Abstract

The atmospheric pressure of Ar + plasma jet has been analyzed and its effects on the poly(methyl methacrylate) (PMMA) surface has been investigated. The PMMA surface treatment was performed at a fixed gas flow-rate discharge voltage, while varying the plasma treatment time. The Ar + plasma was studied with optical emission spectroscopy (OES). Optimum plasma conditions for PMMA surface treatment were determined from relative intensities of Argon, hydroxyl radical (OH), oxygen (O) I emission spectra. The rotational temperature of Ar + plasma was determined from OH emission band. The PMMA surfaces before and after plasma treatment were characterized by contact angle and surface free energy measurements, X-ray photoelectrons spectroscopy (XPS), atomic force microscope (AFM) and UV-spectroscopy. The contact angle decreased and surface free energy increased with plasma treatment time. XPS results revealed the oxygen to carbon ratio (O/C) on plasma-treated PMMA surfaces remarkably increased for short treatment time ≤60 s, beyond which it has weakly dependent on treatment time. The carbon C 1s peak deconvoluted into four components: C–C, C–C=O, C–O–C and O–C=O bonds and their percentage ratio vary in accordance with plasma treatment time. AFM showed the PMMA surface roughness increases with plasma treatment time. UV-visible measurements revealed that plasma treatment has no considerable effect on the transparency of PMMA samples.

1. Introduction

Polymethyl methacrylate (PMMA) has attracted more and more attention in various industrial applications due to its low cost, ease of processing, excellent physical and chemical properties [1]. Its light transmittance is similar to glass, however, its mechanical properties such as rigidity and low density make PMMA more preferable for the use in implantable ophthalmic lenses and hard contact lenses [2]. In addition, PMMA is also used in gate dielectric [3], and various biomedical devices including eye glasses, drug delivery agent, facial prosthesis, artificial bone, jaw implants, nasal stents and others [4]. Despite the excellent PMMA bulk properties, its surface inherited hydrophobic nature limits its compatibility when it is used as implant bio-material. As is known, hydrophobic surfaces have strong tendency to attach proteins such as bacteria and cells irreversibly [5]. In keratoprosthesis patients, the poor interfacial adhesion between the PMMA optical cylinder and the donor corneal tissue can produce various medical problems. For example, perpetual blinking and eyeball movement can exacerbate corneal tissue, causing the PMMA cylinder to become loose, providing an opportunity for the invasion of bacteria and inflammatory cells [6].

Thus, surface modification of PMMA is necessary to improve its bio-compatibility and to reduce implantation complications, while preserving its excellent bulk properties [7]. In that respect, several methods have been developed for PMMA surface modifications, aiming to enhance its surface hydrophilic properties. These included chemical vapour deposition [8], wet chemical [9], lithography or exposure to UV irradiation [10,11]. Plasma surface treatment is an effective technique to improve surface characteristics, and has several advantages over other conventional surface modification methods. Plasma technology is environmentally friendly, solvent-free processing, is flexible, and has short processing time. In addition, plasma treatment preserves polymer bulk properties as the plasma species. Surface interaction is limited to several angstroms [12]. Traditionally, plasma treatments were performed with a low pressure-plasma system, requiring expensive vacuum equipment [13,14]. This can be avoided by atmospheric pressure plasma with benefits of low processing costs, and wide possibilities for surface treatment [15]. The atmospheric pressure plasmas can be realized in different shapes: surface coplanar DBD, volume dielectric barrier discharge (V-DBD) [16], and miniature plasma jet [17]. The latter has advantage over large area surface/volume DBD in surface modification that it has the ability to penetrate into narrow gaps, porous structures and is suitable for treated 3D objects with complex geometries [18].

So far, some researchers have studied plasma effects on PMMA surface [14,19,20,21,22,23]. However, the diversity of the atmospheric pressure characteristics regarding the operating parameters, power scheme and geometrical shape is remarkable. The mechanism of plasma-induced polymer surface modification is varied, depending on plasma gas type, gas compositions, power scheme and etc. Hence, the specific mechanism or the role of plasma species on polymer surface treatment is still a debatable issue. For better control of the treatment processes, it is essential to understand the physical and chemical processes that occur during plasma-polymer surface interaction.

In this work, the optical characteristics of non-thermal atmospheric pressure Ar + plasma is presented and their performance of functionalizing the surface of PMMA is analyzed. The change in water contact angle and surface free energy with respect to plasma treatment time has been measured. X-ray photo-electron spectroscopy (XPS) and atomic force microscopy (AFM) were utilized to analyze the surface chemical composition and surface morphology of the PMMA before and after plasma treatment, and the mechanism has been proposed for the surface functionalization of PMMA with the atmospheric pressure Ar + plasma. The effect of plasma treatment on the transmittance of PMMA is also presented.

