Improved Adhesion of TiAlSiN Nanocomposite Coatings on Cemented Carbide Substrate by Pre-Implantation

Abstract

1. Introduction

2. Experimental Details

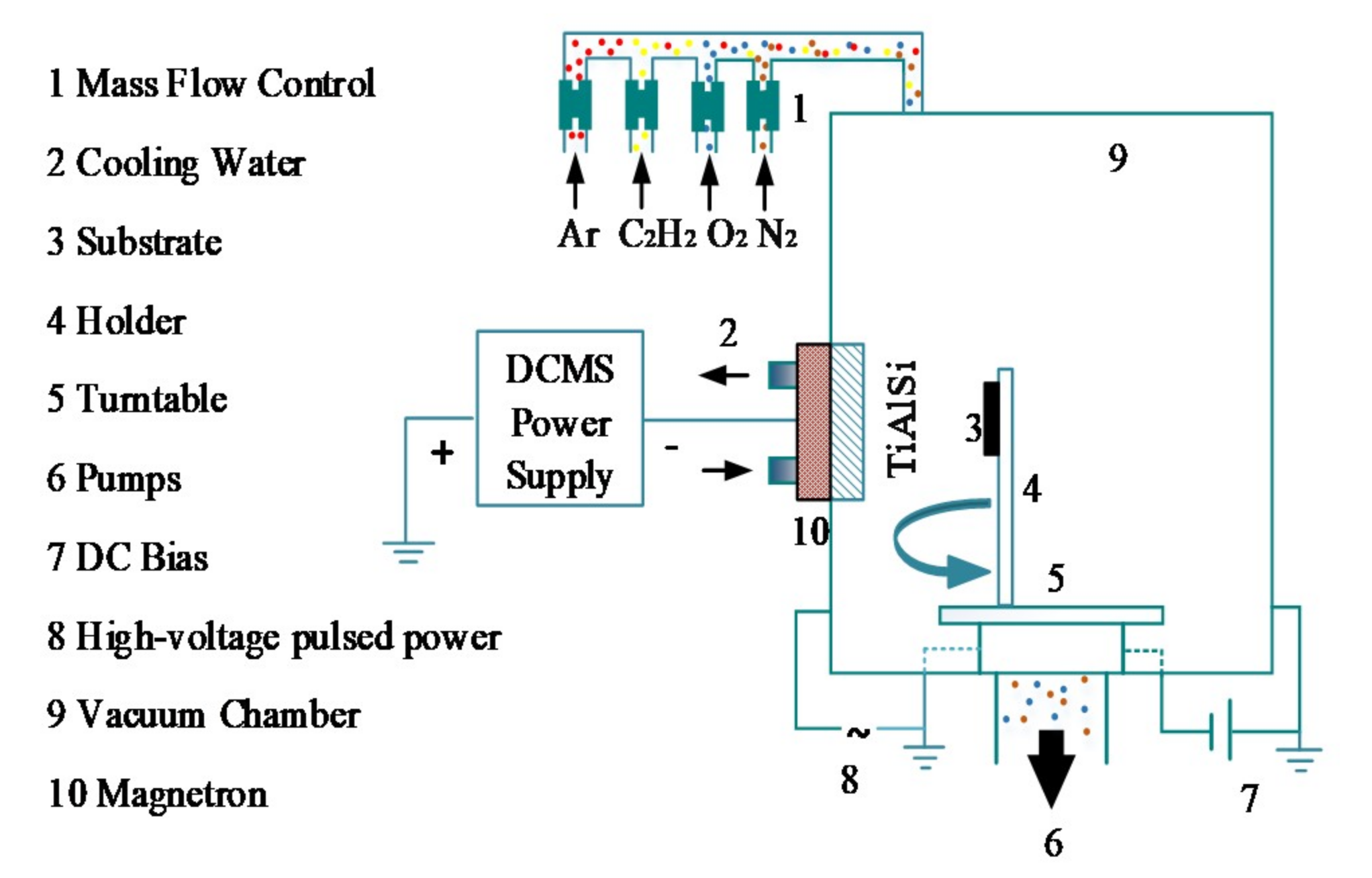

2.1. Pre-Implantation and Deposition

2.2. Characterization

3. Results and Discussion

3.1. Microstructure of As-Deposited Coatings

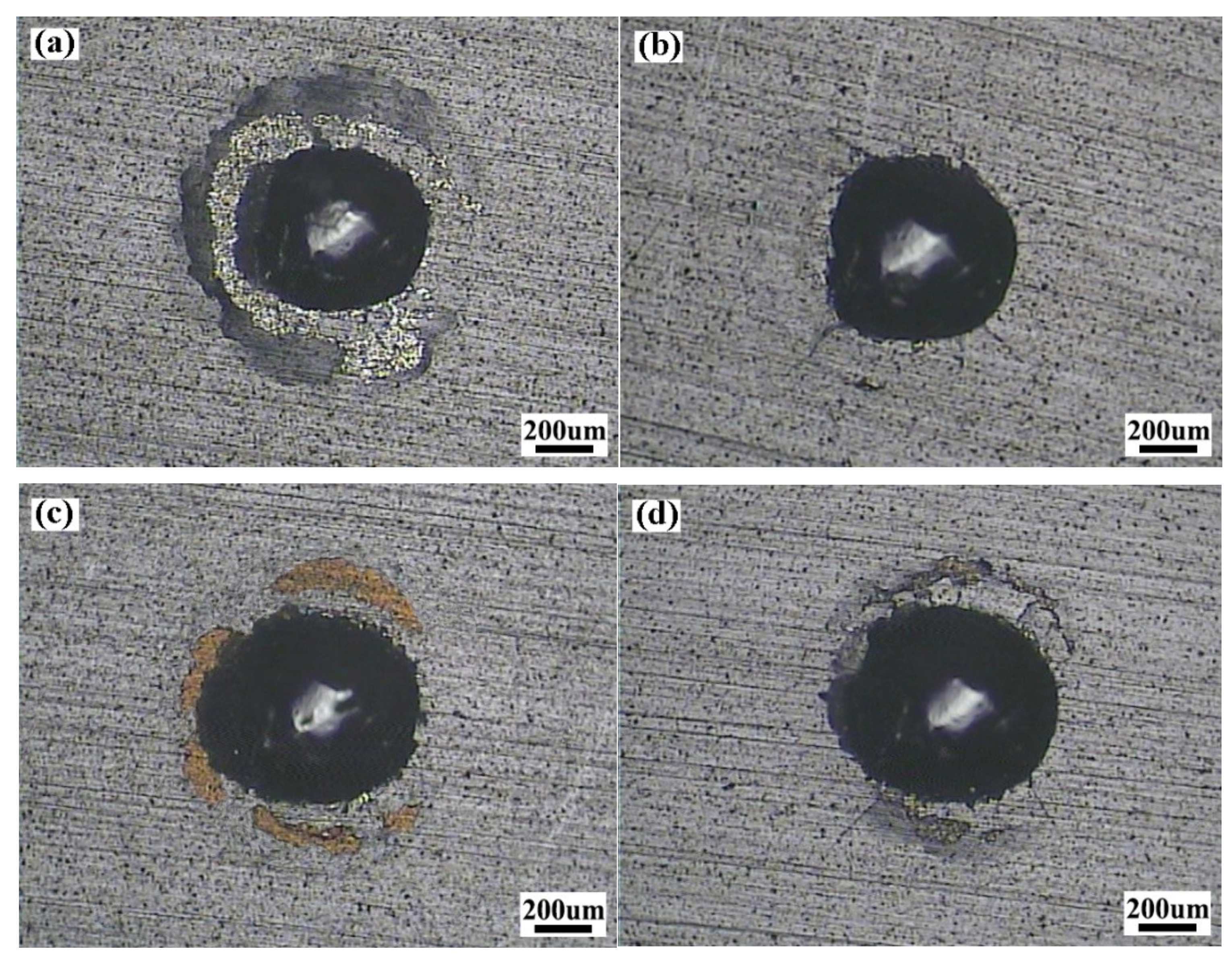

