A Parametric Three-Dimensional Phase-Field Study of the Physical Vapor Deposition Process of Metal Thin Films Aiming at Quantitative Simulations

Abstract

1. Introduction

2. Phase-field Model for the PVD Process of Metal Thin Film

3. Model Parameters and Numerical Solution

4. Results and Discussion

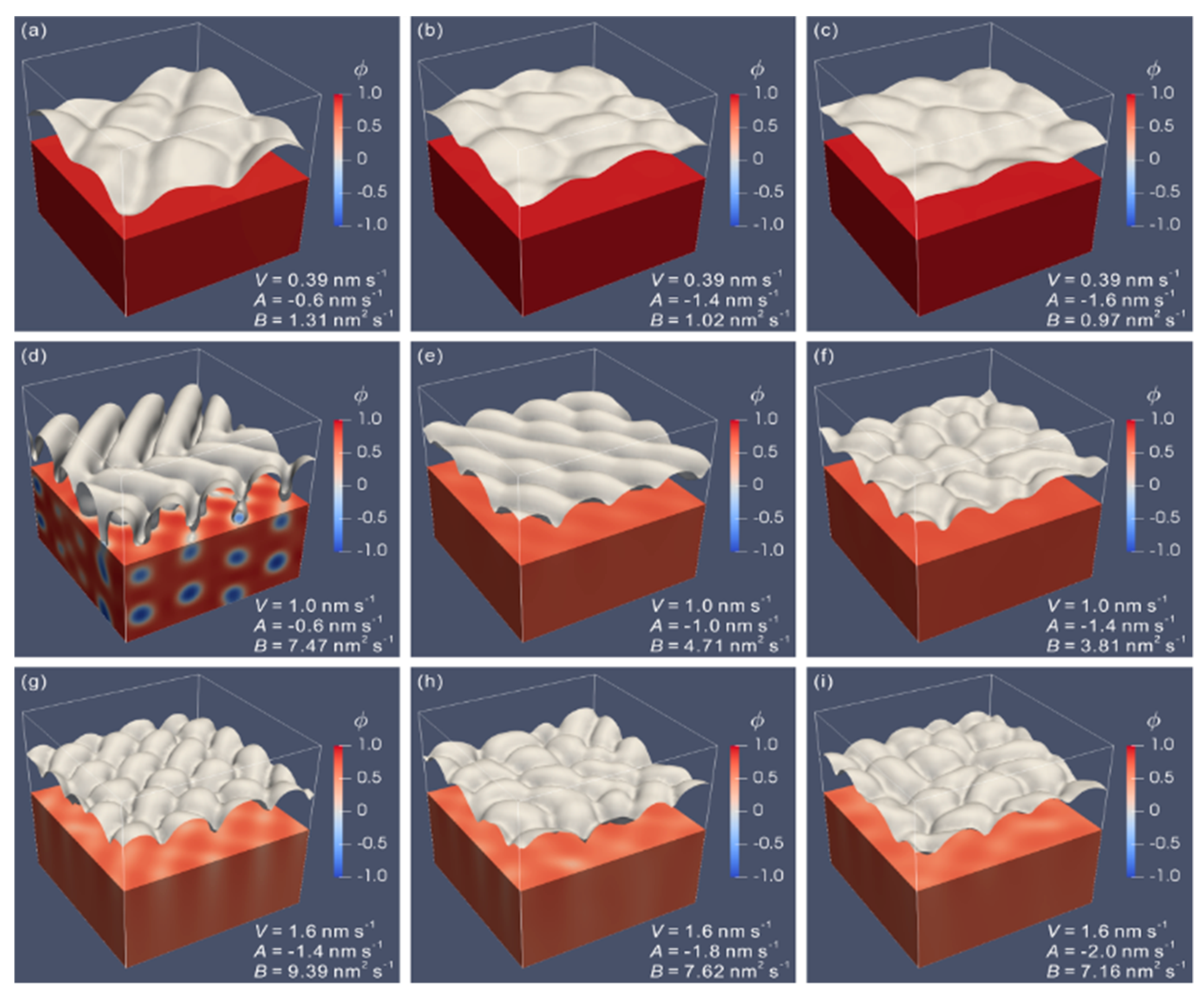

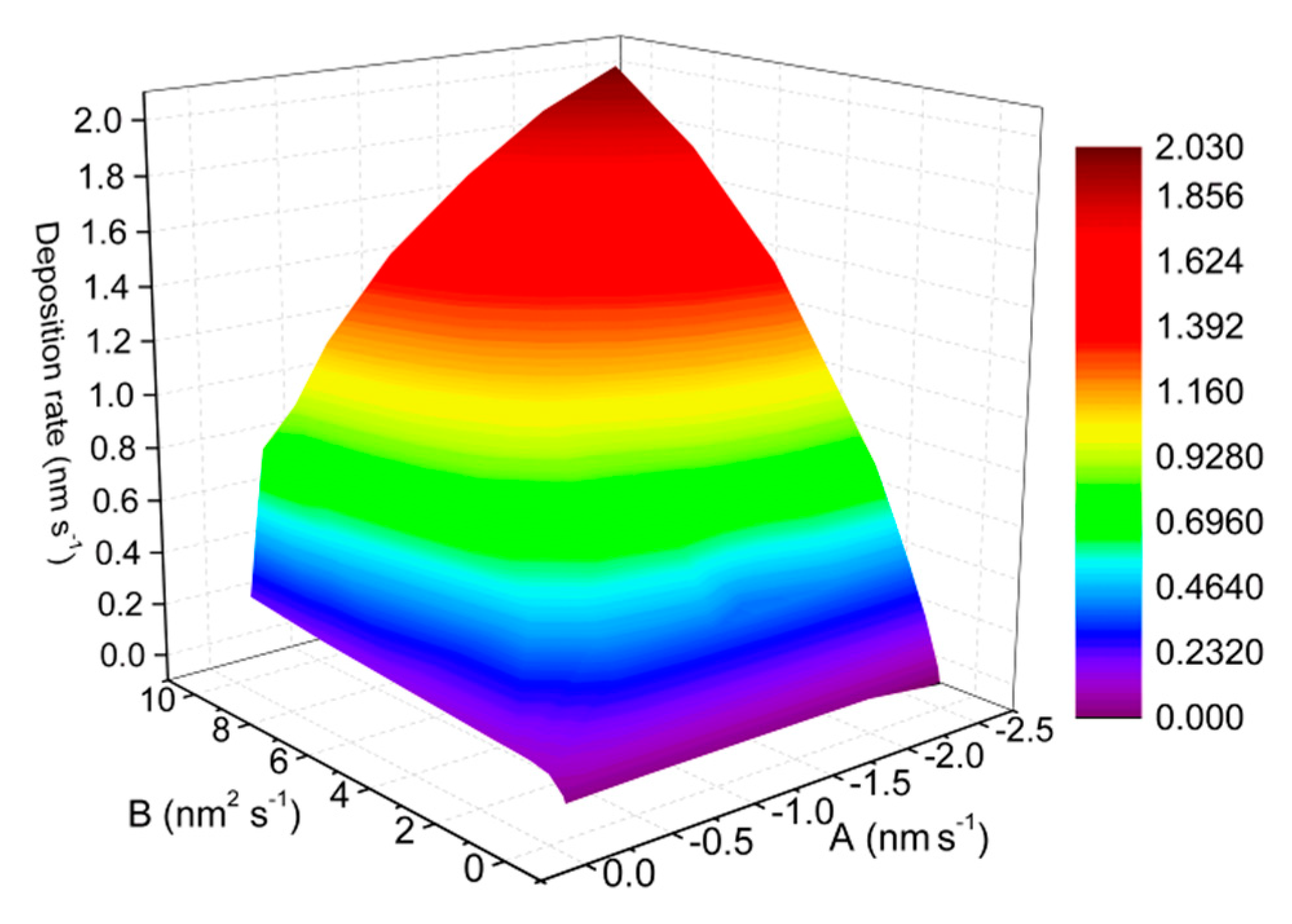

