Anticorrosion Properties of Zn–Al Composite Coating Prepared by Cold Spraying

Abstract

:1. Introduction

2. Experimental Methods

3. Results and Discussion

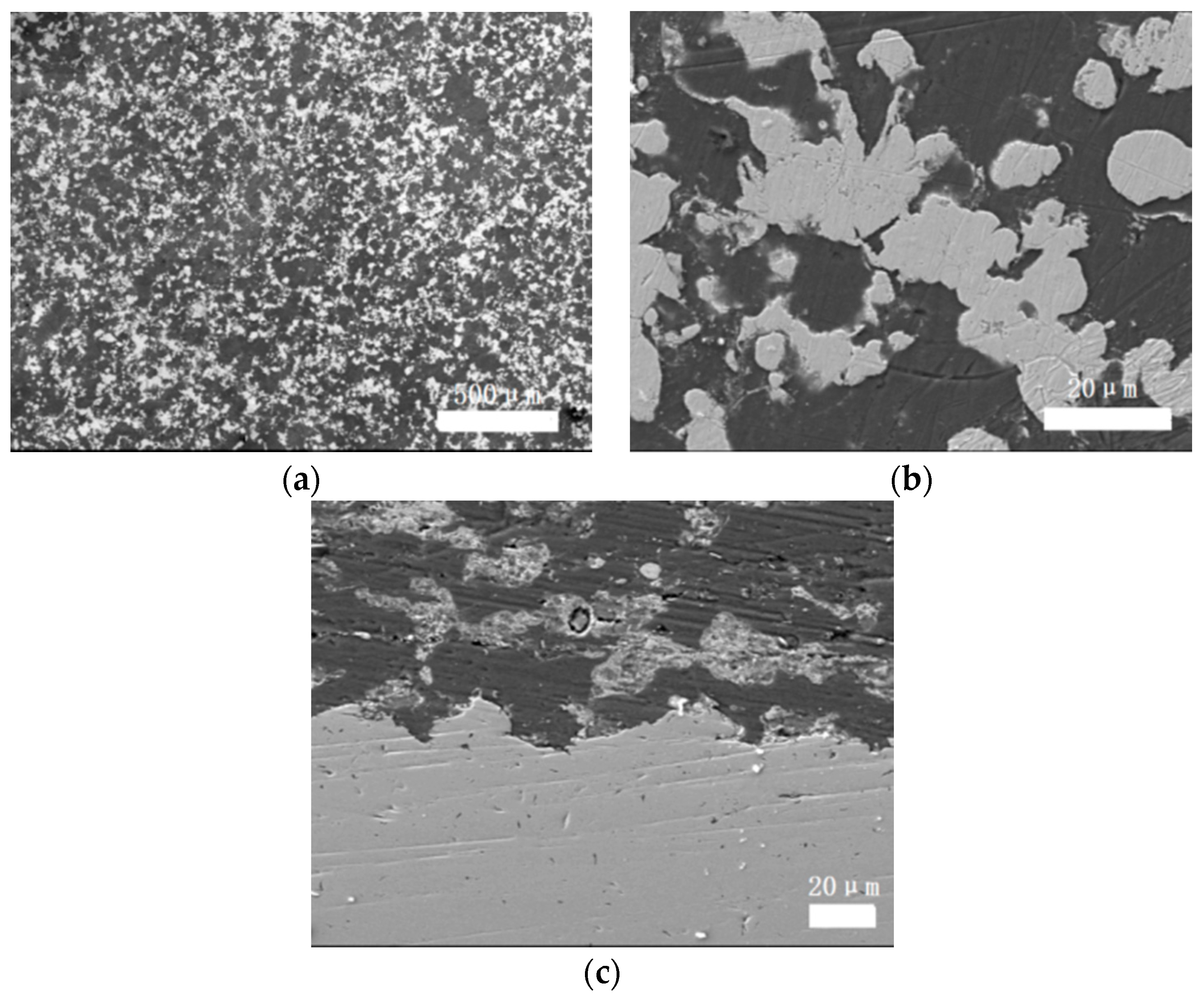

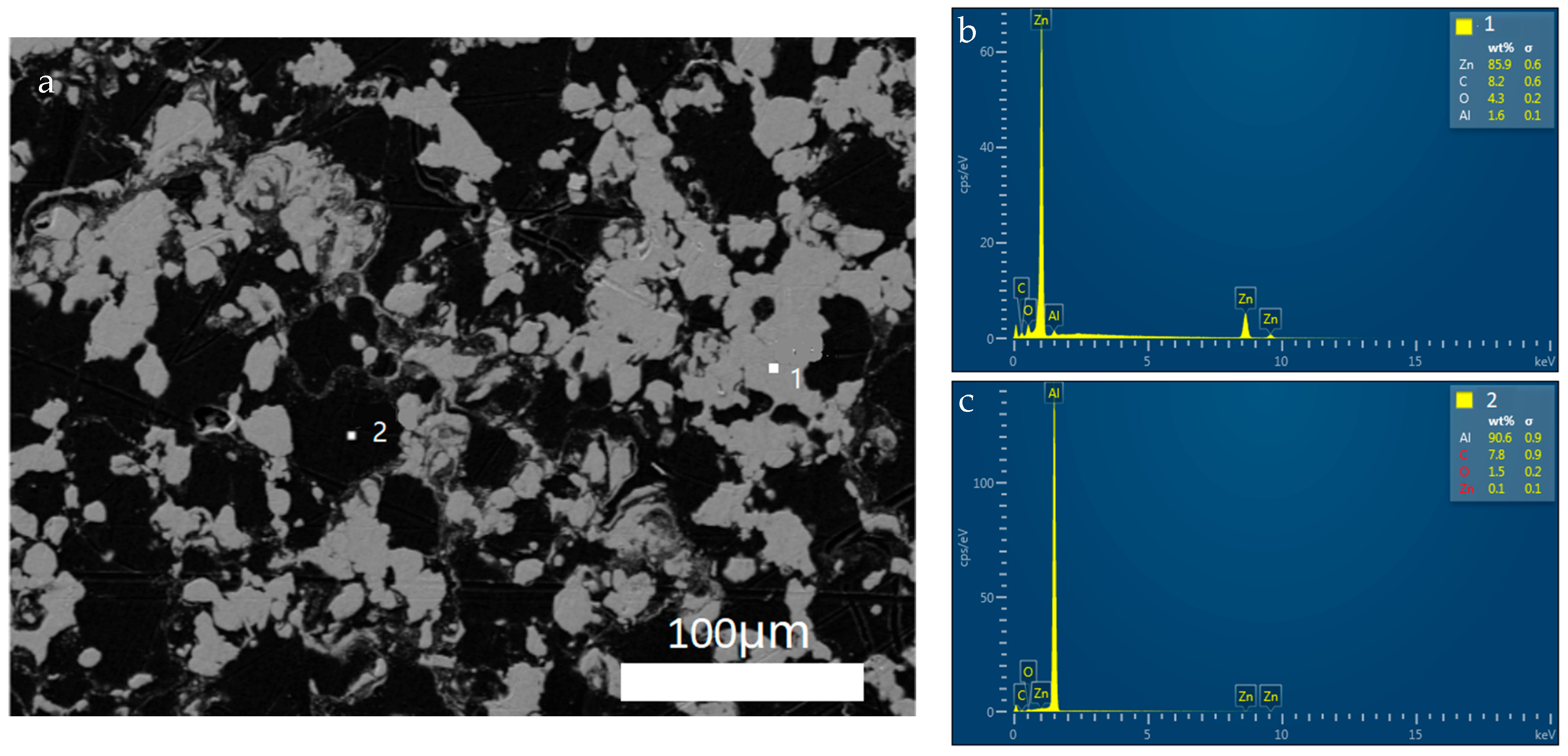

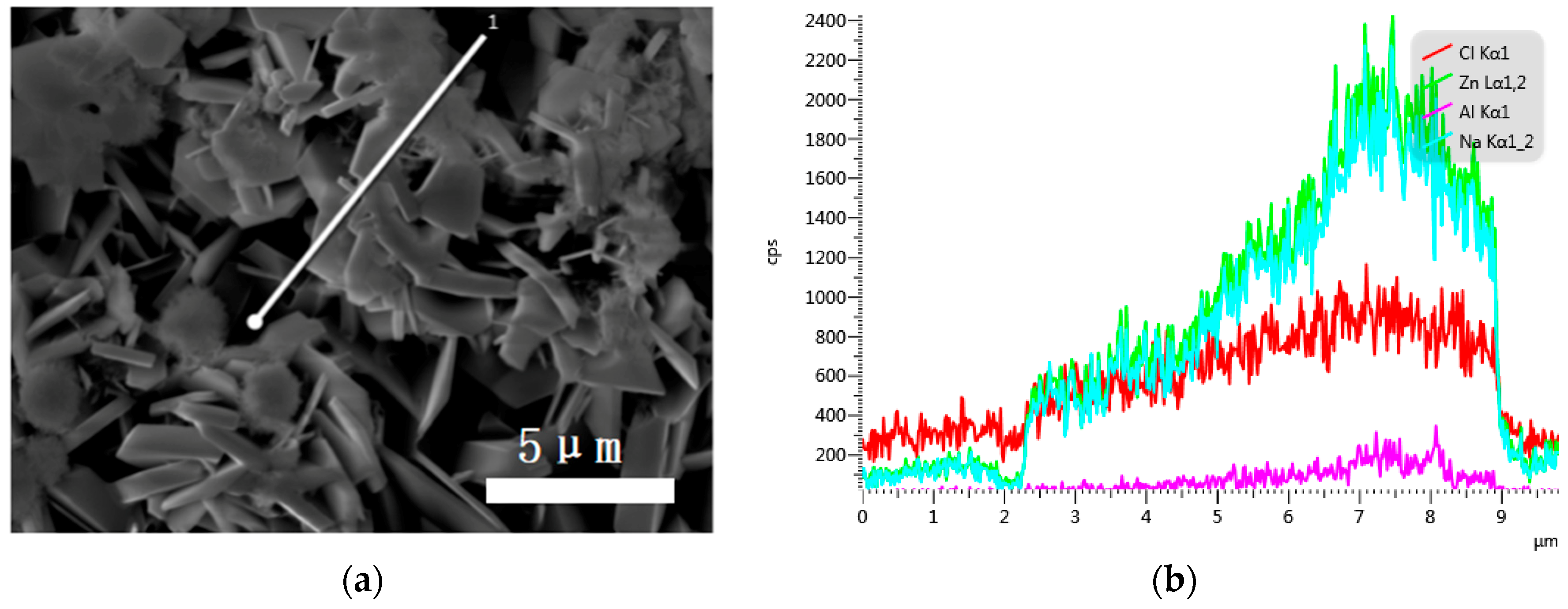

3.1. Microstructure of Zn–Al Composite Coating

