Surface Integrity of Micro EDM Surface Using Electrodes of Various Diameters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mechanism of Current Skin Effect

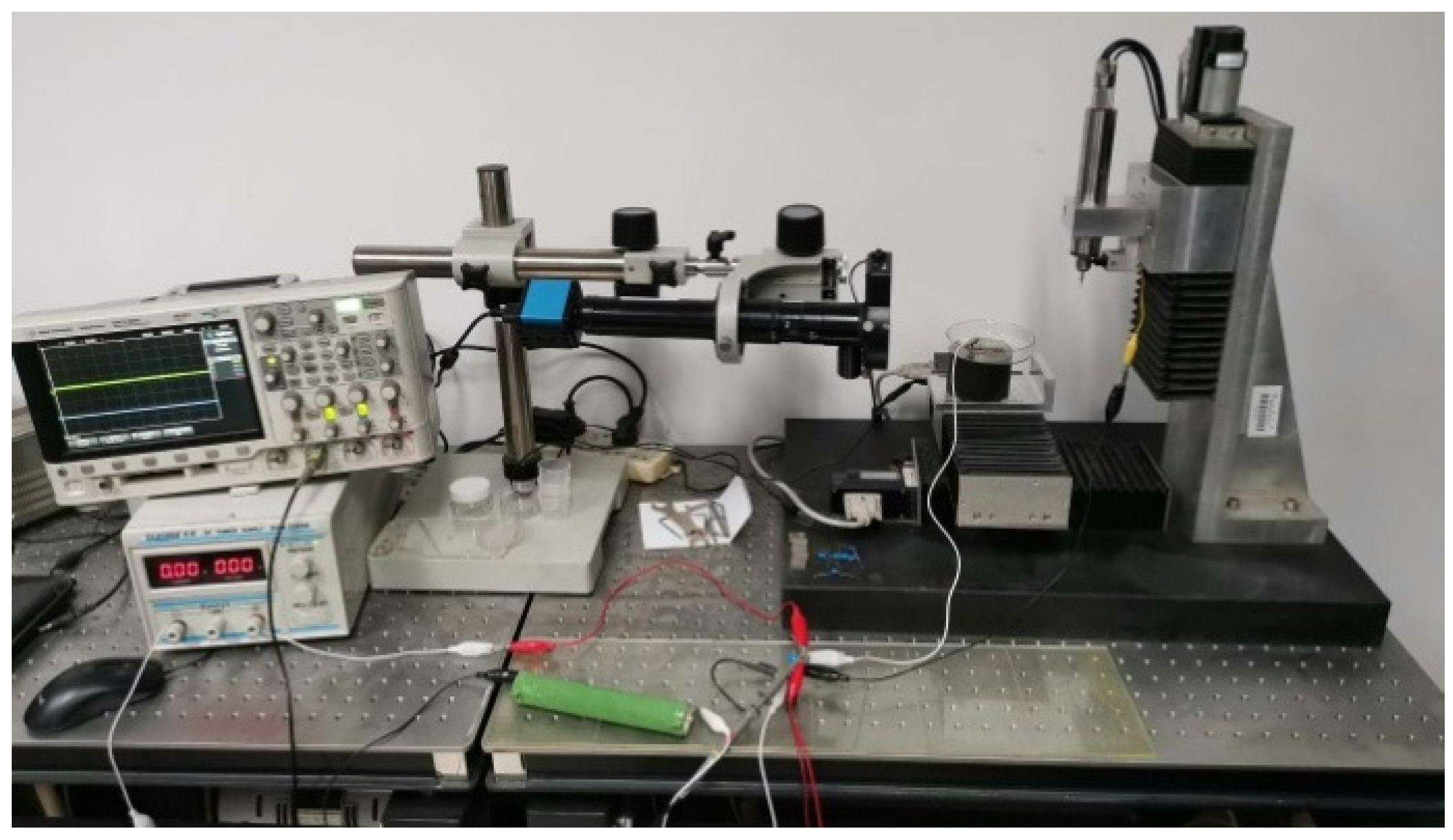

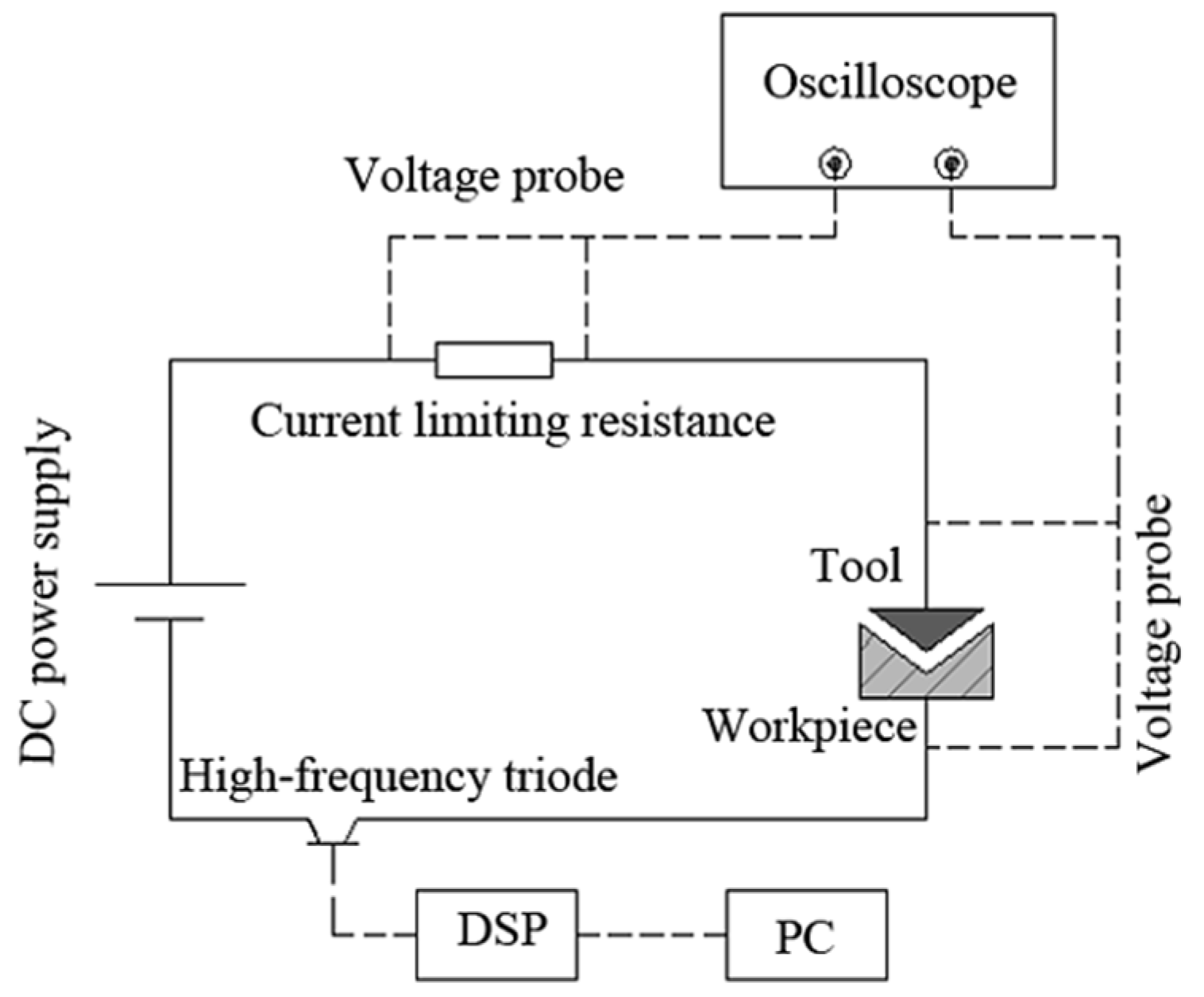

2.2. Experimental Design and Setup

3. Results and Discussion

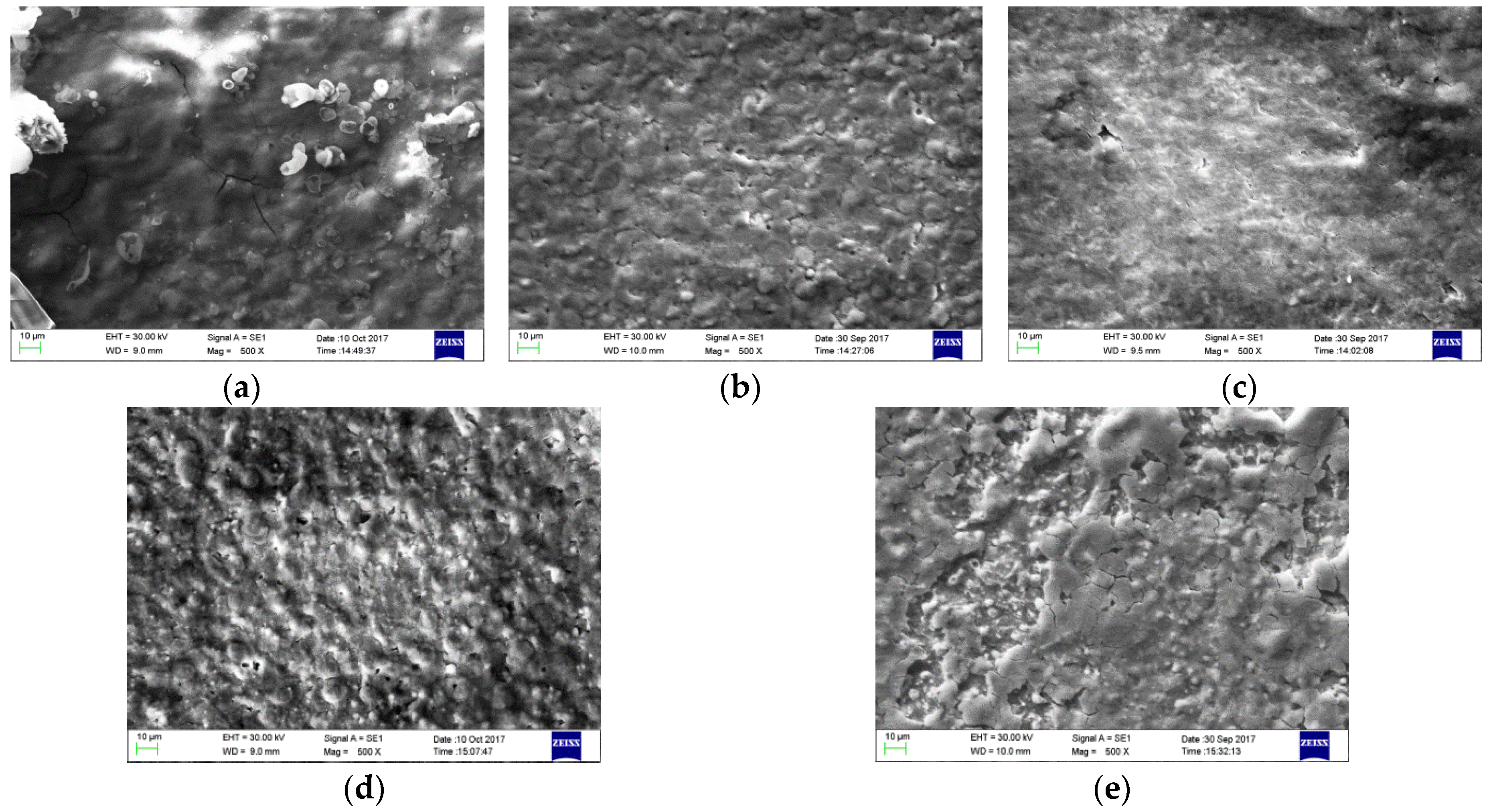

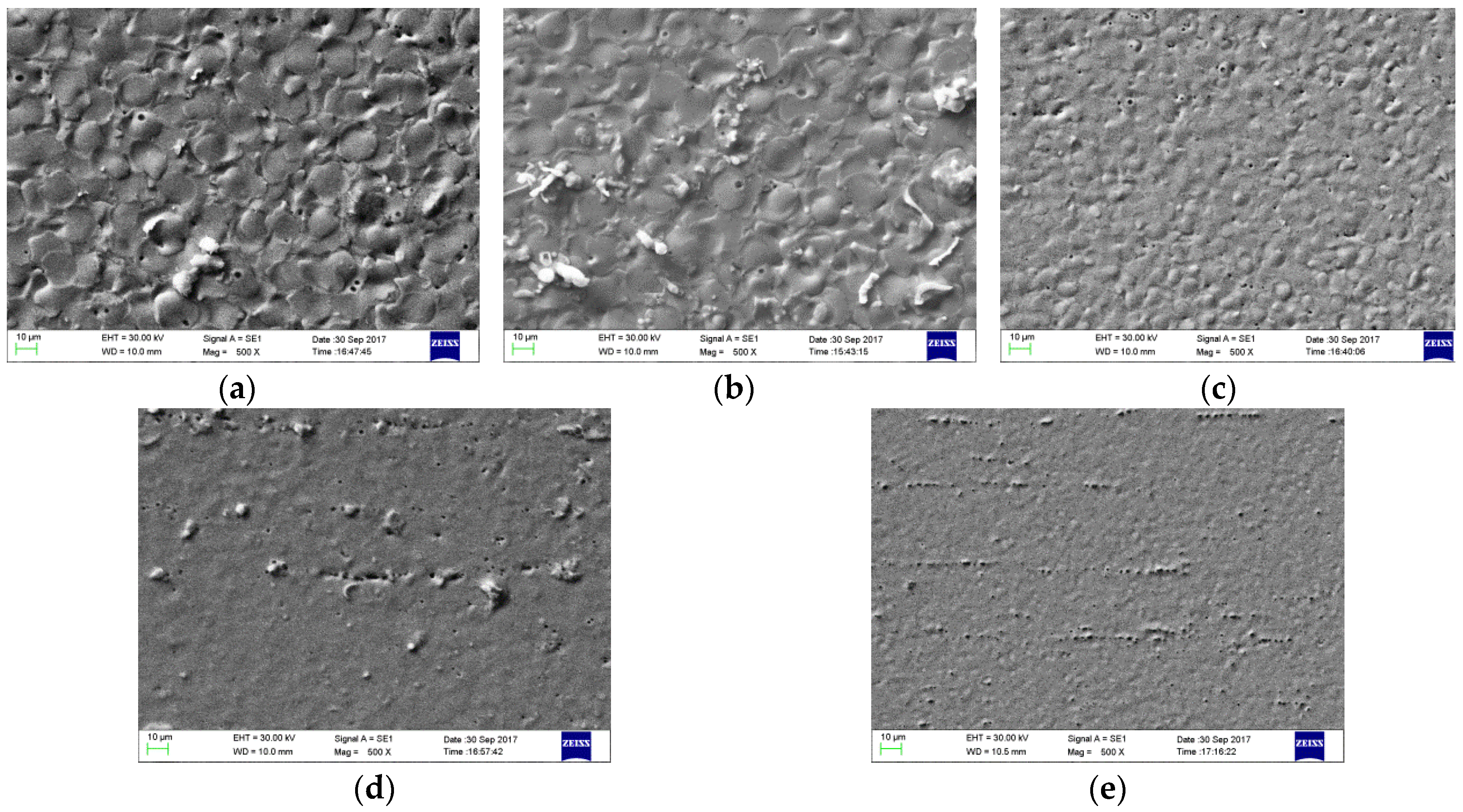

3.1. Influence of Tool Diameter on Surface Topography

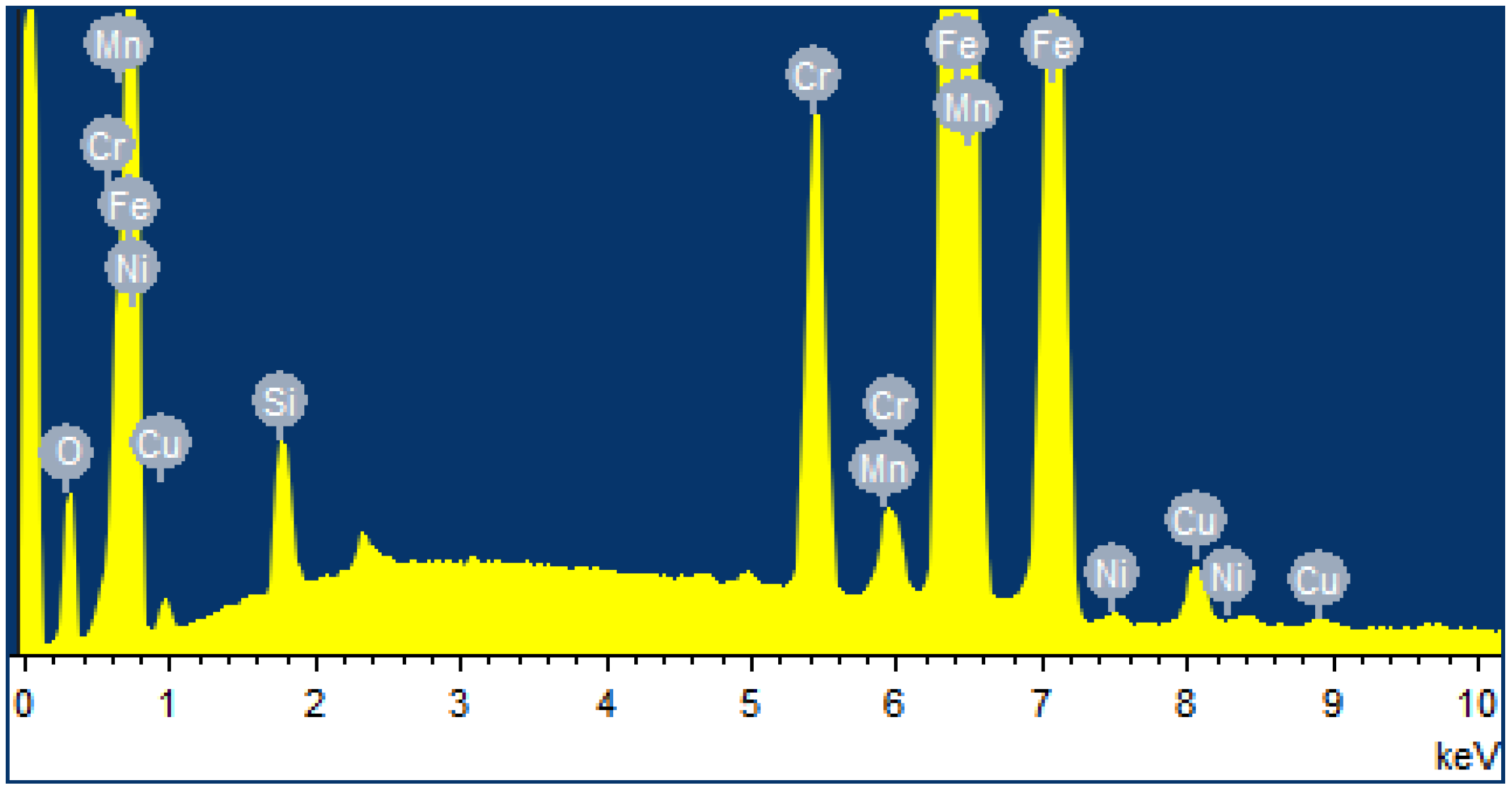

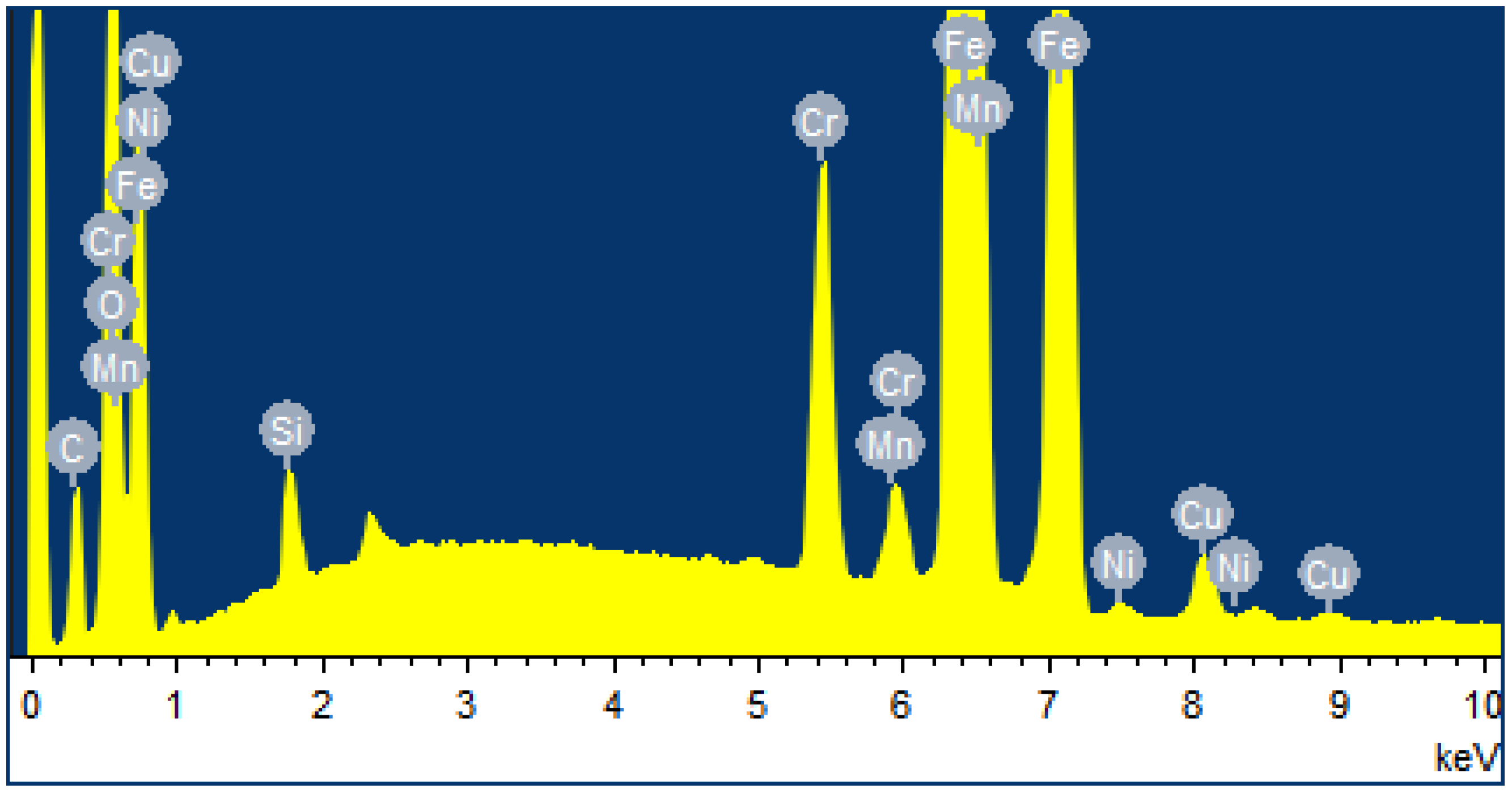

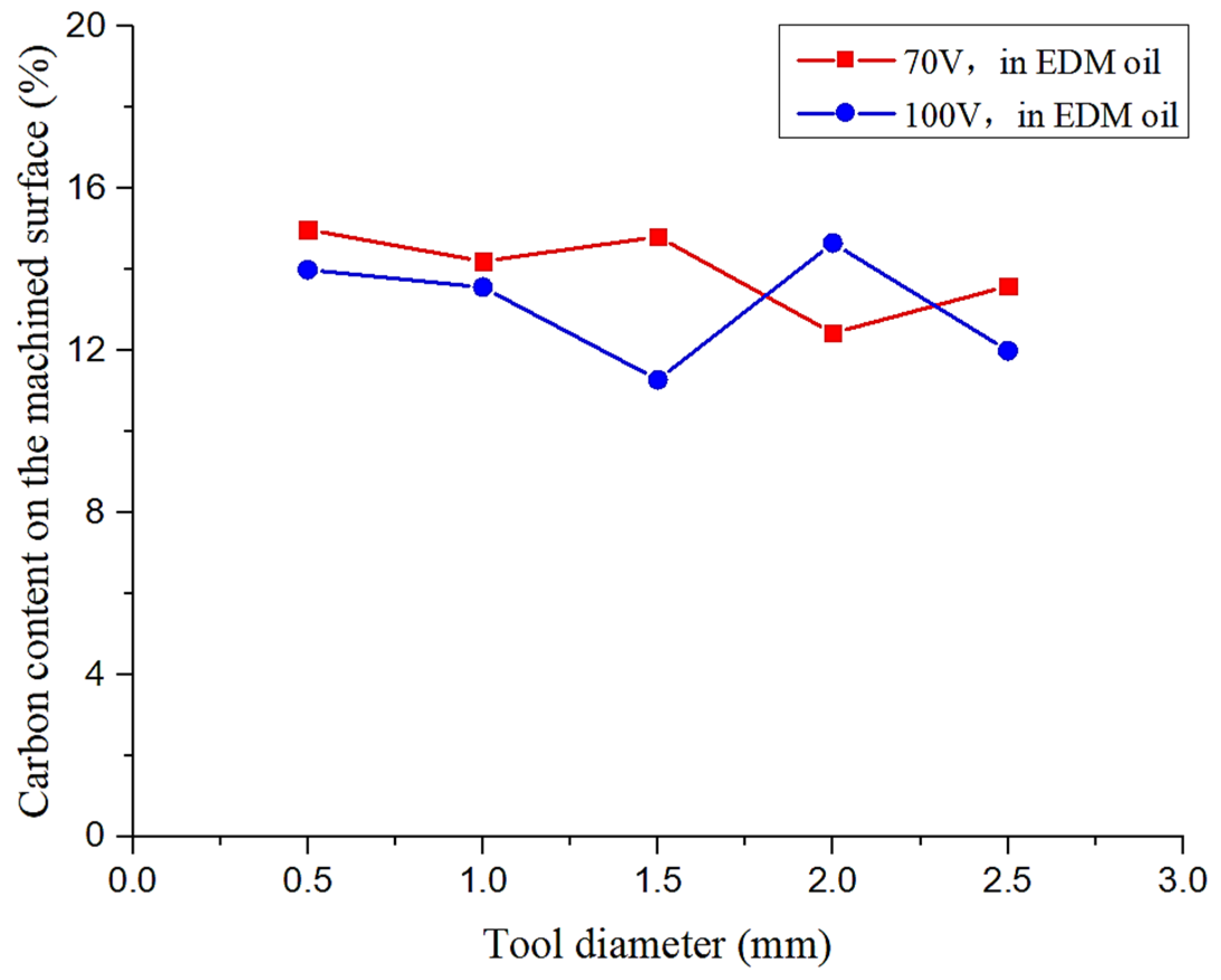

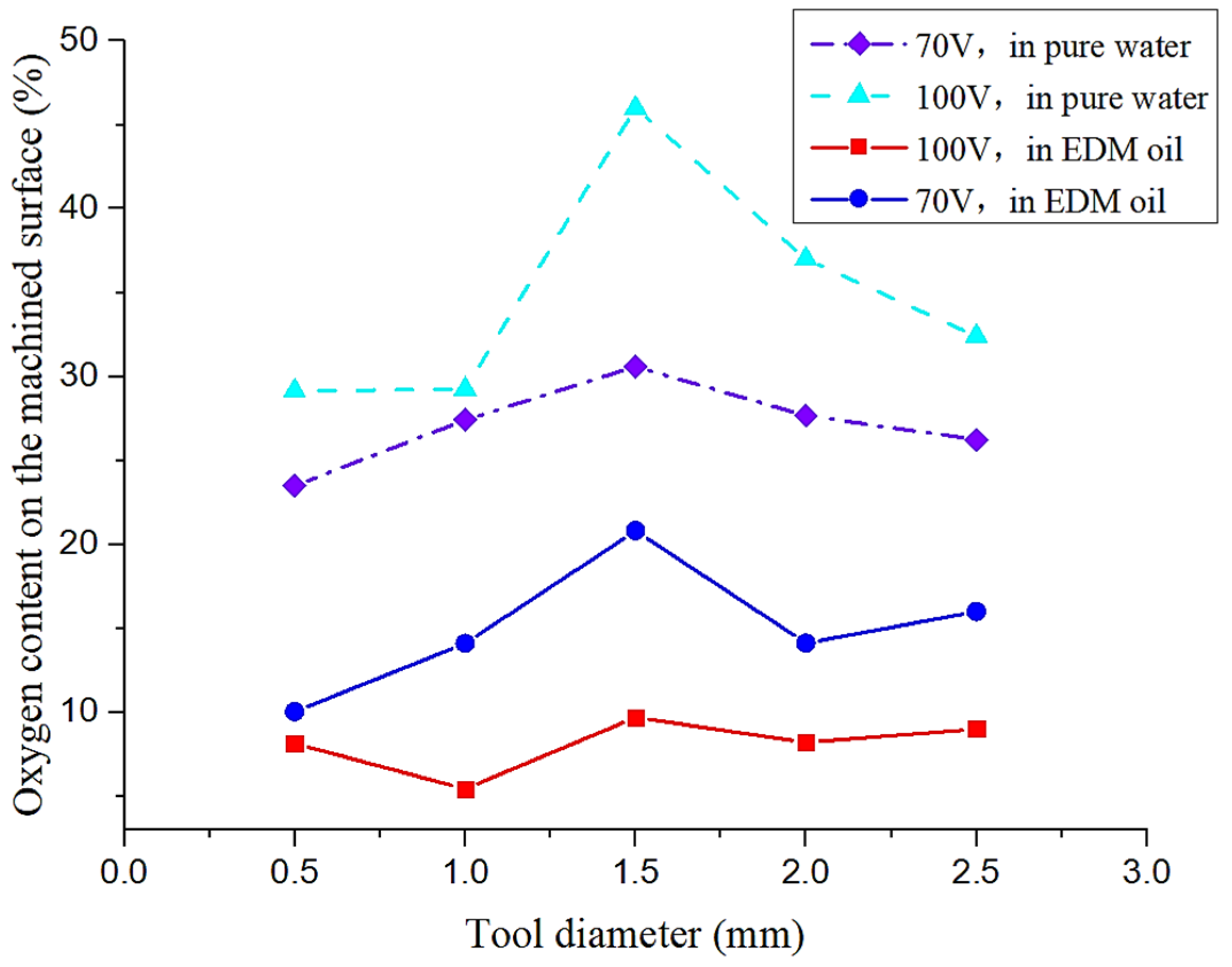

3.2. Influence of Tool Diameter on Element Migration

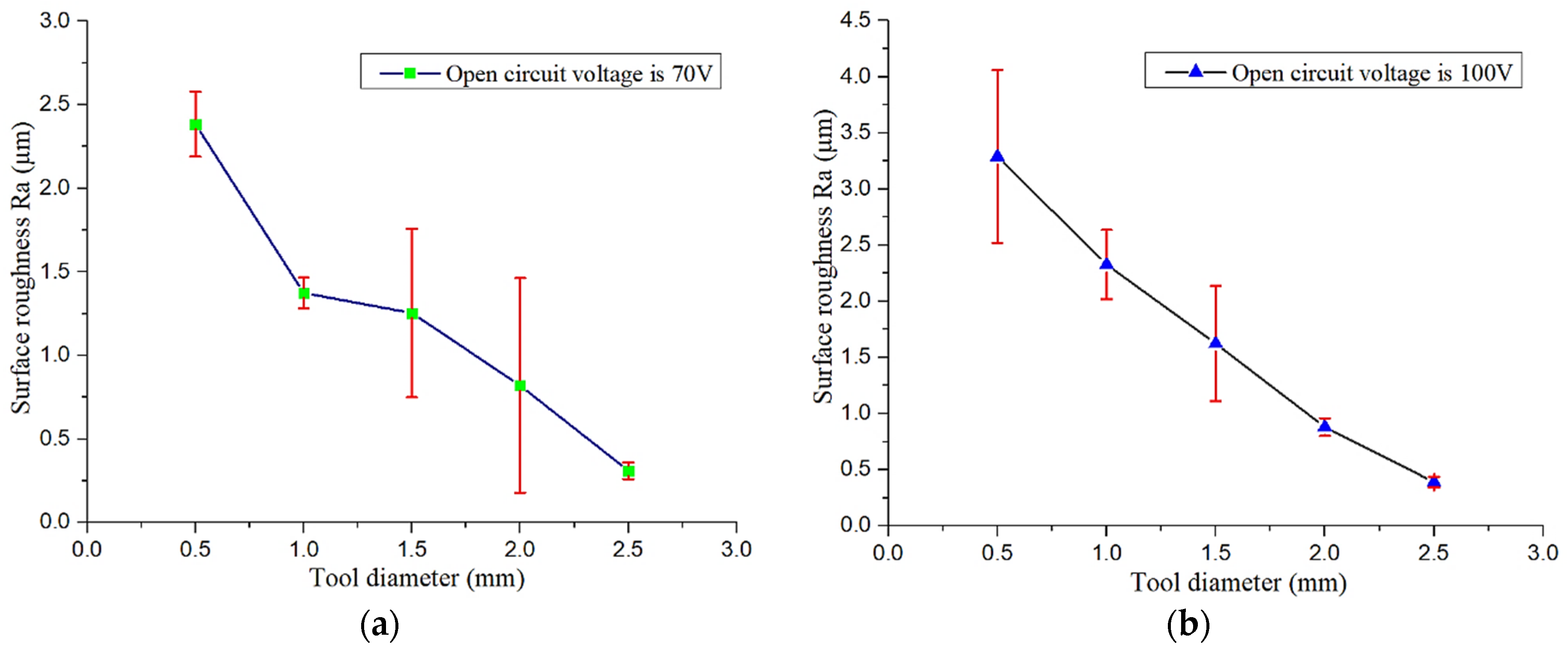

3.3. Influence of Tool Diameter on Surface Roughness

