Electrodeposition of a Ni–P–TiO2/Ti3C2Tx Coating with In Situ Grown Nanoparticles TiO2 on Ti3C2Tx Sheets

Abstract

1. Introduction

2. Experiment Procedure

2.1. Preparation of TiO2/Ti3C2Tx Powders

2.2. Preparation of Composite Coatings

2.3. Material Characterization

3. Results and Discussions

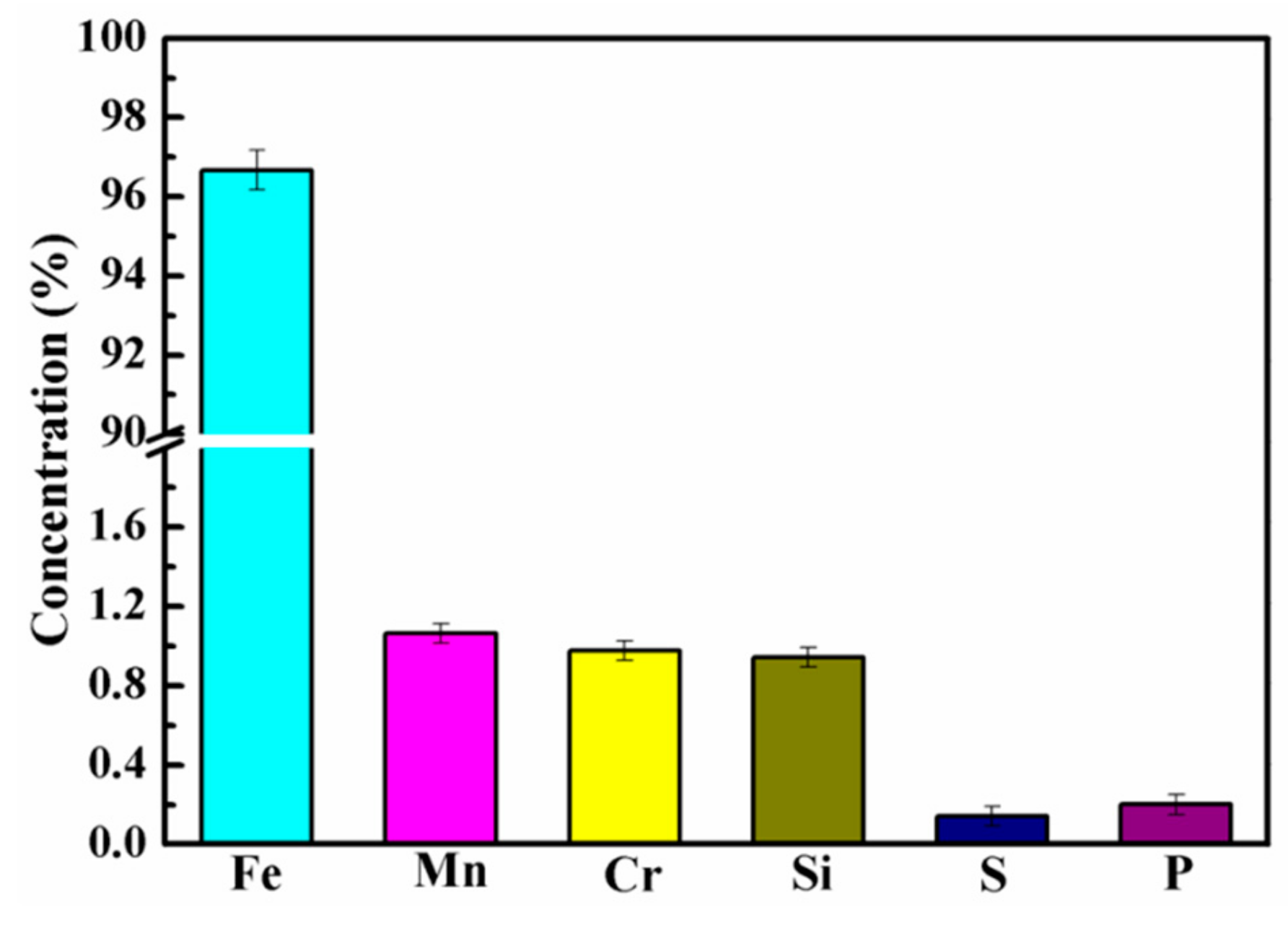

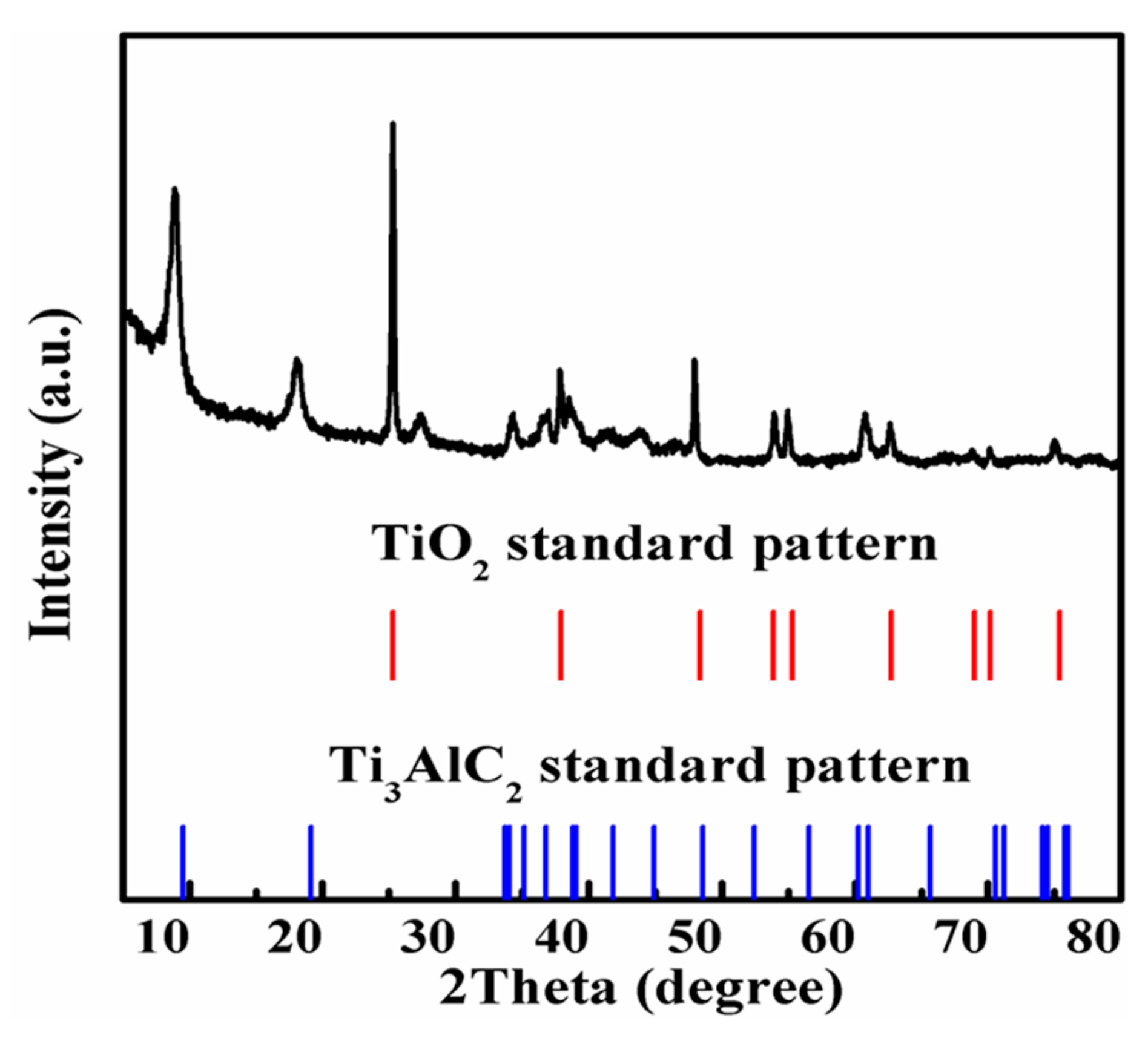

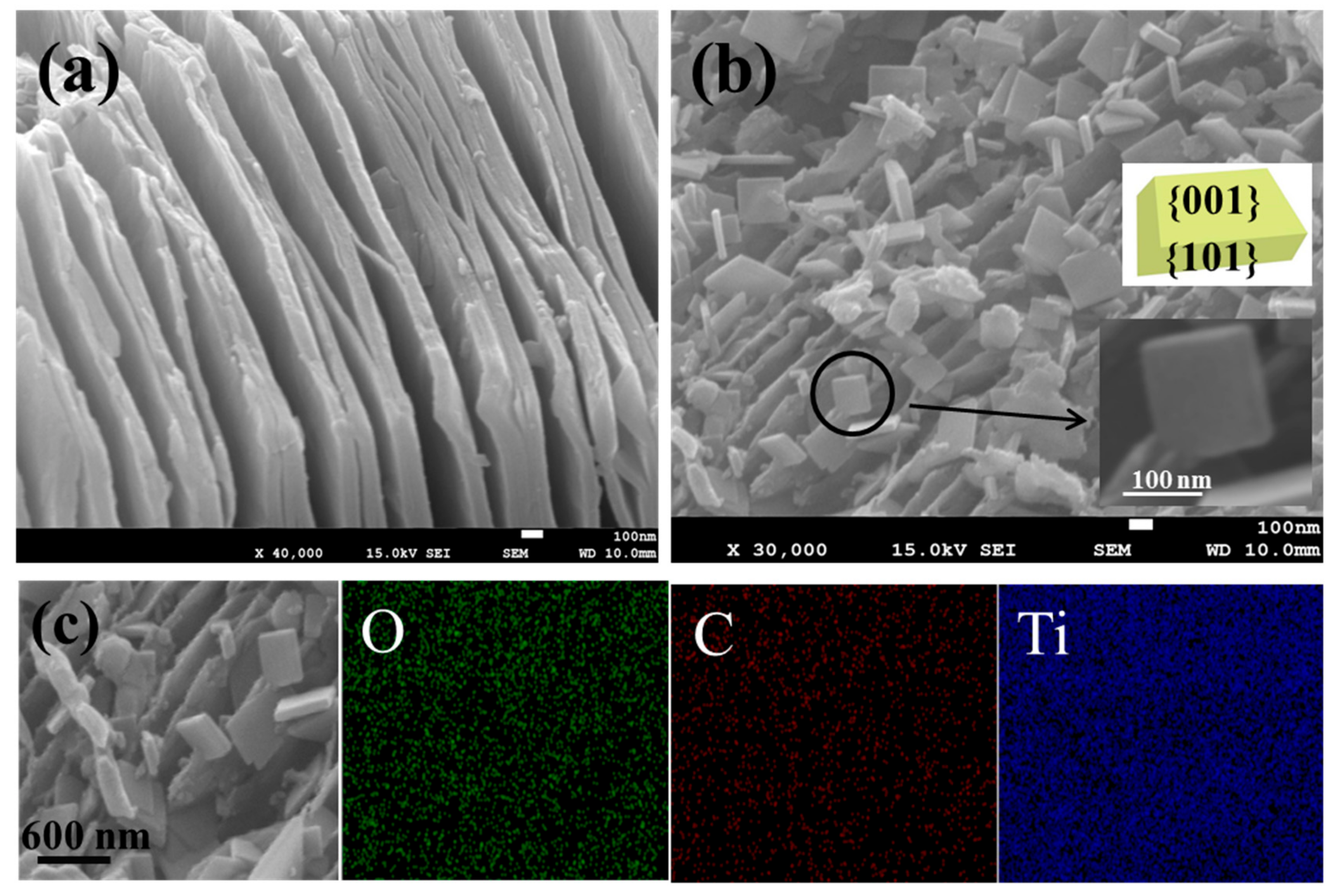

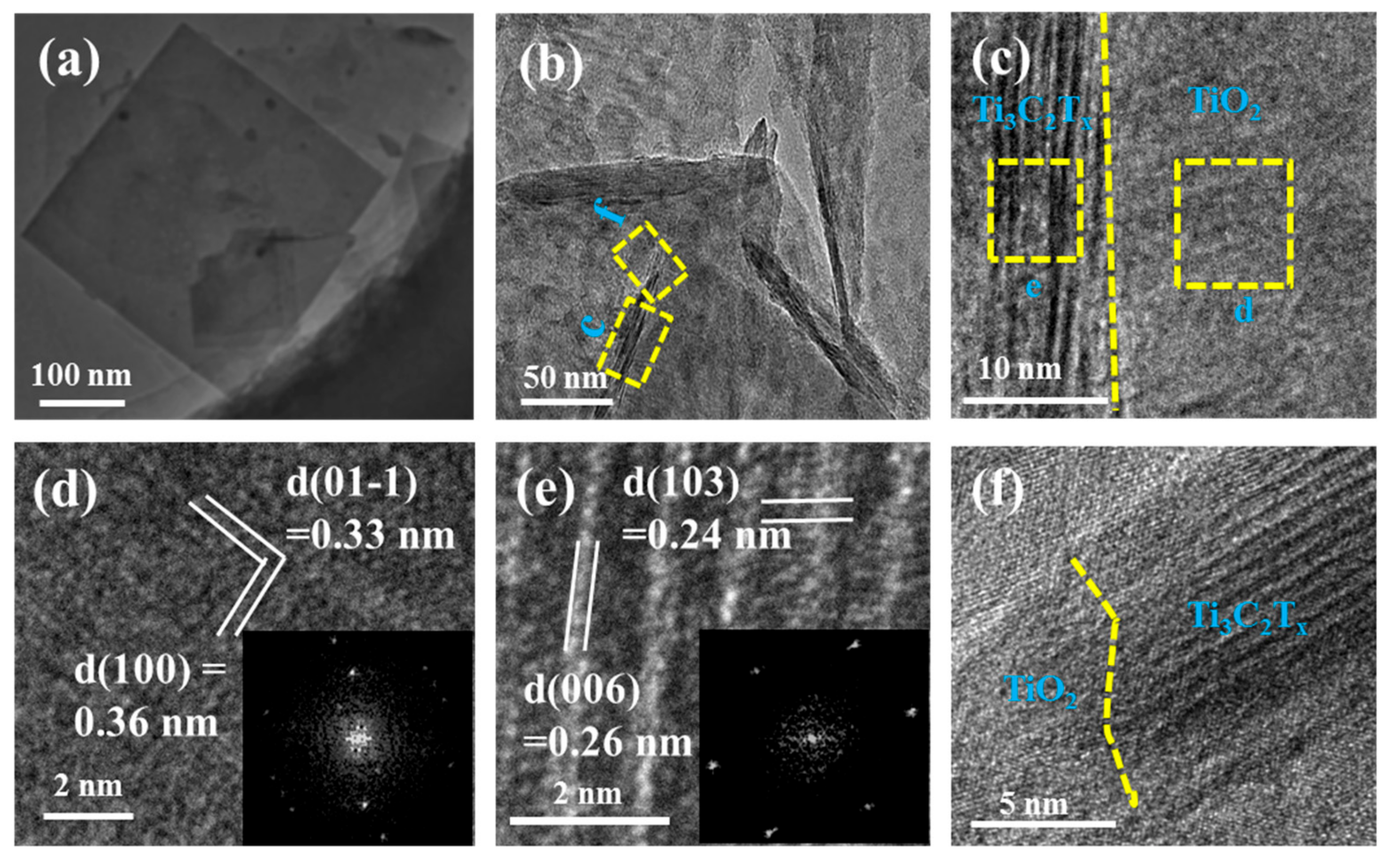

