3.1. CCA Composition Design

The composition of the CCA alloy employed in this work was designed according to theoretical calculations of solid solution formation parameter (Ω), entropy of mixing (Δ

Smix), enthalpy of mixing (Δ

Hmix), atomic size difference (δ) and valence electron concentration (VEC) [

10]:

where

n is the number of components,

i and

j refer to a specific component, c is the atomic fraction, T

m is the melting point of the alloy (defined by the mixing rule),

R is the ideal gas constant,

is the enthalpy of mixing of elements

i and

j,

r is atomic radius and

is the average radius of the alloy.

These thermodynamic parameters can be used in an attempt to predict the phases and crystal structure of a CCA. According to the criteria of phase stability formation calculated by Zhang et al. [

11], if Ω ≥ 1.1 and δ ≤ 6.6 then the solid solution forms. Takeuchi et al. [

12] studied the effects of changes in the mixing entropy, Δ

Smix, on the crystal structure formation. Their findings suggest that the high mixing entropy provided by CCAs could overcome the enthalpy of formation of strong intermetallic compounds, thereby suppressing their generation in favor of a random solid solution. Additionally, the VEC seems to play a decisive role in determining whether FCC or BCC crystal structure solid solution forms in CCAs. Specifically, a high VEC (≥8) favors the formation of FCC-type solid solutions, while a lower VEC (<6.87) favors the formation of BCC-type solid solutions, according to Guo et al. [

13].

In this work, the CCA composition was selected based on its likelihood to provide significant performance in terms of both tribological and corrosion resistance. For tribological performance (e.g., resistance to erosion), a mixture of FCC and BCC structures would be expected to provide adequate performance as the FCC phase is expected to present a ductile nature while the opposite holds for a BCC crystal structure [

14]. Resistance to corrosion is instead expected to be enhanced by elements such as Ni, Mo, and Cr, due to the formation of passive films on the alloys surface [

15]. Therefore, based on the above guidelines and following previous promising work on the CCA of the CoCrFeMo

xNi class as material for corrosion protection in corrosive geothermal steam [

16], this alloy class was selected for further analysis. After an iterative design study on several possible Mo

x concentrations, the CoCrFeMo

0.85Ni composition was identified as CCA for this study. The thermodynamic parameters in Equations (1) to (5) above, calculated for the CoCrFeMo

0.85Ni alloy, are reported in

Table 3. Calculations take into account only the component type and not the fabrication method, so the values are identical for both GA and MA powder.

