Growth of Ultrathin Al2O3 Films on n-InP Substrates as Insulating Layers by RF Magnetron Sputtering and Study on the Optical and Dielectric Properties

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

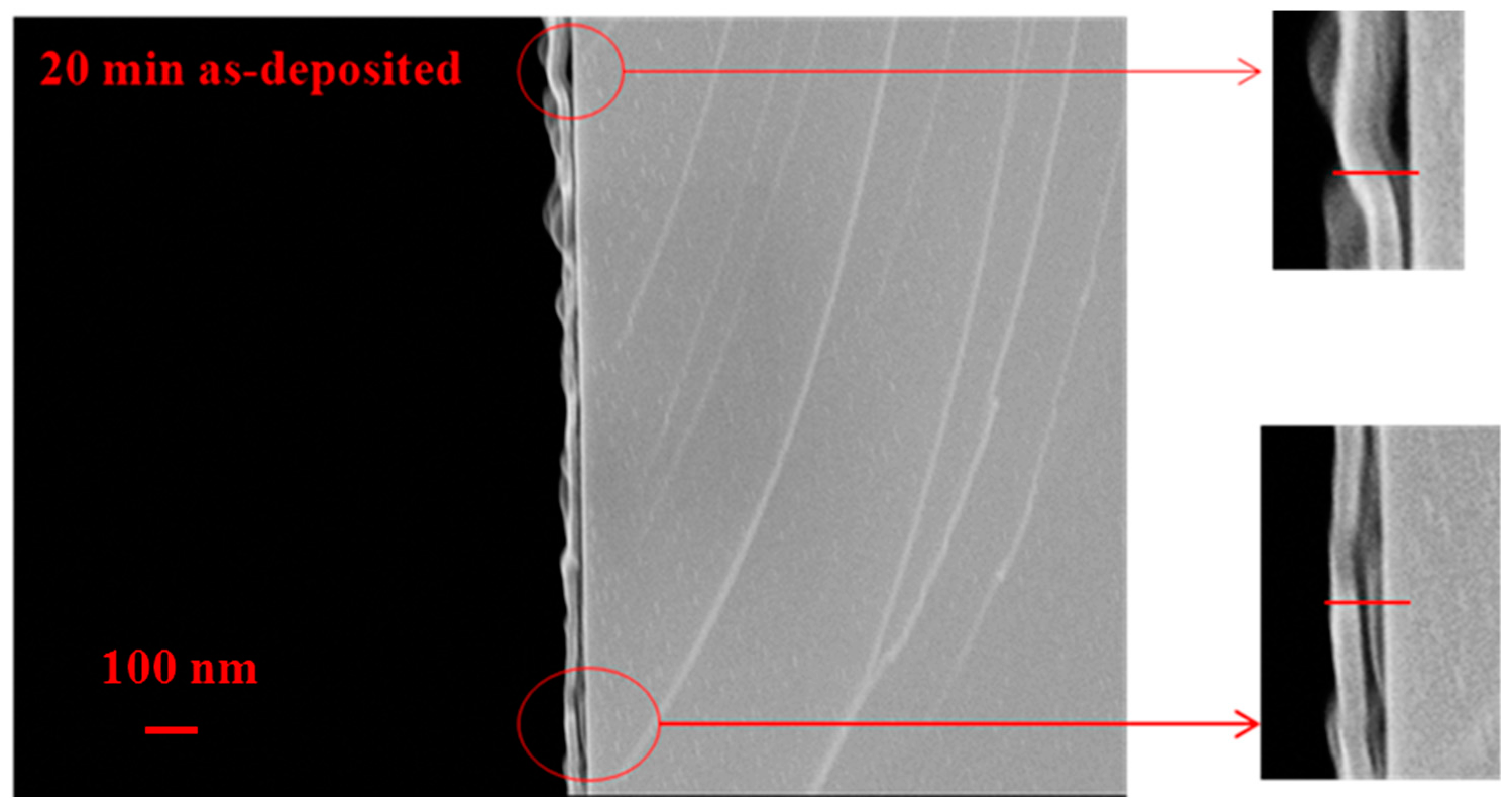

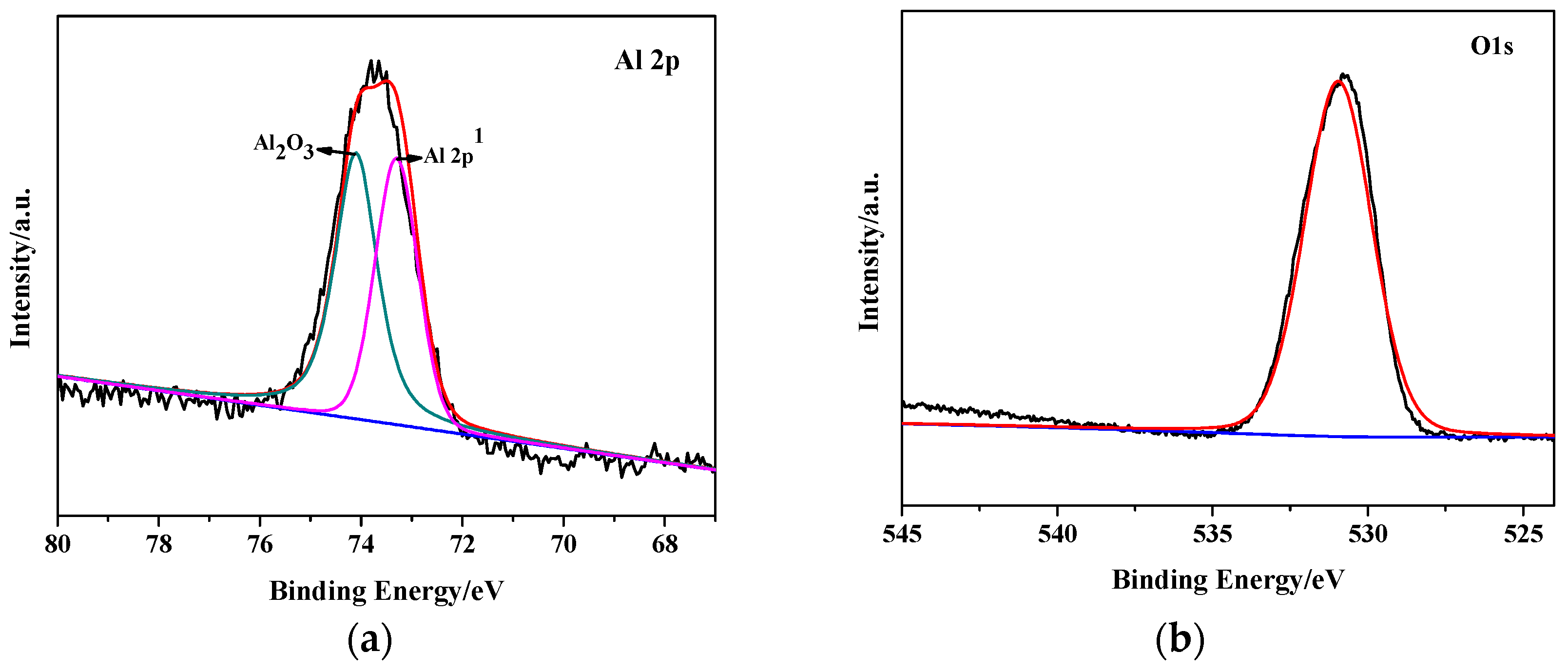

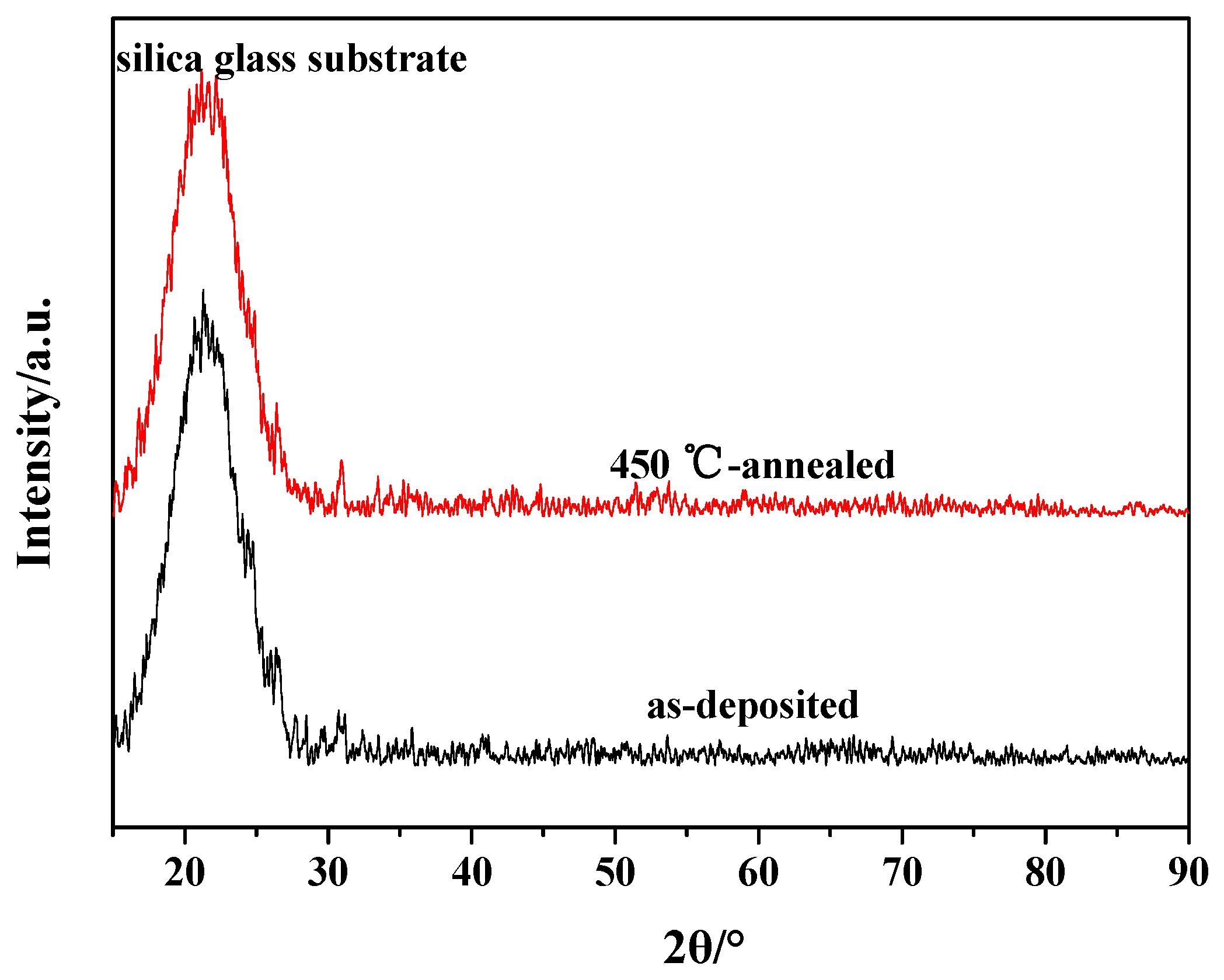

