1. Introduction

The application of thin-film wear-resistant vacuum-plasma coatings (e.g., TiAlN, TiNbAlN, ZrN, TiCN, etc.) as a means of increasing the operational characteristics of various types of cutting tools from high-speed steels and hard alloys is now widespread in the industry. High operational parameters of the coated tools are ensured by an optimal combination of surface properties, such as a high microhardness, and a low coefficient of friction in relation to the material being processed, and volume properties, such as a good strength, toughness, crack resistance, etc. The effect of using thin-film coatings for these types of tools was repeatedly proven to increase their operational characteristics, and their role is obvious. Today, the development of coatings for tools made from hard alloys and high-speed steel is mainly related to the improvement of their architecture and compositions [

1,

2,

3].

When it comes to discussing cutting tools made of ceramics, one of the most effective modern tool materials for the high-speed machining of hardened blanks, things are not so straightforward. On the one hand, the types of ceramics based on Al

2O

3 and Si

3N

4 used in the production of the instruments initially have a high hardness, which is more than 20 GPa, and a low friction coefficient within the range of 0.2–0.4 (compared with the tools mentioned above from high-speed steels and hard alloys), i.e., indicators that are comparable with the corresponding values of thin-film coatings based on the nitrides and carbonitrides of refractory metals [

4,

5,

6,

7]. On the other hand, ceramics (even the most modern brands of reinforced and composite ceramics) are inferior in regards to their strength characteristics compared to better grades of carbide and, especially, to high-speed steels. The main problem of using ceramics in cutting tools is still the occurrence of sudden and unpredictable failures due to the brittle fracturing of the cutting part of ceramic inserts—a consequence of the insufficient strength and sensitivity of ceramics to cyclic and thermal loads [

8,

9,

10]. Because of this, enterprises operating ceramics are forced to significantly underestimate cutting regimes in order to reduce the likelihood of brittle fractures. It is especially characteristic during operations of intermittent cutting (milling) when the cutting part of the tool is subjected to cyclic loading, and the probability of the occurrence of brittle fractures (chipping and dying) increases noticeably.

Today, all areas of the development and improvement of ceramics used in the cutting tools are associated with the improvement of its strength properties, mainly due to the elimination and minimization of defects (e.g., cracks, craters, pores, etc.) formed at various stages of its manufacture and operation.