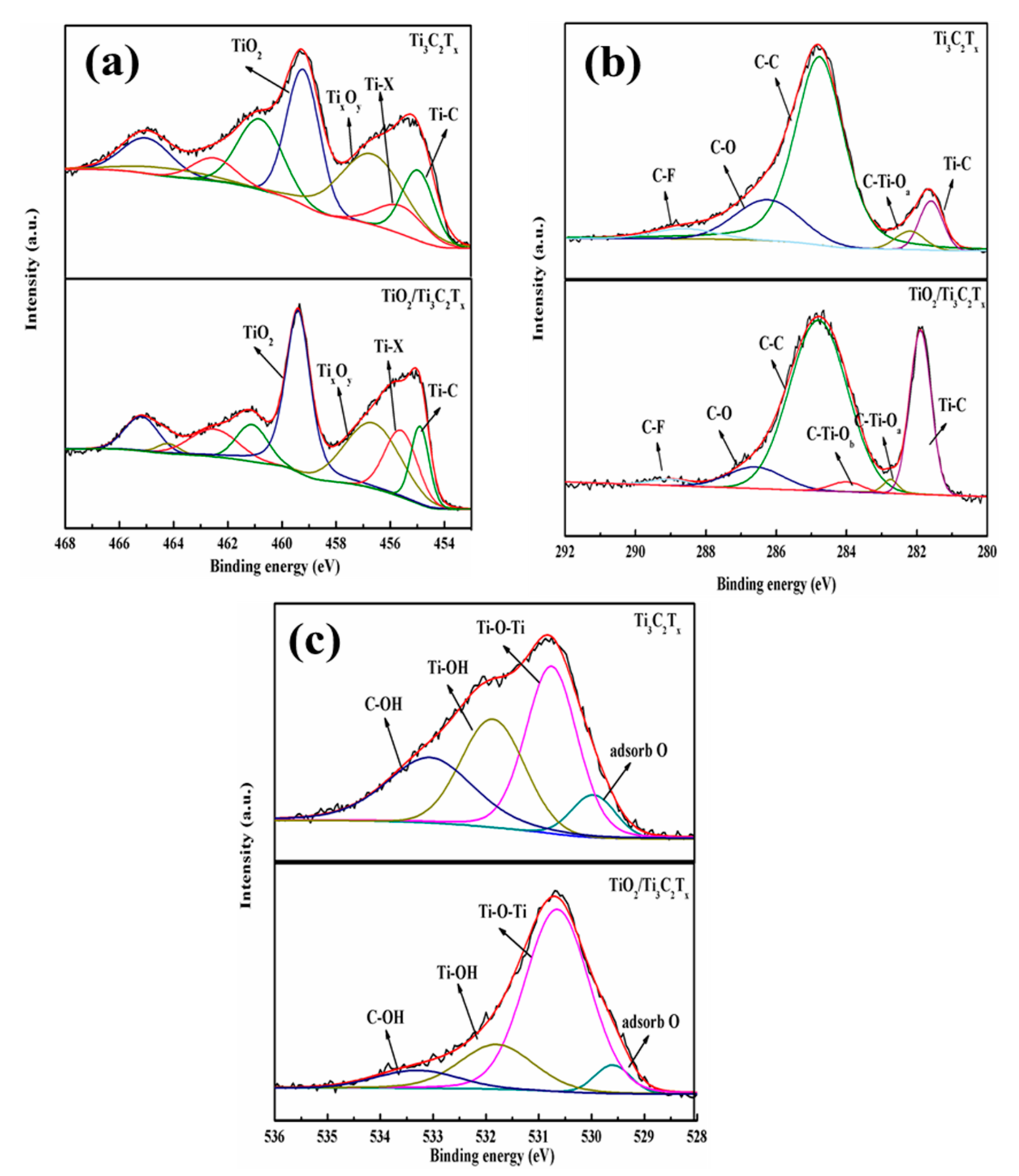

3.1. Characterization of Powders

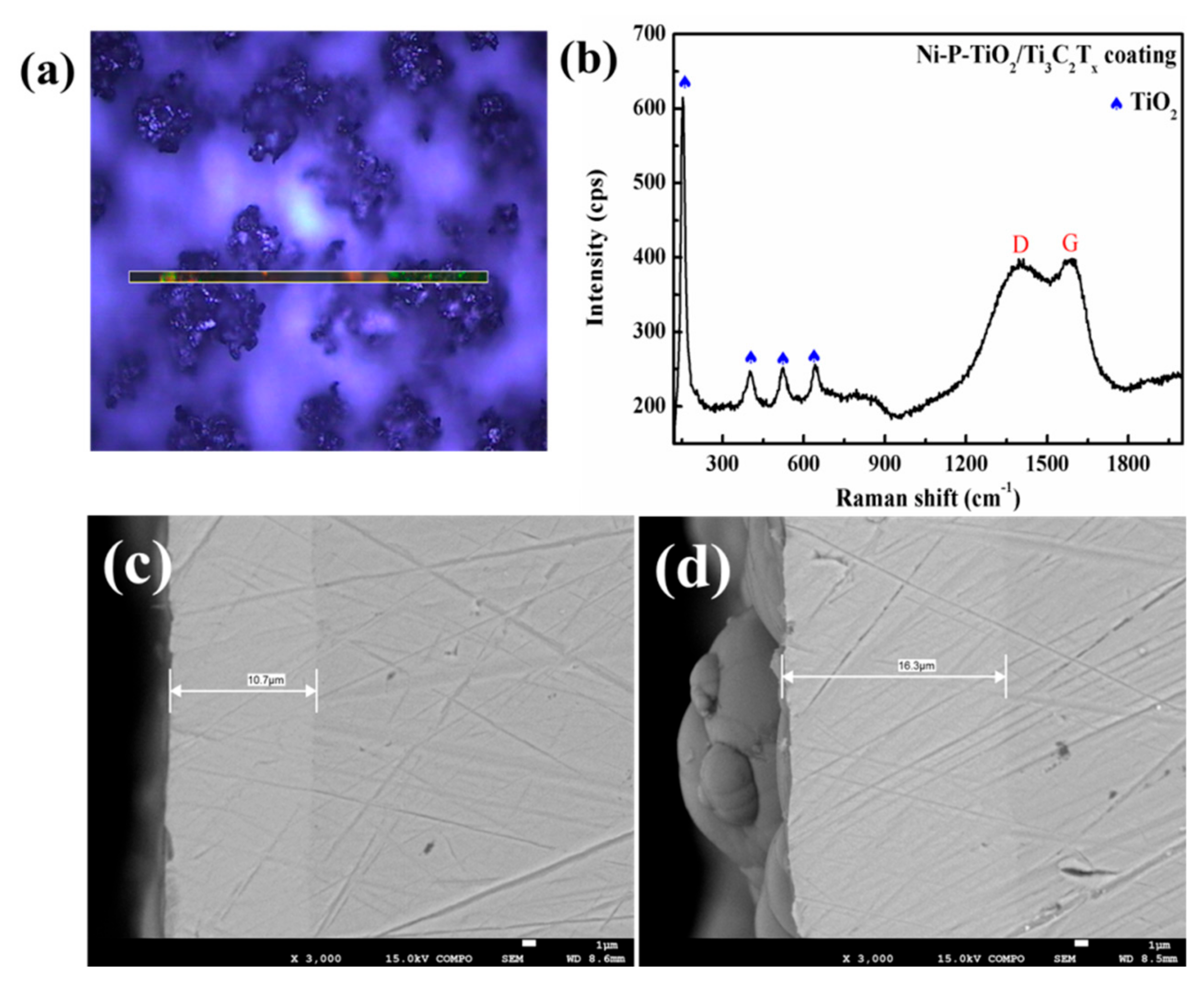

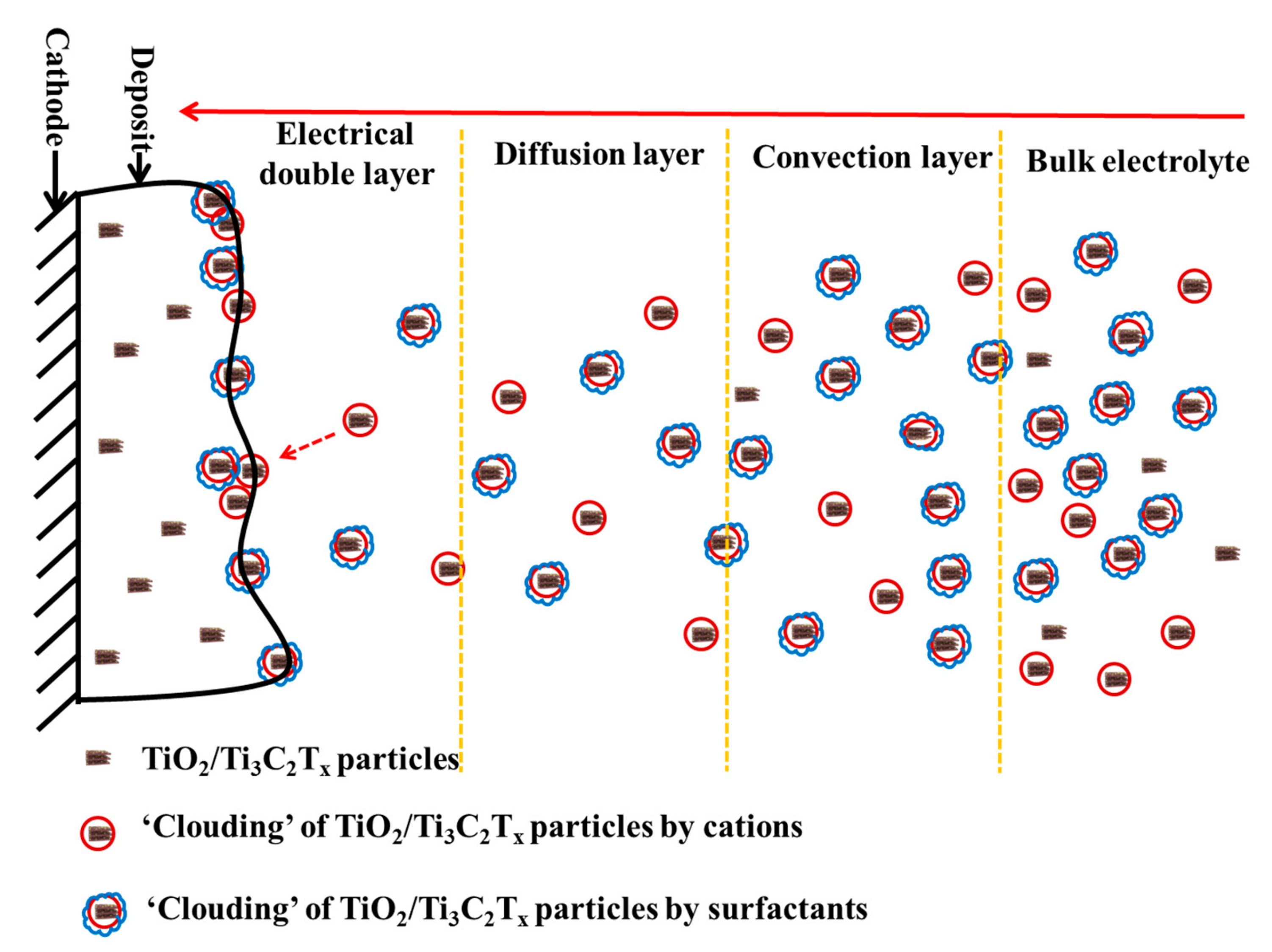

3.2. Characterization of Composite Coatings

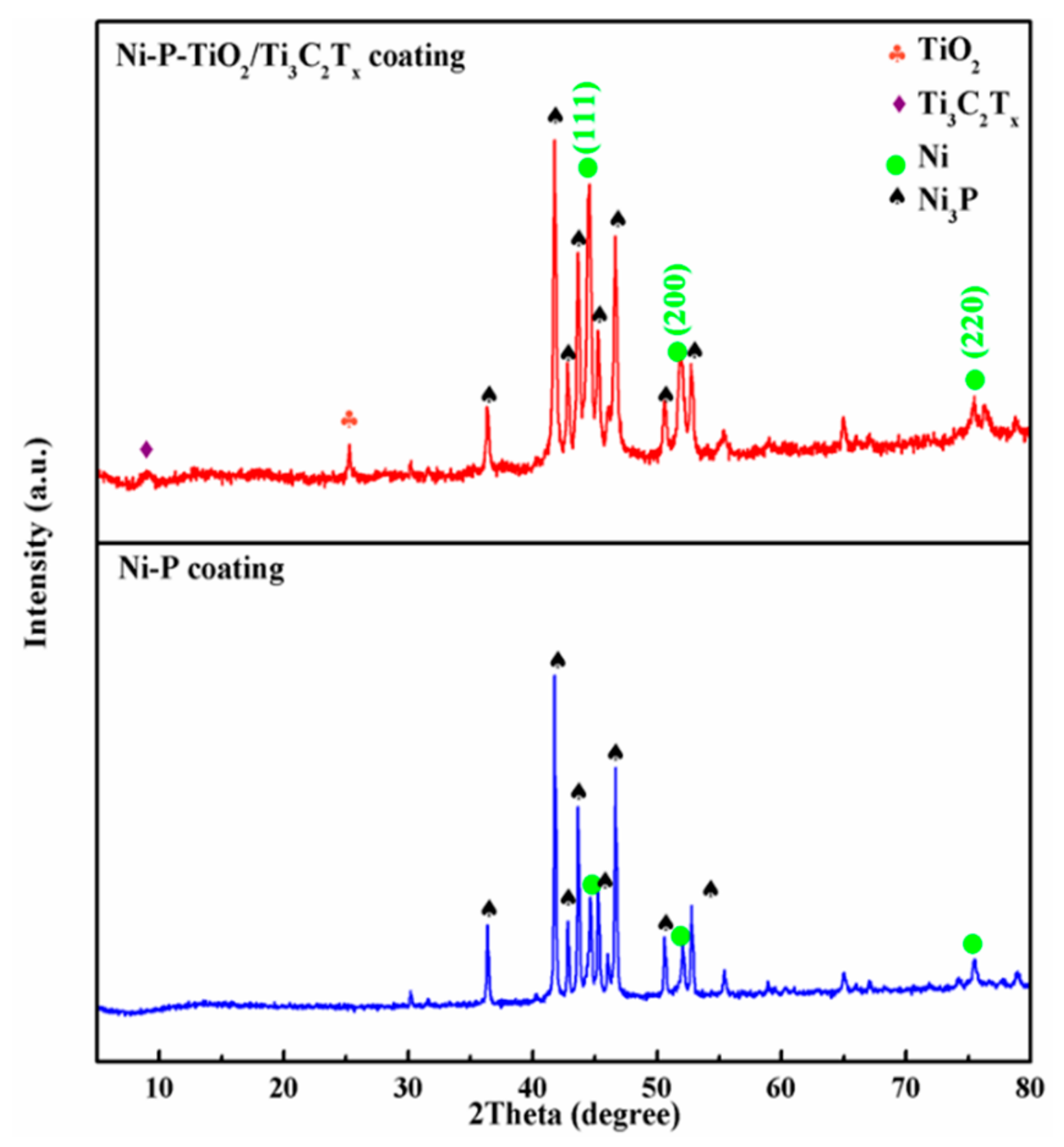