4. Conclusions

- The good fluidity and cooling property of pure water and the effect of electrochemical corrosion cause the surface topography obtained in pure water is significant coarser with more micro cracks than that obtained in EDM oil.

- Pure water is more suitable for high efficiency, low precision micro EDM, while EDM oil is better for high precision micro EDM.

- Tool material migrates to the workpiece surface during micro EDM process, whether pure water or EDM oil is used as working medium. The influence of electrode size on the Cu content on the workpiece surface shows no significant trend.

- Owing to the skin effect and the effect of electrochemical corrosion during micro EDM, the surface roughness Ra decreases as the tool electrode diameter increased, regardless of the open-circuit voltage and dielectric type. The surface roughness Ra of the surface machined in pure water is much larger than that machined in EDM oil.

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, X.; Xu, Q.; Li, H.; Liu, M.; Li, Z.; Yang, K.; Zhao, J.; Qian, L.; Peng, Z.; Zhang, G.; et al. Fabrication of high-performance silver mesh for transparent glass heaters via electric-field-driven microscale 3D printing and UV-assisted microtransfer. Adv. Mater. 2019, 31, 1902479. [Google Scholar] [CrossRef] [PubMed]

- Peng, Z.; Feng, T.; Wei, Z.; Zhang, Y.; Li, Y. Directly Writing Patterning of Conductive material by high voltage induced weak electric arc machining (HV-μEAM). Coatings 2019, 9, 538. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Q.; Zhang, M.; Yang, F.; Rajurkar, K.P. Effects of surface layer of AISI 304 on micro EDM performance. Precis. Eng. 2019, 57, 195–202. [Google Scholar] [CrossRef]

- Świercz, R.; Oniszczuk-Świercz, D. Experimental investigation of surface layer properties of high thermal conductivity tool steel after electrical discharge machining. Metals 2017, 7, 550. [Google Scholar] [CrossRef]

- Abidi, M.H.; Al-Ahmari, A.M.; Siddiquee, A.N.; Mian, S.H.; Mohammed, M.K.; Rasheed, M.S. An investigation of the micro-electrical discharge machining of nickel-titanium shape memory alloy using grey relations coupled with principal component analysis. Metals 2017, 7, 486. [Google Scholar] [CrossRef]

- D’Urso, G.; Giardini, C.; Quarto, M.; Maccarini, G. Cost index model for the process performance optimization of micro-EDM drilling on tungsten carbide. Micromachines 2017, 8, 251. [Google Scholar] [CrossRef]

- Yang, S.; Yu, S.; He, C. The surface integrity of titanium alloy when using micro-textured ball-end milling cutters. Micromachines 2019, 10, 21. [Google Scholar] [CrossRef]

- Jahan, M.P.; Alavi, F. A study on the surface composition and migration of materials and their effect on surface microhardness during micro-EDM of Ti-6Al-4V. J. Mater. Eng. Perform. 2019, 28, 3517–3530. [Google Scholar] [CrossRef]