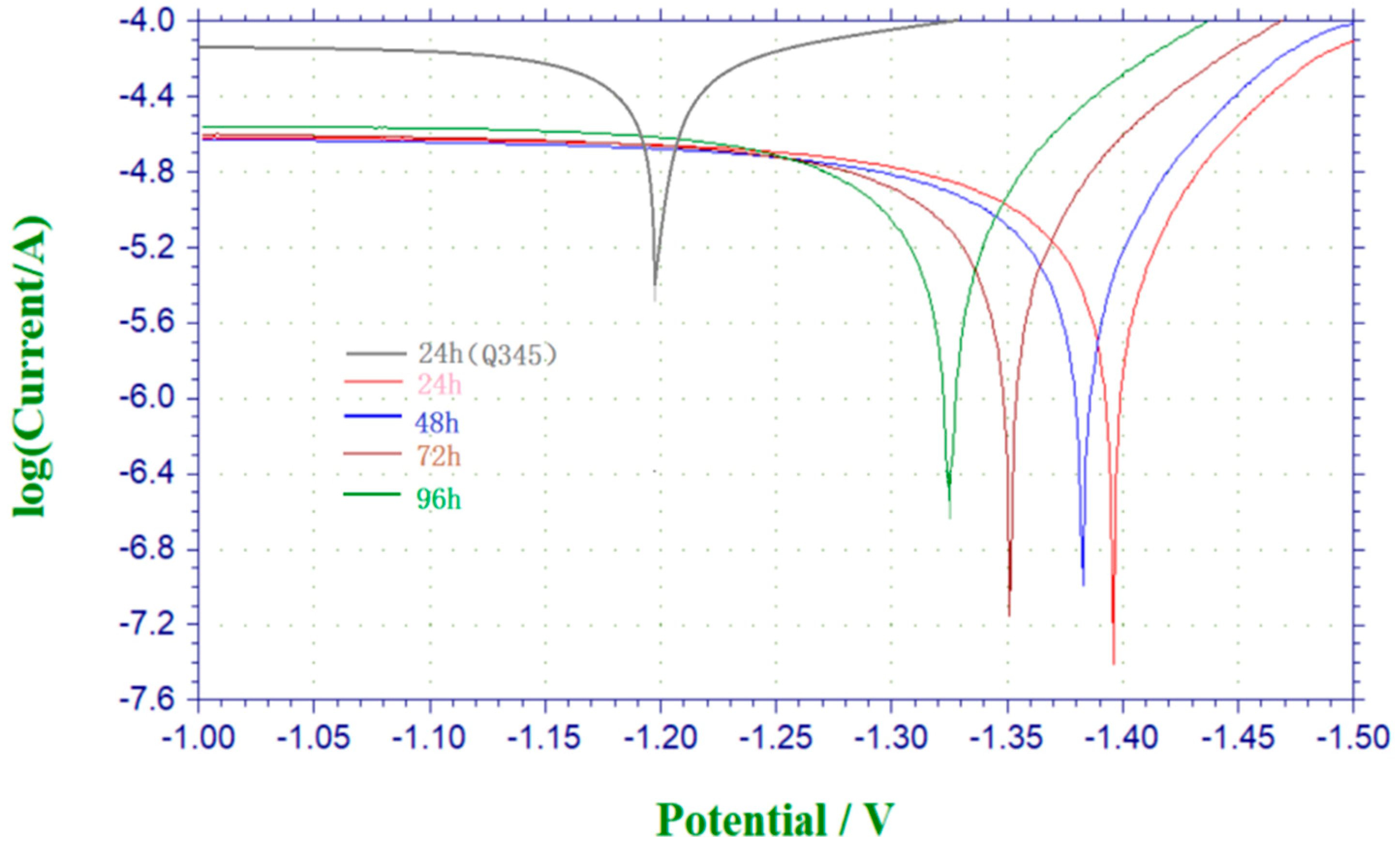

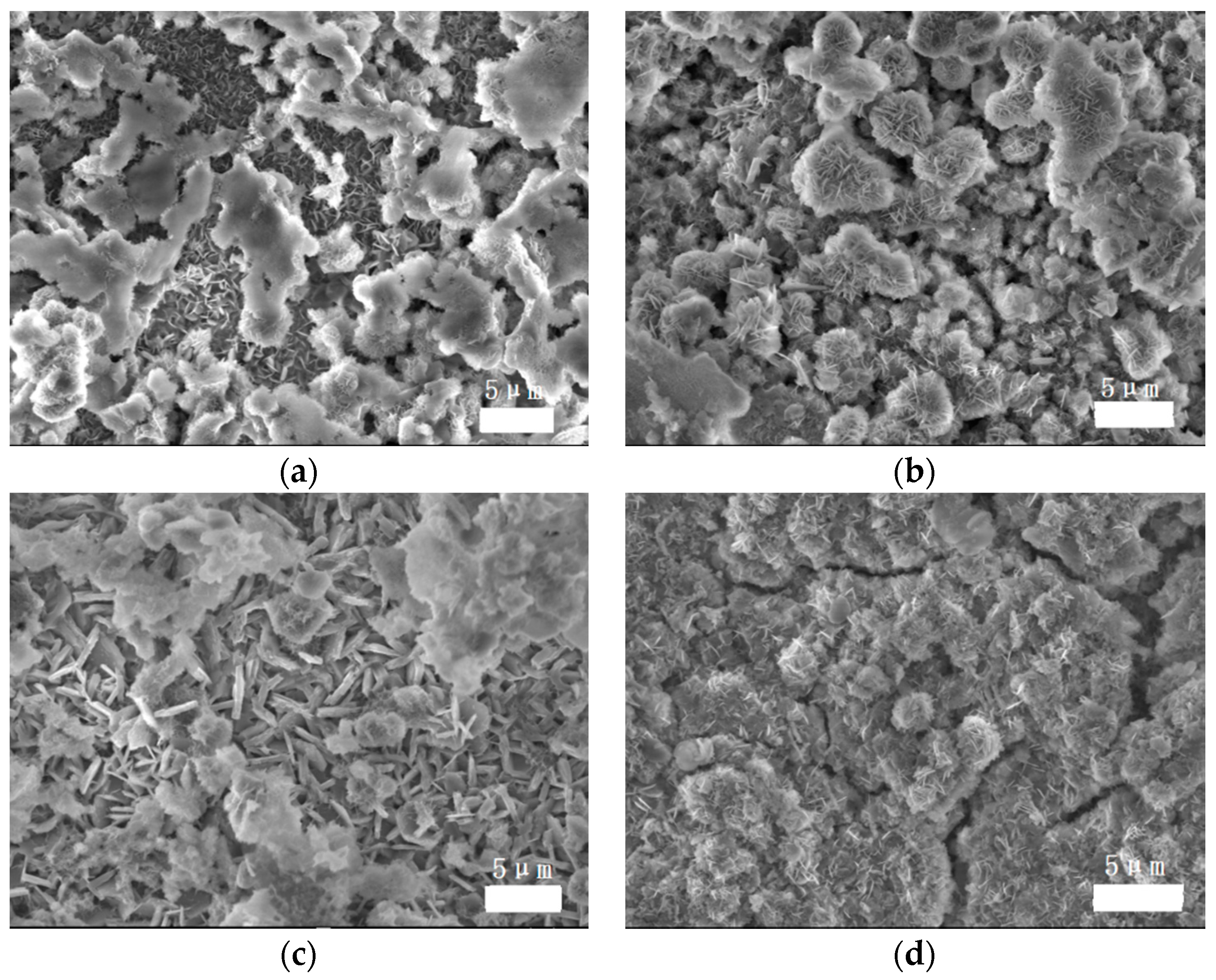

3.2. Corrosion Behavior of the Coating

4. Conclusions

- The Zn–Al composite coating prepared by cold spray technology can be firmly attached to the Q345 substrate. The energy dispersive spectrometer (EDS) analyzed the coating without significant