Enhanced Wear Resistance of Iron-Based Alloy Coating Induced by Ultrasonic Impact

Abstract

:1. Introduction

2. Experimental Procedures

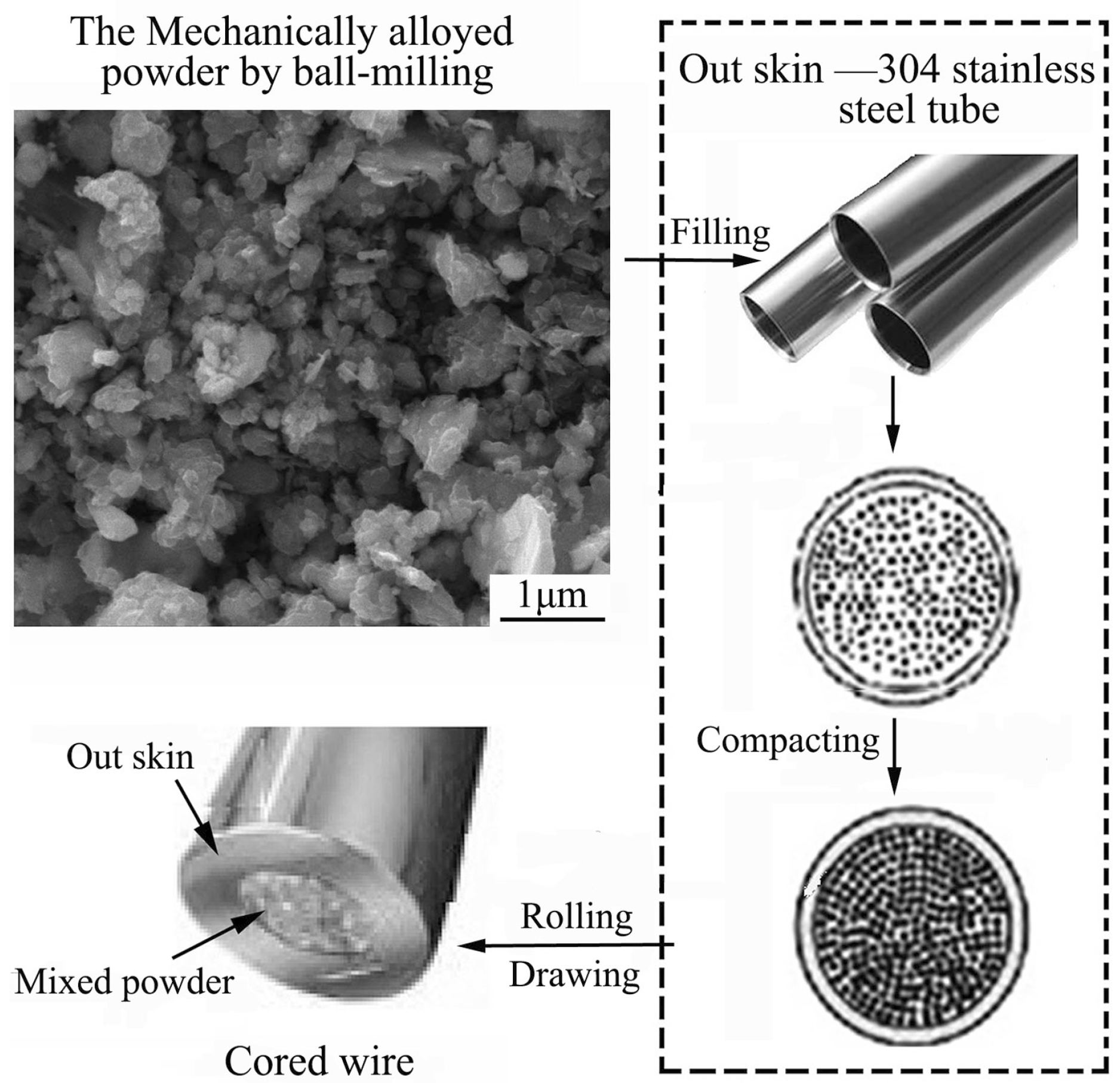

2.1. Materials

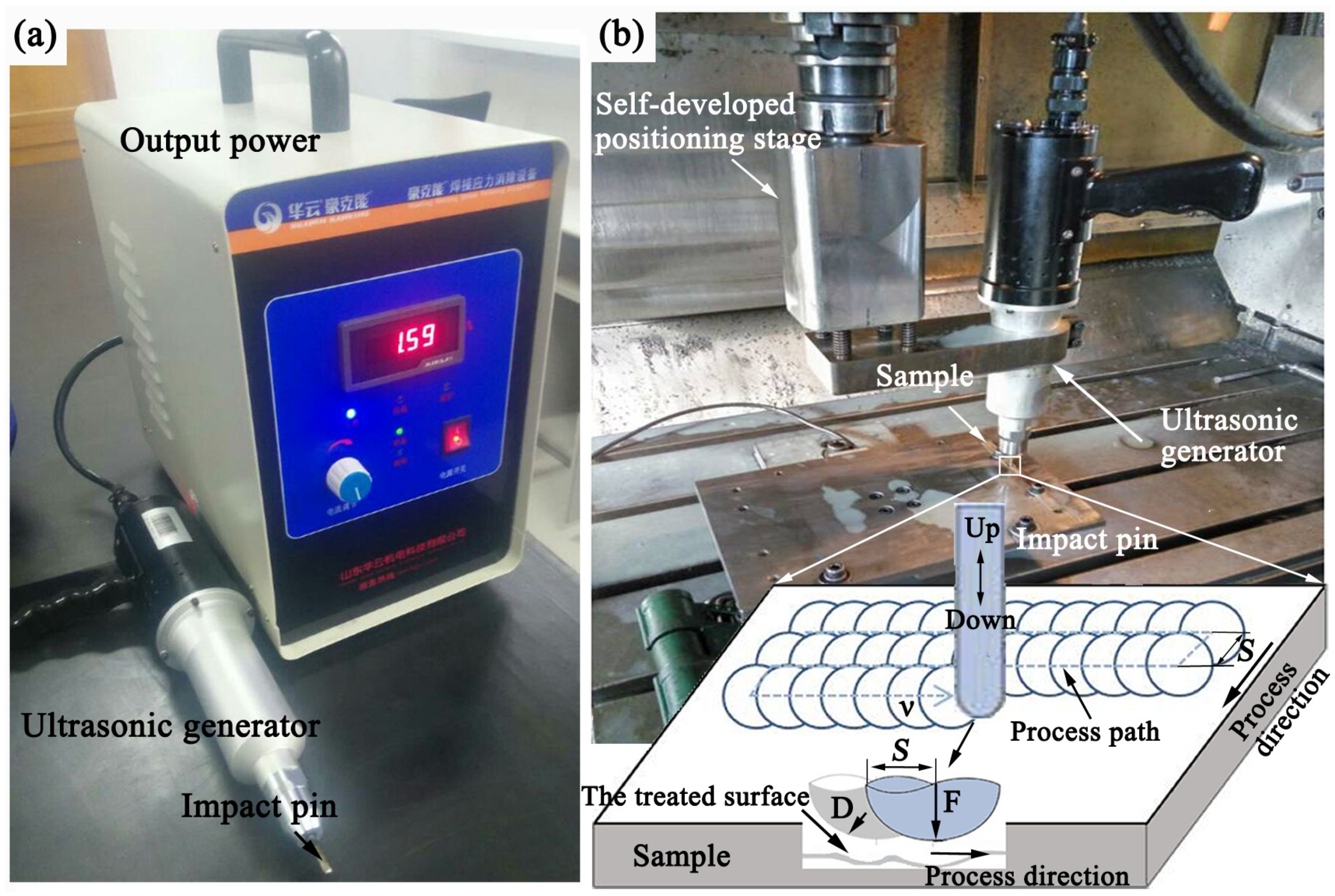

2.2. Preparation of Coating and Ultrasonic Impact Process

2.3. Morphology and Microstructural Characterization

2.4. Nano-Indentation Test

2.5. Wear Tests under Oil-Lubricated Conditions

3. Results and Discussion

