Surfactant-Free Electroless Codeposition of Ni–P–MoS2/Al2O3 Composite Coatings

Abstract

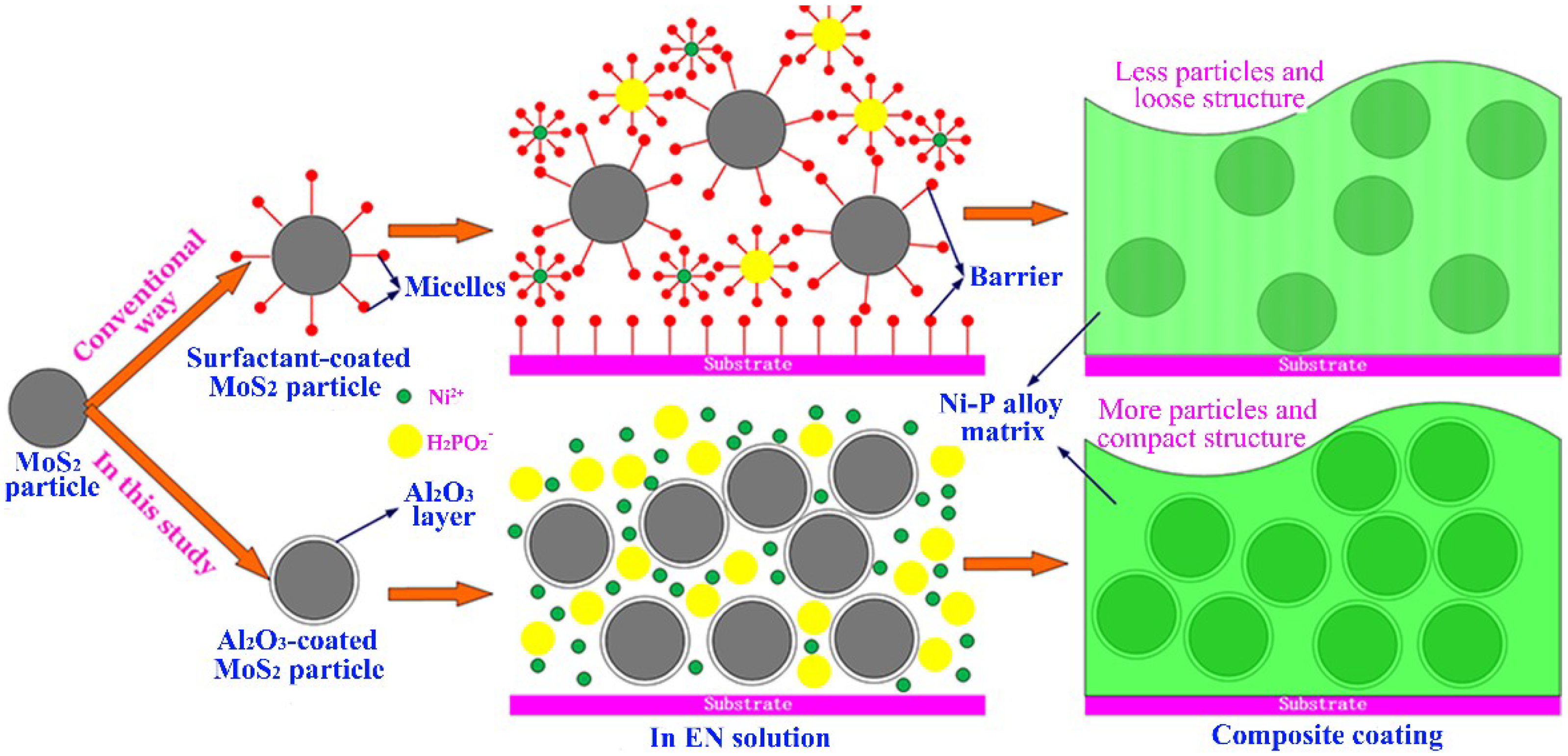

1. Introduction

2. Materials and Methods

2.1. Preparation of Coated Particles