3.2. Microstructure of Powders and Coatings

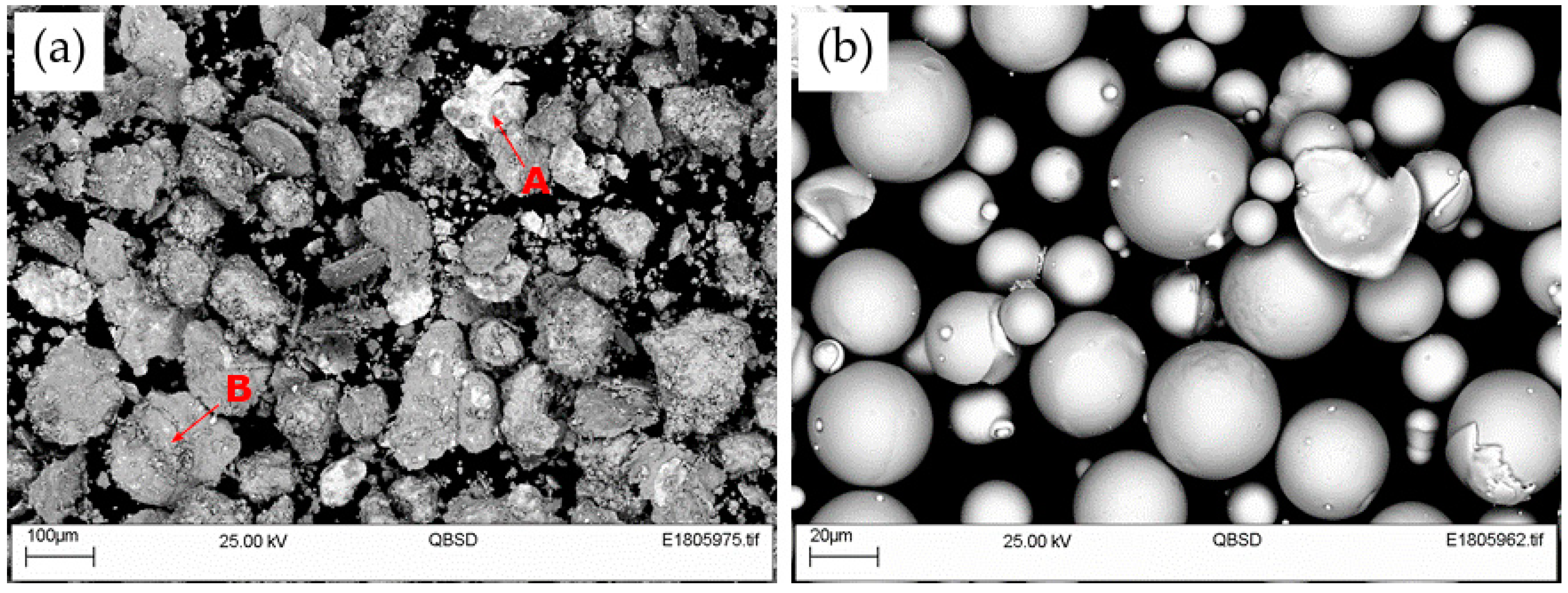

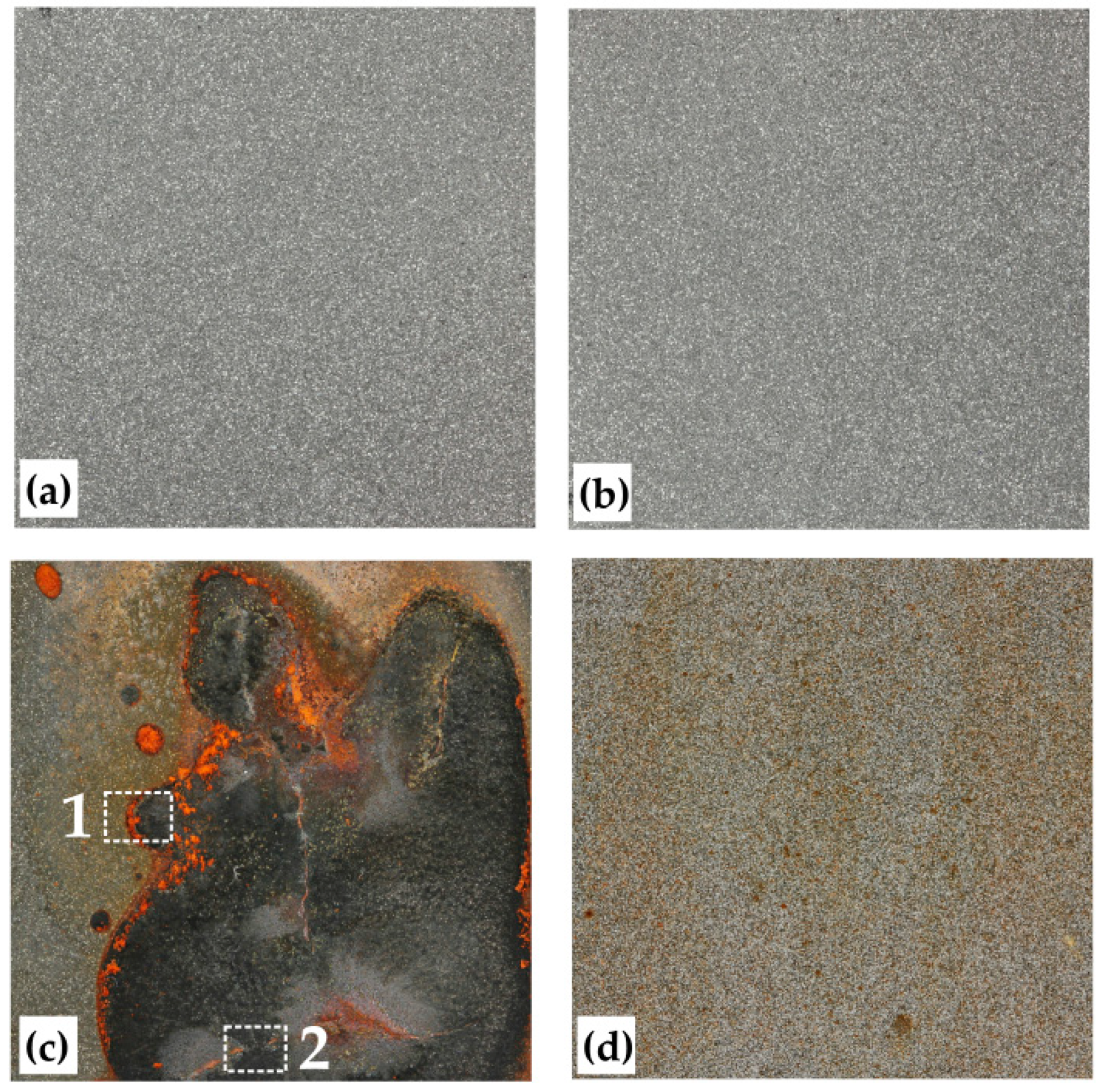

SEM micrographs of the MA and GA powders are reported in

Figure 1. As expected, two completely different morphologies are revealed in the two powders: an irregular shape, with particles of angular and blocky geometry (MA) and homogeneous spherical particles (GA).

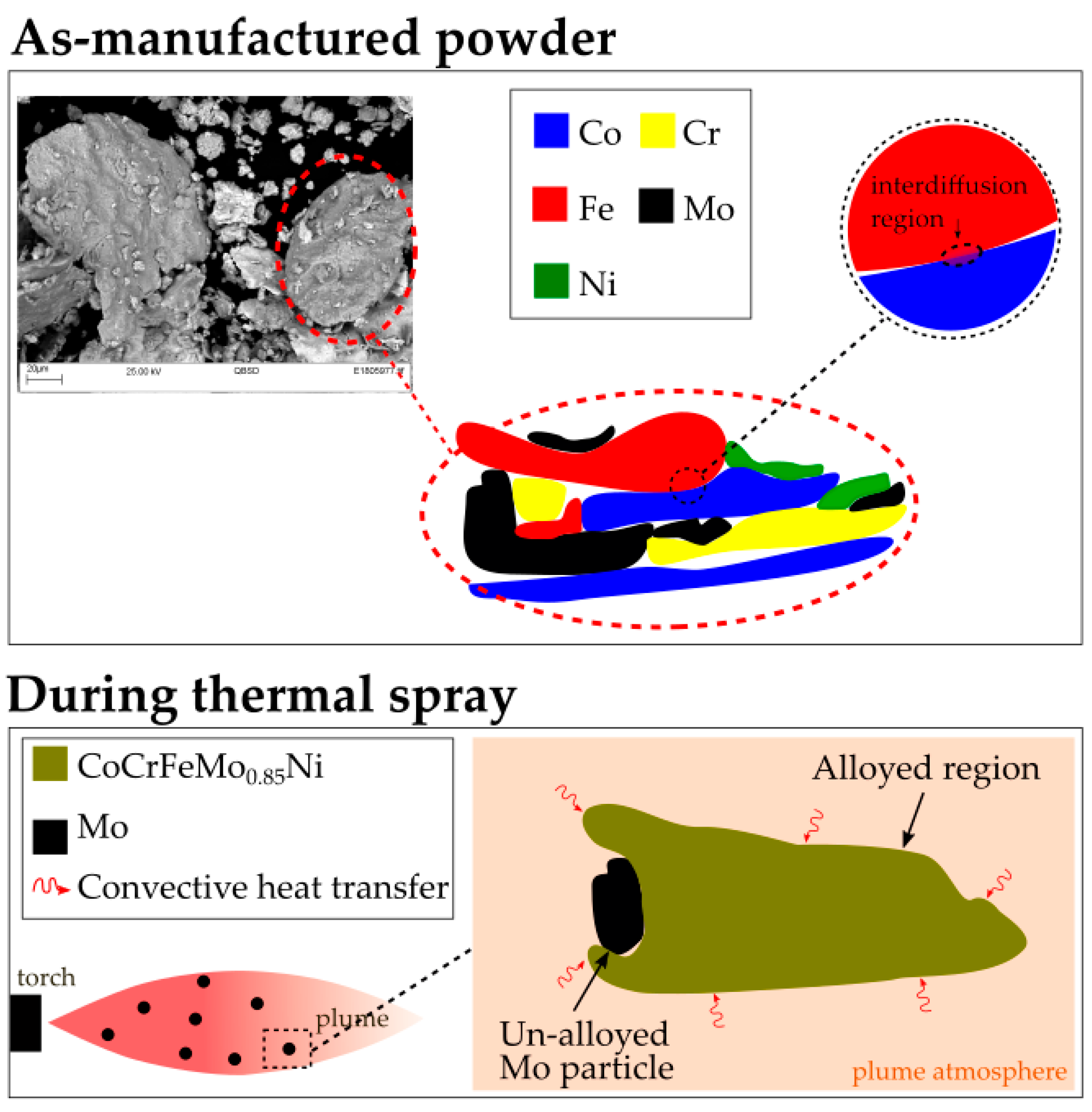

This morphological variation can be attributed to the differences in the mechanical and thermodynamic processes involved in the two manufacturing methods. Mechanical alloying (MA) uses mechanical impact which generates high localized pressure, to break and bond together particles of the elements to be alloyed. The gas atomisation method (GA) instead, relies on the in-flight solidification of particles directly atmoised from a melt of the alloy composition. The spherical geometry then naturally arises due to its lower Gibbs free energy over that of other possible geometries. Localised EDX analysis on the mechanically alloyed powder demonstrates that the bright regions (marked as A in

Figure 1a) are composed of Mo with only traces of the other CCA elements, Co, Cr, Fe and Ni. A variable composition is instead probed in other grey regions in the powder, such as region B, where no clear compositional pattern could be found. This compositional variation, which would suggest incomplete alloying, was somewhat expected at the short total alloying time employed in this study, 210 min, selected in an attempt to provide a final powder size distribution processable by means of HVOF. It is therefore likely that a composition close to the CCA could be achieved at further mechanical alloying processing time, however with a corresponding reduction in particles’ nominal size distribution. Bulk EDX patterns for both powders show similar elemental distribution, although a reduced concentration of Mo is measured in the gas atomised powder, likely due to the differences in vapour pressure between the elements during the melting and solidification of this latter process. EDX analysis performed on the GA powder did not reveal any localised area of a composition different from the theoretical CCA. XRD spectra for the two powders are presented in