oxidation during the preparation process. The SEM microstructure shows that the coating material, Zn, Al powder particles are uniformly mixed and good plastic deformation occurs.

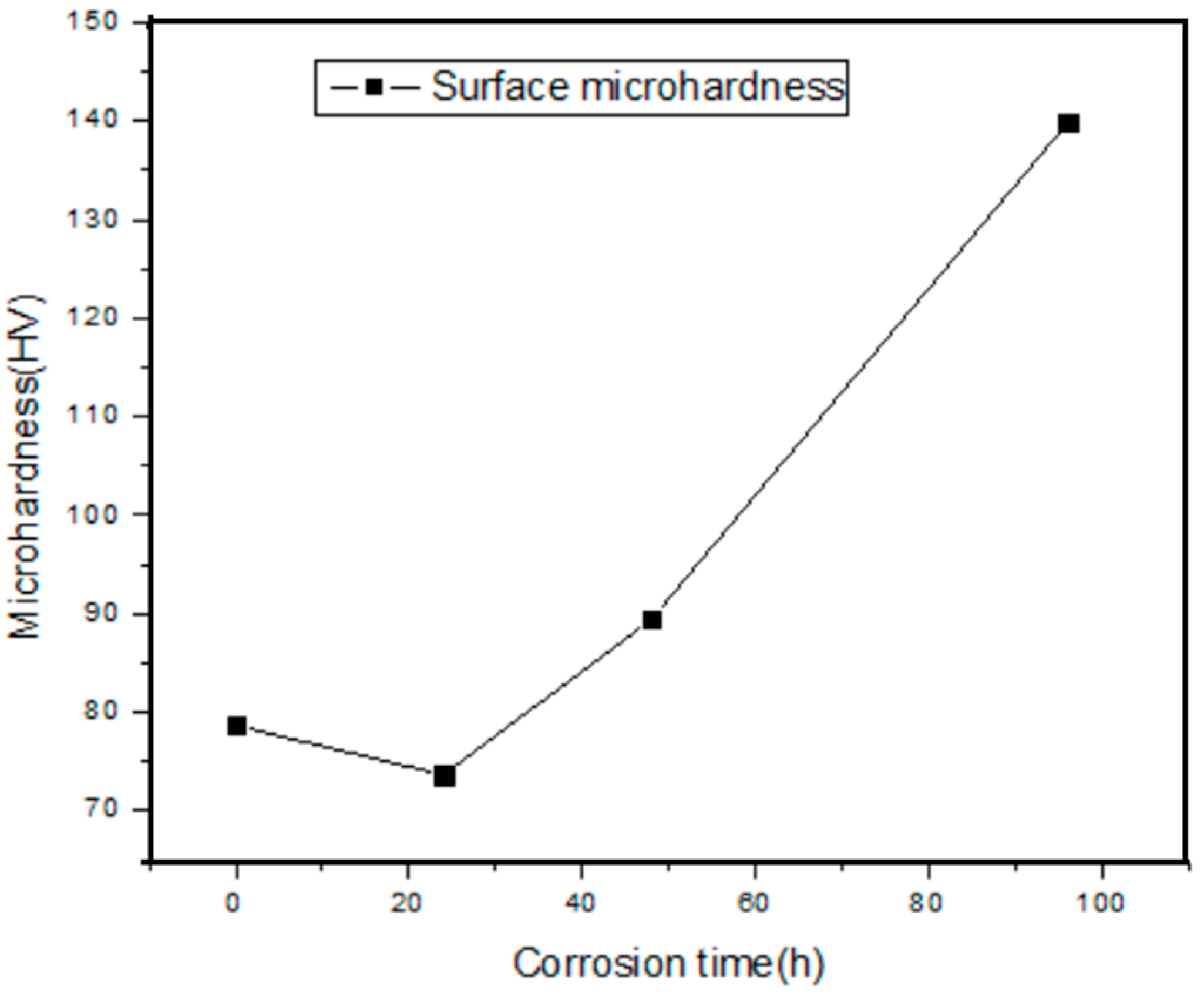

- After the salt spray test and electrochemical test of the sample, the microstructure of the sample at different corrosion time periods showed that the sample had a severe anodization reaction at the beginning of the accelerated corrosion, and a large amount of agglomerated oxidation products were formed. With the accelerated corrosion test, the oxidation products on the microscopic surface of the sample are gradually fine and dense, and the corrosion rate gradually slowed down. The oxidation product can effectively slow the corrosion of the sample surface. The corrosion surface hardness data measured by the hardness tester shows that the longer was the corrosion timein a certain range along the greater is the hardness of the surface, so the better is the wear resistance.