3.1. Basic Characterization

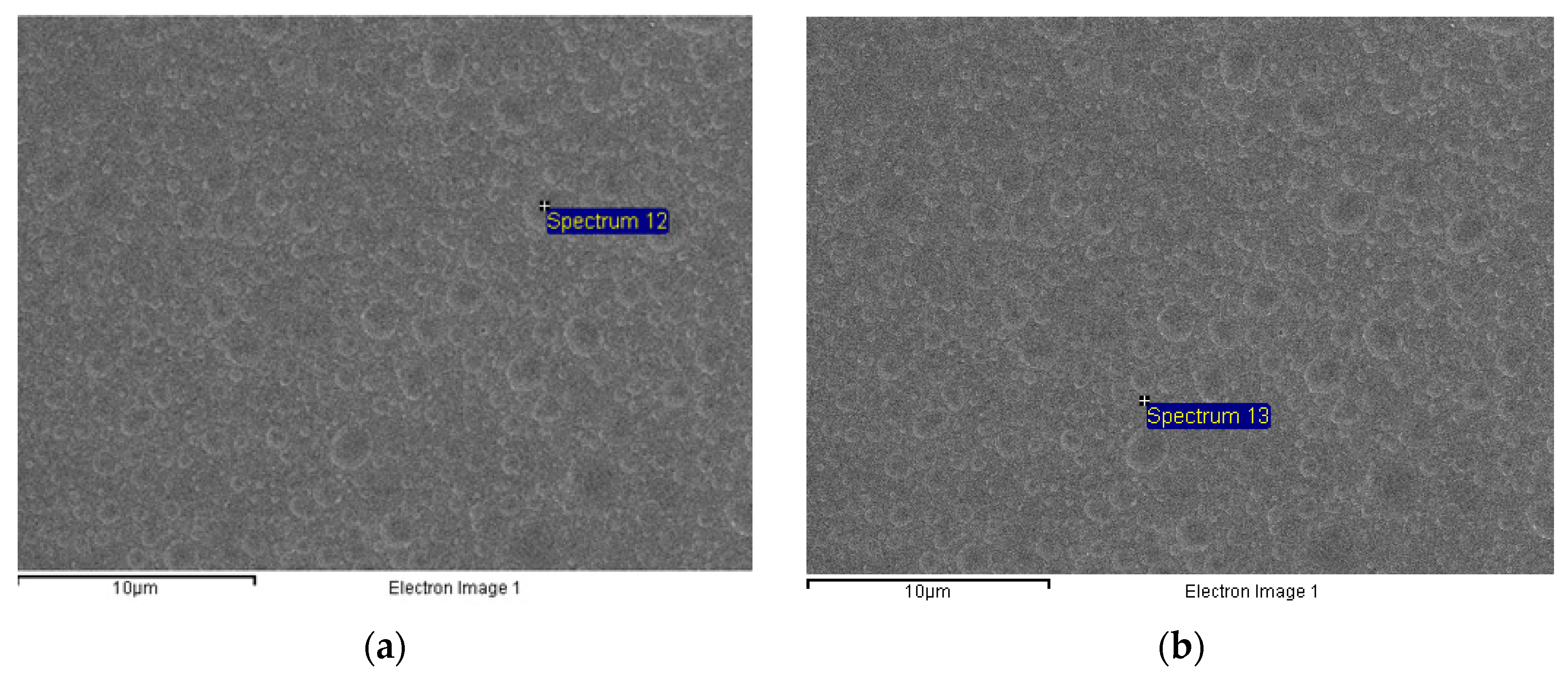

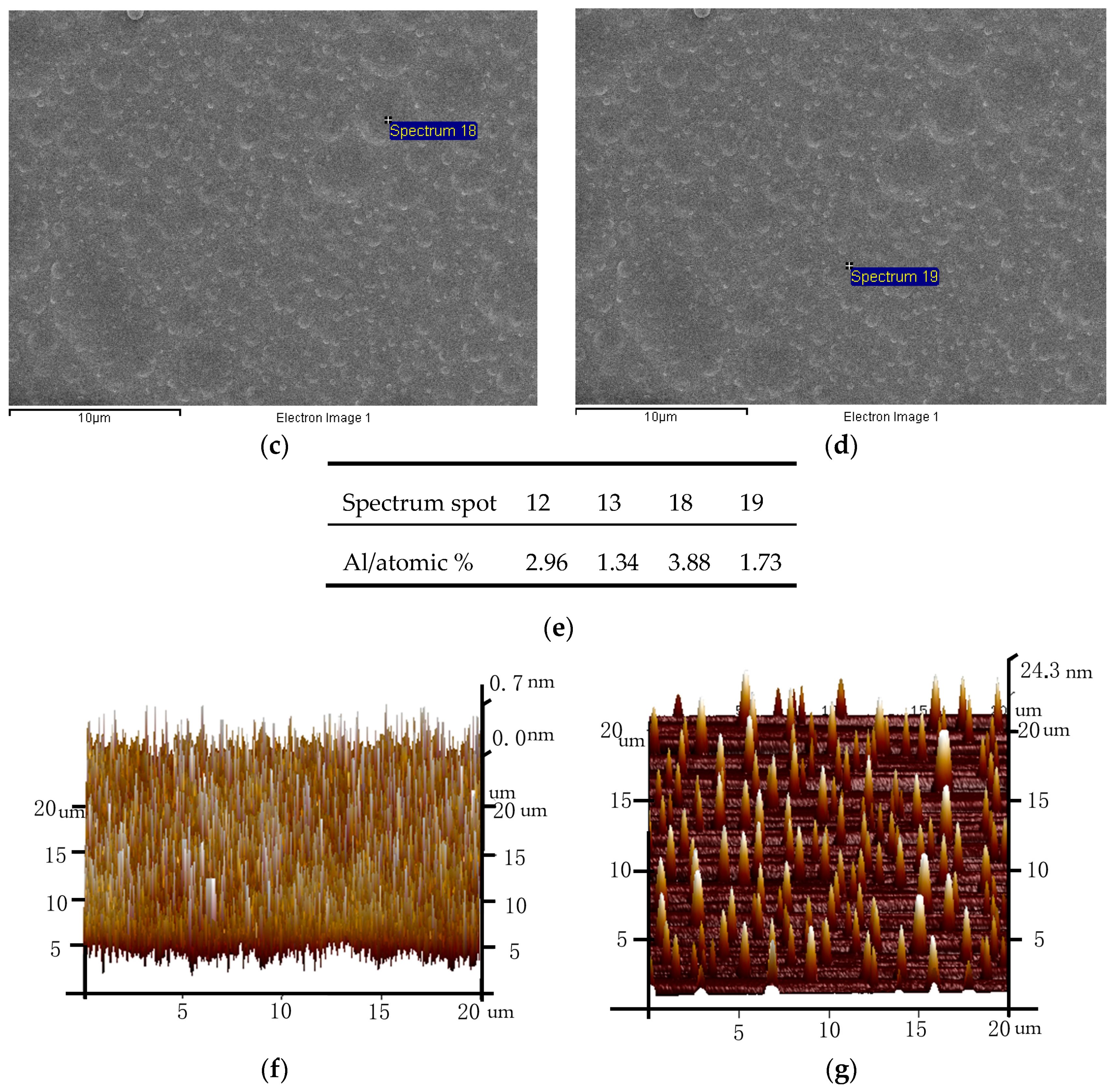

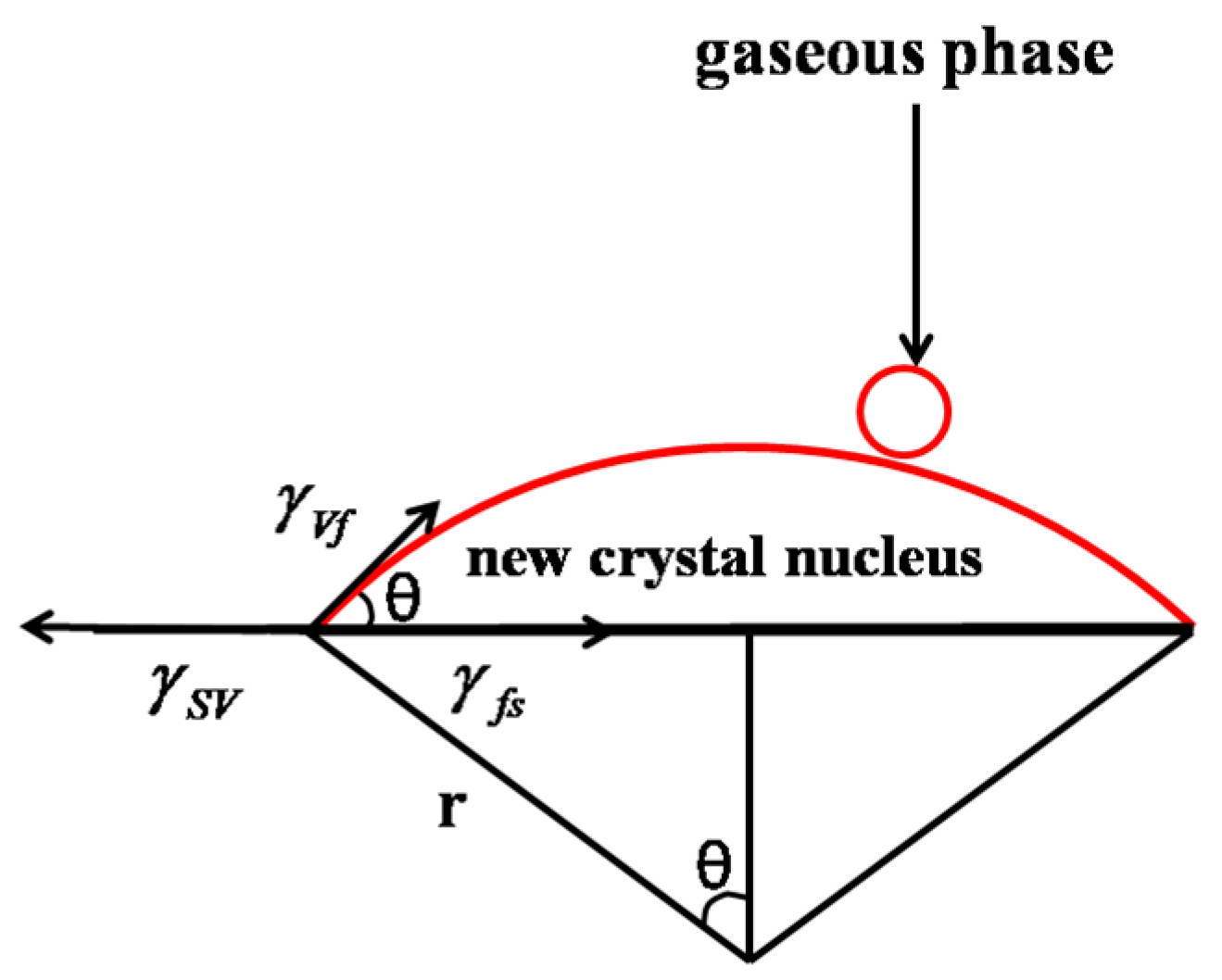