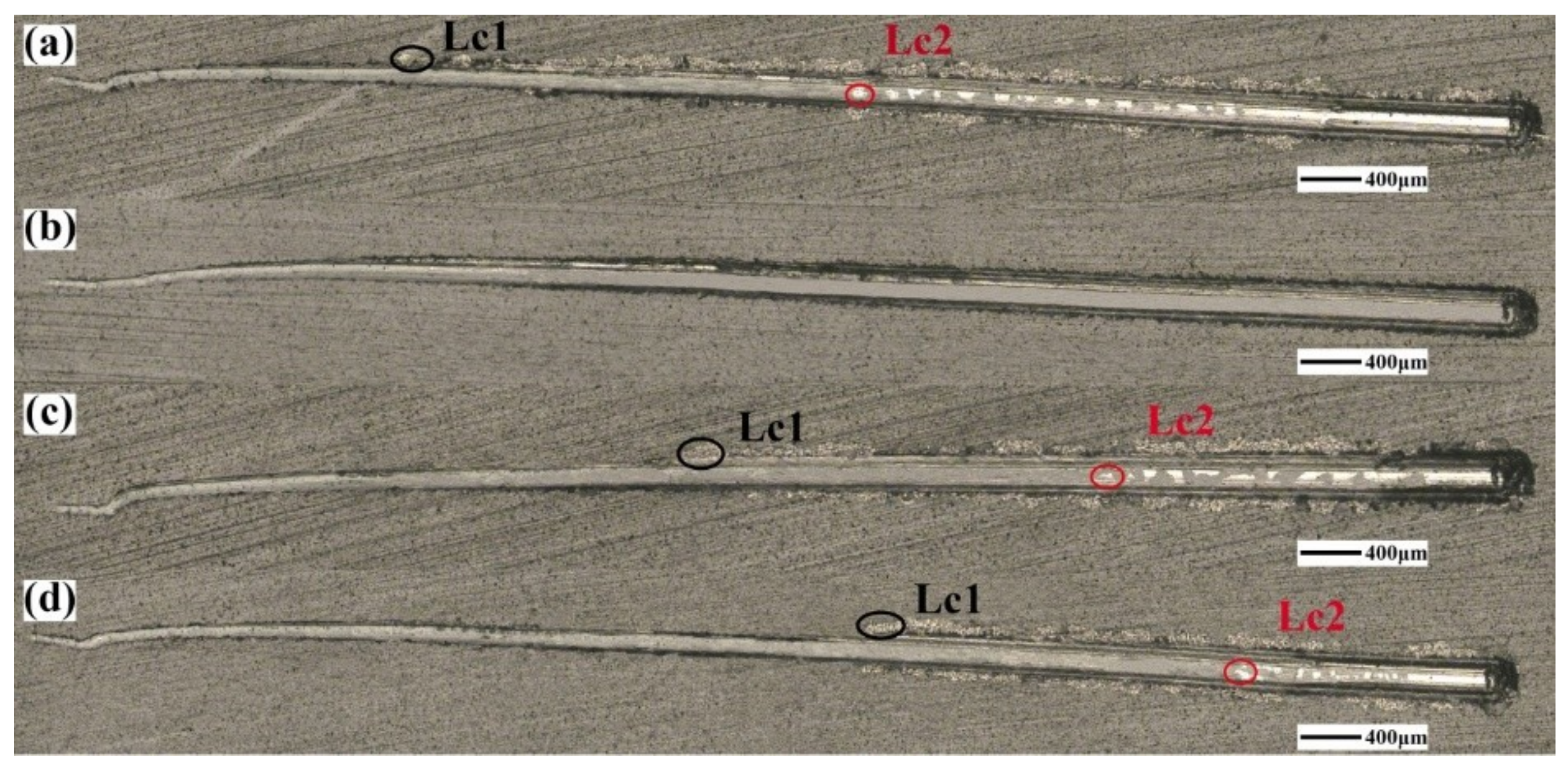

3.2. Adhesion and Mechanical Properties of the Coatings

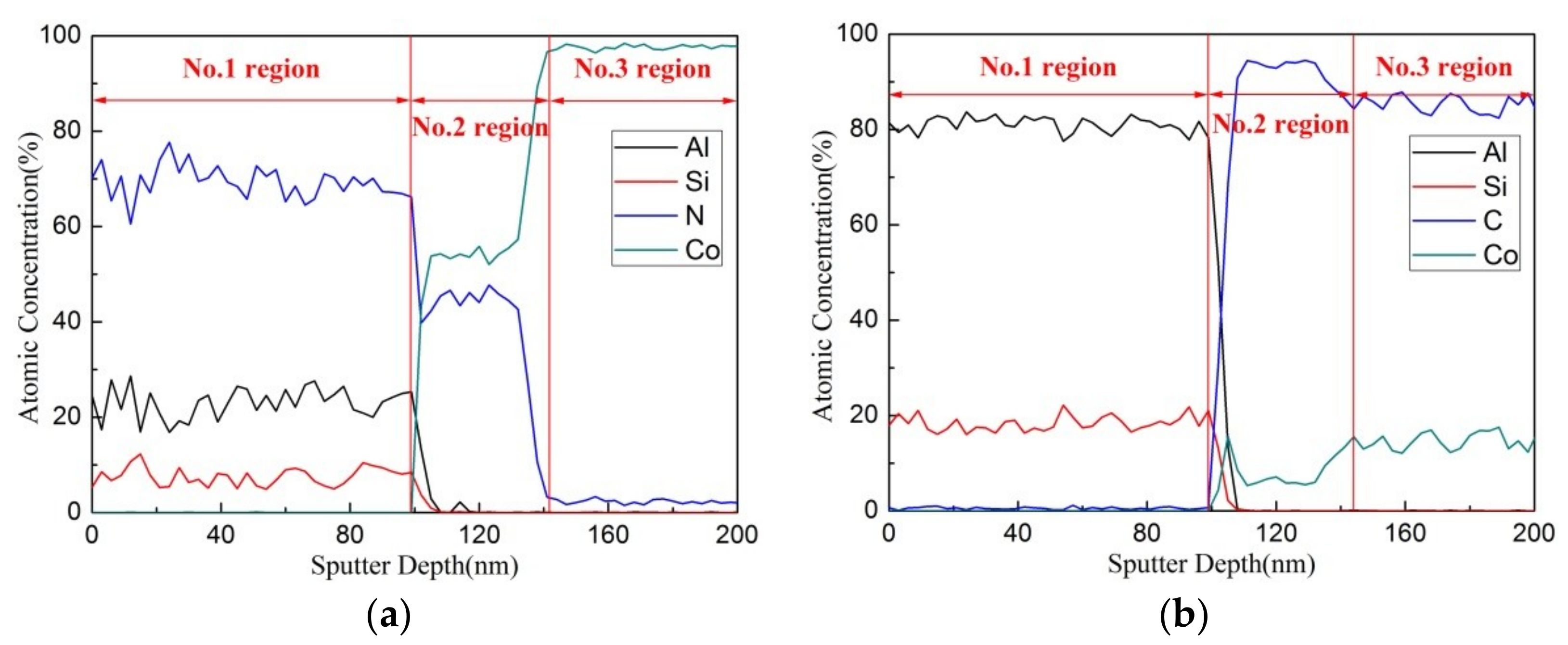

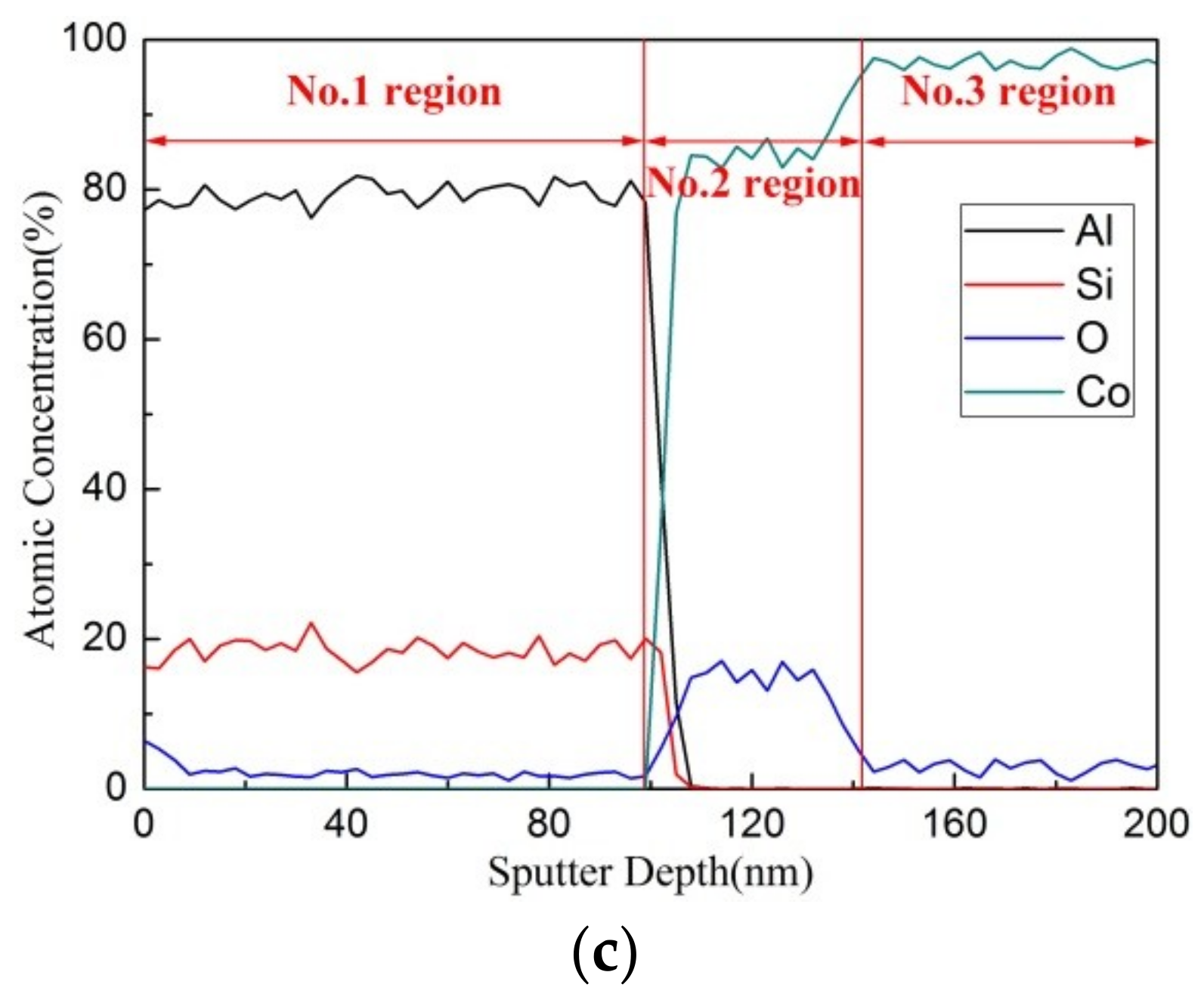

3.3. Auger Electron Spectroscopy Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bagdasaryan, A.A.; Pshyk, A.V.; Coy, L.E.; Konarski, P.; Misnik, M.; Ivashchenko, V.I.; Kempiński, M.; Mediukh, N.R.; Pogrebnjak, A.D.; Beresnev, V.M. A