2. Materials and Methods

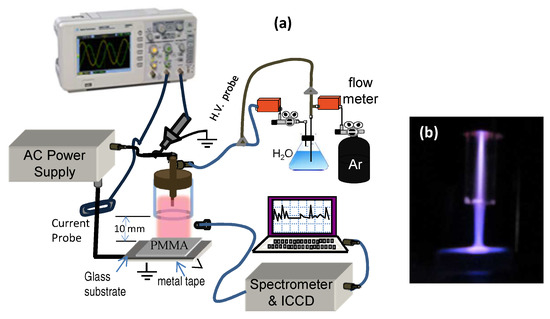

The atmospheric pressure plasma jet APPJ set-up is shown in Figure 1a, together with an image of the plasma jet during PMMA treatment in Figure 1b. The discharge voltage (18 KHz) was applied to tungsten wire (1 mm diameter), which was placed at the center of a quartz capillary tube with a radius of 3 mm. The discharge was generated inside the quartz tube and blown outside the tube orifice. The grounded electrode is a metal plate (3 cm × 3 cm), covered with a glass plate 2 mm thick. The PMMA samples to be treated were placed on the glass plate at a distance of 10 mm from the jet orifice. The gas flow rate was controlled by a gas flow controller (RK1600R, Kofloc, Kyoto, Japan). Water () vapor is introduced to the argon plasma jet via a bubbling system containing distilled water, carried by a secondary argon flow. In the current experiment, Ar flow rate is (5.85 L/min) and Ar carrying vapor is (0.15 L/min). The discharge voltage V waveform at the powered electrode was measured using high-voltage probe 1000:1 (Tektronix P6015A, Beaverton, OR, USA), directly attached to the powered electrode, meanwhile the discharge total current I was monitored using current probe (Tektronix TCP202). The discharge voltage and current waveforms are displayed on digital oscilloscope (DPO4054B, Tektronix). In this study, the discharge voltage is expressed in unit of peak-to-peak () from the observed waveform.

Figure 1.

(a) Schematic diagram of the experimental setup for atmospheric pressures of Ar + and (b) photograph of the plasma jet during treatment.

The optical emission of the atmospheric pressure plasma jet was collected by optical fiber placed 10 mm perpendicular to the (afterglow) plasma jet. The fiber connected to USB2000 spectrometer (Ocean Optics, Winter Park, FL, USA) equipped with a intensified CCD detector, wavelength range 200–1100 nm and resolution of 1.5 nm full width at half-maximum. OES measurements were taken 5 mm below the plasma jet orifice. For rotational and vibrational estimation, we used a second spectrometer with a resolution of 0.5 nm in the wavelength range 300–400 nm. The emission of OH radicals in range of 305–311 nm, has been used to determine the and of atmospheric pressure Ar + plasma jet using SPECAIR software (version 3.0) [24].

The PMMA samples () and 2 mm of thickness were cut off from the PMMA sheet. The sheet surface was covered by a foil which was removed at the time of the sample preparation. Samples were then washed by deionized water in an ultrasonic cleaner for 10 min. Finally, the samples were dried in oven at 40 °C for 30 min and then they were delivered to plasma treatment. To examine the effects of Ar + plasma on the PMMA polymer. The surface characteristics of pristine PMMA and plasma-treated samples were examined using a set of techniques. The chemical composition of the PMMA surface before and after plasma treatment were evaluated using X-ray photo-electron spectroscopy (XPS, Thermo Scientific, Waltham, MA, USA), using a flood gun for charge compensation. The XPS spectra and data analysis, including peak fitting, were performed with Thermo Avantage software (version 5.932). The surface morphology of the pristine and plasma treated PMMA were examined with atomic force microscope (AFM, Bruker, Billerica, MA, USA) equipped with a tapping-mode silicon tip. A UV-5200 Spectrophotometer (Shanghai Xiwen Biotech., Shanghai, China) was used for optical properties. For contact angle and surface energy, was 10 L of three test liquids: deionized (DI) water, ethylene glycol and glycerol were dropped on the top of PMMA surface and the contact angle was measured with a digital microscope (Shenzhen Haiweixun, Shenzhen, China). The contact angle measurements were repeated for each sample four to five times and the average has been taken. The surface free energy of PMMA and its dispersive , polar components as well were calculated using the Owens and Wendt model [25].

