Thermal Fatigue Failure Behavior of Surface/Interface of Plasma Cladding Layer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Plasma Cladding Processing

2.2. Tests

3. Results and Discussions

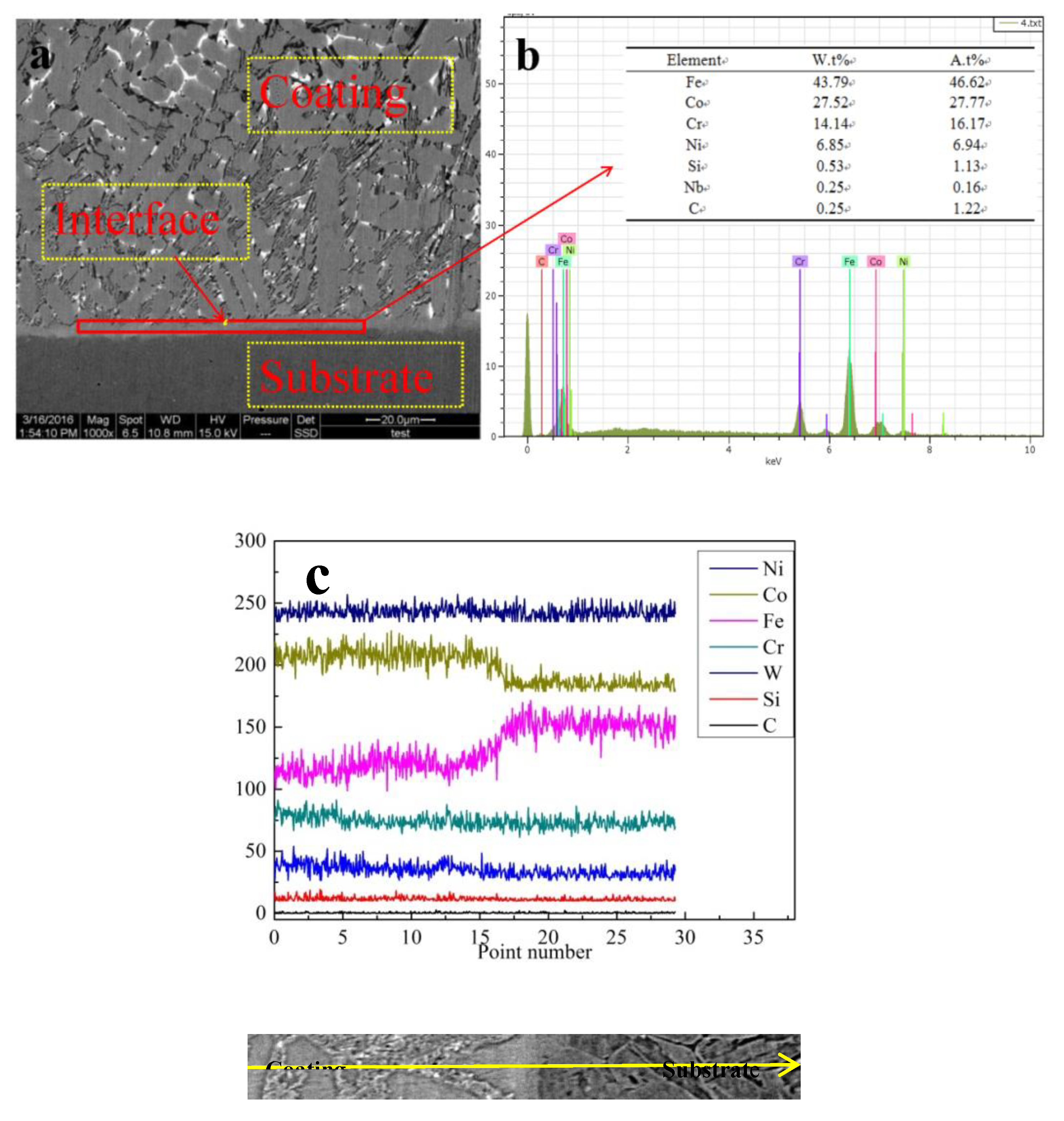

3.1. Scanning Electron Microscope and Energy Disperse Spectroscopy Analysis

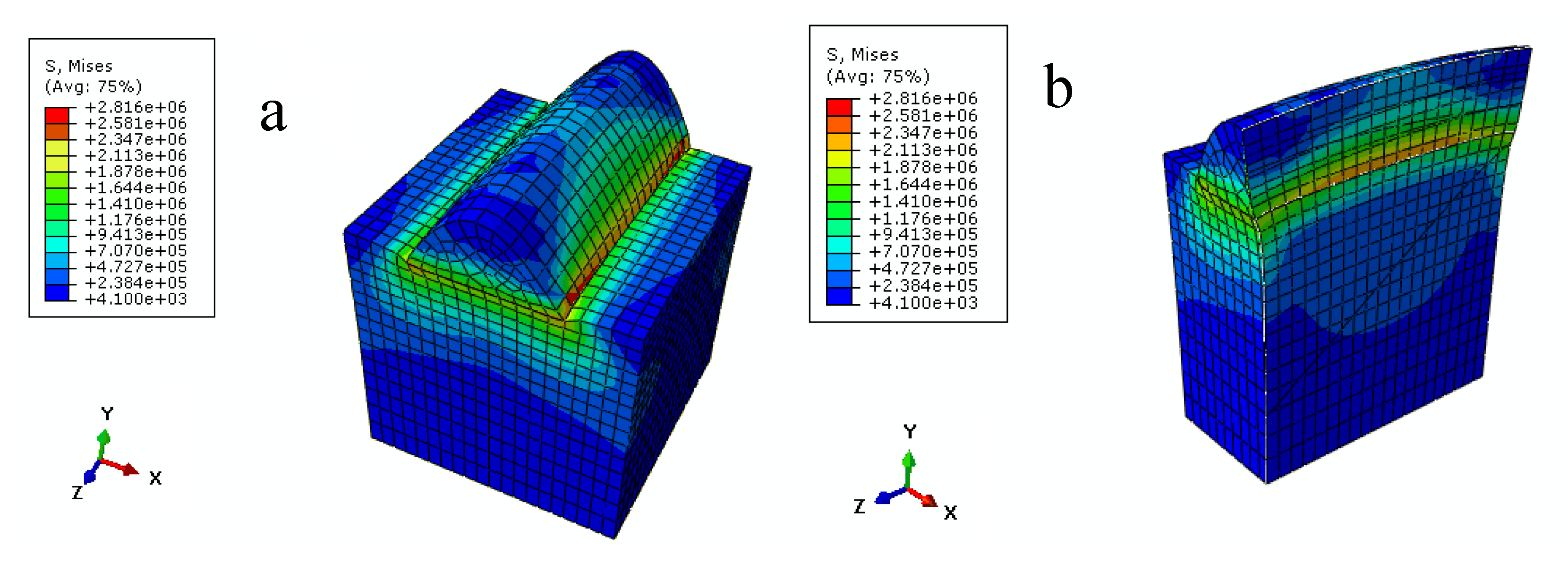