new type of (TiZrNbTaHf)N/MoN nanocomposite coating: Microstructure and properties depending on energy of incident ions. Compos. Part B Eng. 2018, 146, 132–144. [Google Scholar] [CrossRef]

- Pshyk, A.V.; Kravchenko, Y.; Coy, E.; Kempiński, M.; Iatsunskyi, I.; Załęski, K.; Pogrebnjak, A.D.; Jurga, S. Microstructure, phase composition and mechanical properties of novel nanocomposite (TiAlSiY)N and nano-scale (TiAlSiY)N/MoN multifunctional heterostructures. Surf. Coat. Technol. 2018, 350, 376–390. [Google Scholar] [CrossRef]

- Shypylenko, A.; Pshyk, A.V.; Medjanik, K.; Peplinska, B.; Oyoshid, K.; Jurga, S.; Coya, E. Influence of ion implantation on the physical and mechanical properties of multifunctional coatings based on Ti-Si-N. In Proceedings of the International Conference on Nanomaterials: Application & Properties, Atalanta, GA, USA, 15–20 September 2016. [Google Scholar]

- Chen, L.; Wang, S.Q.; Du, Y.; Zhou, S.Z.; Gang, T.; Fen, J.C.; Chang, K.K.; Li, Y.W.; Xiong, X.A. Machining performance of Ti-Al-Si-N coated inserts. Surf. Coat. Technol. 2010, 205, 582–586. [Google Scholar] [CrossRef]