2.2. Preparation of Ni–P Matrix Composite Coatings

2.2.1. Substrate Preparation

2.2.2. Electroless Plating Bath and Operating Conditions

2.3. Post-Treatment of Electroless Coatings

2.4. SEM/EDS/XRD/LSCM Characterization

2.5. Friction and Wear Tests

3. Results and Discussion

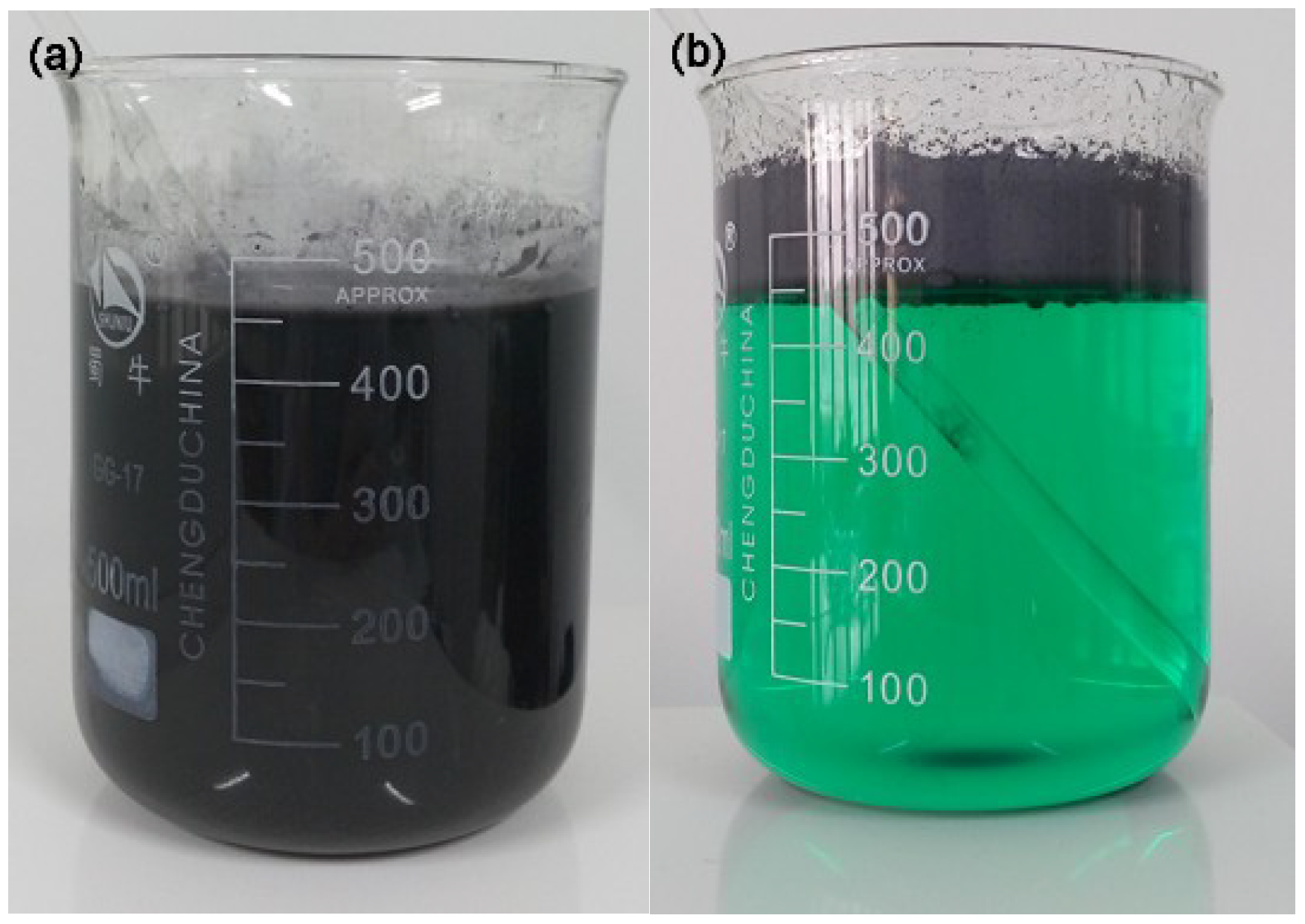

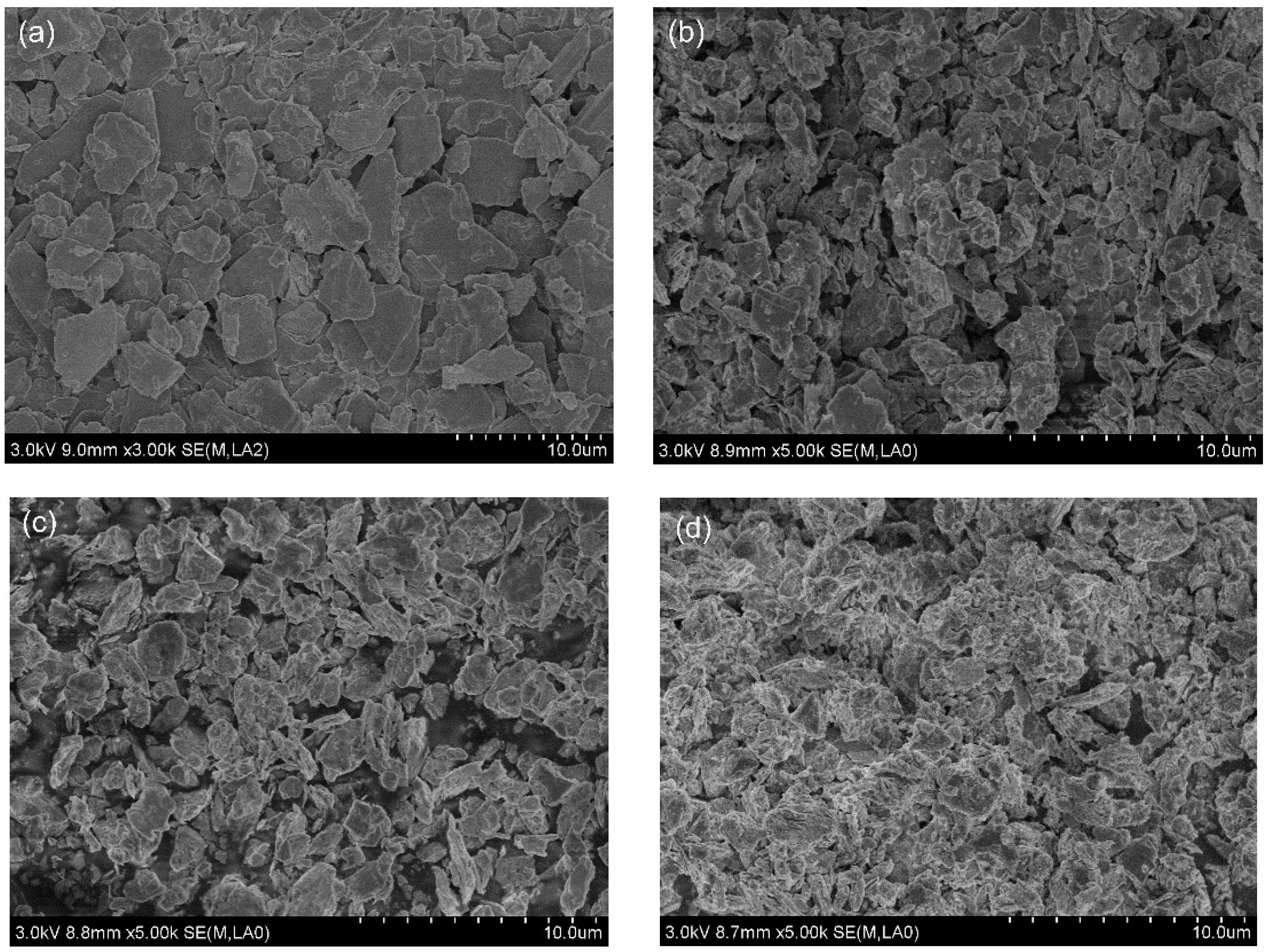

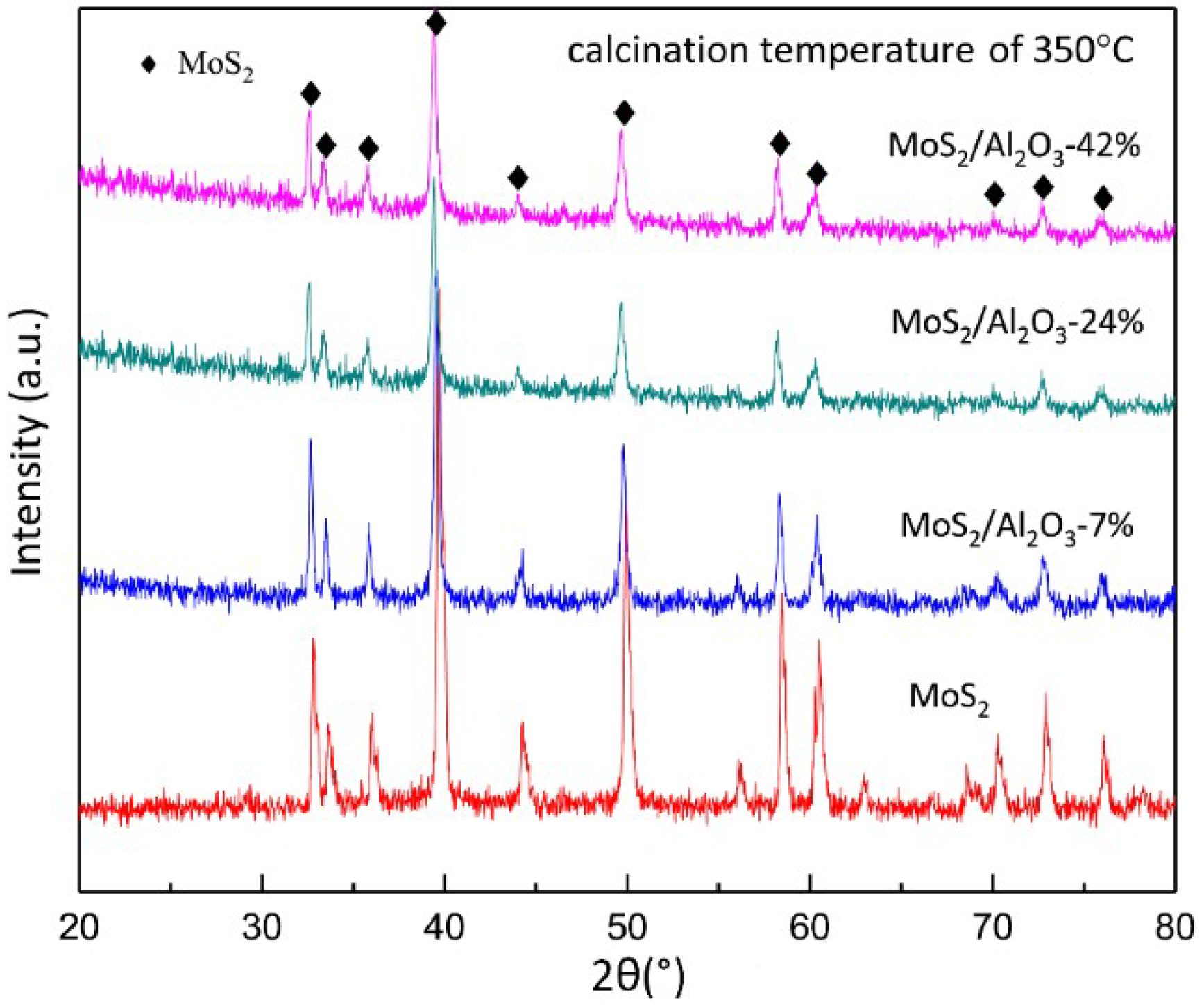

3.1. Al2O3-Coated MoS2 Particles