4.1. Relationship Between Deposition Rate and Model Parameters

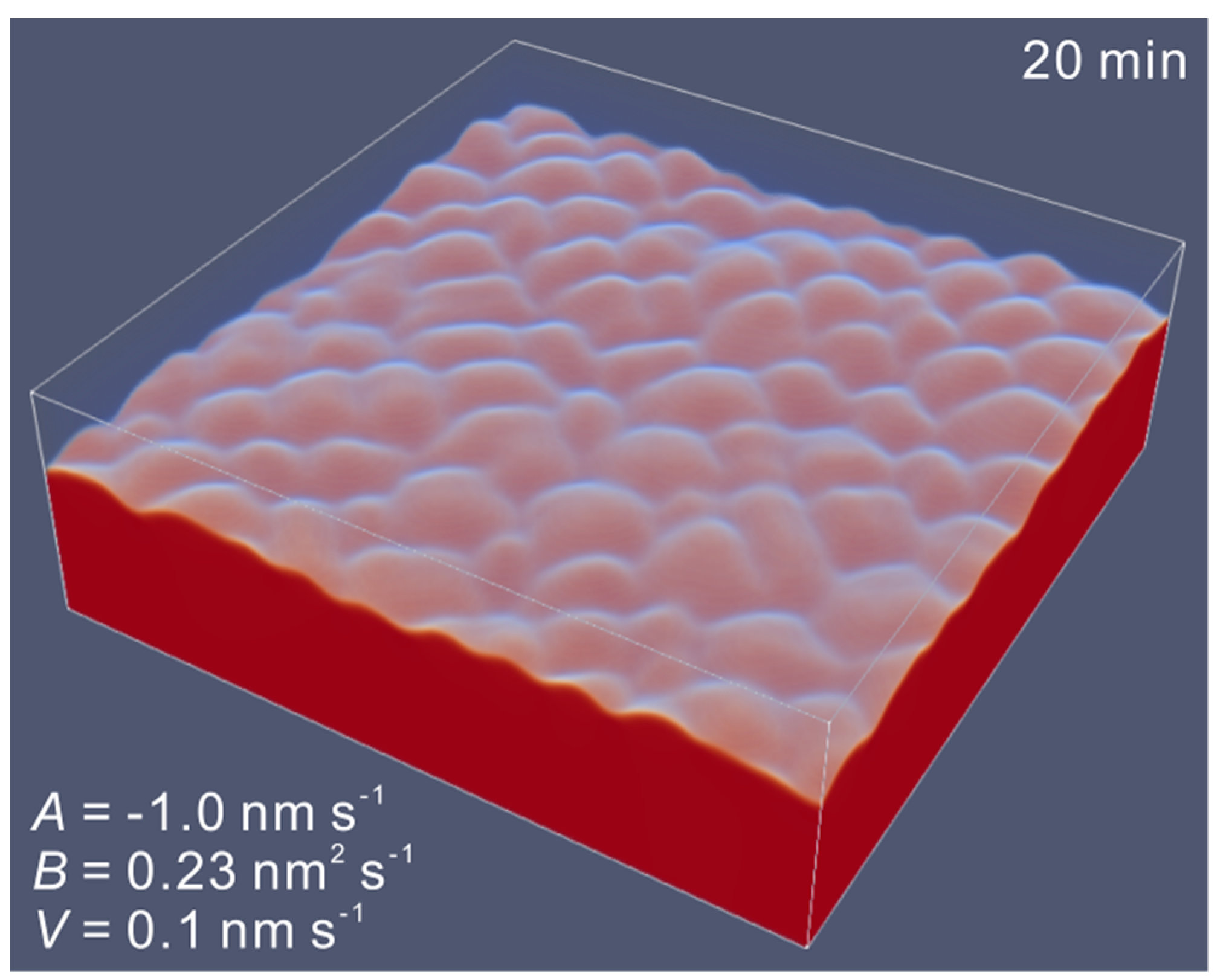

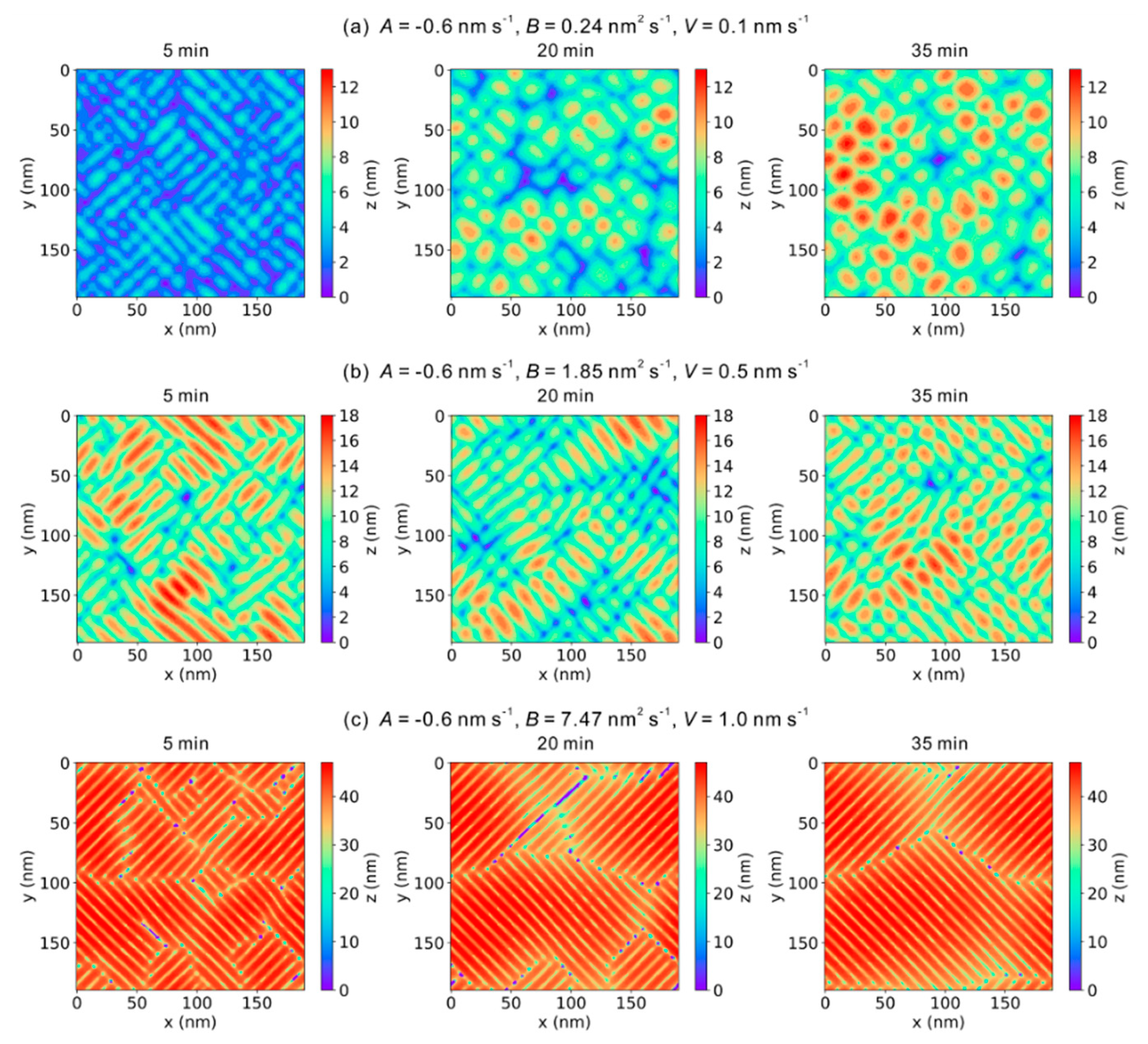

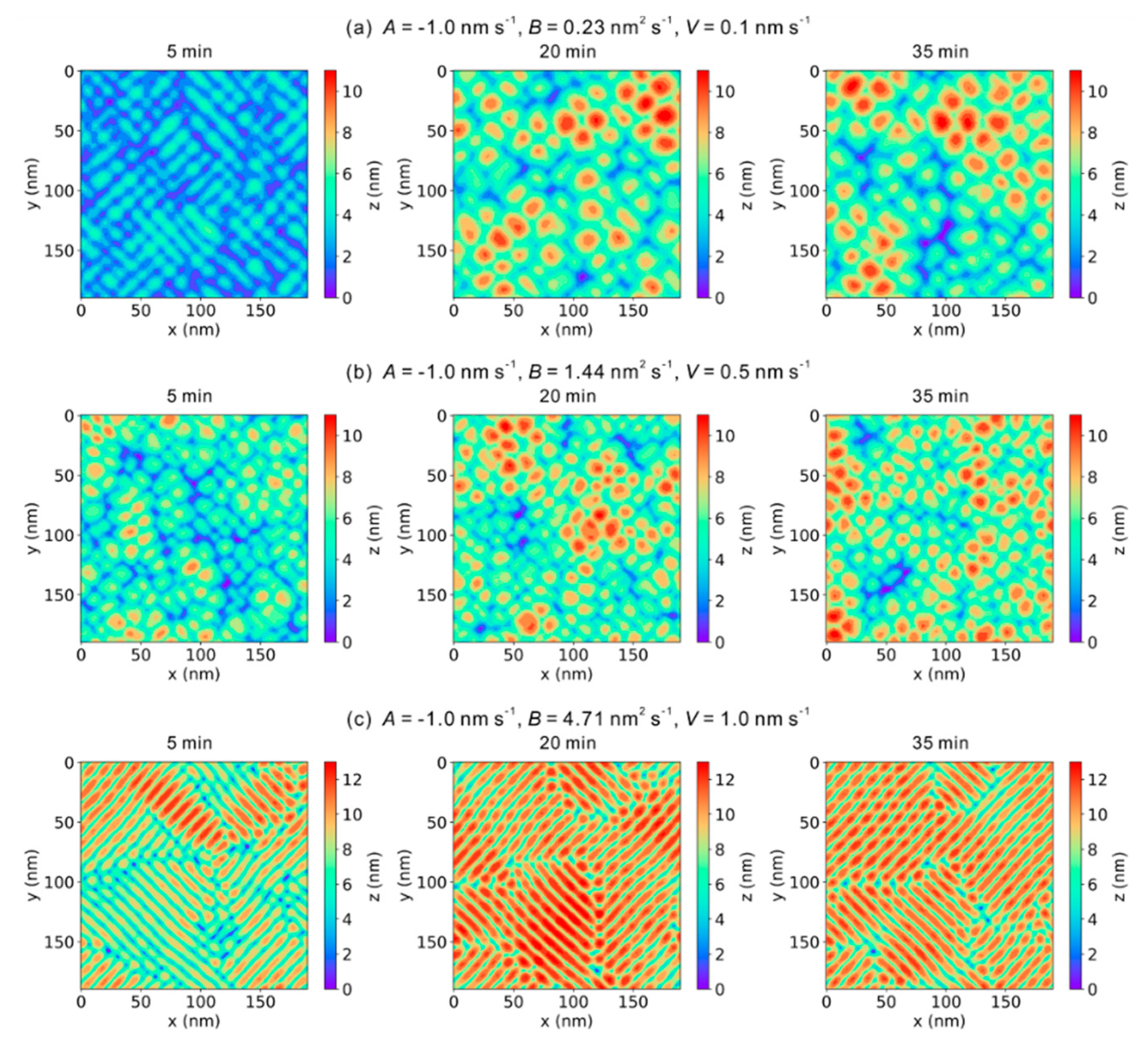

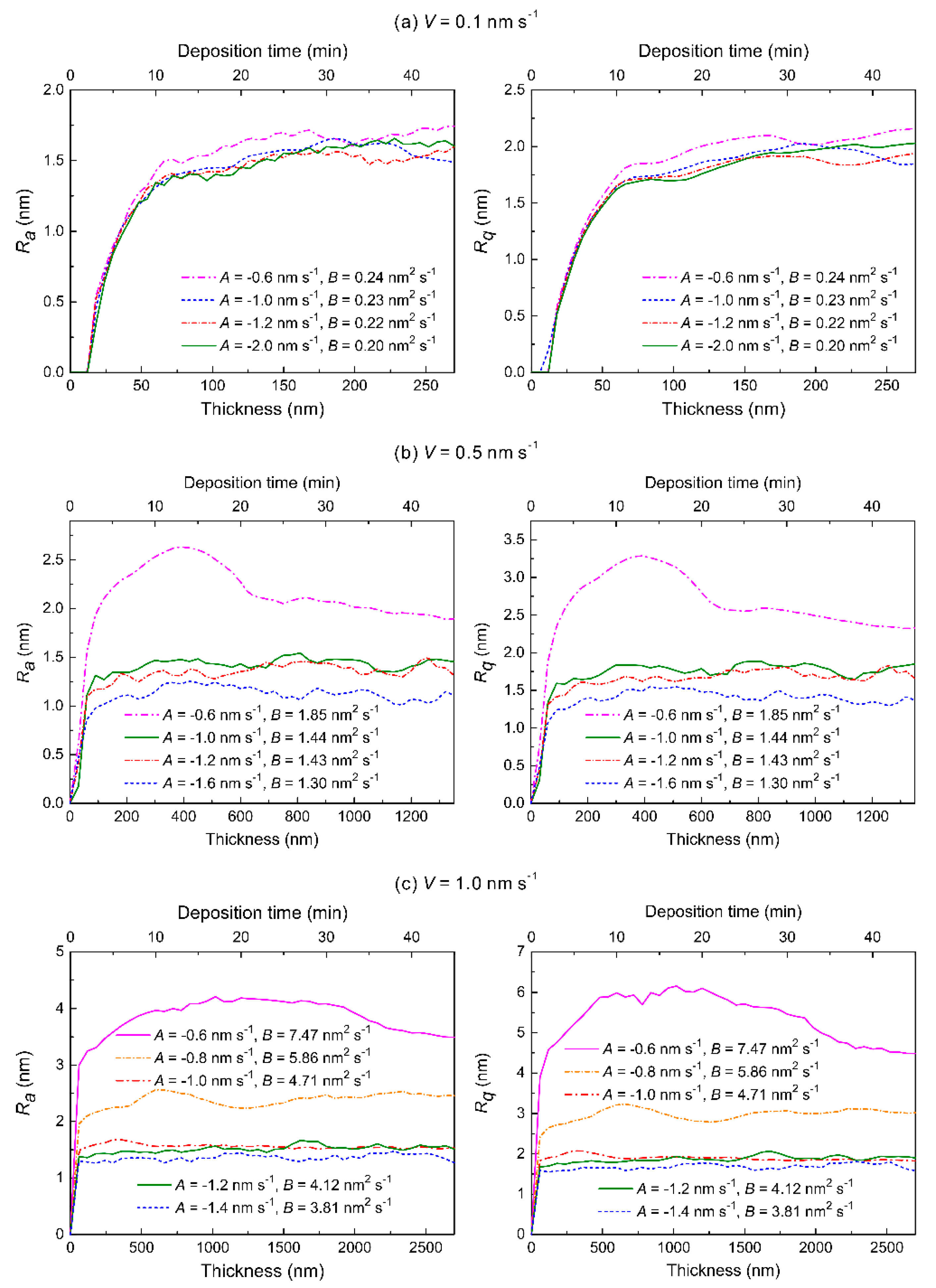

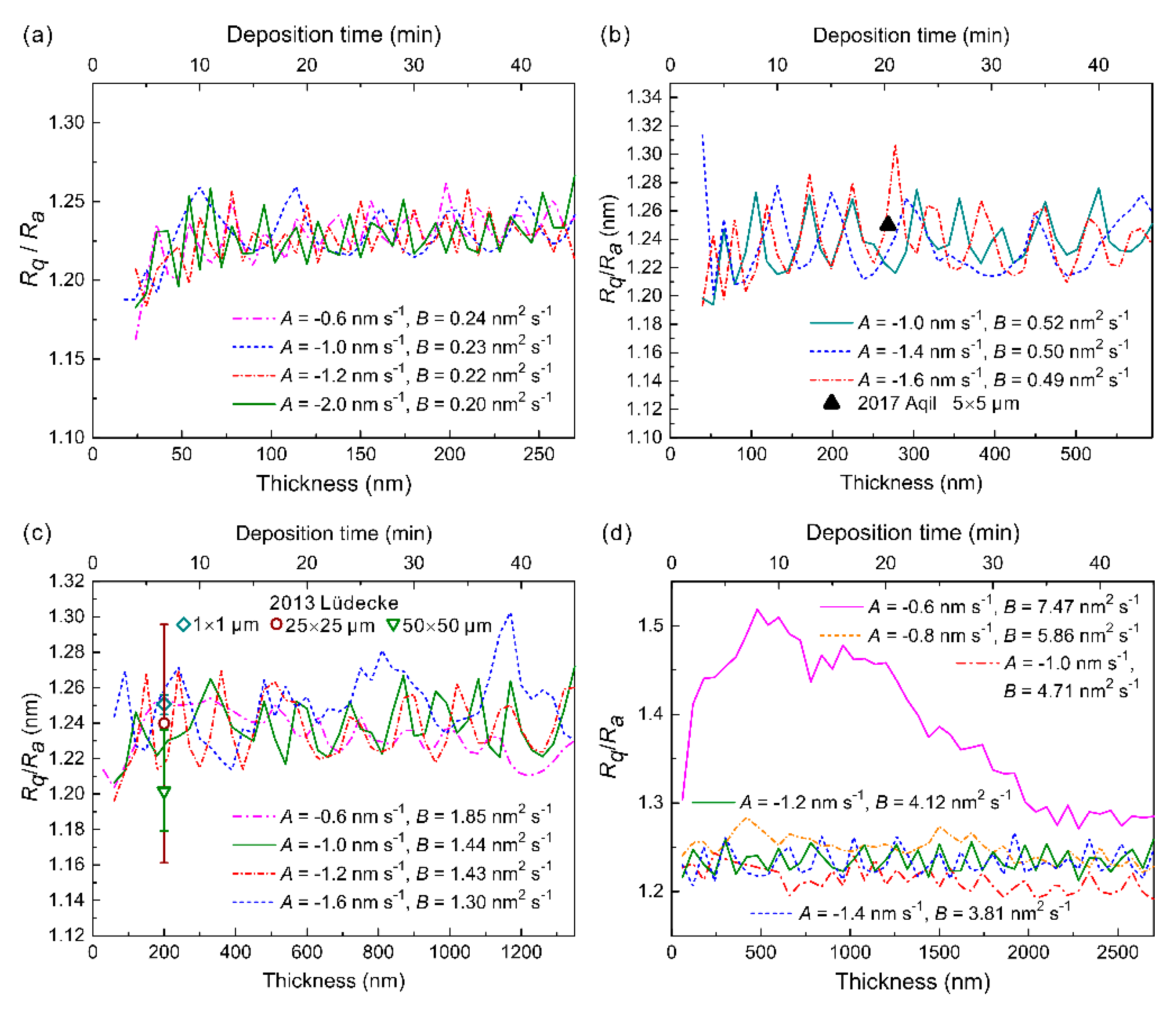

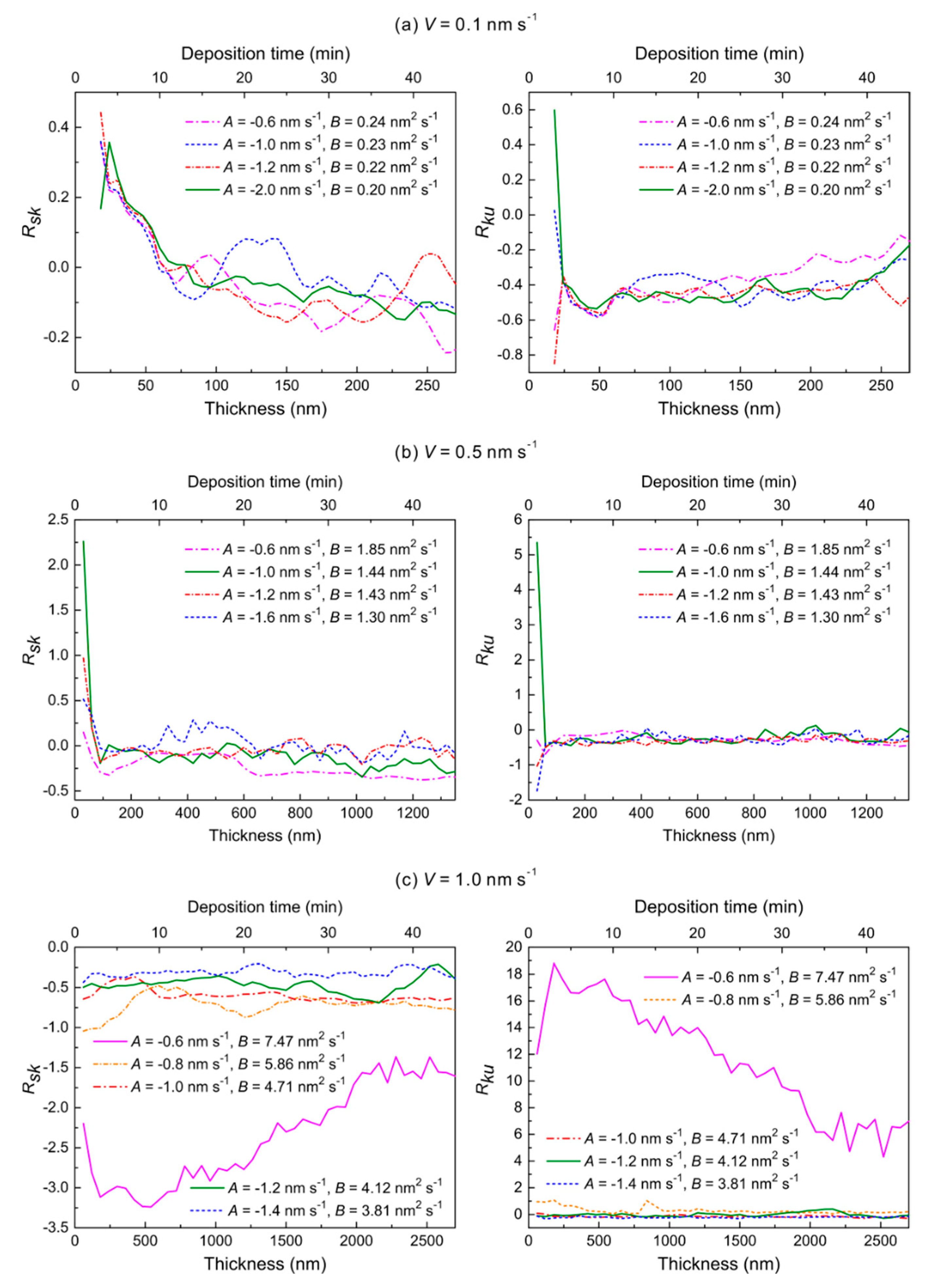

4.2. Effect of Deposition Rate and Time on Surface Roughness