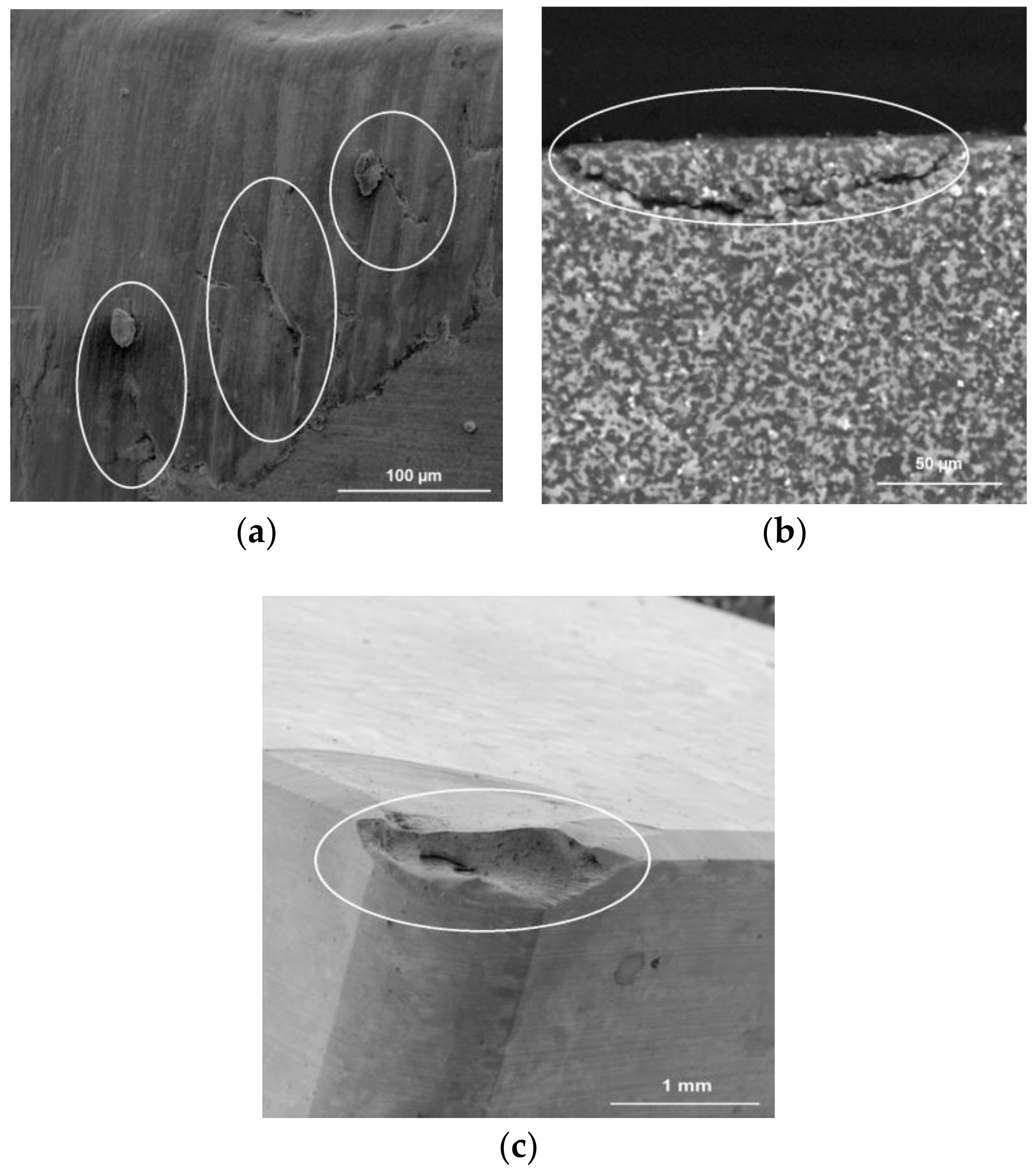

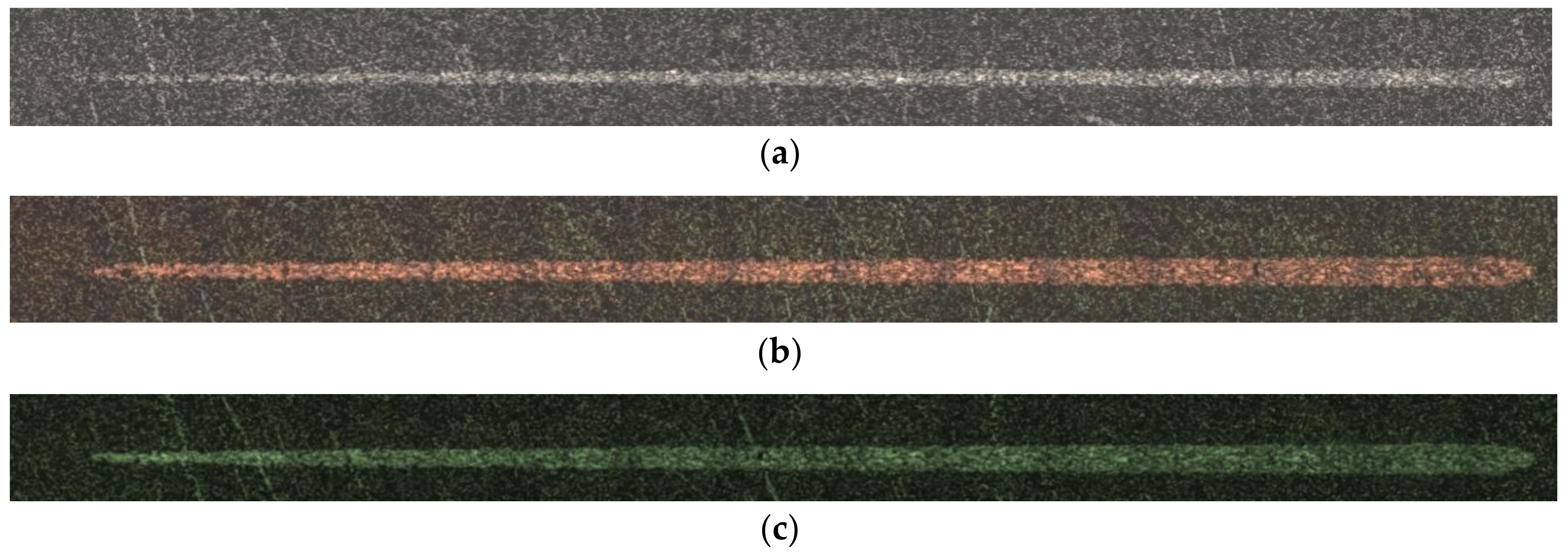

Figure 1 shows the images from a scanning electronic microscope of a classical defect of an insert made of ceramics based on Al

2O

3, leading to its failure during operation: the initial cracks on the main rear surface (

Figure 1a), subsequently leading to the development of a crack (

Figure 1b), and the brittle rupture (shearing) of the cutting edge during the process of cutting (

Figure 1c).

As for the effectiveness of applying thin-film coatings to ceramics in order to improve the performance, there is no single opinion among scientists and manufacturing companies. Many manufacturers of ceramic tools consider the effects of coating of ceramic inserts to be dubious and unproven [

11,

12,

13].

A quantitative effect from the coatings of ceramics, which is comparable to that which is achieved with the coating of high-speed and carbide tools, is often expected. It is well known that the tool life of high-speed steels and hard alloys is increased by up to eight times compared to tools without coatings, owing to innovative coatings. It is unreasonable to expect a comparable result from the coating of ceramics. Ceramics are a structurally heterogeneous material, and have significantly different physical and mechanical characteristics. Their specific features should be taken into account when designing coating technologies. It is evident that the technological principles used for developing and successfully improving high-speed steel and hard alloy tools should not be applied to ceramics, and the increase in durability cannot be repeated. Practice shows that a two-fold increase in the resistance of ceramics should be considered a perfect result.

