Magnetron Sputtered AlN Layers on LTCC Multilayer and Silicon Substrates

Abstract

:1. Introduction

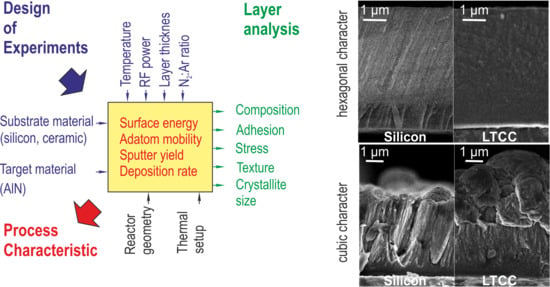

2. Experimental Procedure

2.1. Sample Preparation

2.2. Experimental Design, Statistical Method, and Test Realization

3. Results and Discussion

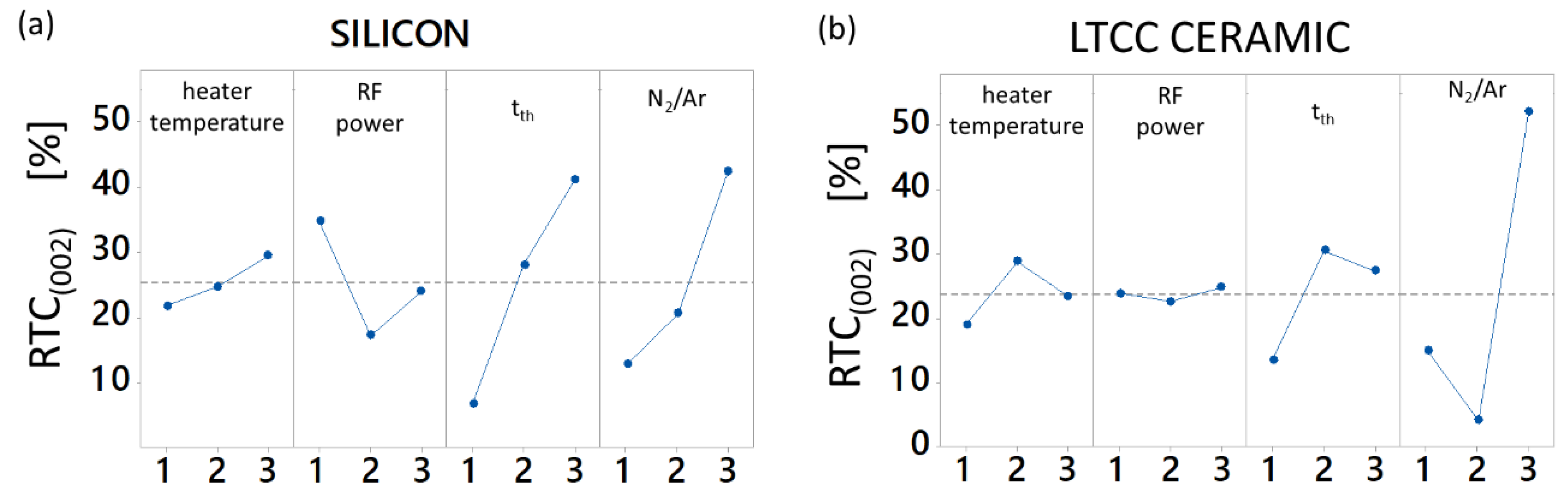

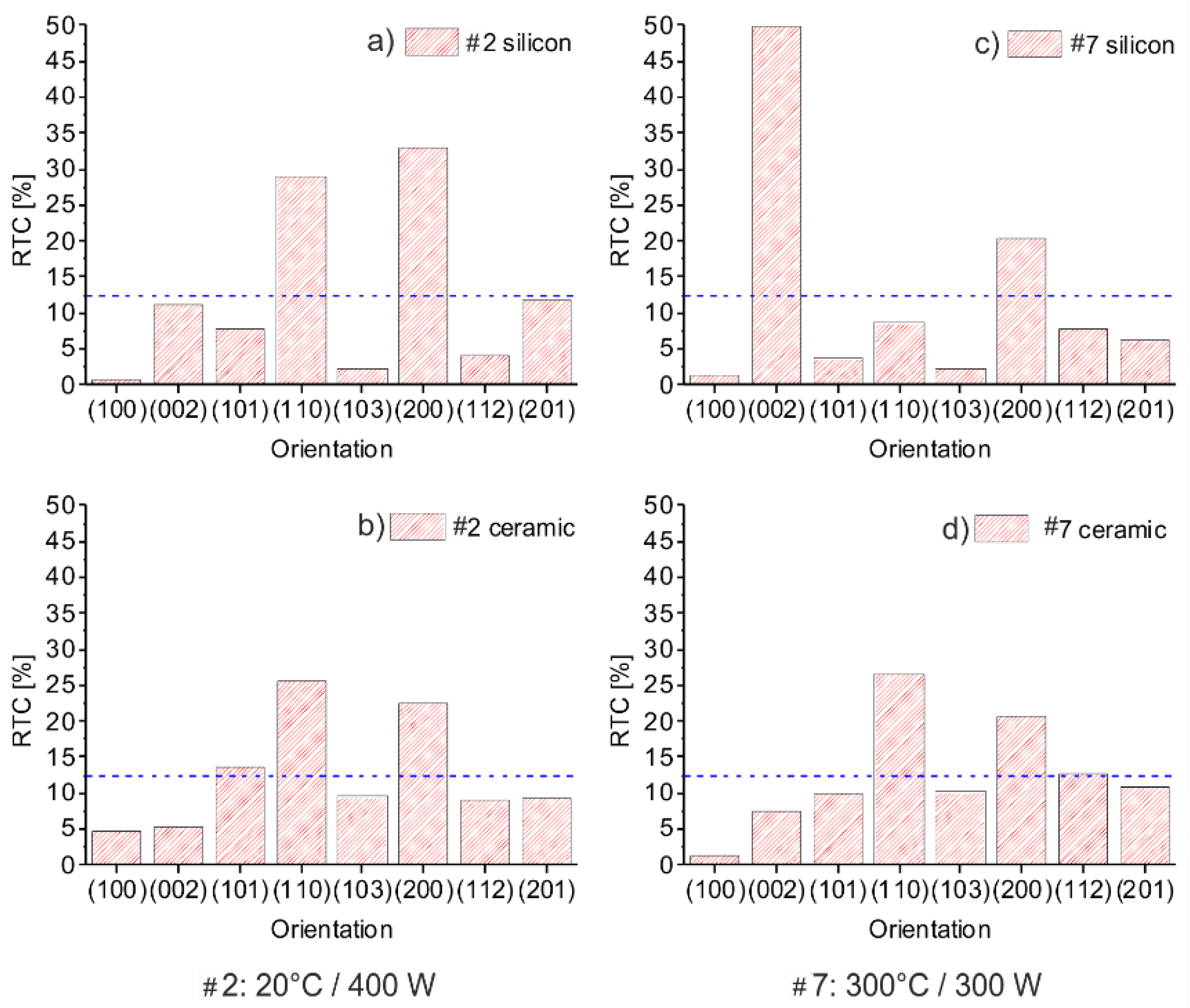

3.1. Influence of Process Parameters on Texture

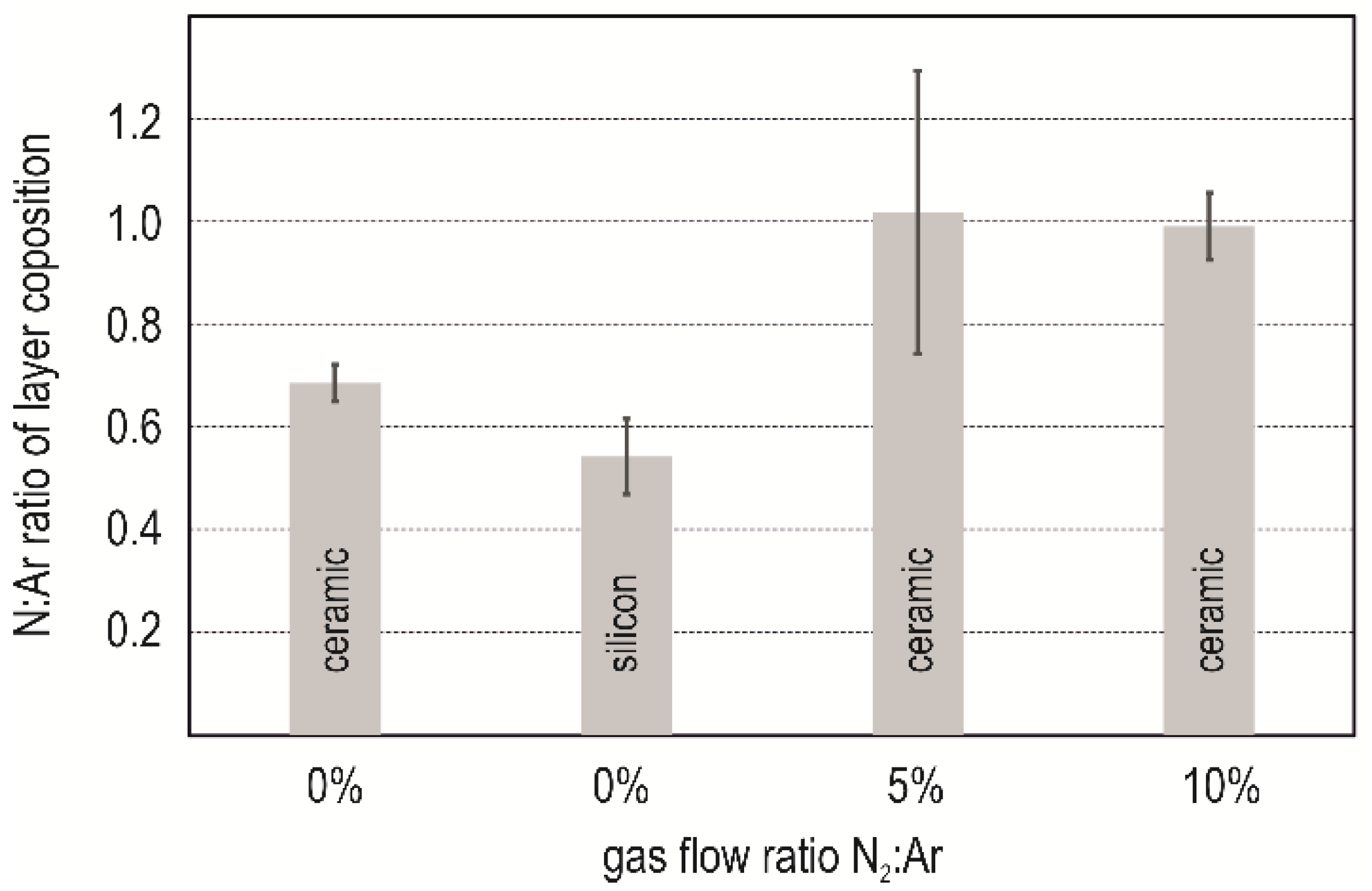

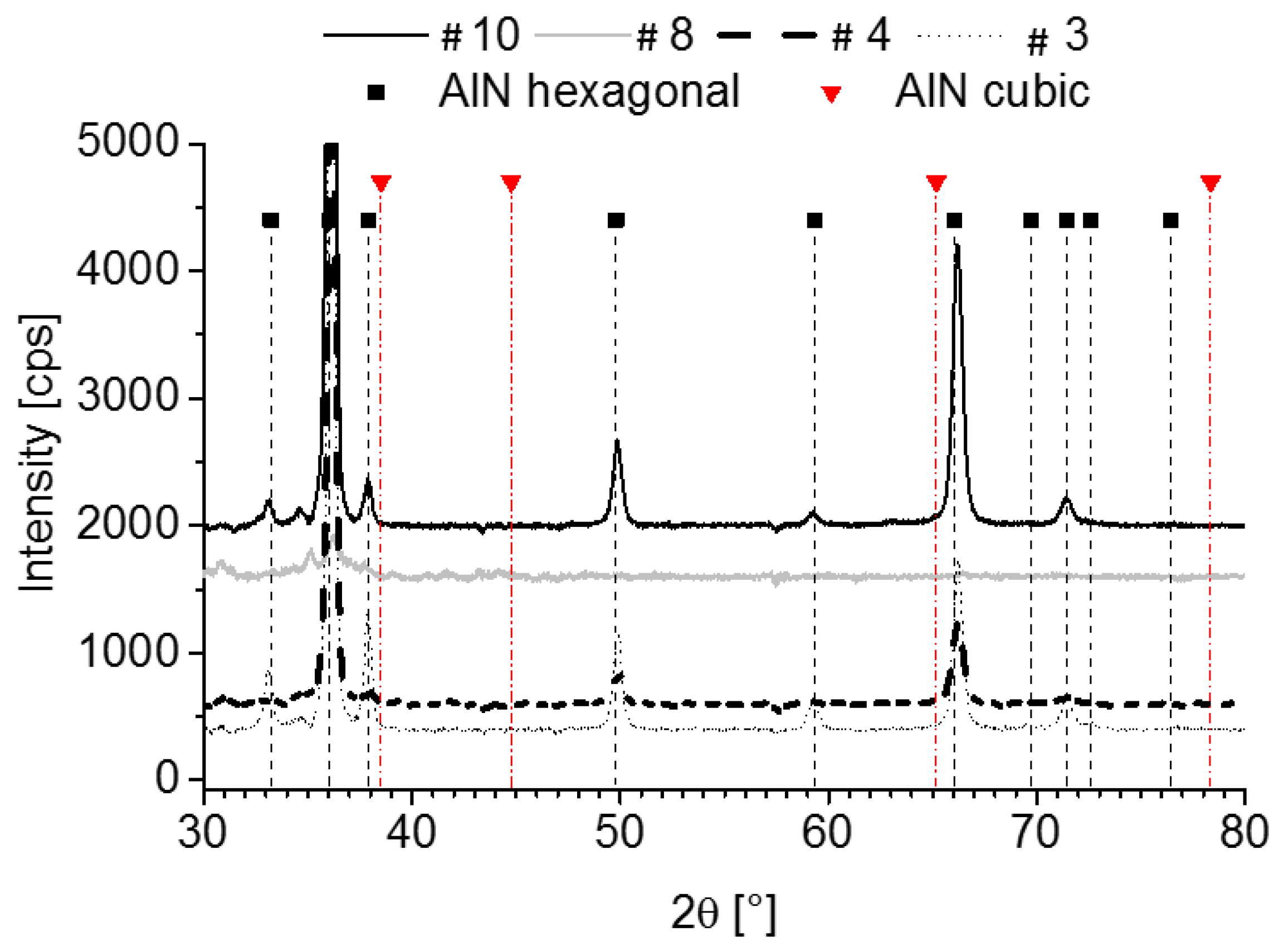