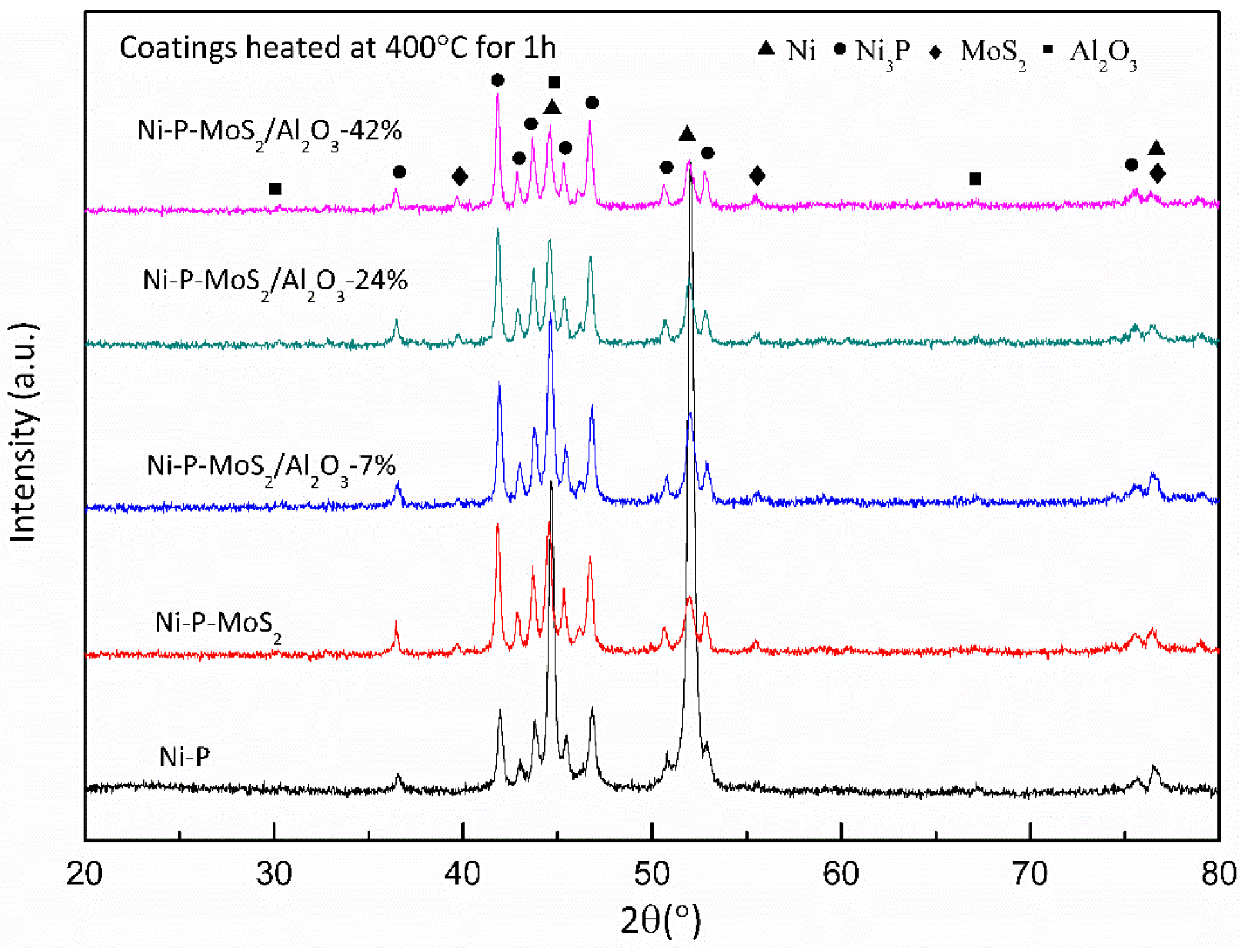

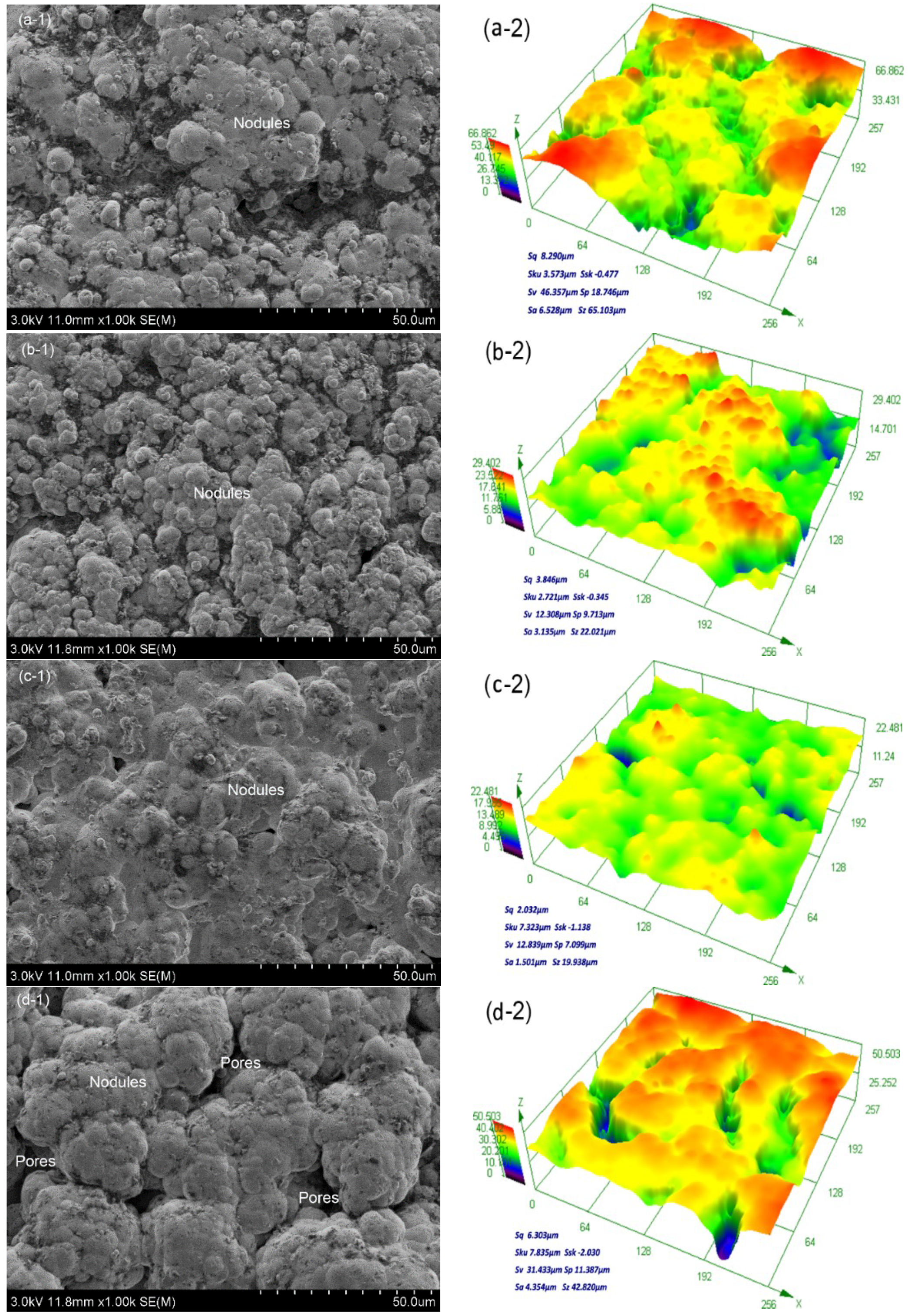

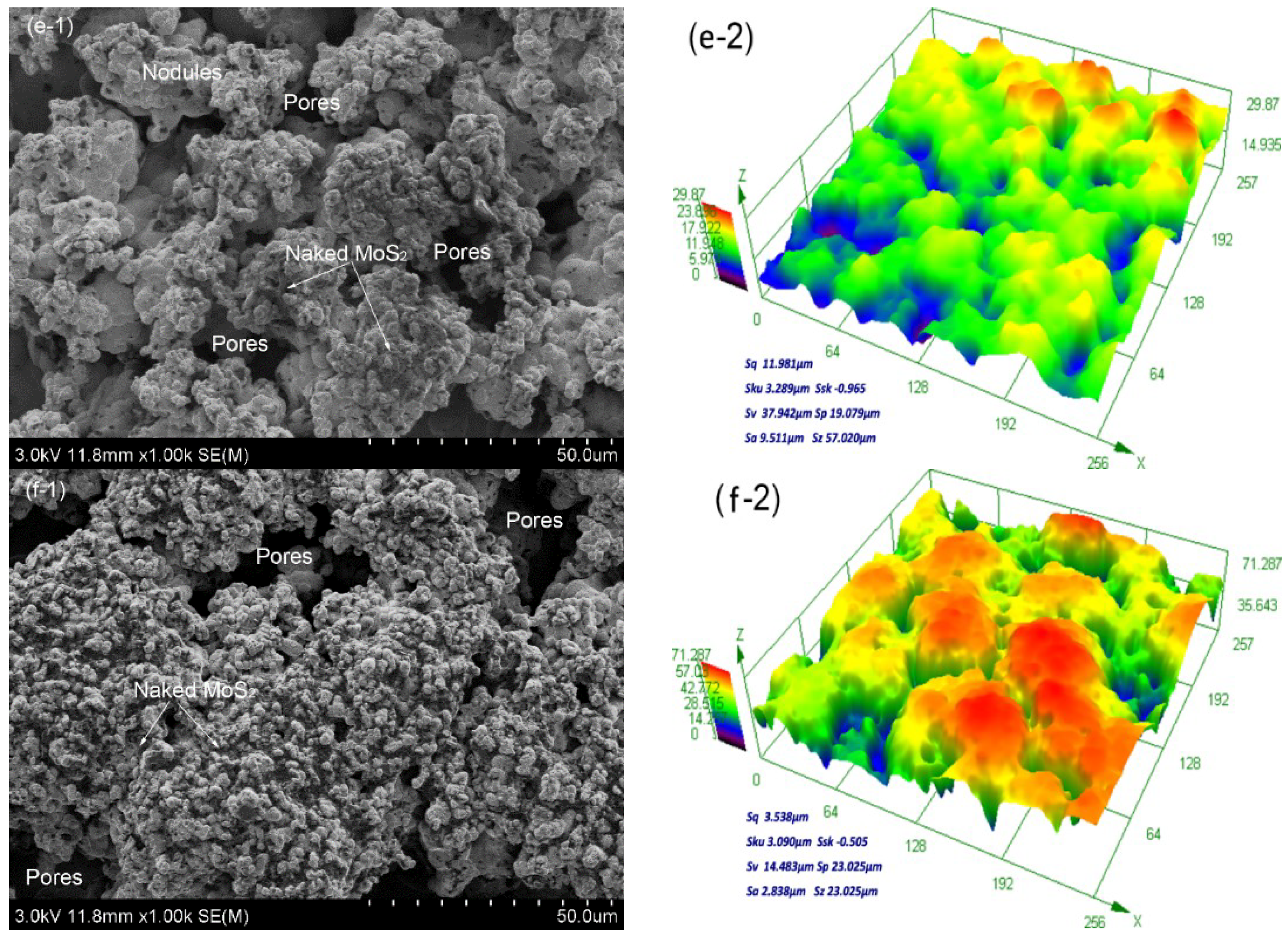

3.2. Ni–P Matrix Composite Coatings

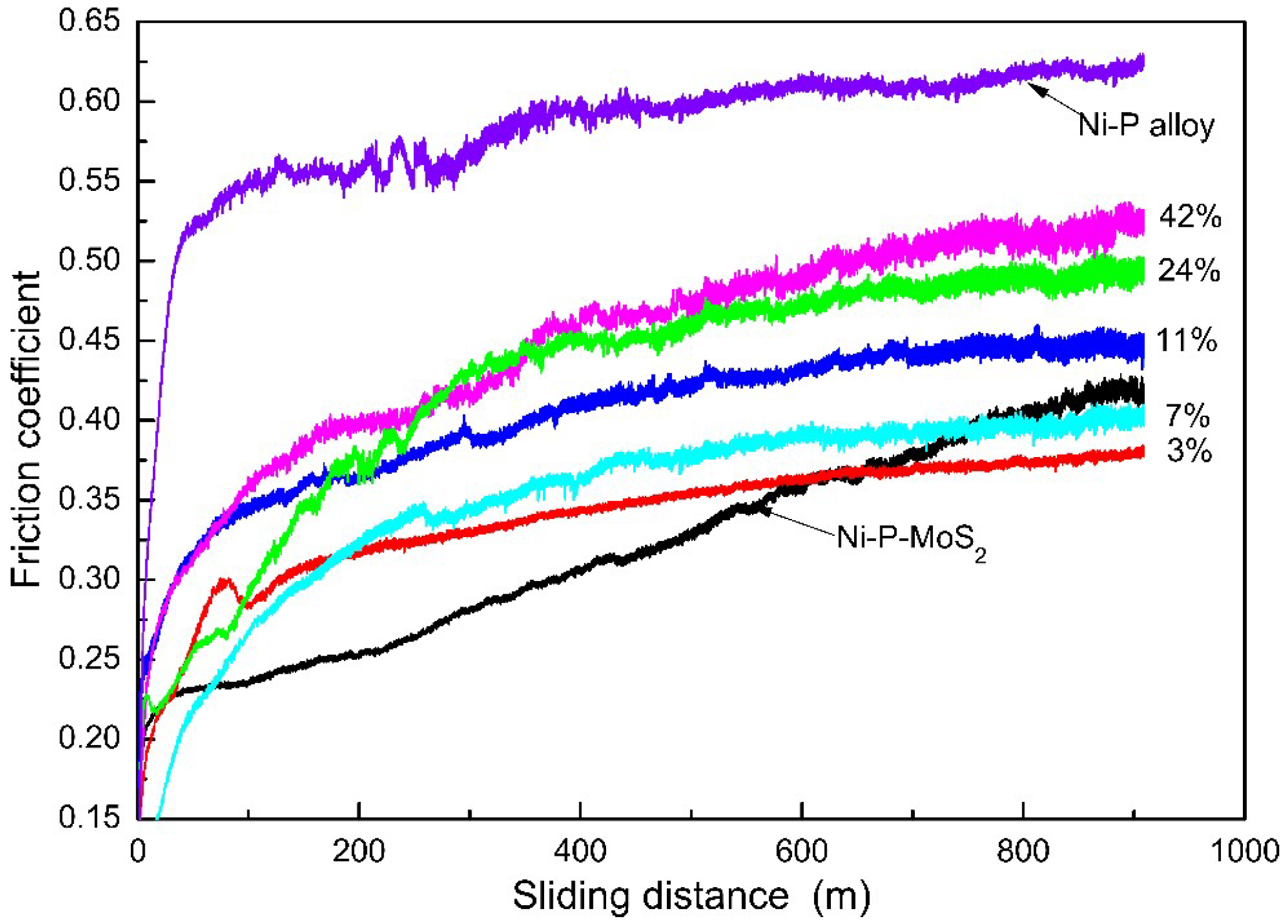