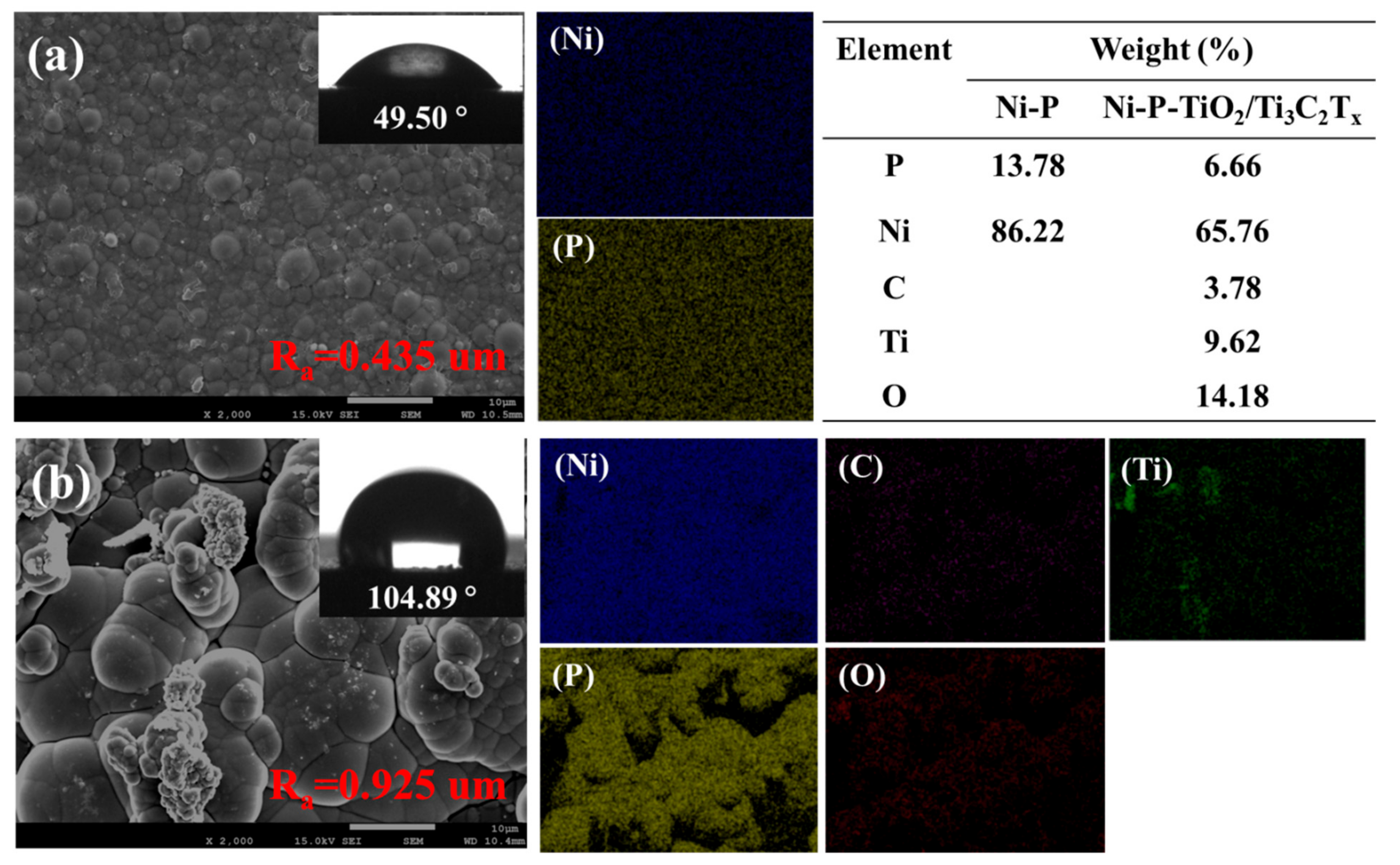

3.2.1. Compositions of Composite Coatings

3.2.2. Wettability of Composite Coatings

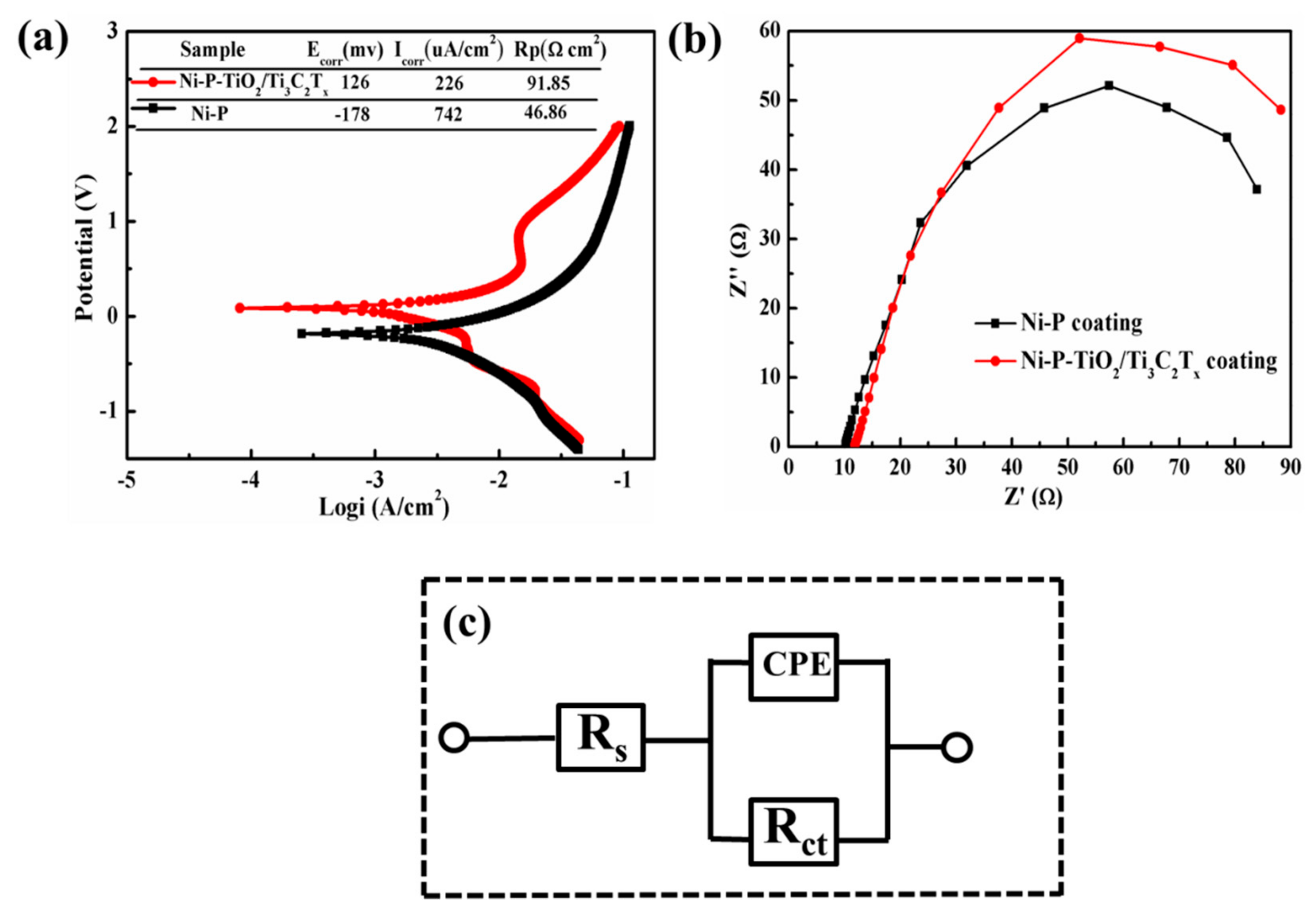

3.2.3. Corrosion Behavior of Composite Coatings

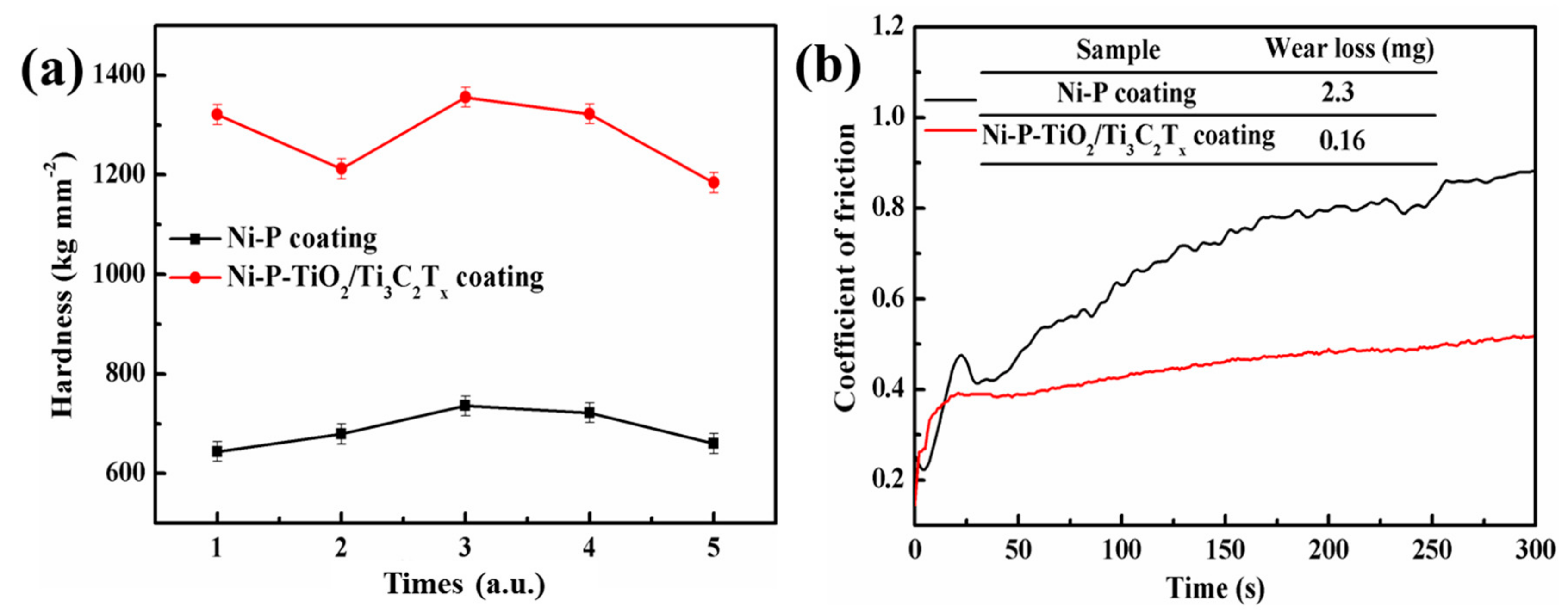

3.2.4. Wear Behavior of Composite Coatings

4. Conclusions

- The in situ grown nanocrystals TiO2 on Ti3C2Tx sheets can still maintain a layered structure. The Ni–P–TiO2/Ti3C2Tx coating is successfully prepared by an electroplating technique;

- The participation of TiO2/Ti3C2Tx can change the wettability of Ni–P composite coatings from hydrophilic to hydrophobic;

- The Ni–P–TiO2/Ti3C2Tx coating shows better properties of corrosion prevention than Ni–P coatings.