- The more positive Ecorr values and lower Icorr values of the base material indicate improved corrosion resistance properties of the uncoated material. On the one hand, the composite coating isolates the substrate from contact with the marine environment, therefore, corrosion of the substrate in direct contact with seawater is avoided. On the other hand, even if the surface of the composite coating is scratched, the coating and the substrate are anodized in a closed loop in seawater, thereby protecting the substrate from corrosion. In summary, the composite coating increases the corrosion behavior of the sample compared to the base material alone.

Author Contributions

Funding

Conflicts of Interest

References

- Olakanmi, E.O.; Doyoyo, M. Laser-assisted cold-sprayed corrosion-and wear-resistant coatings: A review. J. Therm. Spray Technol. 2014, 23, 765–785. [Google Scholar] [CrossRef]

- Zhu, Q.J.; Wang, K.; Wang, X.H.; Hou, B.R. Electrochemical impedance spectroscopy analysis of cold sprayed and arc sprayed aluminium coatings serviced in marine environment. Surf. Eng. 2012, 28, 300–305. [Google Scholar] [CrossRef]

- Chavan, N.M.; Kiran, B.; Jyothirmayi, A.; Phani, P.S.; Sundararajan, G. The corrosion behavior of cold sprayed zinc coatings on mild steel substrate. J. Therm. Spray Technol. 2013, 22, 463–470. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Gillispie, B.A.; Smith, J.R. Coating deposition by the kinetic spray process. Surf. Coat. Technol. 2006, 200, 4746–4754. [Google Scholar] [CrossRef]

- Liang, Y.L.; Wang, Z.B.; Zhang, J.B.; Lu, K. Formation of interfacial compounds and the effects on stripping behaviors of a cold-sprayed Zn–Al coating on interstitial-free steel. Appl. Surf. Sci. 2015, 340, 89–95. [Google Scholar] [CrossRef]

- Gkomoza, P.; Lampropoulos, G.S.; Vardavoulias, M.; Pantelis, D.I.; Karakizis, P.N.; Sarafoglou, Ch. Microstructural investigation of porous titanium coatings, produced by thermal spraying techniques, using plasma atomization and hydride-dehydride powders, for orthopedic implants. Surf. Coat. Technol. 2019, 357, 947–956. [Google Scholar] [CrossRef]

- Chang, L.M.; Liu, W.; Duan, X.Y. Pulse plated Zn transition layer in electroplating Zn–Ni coatings on magnesium alloys. Mater. Corros. 2015, 66, 434–441. [Google Scholar] [CrossRef]

- Matthews, S.; James, B. Review of thermal spray coating applications in the steel Industry: Part 2—Zinc pot hardware in the continuous galvanizing line. J. Therm. Spray Technol. 2010, 19, 1277–1286. [Google Scholar] [CrossRef]

- Cui, H.; Li, N.; Peng, J.; Yin, R.; Li, J.; Wu, Z. Investigation on the thermal performance of a novel spray tower with upward spraying and downward gas flow. Appl. Energy 2018, 231, 12–21. [Google Scholar] [CrossRef]

- Hunter, B.; Aldwell, B.; Jenkins, R.; Lupoi, R. A study on the feasibility of laser annealing to relieve residual stresses in cold spray coatings. Procedia CIRP 2018, 78, 91–96. [Google Scholar] [CrossRef]

- Xie, X.; Chen, C.; Xie, Y.; Aubry, E.; Ren, Z.; Ji, G.; Liao, H. Comparative investigation of microstructure and properties of Ni-coated FeSiAl soft magnetic composite coatings produced by cold spraying and HVOF. Surf. Coat. Technol. 2018, in press. [Google Scholar] [CrossRef]

- Li, C.J.; Li, W.Y.; Wang, Y.Y.; Yang, G.J.; Fukanuma, H. A theoretical model for prediction of deposition efficiency in cold spraying. Thin Solid Films 2005, 489, 79–85. [Google Scholar] [CrossRef]