- D’Urso, G.; Maccarini, G.; Quarto, M.; Ravasio, C. Investigation on power discharge in micro-EDM stainless steel drilling using different electrodes. J. Mech. Sci. Tech. 2015, 29, 4341–4349. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Q.; Zhang, M.; Yang, F. Study on the time-varying characteristics of discharge plasma in micro-electrical discharge machining. Coatings 2019, 9, 718. [Google Scholar] [CrossRef]

- Roy, T.; Datta, D.; Balasubramaniam, R. Numerical modelling, simulation and fabrication of 3-D hemi-spherical convex micro features using Reverse Micro EDM. J. Manuf. Process. 2018, 32, 344–356. [Google Scholar] [CrossRef]

- D’Urso, G.; Giardini, C.; Maccarini, G.; Quarto, M.; Ravasio, C. Analysis of the surface quality of steel and ceramic materials machined by micro-EDM. In Proceedings of the 18th International Conference of the European Society for Precision Engineering and Nanotechnology, EUSPEN, Venice, Italy, 4–8 June 2018; pp. 431–432. [Google Scholar]

- Gianluca, T.; Giuliano, B.; Andrej, L.; Joško, V. Real time power consumption monitoring for energy efficiency analysis in micro EDM milling. Int. J. Adv. Manuf. Technol. 2015, 78, 1511–1521. [Google Scholar]

- Lee, H.T.; Rehbach, W.P.; Tai, T.Y.; Hsu, F.C. Relationship between electrode size and surface cracking in the EDM machining process. J. Mater. Sci. 2004, 39, 6981–6986. [Google Scholar] [CrossRef]

- Peças, P.; Henriques, E. Influence of silicon powder-mixed dielectric on conventional electrical discharge machining. Int. J. Mach. Tool. Manuf. 2003, 43, 1465–1471. [Google Scholar] [CrossRef]