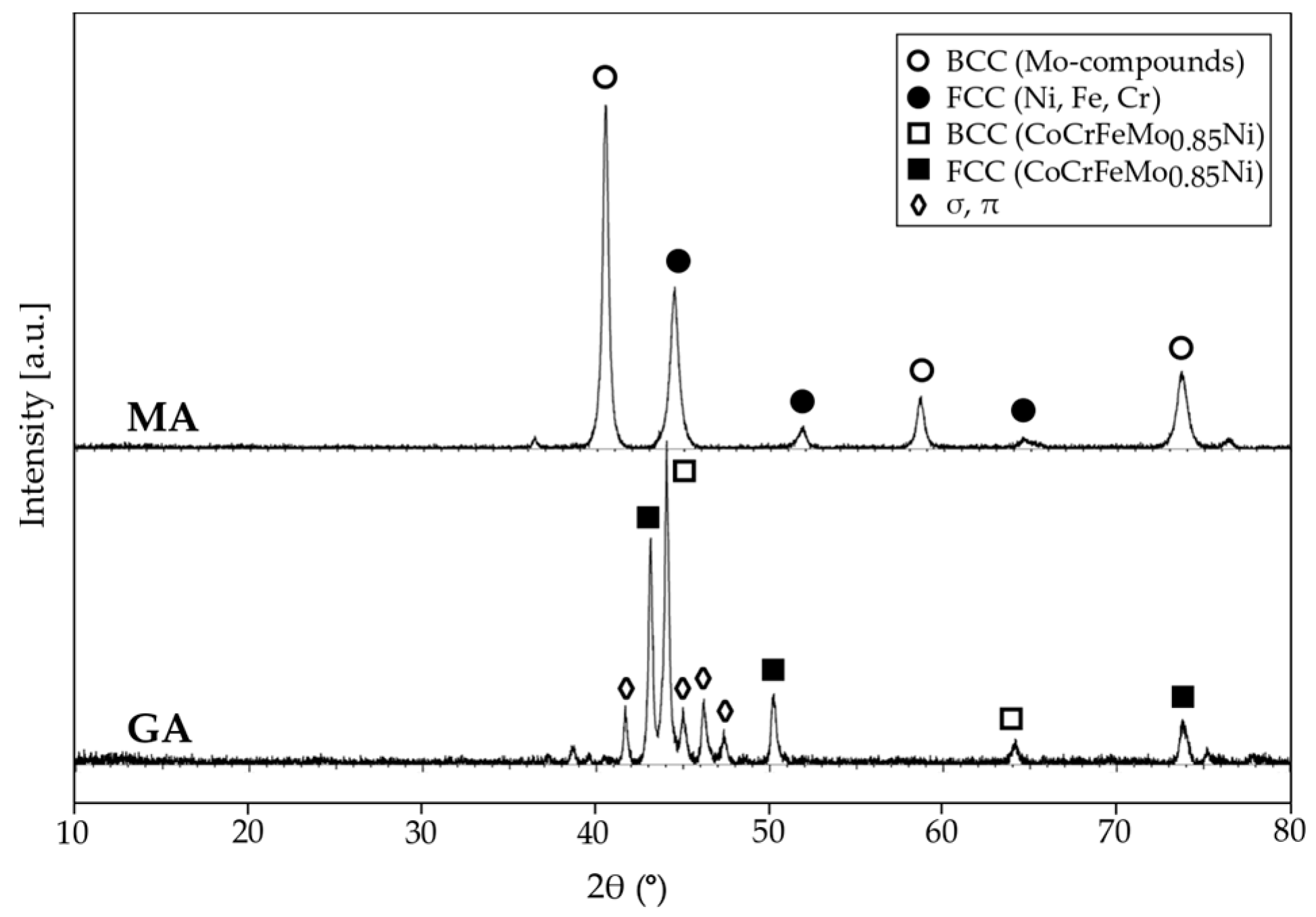

Figure 2.

The scans revealed a clear distinction between the phases identified in the two powders. The MA powder showed peaks characteristic of the single elements composing the CCA (i.e., Ni, Cr, Fe FCC and Mo BCC), thus suggesting incomplete alloying as previously suggested by EDX analysis. The elemental peaks did not appear to be present in the GA powder, where instead new peaks corresponding to the FCC and BCC phases of the CoCrFeMo

0.85Ni composition appeared, thus suggesting the attainment of solid solution. The fact that the measured 2θ location for these peaks corresponds to the same angles was also identified by Shun et al. [

17] on the same alloy composition. Moreover, as in [

17], peaks corresponding to the intermetallic σ and π phases were also measured. It is likely that the FCC phase was stabilized and rich in elements showing a stable FCC structure (Co, Fe and Ni), while the BCC and the small amount of σ phase could be stabilized by Mo.

