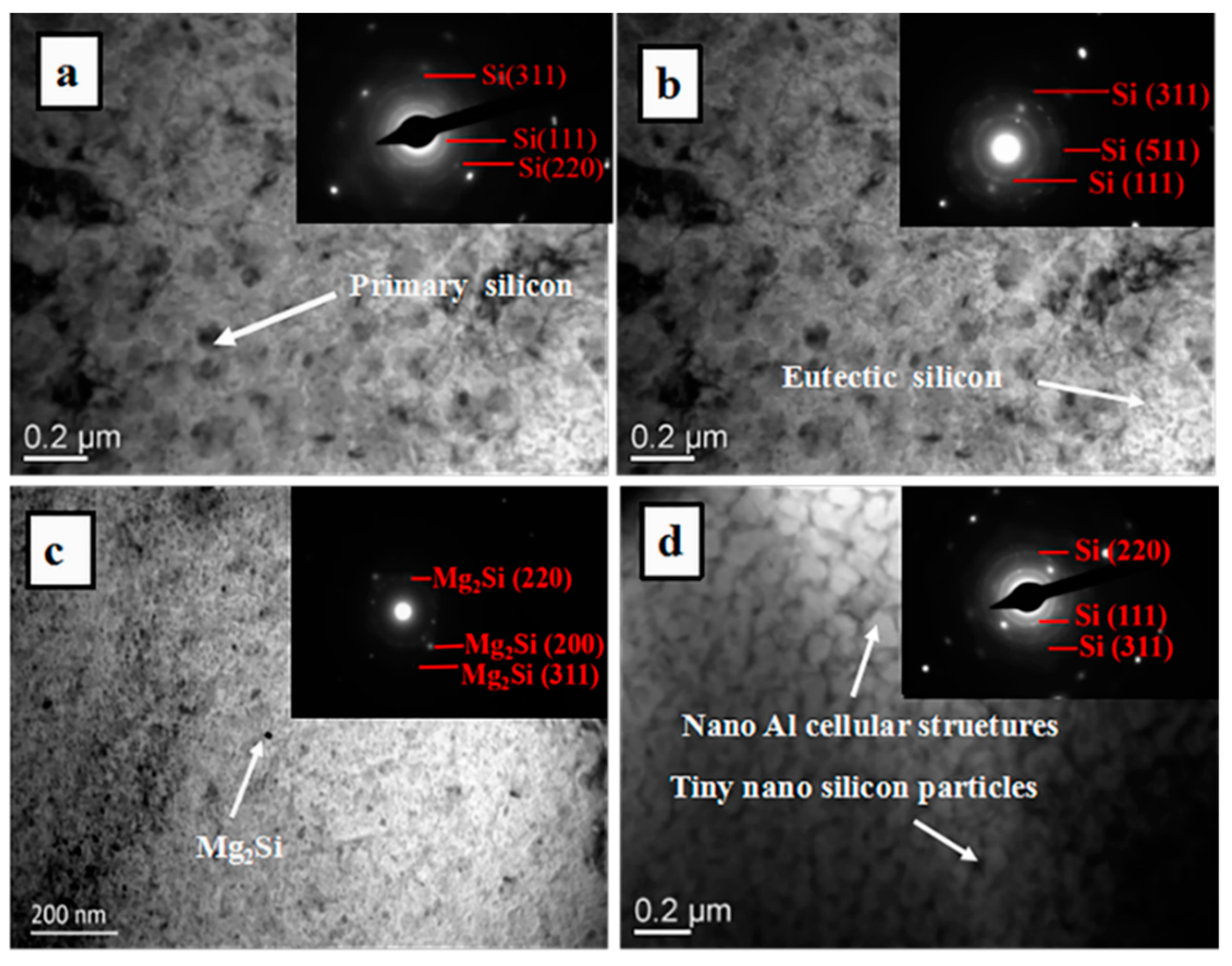

3.2. TEM Analysis of the Surface Morphology

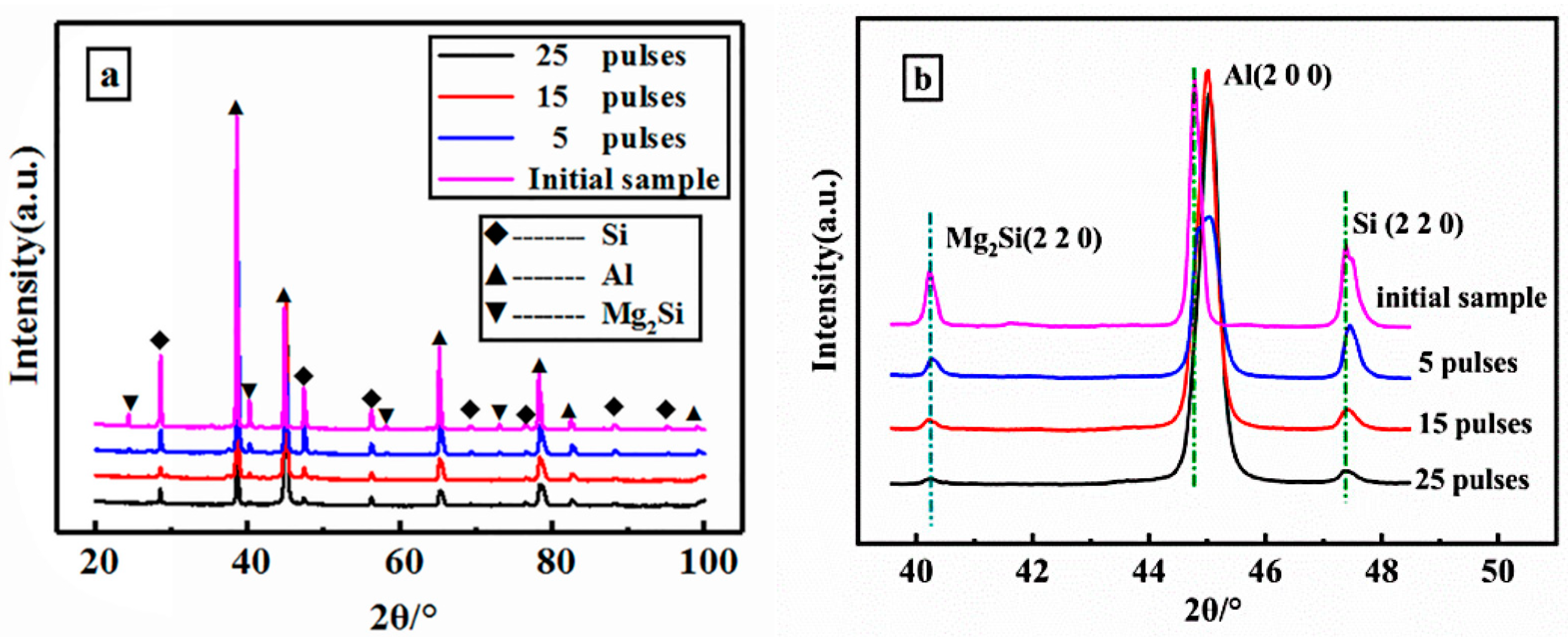

3.3. XRD Analysis of the Surface Morphology

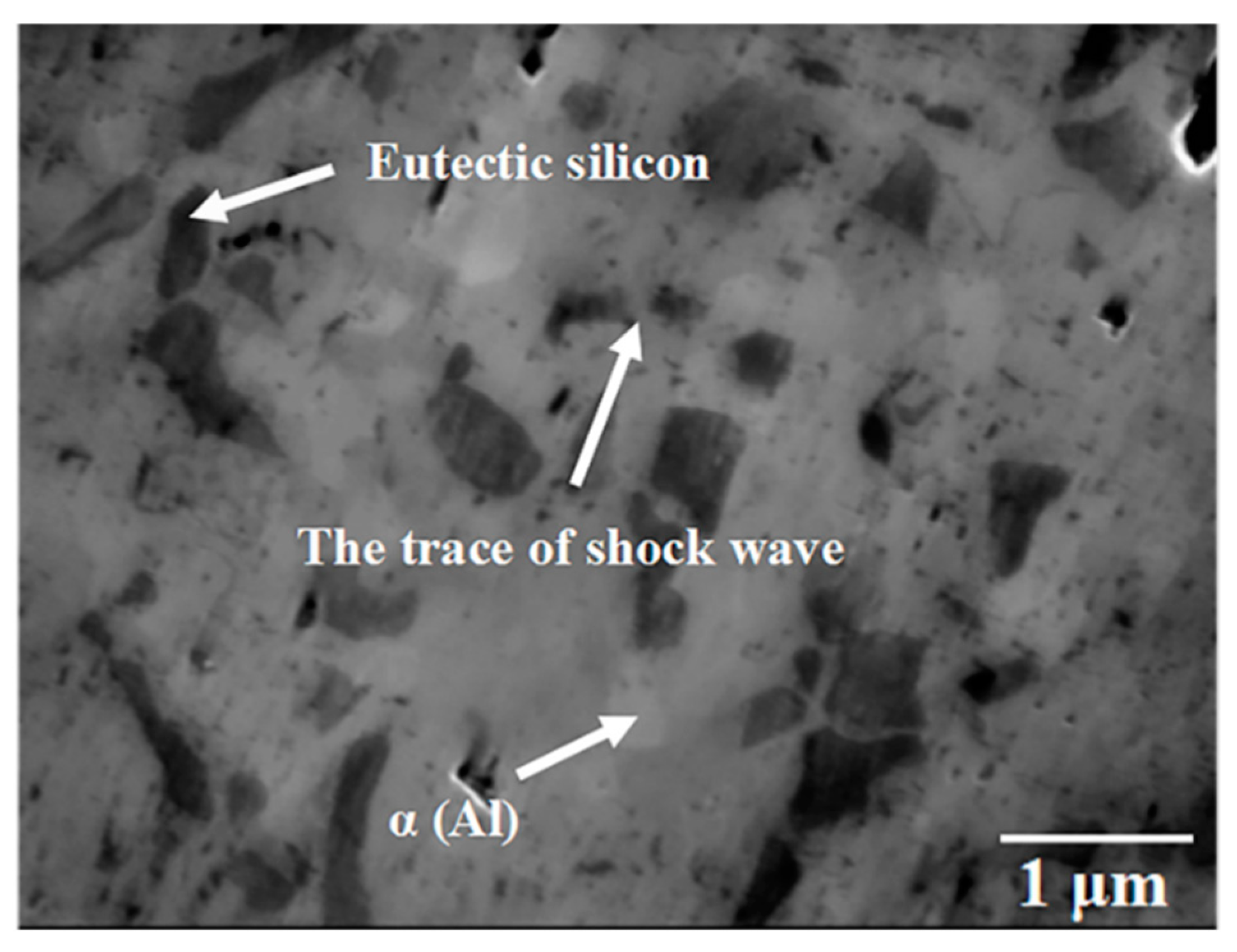

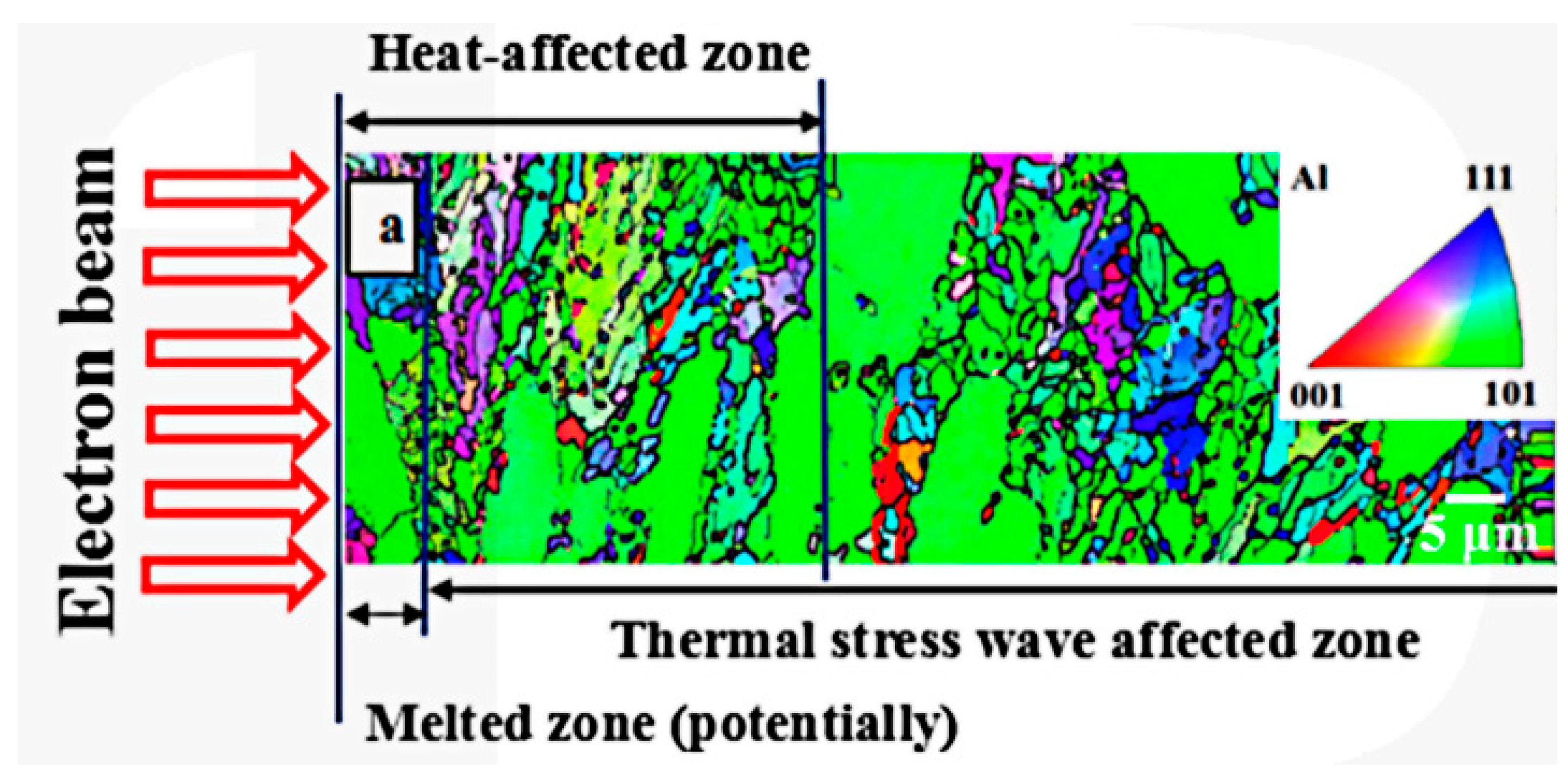

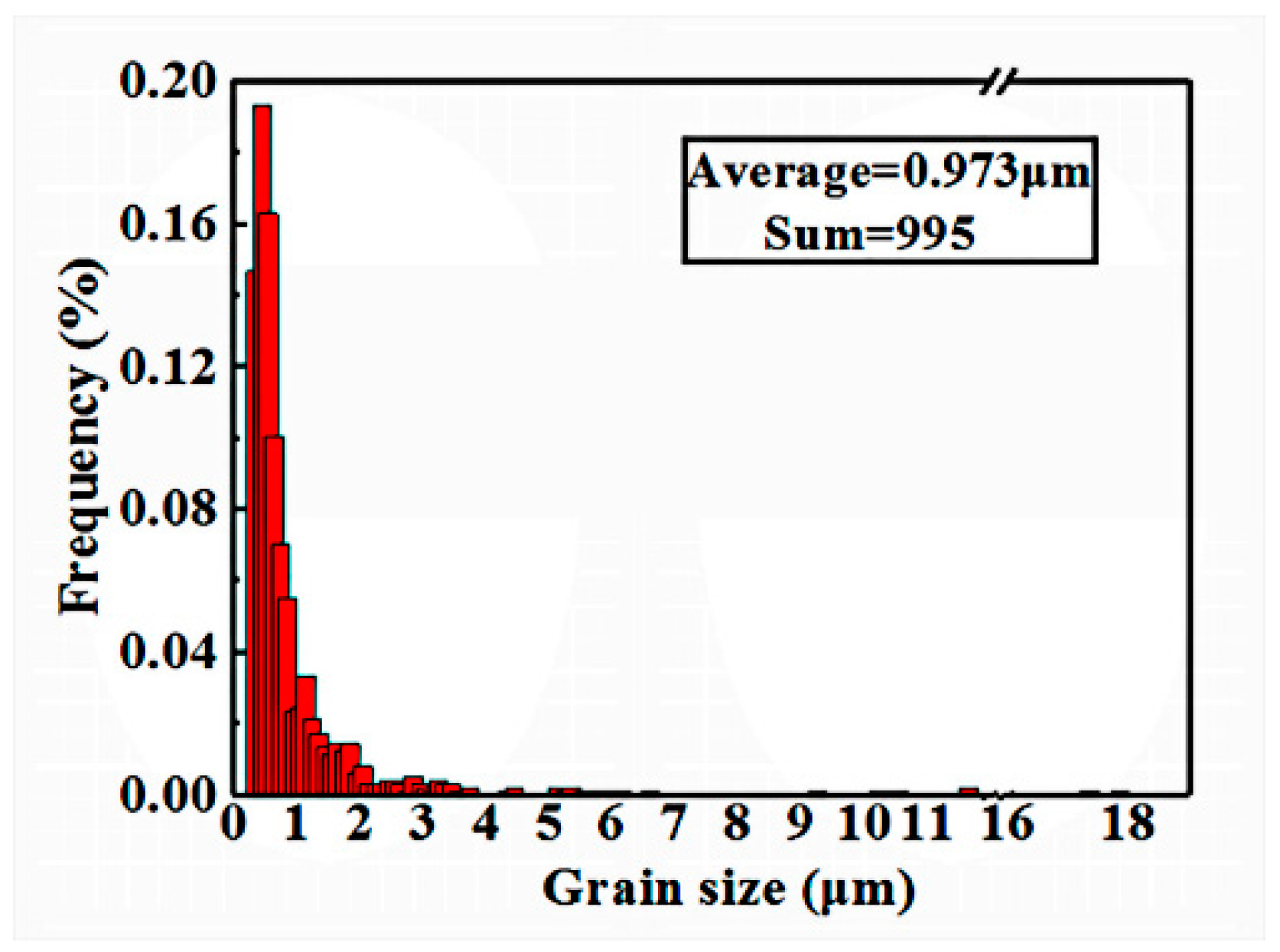

3.4. SEM and EBSD Analyses of the Cross-Sectional Morphology

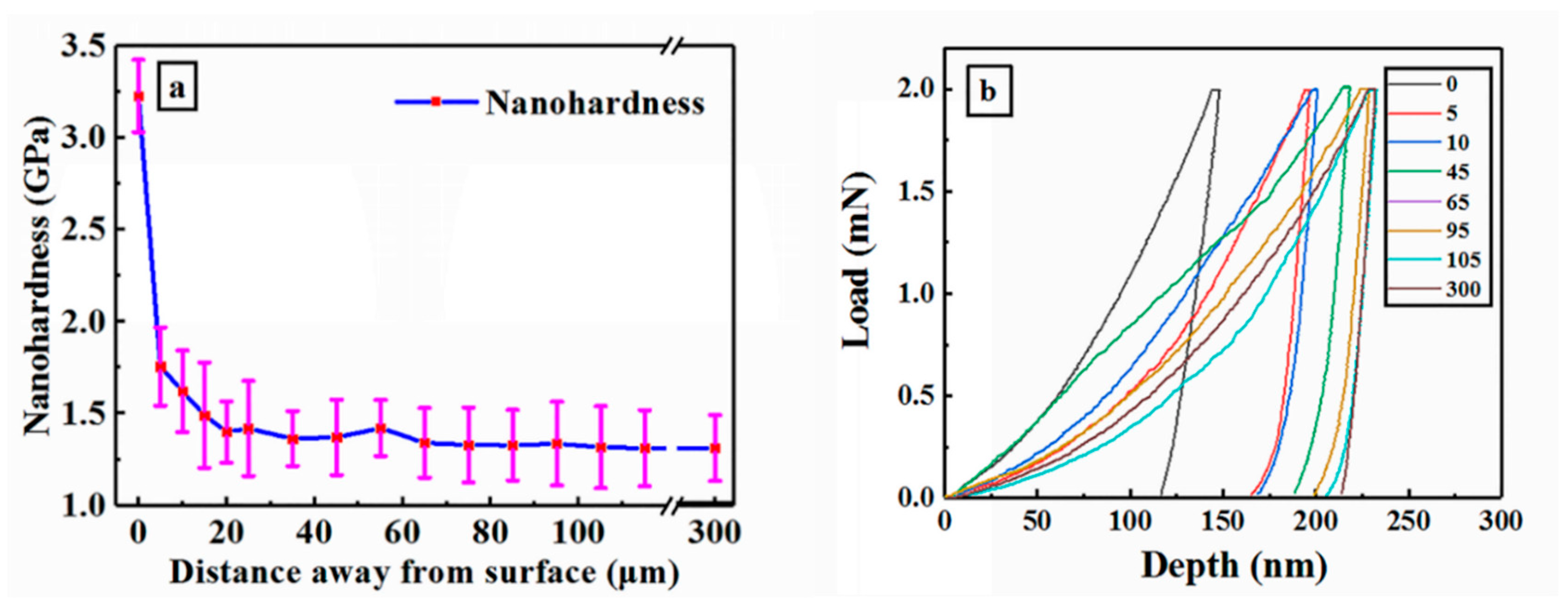

3.5. Nanoindentation Analysis of the Cross-Sectional Structure