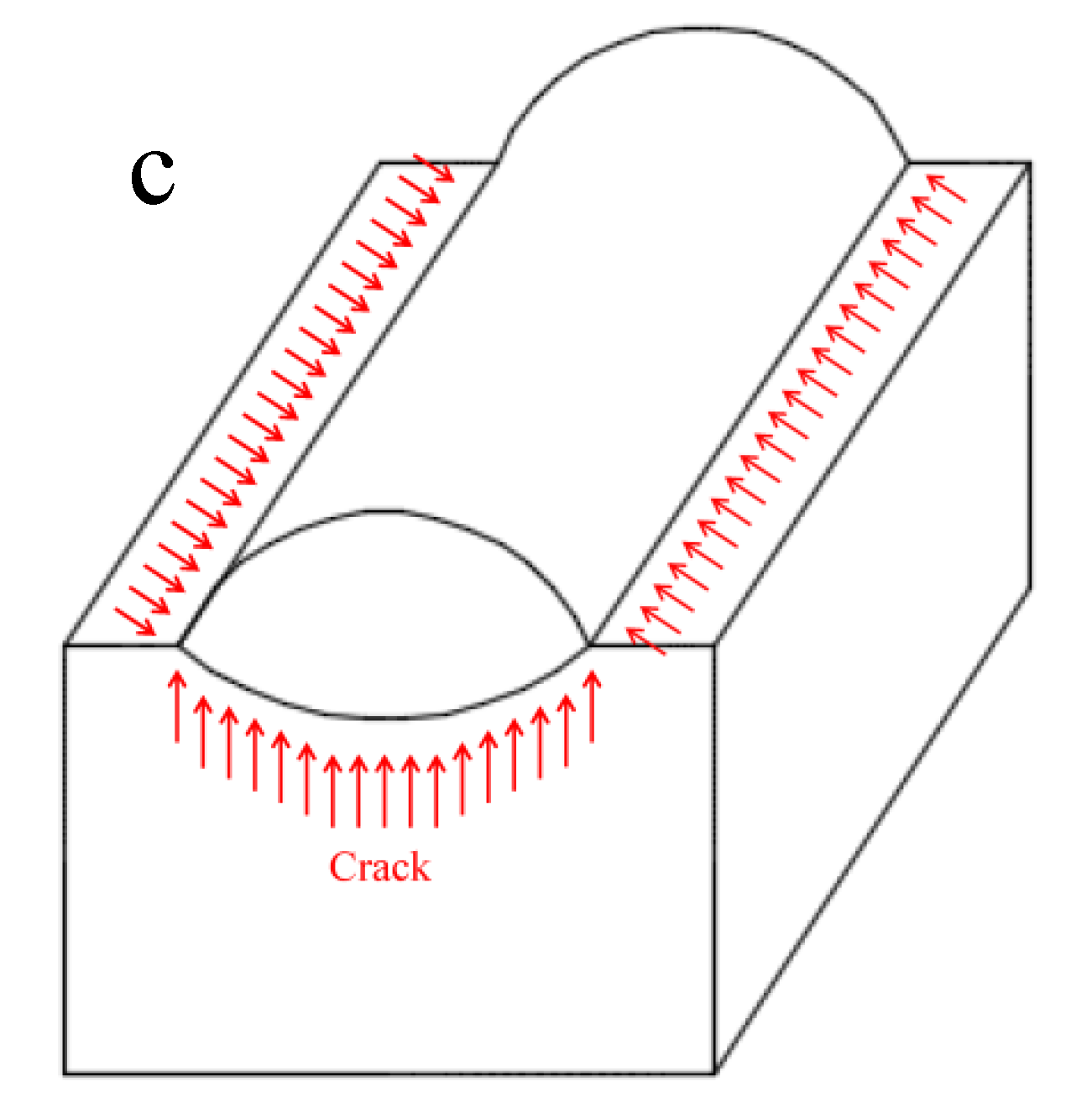

3.2. Prediction of Finite Element Simulation

3.3. Thermal Fatigue Analysis

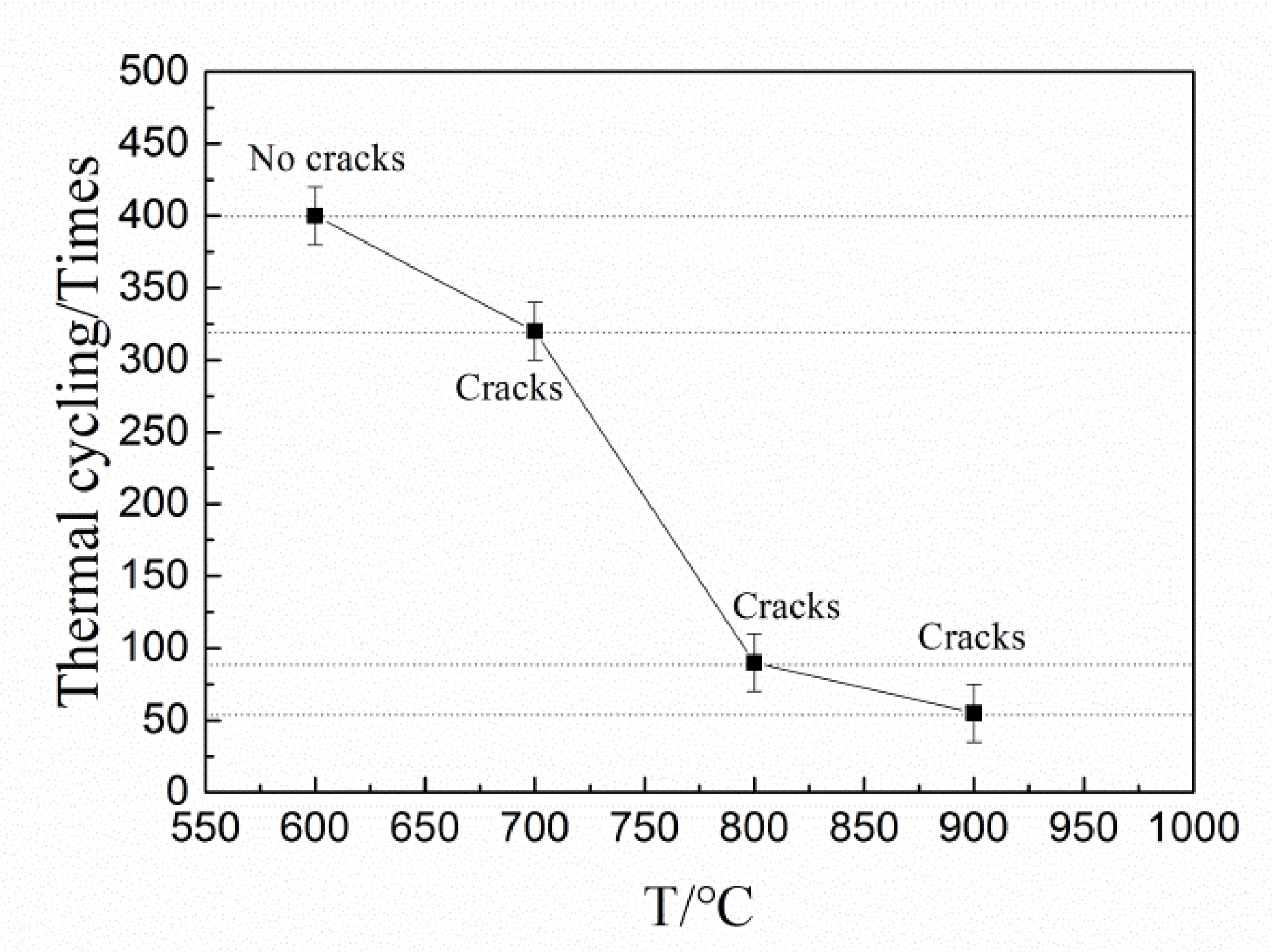