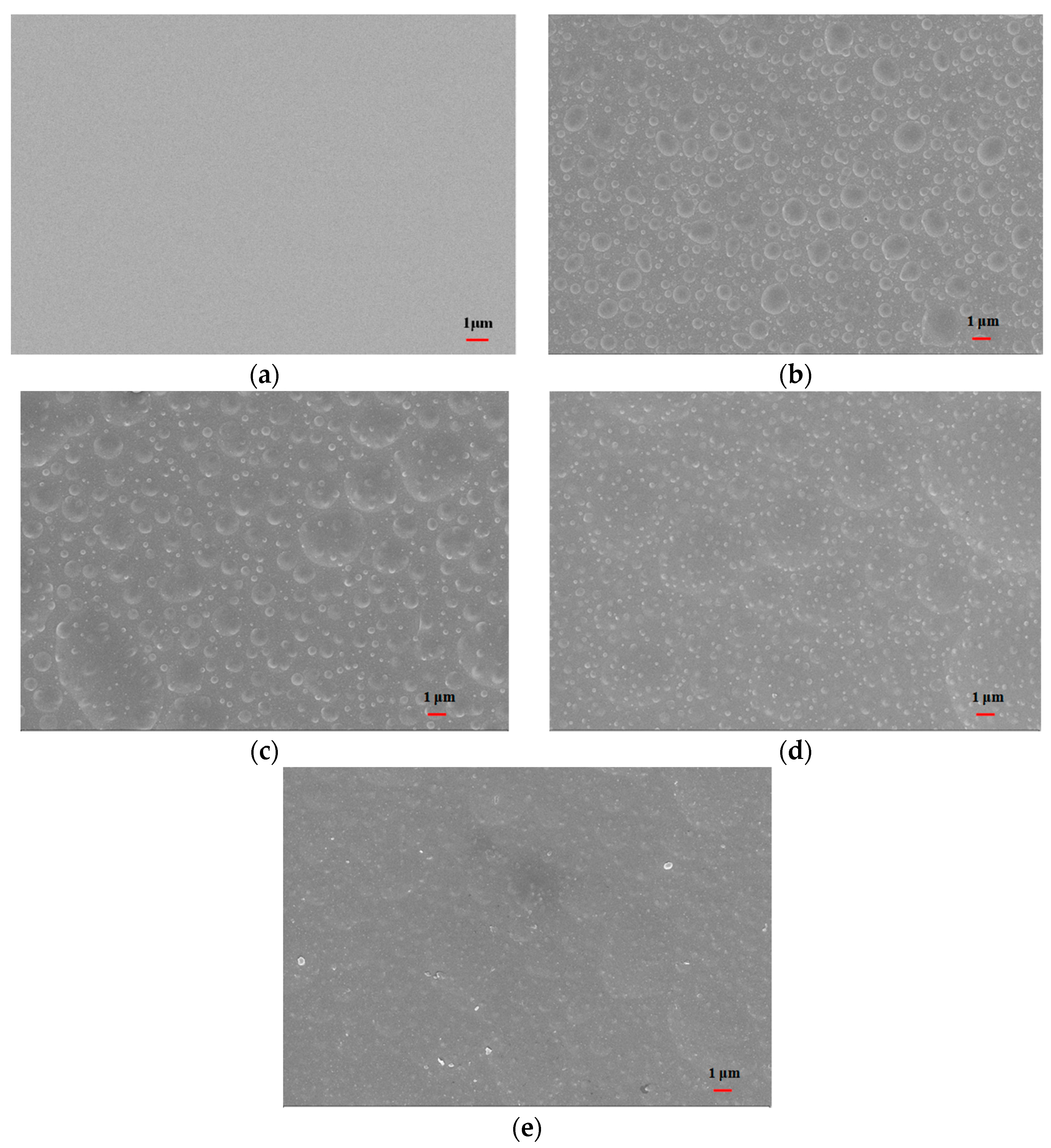

3.2. Film Growth and Surface Morphology

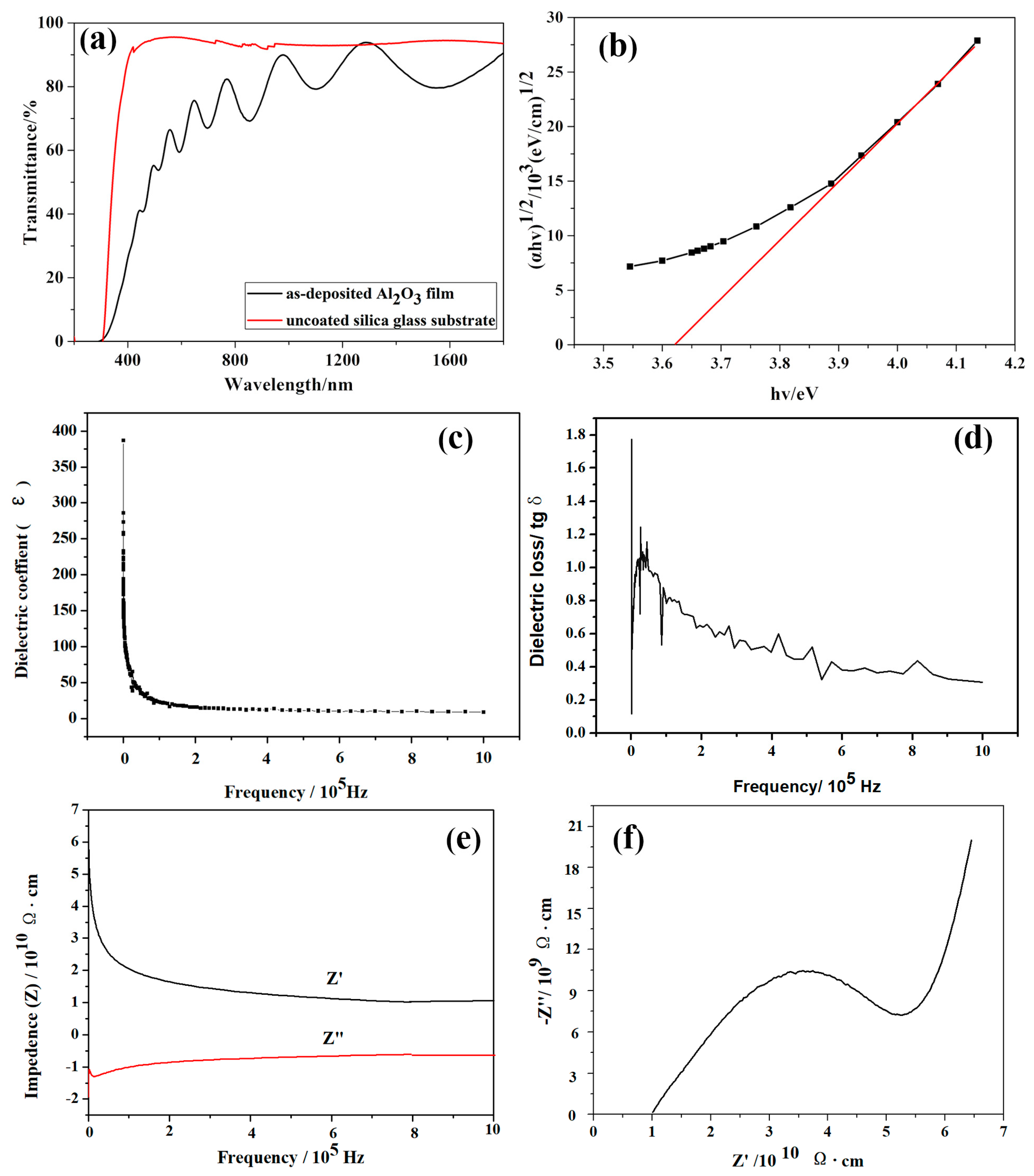

3.3. Optical and Dielectric Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bartzsch, H.; Glöß, D.; Böcher, B.; Frach, P.; Goedicke, K. Properties of SiO2 and Al2O3 films for electrical insulation applications deposited by reactive pulse magnetron sputtering. Surf. Coat. Technol. 2003, 174, 774–778. [Google Scholar] [CrossRef]

