Surface Texture Evolution of Fused Silica in a Combined Process of Atmospheric Pressure Plasma Processing and Bonnet Polishing

Abstract

1. Introduction

2. Combined Process and Experimental Details

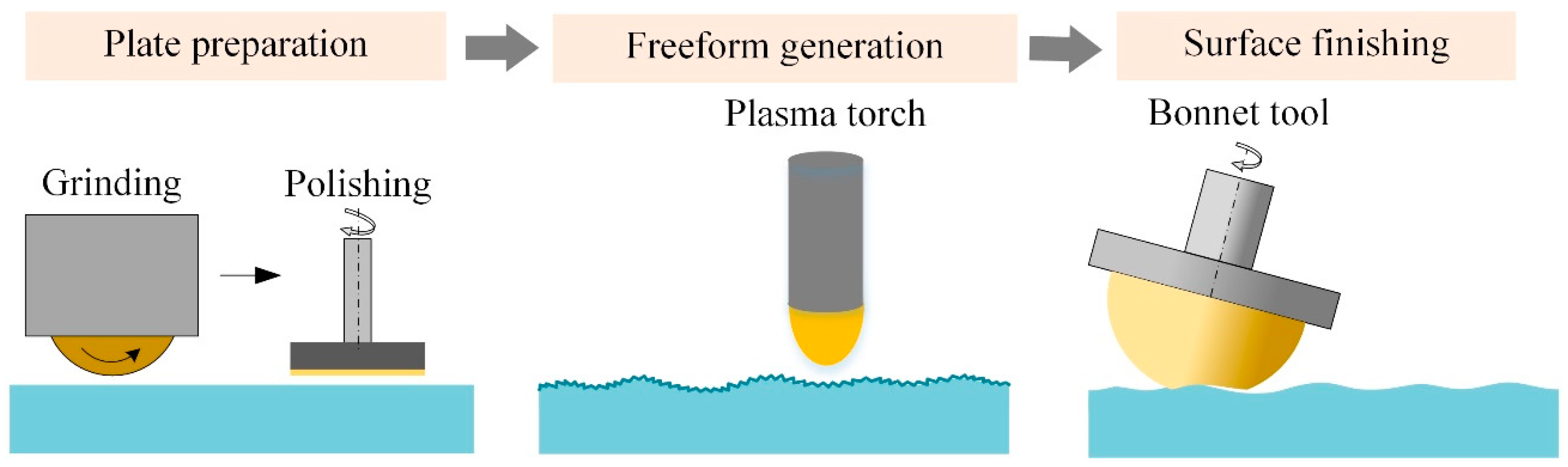

2.1. Combination of APPP and BP

2.2. Preparation of Sample Substrates

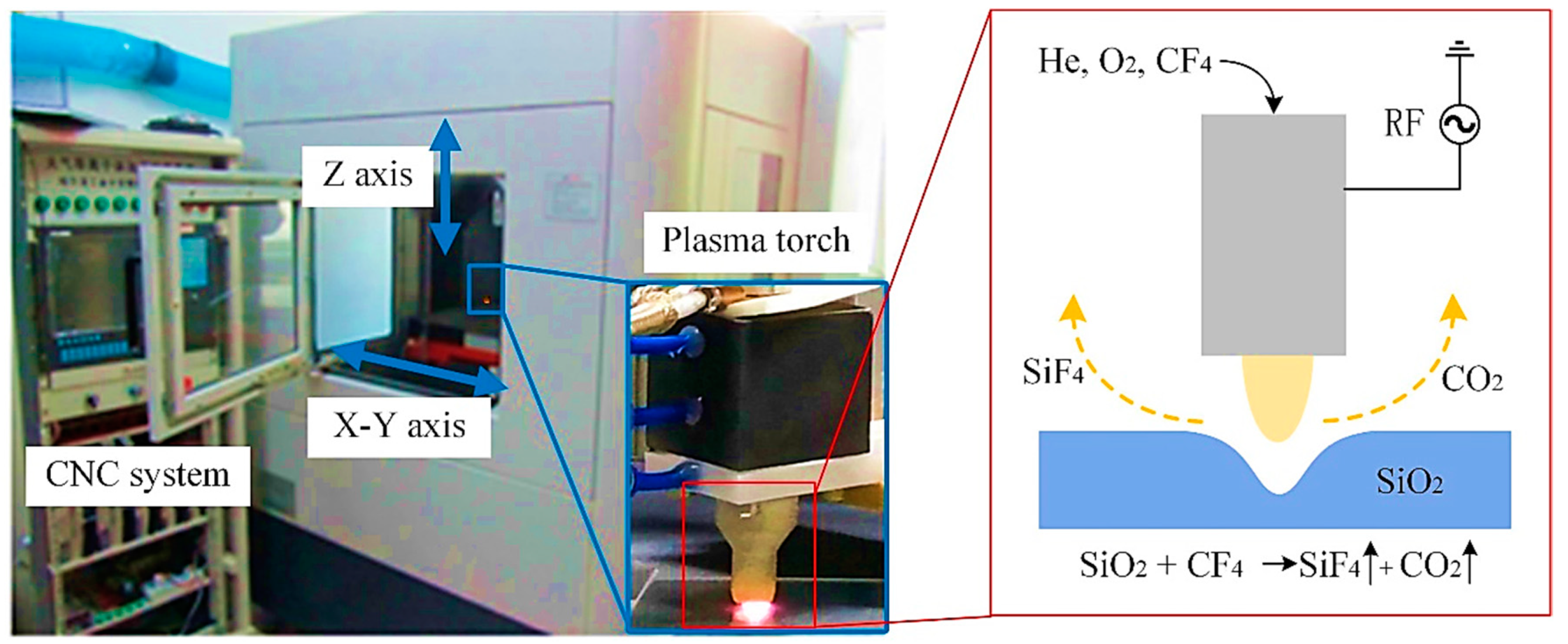

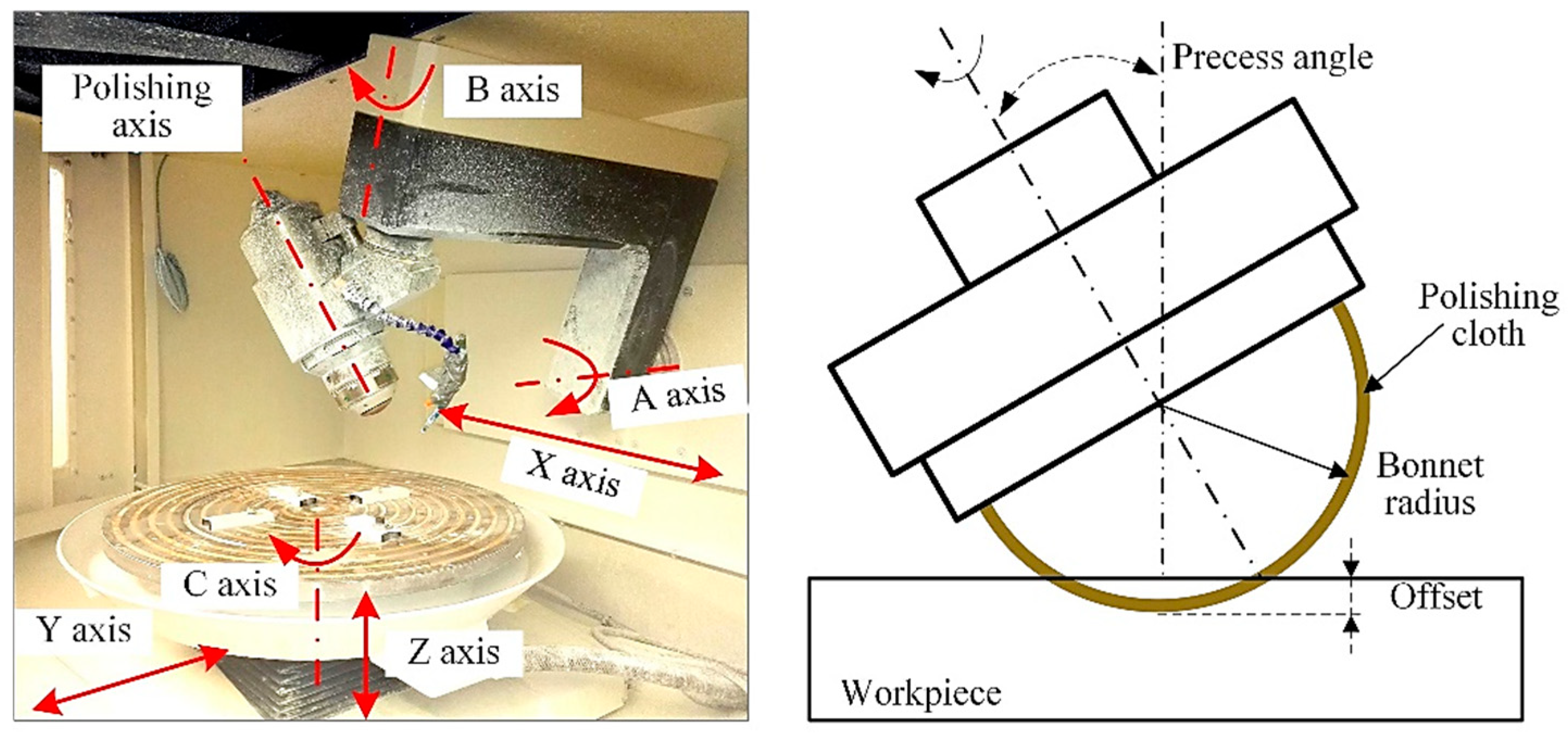

2.3. Experimental Setup

3. Results