3.2. Layer Composition

3.3. Influence of Nitrogen to Argon Ratio on Morphology

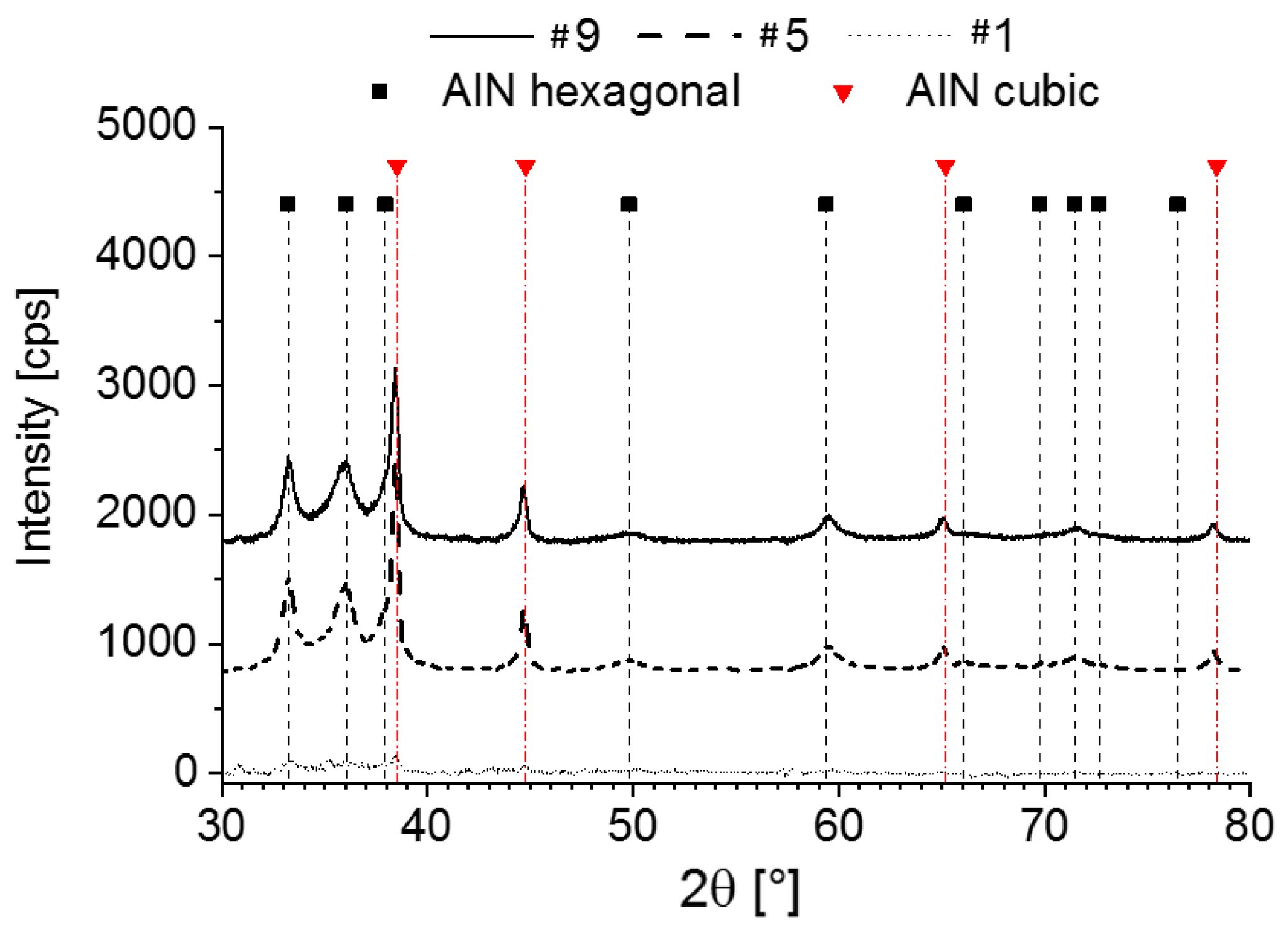

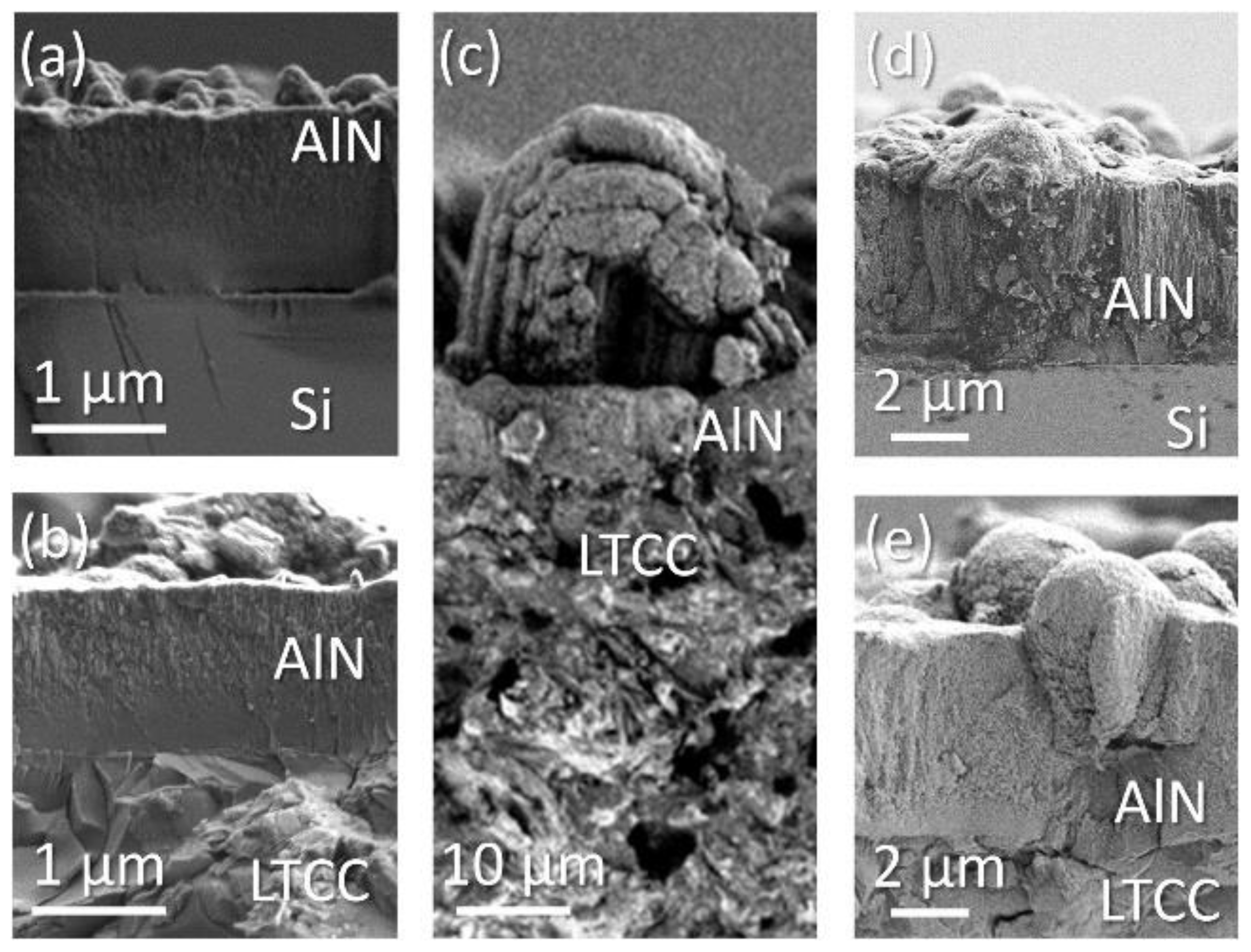

3.3.1. Nitrogen to Argon Ratio 0%

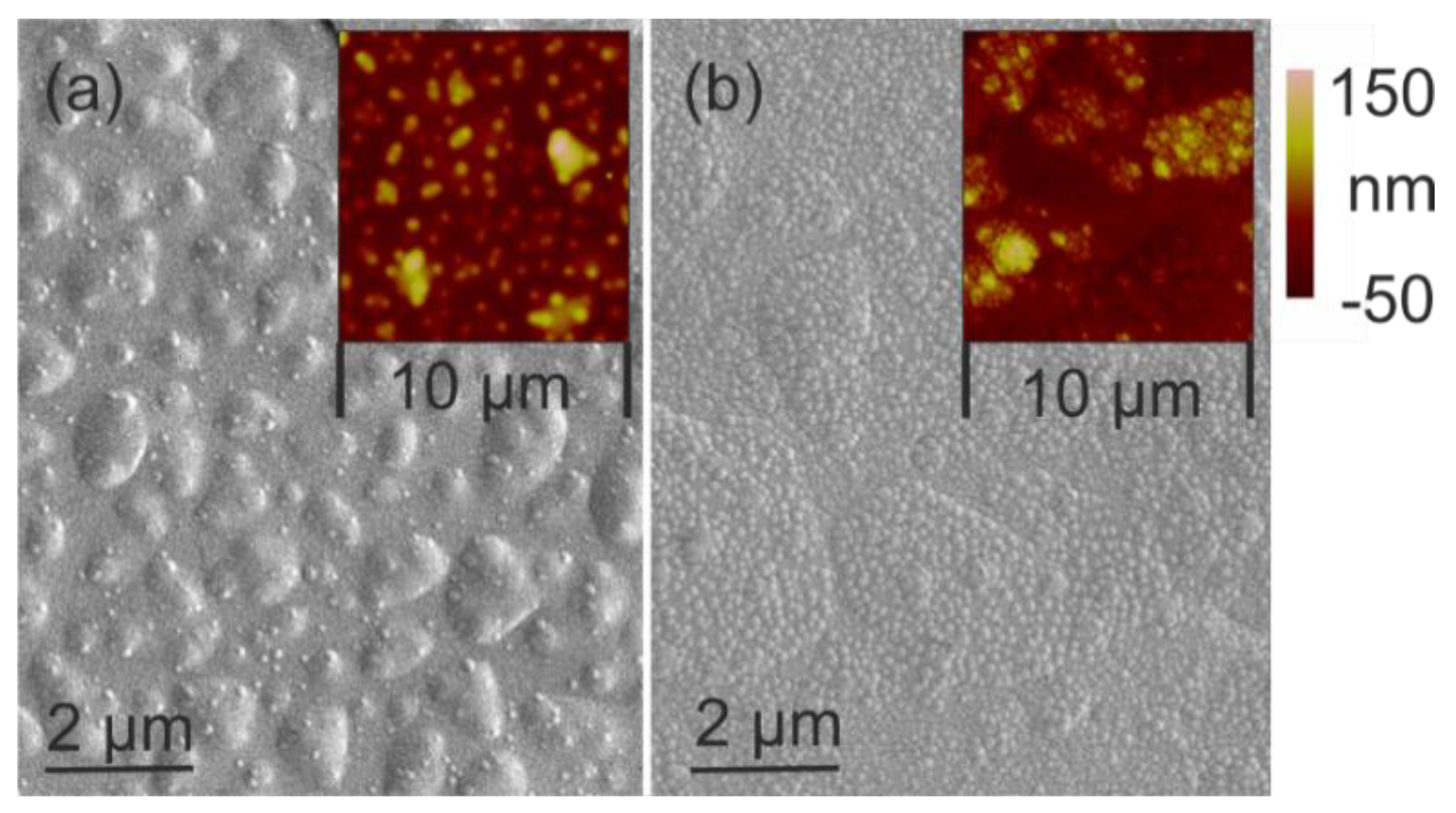