3.4. Coefficient of Expansion and Matching Ability Analysis

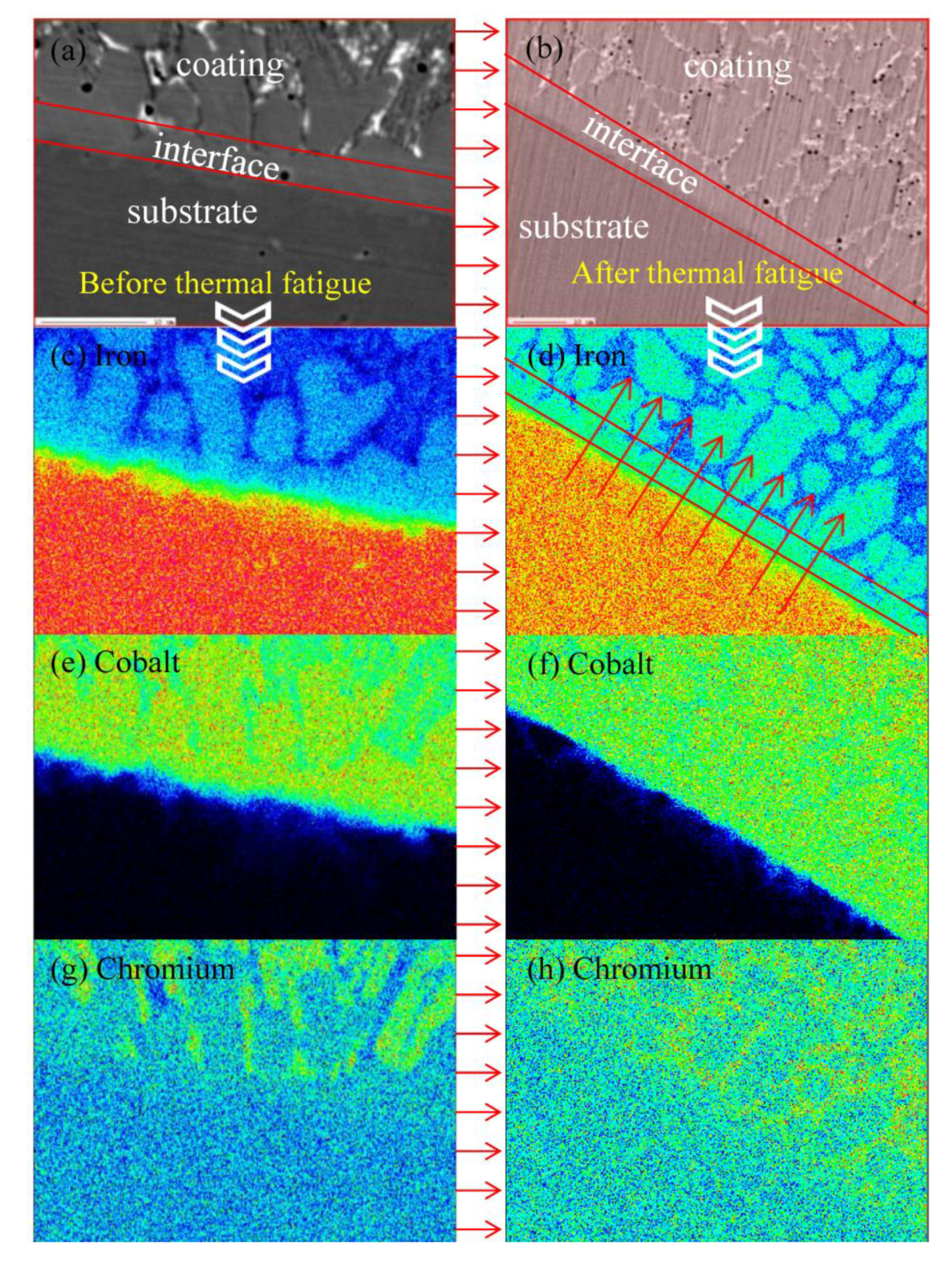

3.5. Evolution Behavior of Elements and Microstructure

4. Conclusions

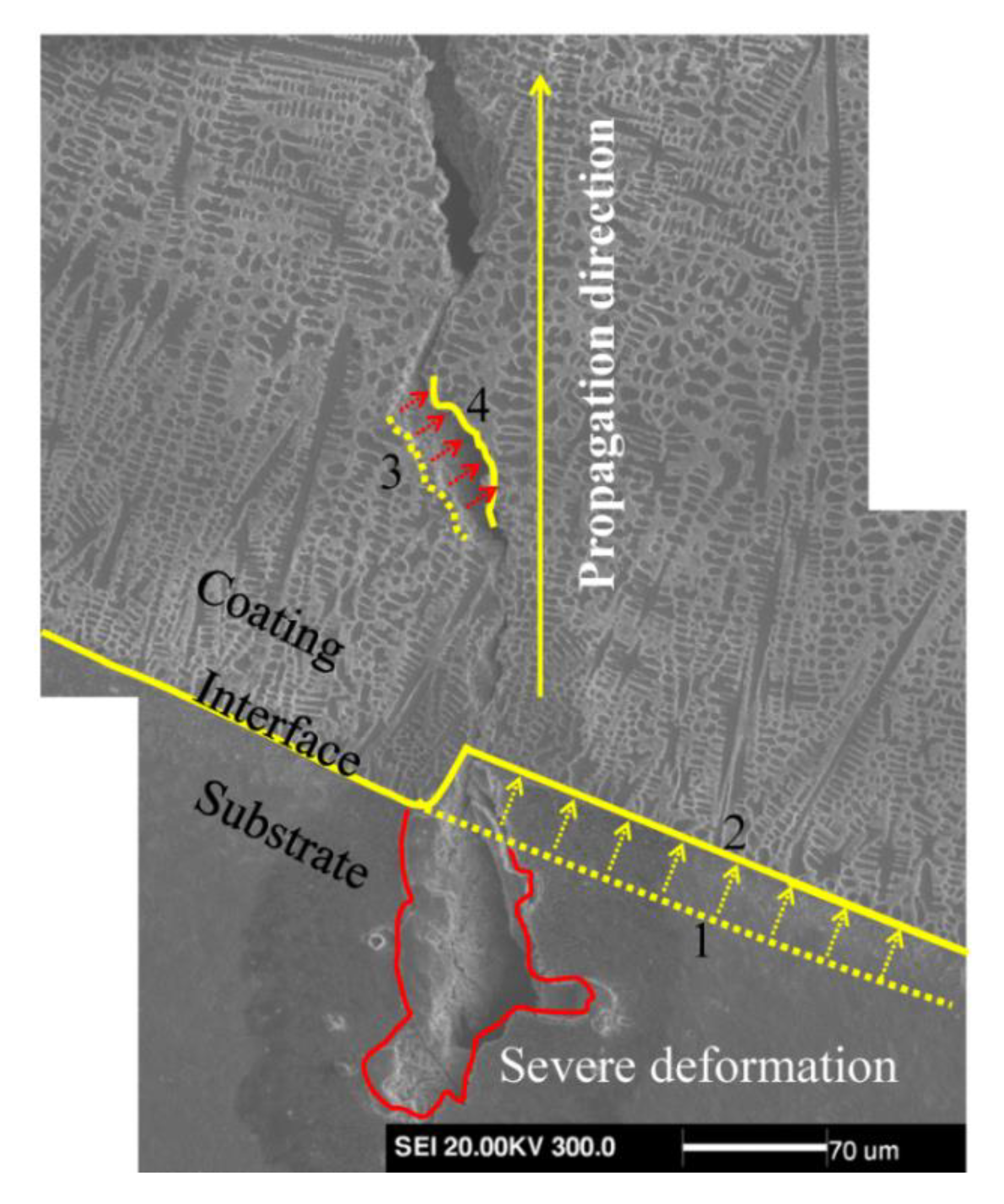

- The maximum stress was distributed near the interface after the thermal cycling simulation. Stress decreased with the distance increasing from the interface.