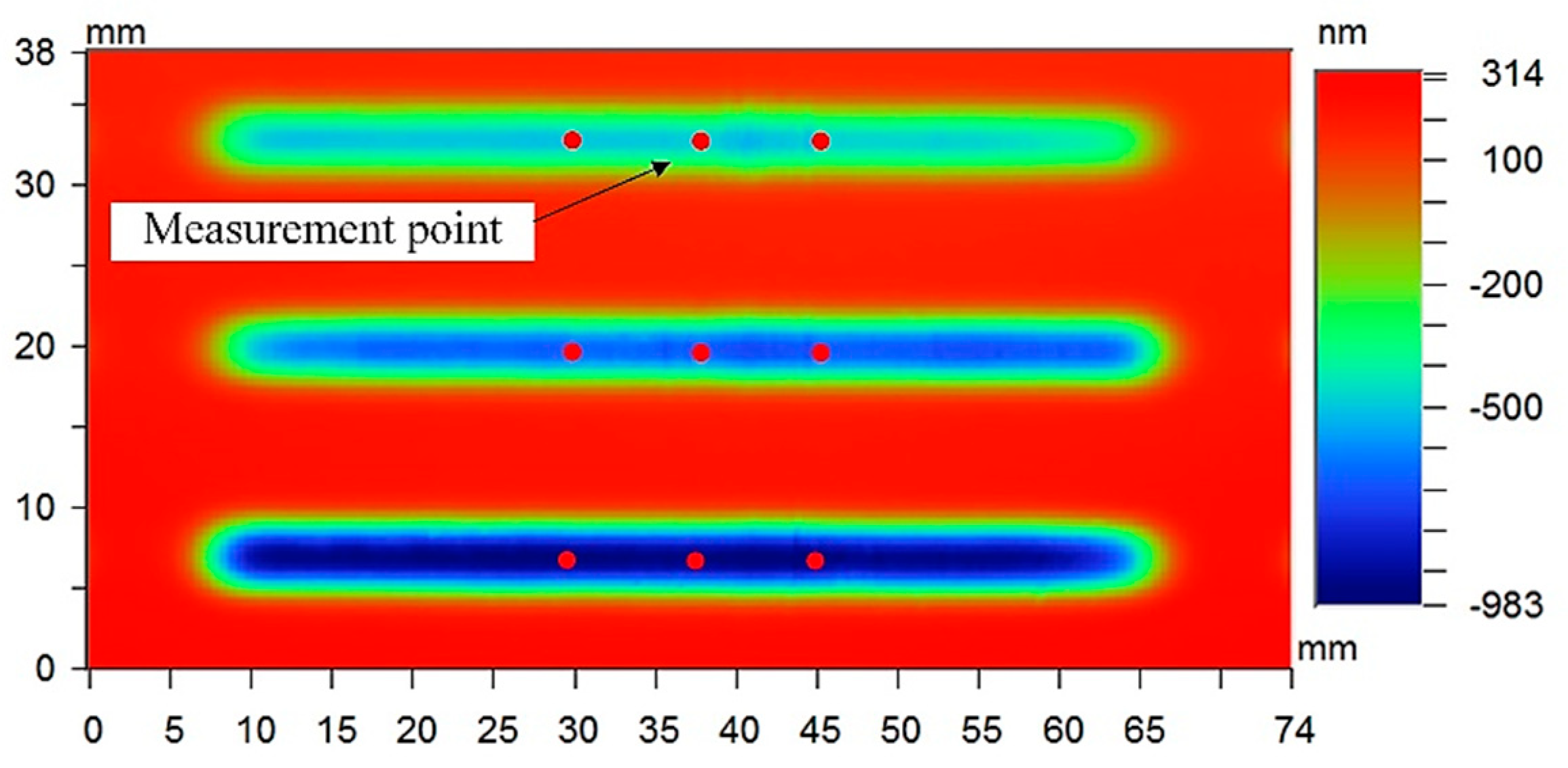

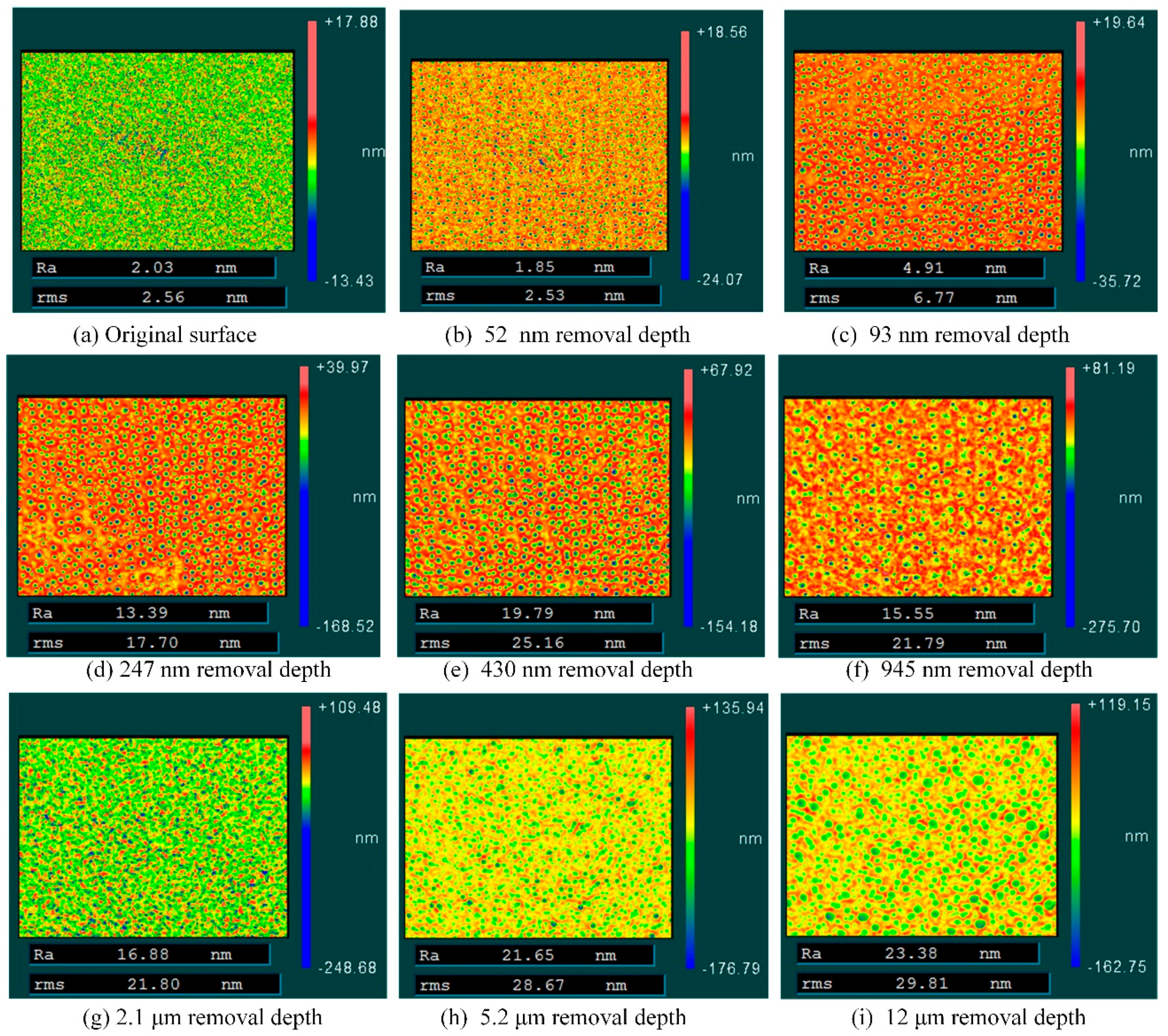

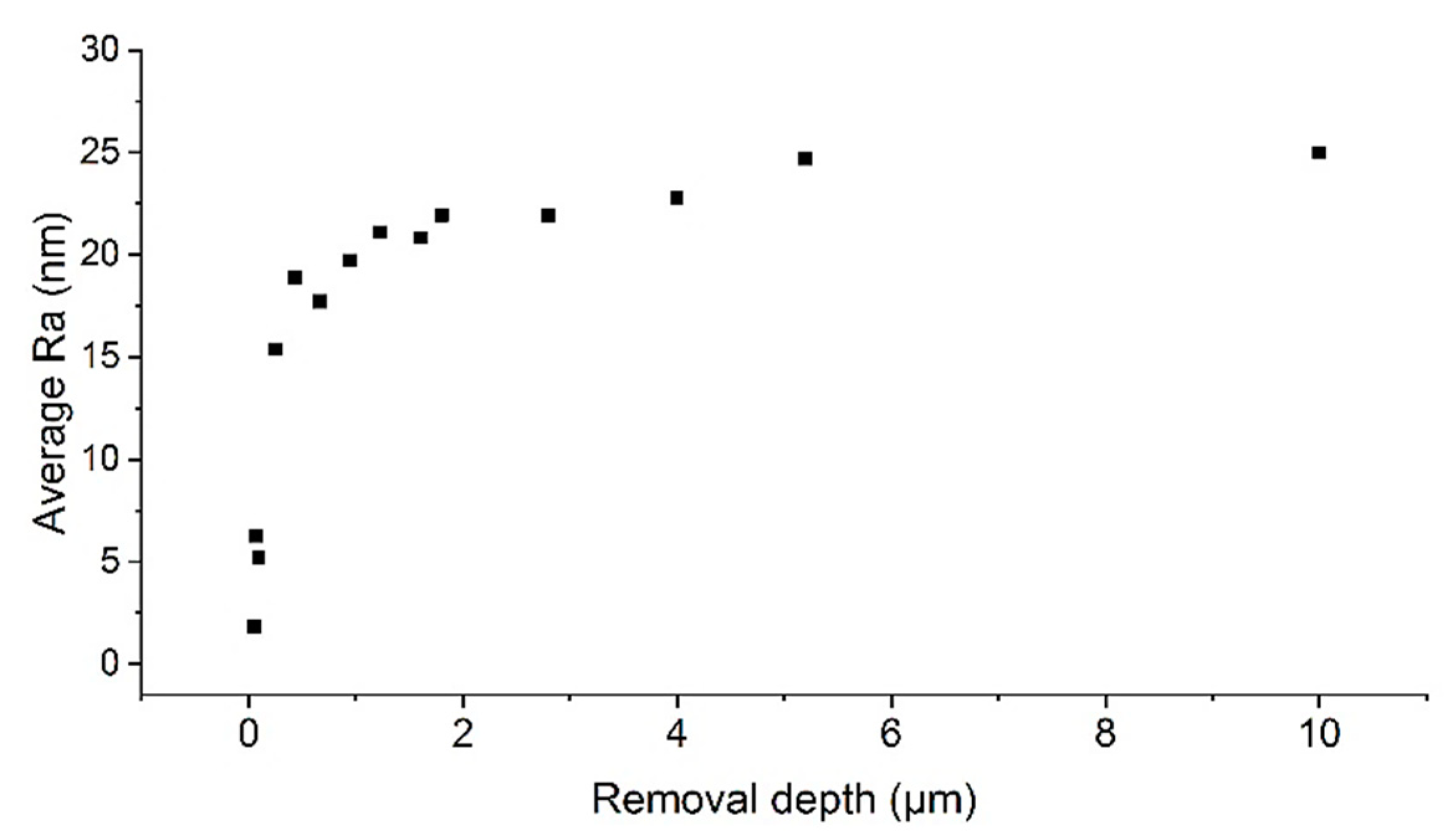

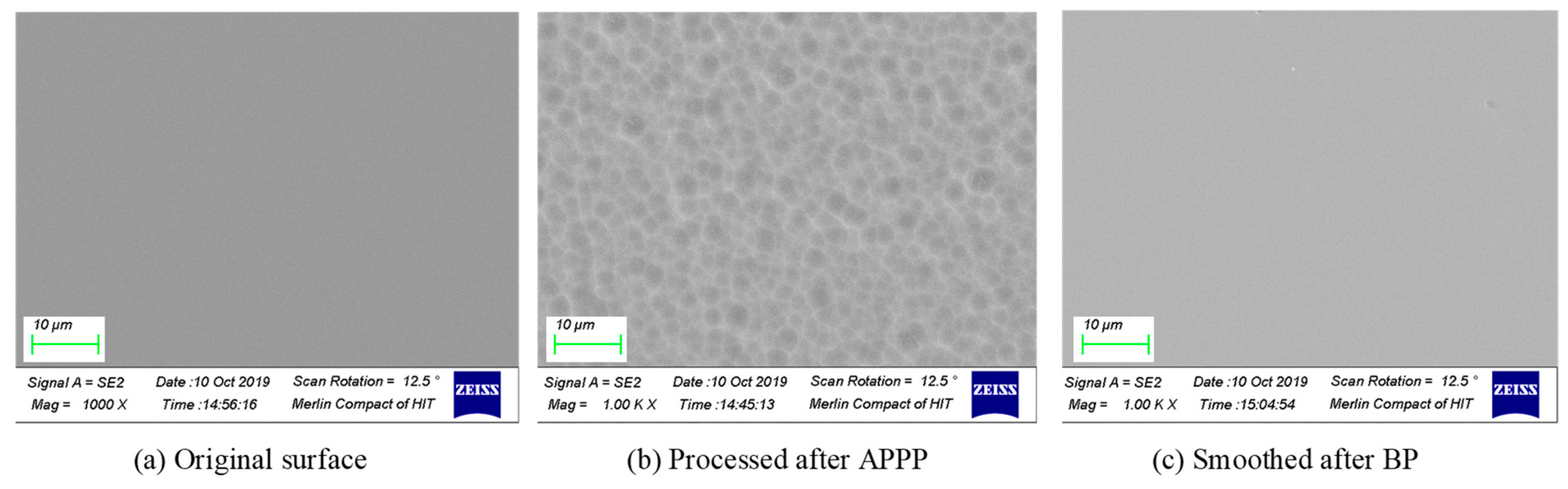

3.1. Surface Texture Evolution after APPP