4. Conclusions

- Ultrafine grains with double layers (remelted layer + heat-affected zone) in the Al–20Si–5Mg alloy are formed by the HCPEB treatment. For the remelted layer, nano-primary silicon, eutectic silicon, Mg2Si, and aluminum cellular structures are generated after the HCPEB treatment owing to the rapid heating and cooling rates. For the heat-affected zone, sub-micron Al, Mg2Si, and eutectic silicon phases are formed due to the cooperative effects of shock waves, thermal stress waves, and quasi-static thermal stress under high-temperature conditions.

- HCPEB can improve the mechanical properties of materials in not only the remelted layer but also the heat-affected zone. The improvement in hardness of the aluminum phase in the remelted layer is the result of grain refinement, which arises due to the rapid melting and cooling rates of the HCPEB treatment. The improvement of nano-hardness in the heat-affected zone is attributed to grain refinement due to the cooperative effect of the shock wave, thermal stress wave, and quasi-static thermal stress under high-temperature conditions.

- Solid evidence for the tracing of the shock wave in the heat-affected zone was demonstrated for the first time and was verified for the formation of broken acicular eutectic silicon in the Al–20Si–5Mg alloy, demonstrating the deep modification effect of shock waves on the cross-section microstructures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, T.C.; Zhang, K.M.; Zou, J.X.; Yan, P.; Yang, H.Y.; Song, L.X.; Zhang, X. Surface microstructure and property modifications in a Mg-8Gd-3Y-0.5 Zr magnesium alloy treated by high current pulsed electron beam. J. Alloy. Compd. 2019, 788, 231–239. [Google Scholar] [CrossRef]

- Cai, J.; Gao, C.Z.; Lv, P.; Zhang, C.L.; Guan, Q.F.; Lu, J.Z.; Xu, X.J. Hot corrosion behaviour of thermally sprayed CoCrAlY coating irradiated by high-current pulsed electron beam. J. Alloy. Compd. 2019, 784, 1221–1233. [Google Scholar] [CrossRef]

- Yan, P.; Grosdidier, T.; Zhang, X.; Zou, J. Formation of large grains by epitaxial and abnormal growth at the surface of pulsed electron beam treated metallic samples. Mater. Des. 2018, 159, 1–10. [Google Scholar] [CrossRef]