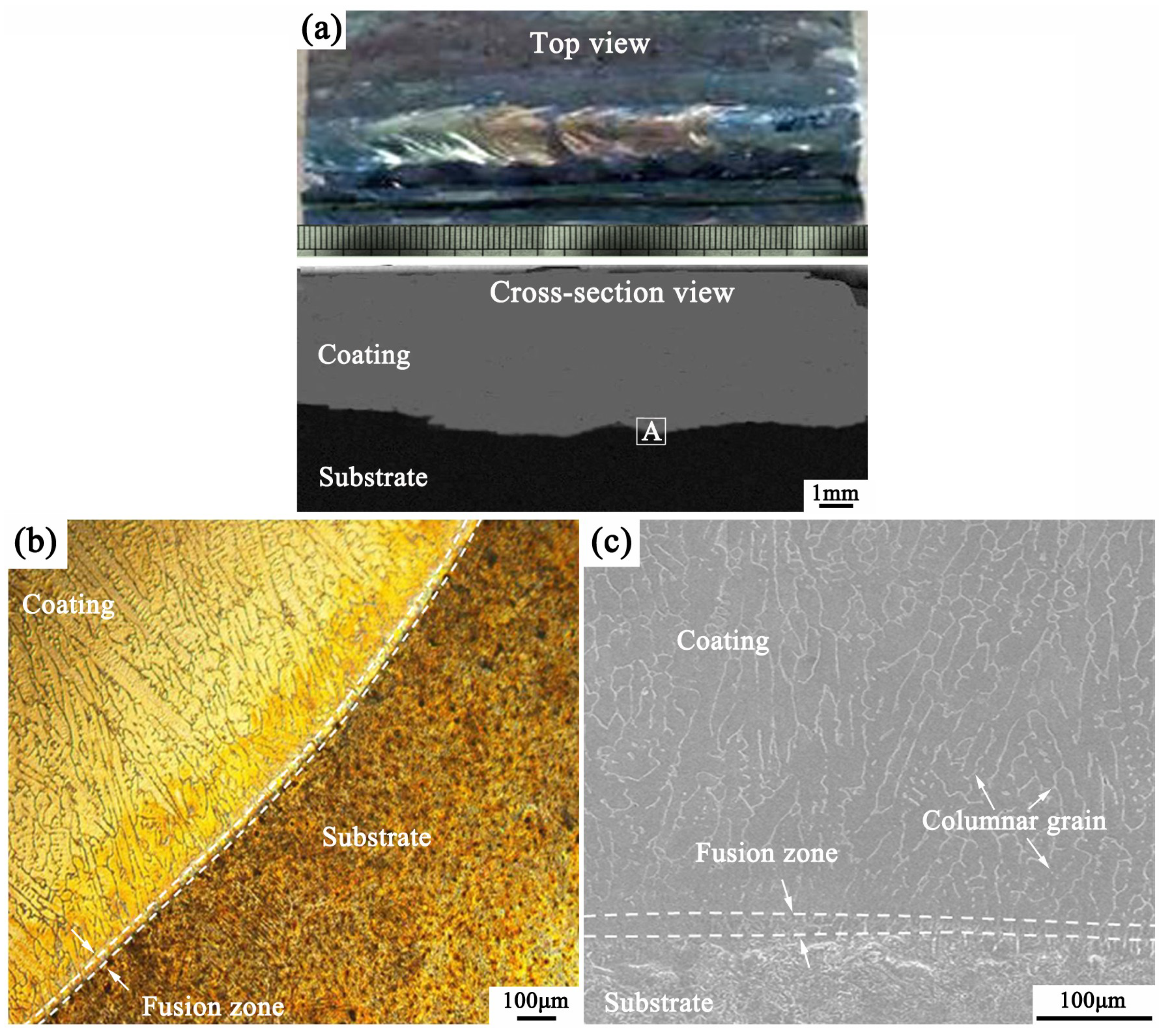

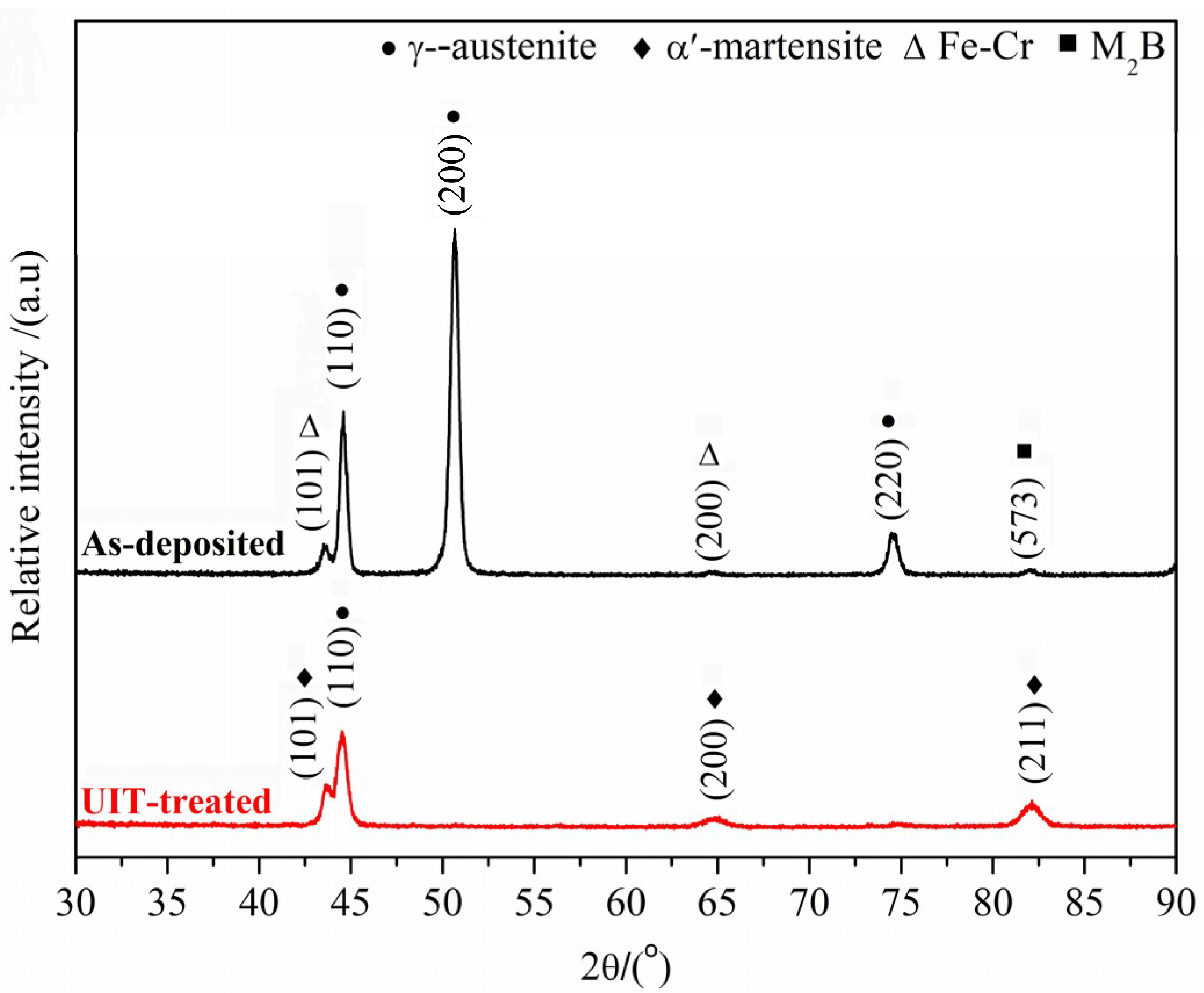

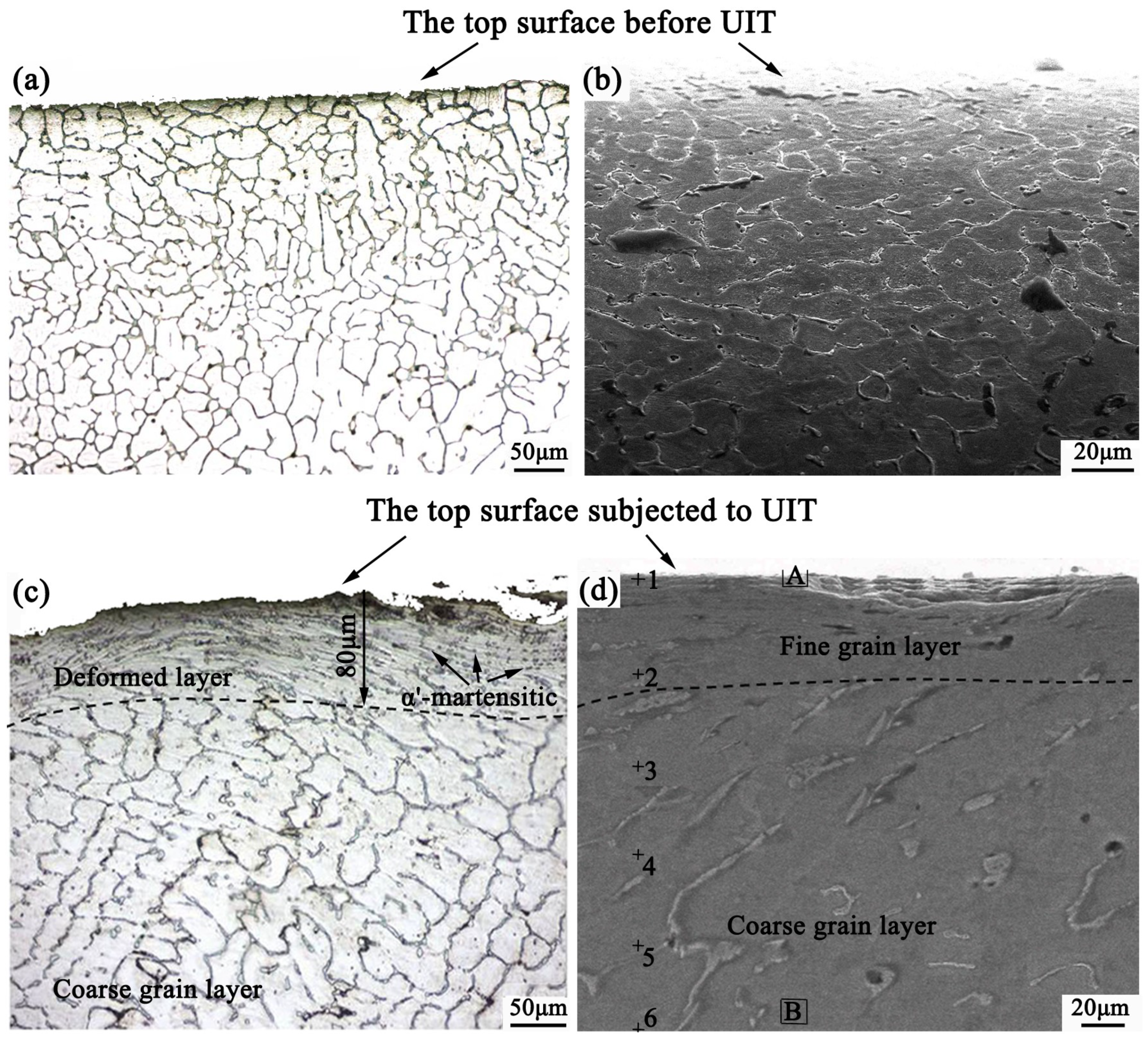

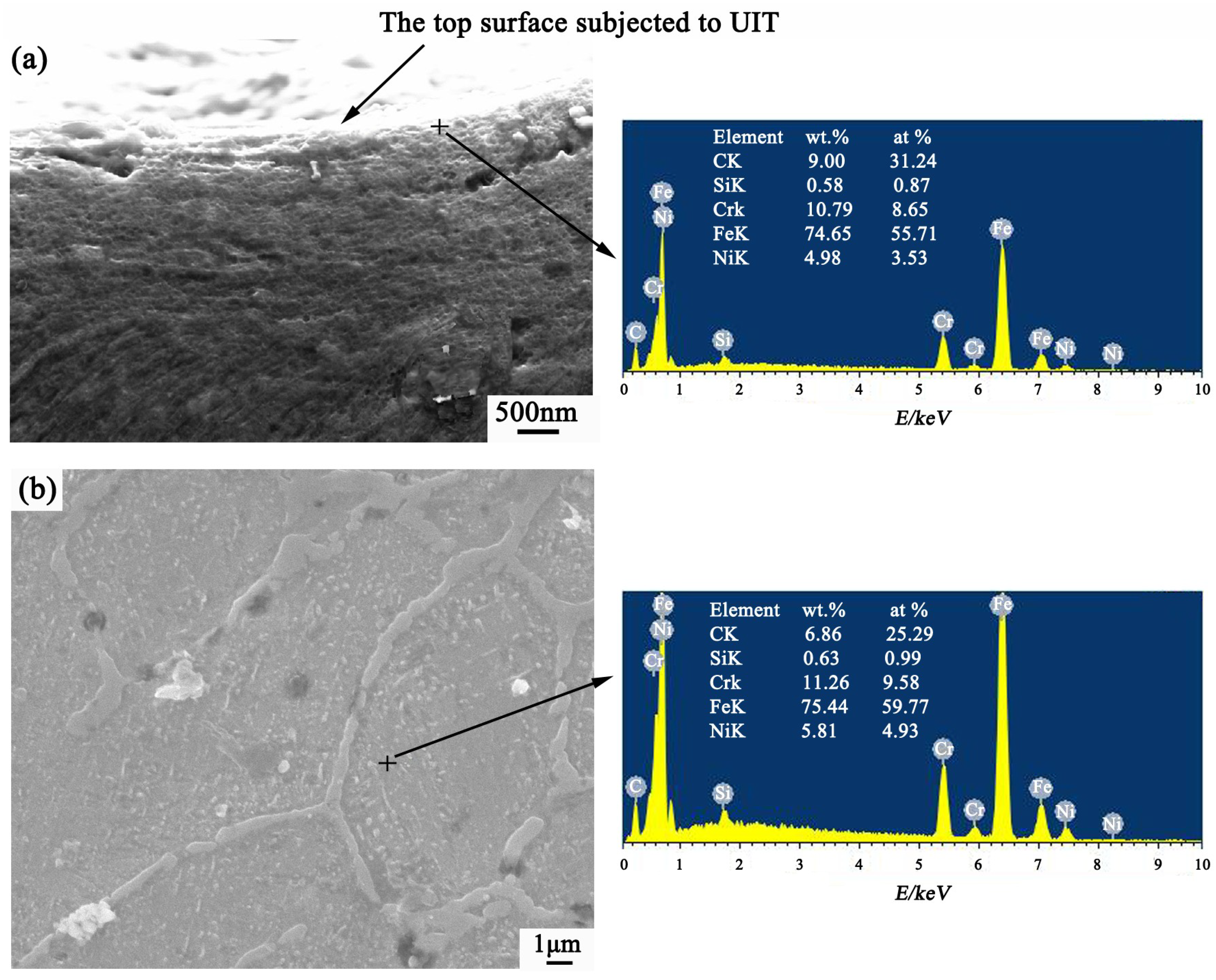

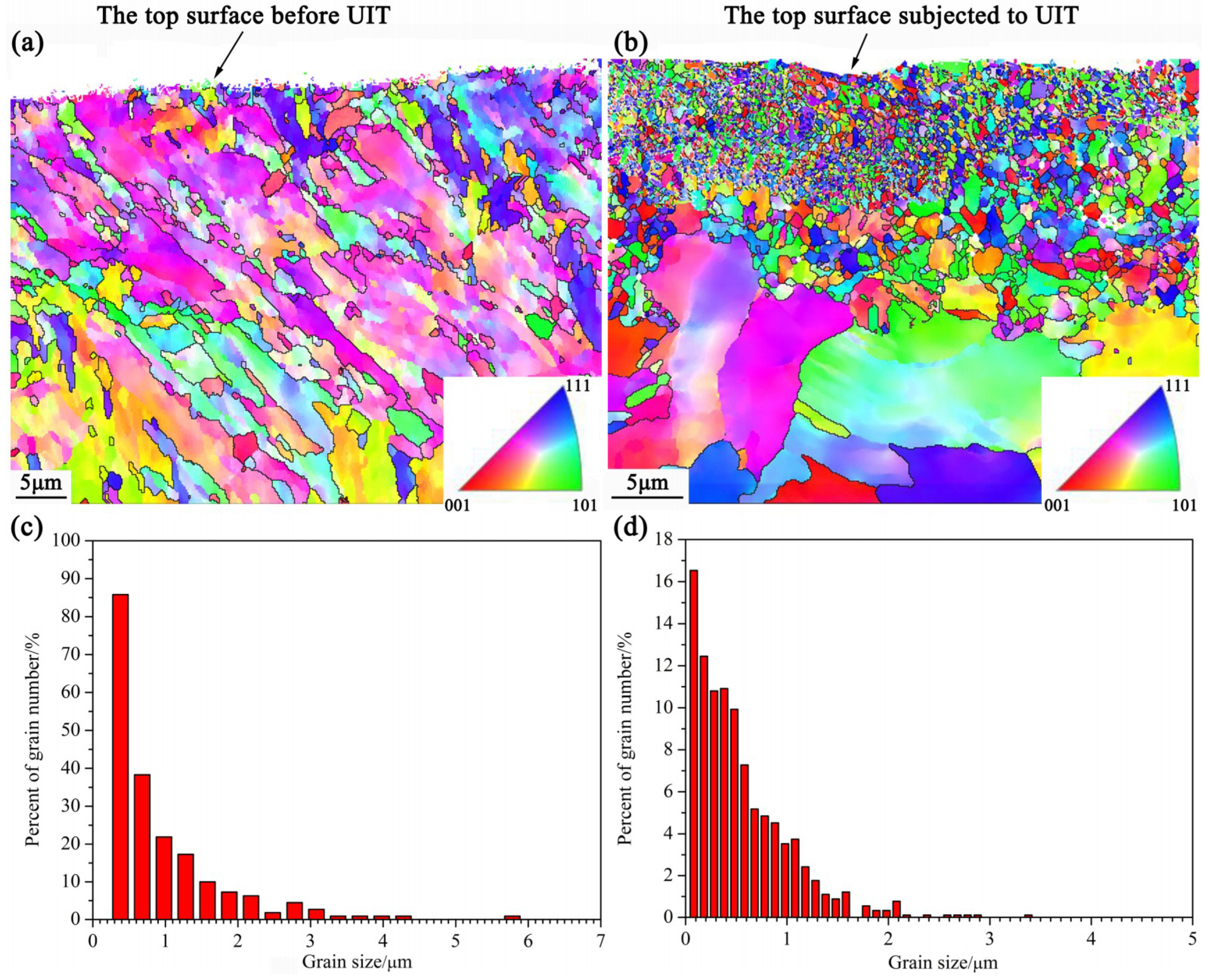

3.1. Morphology and Microstructure Analysis

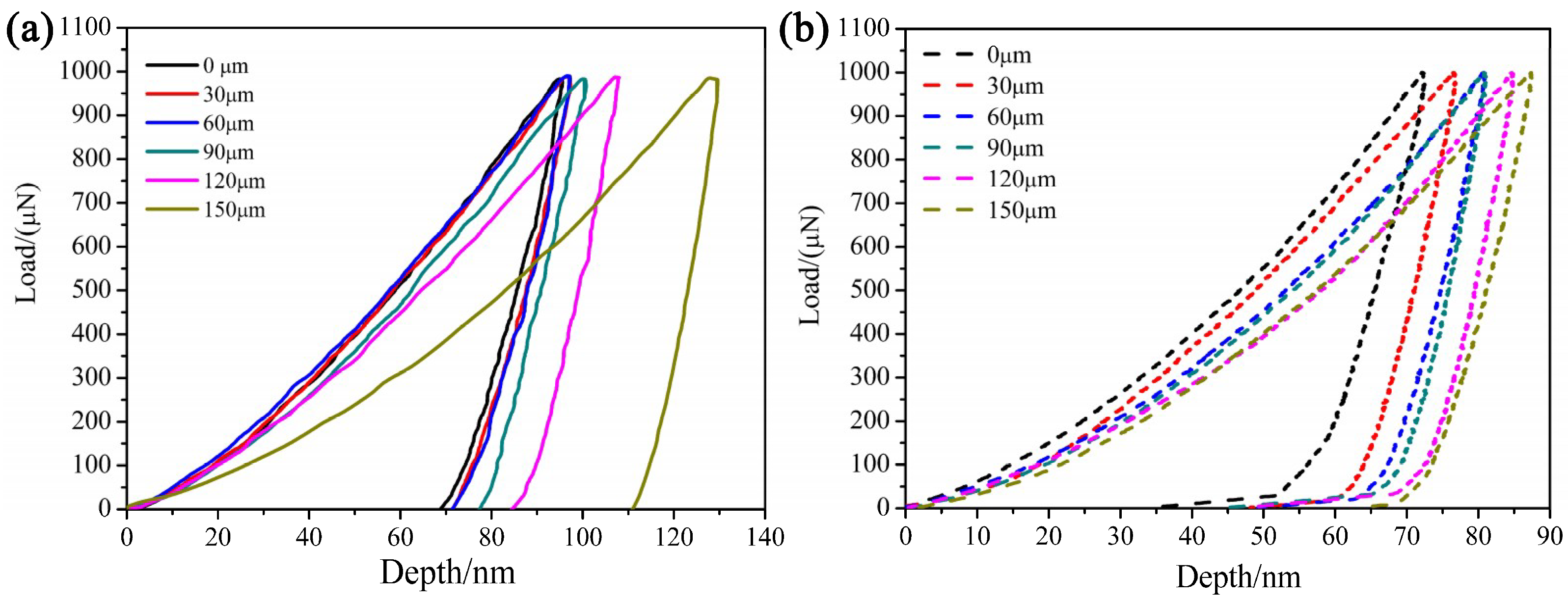

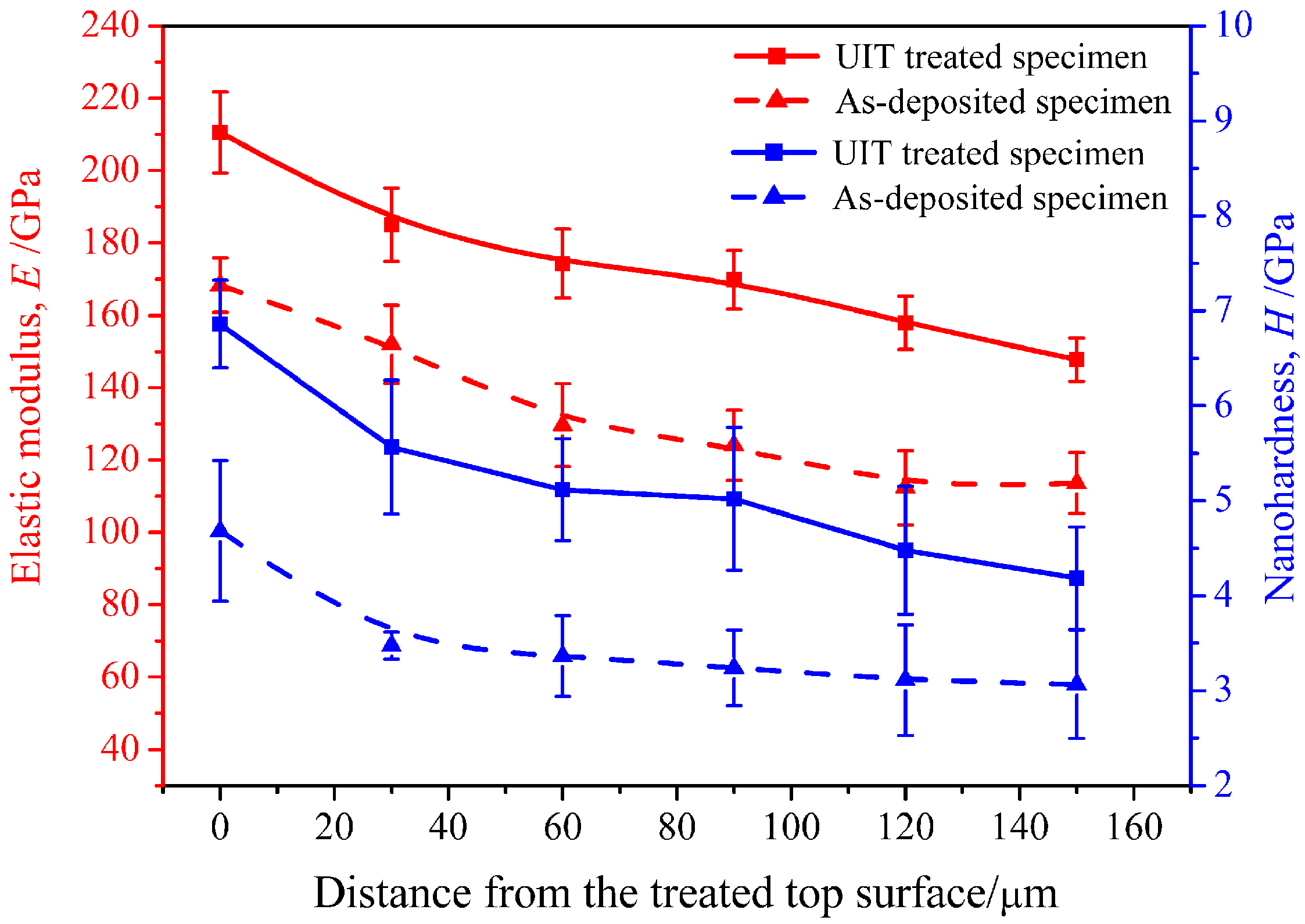

3.2. Mechanical Properties of Surface Layer

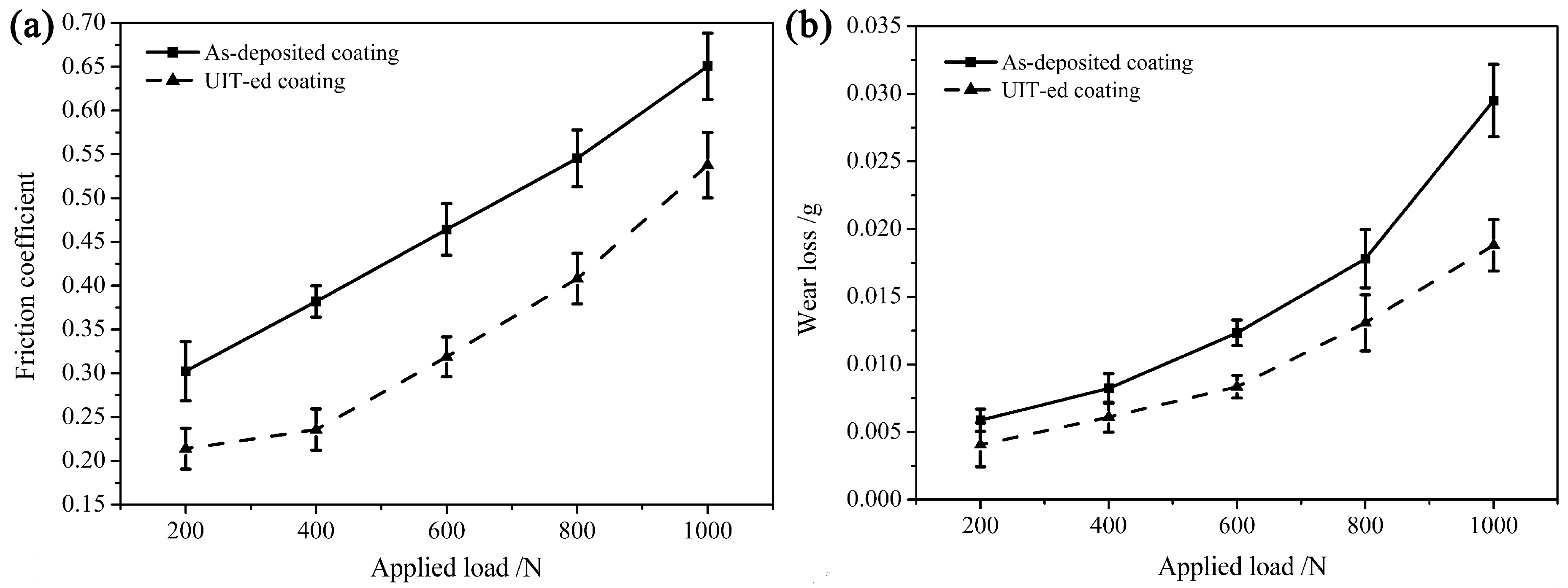

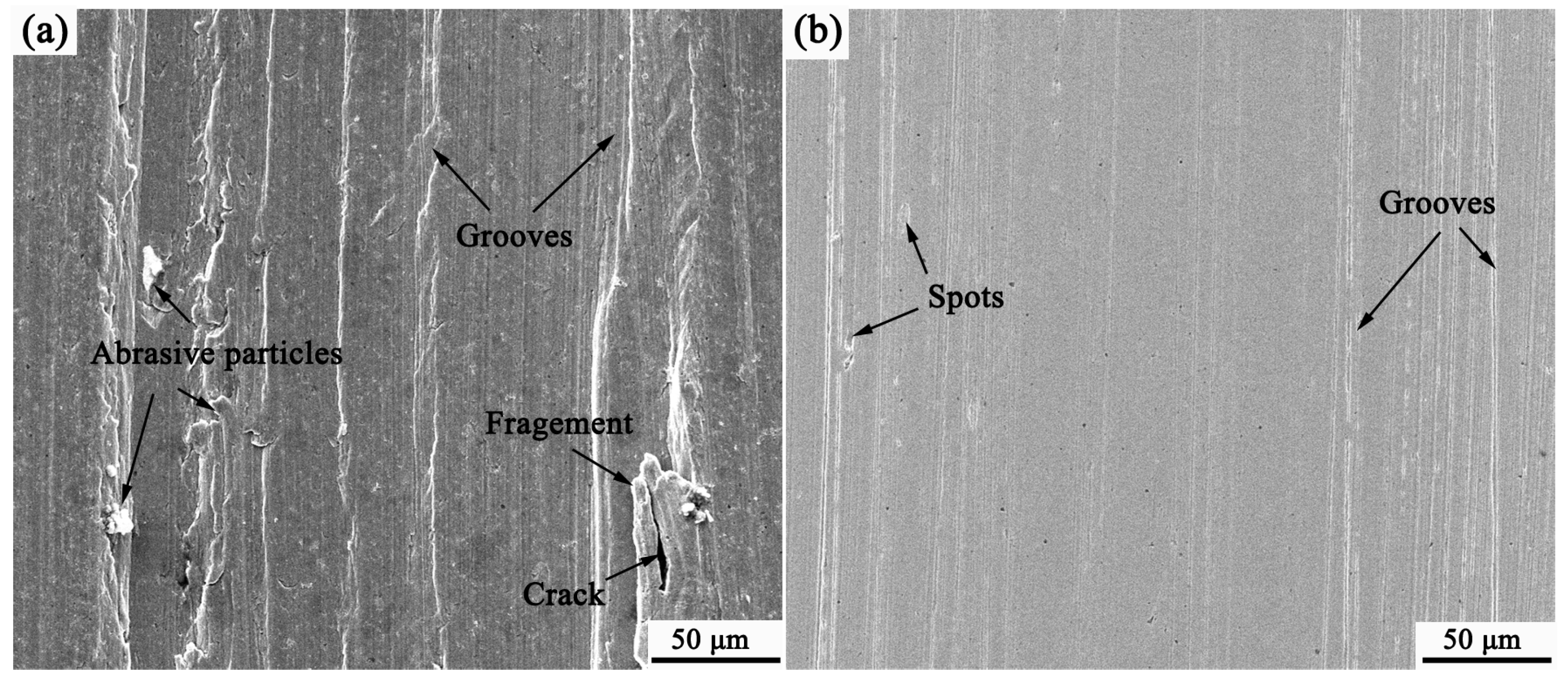