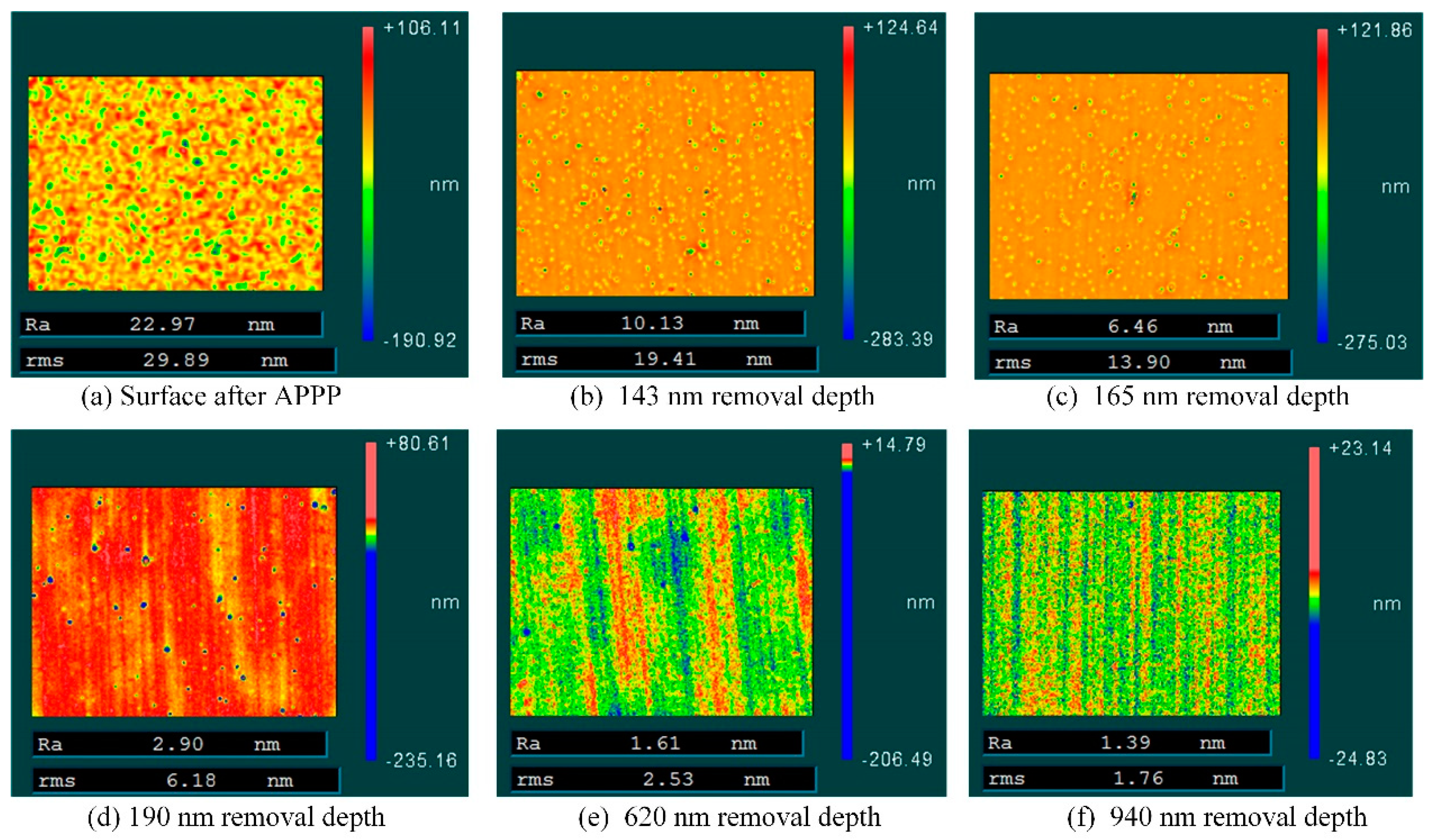

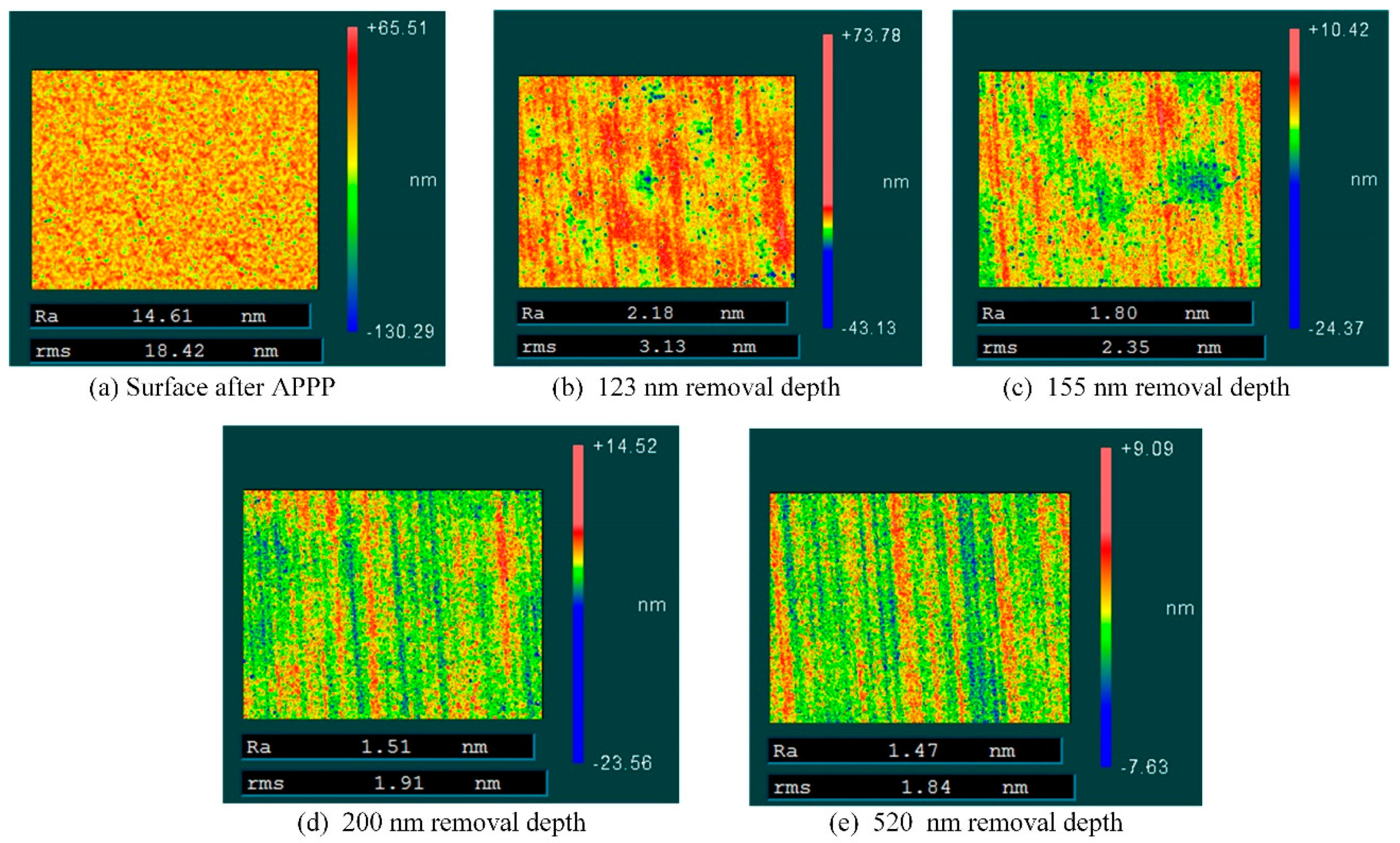

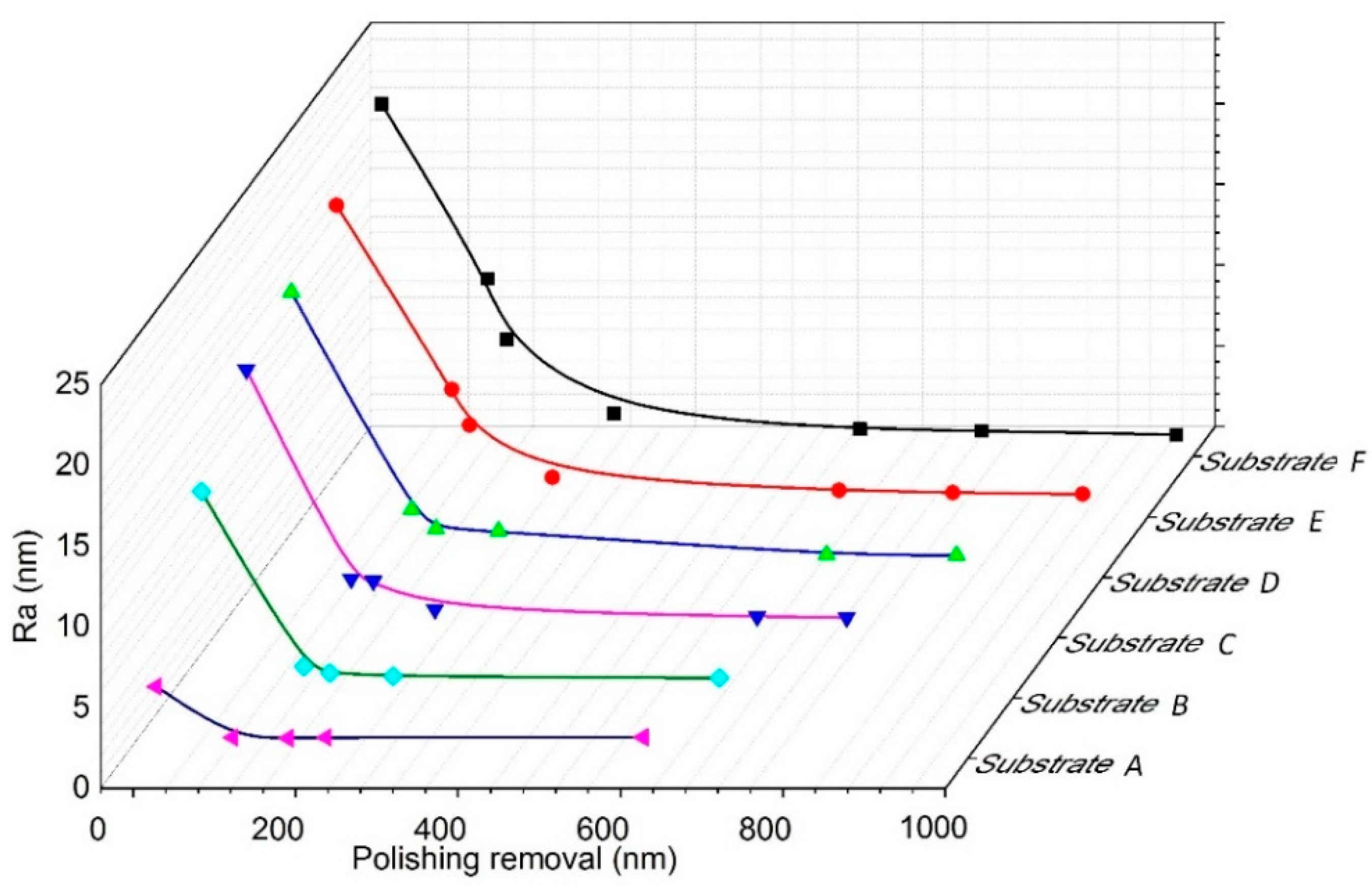

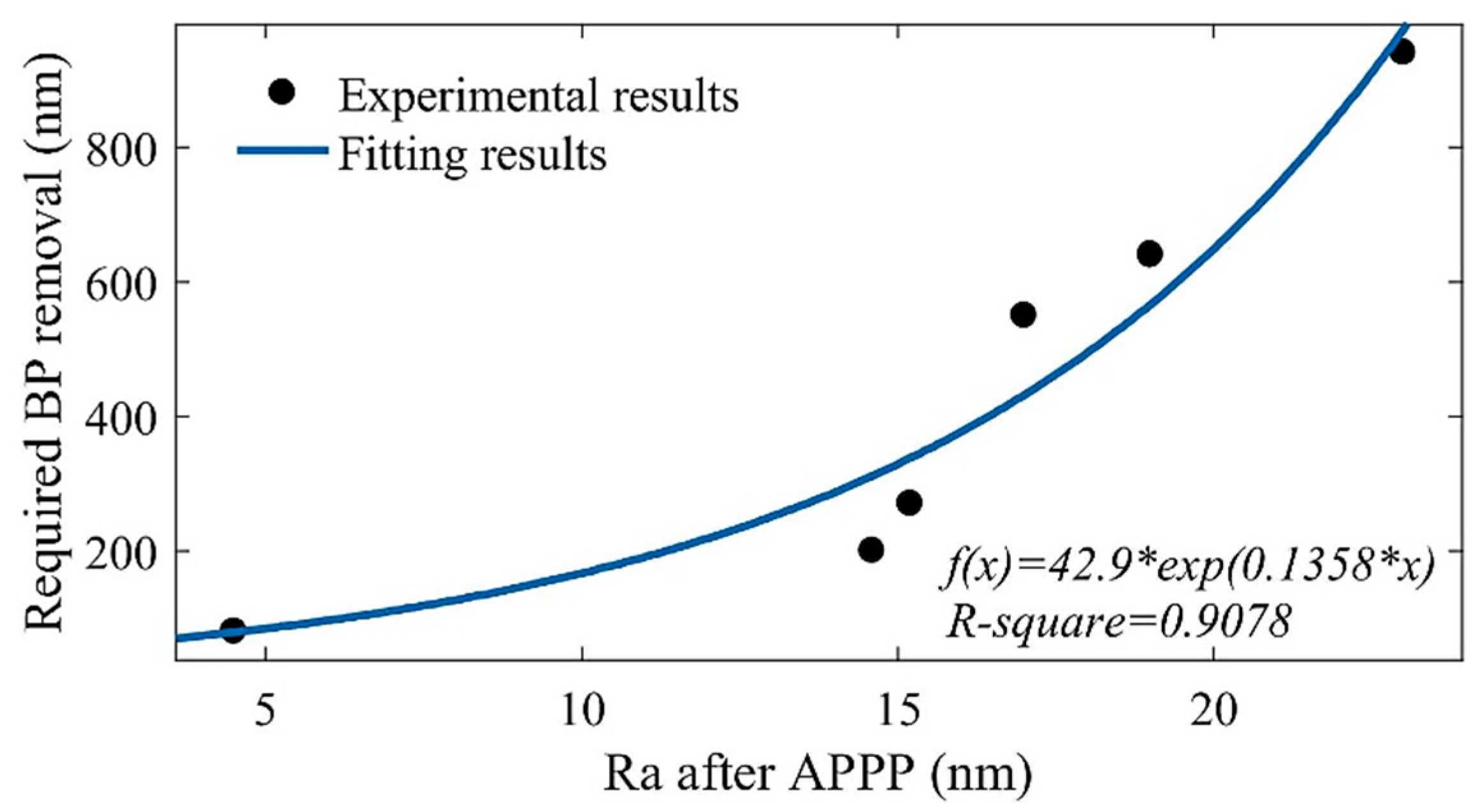

3.2. Finishing of the Plasma Etched Surface Using BP

3.3. Chemical Composition Analysis in the Combined Process

4. Discussion

5. Conclusions

- The surface texture development in APPP can be divided into two stages. In the beginning, separated etched pits appear and become larger and increase in number. With further removal, the etched pits coalesce with each other and irregular convex-concave structures are formed. In addition, the roughness rises rapidly in the first stage and plateaus at about 25 nm Ra.