- Microhardness of the Ni–P–TiO2/Ti3C2Tx coating is approximately 1350 kg mm−2, and the coefficient of friction of Ni–P–TiO2/Ti3C2Tx coatings is about 0.40, which is lower than that of the Ni–P coating.

Author Contributions

Funding

Conflicts of Interest

References

- Subramanian, C.; Cavallaro, G.; Winkelman, G. Wear maps for titanium nitride coatings deposited on copper and brass with electroless nickel interlayers. Wear 2000, 241, 228–233. [Google Scholar] [CrossRef]

- Baghery, P.; Farzam, M.; Mousavi, A.B.; Hosseini, M. Ni-TiO2 nanocomposite coating with high resistance to corrosion and wear. Surf. Coat. Technol. 2010, 204, 3804–3810. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, H.; Qian, B. Friction and wear properties of the co-deposited Ni-SiC nanocomposite coating. J. Appl. Surf. Sci. 2007, 253, 8335–8339. [Google Scholar] [CrossRef]

- Hou, K.H.; Ger, M.D.; Wang, L.M.; Ke, S.T. The wear behaviour of electro-codeposited Ni-SiC composites. Wear 2002, 253, 994–1003. [Google Scholar] [CrossRef]

- Matthews, A. Advanced Surface Coatings: A Handbook of Surface Engineering; Rickerby, D., Ed.; Springer: Heidelberg/Berlin, Germany, 1991; Volume 1. [Google Scholar]

- Walsh, F.C.; Ponce de León, C. A review of the electrodeposition of metal matrix composite coatings by inclusion of particles in a metal layer: An established and diversifying coatings technology. T.I. Met. Finish. 2014, 92, 83–98. [Google Scholar] [CrossRef]

- Wang, S.C.; Zhou, N.; Walsh, F.C. Diverse electrodeposits from modified acid sulphate (watts nickel) baths. T.I. Met. Finish. 2016, 94, 274–282. [Google Scholar] [CrossRef]

- Zhao, G.C.; Xue, Y.; Huang, Y.; Ye, Y.; Walsh, F.C.; Chen, J.; Wang, S. One-Step electrodeposition of a self-cleaning and corrosion resistant Ni/WS2 super hydrophobic surface. RSC Adv. 2016, 6, 59104–59112. [Google Scholar] [CrossRef]

- He, Y.; Sun, W.T.; Wang, S.C.; Chiu, Y.L.; Reed, P.A.S.; Walsh, F.C. An electrodeposited Ni-P-WS2 coating with combined super-hydrophobicity and self-lubricating properties. Electrochim. Acta 2017, 245, 872–882. [Google Scholar] [CrossRef]

- Cheong, W.J.; Luan, B.L.; Shoesmeith, D.W. The effect of stabilizers on the bath stability of electroless Ni deposition and the deposit. Appl. Surf. Sci. 2004, 22, 282–300. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Xiong, D.S. Study on preparation and tribology behaviors of Ni-P electroless deposited nanocrystalline coating. Adv. Mater. Res. 2013, 706, 279–283. [Google Scholar] [CrossRef]

- Ebn Touhami, M.; Cherkaoui, M.; Chassaing, E. Modelisation of Ni-P electroless deposition in ammonical solutions. Electrochim. Acta 2003, 48, 3651–3658. [Google Scholar] [CrossRef]

- Antropov, L.I.; Lebedinskii, Y.N. Composite Electrochemical Coatings and Materials; Tekhnika: Kiev, Ukraine, 1986. (In Russian) [Google Scholar]

- Wörle, M.; Krumeich, F.; Bieri, F.; Muhr, H.J.; Nesper, R. Flexible V7O16 layers as common structural element of vanadium oxide nanotubes and a new crystalline vanadate. Z. Anorg. Allg. Chem. 2002, 62, 2778–2784. [Google Scholar] [CrossRef]

- Volkov, S.V.; Koval’chuk, E.P.; Ohenko, V.M.; Reshetnyak, O.V. Nanochemistry, Nanosystems, and Nanomaterials: A Monograph; Naukova Dumka: Kiev, Ukraine, 2008. (In Ukrainia) [Google Scholar]

- Gadhari, P.; Sahoo, P. Effect of annealing temperature and alumina particles on mechanical and tribological properties of Ni-P-Al2O3 composite coatings. Silicon 2017, 9, 761–774. [Google Scholar]

- Hou, K.-H.; Hwu, W.-H.; Ke, S.-T.; Ger, M.D. Ni-P-SiC composite produced by pulse and direct current plating. Mater. Chem. Phys. 2006, 100, 54–59. [Google Scholar]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.C.; Wang, D.D.; Si, P.C.; Wei, L.Q.; Wang, Y.L.; Yu, B.; Zhang, X.M.; Ye, S.F. Electrodeposition of a Ni-P-Ti3C2Tx/MoS2 coating incorporating MoS2 intercalated Ti3C2Tx particles. Surf. Coat. Technol. 2018, 354, 119–125. [Google Scholar] [CrossRef]

- Uttam, V.; Duchaniya, R.K. Potentiodynamic studies of Ni-P-TiO2 nano-composited coating on the mild steel deposited by electroless plating method. AIP Conf. Proc. 2016, 1725, 020053. [Google Scholar]

- Xu, Y.J.; Wang, S.; Yang, J.; Han, B.; Nie, R.; Wang, J.X.; Wang, J.G.; Jing, H.W. In-Situ grown nanocrystal TiO2 on 2D Ti3C2 nanosheets for artificial photosynthesis of chemical fuels. Nano Energy 2018, 51, 442–450. [Google Scholar] [CrossRef]

- Peng, C.; Yang, X.F.; Li, Y.H.; Yu, H.; Wang, H.J.; Peng, F. Hybrids of two-dimensional Ti3C2 and TiO2 exposing {001} facets toward enhanced photocatalytic activity. ACS Appl. Mater. Interfaces 2016, 8, 6051–6060. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.; Guo, R.S.; Liu, Z.C.; Wang, B.Y.; Meng, L.C.; Li, F.Y.; Li, T.T.; Luo, Y.N. MoS2 intercalated p-Ti3C2 anode materials with sandwich-like three dimensional conductive networks for lithium-ion batteries. J. Alloys Compd. 2018, 735, 1262–1270. [Google Scholar] [CrossRef]

- Naguib, M.; Presser, V.; Tallman, D.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. On the topotactic transformation of Ti2AlC into a Ti-C-O-F cubic phase by heating in molten lithium fluoride in air. J. Am. Ceram. Soc. 2011, 94, 4556–4561. [Google Scholar] [CrossRef]

- Naguib, M.; Mashtalir, O.; Carle, J.; Presser, V.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional transition metal carbides. ACS Nano 2012, 6, 1322–1331. [Google Scholar] [CrossRef] [PubMed]