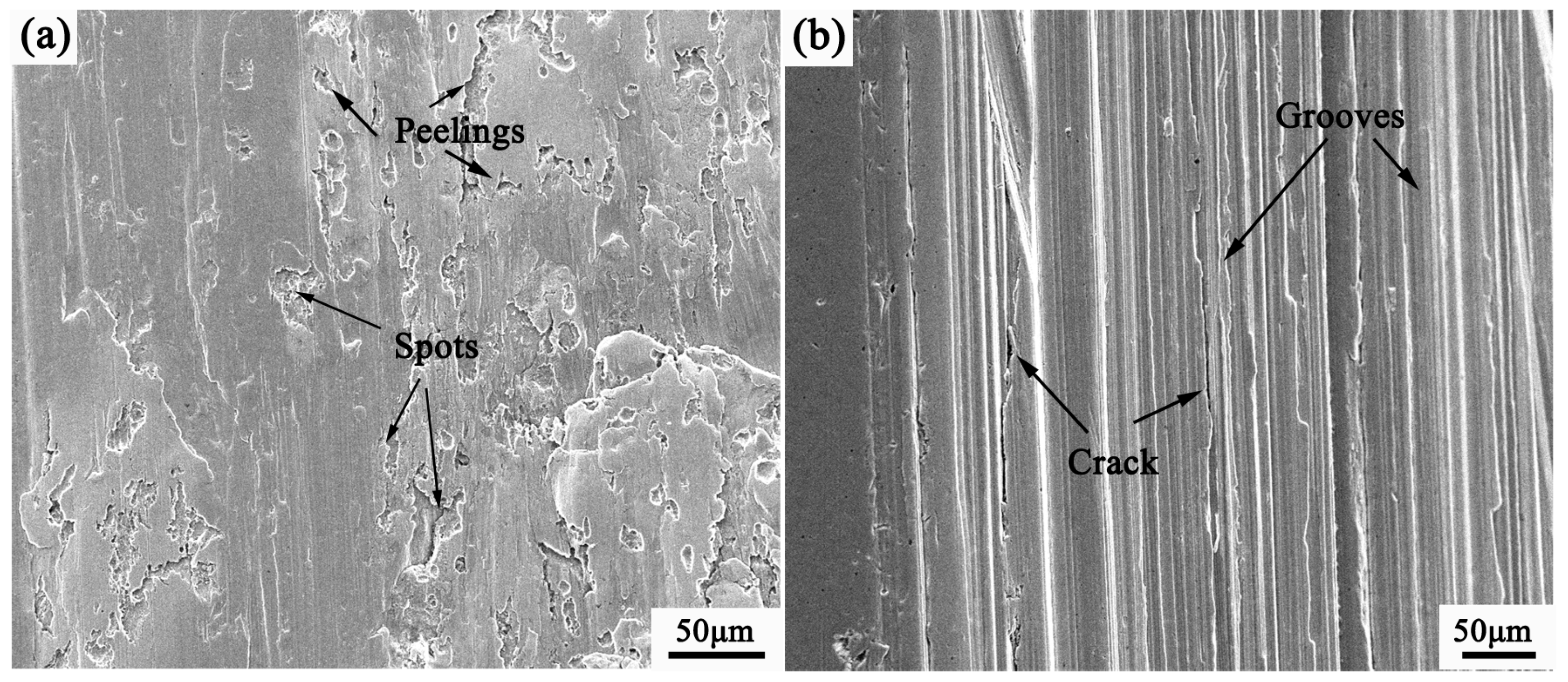

3.3. Wear Properties Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pereira, D.; Gandra, J.; Pamies-Teixeira, J.; Miranda, R.M.; Vilaca, P. Wear behaviour of steel coatings produced by friction surfacing. J. Mater. Process. Technol. 2014, 214, 2858–2868. [Google Scholar] [CrossRef]

- Gholipour, A.; Shamanian, M.; Ashrafizadeh, F. Microstructure and wear behavior of stellite 6 cladding on 17-4 PH stainless steel. J. Alloy Compd. 