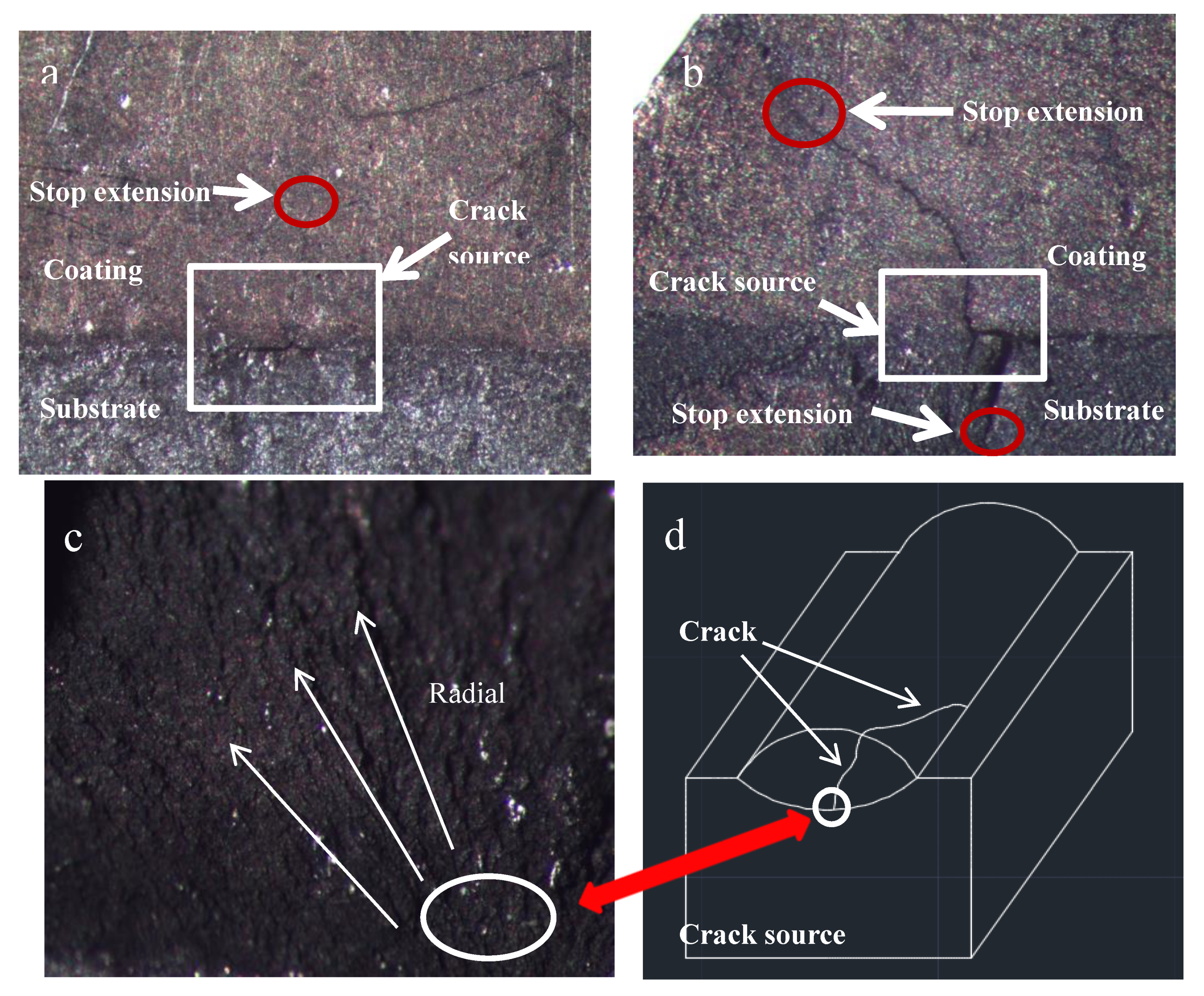

- The thermal fatigue test showed that the thermal fatigue resistance was best at 600 °C. No cracks had initiated at 600 °C when the thermal cycling times reached 400 times. The thermal cycling of fatigue failure reached 50 times, 80 times, and 320 times at 900, 800 and 700 °C, respectively. In addition, the crack source located near the interface shows that the simulated result conformed to the test result, and the crack extended along the brittle grain boundary.

- The thermal fatigue resistance of the coating was good as the expansion coefficient of the coating was close to the that of the substrate at 600 °C. The discrepancy of the expansion coefficient between the plasma cladding layer and substrate material increased with the increase in temperature, which was caused by the phase transition of the substrate materials, so it is easier to fail when the temperature is above 600 °C.