- Sova, A.; Okunkova, A.; Grigoriev, S.; Smurov, I. Velocity of the particles accelerated by a cold spray micronozzle: Experimental measurements and numerical simulation. J. Therm. Spray Technol. 2013, 22, 75–80. [Google Scholar] [CrossRef]

- Lima, R.S.; Karthikeyan, J.; Kay, C.M.; Lindemann, J.; Berndt, C.C. Microstructural characteristics of cold-sprayed nanostructured WCeCo coatings. Thin Solid Films 2002, 416, 129–135. [Google Scholar] [CrossRef]

- Huang, G.; Li, X.; Xing, L. Corrosion behavior of low pressure cold sprayed Zn–Ni composites coating. Anti-Corros. Methods Mater. 2016, 63, 461–469. [Google Scholar] [CrossRef]

- Diab, M.; Pang, X.; Jahed, H. The effect of pure aluminum cold spray coating on corrosion and corrosion fatigue of magnesium (3% Al–1% Zn) extrusion. Surf. Coat. Technol. 2017, 309, 423–435. [Google Scholar] [CrossRef]

- Huang, R.Z.; Sone, M.; Ma, W.; Fukanuma, H. The effects of heat treatment on the mechanical properties of cold-sprayed coatings. Surf. Coat. Technol. 2015, 261, 278–288. [Google Scholar] [CrossRef]

- Loganathan, A.; Sahu, A.; Rudolf, C.; Zhang, C.; Rengifo, S.; Laha, T.; Boesl, B.; Agarwal, A. Multi-scale tribological and nanomechanical behavior of cold sprayed Ti2AlC MAX phase coating. Surf. Coat. Technol. 2018, 334, 384–393. [Google Scholar] [CrossRef]

- Da Silva, F.S.; Bedoya, J.; Dosta, S.; Cinca, N.; Cano, I.G.; Guilemany, J.M.; Benedetti, A.V. Corrosion characteristics of cold gas spray coatings of reinforced aluminum deposited onto carbon steel. Corros. Sci. 2017, 114, 57–71. [Google Scholar] [CrossRef]

- Goupil, G.; Jucken, S.; Poirier, D.; Legoux, J.G.; Irissou, E.; Davis, B.; Guay, D.; Roue, L. Cold sprayed Cu–Ni–Fe anode for Al production. Corros. Sci. 2015, 90, 259–265. [Google Scholar] [CrossRef]

- Zhou, X.L.; Mou, S.J.; Wu, X.K.; Zhang, J.S. Deposition behavior of mixed binary metallic powders in cold spraying process. Appl. Sur. Sci. 2011, 257, 10628–10633. [Google Scholar] [CrossRef]

- Ghelichi, R.; MacDonald, D.; Bagherifard, S.; Jahed, H.; Guagliano, M.; Jodoin, B. Microstructure and fatigue behavior of cold spray coated Al5052. Acta Mater. 2012, 60, 6555–6561. [Google Scholar] [CrossRef]

- Tachibana, K.; Morinaga, Y.; Mayuzumi, M. Hot dip fine Zn and Zn–Al alloy double coating for corrosion resistance at coastal area. Corros. Sci. 2007, 49, 149–157. [Google Scholar] [CrossRef]

- Duchoslav, J.; Steinberger, R.; Arndt, M.; Keppert, T.; Luckeneder, G.; Stellnberger, K.H.; Hagler, J.; Angeli, G.; Riener, C.K.; Stifter, D. Evolution of the surface chemistry of hot dip galvanized Zn–Mg–Al and Zn coatings on steel during short term exposure to sodium chloride containing environments. Corros. Sci. 2015, 91, 311–320. [Google Scholar] [CrossRef]

- Esmaily, M.; Svensson, J.E.; Fajardo, S.; Birbilis, N.; Frankel, G.S.; Virtanen, S.; Arrabal, R.; Thomas, S.; Johansson, L.G. Fundamentals and advances in magnesium alloy corrosion. Prog. Mater. Sci. 2017, 89, 92–193. [Google Scholar] [CrossRef]

- Godinez, J.C.; Fadda, D.; Lee, J.; You, S.M. Enhancement of pool boiling heat transfer in water on aluminum surface with high temperature conductive microporous coating. Int. J. Heat Mass Transf. 2019, 132, 772–781. [Google Scholar] [CrossRef]

- Grégoire, B.; Bonnet, G.; Pedraza, F. Mechanisms of formation of slurry aluminide coatings from Al and Cr microparticles. Surf. Coat. Technol. 2019, 359, 323–333. [Google Scholar] [CrossRef]