2011, 509, 4905–4909. [Google Scholar] [CrossRef]

- Puli, R.; Ram, G.D.J. Corrosion performance of AISI 316L friction surfaced coatings. Corros. Sci. 2012, 62, 95–103. [Google Scholar] [CrossRef]

- Santacruz, G.; Takimi, A.S.; Camargo, F.V.; Bergmann, C.P.; Fragassa, C. Comparative study of jet slurry erosion of martensitic stainless steel with tungsten carbide HVOF coating. Metals 2019, 9, 600. [Google Scholar] [CrossRef]

- Li, J.H.; Kong, D.J. Micro-structures and high-temperature friction-wear performances of laser cladded Cr–Ni coatings. Materials 2018, 11, 137. [Google Scholar]

- Heidarshenas, B.; Hussain, G.; Asmael, M.B.A. Development of a TiC/Cr23C6 composite coating on a 304 stainless steel substrate through a tungsten inert gas process. Coatings 2017, 7, 80. [Google Scholar] [CrossRef]

- Shi, S.H.; Xu, A.Q.; Fan, J.W.; Wei, H.P. Study of cobalt-free, Fe-based alloy powder used for sealing surfaces of nuclear valves by laser cladding. Nucl. Eng. Des. 2012, 245, 8–12. [Google Scholar] [CrossRef]

- Milanti, A.; Koivuluoto, H.; Vuoristo, P.; Bolelli, G.; Bozza, F.; Lusvarghi, L. Microstructural characteristics and tribological behavior of HVOF-sprayed novel Fe-based alloy coatings. Coatings 2014, 4, 98–120. [Google Scholar] [CrossRef]

- Sun, Z.; Retraint, D.; Baudin, T.; Helbert, A.L.; Brisset, F.; Chemkhi, M.; Zhou, J.; Kanouté, P. Experimental study of microstructure changes due to low cycle fatigue of a steel nanocrystallised by Surface Mechanical Attrition Treatment (SMAT). Mater. Charact. 2017, 124, 117–121. [Google Scholar] [CrossRef]

- Bagherifard, S.; Slawik, S.; Fernández-Pariente, I.; Pauly, C.; Mücklich, F.; Guagliano, M. Nanoscale surface modification of AISI 316L stainless steel by severe shot peening. Mater. Des. 2016, 102, 68–77. [Google Scholar] [CrossRef]