3.3.2. Nitrogen to Argon Ratio 5%

3.3.3. Nitrogen to Argon Ratio 10%

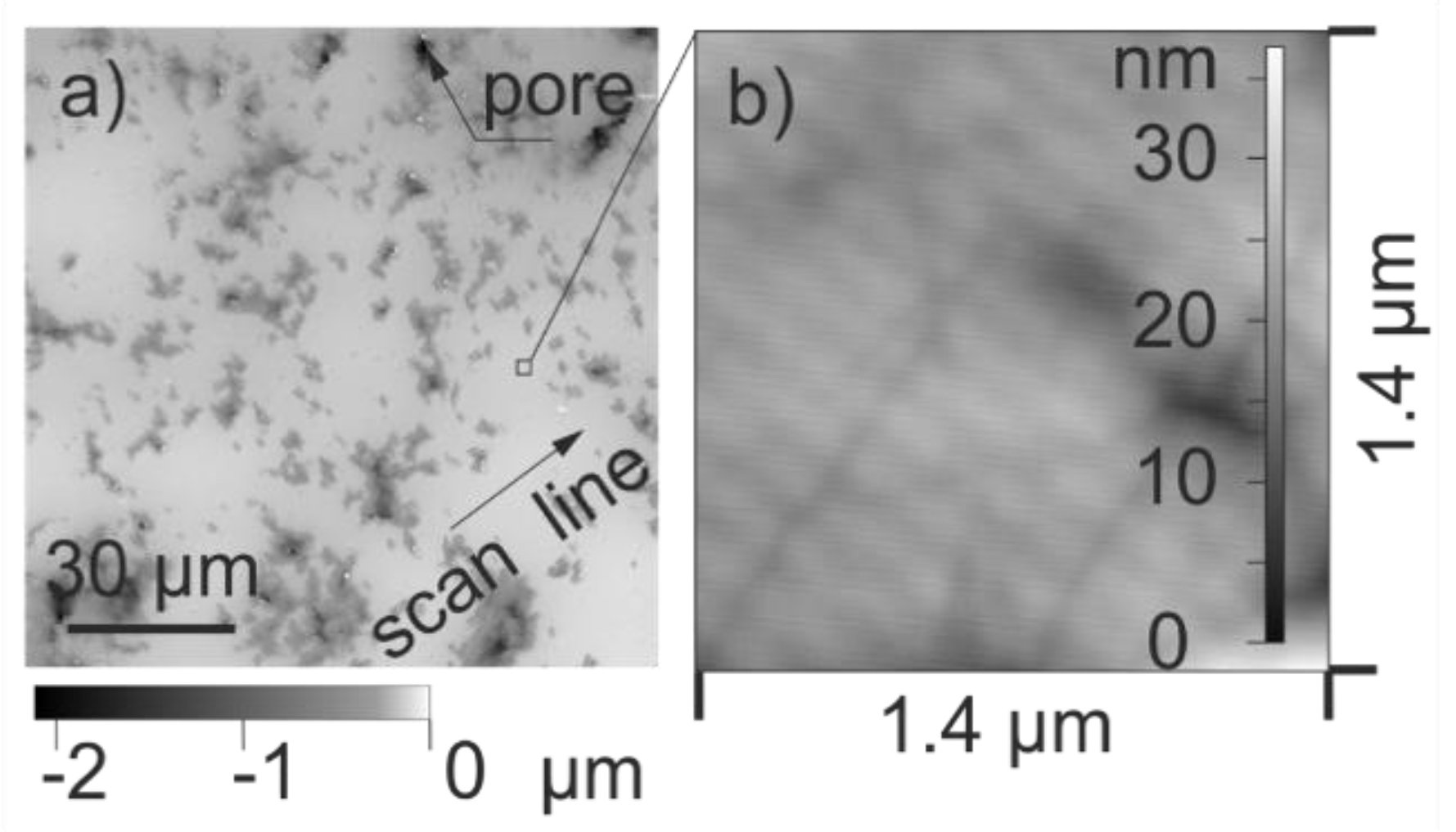

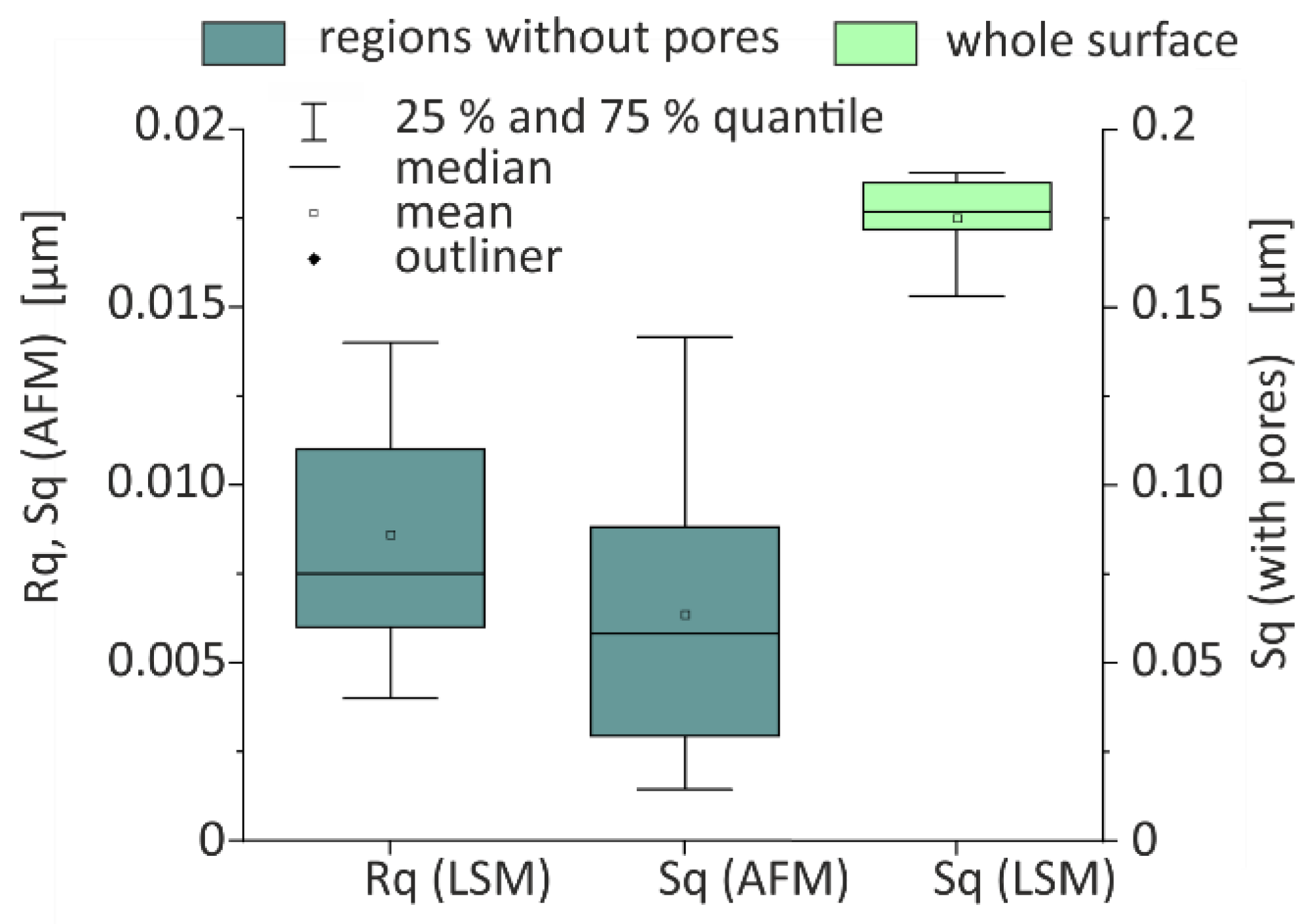

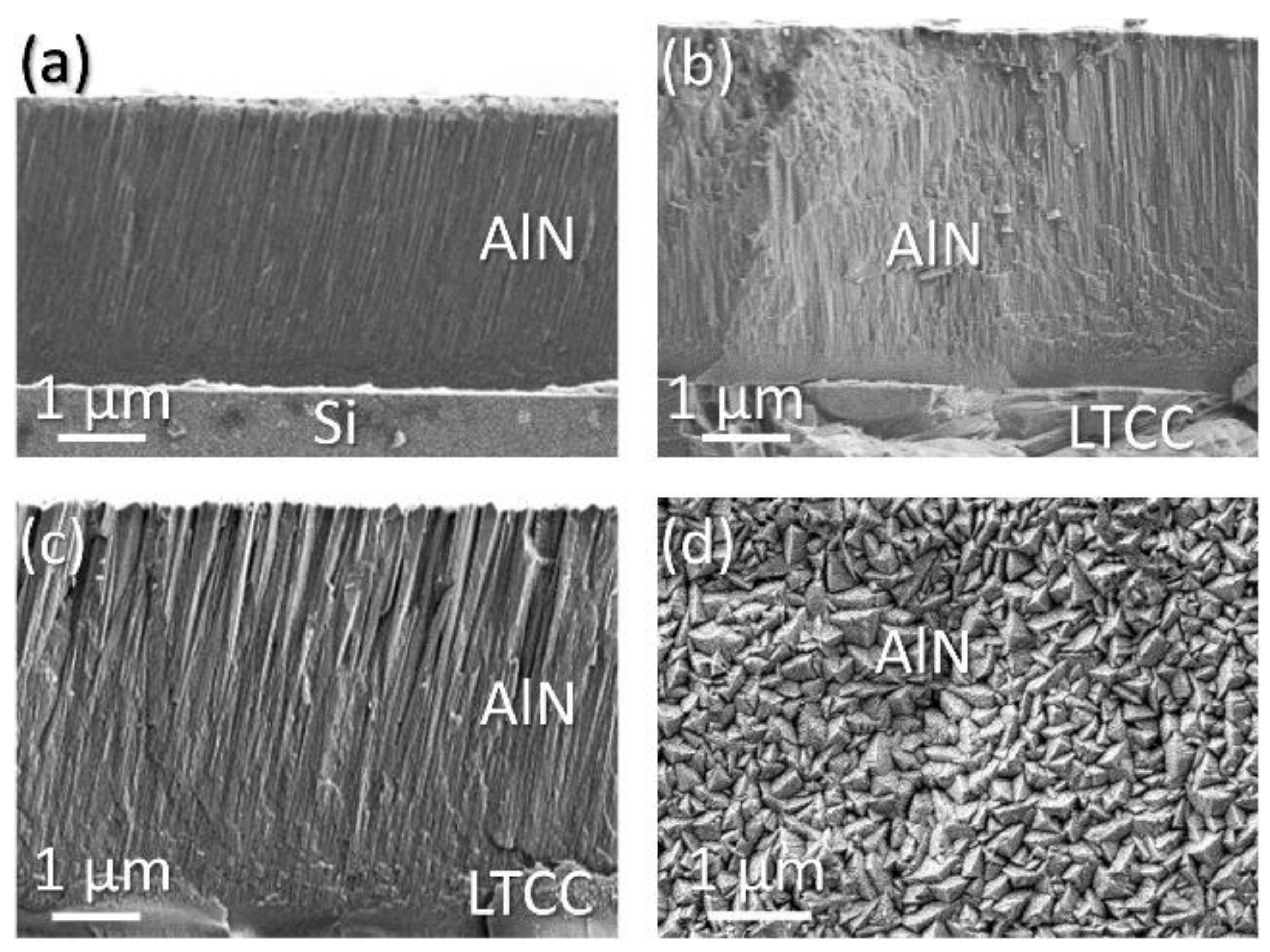

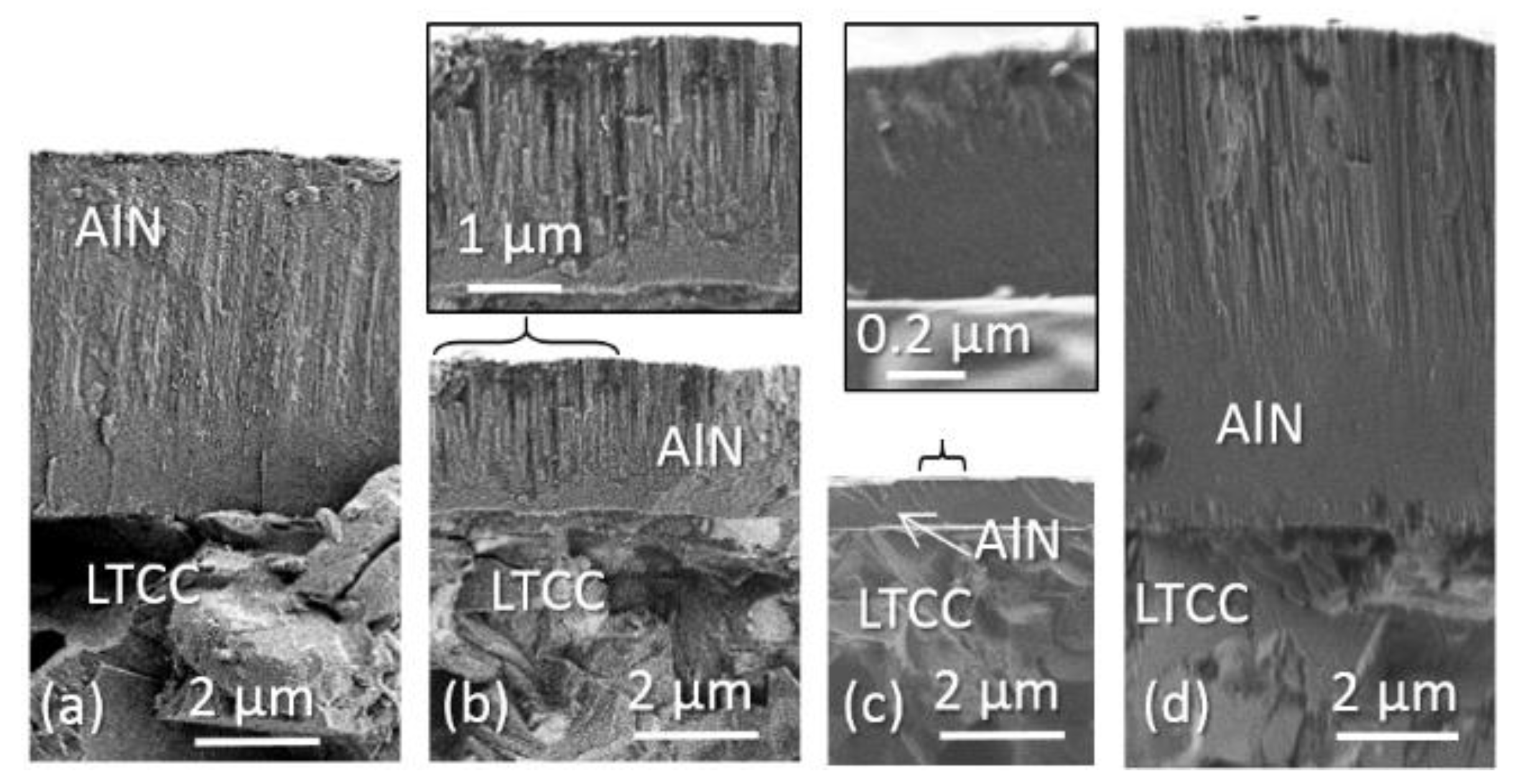

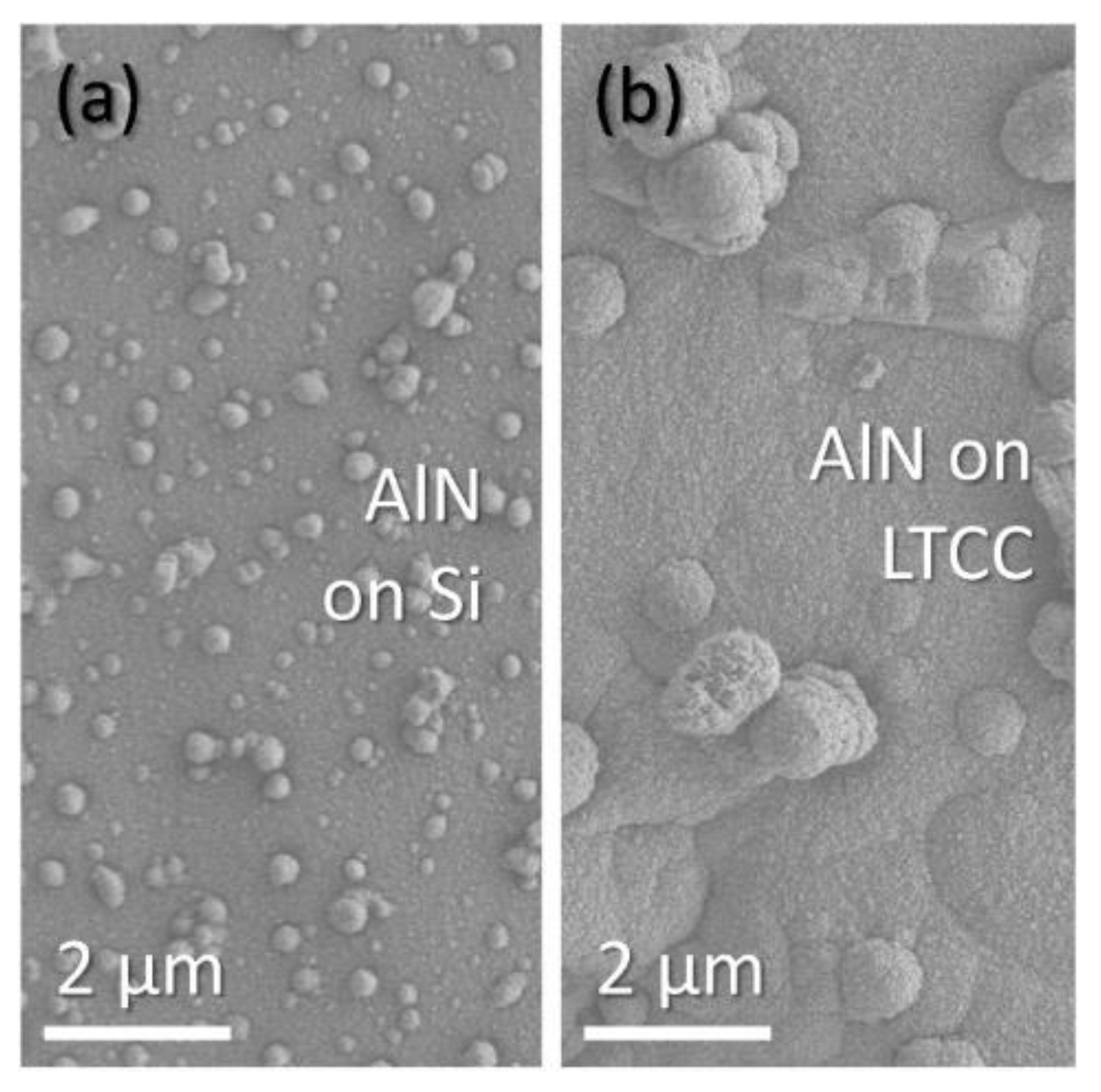