- Bricchi, B.R.; Ghidelli, M.; Mascaretti, L.; Zapelli, A.; Russo, V.; Casari, C.S.; Terraneo, G.; Alessandri, I.; Ducati, C.; Bassi, A.L. Integration of plasmonic Au nanoparticles in TiO2 hierarchical structures in a single-step pulsed laser co-deposition. Mat. Des. 2018, 156, 311–319. [Google Scholar]

- Xue, M.Q.; Wang, Z.Q.; Yuan, F.; Zhang, X.H.; Wei, W.; Tang, H.; Li, C.S. Preparation of TiO2/Ti3C2Tx hybrid nanocomposites and their tribological properties as base oil lubricant additives. RSC Adv. 2017, 7, 4312–4319. [Google Scholar] [CrossRef]

- Yang, H.G.; Sun, C.H.; Qiao, S.Z.; Zou, J.; Liu, G.; Smith, S.C.; Cheng, H.M.; Lu, G.Q. Anatase TiO2 single crystals with a large percentage of reactive facets. Nature 2008, 453, 638–641. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Xi, J.; Ji, Z. Mo+N codoped TiO2 sheets with dominant {001} facets for enhancing visible-light photocatalytic activity. J. Mater. Chem. 2012, 22, 17700–17708. [Google Scholar] [CrossRef]

- Yang, X.; Zhuang, J.; Li, X.; Chen, D.; Ouyang, G.; Mao, Z.; Han, Y.; He, Z.; Liang, C.; Wu, M.; et al. Hierarchically nanostructured rutile arrays: Acid vapor oxidation growth and tunable morphologies. ACS Nano 2009, 3, 1212–1218. [Google Scholar] [CrossRef] [PubMed]

- Lai, Z.; Peng, F.; Wang, Y.; Wang, H.; Yu, H.; Liu, P.; Zhao, H. Low temperature solvothermal synthesis of anatase TiO2 single crystals with wholly {100} and {001} faceted surfaces. J. Mater. Chem. 2012, 22, 23906–23912. [Google Scholar] [CrossRef]

- Rakhi, R.B.; Ahmed, B.; Hedhili, M.N.; Anjum, D.H.; Alshareef, H.N. Effect of postetch annealing gas composition on the structural and electrochemical properties of Ti3C2Tx MXene electrodes for super capacitor applications. Chem. Mater. 2015, 27, 5314–5323. [Google Scholar] [CrossRef]

- Li, B.; Zhao, Z.; Gao, F.; Wang, X.; Qiu, J. Mesoporous microspheres composed of carbon-coated TiO2 nanocrystals with exposed {001} facets for improved visible light photocatalytic activity. Appl. Catal. B 2014, 147, 958–964. [Google Scholar] [CrossRef]

- Abdel Aal, A. Hard and corrosion resistant nanocomposite coating for Al alloy. J. Mater. Sci. Eng. A 2008, 474, 181–187. [Google Scholar] [CrossRef]

- Chen, X.H.; Chen, C.S.; Xiao, H.N.; Cheng, F.Q.; Zhang, G.; Yi, G.J. Corrosion behavior of carbon nanotubes-Ni composite coating. Surf. Coat. Technol. 2005, 191, 351–356. [Google Scholar] [CrossRef]

- Abdel-Gabar, A.M.; Abd-El-Nabey, B.A.; Sidahmed, I.M.; El-Zayady, A.M.; Saadawy, M. Inhibitive action of some plant extracts on the corrosion of steel in acidic media. J. Corros. Sci. 2006, 48, 2765–2779. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, J.; Gao, Y.; Xue, Q.; Hu, L.; Xu, T. Grain size effect in corrosion behavior of electrodeposited nanocrystalline Ni coatings in alkaline solution. J. Scripta Mater. 2006, 55, 657–660. [Google Scholar] [CrossRef]

- Bai, A.; Chuan, P.Y.; Hu, C.C. The corrosion behavior of Ni-P deposits with high phosphorous contents in brine media. J. Mater. Chem. Phys. 2003, 82, 93–100. [Google Scholar] [CrossRef]

- Czagány, M.; Baumli, P.; Kaptay, G. The influence of the phosphorous content and heat treatment on the nano-micro-structure, thickness and micro-hardness of electroless Ni-P coatings on steel. Appl. Surf. Sci. 2017, 423, 160–169. [Google Scholar] [CrossRef]

- Matteo, G.; Marco, S.; Christian, C.; Raphael, G. Determination of the elasticmoduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation. Mat. Des. 2016, 106, 436–445. [Google Scholar]

- He, Y.; Wang, S.C.; Walsh, F.C.; Chiu, Y.L.; Reed, P.A.S. Self-Lubricating Ni-P-MoS2 composite coatings. Surf. Coat. Technol. 2016, 307, 926–934. [Google Scholar] [CrossRef]

| Compositions | Experimental Conditions |

|---|---|

| Nickel sulfate | 250 g L−1 |

| Nickel chloride | 40 g L−1 |

| Boric acid | 40 g L−1 |

| Citric acid | 45 g L−1 |

| Sodium hypophosphite | 30 g L−1 |

| TiO2/Ti3C2Tx powders | 4 g L−1 |

| SDS | 1 g L−1 |

| pH | 3–4 |

| Current condition density | 2 A dm−2 |

| Time | 1 h |

| Temperature | 50 °C |

| Magnetic stirring speed | 600 rpm |

| Crystal Planes | Indices of Crystal Direction (%) |

|---|---|

| (111) | 47.17 |

| (200) | 32.39 |

| (220) | 20.44 |

| Sample | Rs (Ω·cm2) | Rct (Ω cm2) |

|---|---|---|

| Ni–P coating | 10.01 | 75.89 |

| Ni–P–TiO2/Ti3C2Tx coating | 13.08 | 87.69 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Zhang, X.; Wei, L.; Yu, B.; Ma, D.; Ye, S. Electrodeposition of a Ni–P–TiO2/Ti3C2Tx Coating with In Situ Grown Nanoparticles TiO2 on Ti3C2Tx Sheets. Coatings 2019, 9, 750. https://doi.org/10.3390/coatings9110750

Du Y, Zhang X, Wei L, Yu B, Ma D, Ye S. Electrodeposition of a Ni–P–TiO2/Ti3C2Tx Coating with In Situ Grown Nanoparticles TiO2 on Ti3C2Tx Sheets. Coatings. 2019; 9(11):750. https://doi.org/10.3390/coatings9110750

Chicago/Turabian StyleDu, Yingchao, Xiaomeng Zhang, Lianqi Wei, Bo Yu, Daqing Ma, and Shufeng Ye. 2019. "Electrodeposition of a Ni–P–TiO2/Ti3C2Tx Coating with In Situ Grown Nanoparticles TiO2 on Ti3C2Tx Sheets" Coatings 9, no. 11: 750. https://doi.org/10.3390/coatings9110750

APA StyleDu, Y., Zhang, X., Wei, L., Yu, B., Ma, D., & Ye, S. (2019). Electrodeposition of a Ni–P–TiO2/Ti3C2Tx Coating with In Situ Grown Nanoparticles TiO2 on Ti3C2Tx Sheets. Coatings, 9(11), 750. https://doi.org/10.3390/coatings9110750