The total surface energy of solid is given as . The surface energy of the liquids , their polar and dispersive components were taken from [26].

3. Results and Discussion

3.1. Electrical and Optical Characteristics Ar + H2O Plasma Jet

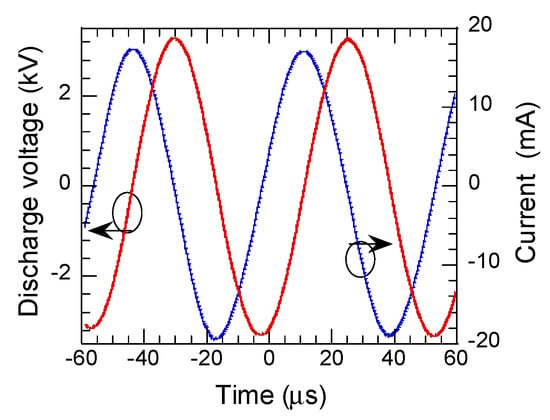

The discharge voltage and total current waveforms of the atmospheric pressure plasma jet in Ar + are shown in Figure 2. The discharge conditions were set at the gas flow rate (Ar 5.85 L/min + 0.15 L/min) and discharge voltage 3.2 k, respectively. As can be seen, the - waveforms were smooth and fairly sinusoidal implying that the Ar + discharge was uniform, filamentary free and comparable to typical diffusive glow discharge. The discharge voltage lags the current, indicating the capacitive nature of the discharge impedance.

Figure 2.

Typical voltage and current waveforms in atmospheric pressure Ar + plasma jet.

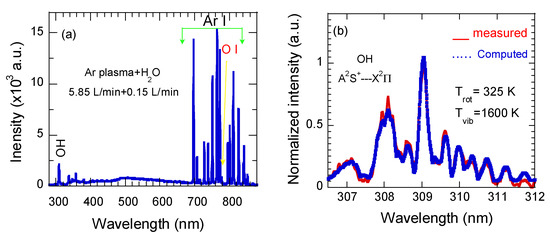

The in-situ OES measurements of the active species existing in the Ar + plasma mixture gives interesting information for understanding the process involved in the plasma-PMMA surface interaction. Figure 3a reveals optical emission of Ar plasma spectrum in the 280–880 nm spectral range. The discharge conditions were: total flow rate 6 L/min and discharge voltage 3.2 k. As shown, the spectrum was dominated with intensive Ar I atomic lines: 696.4, 706.7, 738, 750.2, 763.2, 772.4, 801, 810.6 and 841.4 nm that correspond to () transitions. In addition, one can observe other active radical species such as singlet oxygen atoms (O) I () at 777.41 nm, hydroxyl radicals (OH) at 306–311 nm and neutral nitrogen second positive system (SPS) in the 310–440 nm range. The presence of these reactive plasma species (OH, , and O I) was due to the fact that the energetic electrons, created by atmospheric pressure plasma jet, collide with surrounding molecules. As reactive plasma species (OH, , and O I) together with argon ions are believed to play the crucial role in modifying PMMA surface upon treated with plasma.

Figure 3.

(a) Optical emission spectra of atmospheric pressure Ar + plasma jet during treatment of poly(methyl methacrylate) (PMMA) at a fixed discharge voltage of 3.2 k and total gas flow rate of 6 L/min. (b) Measured and synthetic spectra of the hydroxyl radical (OH) spectrum at same conditions of Figure 3a.

Gas temperature is one of the important parameters to be controlled in plasma treatment process, in particular for heat sensitive material like polymer. At atmospheric pressure, the rotational temperature of gas molecule was comparable to gas temperature owing to their fast collisional relaxation. Whereas, a vibrational temperature was a sensitive probe of changes in the electron energy distribution in the plasma [27]. The rotational and vibrational temperatures of the Ar + plasma mixture (Figure 3a) were estimated using the OH spectra . Figure 3b shows the best fit of the synthetic and measured OH spectra. An excellent reproduction of the measured spectra was obtained for and . The was slightly higher than room temperature, and thus in thermodynamic equilibrium with the background gas and hence can be equated with the gas temperature.