3.3. Friction Coefficient

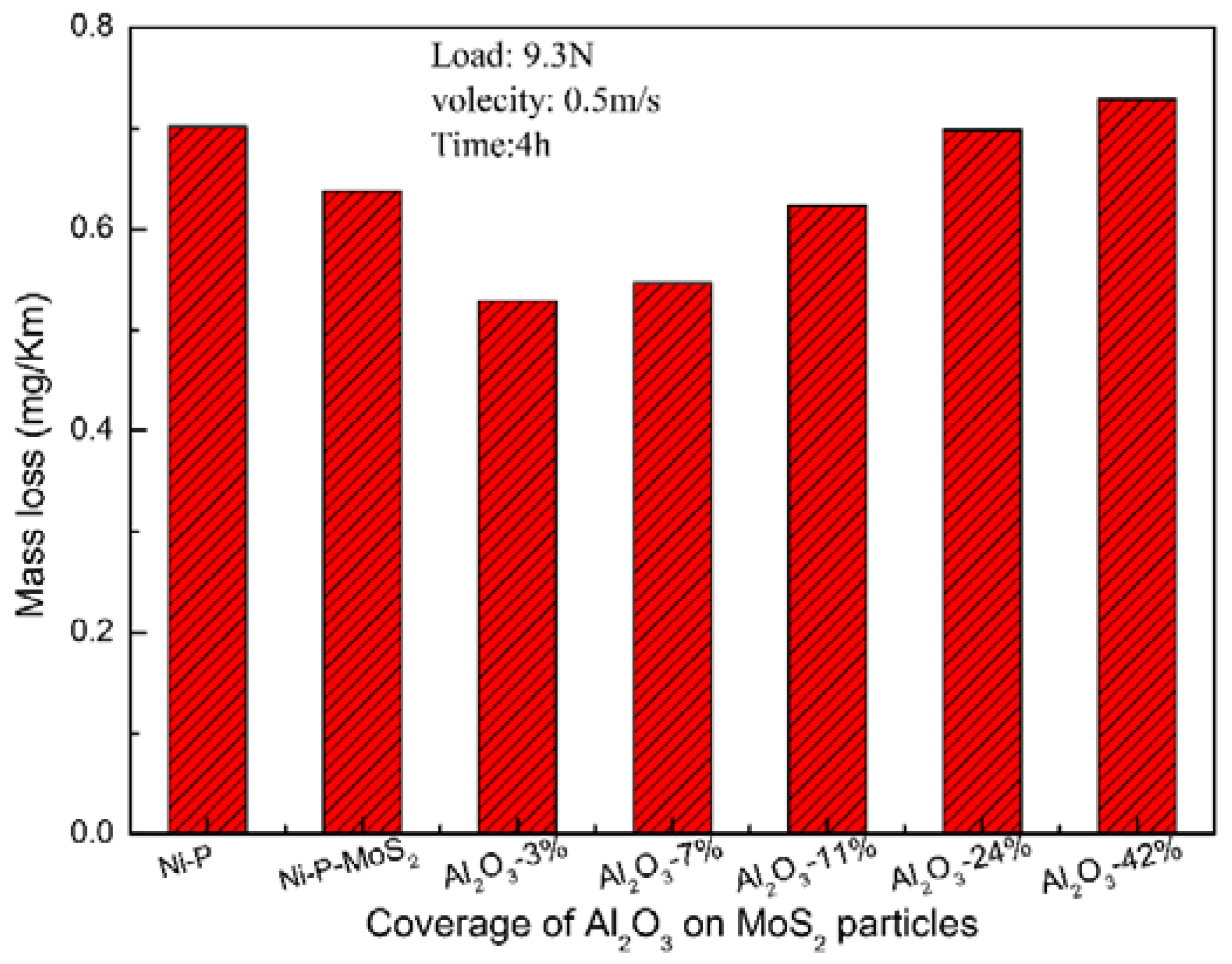

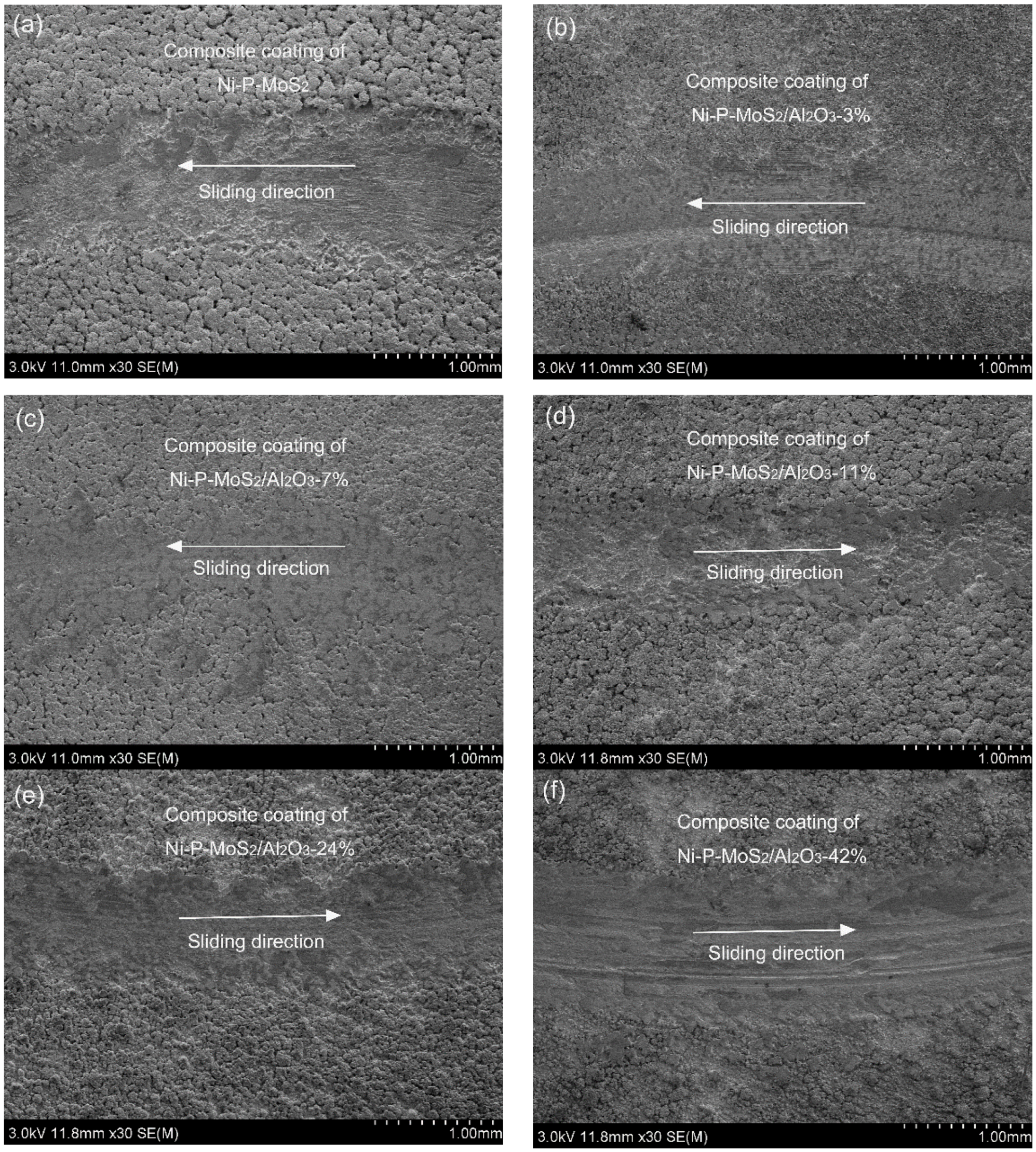

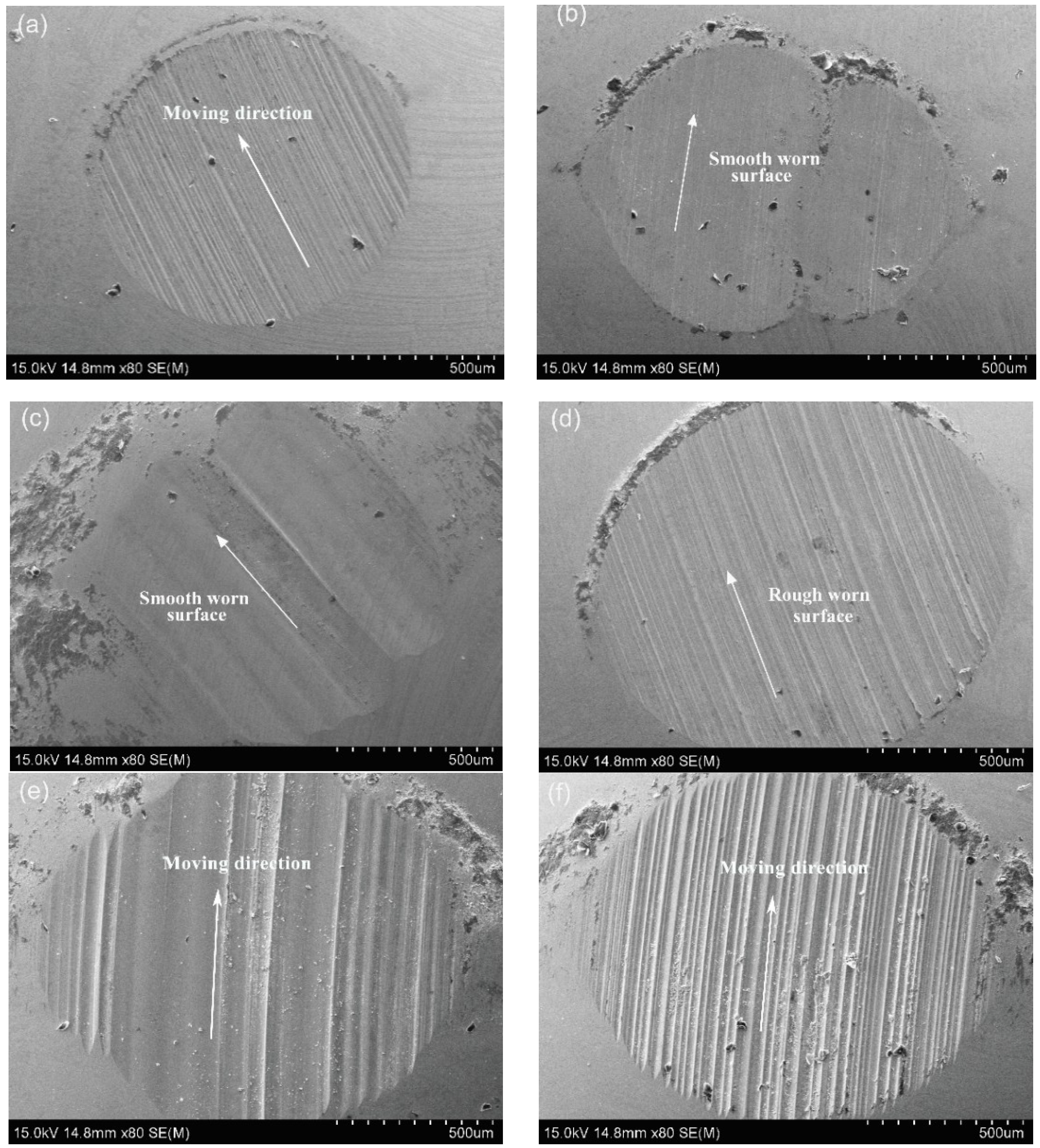

3.4. Wear

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Makkar, P.; Mishra, D.D.; Agarwala, R.C.; Agarwala, V. A novel electroless plating of Ni–P–Al–ZrO2 nanocomposite coatings and their properties. Ceram. Int. 2014, 40, 12013–12021. [Google Scholar] [CrossRef]