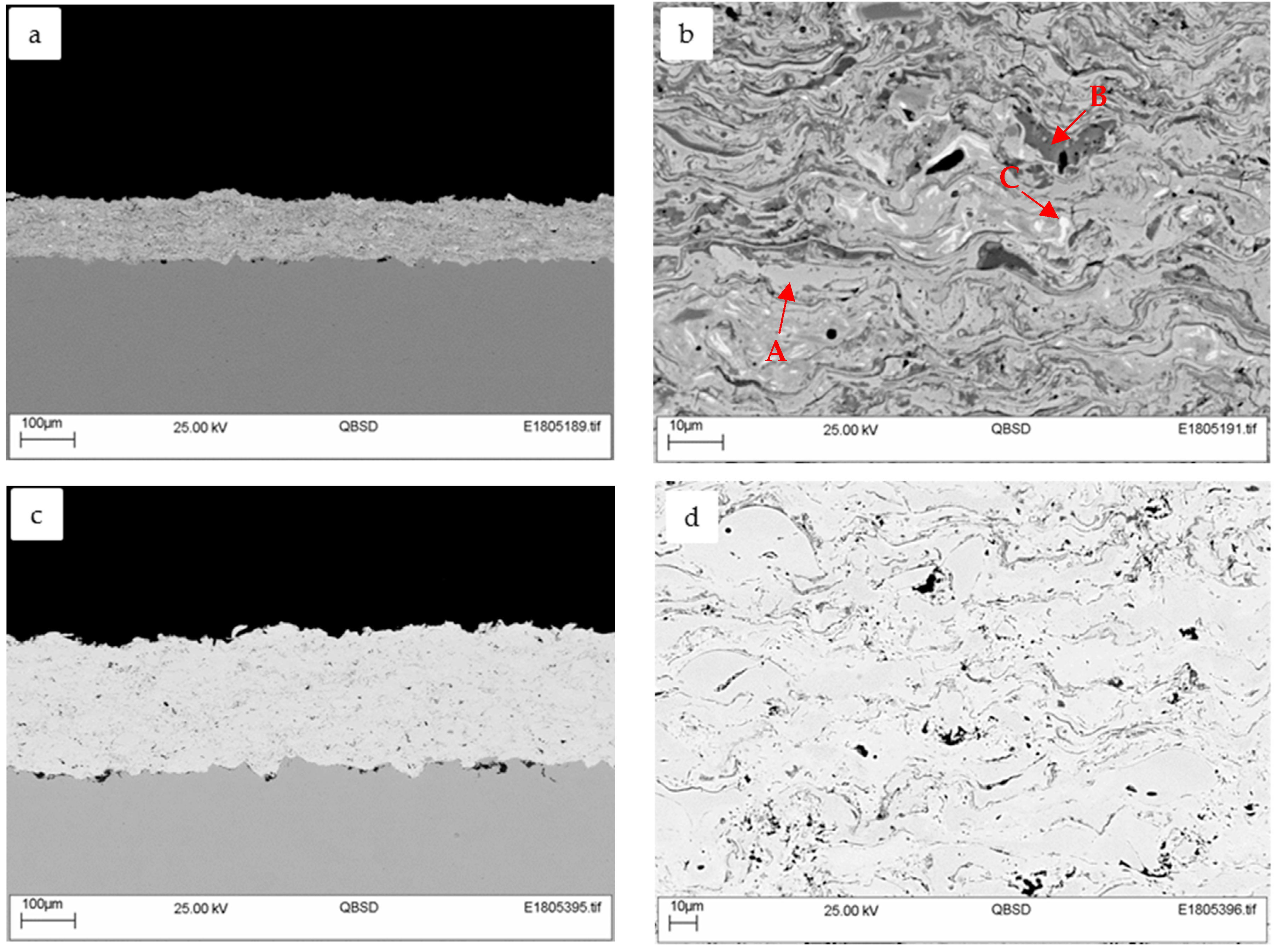

The microstructure of the resulting MA and GA coatings, obtained from HVOF deposition of the powders in

Figure 1, is reported in

Figure 3. Average thicknesses for the two coatings have been measured as ~130 and ~250 μm for MA and GA respectively.

The cross-sections show some interesting features. There seems to be a clear difference in terms of phase distribution in the two coatings. While the GA system showed a homogeneous distribution of what appeared to be a single phase, splats of different composition were observed in the MA system. An EDX analysis of the regions of differing contrast within the MA coating (

Figure 3b) showed that the light grey matrix (labelled as A in

Figure 3b) exhibited peaks for all of the CCA components and is thus likely to represent the FCC (or BCC) structure characteristic of the CoCrFeMo

0.85Ni composition. The darker grey area (labelled as B in

Figure 3b), exhibited similar peaks, but indicated a lower concentration of the element Mo compared with region A. Mo was also the main element composing the lightest region (labelled C in

Figure 3b), which would suggest the presence of powder particles of elemental Mo within the initial powder. Due to the extremely high solidification rates experienced during HVOF deposition, it is unlikely that these Mo-rich regions could be formed by elemental segregation during solidification.

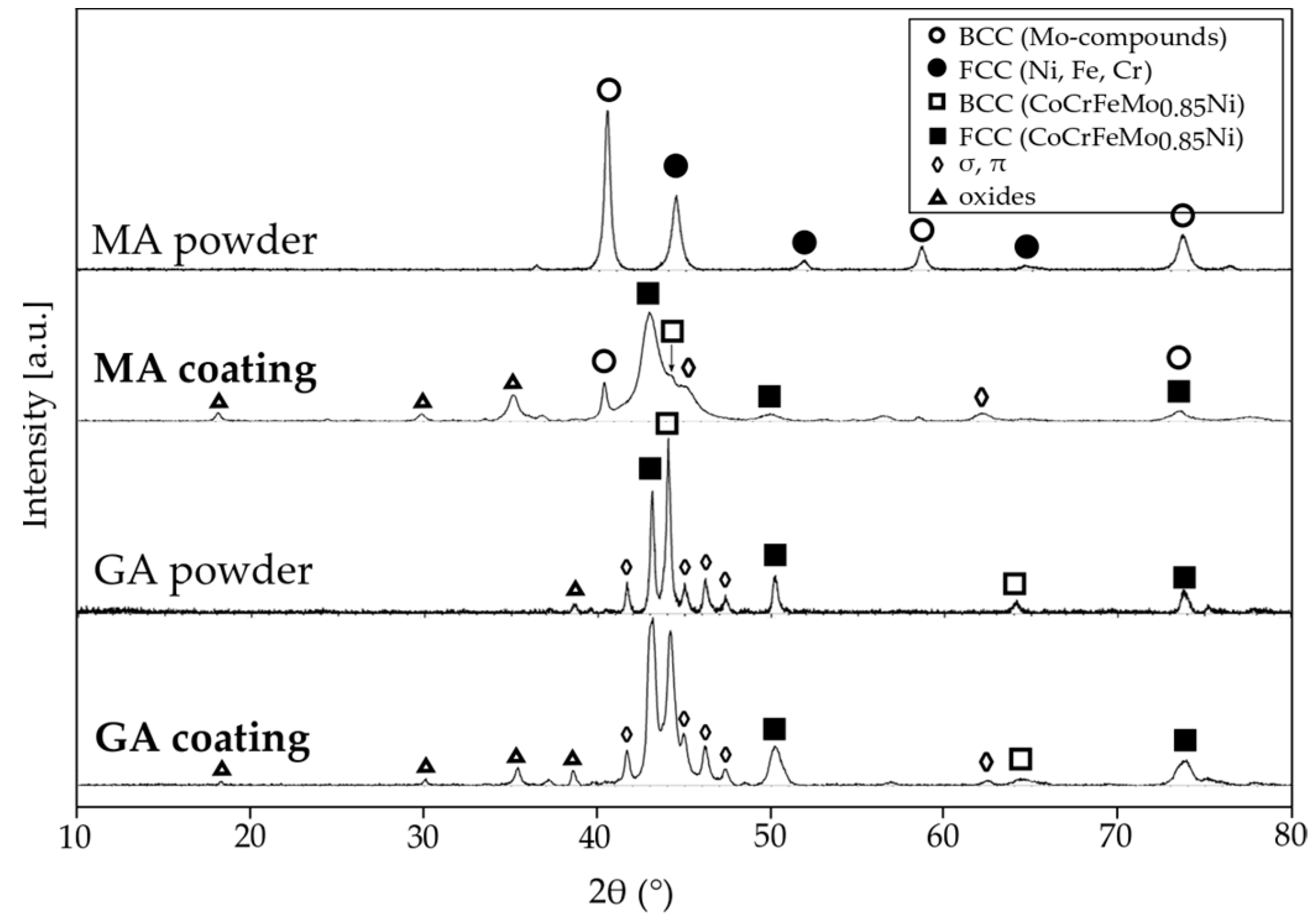

In order to further investigate the nature of the phases observed, XRD analysis was performed on the two coatings, as reported in

Figure 4.