3.2. Contact Angles and Surface Free Energy Measurements

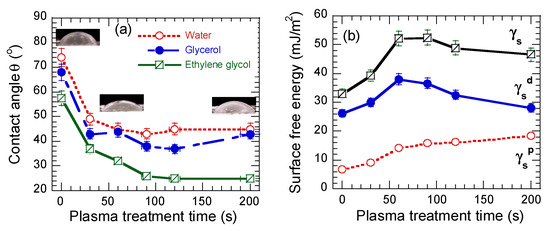

Contact angle is a measure of the wettability of material surfaces. In other words, PMMA surface modification probably induced by plasma treatment can be evaluated using contact angle measurements. As seen in Figure 4a, prior to plasma treatment, the contact angles of pristine PMMA measured with water, glycerol and Ethylene glycol were 74, 68 and 59, respectively. After Ar + plasma treatment for 30 s, the contact angles remarkably decreeased to 49, 43 and 37, for water, glycerol and Ethylene glycol, respectively. This confirms the improvement of PMMA surface wettability, even in as short a time as 30 s. As treatment time increased beyond 30 s up to 200 s, the contact angles were slightly dependent on the treatment time, irrespective of liquid type. These results agree well with previous reports [22,28] for plasma treatment of various types of polymers. The reduction in contact angle of PMMA surface with Ar + plasma treatment suggest that plasma either modifies the chemical composition of PMMA surface and/or enhances surface roughness. The changes in the surface morphology can lead to an improved adhesion through a mechanical interlocking process.

Figure 4.

(a) Liquid contact angle measurements as a function of plasma treatment time. (b) PMMA surface free energy and their polar () and dispersion () components dependence on plasma treatment time. Plasma conditions are Ar + total flow 6 L/min and discharge voltage of 3.2 k.

The surface free energy () of the PMMA samples before and after plasma treatment were determined on the basis of Owens and Wendt model [25]. Three sets of liquid contact angles (water, glycerol and Ethylene glycol) with PMMA have been used, the liquids surface energy were taken from [26]. The corresponding results of the PMMA surface free energy and their polar () and dispersion () components are depicted in Figure 4b, as a function of plasma treatment time. For pristine PMMA, the values of , and were 33.03, 26.18 and 6.84 mJ/, respectively. After plasma treatment, the and dispersive component gradually increase to about 52.4 and 38 mJ/ at treatment time 60–90 s, beyond which it slightly decreased. However, remarkably increased with plasma treatment time. The value of for plasma treated samples was almost triple to that of pristine PMMA sample. The increase of and suggests the functionalization of the PMMA surface with hydrophilic covalent polar groups upon Ar + . In this respect, XPS was used to investigate the chemical structure of the PMMA surfaces.

3.3. XPS

XPS is a standard technique to evaluate the atomic elemental concentration and chemical bonds on material surfaces. From the XPS survey spectra (not shown), the surface elements composition and the oxygen to carbon (O/C) ratio of the pristine and Ar + plasma treated PMMA was calculated and presented in Table 1. The O/C ratio was found to increase from 27% to 48.3% after 30 s exposure to atmospheric pressure Ar + plasma. This is clear evidence that oxygen atoms were grafted into PMMA surface through Ar + plasma treatment process. In fact, Figure 3a shows the existence of atomic oxygen O I at 777.41 nm. Here, the O/C ratio was higher than that reported for PMMA treated in air and oxygen plasma [23]. Increasing the treatment time from 30 to 200 s, surprisingly, the O/C ratio slightly increased up to 50.8 % at treatment time of 120 s, beyond which it decreases to 49% at treatment time of 200 s. Different mechanisms may explain the weak effect of long treatment time on the O/C ratio. Firstly, the long treatment time may increase the depth of treatment effect, knowing that XPS only examines first surface atomic layers (≃). Secondly, during plasma-surface interaction, generation of newly carbon-oxygen group accompanied with the loss of other oxygen-carbon group by converting them to a low weight volatile fragments, such as CO or . Thirdly, the long plasma treatment time may induce cross-link on polymer surface due to UV emission effect [29]. In the current discharge conditions, the UV emission component (≤400 nm) of the Ar + plasma spectrum was relatively weak as seen in Figure 3a, however, the long exposure time probably accumulates the UV effect leading to a slight increase in the C−C bond concentration on the polymer surface through cross-link.

Table 1.

X-ray photoelectrons spectroscopy (XPS) elemental analysis of the pristine and plasma treated PMMA as a function of treatment time at Ar + total flow rate of 6 L/min and discharge voltage 3.2 k.