- Çalışkan, H.; Kurbanoğlu, C.; Panjan, P.; Čekada, M.; Kramar, D. Wear behavior and cutting performance of nanostructured hard coatings on cemented carbide cutting tools in hard milling. Tribol. Int. 2013, 62, 215–222. [Google Scholar] [CrossRef]

- Sui, X.D.; Li, G.J.; Qin, X.S.; Yu, H.D.; Zhou, X.K.; Wang, K.; Wang, Q. Relationship of microstructure, mechanical properties and titanium cutting performance of TiAlN/TiAlSiN composite coated tool. Ceram. Int. 2016, 42, 7524–7532. [Google Scholar] [CrossRef]

- Rafaja, D. XRD characterization of ion-implanted TiN coatings. Surf. Coat. Technol. 1996, 86, 302–308. [Google Scholar] [CrossRef]

- Weng, K.W.; Chen, Y.C.; Lin, T.N.; Wang, D.Y. Characterization of titanium nitride coatings deposited by metal plasma ion pre-implantation and cathodic arc evaporation. J. Nanosci. Nanotechnol. 2009, 9, 1127–1132. [Google Scholar] [CrossRef]

- Narojczyk, J.; Werner, Z.; Barlak, M.; Morozow, D. The effect of Ti preimplantation on the properties of TiN coatings on HS 6-5-2 high-speed steel. Vacuum 2008, 83 (Suppl. 1), S228–S230. [Google Scholar] [CrossRef]

- Shum, P.W.; Xu, Y.F.; Zhou, Z.F.; Li, K.Y. Effects of carbon and nitrogen ion implantations on surface and tribological properties of Ti–Al–Si–N coatings. Surf. Eng. 2012, 28, 149–154. [Google Scholar] [CrossRef]

- Flege, S.; Hatada, R.; Ensinger, W.; Baba, K. Improved adhesion of DLC films on copper substrates by preimplantation. Surf. Coat. Technol. 2014, 256, 37–40. [Google Scholar] [CrossRef]

- Sekler, J.; Steinmann, P.A.; Hintermann, H.E. The scratch test: Different critical load determination techniques. Surf. Coat. Technol. 1988, 36, 519–529. [Google Scholar] [CrossRef]

- Valli, J.; Mäkelä, U. Applications of the scratch test method for coating adhesion assessment. Wear 1987, 115, 215–221. [Google Scholar] [CrossRef]

- Paschke, H.; Weber, M.; Kaestner, P.; Braeuer, G. Influence of different plasma nitriding treatments on the wear and crack behavior of forging tools evaluated by Rockwell indentation and scratch tests. Surf. Coat. Technol. 2010, 205, 1465–1469. [Google Scholar] [CrossRef]

- Roudet, F.; Chicot, D.; Decoopman, X.; Iost, A.; Bürgi, J.; Garcia-Molleja, J.; Nosei, L.; Feugeas, J. Modeling of very thin aluminum nitride film mechanical properties from nanoindentation measurements. Thin Solid Films 2015, 594, 129–137. [Google Scholar] [CrossRef]

- Shypylenko, A.; Pshyk, A.V.; Grześkowiak, B.; Medjanik, K.; Peplinska, B.; Oyoshi, K.; Pogrebnjak, A.; Jurga, S.; Coy, E. Effect of ion implantation on the physical and mechanical properties of Ti-Si-N multifunctional coatings for biomedical applications. Mater. Des. 2016, 110, 821–829. [Google Scholar] [CrossRef]

- Flege, S.; Hatada, R.; Vogel, T.; Bruder, E.; Major, M.; Ensinger, W.; Baba, K. Tightly adhering diamond-like carbon films on copper substrates by oxygen pre-implantation. Surf. Coat. Technol. 2018, 335, 134–139. [Google Scholar] [CrossRef]

- Pshyk, A.V.; Coy, L.E.; Nowaczyk, G.; Kempiński, M.; Peplińska, B.; Pogrebnjak, A.D.; Beresnev, V.M.; Jurga, S. High temperature behavior of functional TiAlBSiN nanocomposite coatings. Surf. Coat. Technol. 2016, 305, 49–61. [Google Scholar] [CrossRef]