The phases present in the MA coating are a mixture of FCC and BCC phases characteristic of the CCA composition, together with some residual BCC linked to the Mo component and newly developed σ/μ phases. This suggests that alloying occurred in-flight during the thermal spray operation. The coating procedure, with exposure of the powder at very high temperature followed by rapid cooling, promoted the appearance of a small amount of BCC phase stabilized by the FeCr pair. The same phenomenon was observed in the CoCrFeMoNi high entropy alloy processed by using vacuum arc remelting and the BCC phase was present in the structure due to the rapid cooling process [

18]. The coating also shows the appearance of oxide phases, naturally generated within the oxidising atmosphere of the thermal spray process. Conversely, similar phases were observed in both GA coating and powder, suggesting that limited modifications occurred in-flight, during the thermal spray operation. The only difference between the GA coating and powder was the appearance of oxide peaks, as expected from the thermal spray operation.

3.3. Electrochemical Corrosion Testing

Photographs of the surfaces of the coated specimens are presented in

Figure 5 for both MA and GA before and after exposure to the corrosion environment.

While the appearance of the as-deposited coatings was comparable between the two coatings (

Figure 5a,b), the condition post exposure showed significant differences. In the MA coating, corrosion products and cracks were observed, while no cracking was visible in the GA system. However, the presence of localised discoloured spots was visible in the GA system. In the case of MA system, it is proposed that permeation of the corrosive solution through the coating has occurred. The permeation of the solution would have led to corrosion of the underlying carbon steel substrate, thereby generating corrosion products. The likely corrosion products for carbon steel would be mixtures of compounds of the steel constituents, which have a Pilling–Bedworth (P–B) ratio >1.5. Pilling–Bedworth ratio is the ratio of the volume of the metal oxide formed from a volume of the corresponding metal (from which the oxide is created). The high P–B ratio indicates that the growth of the corrosion product under the coating would lead to tensile stresses on the top surface of the coating which might crack once the stresses reach a critical level. A more in-depth analysis (SEM-EDX) of regions 1 and 2 in

Figure 5c is presented in

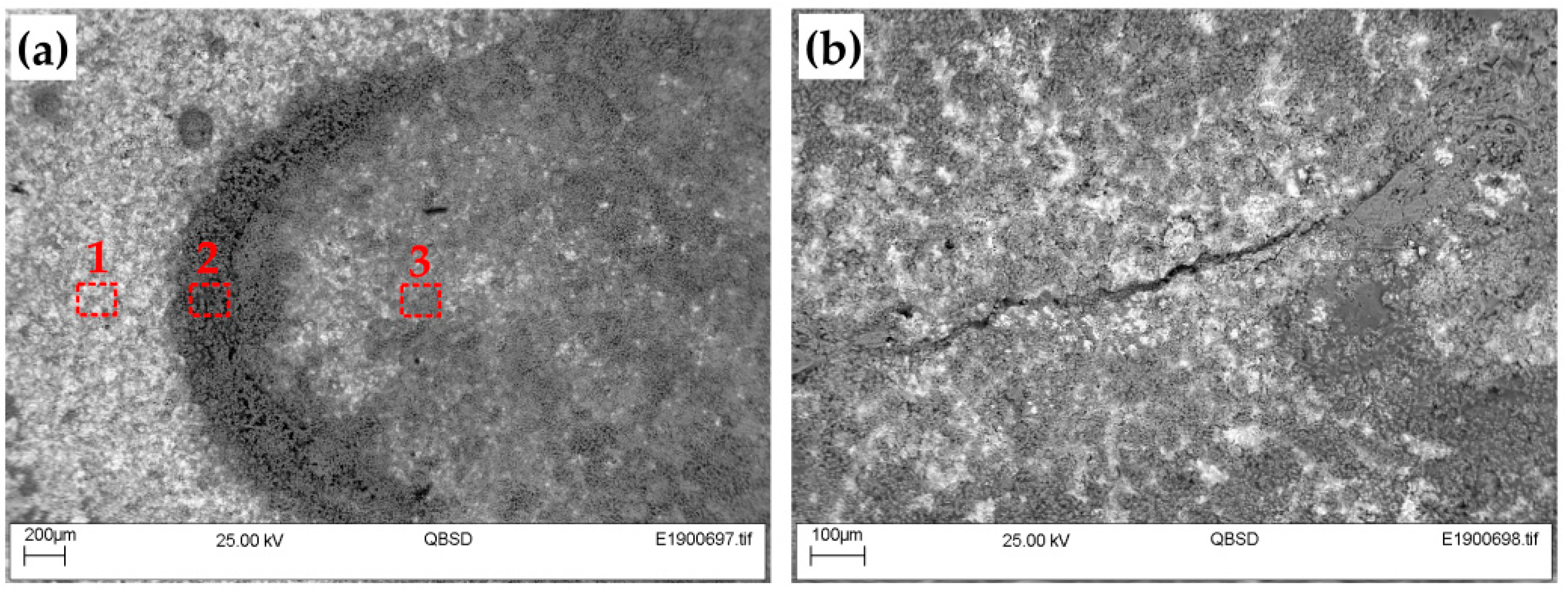

Figure 6a,b respectively.

Figure 6a shows regions of different appearance, corresponding to various corrosion products. An EDX analysis of the three highlighted regions shows the lighter region on the left-hand side of the figure (region 1) containing primarily the constituents of the CCA (i.e., Co, Cr, Fe, Ni and Mo), with Fe having the highest concentration, together with elements O, Cl and Na. The presence of Cl and Na were likely due to the adhering salt solution on the rough coating surface. The darker region 2 is largely dominated by the element Fe, with the additional presence of Cl and O and some traces of the elements of the CCA. Finally, region 3 exhibited peaks comparable to region 2, but with a higher concentration in CCA elements, likely due to a reduced thickness of the oxide layer in the former region.