- For the convex-concave structures on the APPP etched substrates, the protruding peaks can be removed easily with only very modest removal by BP, and the etched pits appeared on the relative flat texture. More additional removal by BP was needed to remove the etched pits, which affects the smoothing efficiency. Overall, the texture etched by APPP can be successfully smoothed to 1.5 nm Ra using BP.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Campbell, J.H.; Hawley-Fedder, R.A.; Stolz, C.J.; Menapace, J.A.; Borden, M.R.; Whitman, P.K.; Yu, J.; Runkel, M.J.; Riley, M.O.; Feit, M.D.; et al. NIF optical materials and fabrication technologies: An overview. In Proceedings of the Optical Engineering at the Lawrence Livermore National Laboratory II: The National Ignition Facility, San Jose, CA, USA, 28 May 2004; Volume 5341, pp. 102–105. [Google Scholar] [CrossRef]

- Bingham, R.G.; Walker, D.D.; Kim, D.H.; Brooks, D.; Freeman, R.; Riley, D. Novel automated process for aspheric surfaces. In Current Developments in Lens Design and Optical Systems Engineering; International Society for Optics and Photonics: San Diego, CA, USA, 2000. [Google Scholar]

- Li, H.; Walker, D.; Yu, G.; Zhang, W. Modeling and validation of polishing tool influence functions for manufacturing segments for an extremely large telescope. Appl. Opt. 2013, 52, 5781–5787. [Google Scholar]

- Su, X.; Ji, P.; Jin, Y.; Li, D.; Walker, D.; Yu, G.; Li, H.; Wang, B. Simulation and experimental study on form-preserving capability of bonnet polishing for complex freeform surfaces. Precis. Eng. 2019, 60, 54–62. [Google Scholar] [CrossRef]

- Cao, Z.C.; Chi, F.C.; Zhao, X. A theoretical and experimental investigation of material removal characteristics and surface generation in bonnet polishing. Wear 2016, 360–361, 137–146. [Google Scholar] [CrossRef]

- Cao, Z.C.; Cheung, C.F.; Liu, M.Y. Model-based self-optimization method for form correction in the computer controlled bonnet polishing of optical freeform surfaces. Opt. Express. 2018, 26, 2065–2078. [Google Scholar] [CrossRef]

- Harris, D.C. History of magnetorheological finishing. In Proceedings of the Window and Dome Technologies and Materials XII, Orlando, FL, USA, 20 May 2011; Volume 8016, pp. 561–566. [Google Scholar] [CrossRef]

- Menapace, J.A.; Dixit, S.N.; Genin, F.Y.; Brocious, W.F. Magnetorheological finishing for imprinting continuous phase plate structure onto optical surfaces. In Proceedings of the Laser-Induced Damage in Optical Materials: 2003, Boulder, CO, USA, 10 June 2004; Volume 5273, pp. 220–230. [Google Scholar]

- Xu, M.; Dai, Y.; Xie, X.; Zhou, L.; Peng, W. Fabrication of continuous phase plates with small structures based on recursive frequency filtered ion beam figuring. Opt. Express 2017, 25, 10765–10778. [Google Scholar]

- Drueding, T.W.; Fawcett, S.C.; Wilson, S.R.; Bifano, T.G. Ion beam figuring of small optical components. Opt. Eng. 1995, 34, 3565–3572. [Google Scholar] [CrossRef]

- Lyu, B.H.; He, Q.K.; Chen, S.H.; Shao, Q.; Chen, Y.; Geng, Z.Y. Experimental study on shear thickening polishing of cemented carbide insert with complex shape. Int. J. Adv. Manuf. Technol. 2019, 103, 585–595. [Google Scholar] [CrossRef]

- Li, M.; Lyu, B.; Yuan, J.; Dong, C.; Dai, W. Shear-thickening polishing method. Int. J. Mach. Tools Manuf. 2015, 94, 88–99. [Google Scholar] [CrossRef]

- Mori, Y.; Yamauchi, K.; Endo, K. Elastic emission machining. Precis. Eng. 1987, 9, 123–128. [Google Scholar] [CrossRef]

- Fähnle, O.W.; Brug, H.V.; Frankena, H.J. Fluid jet polishing of optical surfaces. Appl. Opt. 1998, 37, 6771–6773. [Google Scholar] [CrossRef] [PubMed]

- Castelli, M.; Jourdain, R.; Morantz, P.; Shore, P. Rapid optical surface figuring using reactive atom plasma. Precis. Eng. 2012, 36, 467–476. [Google Scholar] [CrossRef]

- Shi, B.; Dai, Y.; Xie, X.; Li, S.; Zhou, L. Arc-enhanced plasma machining technology for high efficiency machining of silicon carbide. Plasma Chem. Plasma Process. 2016, 36, 891–900. [Google Scholar] [CrossRef]

- Yamamura, K. Improvement of thickness uniformity of quartz crystal wafer by numerically controlled plasma CVM. J. Jpn. Soc. Precis. Eng. Contrib. Pap. 2005, 72. [Google Scholar] [CrossRef]

- Mori, Y.; Yamamura, K.; Yamauchi, K.; Yoshii, K.; Kataoka, T.; Endo, K.; Inagaki, K.; Kakiuchi, H. Plasma CVM (chemical vaporization machining): An ultra precision machining technique using high-pressure reactive plasma. Nanotechnology 1993, 4, 225. [Google Scholar] [CrossRef]

- Li, N.; Xin, Q.; Zhang, P.; Wang, B. Atmospheric pressure plasma processing of fused silica in different discharge modes. Plasma Sci. Technol. 2015, 17, 567–573. [Google Scholar] [CrossRef]