5. Further Discussion on the Relationship between Surface Roughness and Density

6. Conclusions

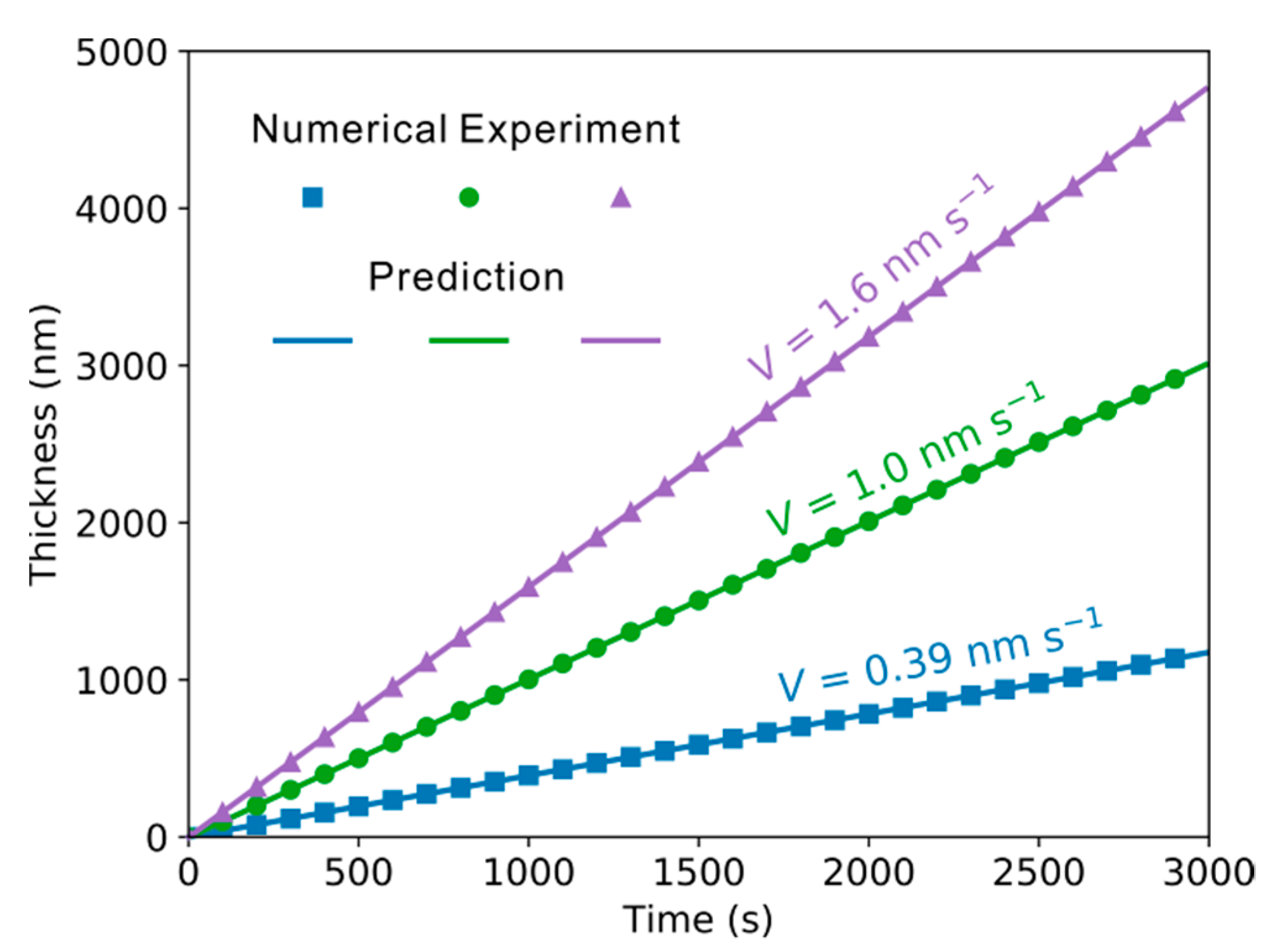

- In this paper, more than 200 sets of 3D phase-field simulations of the PVD process of metal thin films were performed based on the parameterized phase-field model by Keblinski et al. A quantitative relationship between model parameters and deposition rates at steady state was established.

- Insight into the relationship among the industrially concerned properties, i.e., deposition rates, surface roughness and density, and the microstructures and surface morphologies of the metal thin films was further investigated by conducting 3D phase-field simulations with larger domain. Relationship between the surface roughness and the deposition rate is proven to be in accordance with the common sense in experiments, i.e., that the higher deposition rate generally leads to the higher surface roughness. Specially, the calculated ratios of Rq to Ra of metal thin films with deposition rates of 0.22 and 1.0 nm s−1 are in very good agreement with the experimental data of the deposited Mo and Ti thin films.

- Delicate elaboration over the formation of voids and the relation between the density and roughness was acquired by carefully associating the relation among different control parameters. It was found that the metal thin films with the higher roughness usually possess the lower density. Furthermore, the present results reveal the potential difficulties in the PVD process as the control parameters tend to affect the properties of thin films conjointly.