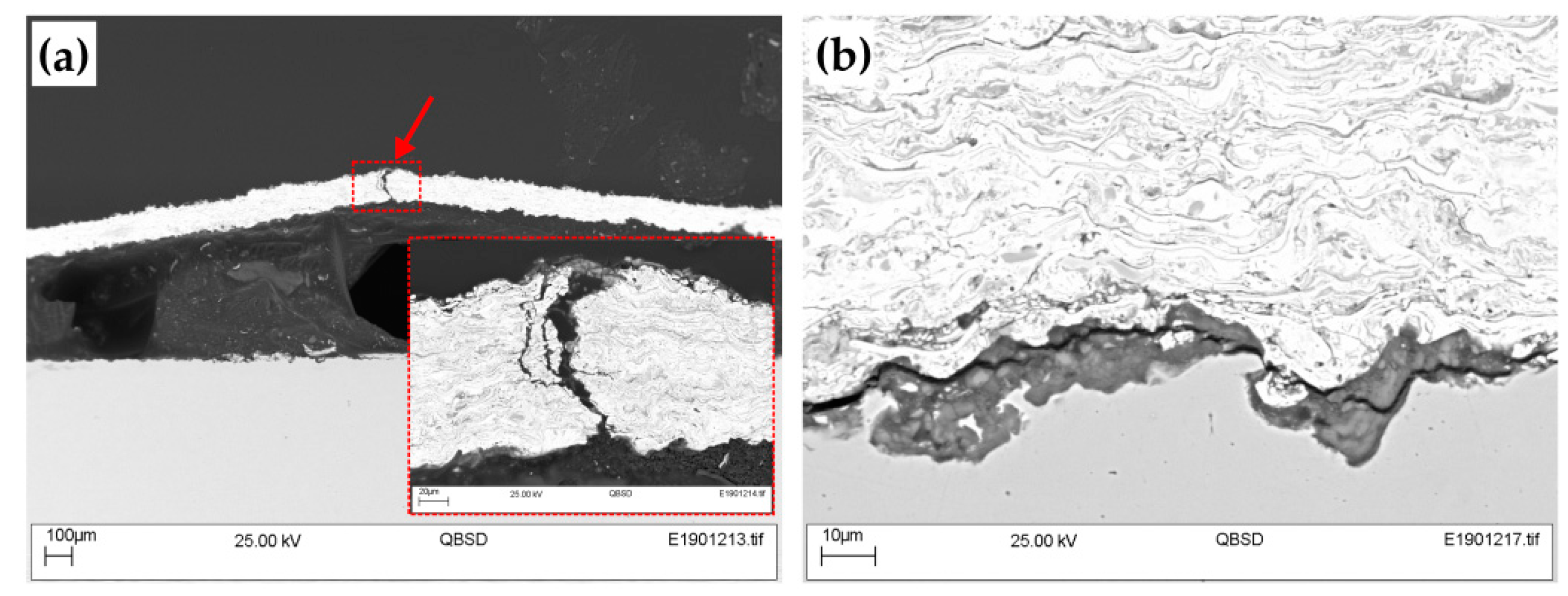

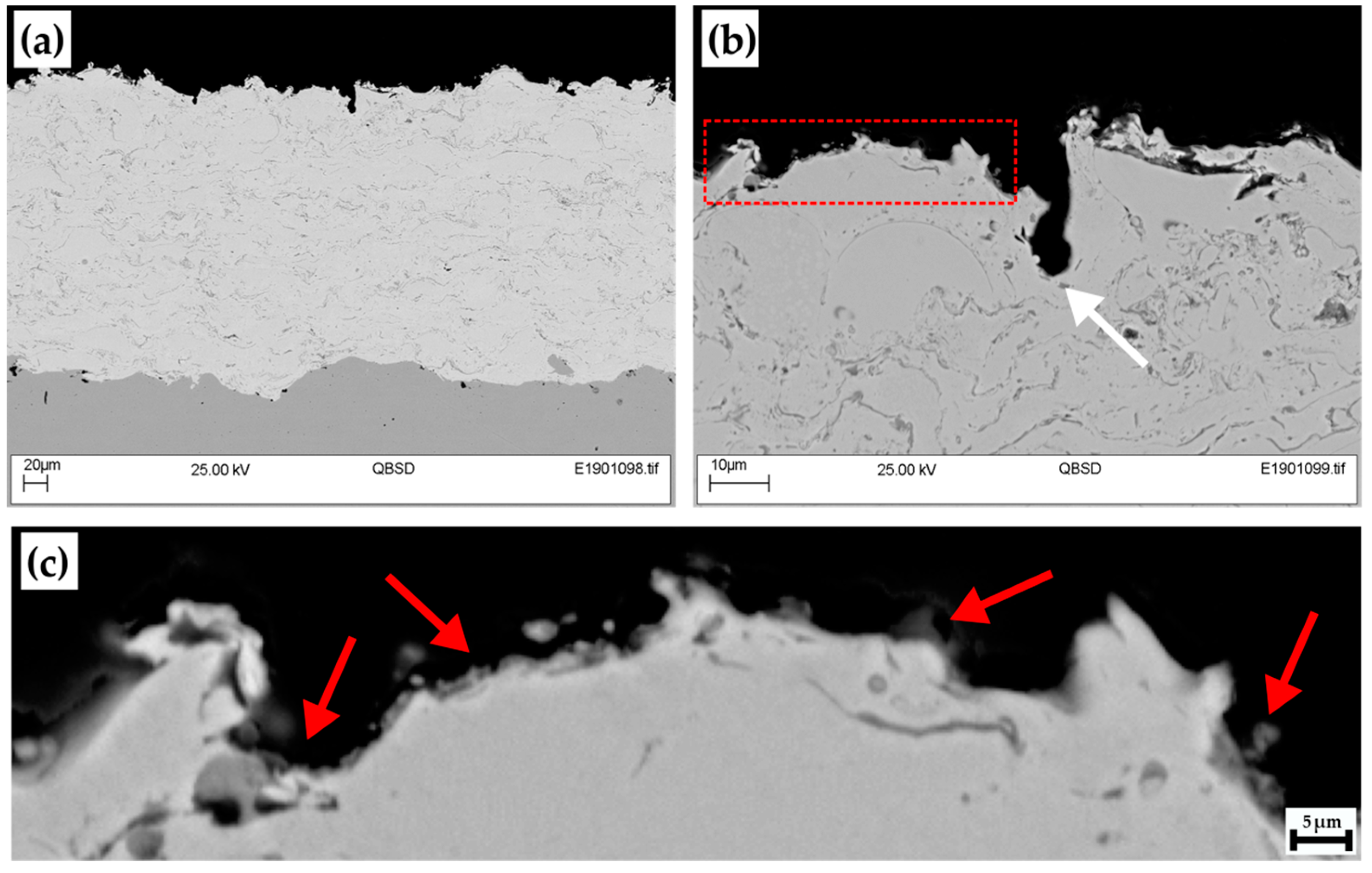

Two types of cracks can be identified in the corroded MA specimen, as is clear from the cross-section micrographs in

Figure 7.

Figure 7a shows a vertical crack within the coating at a location of coating detachment. This type of crack is likely generated by mechanical stresses created by the growth of corrosion product at the substrate/coating interface. The substrate/coating delamination is linked to the low toughness of the corrosion product generated at the substrate/coating interface, as depicted by the SEM micrograph in

Figure 7b, which shows the location of crack initiation. The effect of stress-induced coating cracking from growth of corrosion products has already been observed [

19].

In the case of the GA coating (

Figure 5d), although localised darker areas were observed, the discolored appearance suggests that corrosion products have started to form, even if not covering the entire surface. An in-depth SEM-EDX analysis of the coating surface is presented in

Figure 8.