3.4. Substrate Influence

3.4.1. Nucleation

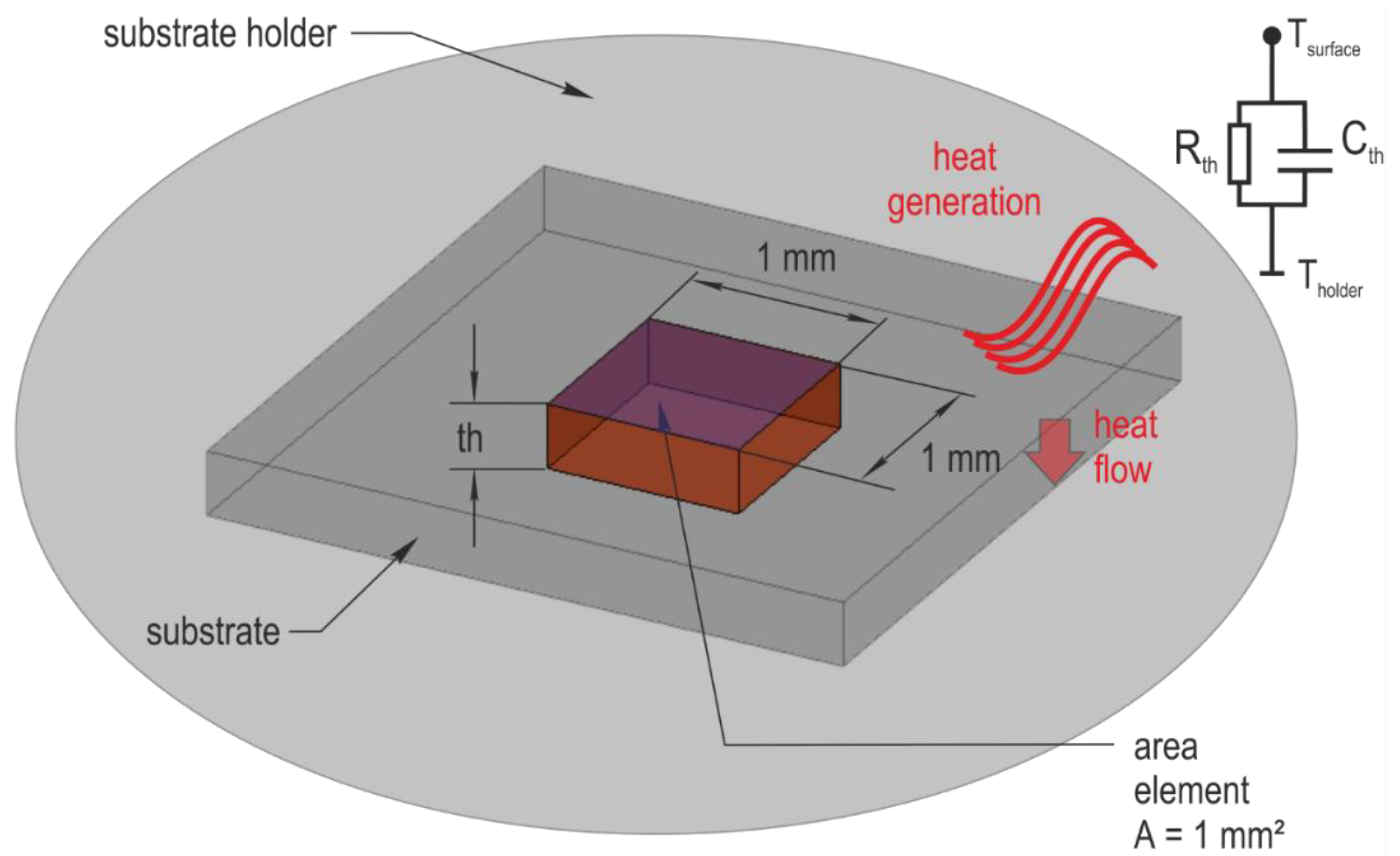

3.4.2. Consideration of the Thermal Conditions

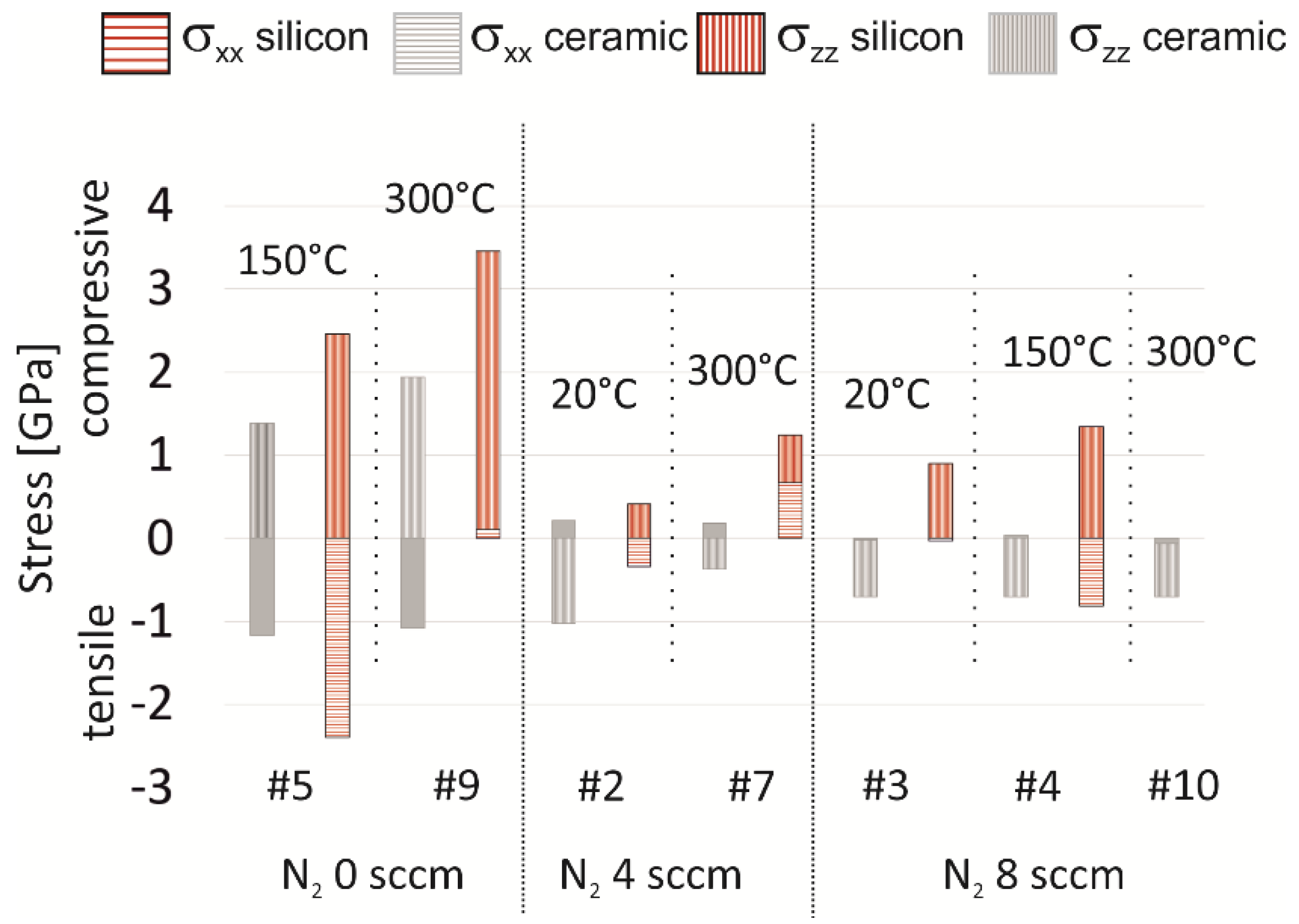

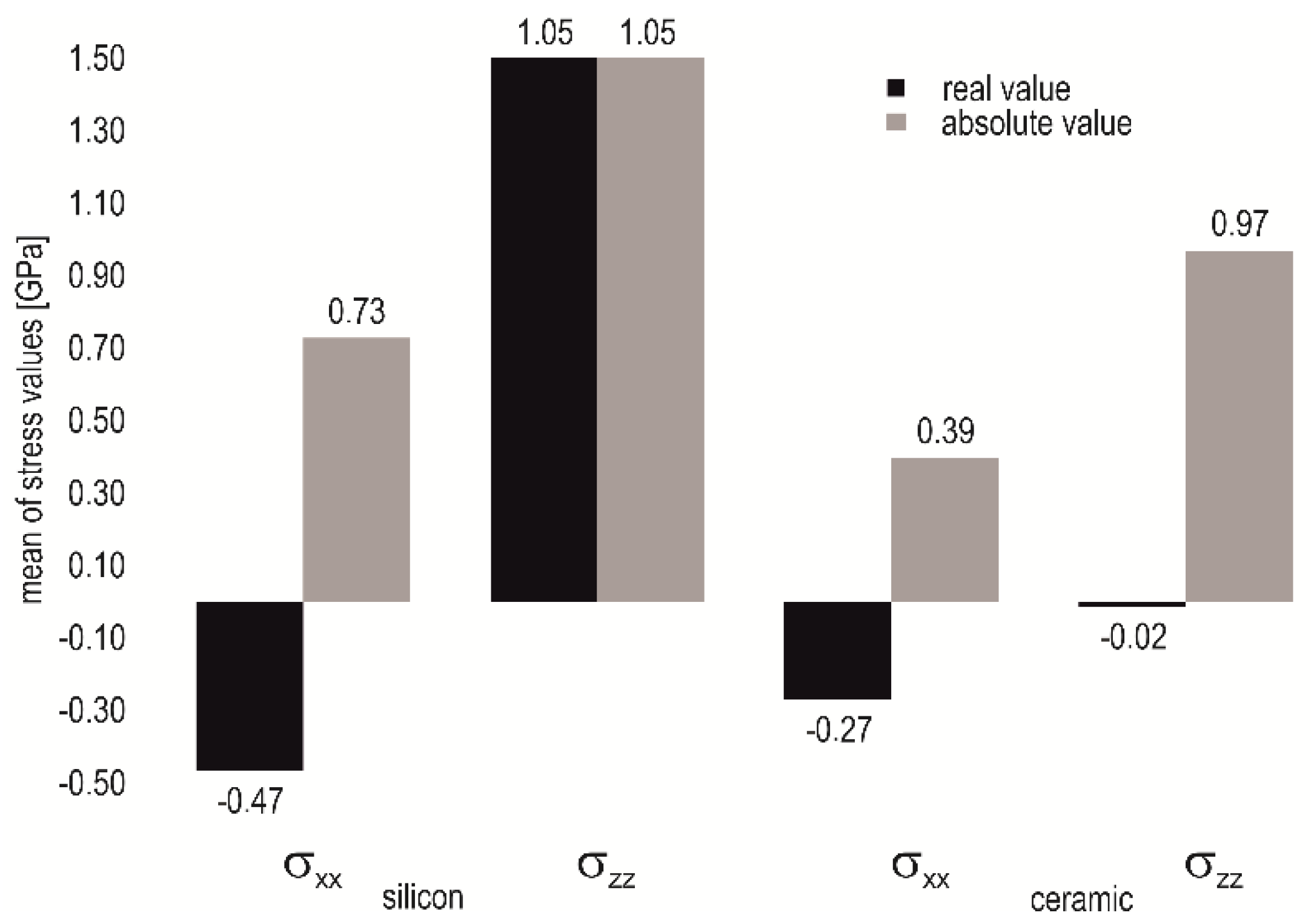

3.4.3. Layer Stress

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Exp. No. | Set Point | Measured results | RTC(002) | |||||

| Heater Temperature [°C] | RF Power [W] | Targeted Thickness [µm] | Nitrogen Gas Flow [sccm] | Rate [nm min−1] | Thickness [nm] | Si | 9k7 | |