- Dr, T.A.; Boehm, G.; Eichentopf, I.M.; Janietz, M.; Meister, J.; Schindler, A. Plasma jet machining. Vak. Forsch. Und Prax. 2010, 22, 10–16. [Google Scholar] [CrossRef]

- Li, D.; Li, N.; Su, X.; Liu, K.; Ji, P.; Wang, B. Characterization of fused silica surface topography in capacitively coupled atmospheric pressure plasma processing. Appl. Surf. Sci. 2019, 489, 648–657. [Google Scholar] [CrossRef]

- Li, D.; Li, N.; Su, X.; Liu, K.; Ji, P.; Wang, B. Modelling of removal characteristics and surface morphology formation in capacitively coupled atmospheric pressure plasma processing of fused silica optics. Opt. Mater. Express 2019, 9, 1893–1906. [Google Scholar] [CrossRef]

- Subrahmanyan, P.; Gardopee, G.; Verma, Y.; Ning, L.; Yu, T.; Kyler, T.; Fiske, P.; Sommer, P. Rapid fabrication of lightweight SiC aspheres using reactive atom plasma (RAPTM) processing. In Proceedings of the Society of Photo-optical Instrumentation Engineers Conference Series; International Society for Optics and Photonics: San Diego, CA, USA, 2007. [Google Scholar]

- Yamamura, K.; Mimura, H.; Yamauchi, K.; Sano, Y.; Saito, A.; Kinoshita, T.; Enso, K.; Mori, Y.; Souvorov, A.; Yabashi, M.; et al. Aspheric surface fabrication in nm-level accuracy by numerically controlled plasma chemical vaporization machining (CVM) and elastic emission machining (EEM). In Proceedings of the X-Ray Mirrors, Crystals, and Multilayers II, Seattle, WA, USA, 24 December 2002; Volume 4782, pp. 265–270. [Google Scholar] [CrossRef]

- Mori, Y.; Yamauchi, Y.; Yamamura, K.; Mimura, H.; Saito, A.; Kishimoto, H.; Sekito, Y.; Kanaoka, M.; Souvorov, A.; Yabashi, M. Development of plasma chemical vaporization machining and elastic emission machining systems for coherent X-ray optics. In X-Ray Mirrors, Crystals, and Multilayers; International Society for Optics and Photonics: San Diego, CA, USA, 2001. [Google Scholar]

- Arnold, T.; Boehm, G.; Paetzelt, H. New freeform manufacturing chain based on atmospheric plasma jet machining. J. Eur. Opt. Soc. Rapid Publ. 2016, 11. [Google Scholar] [CrossRef]

- Su, X.; Xia, L.; Liu, K.; Zhang, P.; Li, P.; Zhao, R.; Wang, B. Fabrication of a large-aperture continuous phase plate in two modes using atmospheric pressure plasma processing. Chin. Opt. Lett. 2018, 16, 102201. [Google Scholar] [CrossRef]

- Su, X.; Zhang, P.; Liu, K.; Xia, L.; Li, P.; Zhao, R.; Wang, B. Fabrication of continuous phase plate using atmospheric pressure plasma processing. Int. J. Adv. Manuf. Technol. 2019, 1–12. [Google Scholar] [CrossRef]

- Su, X.; Ji, P.; Liu, K.; Walker, D.; Yu, G.; Li, H.; Li, D.; Wang, B. Combined processing chain for freeform optics based on atmospheric pressure plasma processing and bonnet polishing. Opt. Express 2019, 27, 17979–17992. [Google Scholar] [CrossRef]

- Carr, J.W.; Fearon, E.; Haack, J.; Hoskins, S.; Hutcheon, I.; Summers, L. Subsurface Structure in Polished Fused Silica and Diamond Turned Single Crystal Silicon; Lawrence Livermore National Lab.: Livermore, CA, USA, 1999. [Google Scholar]

- Xin, Q.; Li, N.; Wang, J.; Wang, B.; Li, G.; Ding, F.; Jin, H. Surface roughening of ground fused silica processed by atmospheric inductively coupled plasma. Appl. Surf. Sci. 2015, 341, 142–148. [Google Scholar] [CrossRef]

| RF Power (W) | He Flow Rate (sccm) | CF4 Flow Rate (sccm) | O2 Flow Rate (sccm) |

|---|---|---|---|

| 100 | 1220 | 48 | 20 |

| Bonnet Radius (mm) | Rotational Speed (rpm) | Inner Pressure (bar) | Polishing Cloth | Offset (mm) | Precess Angle (°) | Slurry |

|---|---|---|---|---|---|---|

| 40 | 1000 | 1 | Uninap | 0.5 | 15 | CeO2 |

| Substrate | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| APPP removal depth (μm) | 0.15 | 0.4 | 0.6 | 1.0 | 2.1 | 10.4 |

| Ra after APPP(nm) | 4.5 | 14.6 | 15.2 | 17 | 19.0 | 22.9 |

| Substrate | Original Surface | Processed after APPP | Smoothed after BP |

|---|---|---|---|

| Atom percent of Si (%) | 37.48 | 37.08 | 37.55 |

| Atom percent of O (%) | 62.52 | 62.92 | 62.45 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, X.; Ji, C.; Xu, Y.; Li, D.; Walker, D.; Yu, G.; Li, H.; Wang, B. Surface Texture Evolution of Fused Silica in a Combined Process of Atmospheric Pressure Plasma Processing and Bonnet Polishing. Coatings 2019, 9, 676. https://doi.org/10.3390/coatings9100676

Su X, Ji C, Xu Y, Li D, Walker D, Yu G, Li H, Wang B. Surface Texture Evolution of Fused Silica in a Combined Process of Atmospheric Pressure Plasma Processing and Bonnet Polishing. Coatings. 2019; 9(10):676. https://doi.org/10.3390/coatings9100676

Chicago/Turabian StyleSu, Xing, Chenglong Ji, Yang Xu, Duo Li, David Walker, Guoyu Yu, Hongyu Li, and Bo Wang. 2019. "Surface Texture Evolution of Fused Silica in a Combined Process of Atmospheric Pressure Plasma Processing and Bonnet Polishing" Coatings 9, no. 10: 676. https://doi.org/10.3390/coatings9100676

APA StyleSu, X., Ji, C., Xu, Y., Li, D., Walker, D., Yu, G., Li, H., & Wang, B. (2019). Surface Texture Evolution of Fused Silica in a Combined Process of Atmospheric Pressure Plasma Processing and Bonnet Polishing. Coatings, 9(10), 676. https://doi.org/10.3390/coatings9100676