- D’Urso, G.; Ravasio, C. The effects of electrode size and discharged power on micro-electro-discharge machining drilling of stainless steel. Adv. Mech. Eng. 2016, 8, 1687814016648646. [Google Scholar] [CrossRef]

- D’Urso, G.; Ravasio, C. Investigation on the effects of exchanged power and electrode properties on micro EDM drilling of stainless steel. Manuf. Technol. 2019, 19, 337–344. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Q.; Zhu, G.; Wang, K.; Zhang, J.; Dong, C. Effect of electrode size on the performances of micro-EDM. Mater. Manuf. Processes. 2016, 31, 391–396. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Q.; Zhu, G.; Zhang, J. Effects of tool electrode size on surface characteristics in micro-EDM. Int. J. Adv. Manuf. Technol. 2018, 96, 3909–3916. [Google Scholar] [CrossRef]

- Wheeler, H.A. Formulas for the skin effect. Proc. IRE 1942, 30, 412–424. [Google Scholar] [CrossRef]

- Li, X.P.; Wang, Y.G.; Zhao, F.L.; Wu, M.H.; Liu, Y. Influence of high frequency pulse on electrode wear in micro-EDM. Def. Technol. 2014, 10, 316–320. [Google Scholar] [CrossRef]

- Geysen, W.; Belmans, R. Algemene Elektrotechniek; Garant: Antwerp, Belgium, 1978. [Google Scholar]

- Myrzak, V.; Dikusar, A.I. On size effect of rate of corrosion of copper nanowire ensemble: Part 2. Size effect of rate of corrosion of copper in pyrophosphate solution. Surf. Eng. Appl. Electrochem. 2016, 52, 140–144. [Google Scholar] [CrossRef]

| Processing Parameter | Value |

|---|---|

| Capacitance (C/pF) | 1000 |

| Open circuit voltage (U/V) | 70, 100 |

| Tool diameter (D/mm) | 0.5, 1, 1.5, 2, 2.5 |

| Feeding depth (H/μm) | 20 |

| Milling length (L/μm) | 1000 |

| Dielectric | Tool Diameter (mm) | Open Circuit Volatage (V) | Surface Roughness Ra1 (μm) | Surface Roughness Ra2 (μm) | Surface Roughness Ra3 (μm) | Average (μm) | Standard Deviation |

|---|---|---|---|---|---|---|---|

| In pure water | 0.5 | 70 | 2.16 | 2.47 | 2.52 | 2.38 | 0.195021 |

| 0.5 | 100 | 2.41 | 3.61 | 3.85 | 3.29 | 0.771492 | |

| 1.0 | 70 | 1.27 | 1.40 | 1.45 | 1.37 | 0.092916 | |

| 1.0 | 100 | 2.57 | 1.98 | 2.43 | 2.33 | 0.308275 | |

| 1.5 | 70 | 1.25 | 1.76 | 0.75 | 1.25 | 0.505008 | |

| 1.5 | 100 | 1.22 | 2.20 | 1.45 | 1.62 | 0.512478 | |

| 2.0 | 70 | 1.56 | 0.48 | 0.42 | 0.82 | 0.641561 | |

| 2.0 | 100 | 0.96 | 0.87 | 0.80 | 0.88 | 0.080208 | |

| 2.5 | 70 | 0.39 | 0.30 | 0.31 | 0.33 | 0.538609 | |

| 2.5 | 100 | 0.41 | 0.47 | 0.38 | 0.42 | 0.045826 | |

| In EDM oil | 0.5 | 70 | 0.43 | 0.34 | 0.48 | 0.42 | 0.070946 |

| 0.5 | 100 | 0.55 | 0.76 | 0.52 | 0.61 | 0.130767 | |

| 1.0 | 70 | 0.41 | 0.33 | 0.27 | 0.34 | 0.070238 | |

| 1.0 | 100 | 0.45 | 0.55 | 0.50 | 0.50 | 0.05 | |

| 1.5 | 70 | 0.25 | 0.19 | 0.28 | 0.24 | 0.045826 | |

| 1.5 | 100 | 0.34 | 0.52 | 0.40 | 0.42 | 0.091652 | |

| 2.0 | 70 | 0.10 | 0.09 | 0.09 | 0.09 | 0.005774 | |

| 2.0 | 100 | 0.26 | 0.28 | 0.25 | 0.26 | 0.015275 | |

| 2.5 | 70 | 0.04 | 0.05 | 0.05 | 0.05 | 0.005774 | |

| 2.5 | 100 | 0.25 | 0.27 | 0.20 | 0.24 | 0.036056 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Yang, F.; Sun, S.; Yang, M.; Shao, J. Surface Integrity of Micro EDM Surface Using Electrodes of Various Diameters. Coatings 2019, 9, 805. https://doi.org/10.3390/coatings9120805

Liu Q, Yang F, Sun S, Yang M, Shao J. Surface Integrity of Micro EDM Surface Using Electrodes of Various Diameters. Coatings. 2019; 9(12):805. https://doi.org/10.3390/coatings9120805

Chicago/Turabian StyleLiu, Qingyu, Fazhan Yang, Shufeng Sun, Man Yang, and Jing Shao. 2019. "Surface Integrity of Micro EDM Surface Using Electrodes of Various Diameters" Coatings 9, no. 12: 805. https://doi.org/10.3390/coatings9120805

APA StyleLiu, Q., Yang, F., Sun, S., Yang, M., & Shao, J. (2019). Surface Integrity of Micro EDM Surface Using Electrodes of Various Diameters. Coatings, 9(12), 805. https://doi.org/10.3390/coatings9120805