| 1 b | 20 | 300 | 0.3 | 0 | 8 | 1400 | n.a. | n.a. |

| 2 | 20 | 400 | 1 | 4 | 27 | 3500 | 12 | 5 |

| 3 | 20 | 500 | 1.7 | 8 | 25 | 4300 | 53 | 52 |

| 4 | 150 | 300 | 1 | 8 | 13 | 2400 | 54 | 64 |

| 5 a | 150 | 400 | 1.7 | 0 | 31 | 6000 | 19 | 22 |

| 6 b | 150 | 500 | 0.3 | 4 | 22 | 700 | n.a. | n.a. |

| 7 | 300 | 300 | 1.7 | 4 | 18 | 5200 | 50 | 7.5 |

| 8 | 300 | 400 | 0.3 | 8 | 17 | 670 | 20 | 40 |

| 9 a | 300 | 500 | 1 | 0 | 43 | 4500 | 18 | 22 |

| 10 | 300 | 400 | 1.7 | 8 | 23 | 7100 | n.a. | 60 |

| Exp. No. | Mean size of Ordered Domains d | Stress [GPa] | Adhesion | |||||

| Si | 9k7 | Si | 9k7 | |||||

| Si [nm] | 9k7 [nm] | σxx | σzz | σxx | σzz | |||

| 1 b | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | + | ++ |

| 2 | 19(200) | 21(110) | −0.34 | 0.41 | 0.21 | −1.03 | − | ++ |

| 3 | 27 | 24 | −0.03 | 0.90 | −0.02 | −0.69 | − | ++ |

| 4 | 23 | 23 | −0.81 | 1.34 | 0.04 | −0.71 | − | ++ |

| 5 a | 13 b | 12 b | −2.40 | 2.46 | −1.17 | 1.39 | − | ++ |

| 6 b | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | ++ | ++ |

| 7 | 26 | 22(110) | 0.67 | 0.57 | 0.18 | −0.37 | − | ++ |

| 8 | 30(112) | 14 | n.a. | n.a. | n.a. | n.a. | ++ | ++ |

| 9 a | 8 c | 13 c | 0.10 | 3.35 | −1.08 | 1.94 | + | ++ |

| 10 | n.a. | 24 | n.a. | n.a. | −0.06 | −0.64 | − − | ++ |

Appendix C

| Material | kth (W/mK) | α (10−6 m2/s) | (103 kg/m3) |

|---|---|---|---|

| Silicon | 156 [53] ~150 [44] | 88.0 [54,55] 76.9 [56] | 2.329002 [57] |

| Alumina | 36.96 [58] 30.5 * [59] | 12 [58] 13.7 [56] | 3.48 * [59] |

| Material | min | csp [J kg−1] average | max |

|---|---|---|---|

| Silicon | 761 | 816 | 871 |

| Alumina | 640 | 710 | 781 |

| Specific Heat Capacity Csp [J kg−1 K−1] | Cth | τ [s] | 5τ [s] | 5τ [min] | ||

|---|---|---|---|---|---|---|

| Si | – | – | – | – | ||

| 871 | 1.017 | 3.4 | 17 | 0.3 | ||

| 703 | 0.821 | 2.7 | 13.7 | 0.2 | ||

| Alumina | glass | ceramic * | ||||

| 990 | 800 | 895 | 2.497 | 681 | 3405 | 57 |

| 640 | 503 | 571 | 1.594 | 435 | 2174 | 36 |

References

- Khoshman, J.M.; Kordesch, M.E. Optical characterization of sputtered amorphous aluminum nitride thin films by spectroscopic ellipsometry. J. Non-Cryst. Solids 2005, 351, 3334–3340. [Google Scholar] [CrossRef]

- Zhao, S.; Wäckelgård, E. The optical properties of sputtered composite of Al–AlN. Sol. Energy Mater. Sol. Cells 2006, 90, 1861–1874. [Google Scholar] [CrossRef]

- Oikawa, H.; Akiyama, R.; Kanazawa, K.; Kuroda, S.; Harayama, I.; Nagashima, K.; Sekiba, D.; Ashizawa, Y.; Tsukamoto, A.; Nakagawa, K.; et al. Deposition and characterization of amorphous aluminum nitride thin films for a gate insulator. Thin Solid Films 2015, 574, 110–114. [Google Scholar] [CrossRef]

- Harris, H.; Biswas, N.; Temkin, H.; Gangopadhyay, S.; Strathman, M. Plasma enhanced metalorganic chemical vapor deposition of amorphous aluminum nitride. J. Appl. Phys. 2001, 90, 5825–5831. [Google Scholar] [CrossRef]

- Piazza, G.; Felmetsger, V.; Muralt, P.; Olsson III, R.H.; Ruby, R. Piezoelectric aluminum nitride thin films for microelectromechanical systems. MRS Bull. 2012, 37, 1051–1061. [Google Scholar] [CrossRef] [Green Version]

- Hou, Y.; Zhang, M.; Han, G.; Si, C.; Zhao, Y.; Ning, J. A review: Aluminum nitride MEMS contour-mode resonator. J. Semicond. 2016, 37, 101001. [Google Scholar] [CrossRef]

- Lee, J.W.; Cuomo, J.J.; Cho, Y.S.; Keusseyan, R.L. Aluminum nitride thin films on an LTCC Substrate. J. Am. Ceram. Soc. 2005, 88, 1977–1980. [Google Scholar] [CrossRef]

- Tadigadapa, S.; Mateti, K. Piezoelectric MEMS sensors: State-of-the-art and perspectives. Meas. Sci. Technol. 2009, 20, 092001. [Google Scholar] [CrossRef]

- Cimalla, V.; Pezoldt, J.; Ambacher, O. Group III nitride and SiC based MEMS and NEMS: Materials properties, technology and applications. J. Phys. D Appl. Phys. 2007, 40, 6386–6434. [Google Scholar] [CrossRef]

- Lin, C.-M.; Chen, Y.-Y.; Felmetsger, V.V.; Lien, W.-C.; Riekkinen, T.; Senesky, D.G.; Pisano, A.P. Surface acoustic wave devices on AlN/3C-SiC/Si multilayer structures. J. Micromech. Microeng. 2013, 23, 025019. [Google Scholar] [CrossRef]

- Di Pietrantonio, F.; Benetti, M.; Cannata, D.; Beccherelli, R.; Verona, E. Guided lamb wave electroacoustic devices on micromachined AlN/Al plates. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 1175–1182. [Google Scholar] [CrossRef] [PubMed]

- Xiong, C.; Pernice, W.H.P.; Sun, X.; Schuck, C.; Fong, K.Y.; Tang, H.X. Aluminum nitride as a new material for chip-scale optomechanics and nonlinear optics. New J. Phys. 2012, 14, 95014. [Google Scholar] [CrossRef] [Green Version]

- Khelif, A.; Wilm, M.; Laude, V.; Ballandras, S.; Djafari-Rouhani, B. Guided elastic waves along a rod defect of a two-dimensional phononic crystal. Phys. Rev. E 2004, 69, 067601. [Google Scholar] [CrossRef] [PubMed]

- Panda, P.; Ramaseshan, R.; Ravi, N.; Mangamma, G.; Jose, F.; Dash, S.; Suzuki, K.; Suematsu, H. Reduction of residual stress in AlN thin films synthesized by magnetron sputtering technique. Mater. Chem. Phys. 2017, 200, 78–84. [Google Scholar] [CrossRef] [Green Version]

- Mehner, H.; Leopold, S.; Hoffmann, M. Variation of the intrinsic stress gradient in thin aluminum nitride films. J. Micromech. Microeng. 2013, 23, 095030. [Google Scholar] [CrossRef]

- Gongora-Rubio, M.R.; Espinoza-Vallejos, P.; Sola-Laguna, L.; Santiago-Avilés, J.J. Overview of low temperature co-fired ceramics tape technology for meso-system technology (MsST). Sens. Actuators A 2001, 89, 222–241. [Google Scholar] [CrossRef]

- Khoong, L.E.; Tan, Y.M.; Lam, Y.C. Overview on fabrication of three-dimensional structures in multi-layer ceramic substrate. J. Eur. Ceram. Soc. 2010, 30, 1973–1987. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Z. LTCC Substrates for RF/MW Application. In RF and Microwave Microelectronics Packaging; Kuang, K., Kim, F., Cahill, S.S., Eds.; Springer: Boston, MA, USA, 2010; pp. 189–206. [Google Scholar]

- Ariza, A.P.G.; Muller, R.; Wollenschlager, F.; Schulz, A.; Elkhouly, M.; Sun, Y.; Glisic, S.; Trautwein, U.; Stephan, R.; Muller, J.; et al. 60 GHz ultrawideband polarimetric MIMO sensing for wireless multi-gigabit and radar. IEEE Trans. Antennas Propagat. 2013, 61, 1631–1641. [Google Scholar] [CrossRef]

- Ullah, U.; Mahyuddin, N.; Arifin, Z.; Abdullah, M.Z.; Marzuki, A. Antenna in LTCC technologies: A review and the current state of the art. IEEE Antennas Propag. Mag. 2015, 57, 241–260. [Google Scholar] [CrossRef]

- Kobe, O.B.; Chuma, J.; Jamisola, R.; Chose, M. A review on quality factor enhanced on-chip microwave planar resonators. Eng. Sci. Technol. 2017, 20, 460–466. [Google Scholar] [CrossRef]

- Ma, M.; Khan, H.; Shan, W.; Wang, Y.; Ou, J.Z.; Liu, Z.; Kalantar-zadeh, K.; Li, Y. A novel wireless gas sensor based on LTCC technology. Sens. Actuators B 2017, 239, 711–717. [Google Scholar] [CrossRef]

- Sobocinski, M.; Bilby, D.; Kubinski, D.; Visser, J.; Andersson, M.; Juuti, J.; Spetz, A.L.; Jantunen, H. SiC MOSFET soot sensor in a co-fired LTCC package. Proced. Eng. 2016, 168, 27–30. [Google Scholar] [CrossRef]

- Maeder, T.; Jacq, C.; Testa, D.; Toussaint, M.; Stöck, M.; Corne, A.; Güniat, L.; Ellenrieder, B.; Jiang, X.; Windischhofer, P.; et al. LTCC and thick-film ceramic magnetic sensors for tokamak nuclear fusion. Proced. Eng. 2016, 168, 646–649. [Google Scholar] [CrossRef]

