Cavitation Erosion and Sliding Wear Mechanisms of AlTiN and TiAlN Films Deposited on Stainless Steel Substrate

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

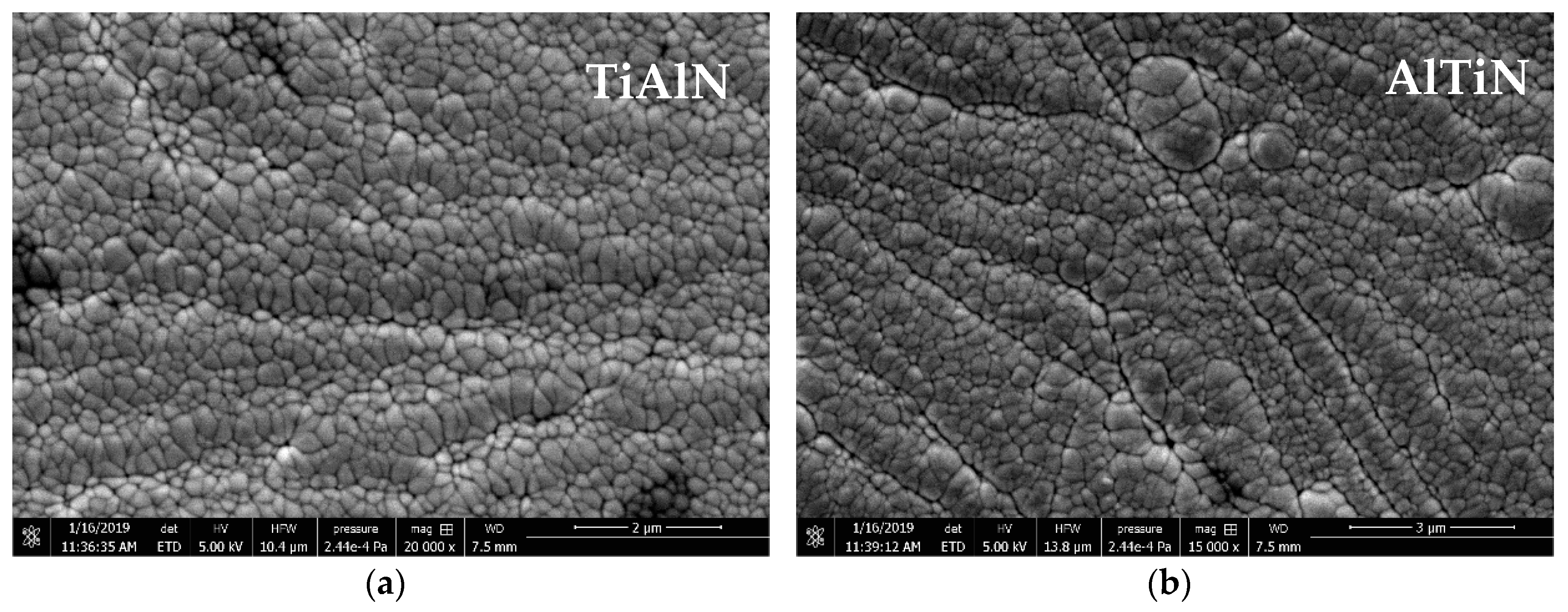

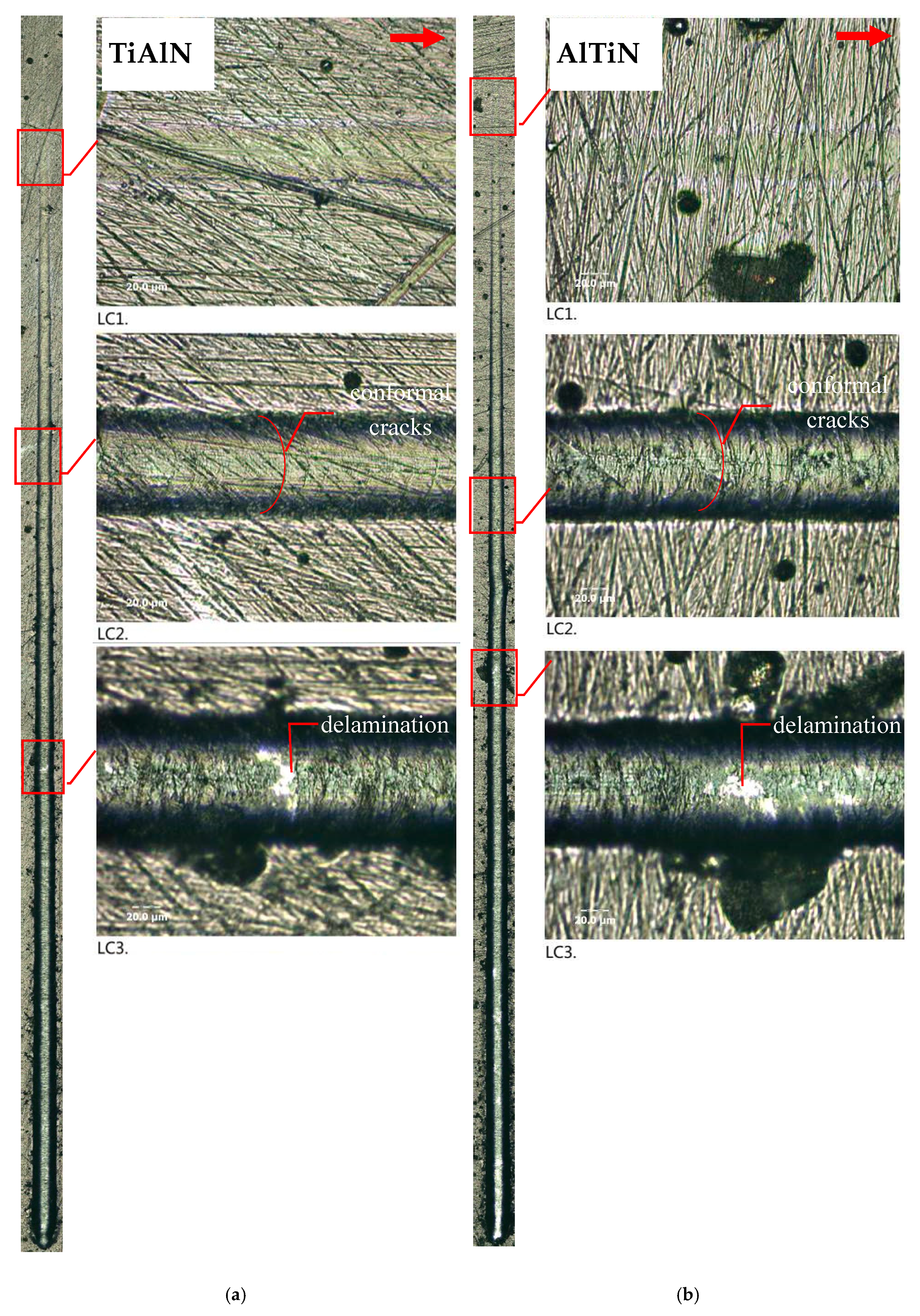

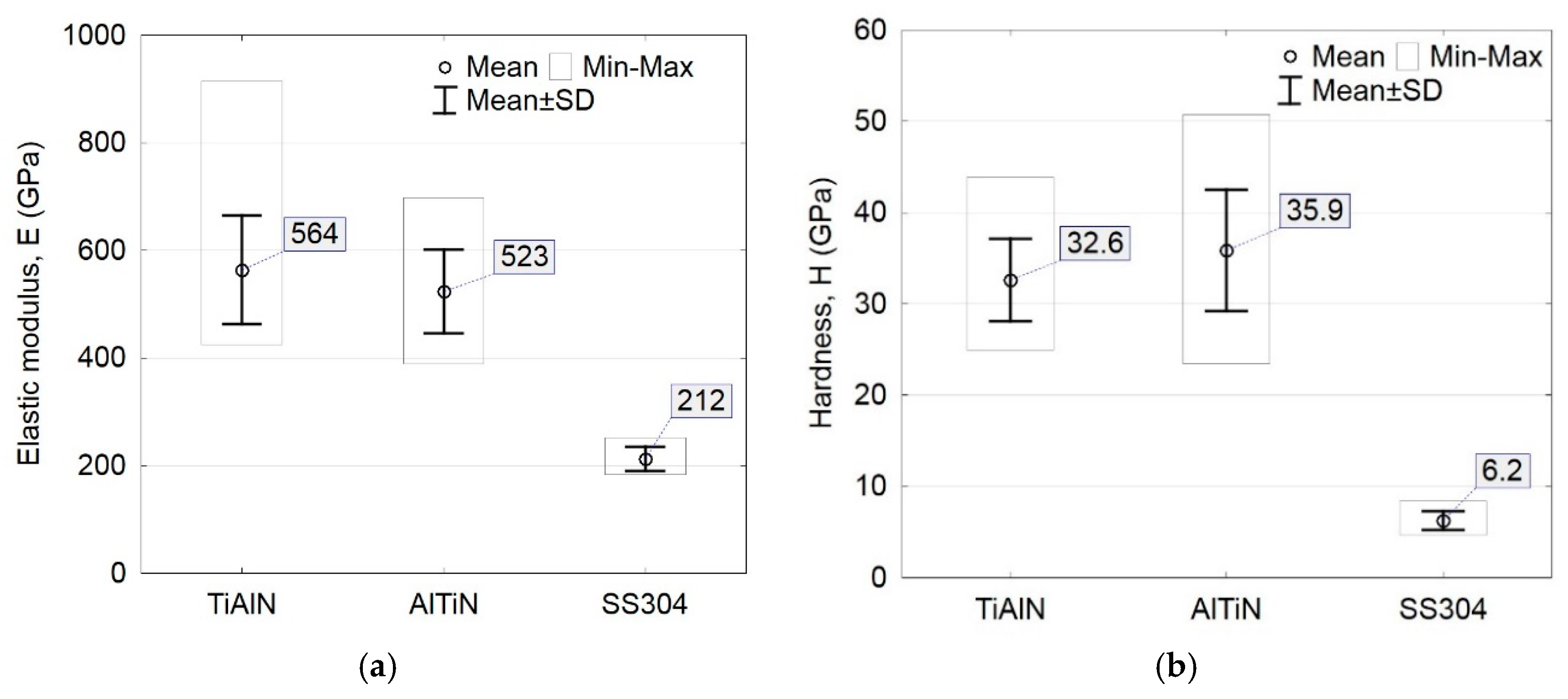

3.1. Description of Film Properties in Relation to Stainless Steel Substrate

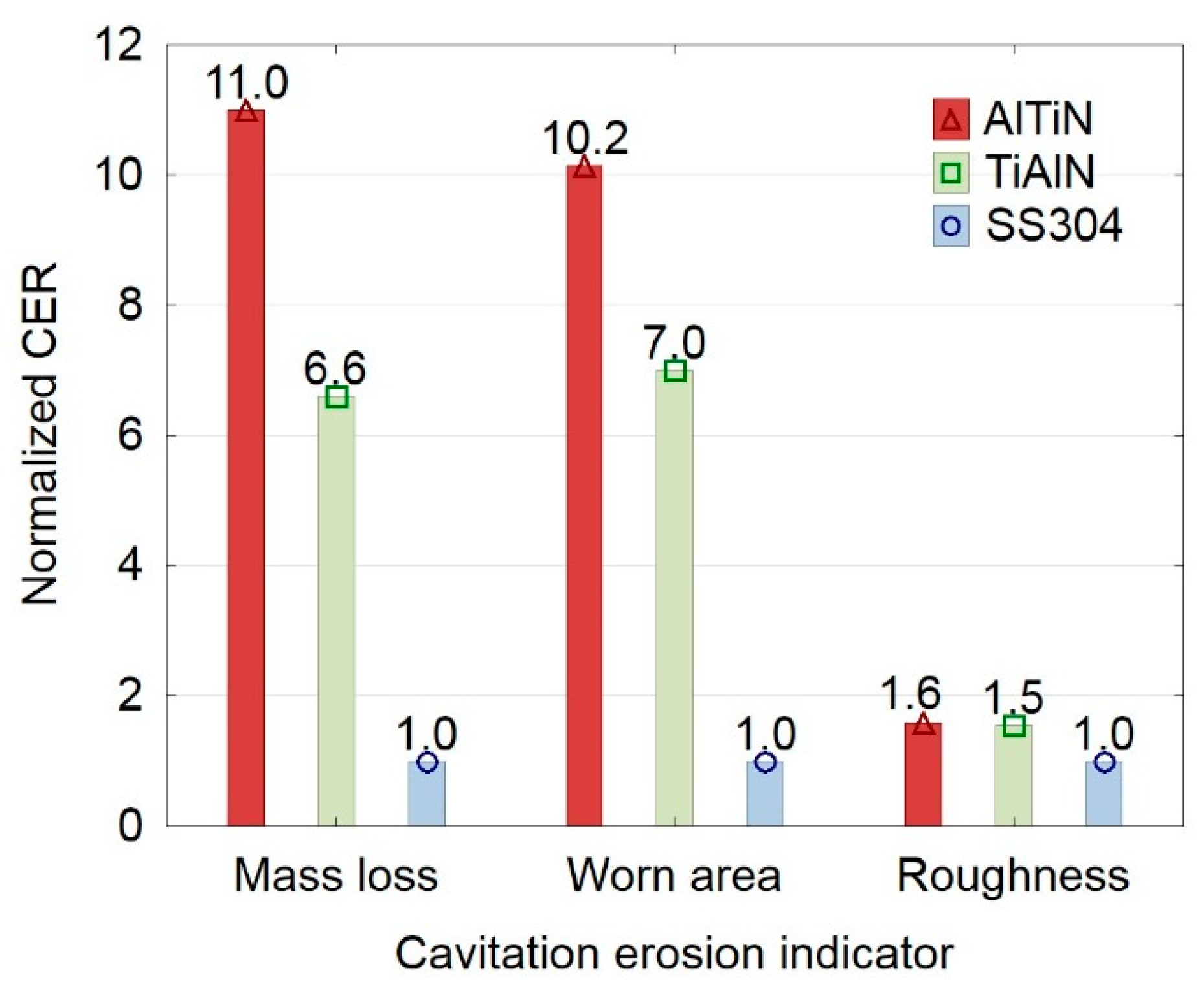

3.2. Cavitaiton Erosion Resitance (CER)

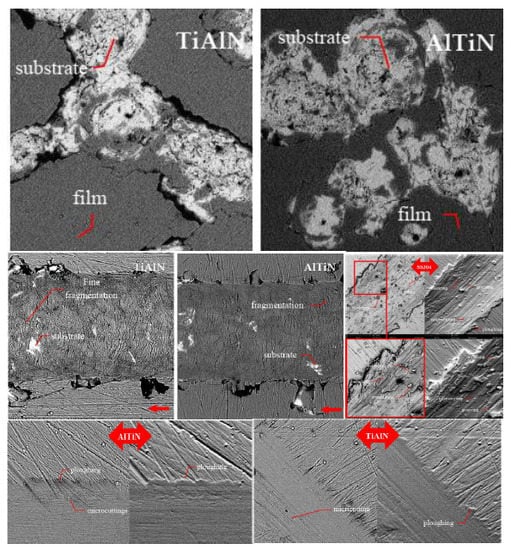