Scientists immersed in this problem, including the scientific team of the Moscow State University of Technology STANKIN, developed the theory that the coating allows for the healing of surface defects, creates a barrier in the surface layer of the ceramic base that hinders the generation of operational defects, and forms an obstacle that prevents the exit of internal cracks in the surface (in their presence or origin), as well as limiting underwater energy at the mouth of the cracks [

14,

15,

16].

Unfortunately, the processes of the nucleation (development) of the cracks, leading to the brittle fracture of the ceramic tool, occur rapidly in the process of cutting. The modern instrument base (vibroacoustic and acoustic-emissive sensors) makes it possible to adequately predict and identify the brittle fracturing process by collecting and processing the diagnostic information from the cutting zone [

17,

18,

19]. However, visualization of the cutting zone is practically impossible due to the specific nature of metalworking, and all conclusions made are based mainly on the results of mathematical modeling [

20,

21,

22,

23,

24].

The purpose of this article is to experimentally study the role of thin-film vacuum-plasma coatings when applied to ceramic inserts based on aluminum oxide, Al2O3 + SiC and Al2O3 + TiC. To achieve this goal, we set upon the task of experimentally evaluating the transformation of important surface characteristics and the surface layer of ceramic inserts that occur during the coating process of diamond-like coating (DLC), TiZrN, and TiCrAlN. In the final part of our research, the quantitative evaluation of the effects of the changes in the surface and surface layer properties on the performance of ceramic inserts during the milling process of hardened bearing steel was studied.