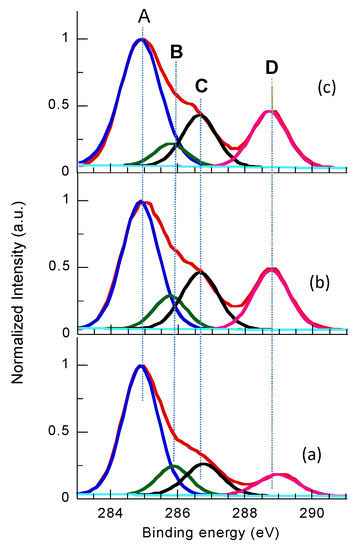

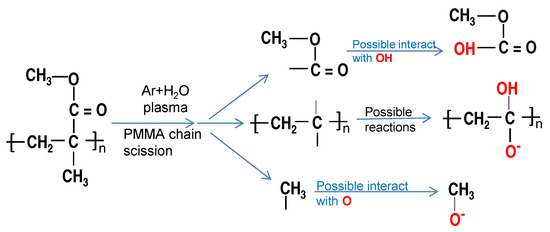

To identify and evaluate functional groups existing on the PMMA surface, the high-resolution carbon C 1s spectra for pristine and plasma treated PMMA have been measured and presented in Figure 5a–c, its components ratio is summarized in Table 2. In general, one can observe the difference in the intensity of individual peaks when comparing C 1s of pristine and plasma treated PMMA samples. The C 1s spectrum of pristine PMMA (Figure 5a) can be deconvoluted into four overlapped components [30]: the large intensity peak at 284.88 eV (label A) corresponds to carbon atoms C–C/C–H bonds methyl (–CH) and methylene –CH group. The peak at 285.8 eV (label B) is assigned to carbon atoms in the PMMA main-chain, linking the chain and the methyl ester and methyl groups –C–C=O, the peak lays at the shoulder around 286.6 eV (label C) is attributed to methyl group single bonded to an oxygen (–CH–O–C) and the peak at 288.6 eV (label D) is assigned to (–O–C=O or –OH–C=O species) carboxyl/ester group. The C 1s of PMMA treated for 30 s with Ar + plasma (Figure 5b), shows same fitted peaks, however, with different intensities. For example, the atomic ratio of –O–C=O group remarkably increased, the –CH–O– bond slightly increased, meanwhile, C–C/C–H bond ratio decreased. When treatment time increased for more than 30 s, less effect on the concentrations of functional groups included in carbon C 1s spectrum was observed (Figure 5c). This is agree with the contact angle measurements shown in Figure 4a). The C–C, C–O and C–H bond characterizes with low bonding energy 3.6, 3.7 and 4.3 eV, respectively. It can be concluded that the Ar ion bombardment effectively ruptured the weak chemical C–C bond, results in chain scission as seen in Figure 6. This effect of Ar ions created numerous number of active sites on the PMMA surface, later saturated with other free oxygen/or OH species and forming various functional group containing oxygen. That explains the increment of carboxyl/ester groups and decreasing C–C bond as observed in Table 2. Functional groups containing oxygen bonded to carbon are polar and tend to improve the hydrophilic properties of PMMA surface.

Figure 5.

High resolution C 1s spectra of PMMA before (a) and after Ar + plasma treatment (b) 30 s and (c) 200 s, at the same plasma conditions of Figure 4.

Table 2.

Relative atomic precentge of functional groups composed of XPS C 1s spectra of the pristine and plasma treated PMMA as a function of treatment time. Same discharge conditions as Table 1.

Figure 6.

Chain scission processes and functionalization of PMMA surface by Ar + plasma treatment.