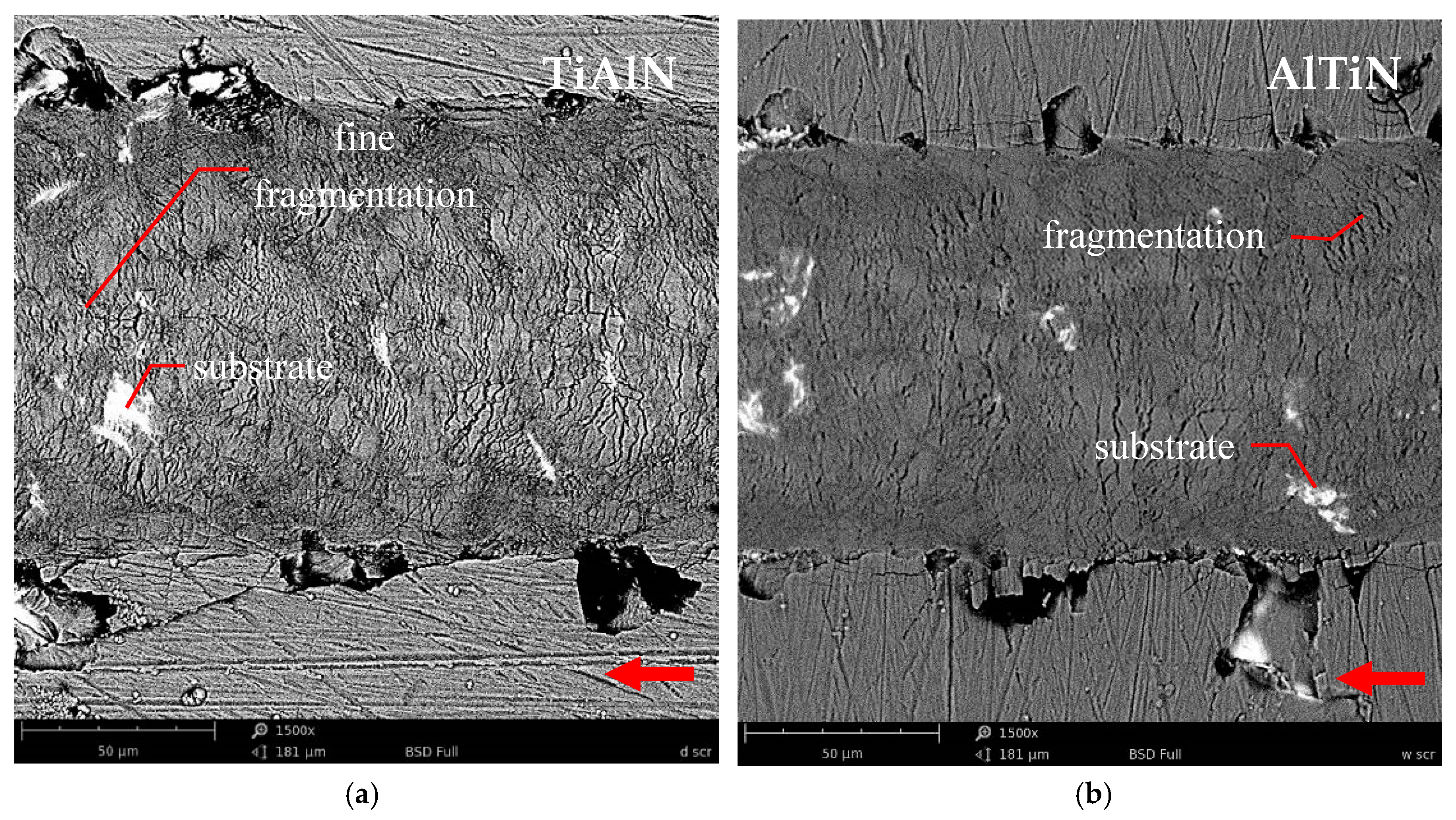

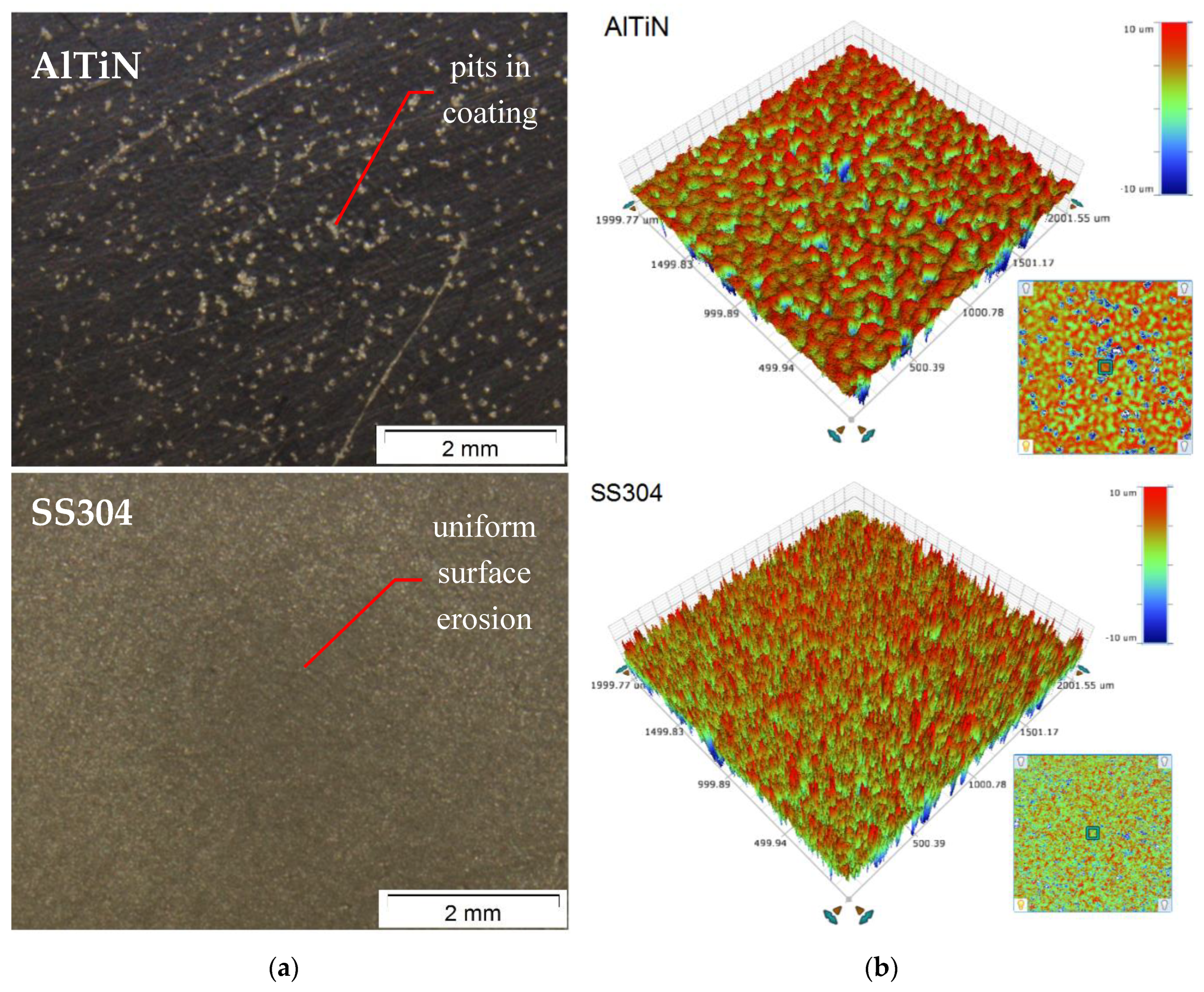

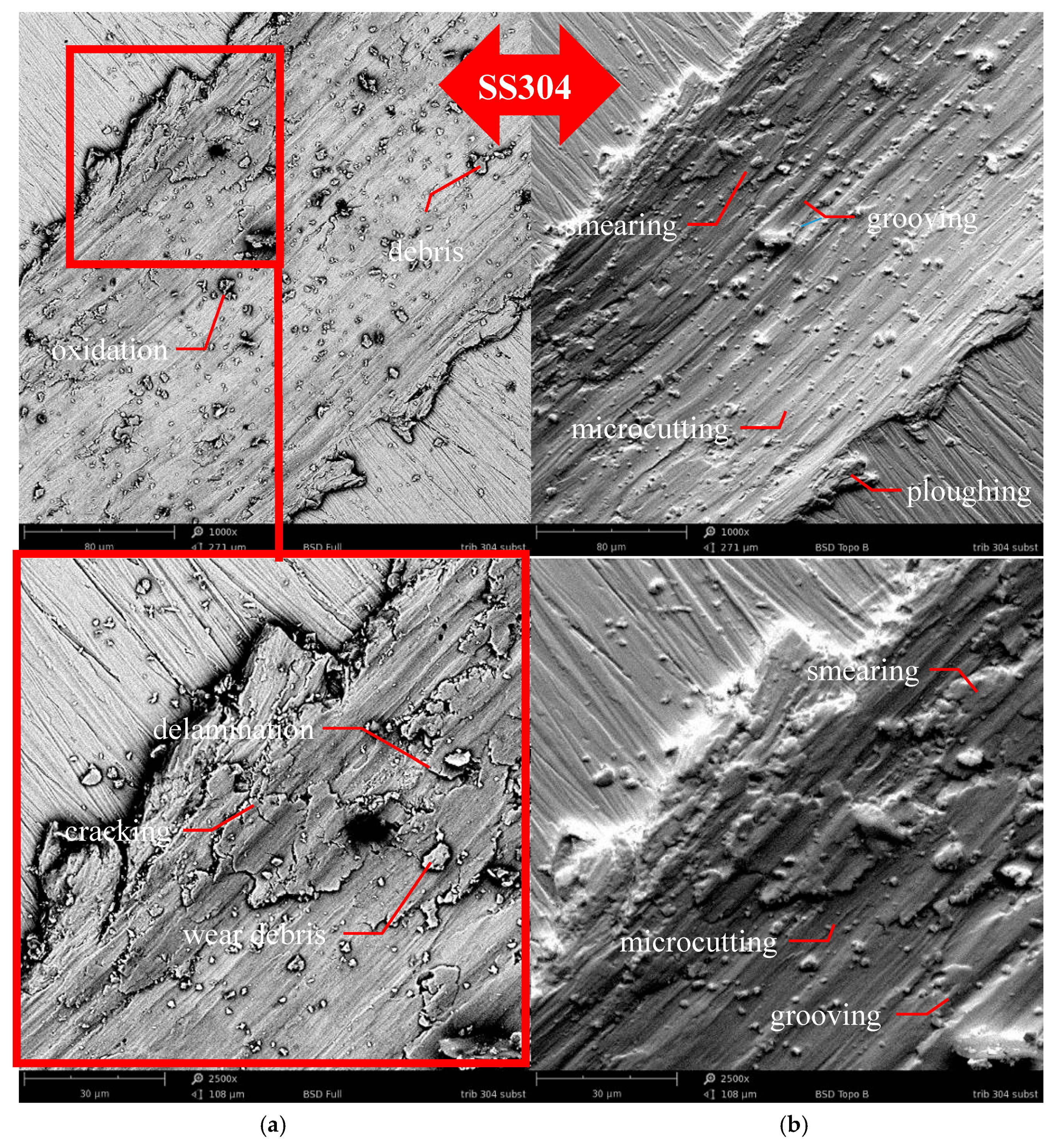

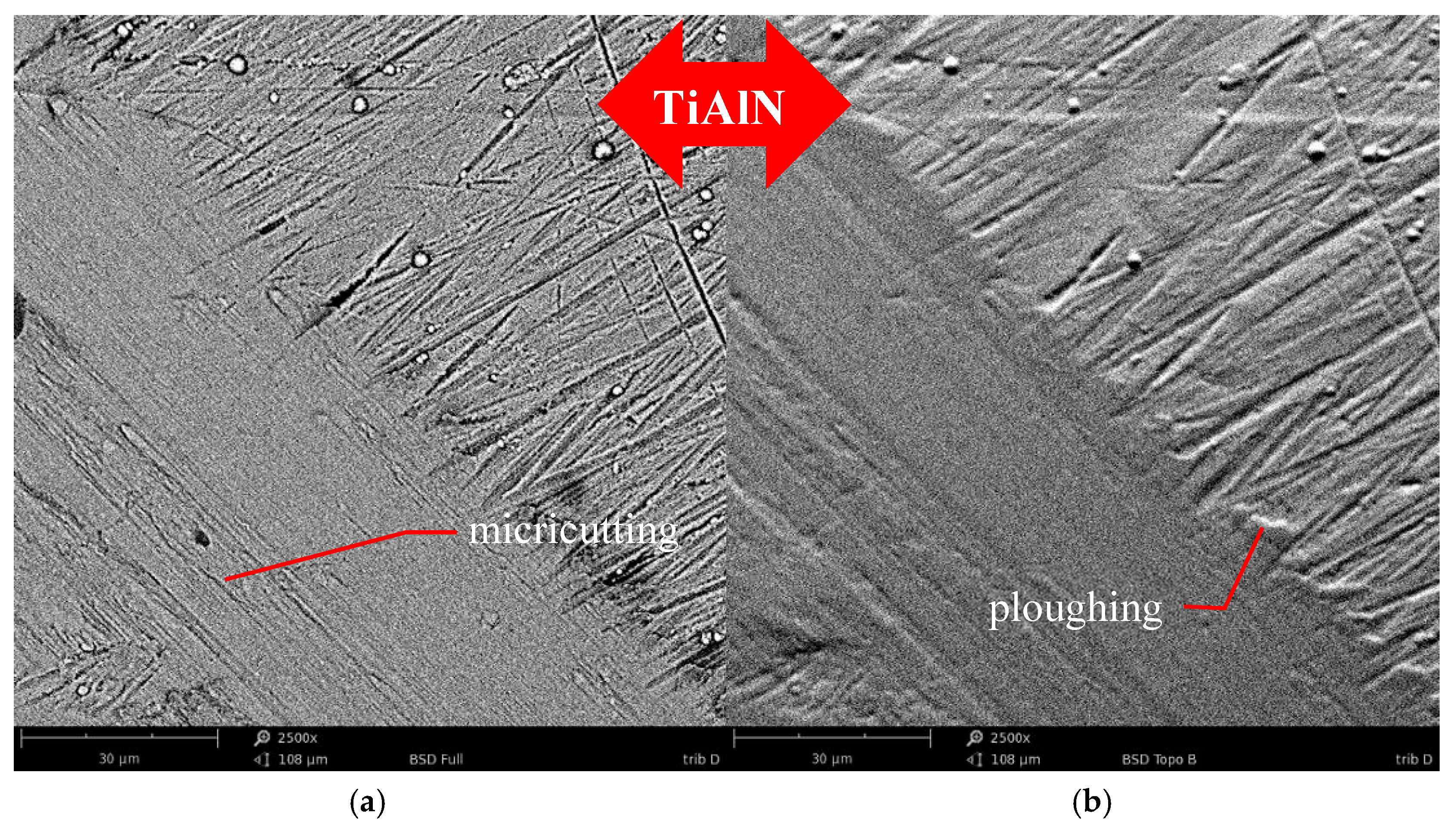

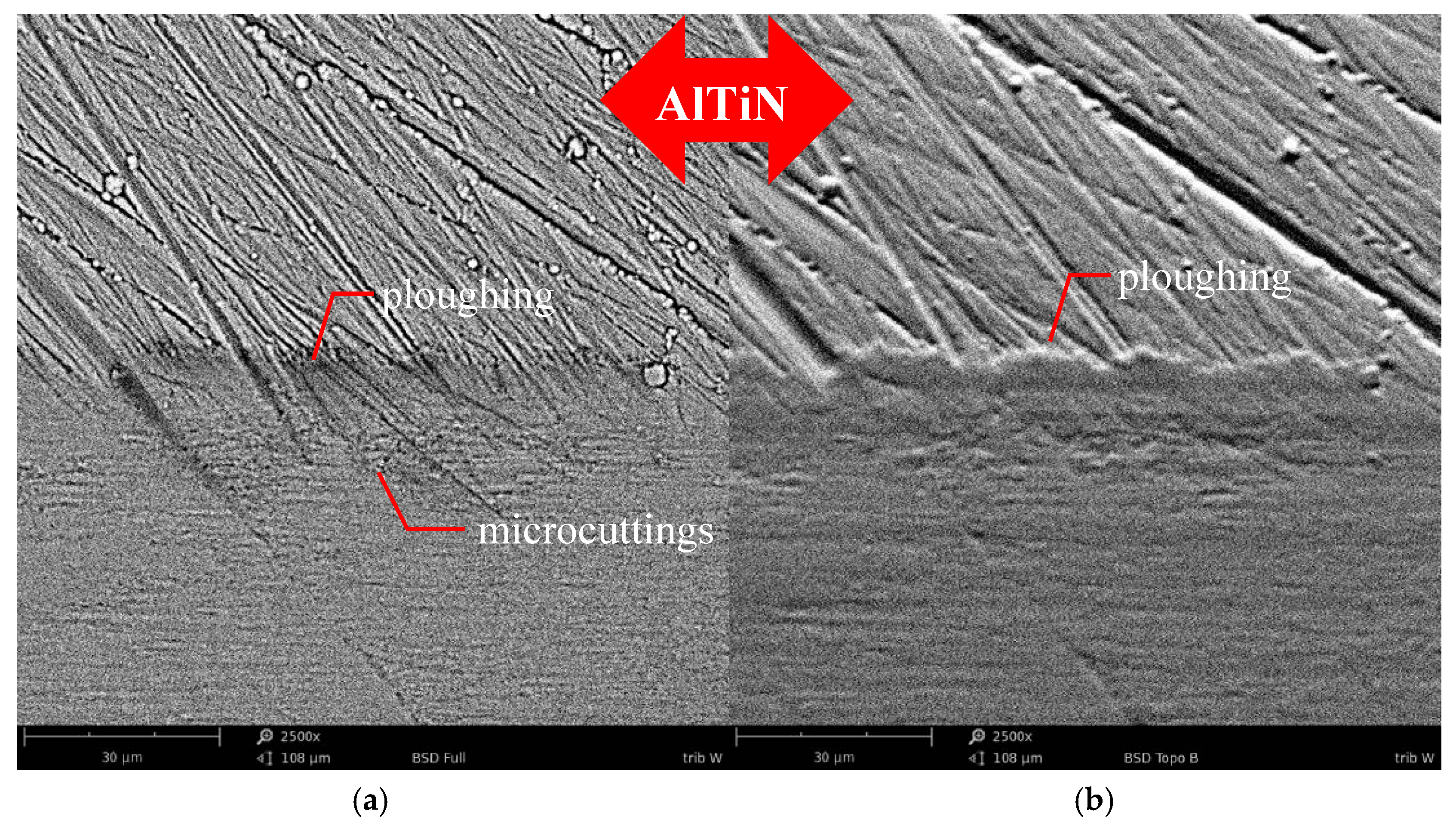

3.2.1. Mechanism of Cavitation Erosion Damage

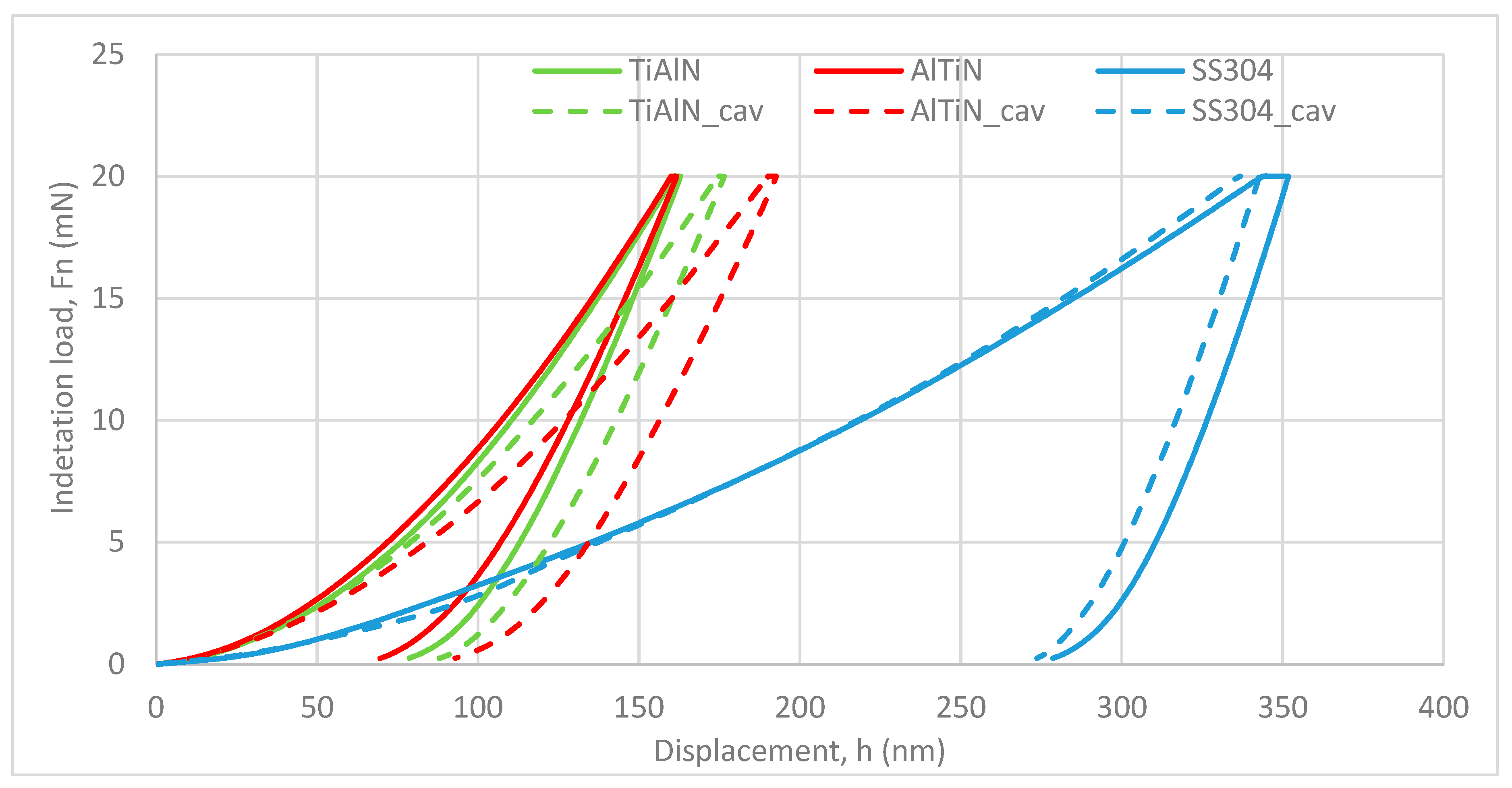

3.2.2. Effect of Cavitation Erosion on Nanoindentation Results

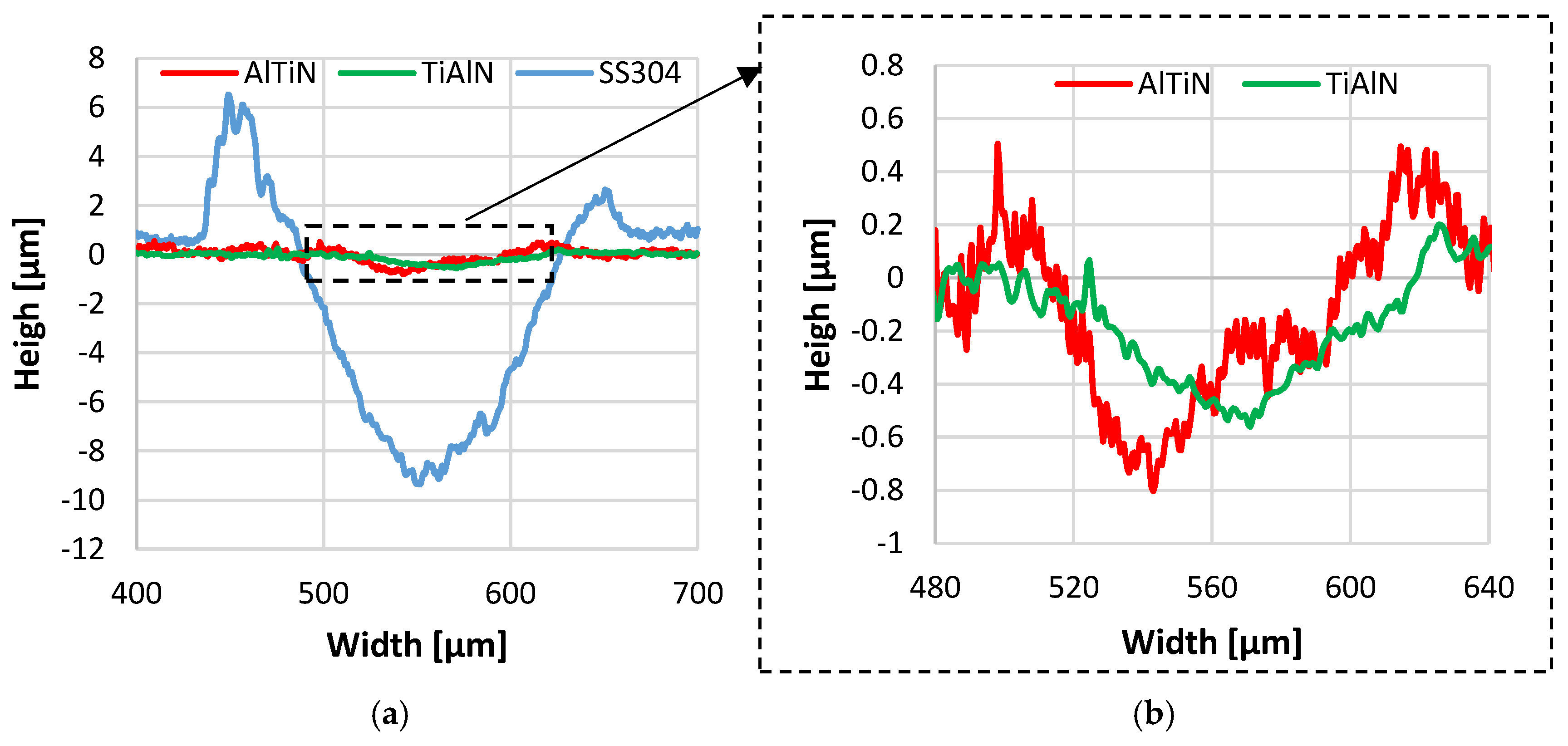

3.3. Sliding Wear Behaviour (Ball-on-disc Test)