2. Materials and Methods

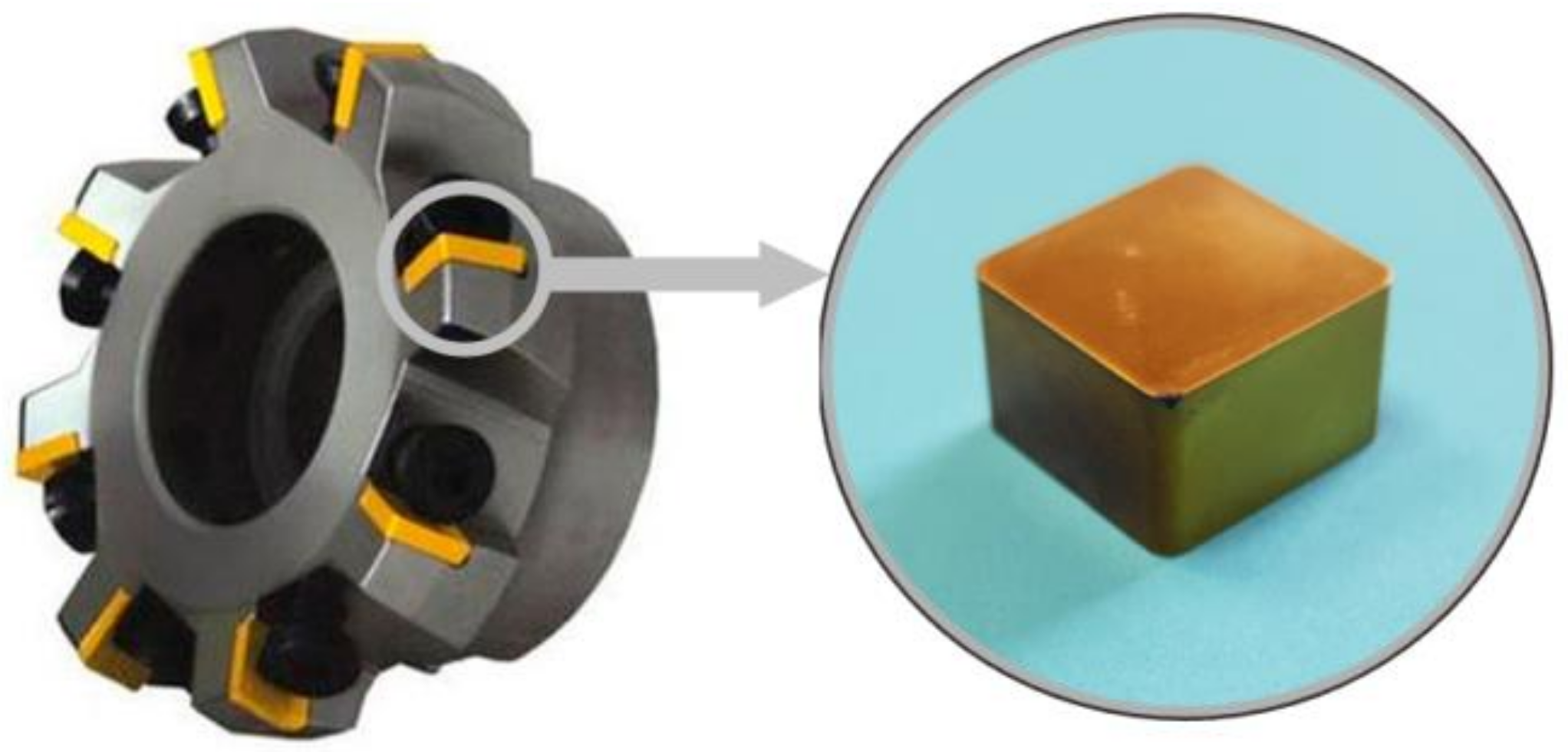

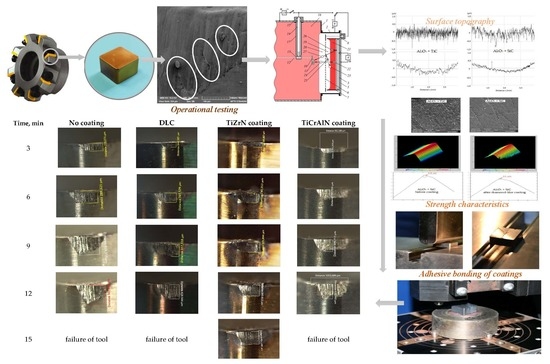

2.1. Cutting Tools and Material Being Processed

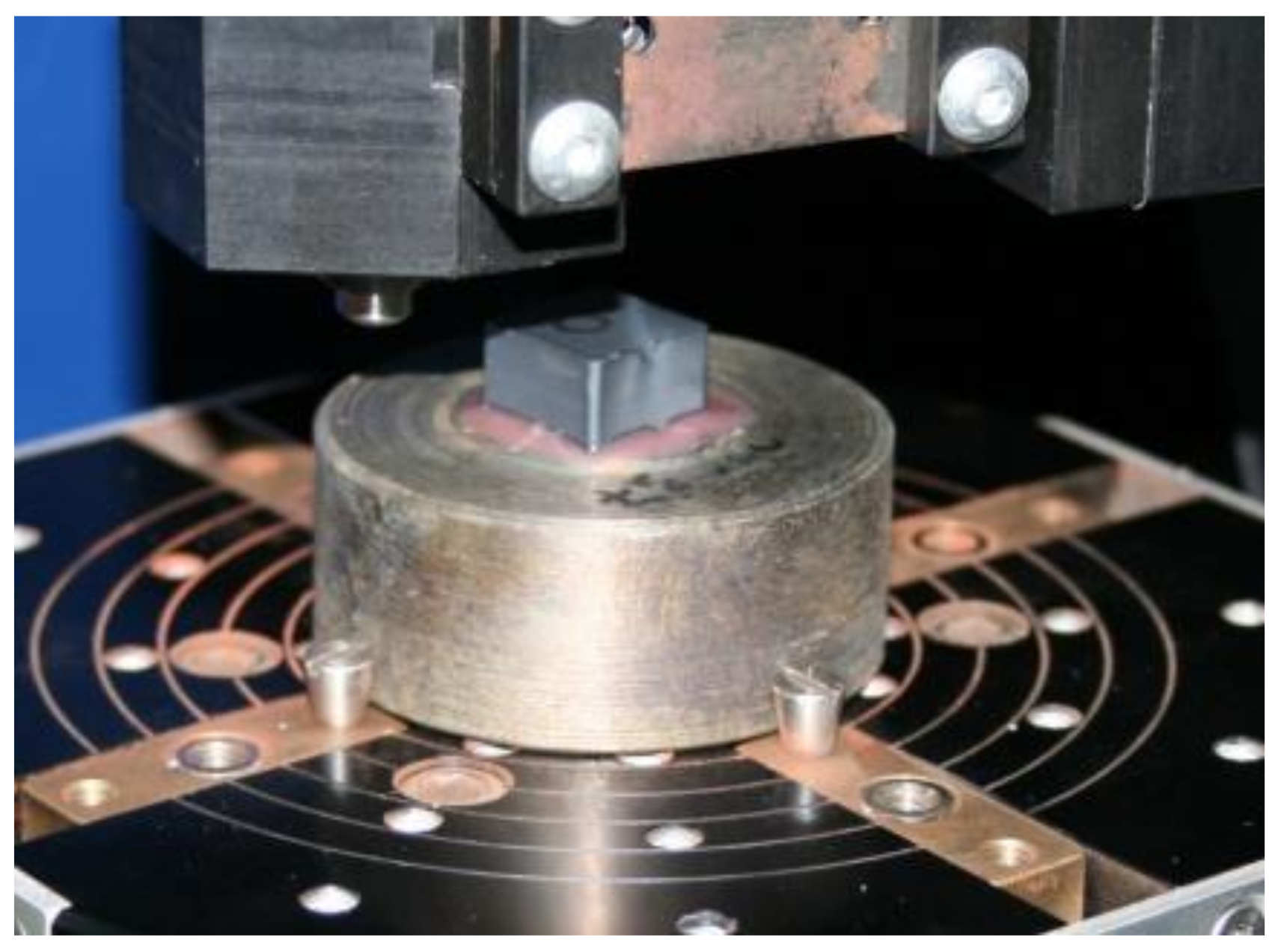

A 125-mm-diameter eight-toothed end mill with a mechanical fastening of ceramic inserts was used as a cutting tool during the experiments (

Figure 2). Hardened steel 102Cr6 with a hardness of 60–62 HRC was used as the material.