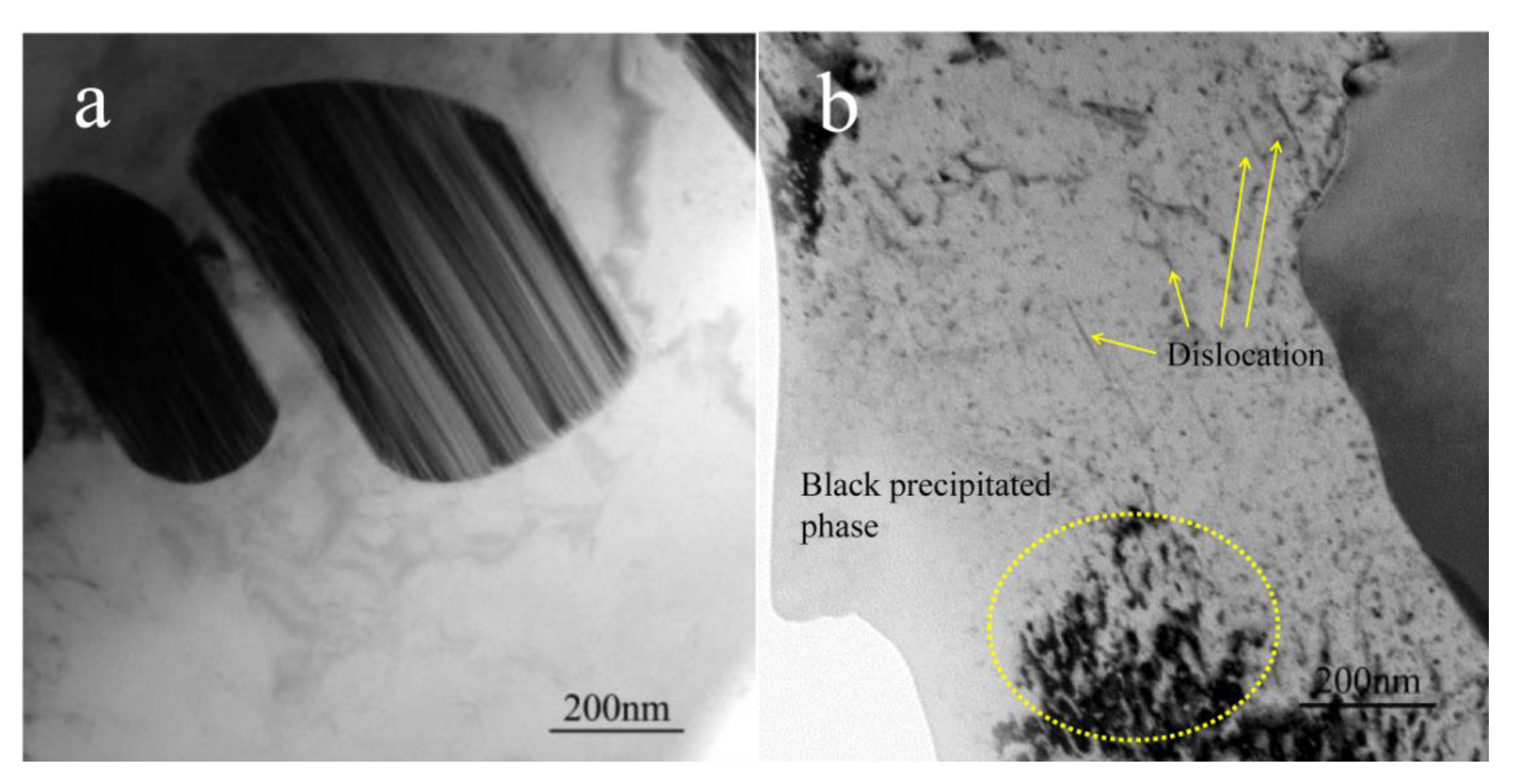

- Element diffusion occurred between the substrate and coating in the process of the thermal cycle, thus increasing the compatibility of heterogeneous materials. Dislocation and the nano-precipitation phase will improve the thermal fatigue property.

Author Contributions

Funding

Conflicts of Interest

References

- Fan, Y.; Jin, G.; Cui, X.; Li, Y.; Gao, Z. Effect of Nb and CeO2 on the mechanical and tribology properties of Co-based cladding coatings. Surf. Coat. Technol. 2016, 288, 25–29. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z. Effect of sequential turning and burnishing on the surface integrity of Cr-Ni-based stainless steel formed by laser cladding process. Surf. Coat. Technol. 2015, 276, 327–335. [Google Scholar] [CrossRef]

- Weng, F.; Yu, H.; Chen, C.; Liu, J.; Zhao, L. Microstructures and properties of TiN reinforced Co-based composite coatings modified with Y2O3 by laser cladding on Ti-6Al-4V alloy. J. Alloy. Compd. 2015, 650, 178–184. [Google Scholar] [CrossRef]

- Hou, G.; An, Y.; Zhao, X.; Zhou, H.; Chen, J. Effect of alumina dispersion on oxidation behavior as well as friction and wear behavior of HVOF-sprayed CoCrAlYTaCSi coating at elevated temperature up to 1000 degrees C. Acta Mater. 2015, 95, 164–175. [Google Scholar] [CrossRef]

- Ang, A.S.M.; Howse, H.; Wade, S.A.; Berndt, C.C. Manufacturing of nickel based cermet coatings by the HVOF process. Surf. Eng. 2016, 32, 713–724. [Google Scholar] [CrossRef]

- Gurbuz, M.; Gunkaya, G.; Dogan, A. Electrospray deposition of SnO2 films from precursor solution. Surf. Eng. 2016, 32, 725–732. [Google Scholar] [CrossRef]

- Tang, M.K.; Huang, X.J.; Yu, J.G.; Li, X.W.; Zhang, Q.X. Simple fabrication of large-area corrosion resistant superhydrophobic surface with high mechanical strength property on TiAl-based composite. J. Mater. Process. Technol. 2017, 239, 178–186. [Google Scholar] [CrossRef]

- Lyu, Y.; Sun, Y.; Jing, F. On the microstructure and wear resistance of Fe-based composite coatings processed by plasma cladding with B4C injection. Ceram. Int. 2015, 41, 10934. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, D.; Yu, H.; Li, H. Characteristics of Fe-based alloy coating produced by plasma cladding process. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 2007, 457, 319–324. [Google Scholar] [CrossRef]

- Jiang, S.Q.; Wang, G.; Chang-Yue, L. Effect of(Ti+B4C)/Fe901 Ratio on Microstructure and Microhardness of Fe-based Coatings Synthesized by Plasma Cladding. Surf. Technol. 2017. Available online: https://www.semanticscholar.org/paper/Effect-of-(Ti%2BB4C)%2FFe901-Ratio-on-Microstructure-of-Shao-qun-Gang/6767ef8cf6e5a290a1d144fbaf25249b816d8ec6 (accessed on 5 October 2019).