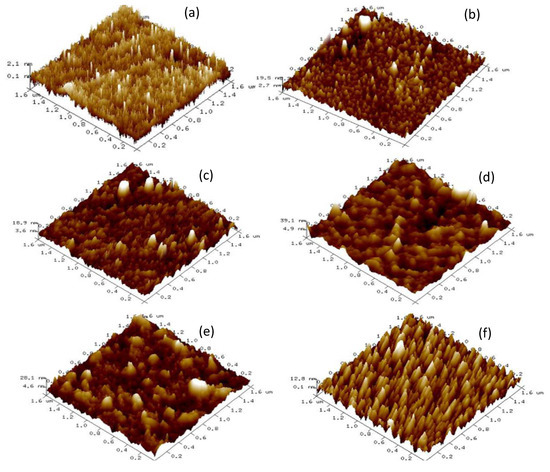

3.4. AFM Surface Morphology

To investigate the effect of Ar + plasma jet on the surface morphology of the PMMA films, pristine and plasma-treated PMMA surfaces were imaged with AFM and the results are shown in Figure 7. The examined surface area of all PMMA samples were fixed to . One can notice that, the surface of untreated PMMA shows very fine grass-like features. Meanwhile, PMMA surface treated with Ar + plasma reveals a clear uniform node-like structure, probably due to argon ion etching effect as revealed from Figure 3a. Alternatively, the formation of new functional groups on PMMA surface increases the surface roughness [31]. The surface roughness (evaluated from the AFM images) for pristine PMMA was 0.78 nm, and it increases to 2.45, 2.99, 6.44, 8.48, 5.18, 3.73 nm for plasma treatment time 30, 60, 90, 120 and 200 s, respectively. Here, it is noted that the roughness of PMMA surface after Ar + plasma significantly increased for treatment time, ranging 60–120 s. The slight decrease in at high value of treatment time is probably due to cross linking or other mechanism that takes place during long plasma treatment time as observed in XPS results. Besides, the newly formed radicals on the surface may partially change its orientation and fill up the surrounding valleys, and hence decrease the surface roughness.

Figure 7.

3D-atomic force microscope (AFM) images of PMMA before and after Ar + plasma treatment, (a) 0 s, (b) 30 s, (c) 60 s, (d) 90 s, (e) 120 s and (f) 200 s.

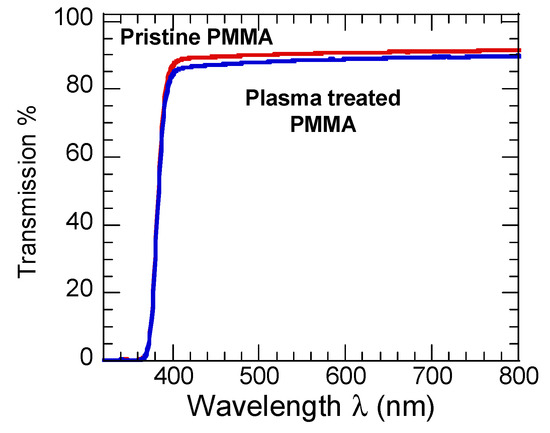

3.5. Optical Properties

In ophthalmology applications, it is important that the PMMA polymer preserves its excellent transmittance after plasma treatment. This is evident in Figure 8, as one observes the pristine PMMA sample exhibit high transmission in the visible region of the spectrum. For the plasma treated sample (120 s), there was small reduction from 91.0% (pristine PMMA) to 89.0% in the spectral intensity. Thus, using plasma treatment for PMMA used as implantable ophthalmic lenses and hard contact lenses, one gets excellent interfacial adhesion together with excellent light transmittance efficiency.

Figure 8.

UV-visible transmission spectrum of pristine and plasma treated PMMA (120 s).

3.6. Ageing Effect

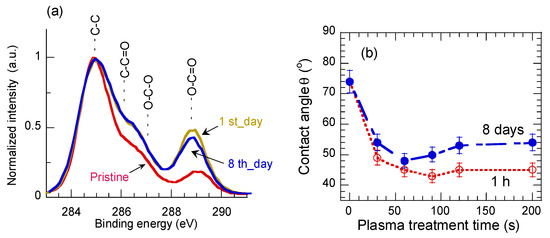

One important issue of polymer surface activation is the ageing effect. For that reason, samples of plasma treated PMMA were stored for eight days in ambient air at room temperature in a closed box. The survey spectra of the stored samples show that the O/C ratio is 44.8% ± 0.2%, irrespective of treatment time. In other words, the O/C ratio decreased by less than 3 % than that recorded for freshly measured one (see Table 1). The carbon spectra C 1s for fresh and stored plasma treated PMMA sample (30 s) is presented in Figure 9a together with the C 1s of pristine PMMA. The C 1s of the stored sample retain mostly the hydrophilic functional groups (C–C=O, O–C–O), while the carboxyl/ester group O–C=O decrease. The measured water contact angle for stored samples shown in Figure 9b, reveals that the aging is more pronounce at high plasma treatment time. Ageing in activated polymer surface is correlated with surface mobility; changing the orientation of the hydrophilic group from the surface into the bulk increases ageing in polymer [32]. The gas temperature of Ar + is low as , may reduce the effect of surface mobility and explain the relatively good stability of the activated PMMA samples.

Figure 9.

(a) High resolution C 1s spectra of pristine, fresh and stored plasma treated PMMA, (b) water contact angle for fresh and stored plasma treated PMMA as function of time. Same plasma conditions of Figure 4.