- Ardakani, S.R.; Afshar, A.; Sadreddini, S.; Ghanbari, A.A. Characterization of Ni–P–SiO2–Al2O3 nano-composite coatings on aluminum substrate. Mater. Chem. Phys. 2017, 189, 207–214. [Google Scholar] [CrossRef]

- Wu, H.; Liu, F.; Gong, W.; Ye, F.; Hao, L.; Jiang, J.; Han, S. Preparation of Ni–P–GO composite coatings and its mechanical properties. Surf. Coat. Technol. 2015, 272, 25–32. [Google Scholar] [CrossRef]

- Novak, M.; Vojtech, D.; Vitu, T. Influence of heat treatment on tribological properties of electroless Ni–P and Ni-P-Al2O3 coatings on Al-Si casting alloy. Appl. Surf. Sci. 2010, 256, 2956–2960. [Google Scholar] [CrossRef]

- Rahimi, A.R.; Modarress, H.; Iranagh, S.A. Effect of alumina nanoparticles as nanocomposites on morphology and corrosion resistance of electroless Ni–P coatings. Surf. Eng. 2011, 27, 26–31. [Google Scholar] [CrossRef]

- Wang, Q.; Callisti, M.; Greer, J.; McKay, B.; Milickovic, T.K.; Zoikis-Karathanasis, A.; Deligkiozi, I.; Polcar, T. Effect of annealing temperature on microstructure, mechanical and tribological properties of nano-SiC reinforced Ni–P coatings. Wear 2016, 356, 86–93. [Google Scholar] [CrossRef]

- Soleimani, R.; Mahboubi, F.; Kazemi, M.; Arman, S.Y. Corrosion and tribological behavior of electroless Ni–P/nano–SiC composite coating on aluminium 6061. Surf. Eng. 2015, 31, 714–721. [Google Scholar] [CrossRef]

- Sadeghzadeh-Attar, A.; AyubiKia, G.; Ehteshamzadeh, M. Improvement in tribological behavior of novel sol-enhanced electroless Ni–P–SiO2 nanocomposite coatings. Surf. Coat. Technol. 2016, 306, 837–848. [Google Scholar] [CrossRef]

- Hosseini, J.; Bodaghi, A. Corrosion behaviour of electroless Ni–P–TiO2 nanocomposite coatings using Taguchi. Surf. Eng. 2013, 29, 183–189. [Google Scholar] [CrossRef]

- Reddy, V.; Ramamoorthy, B.; Nair, P. A study on the wear resistance of electroless Ni-P/Diamond composite coatings. Wear 2000, 239, 111–116. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Lu, J.; Meng, J. Tribological characteristics of electroless Ni–P–MoS2 composite coatings at elevated temperatures. Appl. Surf. Sci. 2013, 264, 516–521. [Google Scholar] [CrossRef]

- Hu, X.; Jiang, P.; Wan, J.; Xu, Y.; Sun, X. Study of corrosion and friction reduction of electroless N–P coating with molybdenum disulfide nanoparticles. J. Coat. Technol. Res. 2009, 6, 275–281. [Google Scholar] [CrossRef]

- Srinivasan, K.N.; John, S. Studies on electroless nickel–PTFE composite coatings. Surf. Eng. 2005, 21, 156–160. [Google Scholar] [CrossRef]

- Hsua, C.I.; Hou, K.H.; Ger, M.D.; Wang, G.L. The effect of incorporated self-lubricated BN(h) particles on the tribological properties of Ni–P–BN(h) composite coatings. Appl. Surf. Sci. 2015, 357, 1727–1735. [Google Scholar] [CrossRef]

- De Hazan, Y.; Knies, F.; Burnat, D.; Graule, T.; Yamada-Pittini, Y.; Aneziris, C.; Kraak, M. Homogeneous functional Ni–P/ceramic nanocomposite coatings via stable dispersions in electroless nickel electrolytes. J. Colloid Interface Sci. 2012, 365, 163–171. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Singh, A.K. Electroless Ni–P–PTFE-Al2O3 dispersion nanocomposite coating for corrosion and wear resistance. J. Mater. Eng. Perform. 2014, 23, 142–151. [Google Scholar] [CrossRef]

- Islama, M.; RizwanAzhar, M.; Fredj, N.; Burleigh, T.D.; Oloyede, O.R.; Almajid, A.A.; Shah, S.I. Influence of SiO2 nanoparticles on hardness and corrosion resistance of electroless Ni–P coatings. Surf. Coat. Technol. 2015, 261, 141–148. [Google Scholar] [CrossRef]

- Gadharia, P.; Sahoo, P. Optimization of Coating Process Parameters to Improve microhardness of Ni–P–TiO2 composite coatings. Mater. Today Proc. 2015, 2, 2367–2374. [Google Scholar] [CrossRef]

- Chen, Y.; Hao, Y.; Huang, W. Corrosion behavior of Ni–P–nano–Al2O3 composite coating in the presence of anionic and cationic surfactants. Surf. Coat. Technol. 2017, 310, 122–128. [Google Scholar] [CrossRef]

- Tamilarasan, T.; Rajendran, R.; Rajagopal, G.; Sudagar, J. Effect of surfactants on the coating properties and corrosion behaviour of Ni–P–nano–TiO2 coatings. Surf. Coat. Technol. 2015, 276, 320–326. [Google Scholar] [CrossRef]

- Afroukhteh, S.; Dehghaniann, C.; Emamy, M. Preparation of electroless Ni–P composite coatings containing nano-scattered alumina in presence of polymeric surfactant. Prog. Nat. Sci. Mater. Int. 2012, 22, 318–325. [Google Scholar] [CrossRef]

- Nwosu, N.; Davidson, A.; Hindle, C.; Barker, M. On the Influence of surfactant incorporation during electroless nickel plating. Ind. Eng. Chem. Res. 2012, 51, 5635–5644. [Google Scholar] [CrossRef]

- Sudagar, J.; Lian, J.; Sha, W. Electroless nickel, alloy, composite and nano coatings—A critical review. J. Alloy. Compd. 2013, 571, 183–204. [Google Scholar] [CrossRef]

- Agarwala, R.C.; Agarwala, V. Electroless alloy/composite coatings: A review. Sadhana 2003, 28, 475–493. [Google Scholar] [CrossRef]

- Sudagar, J.; Lian, J.S.; Jiang, Q.; Jiang, Z.H.; Li, G.Y.; Elansezhian, R. The performance of surfactant on the surface characteristics of electroless nickel coating on magnesium alloy. Prog. Org. Coat. 2012, 74, 788–793. [Google Scholar] [CrossRef]

- Zielinska, K.; Stankiewicz, A.; Szczygie, I. Electroless deposition of Ni–P–nano–ZrO2 composite coatings in the presence of various types of surfactants. J. Colloid Interface Sci. 2012, 377, 362–367. [Google Scholar] [CrossRef] [PubMed]

- Der Ger, M.; Hwang, B.J. Effect of surfactants on codeposition of PTFE particles with electroless Ni–P coating. Mater. Chem. Phys. 2002, 76, 38–45. [Google Scholar] [CrossRef]

- Mafi, I.R.; Dehghanian, C. Comparison of the coating properties and corrosion rates in electroless Ni–P–PTFE composites prepared by different types of surfactants. Appl. Surf. Sci. 2011, 257, 8653–8658. [Google Scholar] [CrossRef]