- Zhang, D.; Yu, R.; Kai, C.; Yang, X.; Yuan, L.; Yan, Y. Corrosion and corrosion-friction properties of plasma cladding wear-resistant layer on Fe-based alloy. Mater. Res. Express. 2018, 5, 026525. [Google Scholar] [CrossRef]

- Cai, Z.; Wang, Y.; Cui, X.; Guo, J.; Yang, L.; Zhe, L. Design and microstructure characterization of FeCoNiAlCu high-entropy alloy coating by plasma cladding: In comparison with thermodynamic calculation. Surf. Coat. Technol. 2017, 330, S0257897217310198. [Google Scholar] [CrossRef]

- Li, Y.; Cui, X.; Jin, G.; Cai, Z.; Tan, N.; Lu, B. Interfacial bonding properties between cobalt-based plasma cladding layer and substrate under tensile conditions. Mater. Des. 2017, 123, 54–63. [Google Scholar] [CrossRef]

- Mansuri, M.; Hadavi, S.M.M.; Zare, E.; Nabi, M.M. Thermal fatigue behaviour of Al-Si coated Inconel 713LC. Surf. Eng. 2016, 32, 201–206. [Google Scholar] [CrossRef]

- Pourbafrani, M.; Razavi, R.S.; Bakhshi, S.R.; Loghman-Estarki, M.R.; Jamali, H. Effect of microstructure and phase of nanostructured YSZ thermal barrier coatings on its thermal shock behaviour. Surf. Eng. 2015, 31, 64–73. [Google Scholar] [CrossRef]

- Li, J.; Shi, Y.; Wu, X. Effect of initial hardness on the thermal fatigue behavior of AISI H13 steel by experimental sand numerical investigations. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1260–1274. [Google Scholar] [CrossRef]

- Kundalkar, D.; Mavalankar, M.; Tewari, A. Effect of gas nitriding on the thermal fatigue behavior of martensitic chromium hot-work tool steel. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 2016, 651, 391–398. [Google Scholar] [CrossRef]

- Belyakov, A.V.; Gorbachev, A.N.; Mikhailov, V.V.; Reutov, B.F.; Fokin, A.A. Installations for producing electrospark erosion- and abrasion-resistant coatings on the blades of steam turbines of thermal and nuclear power plants. Surf. Eng. Appl. Electrochem. 2017, 53, 274–284. [Google Scholar] [CrossRef]

- Zhe, Z.; Yu, T.; Kovacevic, R. Erosion and corrosion resistance of laser cladded AISI 420 stainless steel reinforced with VC. Appl. Surf. Sci. 2017, 410, 225–240. [Google Scholar]

- Irfan, O.M.; Al-Mufadi, F.A.; Djavanroodi, F. Surface Properties and Erosion–Corrosion Behavior of Nanostructured Pure Titanium in Simulated Body Fluid. Metall. Mater. Trans. A 2018, 11, 1–10. [Google Scholar] [CrossRef]

- Przestacki, D.; Majchrowski, R.; Marciniak-Podsadna, L. Experimental research of surface roughness and surface texture after laser cladding. Appl. Surf. Sci. 2016, 388, 420–423. [Google Scholar] [CrossRef]

- Maliutina, I.N.; Si-Mohand, H.; Sijobert, J.; Bertrand, P.; Lazurenko, D.V.; Bataev, I.A. Structure and oxidation behavior of γ-TiAl coating produced by laser cladding on titanium alloy. Surf. Coat. Technol. 2017, 319, 136–144. [Google Scholar] [CrossRef]

- McDonald, G.; Hendricks, R.C. Effect of thermal cycling on ZrO2-Y2O3 thermal barrier coatings. Thin Solid Film. 1980, 73, 491–496. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Tan, N.; Jin, G.; Cui, X.; Li, Q. Thermal Fatigue Failure Behavior of Surface/Interface of Plasma Cladding Layer. Coatings 2019, 9, 646. https://doi.org/10.3390/coatings9100646

Li Y, Tan N, Jin G, Cui X, Li Q. Thermal Fatigue Failure Behavior of Surface/Interface of Plasma Cladding Layer. Coatings. 2019; 9(10):646. https://doi.org/10.3390/coatings9100646

Chicago/Turabian StyleLi, Yang, Na Tan, Guo Jin, Xiufang Cui, and Qiu Li. 2019. "Thermal Fatigue Failure Behavior of Surface/Interface of Plasma Cladding Layer" Coatings 9, no. 10: 646. https://doi.org/10.3390/coatings9100646

APA StyleLi, Y., Tan, N., Jin, G., Cui, X., & Li, Q. (2019). Thermal Fatigue Failure Behavior of Surface/Interface of Plasma Cladding Layer. Coatings, 9(10), 646. https://doi.org/10.3390/coatings9100646