- Bleicher, F.; Lechner, C.; Habersohn, C.; Kozeschnik, E.; Adjassoho, B.; Kaminski, H. Mechanism of surface modification using machine hammer peening technology. CIRP Ann. 2012, 61, 375–378. [Google Scholar] [CrossRef]

- Luo, K.Y.; Lu, J.Z.; Zhang, Y.K.; Zhou, J.Z.; Zhang, L.F.; Dai, F.Z.; Zhang, L.; Zhong, J.W.; Cui, C.Y. Effects of laser shock processing on mechanical properties and micro-structure of ANSI 304 austenitic stainless steel. Mater. Sci. Eng. A 2011, 528, 4783–4788. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.; Ling, X.; Wang, D.X. Enhanced mechanical behaviors of gradient nano-grained austenite stainless steel by means of ultrasonic impact treatment. Results Phys. 2017, 7, 1412–1421. [Google Scholar] [CrossRef]

- Gao, H.; Dutta, R.K.; Huizenga, R.M.; Amirthalingam, M.; Hermans, M.J.M.; Buslaps, T.; Richardson, I.M. Stress relaxation due to ultrasonic impact treatment on multi-pass welds. Sci. Technol. Weld. Join. 2014, 19, 505–513. [Google Scholar] [CrossRef]

- Liu, C.; Ge, Q.; Chen, D.; Gao, F.; Zou, J.S. Residual stress variation in a thick welded joint after ultrasonic impact treatment. Sci. Technol. Weld. Join. 2016, 21, 624–631. [Google Scholar] [CrossRef]

- Yu, Y.X.; He, B.L.; Liu, J.; Chen, Z.X.; Man, H. Surface plastic deformation and nanocrystallization mechanism of welded joint of 16MnR steel treated by ultrasonic impact. Mater. Sci. 2015, 21, 612–615. [Google Scholar] [CrossRef]

- He, B.L.; Xiong, L.; Jiang, M.M.; Yu, Y.Y.; Li, L. Surface grain refinement mechanism of SMA490BW steel cross joints by ultrasonic impact treatment. Int. J. Miner. Metall. Mater. 2017, 24, 410–414. [Google Scholar] [CrossRef]

- He, B.; Deng, H.; Jiang, M.; Wei, K.; Li, L. Effect of ultrasonic impact treatment on the ultra high cycle fatigue properties of SMA490BW steel welded joints. Int. J Adv. Manuf. Technol. 2018, 96, 1571–1577. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, D.; Xia, L.; Lei, Z.Y.; Li, Y.Z. Effects of ultrasonic impact treatment on pre-fatigue loaded high-strength steel welded joints. Int. J. Fatigue 2015, 80, 278–287. [Google Scholar] [CrossRef]

- Monshi, A.; Foroughi, M.R.; Monshi, M.R. Modified Scherrer equation to estimate more accurately nano-crystallite size using XRD. World J. Nano Sci. Eng. 2012, 2, 154–160. [Google Scholar] [CrossRef]

- Huang, H.F.; Li, J.J.; Li, D.H.; Liu, R.D.; Lei, G.H.; Huang, Q.; Yan, L. TEM, XRD and nanoindentation characterization of Xenon ion irradiation damage in austenitic stainless steels. J. Nucl. Mater. 2014, 454, 168–172. [Google Scholar] [CrossRef]

- Zhou, X.; Li, L.; Wen, D.; Liu, X.X.; Wu, C.W. Effect of hybrid ratio on friction and wear behavior of AZ91D matrix nanocomposites under oil lubricated conditions. Trans. Nonferrous Met. Soc. China 2018, 28, 440–450. [Google Scholar] [CrossRef]

- Yasuoka, M.; Wang, P.; Zhang, K.; Qiu, Z.Y.; Kusaka, K.; Pyoun, Y.S.; Murakami, R. Improvement of the fatigue strength of SUS304 austenite stainless steel using ultrasonic nanocrystal surface modification. Surf. Coat. Technol. 2013, 218, 93–98. [Google Scholar] [CrossRef]

- Wang, H.; Song, G.; Tang, G. Effect of electropulsing on surface mechanical properties and microstructure of AISI 304 stainless steel during ultrasonic surface rolling process. Mater. Sci. Eng. A 2016, 662, 456–467. [Google Scholar] [CrossRef]

- Amanov, A.; Penkov, O.V.; Pyun, Y.S.; Kim, D.E. Effects of ultrasonic nanocrystalline surface modification on the tribological properties of AZ91D magnesium alloy. Tribol. Int. 2012, 54, 106–113. [Google Scholar] [CrossRef]

- He, B.; Yu, Y.; Xia, S.; Lv, Z.M. Effect of ultrasonic impact treating on wear resistance and microhardness of AZ91D magnesium alloy. Rare Met. Mater. Eng. 2017, 46, 17–22. [Google Scholar]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

| Element | C | Mn | Ni | Cr | Mo | Fe |

|---|---|---|---|---|---|---|

| Content (wt.%) | ≤0.1 | 0.26 | 0.010 | 0.016 | ≤0.005 | Bal. |

| Parameter | Condition |

|---|---|

| Power polarity | Direct current straight polarity (DCSP) |

| Gas flow (L/min) | 12−15 |

| Welding current (A) | 140−160 |

| Tungsten electrode diameter (mm) | 3.2 |

| Inter-pass temperature (°C) | 100−150 |

| Welding speed (mm/min) | 80−120 |

| Tip Diameter D/(mm) | Static Load F/(kg) | Number of Vibration Strike per∙mm2 | Amplitude/(μm) | Step Distance S/(mm) | Feeding Rate ν/(mm/min) | Impact Current/(A) |

|---|---|---|---|---|---|---|

| 2 | 10 | 58246 | 30 | 0.01 | 1000 | 1.4–1.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Zhao, S.; Zhang, N.; Guo, Y.; Gan, H. Enhanced Wear Resistance of Iron-Based Alloy Coating Induced by Ultrasonic Impact. Coatings 2019, 9, 804. https://doi.org/10.3390/coatings9120804

Li L, Zhao S, Zhang N, Guo Y, Gan H. Enhanced Wear Resistance of Iron-Based Alloy Coating Induced by Ultrasonic Impact. Coatings. 2019; 9(12):804. https://doi.org/10.3390/coatings9120804

Chicago/Turabian StyleLi, Li, Suyan Zhao, Nannan Zhang, Yanhui Guo, and Hongyan Gan. 2019. "Enhanced Wear Resistance of Iron-Based Alloy Coating Induced by Ultrasonic Impact" Coatings 9, no. 12: 804. https://doi.org/10.3390/coatings9120804

APA StyleLi, L., Zhao, S., Zhang, N., Guo, Y., & Gan, H. (2019). Enhanced Wear Resistance of Iron-Based Alloy Coating Induced by Ultrasonic Impact. Coatings, 9(12), 804. https://doi.org/10.3390/coatings9120804