- Chen, B.H.; Hong, L.; Ma, Y.; Ko, T.M. Effects of Surfactants in an Electroless Nickel–Plating Bath on the Properties of Ni–P Alloy Deposits. Ind. Eng. Chem. Res. 2002, 41, 2668–2678. [Google Scholar] [CrossRef]

- Amell, A.; Muller, C.; Sarret, M. Influence of fluoro surfactants on the codeposition of ceramic nanoparticles and the morphology of electroless Ni–P coatings. Surf. Coat. Technol. 2010, 205, 356–362. [Google Scholar] [CrossRef]

- Nwosu, N.O.; Davidson, A.M.; Hindle, C.S. Effect of Sodium Dodecyl Sulphate on the Composition of Electroless Nickel-Yttria Stabilized Zirconia Coatings. Adv. Chem. Eng. Sci. 2011, 1, 118–124. [Google Scholar] [CrossRef]

- Mai, Y.; Zhou, M.; Ling, H.; Chen, F.; Lian, W.; Jie, X. Surfactant-free electrodeposition of reduced graphene oxide/copper composite coatings with enhanced wear resistance. Appl. Surf. Sci. 2018, 433, 232–239. [Google Scholar] [CrossRef]

- Abdoli, M.; Sabour Rouhaghdam, A. Preparation and characterization of Ni–P/nanodiamond coatings: Effects of surfactants. Diam. Relat. Mater. 2013, 31, 30–37. [Google Scholar] [CrossRef]

- Zarebidaki, A.; Allahkaram, S.R. Effect of surfactant on the fabrication and characterization of Ni–P–CNT composite coatings. J. Alloy. Compd. 2011, 509, 1836–1840. [Google Scholar] [CrossRef]

- Bulasara, V.K.; Babu, C.S.N.M.; Uppaluri, R. Effect of surfactants on performance of electroless plating baths for nickel-ceramic composite membrane fabrication. Surf. Eng. 2012, 28, 44–48. [Google Scholar] [CrossRef]

- Tamilarasan, T.R.; Rajendran, R.; Sivashankar, M.; Sanjith, U.; Rajagopal, G.; Sudagar, J. Wear and scratch behaviour of electroless Ni-P-nano-TiO2: Effect of surfactants. Wear 2016, 346, 148–157. [Google Scholar] [CrossRef]

- Song, X.; Jiang, N.; Li, Y.; Xu, D.; Qiu, G. Synthesis of CeO2-coated SiO2 nanoparticle and dispersion stability of its suspension. Mater. Chem. Phys. 2008, 128–135. [Google Scholar] [CrossRef]

- Zuo, D.; Tian, G.; Li, X.; Chen, D.; Shu, K. Recent progress in surface coating of cathode materials for lithium ion secondary batteries. J. Alloy. Compd. 2017, 706, 24–40. [Google Scholar] [CrossRef]

- Zuo, D.; Tian, G.; Chen, D.; Shen, H.; Lv, C.; Shu, K.; Zhou, Y. Comparative study of Al2O3-coated LiCoO2 electrode derived from different Al precursors uniformity, microstructure and electrochemical properties. Electrochim. Acta 2015, 178, 447–457. [Google Scholar] [CrossRef]

- Liu, P.; Zhu, Y.; Zhang, S. Hydrophilicity characterization of Al2O3-coated MoS2 particles by using thin layer wicking and sessile drop method. Powder Technol. 2015, 281, 83–90. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, Y.; Liu, P.; Liu, T. Surface coating and application in plating of MoS2 powders with Al2O3. China Surf. Eng. 2012, 25, 97–102. (In Chinese) [Google Scholar]

- Liu, T.; Zhu, Y.; Liu, Y.; Zhang, S. Preparation and properties of Ni–P–MoS2/Al2O3 composite coating. Lubr. Eng. 2013, 38, 46–50. (In Chinese) [Google Scholar]

- Liu, Y.F.; Zhu, Y.W.; Liu, T.T.; Zhang, S.W.; Peng, Y. Friction and wear properties of Ni–P electroless composite coatings with core-shell nanodiamond. Tribology 2013, 33, 267–274. [Google Scholar]

- Gan, B.K.; Madsen, I.C.; Hockridge, J.G. In situ X-ray diffraction of the transformation of gibbsite to a-alumina through calcination: Effect of particle size and heating rate. J. Appl. Crystallogr. 2009, 42, 697–705. [Google Scholar] [CrossRef]

- Bigdeli, F.; Allahkaram, S.R. An investigation on corrosion resistance of asapplied and heat treated Ni–P/nanoSiC coatings. Mater. Des. 2009, 30, 4450–4453. [Google Scholar] [CrossRef]

- Apachitei, I.; Tichelaar, F.D.; Duszczyk, J.; Katgerman, L. The effect of heat treatment on the structure and abrasive wear resistance of autocatalytic NiP and NiP–SiC coatings. Surf. Coat. Technol. 2002, 149, 263–278. [Google Scholar] [CrossRef]

- Hu, X.G.; Cai, W.J.; Xu, Y.F.; Wan, J.C.; Sun, X.J. Electroless Ni–P–(nano-MoS2) composite coatings and their corrosion properties. Surf. Eng. 2009, 25, 361–366. [Google Scholar] [CrossRef]

- Elansezhian, R.; Ramamoorthy, B.; Nair, P.K. The influence of SDS and CTAB surfactants on the surface morphology and surface topography of electroless Ni–P deposits. J. Mater. Proc. Technol. 2009, 209, 233–240. [Google Scholar] [CrossRef]

- Moonir-Vaghefi, S.M.; Saatchi, A.; Hejazi, J. Deposition and properties of electroless nickel–phosphorus–molybdenum disulfide composites. Met. Finish. 1997, 95, 46, 48, 50–52. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Zhu, Y.; Shen, Q.; Jin, M.; Zhong, G.; Hou, Z.; Zhao, X.; Wang, S.; Yang, S. Surfactant-Free Electroless Codeposition of Ni–P–MoS2/Al2O3 Composite Coatings. Coatings 2019, 9, 116. https://doi.org/10.3390/coatings9020116

Liu P, Zhu Y, Shen Q, Jin M, Zhong G, Hou Z, Zhao X, Wang S, Yang S. Surfactant-Free Electroless Codeposition of Ni–P–MoS2/Al2O3 Composite Coatings. Coatings. 2019; 9(2):116. https://doi.org/10.3390/coatings9020116

Chicago/Turabian StyleLiu, Ping, Yongwei Zhu, Qi Shen, Meifu Jin, Gaoyan Zhong, Zhiwei Hou, Xiao Zhao, Shuncai Wang, and Shoufeng Yang. 2019. "Surfactant-Free Electroless Codeposition of Ni–P–MoS2/Al2O3 Composite Coatings" Coatings 9, no. 2: 116. https://doi.org/10.3390/coatings9020116

APA StyleLiu, P., Zhu, Y., Shen, Q., Jin, M., Zhong, G., Hou, Z., Zhao, X., Wang, S., & Yang, S. (2019). Surfactant-Free Electroless Codeposition of Ni–P–MoS2/Al2O3 Composite Coatings. Coatings, 9(2), 116. https://doi.org/10.3390/coatings9020116