- Zhang, C.; Lv, P.; Cai, J.; Zhang, Y.; Xia, H.; Guan, G. Enhanced corrosion property of W-Al coatings fabricated on aluminum using surface alloying under high-current pulsed electron beam. J. Alloy. Compd. 2017, 723, 258–265. [Google Scholar] [CrossRef]

- Proskurovsky, D.I.; Rotshtein, V.P.; Ozur, G.E.; Ivanov, Y.F.; Markov, A.B. Physical foundations for surface treatment of materials with low energy, high current electron beams. Surf. Coat. Technol. 2000, 125, 49–56. [Google Scholar] [CrossRef]

- Gao, B.; Hao, S.; Zou, J.; Grosdidier, T.; Jiang, L.; Zhou, J.; Dong, C. High current pulsed electron beam treatment of AZ31 Mg alloy. J. Vac. Sci. Technol. A 2005, 23, 1548–1553. [Google Scholar] [CrossRef]

- Zou, J.X.; Grosdidier, T.; Bolle, B.; Zhang, K.M.; Dong, C. Texture and microstructure at the surface of an AISI D2 steel treated by high current pulsed electron beam. Metall. Mater. Trans. A 2007, 38, 2061–2071. [Google Scholar] [CrossRef]

- Grosdidier, T.; Zou, J.X.; Bolle, B.; Hao, S.Z.; Dong, C. Grain refinement, hardening and metastable phase formation by high current pulsed electron beam (HCPEB) treatment under heating and melting modes. J. Alloy. Compd. 2010, 504, 508–511. [Google Scholar] [CrossRef]

- Qin, Y.; Zou, J.; Dong, C.; Wang, X.; Wu, A.; Liu, Y.; Hao, S.; Guan, Q. Temperature–stress fields and related phenomena induced by a high current pulsed electron beam. Nucl. Instrum. Methods Phys. Res. 2004, 225, 544–554. [Google Scholar] [CrossRef]

- Zou, J.X.; Zhang, K.M.; Hao, S.Z.; Dong, C.; Grosdidier, T. Mechanisms of hardening, wear and corrosion improvement of 316 L stainless steel by low energy high current pulsed electron beam surface treatment. Thin Solid Films 2010, 519, 1404–1415. [Google Scholar] [CrossRef]

- Proskurovsky, D.I.; Rotshtein, V.P.; Ozur, G.E.; Markov, A.B.; Nazarrov, D.S. Pulsed electron-beam technology for surface modification of metallic materials. J. Vac. Sci. Technol. A 1998, 16, 2480–2488. [Google Scholar] [CrossRef]

- Li, B.; Wang, K.; Liu, M.; Han, H.; Zhu, Z.; Liu, C. Effects of temperature on fracture behavior of Al-based in-situ composites reinforced with Mg2Si and Si particles fabricated by centrifugal casting. Trans. Nonferrous Met. Soc. China 2013, 23, 923–930. [Google Scholar] [CrossRef]

- Gao, B.; Xu, N.; Xing, P. Shock wave induced nanocrystallization during the high current pulsed electron beam process and its effect on mechanical properties. Mater. Lett. 2019, 237, 180–184. [Google Scholar] [CrossRef]

- Hu, L.; Gao, B.; Lv, J.K.; Hao, Y.; Tu, G.F.; Hao, S.Z.; Dong, C. The metastable structure of hypereutectic Al-17.5Si alloy surface induced by high current pulsed electron beam. Meter. Res. Innov. 2015, 19, S5-320–S5-324. [Google Scholar]

- Hao, Y.; Gao, B.; Tu, G.F.; Li, S.W.; Dong, C.; Zhang, Z.G. Improved wear resistance of Al–15Si alloy with a high current pulsed electron beam treatment. Nucl. Instrum. Methods Phys. Res. 2011, 269, 1499–1505. [Google Scholar] [CrossRef]