- Aramesh, M.; Djalalian-Assl, A.; Yajadda, M.M.A.; Prawer, S.; Ostrikov, K. Thin nanoporous metal–insulator–metal membranes. ACS Appl. Mater. Interfaces 2016, 8, 4292–4297. [Google Scholar] [CrossRef]

- Nigro, R.L.; Schilirò, E.; Greco, G.; Fiorenza, P.; Roccaforte, F. Surface treatments on AlGaN/GaN heterostructures for gate dielectric Al2O3 thin films grown by atomic layer deposition. Thin Solid Film. 2016, 617, 138–142. [Google Scholar] [CrossRef]

- Tang, X.; Luo, F.; Ou, F.; Zhou, W.; Zhu, D.; Huang, Z. Effects of negative substrate bias voltage on the structure and properties of aluminum oxide films prepared by DC reactive magnetron sputtering. Appl. Surf. Sci. 2012, 259, 448–453. [Google Scholar] [CrossRef]

- Cueff, R.; Baud, G.; Benmalek, M.; Besse, J.; Butruille, J.; Jacquet, M. X-ray photoelectron spectroscopy studies of plasma-modified PET surface and alumina/PET interface. Appl. Surf. Sci. 1997, 115, 292–298. [Google Scholar] [CrossRef]

- Shih, K.K. Deposition of aluminum oxide films with high refractive index. J. Vac. Sci. Technol. A 1994, 12, 321–322. [Google Scholar] [CrossRef]

- Lin, H.C.; Yang, T.; Sharifi, H.; Kim, S.K.; Xuan, Y.; Shen, T.; Mohammadi, S.; Ye, P.D. Enhancement-mode GaAs metal-oxide-semiconductor high-electron mobility transistors with atomic layer deposited Al2O3 as gate dielectric. Appl. Phys. Lett. 2007, 91, 212101. [Google Scholar] [CrossRef]

- Poodt, P.; Lankhorst, A.; Roozeboom, F.; Spee, K.; Maas, D.; Vermeer, A.; Spee, C. High-speed spatial atomic-layer deposition of aluminum oxide layers for solar cell passivation. Adv. Mater. 2010, 22, 3564–3567. [Google Scholar] [CrossRef] [PubMed]

- Chen, X. Design of plasmonic-semiconductor nano-resonator lasers, geometrical energy velocity, and laser output-coupler optimization. Ph.D. Thesis, Northwestern University, Evanston, IL, USA, 2012. [Google Scholar]

- Zhu, L.; Liu, Y.; Zhang, H.; Xiao, H.; Guo, L. Atomic layer deposited Al2O3 films for anti-reflectance and surface passivation applications. Appl. Surf. Sci. 2014, 288, 430–434. [Google Scholar] [CrossRef]

- Von Gastrow, G.; Alcubilla, R.; Ortega, P.; Yli-Koski, M.; Conesa-Boj, S.; I Morral, A.F.; Savin, H. Analysis of the atomic layer deposited Al2O3 field-effect passivation in black silicon. Sol. Energy Mater. Sol. Cells 2015, 142, 29–33. [Google Scholar] [CrossRef]

- George, S.M. Atomic layer deposition: An overview. Chem. Rev. 2010, 110, 111–131. [Google Scholar] [CrossRef]

- Cuevas, A.; Li, T.-T.; Li, T. Effective surface passivation of crystalline silicon by RF sputtered aluminum oxide. Phys. Status Solidi RRL Rapid Res. Lett. 2009, 3, 160–162. [Google Scholar]

- Compaan, A.D.; Gupta, A.; Lee, S.; Wang, S.; Drayton, J. High efficiency, magnetron sputtered CdS/CdTe solar cells. Sol. Energy 2004, 77, 815–822. [Google Scholar] [CrossRef]

- Shimanovich, D.L.; Vorobjova, A.I.; Tishkevich, D.I.; Trukhanov, A.V.; Zdorovets, M.V.; Kozlovskiy, A.L. Preparation and morphology-dependent wettability of porous alumina membranes. Beilstein J. Nanotechnol. 2018, 9, 1423–1436. [Google Scholar] [CrossRef]

- Li, T.-T.A.; Ruffell, S.; Tucci, M.; Mansoulie, Y.; Samundsett, C.; De Iullis, S.; Serenelli, L.; Cuevas, A. Influence of oxygen on the sputtering of aluminum oxide for the surface passivation of crystalline silicon. Sol. Energy Mater. Sol. Cells 2011, 95, 69–72. [Google Scholar] [CrossRef]

- Cremer, R.; Witthaut, M.; Neuschütz, D.; Erkens, G.; Leyendecker, T.; Feldhege, M. Comparative characterization of alumina coatings deposited by RF, DC and pulsed reactive magnetron sputtering. Surf. Coat. Technol. 1999, 120, 213–218. [Google Scholar] [CrossRef]

- Ha, W.; Choo, M.; Im, S. Electrical properties of Al2O3 film deposited at low temperatures. J. Non-Cryst. Solids 2002, 303, 78–82. [Google Scholar] [CrossRef]