- Liang, Y.L.; Wang, Z.B.; Zhang, J.; Zhang, J.B.; Lu, K. Enhanced bonding property of cold-sprayed Zn–Al coating on interstitial-free steel substrate with a nanostructured surface layer. Appl. Surf. Sci. 2016, 385, 341–348. [Google Scholar] [CrossRef]

- Zhou, X.L.; Mou, S.J.; Wu, X.K.; Zhang, J.S. Deposition behavior of mixed binary metallic powders in cold spraying process. Spec. Cast. Nonferrous Alloy. 2010, 30, 702–704. (In Chinese) [Google Scholar] [CrossRef]

- Li, H.X.; Sun, M.X.; Li, X.B.; Wang, H.R.; Huang, G.S. Depositing characteristic of 65% Zn–Al coatings produced by cold gas dynamic spray. Chin. J. Nonferrous Met. 2010, 20, 1353–1359. (In Chinese) [Google Scholar] [CrossRef]

- Li, H.X.; Li, X.B.; Sun, M.-X.; Wang, H.R.; Huang, G.S. Corrosion resistance of cold-sprayed Zn–50Al coatings in seawater. J. Chin. Soc. Corros. Prot. 2010, 30, 62–66. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Duval, T.; Hung, U.D.; Yeh, J.W.; Shih, H.C. Microstructure and electrochemical properties of high entropy alloys—A comparison with type-304 stainless steel. Corros. Sci. 2005, 47, 2257–2279. [Google Scholar] [CrossRef]

- Da Silva, F.S.; Cinca, N.; Dosta, S.; Cano, I.G.; Couto, M.; Guilemany, J.M.; Benedetti, A.V. Corrosion behavior of WC-Co coatings deposited by cold gas spray onto AA 7075-T6. Corros. Sci. 2018, 136, 231–243. [Google Scholar] [CrossRef]

| HEACs | Regions | Elements (at.%) | |||

|---|---|---|---|---|---|

| Zn | Al | O | C | ||

| Zn–Al coating | 1 (bright) | 85.9 | 1.6 | 4.6 | 8.2 |

| 2 (gray) | 90.6 | 0.1 | 7.8 | 1.5 | |

| Times/h | Ecorr (VSCE) | Icorr (A·cm−2) | Ipass (A·cm−2) | Ba (mVdec−1) | Bc (mVdec−1) |

|---|---|---|---|---|---|

| 24 (Q345) | −1.192 ± 0.03 | 6.589 × 10−5 | 8.37 × 10−4 | 3.392 | 3.947 |

| 24 | −1.396 ± 0.03 | 1.737 × 10−4 | 2.39 × 10−3 | 2.743 | 8.729 |

| 48 | −1.384 ± 0.04 | 1.456 × 10−4 | 1.63 × 10−3 | 2.571 | 8.134 |

| 72 | −1.351 ± 0.01 | 1.248 × 10−4 | 0.96 × 10−3 | 2.397 | 8.222 |

| 96 | −1.325 ± 0.02 | 1.154 × 10−4 | 0.622 × 10−3 | 2.375 | 7.915 |

| Corrosion Times/h | Microhardness (HV) | ||||

|---|---|---|---|---|---|

| 0 | 79.6 | 75.2 | 77.6 | 80.5 | 77.8 |

| 24 | 80.6 | 60.1 | 70.6 | 68.3 | 73.4 |

| 48 | 81.0 | 91.7 | 77.5 | 87.3 | 85.8 |

| 96 | 132.0 | 122.3 | 163.8 | 150.5 | 145.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Wang, S.; Xiong, T.; Wen, D.; Wang, G.; Du, H. Anticorrosion Properties of Zn–Al Composite Coating Prepared by Cold Spraying. Coatings 2019, 9, 210. https://doi.org/10.3390/coatings9030210

Lu X, Wang S, Xiong T, Wen D, Wang G, Du H. Anticorrosion Properties of Zn–Al Composite Coating Prepared by Cold Spraying. Coatings. 2019; 9(3):210. https://doi.org/10.3390/coatings9030210

Chicago/Turabian StyleLu, Xinqiang, Shouren Wang, Tianying Xiong, Daosheng Wen, Gaoqi Wang, and Hao Du. 2019. "Anticorrosion Properties of Zn–Al Composite Coating Prepared by Cold Spraying" Coatings 9, no. 3: 210. https://doi.org/10.3390/coatings9030210

APA StyleLu, X., Wang, S., Xiong, T., Wen, D., Wang, G., & Du, H. (2019). Anticorrosion Properties of Zn–Al Composite Coating Prepared by Cold Spraying. Coatings, 9(3), 210. https://doi.org/10.3390/coatings9030210