Square inserts of 12 mm × 12 mm × 4.76 mm made from oxide ceramics strengthened with silicon carbides were used for the conducted experiments. This kind of ceramic has a composite structure which was achieved by adding ceramic powdered SiC to the main powdered Al

2O

3 in the form of whiskers [

25,

26,

27,

28,

29,

30,

31,

32]. The whiskers provide higher strength characteristics during sintering. Samples of the same shape and dimensions made from the most common ceramics, Al

2O

3 + TiC, were used to complementarily refine and confirm the obtained results [

33,

34,

35]. CC650 and CC670 ceramic inserts produced by Sandvik Coromant (Stockholm, Sweden) were used during the experiments.

All the inserts used in the present studies were from one batch, and were manufactured serially according to a process excluding the influence of additional factors on the experimental results, related to the technology of sintering ceramic inserts [

36,

37,

38,

39] and their diamond sharpening.

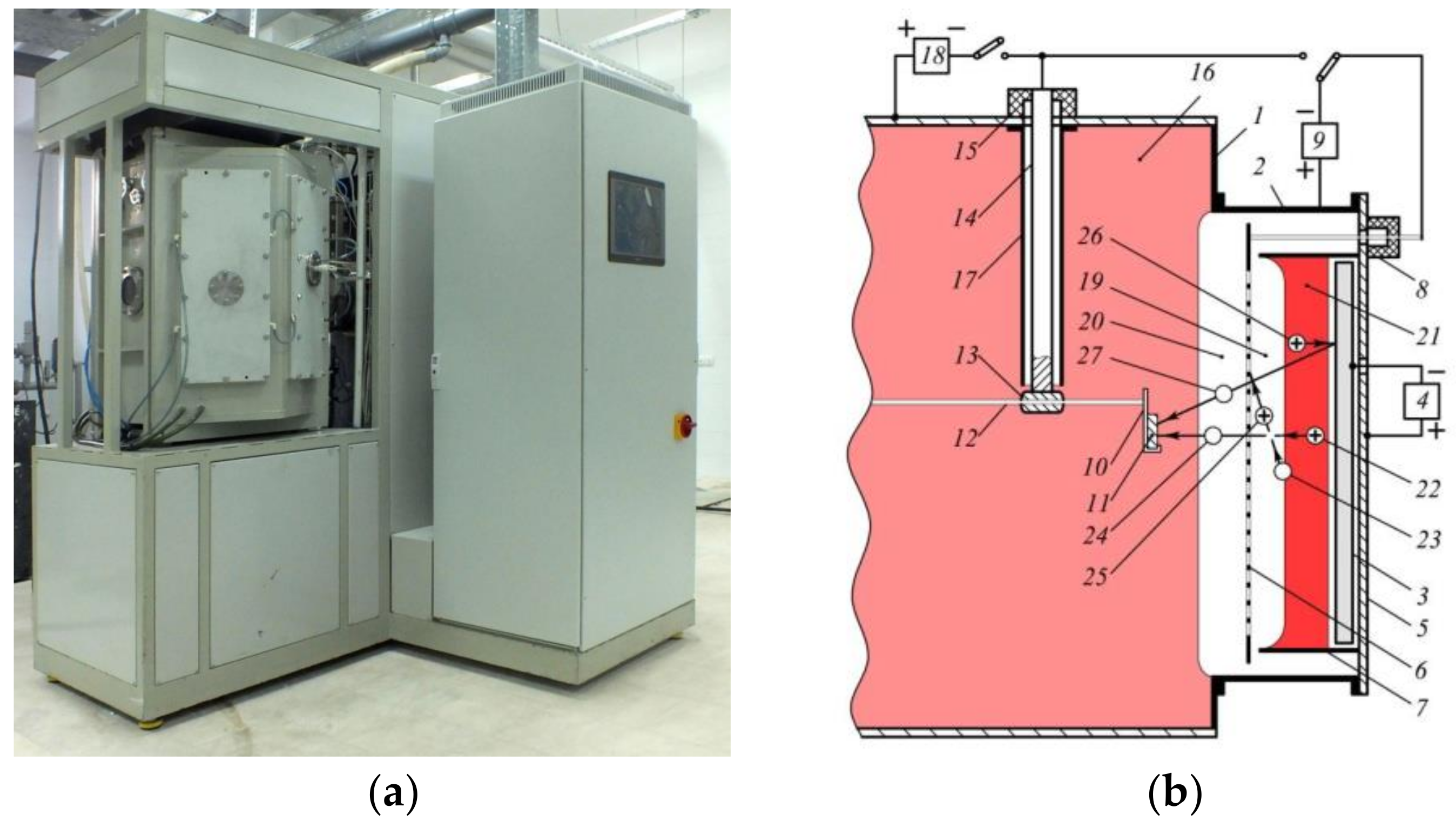

2.2. Deposition of Vacuum-Plasma Coatings on Ceramics and Coating Compositions

A unique technological vacuum-plasma plant, developed by the scientific group of scientists of Moscow State University of Technology STANKIN (Moscow, Russia), was used for the deposition of coatings onto ceramic inserts based on aluminum oxide, Al

2O

3 + SiC and Al

2O

3 + TiC. The construction of the plant ensures bombardment of the synthesized coatings using high-energy particles as fast atoms and gas molecules (

Figure 3).