4. Conclusions

Uniform non-thermal atmospheric pressure Ar + plasma jet has been generated. The PMMA films exposed to Ar + plasma shows decrease in contact angles and an increase in surface free energy. This enhancement of PMMA surface wettability is attributed to increasing hydrophilic O–C=O group on the treated PMMA surface as well as change of surface roughness, as revealed with XPS and AFM measurements. Increasing plasma treatment time ≥120 s slightly decrease the wettability of the PMMA surface in comparison to the short treatment time ≤60 s, in this experimental conditions. Plasma treatment preserves the excellent optical characteristics of pristine PMMA. In addition, the functional surface is stable within the examined several days.

Funding

This research received no external funding.

Conflicts of Interest

The author declares no conflict of interest.

References

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A review of the properties and applications of poly (methyl methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Hamouda, A.M.S. The influence of humidity on the deformation and fracture behavior of PMMA. J. Mater. Process. Technol. 2002, 124, 238–243. [Google Scholar] [CrossRef]

- Sanne, A.; Movva, H.C.P.; Kang, S.; McClellan, C.; Corbet, C.M.; Banerjee, S.K. Poly(methyl methacrylate) as a self-assembled gate dielectric for graphene field-effect transistors. Appl. Phys. Lett. 2014, 104, 083106. [Google Scholar] [CrossRef]

- Stickler, M.; Rhein, T. Polymethacrylates. In Ullmann’s Encyclopedia of Industrial Chemistry, 5th ed.; Elvers, B., Hawkins, S., Schulz, G., Eds.; Wiley-VHS: New York, NY, USA, 1992; p. 473. [Google Scholar]

- Garrett, T.R.; Bhakoo, M.; Zhang, Z. Bacterial adhesion and biofilms on surfaces. Prog. Nat. Sci. 2008, 18, 1049–1056. [Google Scholar] [CrossRef]

- Riau, A.K.; Venkatraman, S.S.; Dohlman, C.H.; Mehta, J.S. Surface modifications of the PMMA optic of a keratoprosthesis to improve biointegration. Cornea 2017, 36, S15–S25. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Chen, Y.; Liu, P.; Gao, O.; Sun, Y.; Huang, C. Surface modification of hydrophobic PMMA intraocular lens by the immobilization of hydroxyethyl methacrylate for improving application in ophthalmology. Plasma Chem. Plasma Process. 2011, 31, 811–825. [Google Scholar] [CrossRef]

- Chen, N.; Kim, D.H.; Kovacik, P.; Sojoudi, H.; Wang, M.; Gleason, K.K. Polymer thin films and surface modification by chemical vapor deposition: Recent progress. Annu. Rev. Chem. Biomol. Eng. 2016, 7, 373–393. [Google Scholar] [CrossRef] [PubMed]

- Ortiz, R.; Chen, J.L.; Stuckey, D.C.; Steele, T.W. Poly(methyl methacrylate) surface modification for surfactant-free real-time toxicity assay on droplet microfluidic platform. ACS Appl. Mater. Interfaces 2017, 9, 13801–13811. [Google Scholar] [CrossRef]

- Evea, S.; Mohr, J. Study of the surface modification of the PMMA by UV-radiation. Procedia Eng. 2009, 1, 237–240. [Google Scholar] [CrossRef]

- Shin, J.; Liu, X.; Chikthimmah, N.; Lee, Y.S. Polymer surface modification using UV treatment for attachment of natamycin and the potential applications for conventional food clingwrap (LDPE). Appl. Surf. Sci. 2016, 386, 276–284. [Google Scholar] [CrossRef]

- Abdel-Fattah, E.; Ogawa, D.; Nakamura, K. Oxygen functionalization of MWCNTs in RF-dielectric barrier discharge Ar/O2 plasma. J. Phys. D Appl. Phys. 2017, 50, 265301. [Google Scholar] [CrossRef]

- Krüger, P.; Knes, R.; Fredrich, J. Surface cleaning by plasma-enhanced desorption of contaminants (PEDC). Surf. Coat. Technol. 1999, 112, 240–244. [Google Scholar] [CrossRef]

- Nabesawa, H.; Hiruma, T.; Hitobo, T.; Wakabayashi, S.; Asaji, T.; Abe, T.; Seki, M. Low-pressure plasma-etching of bulk polymer materials using gas mixture of CF4 and O2. AIP Adv. 2013, 3, 112105. [Google Scholar] [CrossRef]