- Garcıa-Serrano, J.; Galindo, A.G.; Pal, U. Au–Al2O3 nanocomposites: XPS and FTIR spectroscopic studies. Sol. Energy Mater. Sol. Cells 2004, 82, 291–298. [Google Scholar] [CrossRef]

- Sun, C.; Zeng, R.; Zhang, J.; Qiu, Z.J.; Wu, D. Effects of UV-Ozone treatment on sensing behaviors of EGFETs with Al2O3 sensing film. Materials 2017, 10, 1432. [Google Scholar] [CrossRef] [PubMed]

- Afify, N.D.; Dalba, G.; Koppolu, U.M.K.; Armellini, C.; Jestin, Y.; Rocca, F. XRD and EXAFS studies of HfO2 crystallisation in SiO2–HfO2 films. Mater. Sci. Semicond. Process. 2006, 9, 1043–1048. [Google Scholar] [CrossRef]

- Takagi, A.; Nomura, K.; Ohta, H.; Yanagi, H.; Kamiya, T.; Hirano, M.; Hosono, H. Carrier transport and electronic structure in amorphous oxide semiconductor, a-InGaZnO4. Thin Solid Film. 2005, 486, 38–41. [Google Scholar] [CrossRef]

- Grover, M.S.; A Hersh, P.; Chiang, H.Q.; Kettenring, E.S.; Wager, J.F.; A Keszler, D. Thin-film transistors with transparent amorphous zinc indium tin oxide channel layer. J. Phys. D Appl. Phys. 2007, 40, 1335–1338. [Google Scholar] [CrossRef]

- Lüth, H. Solid Surfaces, Interfaces and Thin Films; Springer Nature: Aachen, Germany, 2010. [Google Scholar]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Khanna, A.; Bhat, D.G. Nanocrystalline gamma alumina coatings by inverted cylindrical magnetron sputtering. Surf. Coat. Technol. 2006, 201, 168–173. [Google Scholar] [CrossRef]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical properties and electronic structure of amorphous germanium. Phys. Status Solidi b 1966, 15, 627–637. [Google Scholar] [CrossRef]

- Prathap, P.; Subbaiah, Y.; Devika, M.; Reddy, K.R. Optical properties of In2O3 films prepared by spray pyrolysis. Mater. Chem. Phys. 2006, 100, 375–379. [Google Scholar] [CrossRef]

- Hu, B.; Yao, M.; Xiao, R.; Chen, J.; Yao, X. Optical properties of amorphous Al2O3 thin films prepared by a sol–gel process. Ceram. Int. 2014, 40, 14133–14139. [Google Scholar] [CrossRef]

- Adamopoulos, G.; Thomas, S.; Bradley, D.D.; McLachlan, M.A.; Anthopoulos, T.D. Low-voltage ZnO thin-film transistors based on Y2O3 and Al2O3 high-k dielectrics deposited by spray pyrolysis in air. Appl. Phys. Lett. 2011, 98, 123503. [Google Scholar] [CrossRef]

- Costina, I.; Franchy, R. Band gap of amorphous and well-ordered Al2O3 on Ni3Al (100). Appl. Phys. Lett. 2011, 78, 4139. [Google Scholar] [CrossRef]

- Shamala, K.; Murthy, L.; Rao, K.N. Studies on optical and dielectric properties of Al2O3 thin films prepared by electron beam evaporation and spray pyrolysis method. Mater. Sci. Eng. B 2004, 106, 269–274. [Google Scholar] [CrossRef]

- Segda, B.; Jacquet, M.; Besse, J. Elaboration, characterization and dielectric properties study of amorphous alumina thin films deposited by r.f. magnetron sputtering. Vacuum 2001, 62, 27–38. [Google Scholar] [CrossRef]

- Hu, B.; Yao, M.; Yang, P.; Shan, W.; Yao, X. Preparation and dielectric properties of dense and amorphous alumina film by sol–gel technology. Ceram. Int. 2013, 39, 7613–7618. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, X.; Li, Z.; Liao, H.; Zhang, J. Growth of Ultrathin Al2O3 Films on n-InP Substrates as Insulating Layers by RF Magnetron Sputtering and Study on the Optical and Dielectric Properties. Coatings 2019, 9, 341. https://doi.org/10.3390/coatings9050341

Tang X, Li Z, Liao H, Zhang J. Growth of Ultrathin Al2O3 Films on n-InP Substrates as Insulating Layers by RF Magnetron Sputtering and Study on the Optical and Dielectric Properties. Coatings. 2019; 9(5):341. https://doi.org/10.3390/coatings9050341

Chicago/Turabian StyleTang, Xiufeng, Zhixin Li, Huizhen Liao, and Jiong Zhang. 2019. "Growth of Ultrathin Al2O3 Films on n-InP Substrates as Insulating Layers by RF Magnetron Sputtering and Study on the Optical and Dielectric Properties" Coatings 9, no. 5: 341. https://doi.org/10.3390/coatings9050341

APA StyleTang, X., Li, Z., Liao, H., & Zhang, J. (2019). Growth of Ultrathin Al2O3 Films on n-InP Substrates as Insulating Layers by RF Magnetron Sputtering and Study on the Optical and Dielectric Properties. Coatings, 9(5), 341. https://doi.org/10.3390/coatings9050341