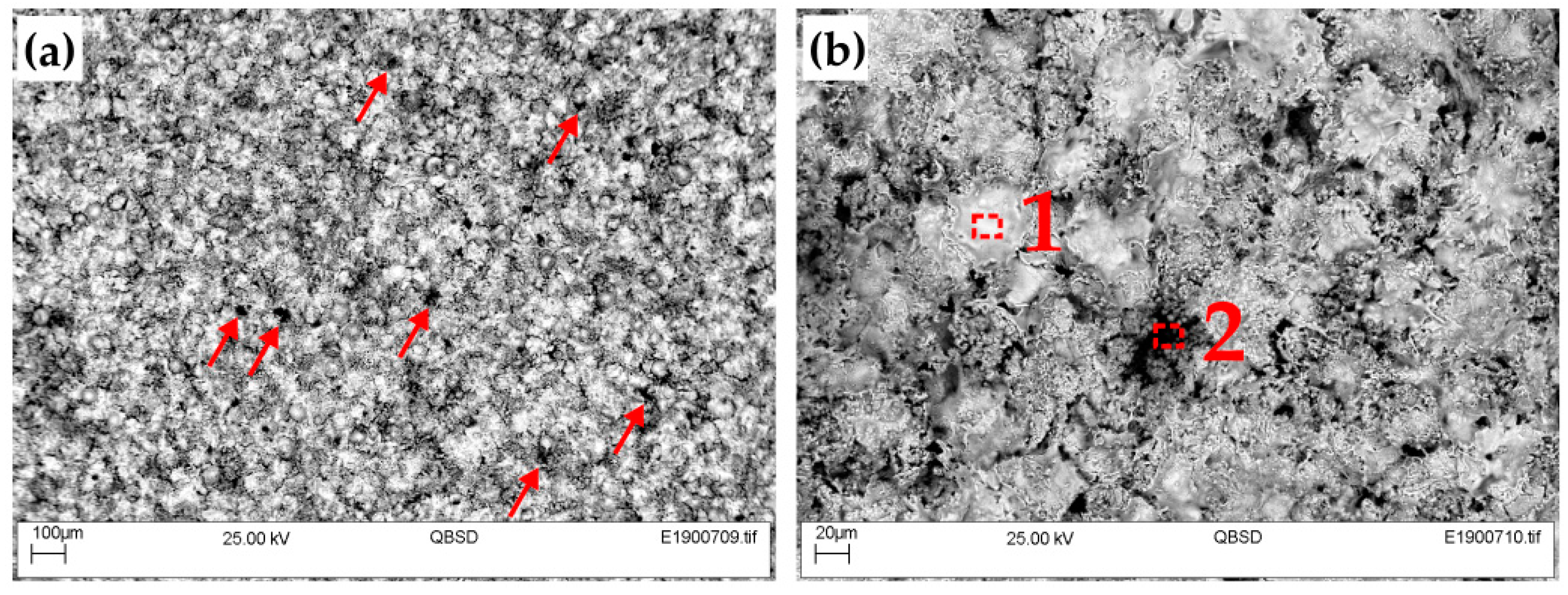

The low-magnification micrograph,

Figure 8a, shows the presence of darker areas on the coating surface (highlighted by red arrow in the figure), representing a combination of initial surface porosity and localised areas of corrosion (as also seen in

Figure 5d). EDX analysis performed at high-magnification (

Figure 8b), showed that the lighter particles (region 1), of flat splat-like morphology, contain the CCA elements in the theoretical stoichiometry, while Fe has the highest concentration amongst the other CCA elements in the dark areas (region 2). This would suggest that corrosion was occurring preferentially in those regions. An in-depth analysis of this effect is provided by an SEM-EDX analysis of the specimen cross-section (

Figure 9).

The low-magnification micrograph (

Figure 9a) showed no evidence of through-coating permeation, while higher magnification micrographs (

Figure 9b,c) showed evidence of corrosion products. These corrosion products could not be uniquely identified by using XRD or EDX analysis due to their small dimensions. It is worth noting the feature identified by a white arrow in

Figure 9b, where the shape observed is unlikely to be representative of an as-deposited coating, due to the tall vertical wall observed at the right side. This, together with analysis of current density data showing several peaks, suggests that pitting occurred in the specimen at such locations. Areas on the bottom of features in rough specimens generate localized areas of higher Cl

− concentration, therefore locally increasing the dissolution kinetics of the metal. It is suggested that in this sample, the passive film naturally generated on the surface breaks down at localized areas of higher roughness. If the local breakdown region is then re-passivated, and if the solution is agitated so as to take away loosely bound corrosion products from the surface, it is possible that a continuous depassivation/re-passivation cycle is repeated. This may explain the absence of corrosion product on the bottom of the identified feature.

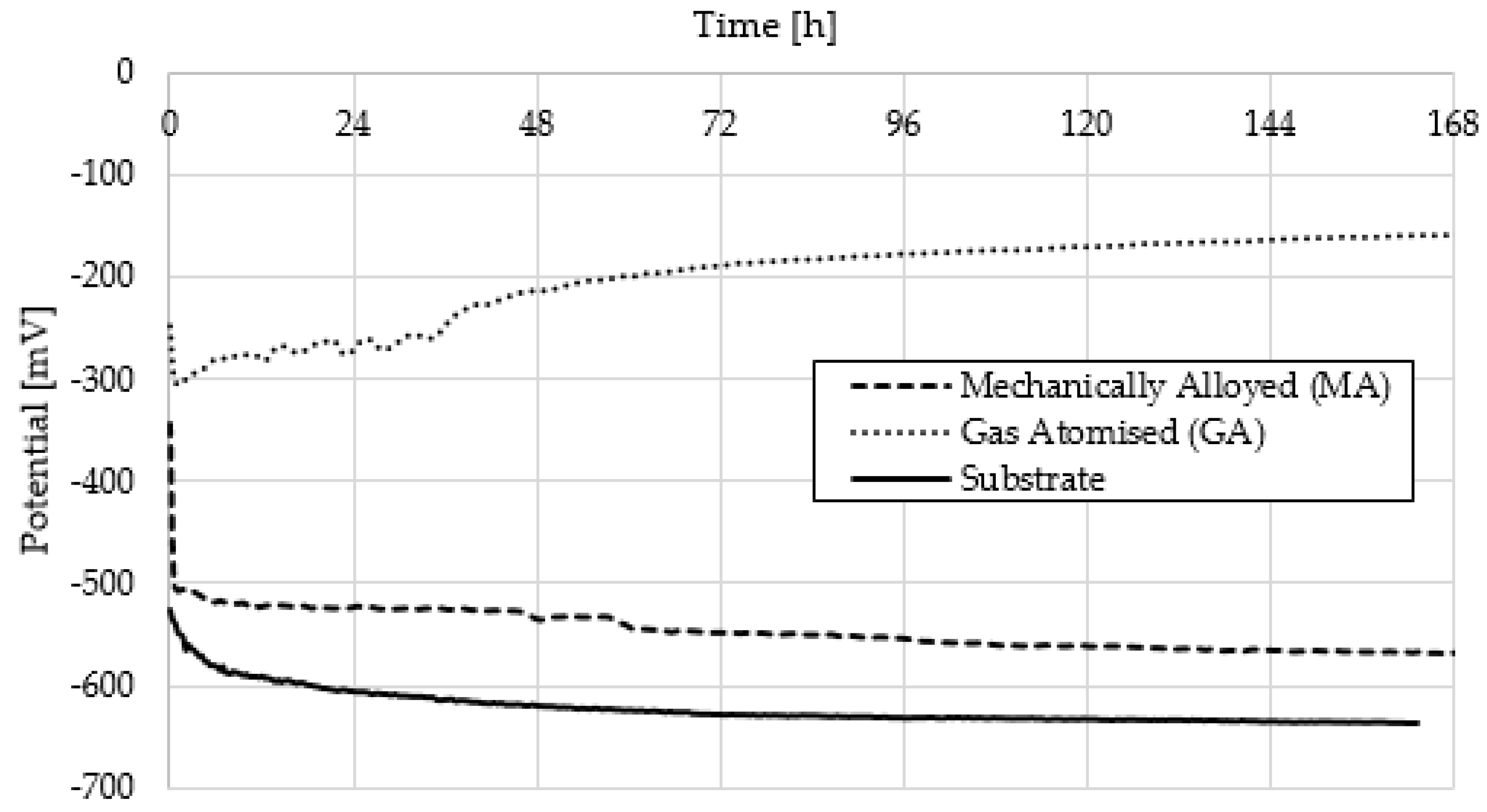

Finally, an understanding of the corrosion mechanism can be appreciated also by analysing the corrosion potential over time for the two specimens as well as the substrate alone (

Figure 10). The two coatings show different behaviours. The corrosion potential of the MA coating showed a decreasing trend throughout the test, which approached asymptotically the corrosion potential of the substrate. This would confirm that the corrosive solution had reached the interface between coating and substrate, causing the latter to preferentially corrode. The potential gap between MA coating and substrate is given by the fact that it is likely that not only is the substrate corroding but a mixture between coating and substrate. The gas atomized coating (GA), conversely, showed a corrosion potential of increasing trend and of much higher magnitude compared with the GA coating and substrate. This increasing trend could be justified either by the formation and growth of a passive film on the coating surface or closing of open porosity (naturally present within the as-deposited coating) or a combination of the two. This possible phenomenon needs to be further verified by further testing.