Because ceramics have low electrical conductivity, the application of traditional technological principles to them and the supply of negative voltage to them are less effective than with conductive materials (e.g., high-speed steels and hard alloys). Furthermore, the spraying of the surface of ceramics during cleaning is less intense, and when the coating is condensed due to insufficient surface activation, low-density coatings and low adhesion strength are often the result. It is essential to ensure continuity of the bombardment of the coating on the entire surface of the product during the synthesis of high-quality coatings. For this, the trajectories of the deposited atoms and the bombarded synthesized coating of fast molecules must coincide [

40,

41]. Otherwise, metal atoms and fast molecules will affect separate parts of the surface in turn, resulting in the deposition of coatings without the bombardment with fast particles alternating with the bombardment with fast particles without deposition of the coating. Thus, the conditions for obtaining the essential properties of the coatings will not be created. A complete coincidence of the trajectories was achieved as a result of the fact that both sources were combined in the same device with the emission surface common to the particles. As seen in

Figure 3, the high-energy gas atoms (24) obtained by a charge exchange of ions (22) accelerated by high-voltage pulses applied to the grid (6) bombarded and synthesized on the ceramic substrate (11) from the atoms (27) of the sputtered target (3) and the nitride coating. The material of the target (3) can be changed depending on the composition of the applied coatings. The bombardment by high-energy gas atoms in the process of the coating deposition ensures the formation of high-quality coatings with grain sizes less than 100 nm. The choice of composition of the wear-resistant coatings for the cutting inserts made of ceramics is not a trivial task. It is necessary to choose or develop a coating composition that will create a compatible and practically useful system in combination with the main ceramic material. The following three systems were chosen as wear-resistant coatings for the ceramic inserts made from aluminum oxide of two systems, Al

2O

3 + SiC and Al

2O

3 + TiC, based on the results of previous works [

42,

43] and an in-depth analysis of the operating conditions of ceramics during the milling of hardened steels.

A diamond-like coating (DLC) was obtained by sputtering a graphite target in a glow discharge plasma, resulting in an amorphous coating structure consisting of carbon atoms with both diamond- and graphite-like bonds [

44,

45]. This coating is traditionally characterized by a low friction coefficient and has noticeably higher microhardness values in comparison to tool ceramics.

TiZrN coating is characterized by a relatively high microhardness, with a change in the coefficient of linear expansion close to the ceramic under heating, which is essential when resisting thermal loads arising in the cutting zone [

46,

47]. Moreover, it is possible to predict a sufficiently high thermodynamic stability and resistance to the propagation of cracks during operation caused by the high binding energy in the crystal lattice of this coating. TiCrAlN coating has a microhardness comparable to the hardness of the ceramic substrate, which eliminates the formation of stress at the interface due to the difference in properties; however, it is characterized by good elasticity and high resistance to the adhesion processes [

48,

49].

It is critical to select the optimum holding time in the vacuum chamber for deposition of the coatings, on which the thickness of the formed coating depends. Films which are too thick (over 6 μm) can significantly increase the number of defects in the coating, can reduce the adhesion bond strength of the coating to the ceramic substrate, and can reduce the ability of the coating to resist elastoplastic deformation. Excessively thin films (1 μm or less) will not have a noticeable effect on the operational properties of the ceramic inserts, because they will not be able to resist the adhesion processes and will not be a barrier preventing the development of cracks and their emergence on the surface. The preliminary experiments made it possible to find the rational thicknesses of the coatings for the current investigation under conditions of interrupted cutting for the diamond-like coating of 2 μm, and for the TiZrN and TiCrAlN coatings of 3.5 μm. The thickness of the coatings was directly dependent on the holding time of the ceramic inserts. The thickness was determined on a witness sample, which was placed in the vacuum chamber of the experimental plant along with the ceramic inserts. The control and quantitative evaluation were carried out using the standard method on an industrial coating thickness tester, CALOTEST, equipped with an optical measuring system.

After deposition of the coatings according to the described technology, their microhardness values were determined as follows: DLC coating—36 GPa, TiZrN coating—28 GPa, TiCrAlN coating—24 GPa.

2.3. Surface Topography and Microgeometry of Ceramic Cutting Inserts

A high-precision profilometer, Hommel Tester T8000 (JENOPTIK Industrial Metrology, Jena, Germany), was used to assess the roughness of the working surfaces of the ceramic inserts before and after coating. An additional analysis of the working surfaces of the ceramic inserts was carried out using a scanning electron microscope (SEM), Tescan VEGA3 LMH (Brno, Czech Republic).