- Penkov, O.V.; Khadem, M.; Lim, W.S.; Kim, D.E. A review of recent applications of atmospheric pressure plasma jets for materials processing. J. Coat. Technol. Res. 2015, 12, 225–235. [Google Scholar] [CrossRef]

- Kogelschatz, U. Dielectric-barrier discharges: Their history, discharge physics, and industrial applications. Plasma Chem. Plasma Process. 2003, 23, 1–46. [Google Scholar] [CrossRef]

- Abdel-Fattah, E.; Yehia, A.; Bazavan, M.; Ishijima, T. Optical emission and surface characterization of stainless steel treated by pulsed microwave-atmospheric helium plasma jet. Eur. Phys. J. D 2017, 71, 178. [Google Scholar] [CrossRef]

- Ehlbeck, J.; Schnabel, U.; Polak, M.; Winter, J.; Von Woedtke, T.; Brandenburg, R.; von dem Hagen, T.; Weltmann, K.D. Low temperature atmospheric pressure plasma sources for microbial decontamination. J. Phys. D Appl. Phys. 2010, 44, 013002. [Google Scholar] [CrossRef]

- Schulz, U.; Munzert, P.; Kaiser, N. Surface modification of PMMA by DC glow discharge and microwave plasma treatment for the improvement of coating adhesion. Surf. Coat. Technol. 2001, 142–144, 507–511. [Google Scholar] [CrossRef]

- Vesel, A.; Mozetic, M. Surface modification and ageing of PMMA polymer by oxygen plasma treatment. Vacuum 2012, 86, 634–637. [Google Scholar] [CrossRef]

- Chiper, A.; Borcia, G. Argon versus helium dielectric barrier discharge for surface modification of polypropylene and poly(methyl methacrylate) films. Plasma Chem. Plasma Process. 2013, 33, 553–568. [Google Scholar] [CrossRef]

- Fang, Z.; Liu, Y.; Liu, K.; Shao, T.; Zhang, C. Surface modifications of polymethylmetacrylate films using atmospheric pressure air dielectric barrier discharge plasma. Vacuum 2012, 86, 1305–1312. [Google Scholar] [CrossRef]

- Pawde, S.M.; Deshmukh, K. Surface characterization of air plasma treated poly vinylidene fluoride and poly methyl methacrylate films. Polym. Eng. Sci. 2009, 49, 808–818. [Google Scholar] [CrossRef]

- Laux, C.O. Radiation and nonequilibrium collisional-radiative models, in van karman Institute Lecture Series 2002-07. In Physico-Chemical Modeling of High Enthalpy and Plasma Flows; Fletcher, D., Magin, T., Charbonnier, J.M., Sarma, G., Eds.; Von Karman Institute: Rhode-Saint-Genese, Belgium, 2002. [Google Scholar]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741. [Google Scholar] [CrossRef]

- Surface Tension Components and Molecular Weight of Selected Liquids. Available online: https://www.accudynetest.com/surface_tension_table.html (accessed on 28 February 2019).

- Abdel-Fattah, E.; Bazavan, M.; Shindo, H. Temperature measurements in microwave argon plasma source by using overlapped molecular emission spectra. Phys. Plasma 2015, 22, 093509. [Google Scholar] [CrossRef]

- Huang, C.; Chang, Y.C.; Wu, S.Y. Contact angle analysis of low temperature cyclonic atmospheric pressure plasma modified polyethylene terephthalate. Thin Solid Films 2010, 518, 3575–3580. [Google Scholar] [CrossRef]

- Wertheimer, M.R.; Fozza, A.C.; Holländer, A. Industerial processing of polymers by low pressure plasmas: The role of UV radiation. Nucl. Instrum. Meth. Phys. Res. Sect. B 1999, 151, 65. [Google Scholar] [CrossRef]

- Beamson, G.; Briggs, D. High Resolution XPS of Organic Polymers: The Scienta ESCA300 Database; John Wiley and Sons: Chichester, UK, 1992. [Google Scholar]

- Kostova, K.G.; Nishime, T.M.C.; Castro, A.H.R.; Toth, A.; Hein, L.R.D.O. Surface modification of polymeric materials by cold atmospheric plasma jet. Appl. Surf. Sci. 2014, 314, 367–375. [Google Scholar] [CrossRef]

- Siow, K.S.; Britcher, L.; Kumar, S.; Griesser, H.J. Plasma methods for the generation of chemically reactive surfaces for biomolecule immobilization and cell colonization. Plasma Process. Polym. 2006, 3, 392–418. [Google Scholar] [CrossRef]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).