- Wu, W.Y.; Su, A.; Liu, Y.; Yeh, C.M.; Chen, W.C.; Chang, C.L. Effect of DC input power and nitrogen ratio on the deposition of Ti1−xAlxN thin films using high power impulse magnetron sputtering technique. Surf. Coat. Technol. 2016, 303, 48–53. [Google Scholar] [CrossRef]

- Zhu, L.H.; Song, C.; Ni, W.Y.; Liu, Y.X. Effect of 10% Si addition on cathodic arc evaporated TiAlSiN coatings. Trans. Nonferrous Met. Soc. China 2016, 26, 1638–1646. [Google Scholar] [CrossRef]

- Zheng, Z.; Yu, Z. Characteristics and machining applications of Ti(Y)N coatings. Surf. Coat. Technol. 2010, 204, 4107–4113. [Google Scholar] [CrossRef]

- Du, H.; Xiong, J.; Zhao, H.; Wu, Y.; Wan, W.; Wang, L. Structure and properties of TiAlLaN films deposited at various bias voltages. Appl. Surf. Sci. 2014, 292, 688–694. [Google Scholar] [CrossRef]

- Shum, P.W.; Zhou, Z.F.; Li, K.Y. Friction and wear reduction of hard TiAlSiN coatings by an integrated approach of laser surface texturing and high-energy ion implantation. Surf. Coat. Technol. 2014, 259, 136–140. [Google Scholar] [CrossRef]

- Tsai, D.C.; Huang, Y.L.; Lin, S.R.; Liang, S.C.; Shieu, F.S. Effect of nitrogen flow ratios on the structure and mechanical properties of (TiVCrZrY)N coatings prepared by reactive magnetron sputtering. Appl. Surf. Sci. 2010, 257, 1361–1367. [Google Scholar] [CrossRef]

- Chen, J.S.; Sun, Z.; Guo, P.S.; Zhang, Z.B.; Xu, H.J. Effect of ion implantation on surface energy of ultrahigh molecular weight polyethylene. J. Appl. Phys. 2003, 93, 5103–5108. [Google Scholar] [CrossRef]

- Kumar, S.S.; Sharma, A.; Rao, G.M.; Suwas, S. Investigations on the effect of substrate temperature on the properties of reactively sputtered zirconium carbide thin films. J. Alloy. Compd. 2017, 695, 1020–1028. [Google Scholar] [CrossRef]

- Shum, P.W.; Xu, Y.F.; Zhou, Z.F.; Cheng, W.L.; Li, K.Y. Study of TiAlSiN coatings post-treated with N and C + N ion implantations. Part 2: The tribological analysis. Wear 2012, 274–275, 274–280. [Google Scholar] [CrossRef]

- Lee, J.W.; Tien, S.K.; Kuo, Y.C. The effects of pulse frequency and substrate bias to the mechanical properties of CrN coatings deposited by pulsed DC magnetron sputtering. Thin Solid Films 2006, 494, 161–167. [Google Scholar] [CrossRef]

- Ma, Q.; Li, L.; Ye, X.; Gu, J.; Lei, W.; Yi, X. Effect of bias voltage on TiAlSiN nanocomposite coatings deposited by HiPIMS. Appl. Surf. Sci. 2016, 392, 826–833. [Google Scholar] [CrossRef]

- Gerth, J.; Wiklund, U. The influence of metallic interlayers on the adhesion of PVD TiN coatings on high-speed steel. Wear 2008, 264, 885–892. [Google Scholar] [CrossRef]

- Lv, Y.; Li, J.; Liu, X.; Li, H.; Zhou, H.; Chen, J. Influence of substrate bias voltage on structure and properties of the CrAlN films deposited by unbalanced magnetron sputtering. Appl. Surf. Sci. 2012, 258, 3864–3870. [Google Scholar] [CrossRef]

- Wang, L.; Li, L.; Kuang, X. Effect of substrate bias on microstructure and mechanical properties of WC-DLC coatings deposited by HiPIMS. Surf. Coat. Technol. 2018, 352, 33–41. [Google Scholar] [CrossRef]