4. Conclusions

- The properties of the films demonstrate that they have a satisfactory structure, i.e., they exhibit a typical columnar morphology comparable to the roughness of the SS substrate, however it varies in thickness, amounting to ≈2.7 µm for TiAlN and ≈3.8 µm for AlTiN. Also, the Rockwell and scratch test results of the films indicate their satisfactory adhesion to the SS substrate, even though a higher force of the Lc2 parameters for AlTiN than TiAlN suggests that AlTiN adheres more strongly to the substrate. The AlTiN film exhibits highly elastic behavior and high resistance to plastic deformation, i.e., its H/E and H3/E2 coefficients are higher than those of TiAlN, which can be attributed to its chemical composition, i.e., a higher Al/(Ti + Al) ratio of the AlTiN film.

- The cavitation erosion resistance of AlTiN is almost one third higher than that of the TiAlN film and almost ten times higher than that of the SS304 sample. The effect of the chemical composition and mechanical properties of the films on their cavitation erosion resistance have been confirmed. The higher Al content, adhesion and H/E and H3/E2 coefficients are beneficial for the CER of a film, and can thus serve as a basis for predicting the CER of AlTiN and AlTiN coatings.

- The cavitation erosion mechanism of both AlTiN and AlTiN coatings is brittle in nature, and depends on fatigue processes that cause rupture and spallation of the coating. However, a comparison of the cavitation-worn TiAlN and AlTiN films reveals a higher degree of fragmentation of the TiAlN film, which ultimately accelerates the wear of the TiAlN film. Additionally, the nanoindentation results (H and E) of the films measured before and after cavitation testing indicate the presence of film material decohesion due to the fatigue-dependent nature of cavitation impact. The film wear mechanism consists in fatigue-induced flake spallation.