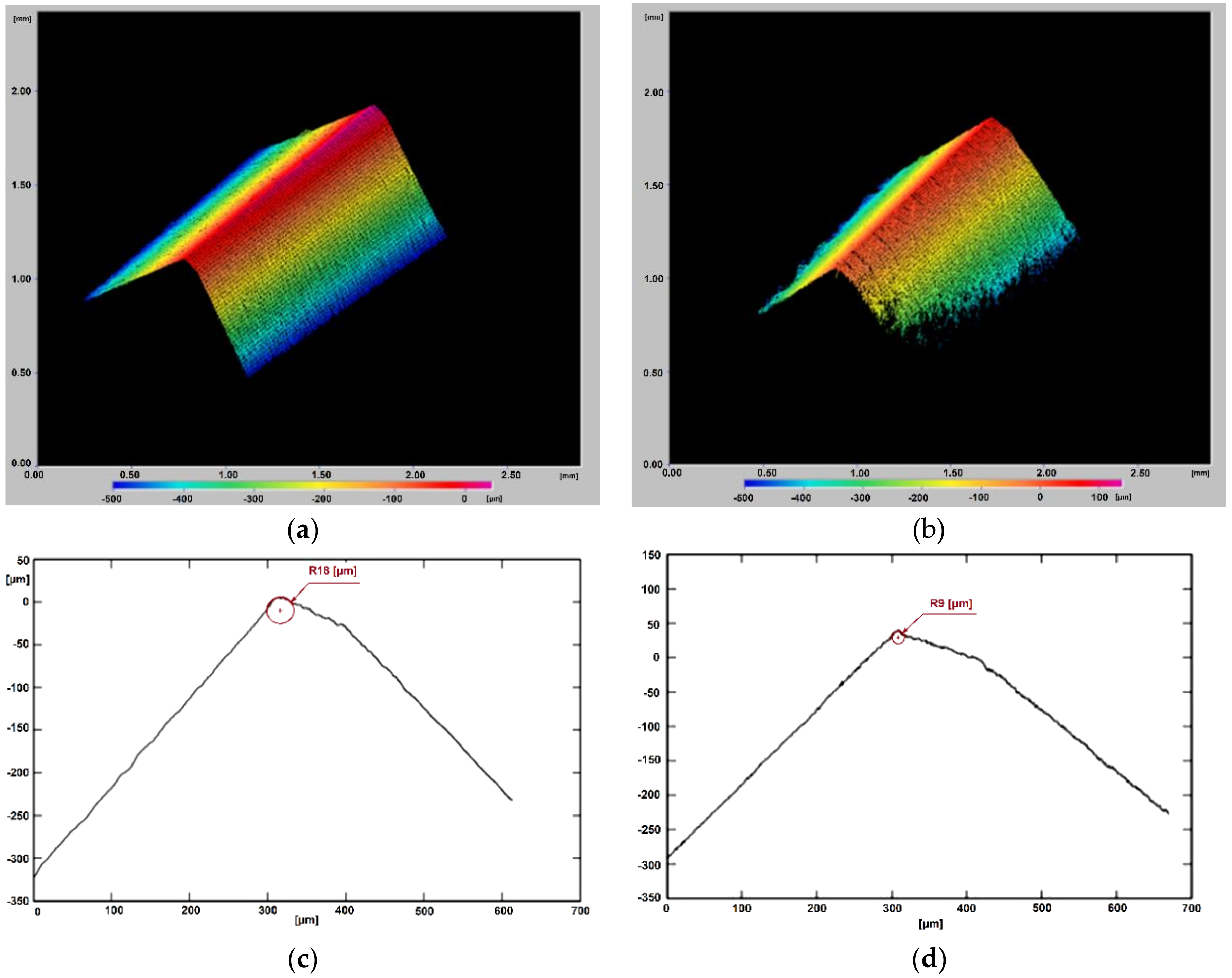

The rounding radius of the cutting edges of the ceramic inserts was determined and measured using a certified high-precision three-dimensional (3D) microscope, MicroCAD Premium+ (GFMesstechnik GmbH, Teltow, Germany), with an error of ±1 μm. A color-imitating 3D model and a profilogram of the radius of the cutting edge were drawn based on the light-section method for each sample.