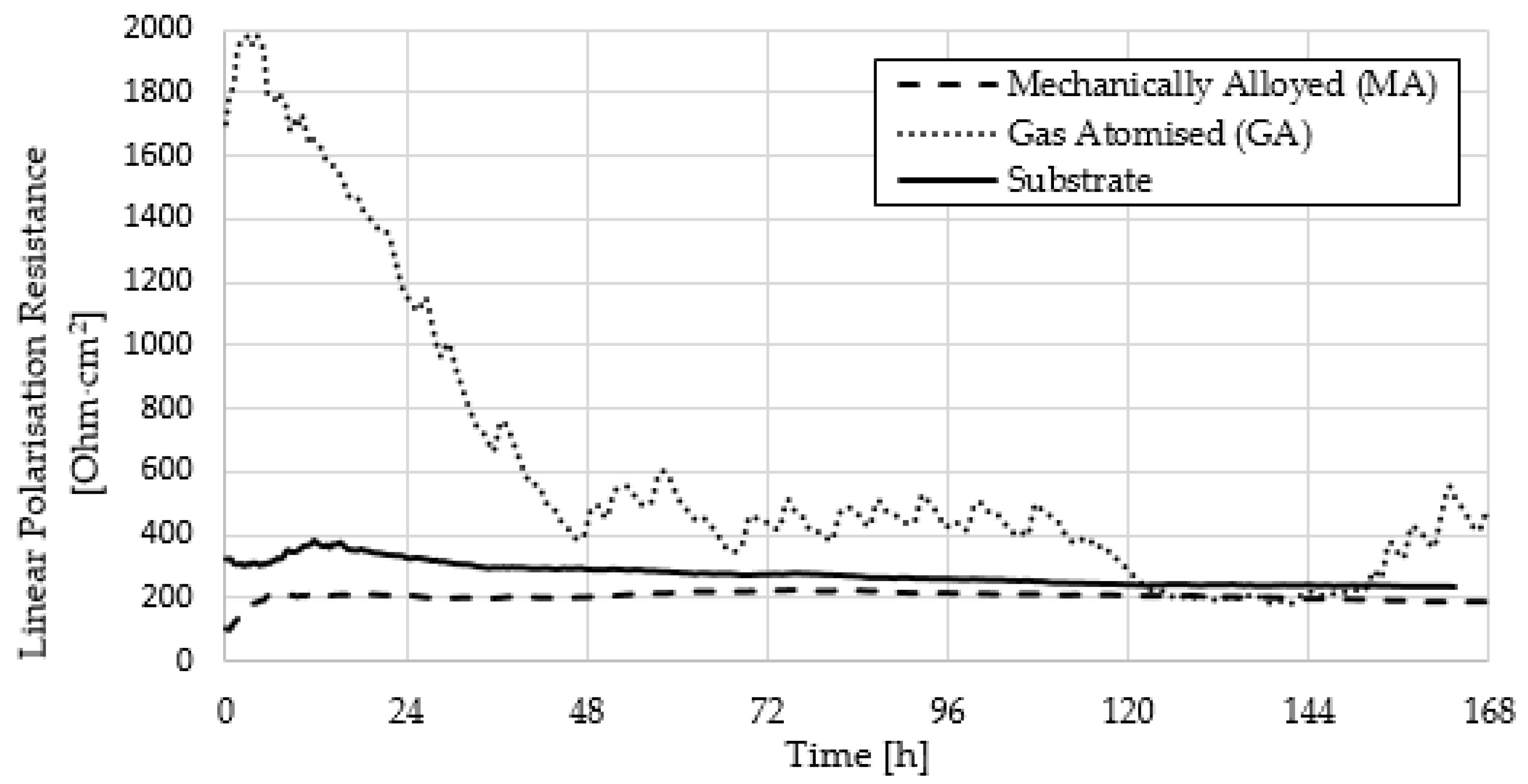

Further insights can be provided by analyzing the linear polarization resistance (LPR) curves of the systems tested (

Figure 11).

The values measured for the MA and substrate systems exhibit a rather constant behavior throughout the exposure, suggesting that uniform corrosion is occurring. The low absolute LPR values measured for these two systems show that little resistance to the corrosive environment at the conditions employed. A different behavior is observed in the GA system, with an initially higher LPR followed by a decreasing trend with exposure time. This trend suggests the initial generation of a passive film onto the coating surface, followed by breakdown as exposure progresses. The local spikes observed in the curve of the GA system suggests local passive film formation/breakdown, which could be corresponding to the events observed at the areas of higher localised roughness (see

Figure 9). The nature and formation mechanism of passive film onto Cr

− and Mo-containing alloys has received considerable interest during the years. For instance, Duarte et al. [

15] have evaluated the passivation scheme for amorphous and nanocrystalline Fe

50Cr

15Mo

14C1

5B

6 stainless-type glass-forming alloy. According to the study, although the crystallinity and nature of the corrosive environment have a great effect on the nature of the passive film, in general the Fe element is observed to corrode first, followed by a surface enrichment in Cr due to the passive film generation. The growth and/or breakdown of the passive film is then a complex phenomenon, driven by the specific alloy composition due to the formation of Cr-depleted and Mo-rich regions within the material. Although this cannot be conclusively proven by this work, it is likely that the more homogeneous nature of the phases present within the GA-type coating could lead to the consistent formation of a Cr-rich passive layer on the exposed splats’ surface, with local breakdowns only linked to the rough nature of the surface, generating localized areas of high ions concentration. Conversely, it is likely that the inhomogeneous nature of the MA coating, with splats of single elements composition, leads to the quick preferential corrosion of Fe-rich regions already within the initial stages of exposure, thus irreversibly damaging the coating structure and generating preferential paths for corrosive medium permeation. In this case, the rapid corrosion kinetics of the Fe-rich phases highly overcomes the possible formation of passive films on other areas of the coating. It is worth noting that open porosity was present in both as-deposited MA and GA coating systems at comparable levels (see

Figure 3). The fact that permeation was observed only within specimen MA, and the fact that multiple phases (as opposed to the solid solution of specimen GA) are present within this coating, would suggest that galvanic effects between phases have a major effect in generating preferential corrosion paths.

Finally, it is worth noting that the LPR approach employed for corrosion evaluation, only acts as a preliminary approach to corrosion evaluation. Additional electrochemical tests are currently being undertaken on freestanding coatings to understand the fundamental passivation/depassivation mechanisms which determine the corrosion behaviour of the studied systems.