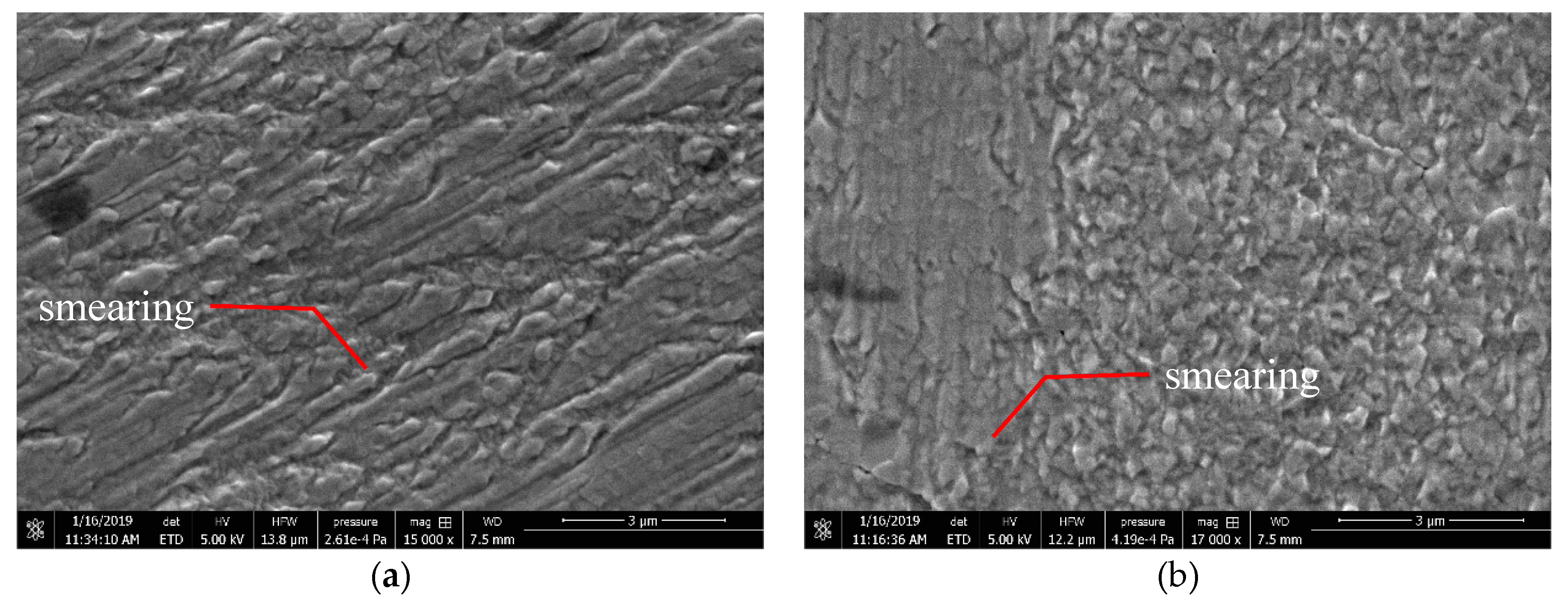

- The sliding wear of the uncoated SS304 sample is higher than that of the sample after PVD coating. The sliding wear resistance of AlTiN and TiAlN is similar yet it is more than 24 times higher than that of the stainless steel sample. Additionally, the application of PVD films onto stainless steel substrates leads to an almost twofold decrease in the friction coefficient. The sliding wear mechanism of the AlTiN and TiAlN films takes the form of grooving, micro-scratching, micro-ploughing and smearing of the columnar grain top hills.

- The results confirm that cavitation erosion of various fluid machinery components made of austenitic stainless steel can be prevented by depositing AlTiN and TiAlN films.

Author Contributions

Funding

Conflicts of Interest

References

- Ha, H.-Y.; Jang, J.H.; Lee, T.-H.; Won, C.; Lee, C.-H.; Moon, J.; Lee, C.-G. Investigation of the localized corrosion and passive behavior of type 304 stainless steels with 0.2–1.8 wt % B. Materials 2018, 11, 2097. [Google Scholar] [CrossRef]

- Ławrynowicz, Z. Effect of the degree of cold work and sensitization time on intergranular corrosion behavior in austenitic stainless steel. Adv. Mater. Sci. 2019, 19, 32–43. [Google Scholar] [CrossRef]

- España, P.C.; Recco, A.A.C.; Olaya, J.J. A microstructural and wear resistance study of stainless steel-ag coatings produced through magnetron sputtering. Coatings 2018, 8, 381. [Google Scholar]

- Ha, H.-Y.; Lee, T.-H.; Bae, J.-H.; Chun, D.W. Molybdenum Effects on pitting corrosion resistance of fecrmnmonc austenitic stainless steels. Metals 2018, 8, 653. [Google Scholar] [CrossRef]

- Szala, M.; Beer-Lech, K.; Walczak, M. A study on the corrosion of stainless steel floor drains in an indoor swimming pool. Eng. Fail. Anal. 2017, 77, 31–38. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, Y.; Yu, D. Microstructure and mechanical properties of pressure-quenched ss304 stainless steel. Materials 2019, 12, 290. [Google Scholar] [CrossRef]

- Krella, A.K. The new parameter to assess cavitation erosion resistance of hard PVD coatings. Eng. Fail. Anal. 2011, 18, 855–867. [Google Scholar] [CrossRef]

- Subramanian, B.; Umamaheswari, G.; Jayachandran, M. Properties and corrosion behaviour of reactive magnetron sputtered TiAlN coatings on AISI 316L SS in simulated bodily fluid. Corros. Eng. Sci. Technol. 2007, 42, 349–355. [Google Scholar] [CrossRef]

- Chen, L.; Paulitsch, J.; Du, Y.; Mayrhofer, P.H. Thermal stability and oxidation resistance of Ti–Al–N coatings. Surf. Coat. Technol. 2012, 206, 2954–2960. [Google Scholar] [CrossRef]

- Özkan, D. Friction behavior of TiAlN, AlTiN and AlCrN multilayer coatings at nanoscale. Erzincan Üniversitesi Fen Bilim. Enstitüsü Derg. 2018, 11, 451–458. [Google Scholar] [CrossRef][Green Version]

- Hans, M.; Patterer, L.; Music, D.; Holzapfel, D.M.; Evertz, S.; Schnabel, V.; Stelzer, B.; Primetzhofer, D.; Völker, B.; Widrig, B.; et al. Stress-dependent elasticity of tialn coatings. Coatings 2019, 9, 24. [Google Scholar] [CrossRef]

- Kulkarni, A.P.; Sargade, V.G. Characterization and performance of AlTiN, AlTiCrN, TiN/TiAlN PVD coated carbide tools while turning ss 304. Mater. Manuf. Process. 2015, 30, 748–755. [Google Scholar] [CrossRef]

- Kohlscheen, J.; Bareiss, C. Effect of hexagonal phase content on wear behaviour of AlTiN Arc PVD coatings. Coatings 2018, 8, 72. [Google Scholar] [CrossRef]

- Fan, Q.-X.; Wang, T.-G.; Liu, Y.-M.; Wu, Z.-H.; Zhang, T.; Li, T.; Yang, Z.-B. Microstructure and corrosion resistance of the AlTiN coating deposited by arc ion plating. Acta Metall. Sin. Engl. Lett. 2016, 29, 1119–1126. [Google Scholar] [CrossRef]

- Shen, W.-J.; Tsai, M.-H.; Yeh, J.-W. Machining performance of sputter-deposited (Al0.34Cr0.22Nb0.11Si0.11Ti0.22)50N50 high-entropy nitride coatings. Coatings 2015, 5, 312–325. [Google Scholar] [CrossRef]

- Krella, A.; Czyżniewski, A. Cavitation erosion resistance of nanocrystalline TiN coating deposited on stainless steel. Wear 2008, 265, 963–970. [Google Scholar] [CrossRef]

- Itoh, T.; Hattori, S.; Lee, K.-Y. Cavitation erosion of 6061 aluminum alloy coated with TiAlN thin film. J. Solid Mech. Mater. Eng. 2010, 4, 1444–1454. [Google Scholar] [CrossRef][Green Version]

- Łępicka, M.; Grądzka-Dahlke, M.; Pieniak, D.; Pasierbiewicz, K.; Kryńska, K.; Niewczas, A. Tribological performance of titanium nitride coatings: A comparative study on TiN-coated stainless steel and titanium alloy. Wear 2019, 422–423, 68–80. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Berg, G.; Friedrich, C.; Broszeit, E.; Berger, C. Development of chromium nitride coatings substituting titanium nitride. Surf. Coat. Technol. 1996, 86–87, 184–191. [Google Scholar] [CrossRef]

- Mattox, D.M. Chapter 10: Film characterization and some basic film properties. In Handbook of Physical Vapor Deposition (PVD) Processing; Mattox, D.M., Ed.; William Andrew Publishing: Westwood, NJ, USA, 1998; pp. 569–615. ISBN 978-0-8155-1422-0. [Google Scholar]

- Cai, F.; Huang, X.; Yang, Q. Mechanical properties, sliding wear and solid particle erosion behaviors of plasma enhanced magnetron sputtering CrSiCN coating systems. Wear 2015, 324–325, 27–35. [Google Scholar] [CrossRef]

- Walczak, M.; Pasierbiewicz, K.; Szala, M. Adhesion and mechanical properties of TiAlN and AlTiN magnetron sputtered coatings deposited on DMSL titanium alloy substrate. Acta Phys. Pol. A 2019, in press. [Google Scholar]

- Vidakis, N.; Antoniadis, A.; Bilalis, N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds. J. Mater. Process. Technol. 2003, 143–144, 481–485. [Google Scholar] [CrossRef]

- ASTM G32-10: Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; West Conshohocken: Philadelphia, PA, USA, 2010.