- Hu, L.; Gao, B.; Lv, J.K.; Sun, S.C.; Hao, Y.; Tu, G.F. Halo evolution of hypereutectic Al-17.5Si alloy treated with high-current pulsed electron beam. J. Nanomater. 2015, 2015, 806151. [Google Scholar] [CrossRef]

- Guan, Q.F.; Zou, H.; Zou, G.T.; Hu, A.M.; Hao, S.Z.; Zou, J.X.; Qin, Y.; Dong, C.; Zhang, Q.Y. Surface nanostructure and amorphous state of a low carbon steel induced by high-current pulsed electron beam. Surf. Coat. Technol. 2005, 196, 145–149. [Google Scholar] [CrossRef]

- Le, X.; Yan, S.; Zhao, W.; Han, B.; Wang, Y.; Xue, J. Computer simulation of thermal–mechanical effects of high intensity pulsed ion beams on a metal surface. Surf. Coat. Technol. 2000, 128–129, 381–386. [Google Scholar]

- Goloborodko, A.; Sitdikov, O.; Sakai, T.; Kaibyshev, R.; Miura, H. Grain refinement in as-cast 7475 aluminum alloy under hot equal-channel angular pressing. Mater. Trans. 2003, 44, 766–774. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Sitdikov, O.; Goloborodko, A.; Sakai, T. Grain refinement in as-cast 7475 aluminum alloy under hot deformation. Mater. Sci. Eng. A 2003, 344, 348–356. [Google Scholar] [CrossRef]

- Farayibi, P.K.; Abioye, T.E.; Murray, J.W.; Kinnell, P.K.; Clare, T.A. Surface improvement of laser clad Ti–6Al–4V using plain waterjet and pulsed electron beam irradiation. J. Mater. Process. Technol. 2015, 218, 1–11. [Google Scholar] [CrossRef][Green Version]

- Zenker, R.; John, W.; Rathjen, D.; Fritsche, G.; Kdmpfe, B. Electron beam hardening. II. Influence on microstructure and properties. Heat Treat. Met. 1998, 16, 43–51. [Google Scholar]

- Kozar, R.W.; Suzuki, A.; Milligan, W.W.; Schirra, J.J.; Savage, M.F.; Pollock, T.M. Strengthening mechanisms in polycrystalline multimodal nickel-base superalloys. Metall. Mater. Trans. A 2009, 40, 1588–1603. [Google Scholar] [CrossRef]

- Ghaffarianmalmiri, H.; Kang, K.; Ryu, S. Molecular dynamics simulation study of the effect of temperature and grain size on the deformation behavior of polycrystalline cementite. Scr. Mater. 2015, 95, 23–26. [Google Scholar] [CrossRef]

| Background Vacuum (10−3 Pa) | Acceleration Voltage (kV) | Energy Density (J/cm2) | Distance from Anode to Target (cm) | Pulse Duration (μs) | Pulse Interval (s) |

|---|---|---|---|---|---|

| 6 | 27 | 5–6 | 10 | 2 | 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, B.; Li, K.; Xing, P. Formation of a Double-Layer Ultrafine Crystal Structure for High-Current Pulsed Electron Beam-Treated Al–20Si–5Mg Alloy. Coatings 2019, 9, 413. https://doi.org/10.3390/coatings9070413

Gao B, Li K, Xing P. Formation of a Double-Layer Ultrafine Crystal Structure for High-Current Pulsed Electron Beam-Treated Al–20Si–5Mg Alloy. Coatings. 2019; 9(7):413. https://doi.org/10.3390/coatings9070413

Chicago/Turabian StyleGao, Bo, Kui Li, and Pengfei Xing. 2019. "Formation of a Double-Layer Ultrafine Crystal Structure for High-Current Pulsed Electron Beam-Treated Al–20Si–5Mg Alloy" Coatings 9, no. 7: 413. https://doi.org/10.3390/coatings9070413

APA StyleGao, B., Li, K., & Xing, P. (2019). Formation of a Double-Layer Ultrafine Crystal Structure for High-Current Pulsed Electron Beam-Treated Al–20Si–5Mg Alloy. Coatings, 9(7), 413. https://doi.org/10.3390/coatings9070413