- With the present quantitative phase-field simulations, the relationship between the control parameters and microstructures and properties of the deposited thin films can be efficiently established, which is anticipated to be used for precisely guiding the manufacture of thin films with the desired properties by means of the PVD technique.

Author Contributions

Funding

Conflicts of Interest

References

- Chan, K.Y.; Tou, T.Y.; Teo, B.-S. Effects of substrate temperature on electrical and structural properties of copper thin films. Microelectron. J. 2006, 37, 930–937. [Google Scholar] [CrossRef]

- Aqil, M.M.; Azam, M.A.; Aziz, M.F.; Latif, R. Deposition and characterization of molybdenum thin film using direct current magnetron and atomic force microscopy. J. Nanotechnol. 2017, 2017, 4862087. [Google Scholar] [CrossRef]

- Lüdecke, C.; Bossert, J.; Roth, M.; Jandt, K.D. Physical vapor deposited titanium thin films for biomedical applications: Reproducibility of nanoscale surface roughness and microbial adhesion properties. Appl. Surf. Sci. 2013, 280, 578–589. [Google Scholar] [CrossRef]

- Singh, A.; Kuppusami, P.; Thirumurugesan, R.; Ramaseshan, R.; Kamruddin, M.; Dash, S.; Ganesan, V.; Mohandas, E. Study of microstructure and nanomechanical properties of Zr films prepared by pulsed magnetron sputtering. Appl. Surf. Sci. 2011, 257, 9909–9914. [Google Scholar] [CrossRef]

- Li, C.; Guo, H.; Gao, L.; Wei, L.; Gong, S.; Xu, H. Microstructures of yttria-stabilized zirconia coatings by plasma spray-physical vapor deposition. J. Therm. Spray Technol. 2015, 24, 534–541. [Google Scholar] [CrossRef]

- Ta, N.; Zhang, L.; Tang, Y.; Chen, W.; Du, Y. Effect of temperature gradient on microstructure evolution in Ni–Al–Cr bond coat/substrate systems: A phase-field study. Surf. Coat. Technol. 2015, 261, 364–374. [Google Scholar] [CrossRef]

- Ta, N.; Zhang, L.; Du, Y. A trial to design γ/γ′ bond coat in Ni–Al–Cr Mode TBCs Aided by Phase-Field Simulation. Coatings 2018, 8, 421. [Google Scholar] [CrossRef]

- Zhou, J.; Zhong, J.; Chen, L.; Zhang, L.; Du, Y.; Liu, Z.-K.; Mayrhofer, P.H. Phase equilibria, thermodynamics and microstructure simulation of metastable spinodal decomposition in c–Ti1− xAlxN coatings. Calphad 2017, 56, 92–101. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Metel, A.; Sitnikov, N.; Milovich, F.; Andreev, N.; Shevchenko, S.; Rozhkova, Y. Investigation into Performance of multilayer composite nano-structured Cr-CrN-(Cr0.35Ti0.40Al0.25) N coating for metal cutting tools. Coatings 2018, 8, 447. [Google Scholar] [CrossRef]

- Bujak, J.; Walkowicz, J.; Kusiński, J. Influence of the nitrogen pressure on the structure and properties of (Ti, Al) N coatings deposited by cathodic vacuum arc PVD process. Surf. Coat. Technol. 2004, 180, 150–157. [Google Scholar] [CrossRef]

- Kazmanli, M.; Ürgen, M.; Cakir, A. Effect of nitrogen pressure, bias voltage and substrate temperature on the phase structure of Mo–N coatings produced by cathodic arc PVD. Surf. Coat. Technol. 2003, 167, 77–82. [Google Scholar] [CrossRef]

- Ahlgren, M.; Blomqvist, H. Influence of bias variation on residual stress and texture in TiAlN PVD coatings. Surf. Coat. Technol. 2005, 200, 157–160. [Google Scholar] [CrossRef]

- Sprute, T.; Tillmann, W.; Grisales, D.; Selvadurai, U.; Fischer, G. Influence of substrate pre-treatments on residual stresses and tribo-mechanical properties of TiAlN-based PVD coatings. Surf. Coat. Technol. 2014, 260, 369–379. [Google Scholar] [CrossRef]

- Nastac, L.; Dong, H.; Dax, F.R.; Hanusiak, W. The CFD modeling of the EB-PVD of SiC/Ti-6Al-4V coatings. JOM 2004, 56, 49–53. [Google Scholar] [CrossRef]

- Adebiyi, D.; Popoola, A.; Botef, I. Experimental verification of statistically optimized parameters for low-pressure cold spray coating of titanium. Metals 2016, 6, 135. [Google Scholar] [CrossRef]

- Kapopara, J.M.; Mengar, A.R.; Chauhan, K.V.; Rawal, S.K. CFD analysis of sputtered TiN coating. Mater. Today Proc. 2017, 4, 9390–9393. [Google Scholar] [CrossRef]

- Pinto, G.; Silva, F.; Porteiro, J.; Mínguez, J.; Baptista, A. Numerical simulation applied to PVD reactors: An overview. Coatings 2018, 8, 410. [Google Scholar] [CrossRef]

- Raghavan, S.; Mayo, M.J.; Wang, H.; Dinwiddie, R.B.; Porter, W.D. The effect of grain size, porosity and yttria content on the thermal conductivity of nanocrystalline zirconia. Scr. Mater. 1998, 39, 1119–1125. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Tischler, G.; Mitterer, C. Microstructure and mechanical/thermal properties of Cr–N coatings deposited by reactive unbalanced magnetron sputtering. Surf. Coat. Technol. 2001, 142, 78–84. [Google Scholar] [CrossRef]

- Kulkarni, A.; Vaidya, A.; Goland, A.; Sampath, S.; Herman, H. Processing effects on porosity-property correlations in plasma sprayed yttria-stabilized zirconia coatings. Mater. Sci. Eng. A 2003, 359, 100–111. [Google Scholar] [CrossRef]

- Mayrhofer, P.; Mitterer, C.; Musil, J. Structure–property relationships in single-and dual-phase nanocrystalline hard coatings. Surf. Coat. Technol. 2003, 174, 725–731. [Google Scholar]