- Higuchi, Y.; Sugimoto, Y.; Harada, J.; Tamura, H. LTCC system with new high-ɛr and high-Q material co-fired with conventional low-ɛr base material for wireless communications. J. Eur. Ceram. Soc. 2007, 27, 2785–2788. [Google Scholar] [CrossRef]

- Sebastian, M.T.; Jantunen, H. Low loss dielectric materials for LTCC applications: A review. Int. Mater. Rev. 2008, 53, 57–90. [Google Scholar] [CrossRef]

- Müller, J.; Perrone, R.; Drüe, K.-H.; Stephan, R.; Trabert, J.; Hein, M.; Schwanke, D.; Pohlner, J.; Reppe, G.; Kulke, R.; et al. Comparison of high-resolution patterning technologies for LTCC microwave circuits. J. Microelectron. Electron. Packag. 2007, 4, 99–104. [Google Scholar] [CrossRef]

- Bittner, A.; Ababneh, A.; Seidel, H.; Schmid, U. Influence of the crystal orientation on the electrical properties of AlN thin films on LTCC substrates. Appl. Surf. Sci. 2010, 257, 1088–1091. [Google Scholar] [CrossRef]

- Yim, W.M.; Paff, R.J. Thermal expansion of AlN, sapphire, and silicon. J. Appl. Phys. 1974, 45, 1456–1457. [Google Scholar] [CrossRef]

- Gutzeit, N.; Fischer, M.; Bartsch, H.; Müller, J. Lapping and polishing of different LTCC substrates for thin film applications. In Proceedings of the 2015 European Microelectronics Packaging Conference (EMPC), Friedrichshafen, Germany, 14–16 September 2015; pp. 1–4. [Google Scholar]

- Bengoa, L.N.; Tuckart, W.R.; Zabala, N.; Prieto, G.; Egli, W.A. Tin coatings electrodeposited from sulfonic acid-based electrolytes: Tribological behavior. J. Mater. Eng. Perform. 2015, 24, 2274–2281. [Google Scholar] [CrossRef]

- Camargo, M.K.; Schmidt, U.; Grieseler, R.; Wilke, M.; Bund, A. Electrodeposition of Zn-TiO2 dispersion coatings: Study of particle incorporation in chloride and sulfate baths. J. Electrochem. Soc. 2014, 161, D168–D175. [Google Scholar] [CrossRef]

- Mittemeijer, E.J.; Welzel, U. Modern Diffraction Methods; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2012. [Google Scholar]

- Cheng, H.; Sun, Y.; Zhang, J.X.; Zhang, Y.B.; Yuan, S.; Hing, P. AlN films deposited under various nitrogen concentrations by RF reactive sputtering. J. Cryst. Growth 2003, 254, 46–54. [Google Scholar] [CrossRef]

- Cho, S. Effect of nitrogen flow ratio on the structural and optical properties of aluminum nitride thin films. J. Cryst. Growth 2011, 326, 179–182. [Google Scholar] [CrossRef]

- Lin, W.T.; Meng, L.C.; Chen, G.J.; Liu, H.S. Epitaxial growth of cubic AlN films on (100) and (111) silicon by pulsed laser ablation. Appl. Phys. Lett. 1995, 66, 2066–2068. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kim, C.S.; Noh, Y.K.; Kim, M.D.; Oh, J.E. Substrate temperature dependence of the phase transition behavior of AlN layers grown on Si(111) substrate by metalorganic chemical vapor deposition. J. Cryst. Growth 2011, 334, 189–194. [Google Scholar] [CrossRef]

- Lebedev, V.; Cimalla, V.; Kaiser, U.; Foerster, C.; Pezoldt, J.; Biskupek, J.; Ambacher, O. Effect of nanoscale surface morphology on the phase stability of 3C-AlN films on Si(111). J. Appl. Phys. 2005, 97, 114306. [Google Scholar] [CrossRef]

- Johnson, G.R.; Holmquist, T.J.; Beissel, S.R. Response of aluminum nitride (including a phase change) to large strains, high strain rates, and high pressures. J. Appl. Phys. 2003, 94, 1639–1646. [Google Scholar] [CrossRef]

- Zang, Y.; Li, L.; Ren, Z.; Cao, L.; Zhang, Y. Characterization of AlN thin film prepared by reactive sputtering. Surf. Interface Anal. 2016, 48, 1029–1032. [Google Scholar] [CrossRef]

- Yuan, Q.; Döll, J.; Romanus, H.; Wang, H.; Bartsch, H.; Albrecht, A.; Hoffmann, M.; Schaaf, P.; Wang, D. Surface-nanostructured Al-AlN composite thin films with excellent broad-band antireflection properties fabricated by limited reactive sputtering. ACS Appl. Nano Mater. 2018, 1, 1124–1130. [Google Scholar] [CrossRef]

- Thornton, J.A. High rate thick film growth. Ann. Rev. Mater. Sci. 1977, 7, 239–260. [Google Scholar] [CrossRef]

- Ambacher, O.; Smart, J.; Shealy, J.R.; Weimann, N.G.; Chu, K.; Murphy, M.; Schaff, W.J.; Eastman, L.F.; Dimitrov, R.; Wittmer, L.; et al. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in N- and Ga-face AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 85, 3222–3233. [Google Scholar] [CrossRef]

- Childs, G.E.; Ericks, L.J.; Powell, R.L. Thermal Conductivity of Solids at Room Temperature and Below: A Review and Compilation of the Literature; U.S. Department of Commerce, National Bureau of Standards: Olympia, WA, USA, 1973.

- DuPontTM GreenTapeTM 9k7 Low Temperature Co-fired Ceramic Material System. Available online: http://www.dupont.com/products-and-services/electronic-electrical-materials/low-temperature-co-fire-ceramic-materials/brands/greentape-ceramic-circuit/products/green-tape-9k7-ltcc-material-system.html (accessed on 16 August 2018).

- Nölle, G. Technik der Glasherstellung; Wiley-VCH: Weinheim, Germany, 2009. (In German) [Google Scholar]

- LUMITOS GmbH, Berlin, Germany. Spezifische Wärmekapazität. Available online: http://www.chemie.de/lexikon/Spezifische_W%C3%A4rmekapazit%C3%A4t.html (accessed on 11 July 2018).

- Soda-Lime (Float) Glass. Available online: https://www.makeitfrom.com/material-properties/Soda-Lime-Float-Glass/ (accessed on 11 July 2018).

- Binder, H.H. Lexikon der chemischen Elemente. Das Periodensystem in Fakten, Zahlen und Daten; Hirzel: Stuttgart, Germany, 1999. (In German) [Google Scholar]

- Wikimedia Foundation Inc. Wikibooks: Tabellensammlung Chemie/Spezifische Wärmekapazitäten. Available online: https://de.wikibooks.org/wiki/Tabellensammlung_Chemie/_spezifische_W%C3%A4rmekapazit%C3%A4ten (accessed on 12 July 2018).

- Al2O3 Aluminiumoxid Technische Hochleistungskeramik. Available online: https://www.pgo-online.com/de/al2o3.html (accessed on 12 July 2018).

- HiDur® Aluminiumoxid-Kugeln. Available online: http://www.rvtpe.com/wp-content/uploads/2013/06/Kugeln-Aluminiumoxid.pdf (accessed on 12 July 2018).

- Glassbrenner, C.J.; Slack, G.A. Thermal conductivity of silicon and germanium from 3°K to the melting point. Phys. Rev. 1964, 134, A1058–A1069. [Google Scholar] [CrossRef]

- ASTM E1461-01 Standard Test Method for Thermal Diffusivity of Solids by the Flash Method; ASTM International: West Conshohocken, PA, USA, 2001.

- King, J. Material Handbook for Hybrid Microelectronics; Artec House: Washington, DC, USA, 1988. [Google Scholar]

- Touloukian, Y.S.; Powell, R.W.; Ho, C.Y.; Klemens, P.G. Thermophysical Properties of Matter; IFI/Plenum Data Corp.: New York, NY, USA; Washington, DC, USA, 1970. [Google Scholar]

- Henins, I. Precision Density Measurement of Silicon. J. Res. Natl. Bur. Stand. A Phys. Chem. 1964, 68A, 529–533. [Google Scholar] [CrossRef]

- Touloukian, Y.S. Thermophysical Properties of High Temperature Solid Materials; Macmillan: New York, NY, USA, 1967. [Google Scholar]

- Touloukian, Y.S.; Powell, R.W.; Ho, C.Y.; Klemens, P.G. Thermophysical Properties of Matter. Thermal Conductivity; IFI/Plenum Data Corp.: New York, NY, USA; Washington, DC, USA, 1970. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartsch, H.; Grieseler, R.; Mánuel, J.; Pezoldt, J.; Müller, J. Magnetron Sputtered AlN Layers on LTCC Multilayer and Silicon Substrates. Coatings 2018, 8, 289. https://doi.org/10.3390/coatings8080289

Bartsch H, Grieseler R, Mánuel J, Pezoldt J, Müller J. Magnetron Sputtered AlN Layers on LTCC Multilayer and Silicon Substrates. Coatings. 2018; 8(8):289. https://doi.org/10.3390/coatings8080289

Chicago/Turabian StyleBartsch, Heike, Rolf Grieseler, Jose Mánuel, Jörg Pezoldt, and Jens Müller. 2018. "Magnetron Sputtered AlN Layers on LTCC Multilayer and Silicon Substrates" Coatings 8, no. 8: 289. https://doi.org/10.3390/coatings8080289

APA StyleBartsch, H., Grieseler, R., Mánuel, J., Pezoldt, J., & Müller, J. (2018). Magnetron Sputtered AlN Layers on LTCC Multilayer and Silicon Substrates. Coatings, 8(8), 289. https://doi.org/10.3390/coatings8080289