- Szala, M.; Hejwowski, T. Cavitation erosion resistance and wear mechanism model of flame-sprayed Al2O3-40%TiO2/NiMoAl cermet coatings. Coatings 2018, 8, 254. [Google Scholar] [CrossRef]

- Szala, M. Application of computer image analysis software for determining incubation period of cavitation erosion—Preliminary results. EDP Sci. 2017, 15, 06003. [Google Scholar] [CrossRef]

- Budzyński, P.; Kamiński, M.; Wiertel, M.; Pyszniak, K.; Droździel, A. Mechanical properties of the stellite 6 cobalt alloy implanted with nitrogen ions. Acta Phys. Pol. A 2017, 132, 203–205. [Google Scholar] [CrossRef]

- Kamiński, M.; Budzyński, P.; Szala, M.; Turek, M. Tribological properties of the Stellite 6 cobalt alloy implanted with manganese ions. IOP Conf. Ser. Mater. Sci. Eng. 2018, 421, 032012. [Google Scholar] [CrossRef]

- Walczak, M.; Pieniak, D.; Niewczas, A.M. Effect of recasting on the useful properties CoCrMoW alloy. Eksploat. Niezawodn. Maint. Reliab. 2014, 16, 330–336. [Google Scholar]

- Kalss, W.; Reiter, A.; Derflinger, V.; Gey, C.; Endrino, J.L. Modern coatings in high performance cutting applications. Int. J. Refract. Met. Hard Mater. 2006, 24, 399–404. [Google Scholar] [CrossRef]

- Krella, A. The influence of TiN coatings properties on cavitation erosion resistance. Surf. Coat. Technol. 2009, 204, 263–270. [Google Scholar] [CrossRef]

- Hattori, S.; Mikami, N. Cavitation erosion resistance of stellite alloy weld overlays. Wear 2009, 267, 1954–1960. [Google Scholar] [CrossRef]

- Mesa, D.H.; Garzón, C.M.; Tschiptschin, A.P. Influence of cold-work on the cavitation erosion resistance and on the damage mechanisms in high-nitrogen austenitic stainless steels. Wear 2011, 271, 1372–1377. [Google Scholar] [CrossRef]

- Wu, Y.; Hong, S.; Zhang, J.; He, Z.; Guo, W.; Wang, Q.; Li, G. Microstructure and cavitation erosion behavior of WC–Co–Cr coating on 1Cr18Ni9Ti stainless steel by HVOF thermal spraying. Int. J. Refract. Met. Hard Mater. 2012, 32, 21–26. [Google Scholar] [CrossRef]

- Szala, M. Coatings for Increasing Cavitation Wear Resistance of Machine Parts and Elements. Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 2016. [Google Scholar]

- Lee, S.-C.; Ho, W.-Y.; Lai, F.D. Effect of substrate surface roughness on the characteristics of CrN hard film. Mater. Chem. Phys. 1996, 43, 266–273. [Google Scholar] [CrossRef]

- Johnson, K.L.; Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987; ISBN 978-0-521-34796-9. [Google Scholar]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Anders, A.; Brown, I.G. Mechanical behavior of diamond and other forms of carbon. Mater. Res. Soc. Symp. Proc. 1995, 383, 447. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Solis, J.; Zhao, H.; Wang, C.; Verduzco, J.A.; Bueno, A.S.; Neville, A. Tribological performance of an H-DLC coating prepared by PECVD. Appl. Surf. Sci. 2016, 383, 222–232. [Google Scholar] [CrossRef]

| Film | Spot | Chemical Element | ||||||

|---|---|---|---|---|---|---|---|---|

| Ti (wt%) | Al (wt%) | N (wt%) | Ti (at%) | Al (at%) | N (at%) | Al/(Ti + Al) | ||

| TiAlN | 1 | 52.93 | 30.63 | 16.43 | 32.39 | 33.25 | 34.36 | 0.507 |

| 2 | 52.27 | 30.07 | 17.67 | 31.49 | 32.14 | 36.38 | 0.505 | |

| 3 | 50.20 | 31.10 | 18.70 | 29.66 | 32.59 | 37.75 | 0.524 | |

| Average | 51.80 | 30.60 | 17.60 | 31.16 | 32.66 | 36.18 | 0.512 | |

| AlTiN | 1 | 41.93 | 35.63 | 22.43 | 23.06 | 34.77 | 42.17 | 0.601 |

| 2 | 43.30 | 35.10 | 21.60 | 24.14 | 34.71 | 41.15 | 0.590 | |

| 3 | 44.97 | 35.47 | 19.57 | 25.73 | 36.00 | 38.27 | 0.583 | |

| Average | 43.40 | 35.40 | 21.20 | 24.29 | 35.15 | 40.55 | 0.591 | |

| Film | Lc1 [N] | Lc2 [N] | Lc3 [N] |

|---|---|---|---|

| TiAlN | 0.91 ± 0.54 | 7.23 ± 1.19 | 15.38 ± 3.43 |

| AlTiN | 0.91 ± 0.61 | 8.87 ± 2.40 | 18.93 ± 4.76 |

| Parameter | Before Cavitation Test | After Cavitation Test | ||||

|---|---|---|---|---|---|---|

| SS304 | TiAlN | AlTiN | SS304_cav | TiAlN_cav | AlTiN_cav | |

| H [GPa] | 6.2 ± 1.0 | 31.0 ± 4.9 | 35.8 ± 6.6 | 6.7 ± 0.3 | 30.0 ± 6.6 | 25.4 ± 5.0 |

| E [GPa] | 212.4 ± 22.7 | 564.1 ± 100.9 | 523.3 ± 77.9 | 232.8 ± 10.2 | 452.1 ± 76.9 | 365.4 ± 57.7 |

| H/E | 0.029 | 0.059 | 0.068 | 0.029 | 0.066 | 0.070 |

| H3/E2 | 4.012 × 10−6 | 6.067 × 10−6 | 8.944 × 10−6 | 3.558 × 10−6 | 9.740 × 10−6 | 1.322 × 10−5 |

| Sample | Wear Factor, K (mm3·N−1·m−1) | Coefficient of Friction, µ (−) |

|---|---|---|

| TiAlN | 1.35 × 10−5 ± 4.36 × 10−6 | 0.319 ± 0.037 |

| AlTiN | 2.09 × 10−5 ± 3.49 × 10−6 | 0.340 ± 0.031 |

| SS304 | 50.17 × 10−5 ± 61.52 × 10−6 | 0.628 ± 0.088 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szala, M.; Walczak, M.; Pasierbiewicz, K.; Kamiński, M. Cavitation Erosion and Sliding Wear Mechanisms of AlTiN and TiAlN Films Deposited on Stainless Steel Substrate. Coatings 2019, 9, 340. https://doi.org/10.3390/coatings9050340

Szala M, Walczak M, Pasierbiewicz K, Kamiński M. Cavitation Erosion and Sliding Wear Mechanisms of AlTiN and TiAlN Films Deposited on Stainless Steel Substrate. Coatings. 2019; 9(5):340. https://doi.org/10.3390/coatings9050340

Chicago/Turabian StyleSzala, Mirosław, Mariusz Walczak, Kamil Pasierbiewicz, and Mariusz Kamiński. 2019. "Cavitation Erosion and Sliding Wear Mechanisms of AlTiN and TiAlN Films Deposited on Stainless Steel Substrate" Coatings 9, no. 5: 340. https://doi.org/10.3390/coatings9050340

APA StyleSzala, M., Walczak, M., Pasierbiewicz, K., & Kamiński, M. (2019). Cavitation Erosion and Sliding Wear Mechanisms of AlTiN and TiAlN Films Deposited on Stainless Steel Substrate. Coatings, 9(5), 340. https://doi.org/10.3390/coatings9050340