- Zhang, C.X.; Liu, F.S.; Gong, S.K.; Xu, H.B. Characterization and evaluation of EB-PVD thermal barrier coatings by impedance spectroscopy. Mater. Sci. Forum 2005, 475–479, 3997–4000. [Google Scholar]

- Jang, B.-K.; Matsubara, H. Influence of porosity on thermophysical properties of nano-porous zirconia coatings grown by electron beam-physical vapor deposition. Scr. Mater. 2006, 54, 1655–1659. [Google Scholar] [CrossRef]

- Sohn, Y.; Biederman, R.; Sisson, R., Jr. Microstructural development in physical vapour-deposited partially stabilized zirconia thermal barrier coatings. Thin Solid Films 1994, 250, 1–7. [Google Scholar]

- Schulz, U.; Schmücker, M. Microstructure of ZrO2 thermal barrier coatings applied by EB-PVD. Mater. Sci. Eng. A 2000, 276, 1–8. [Google Scholar] [CrossRef]

- Yang, Y.; Johnson, R.; Wadley, H. A Monte Carlo simulation of the physical vapor deposition of nickel. Acta Mater. 1997, 45, 1455–1468. [Google Scholar]

- Zhang, J.; Adams, J.B. Modeling and visualization of polycrystalline thin film growth. Comput. Mater. Sci. 2004, 31, 317–328. [Google Scholar] [CrossRef]

- Cho, J.; Terry, S.; LeSar, R.; Levi, C. A kinetic Monte Carlo simulation of film growth by physical vapor deposition on rotating substrates. Mater. Sci. Eng. A 2005, 391, 390–401. [Google Scholar] [CrossRef]

- Wang, P.; He, W.; Mauer, G.; Mücke, R.; Vaßen, R. Monte Carlo simulation of column growth in plasma spray physical vapor deposition process. Surf. Coat. Technol. 2018, 335, 188–197. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, D.; Ke, P.; Liu, X.; Wang, A. Influence of substrate negative bias on structure and properties of TiN coatings prepared by hybrid HIPIMS method. J. Mater. Sci. Technol. 2015, 31, 37–42. [Google Scholar]

- Raoufi, D.; Kiasatpour, A.; Fallah, H.R.; Rozatian, A.S.H. Surface characterization and microstructure of ITO thin films at different annealing temperatures. Appl. Surf. Sci. 2007, 253, 9085–9090. [Google Scholar] [CrossRef]

- Huang, Y.; Lü, X.; Jing, W.M.; Huang, N. In vitro investigation of protein adsorption and platelet adhesion on inorganic biomaterial surfaces. Appl. Surf. Sci. 2008, 255, 257–259. [Google Scholar] [CrossRef]

- Puckett, S.D.; Taylor, E.; Raimondo, T.; Webster, T.J. The relationship between the nanostructure of titanium surfaces and bacterial attachment. Biomaterials 2010, 31, 706–713. [Google Scholar] [CrossRef] [PubMed]

- Keblinski, P.; Maritan, A.; Toigo, F.; Messier, R.; Banavar, J.R. Continuum model for the growth of interfaces. Phys. Rev. E 1996, 53, 759. [Google Scholar] [CrossRef] [PubMed]

- Warren, J.A.; Kobayashi, R.; Lobkovsky, A.E.; Carter, W.C. Extending phase-field models of solidification to polycrystalline materials. Acta Mater. 2003, 51, 6035–6058. [Google Scholar] [CrossRef]

- Stewart, J.A.; Spearot, D.E. Phase-field models for simulating physical vapor deposition and grain evolution of isotropic single-phase polycrystalline thin films. Comput. Mater. Sci. 2016, 123, 111–120. [Google Scholar] [CrossRef]

- Stewart, J.A.; Spearot, D.E. Phase-field simulations of microstructure evolution during physical vapor deposition of single-phase thin films. Comput. Mater. Sci. 2017, 131, 170–177. [Google Scholar] [CrossRef]

- Bhushan, B. Surface roughness analysis and measurement techniques. In Modern Tribology Handbook, Two Volume Set, 1st ed.; CRC press: Boca Raton, FL, USA, 2000; pp. 79–150. [Google Scholar]

- Kumar, B.R.; Rao, T.S. AFM Studies on surface morphology, topography and texture of nanostructured zinc aluminum oxide thin films. Dig. J. Nanomater. Bios. 2012, 7, 1881–1889. [Google Scholar]

- Thomas, T.R. Rough Surfaces, 2nd ed.; Imperial College Press: London, UK, 1999; pp. 133–150. [Google Scholar]

| Parameters | Symbols | Values |

|---|---|---|

| Grid spacing | Δx | 1.0 nm |

| Interfacial gradient coefficient | a | 0.5 J m2 |

| Noise amplitude | C | 2.5 J m−1 |

| Gaussian noise factor | η | 0.5 |

| Supplied incident vapor | g0 | 1.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Zhong, J.; Chen, M.; Zhang, L. A Parametric Three-Dimensional Phase-Field Study of the Physical Vapor Deposition Process of Metal Thin Films Aiming at Quantitative Simulations. Coatings 2019, 9, 607. https://doi.org/10.3390/coatings9100607

Yang S, Zhong J, Chen M, Zhang L. A Parametric Three-Dimensional Phase-Field Study of the Physical Vapor Deposition Process of Metal Thin Films Aiming at Quantitative Simulations. Coatings. 2019; 9(10):607. https://doi.org/10.3390/coatings9100607

Chicago/Turabian StyleYang, Shenglan, Jing Zhong, Miao Chen, and Lijun Zhang. 2019. "A Parametric Three-Dimensional Phase-Field Study of the Physical Vapor Deposition Process of Metal Thin Films Aiming at Quantitative Simulations" Coatings 9, no. 10: 607. https://doi.org/10.3390/coatings9100607

APA StyleYang, S., Zhong, J., Chen, M., & Zhang, L. (2019). A Parametric Three-Dimensional Phase-Field Study of the Physical Vapor Deposition Process of Metal Thin Films Aiming at Quantitative Simulations. Coatings, 9(10), 607. https://doi.org/10.3390/coatings9100607