- Holzwarth, U.; Gibson, N. The Scherrer equation versus the ‘Debye-Scherrer equation’. Nat. Nanotechnol. 2011, 6, 534. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.S.; Li, L.H.; Xu, Y.; Ma, X.; Xu, Y.; Liu, H.T. Effect of Ti content on the microstructure and mechanical properties of TiAlSiN nanocomposite coatings. Int. J. Refract. Met. Hard Mater. 2016, 59, 114–120. [Google Scholar] [CrossRef]

| Implantation Stage | Substrate Bias (V) | Temperature (°C) | Pressure (Pa) | Implantation Time (min) |

|---|---|---|---|---|

| Stage I | −10,000 (pulse) | 150 | 1 | 8 |

| Stage II | −8000 (pulse) | 150 | 1 | 5 |

| Stage III | −1600 (DC) | 150 | 1 | 5 |

| Stage IV | −1200 (DC) | 150 | 1 | 5 |

| Target-Substrate Distance (cm) | Substrate Bias (V) | Temperature (°C) | PN2/PAr | Working Pressure (Pa) | Target Current (A) | Sputtering Power (W) |

|---|---|---|---|---|---|---|

| 9 | −100 | 150 | 1/3 | 0.8 | 2 | 900 |

| Sample Number | Sample 1 | Sample 2 | Sample 3 | Sample 4 | |

|---|---|---|---|---|---|

| Element of Pre-Implantation | None | Nitrogen (N) | Carbon (C) | Oxygen (O) | |

| Element Concentration (at.%) | Ti | 33.48 ± 0.35 | 32.89 ± 0.28 | 33.97 ± 0.40 | 33.16 ± 0.38 |

| Al | 16.32 ± 0.25 | 15.94 ± 0.33 | 16.04 ± 0.18 | 16.49 ± 0.22 | |

| Si | 3.60 ± 0.05 | 3.54 ± 0.08 | 3.78 ± 0.11 | 3.39 ± 0.06 | |

| N | 46.60 ± 0.43 | 47.63 ± 0.52 | 45.57 ± 0.62 | 46.11 ± 0.36 | |

| C | 0 | 0 | 0.64 ± 0.05 | 0 | |

| O | 0 | 0 | 0 | 0.85 ± 0.03 | |

| Samples | Pre-Implantation | Adhesion | Hardness (GPa) | Elastic Modulus (GPa) | H/E | ||

|---|---|---|---|---|---|---|---|

| Rockwell | LC1 (N) | LC2 (N) | |||||

| Sample 1 | None | HF3 | 26 | 56 | 22.6 ± 2.3 | 402.8 ± 8.5 | 0.056 |

| Sample 2 | Nitrogen (N) | HF1 | 100 | 100 | 28.5 ± 3.1 | 466.4 ± 9.2 | 0.061 |

| Sample 3 | Carbon (C) | HF3 | 47 | 69 | 23.2 ± 2.1 | 399.7 ± 8.7 | 0.058 |

| Sample 4 | Oxygen (O) | HF2 | 55 | 78 | 26.7 ± 2.9 | 468.8 ± 9.1 | 0.057 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Li, L.; Li, G.; Ma, Q. Improved Adhesion of TiAlSiN Nanocomposite Coatings on Cemented Carbide Substrate by Pre-Implantation. Coatings 2019, 9, 209. https://doi.org/10.3390/coatings9030209

Wang L, Li L, Li G, Ma Q. Improved Adhesion of TiAlSiN Nanocomposite Coatings on Cemented Carbide Substrate by Pre-Implantation. Coatings. 2019; 9(3):209. https://doi.org/10.3390/coatings9030209

Chicago/Turabian StyleWang, Lei, Liuhe Li, Guodong Li, and Quansheng Ma. 2019. "Improved Adhesion of TiAlSiN Nanocomposite Coatings on Cemented Carbide Substrate by Pre-Implantation" Coatings 9, no. 3: 209. https://doi.org/10.3390/coatings9030209

APA StyleWang, L., Li, L., Li, G., & Ma, Q. (2019). Improved Adhesion of TiAlSiN Nanocomposite Coatings on Cemented Carbide Substrate by Pre-Implantation. Coatings, 9(3), 209. https://doi.org/10.3390/coatings9030209