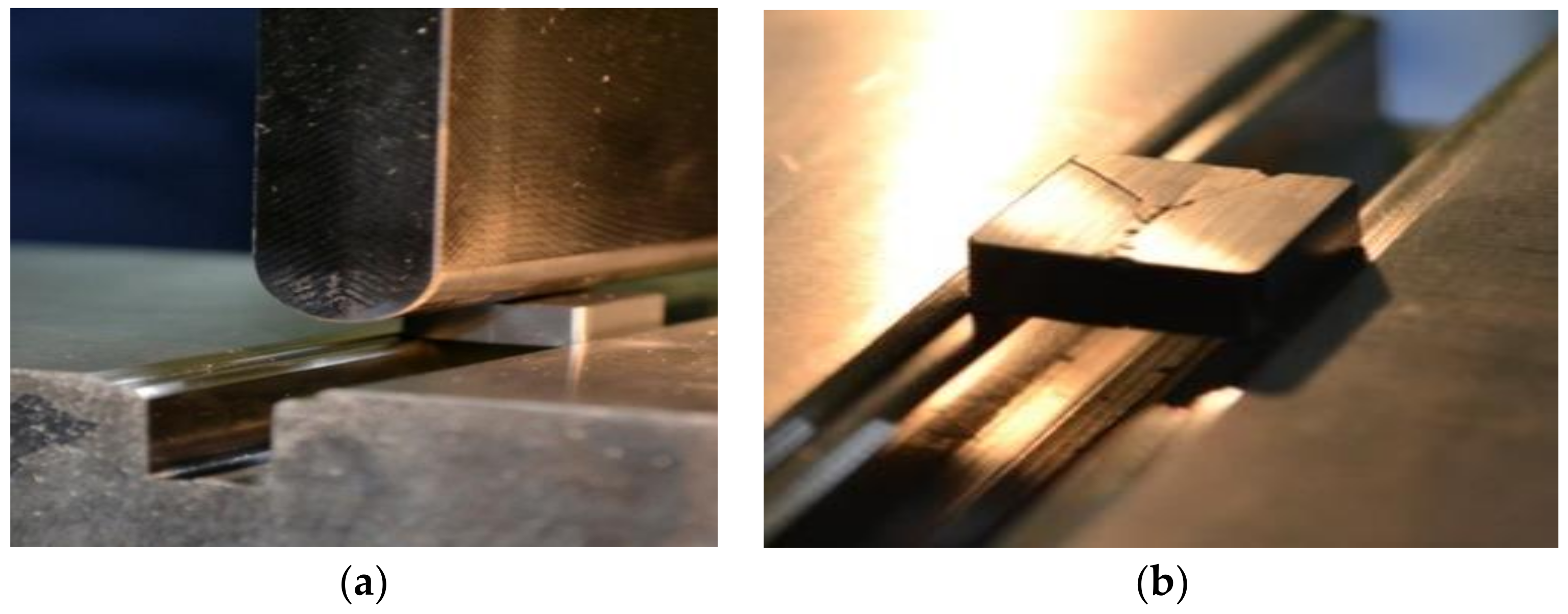

2.4. Strength Characteristics of Ceramic Cutting Inserts

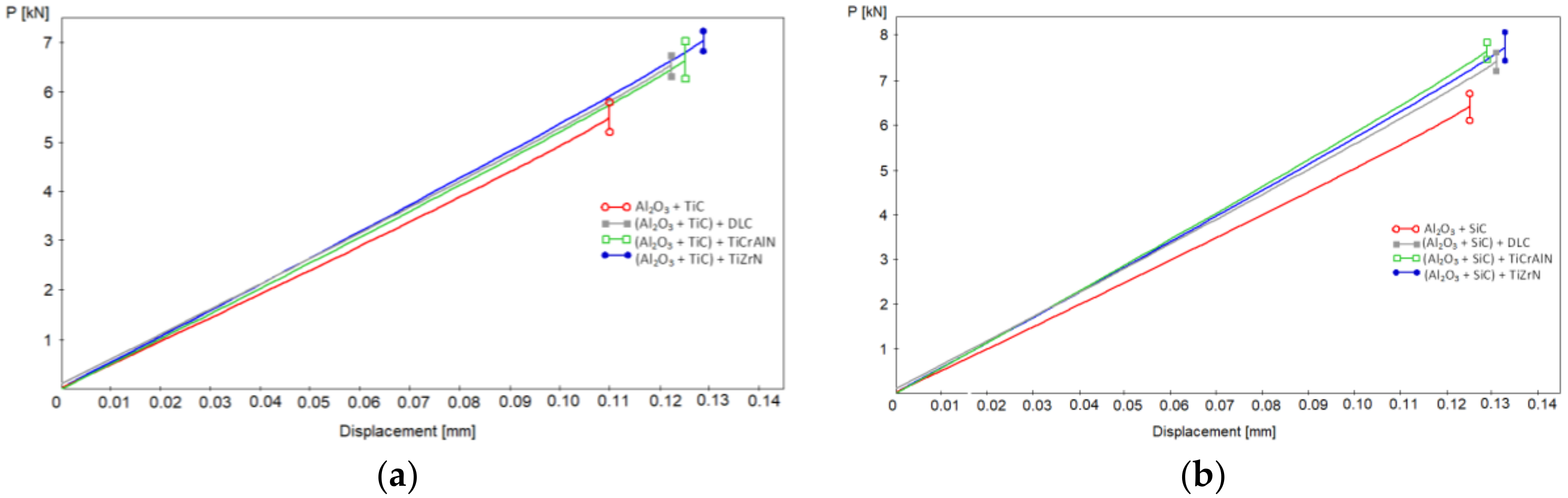

Traditionally, the bending strength tests of coated samples are carried out using three- or four-point bending methods, for which particular control samples (bunches) of a specific geometric shape are made. In the frames of this article, the idea was to maximally approximate the control samples to the configuration of the real cutting ceramic inserts. It was necessary to evaluate the effect of coating directly on the strength of the ceramic cutting insert. The rigging and experimental protocol were developed for the current research (

Figure 4a,b). The device presented as a massive parallelepiped with a groove and ledge, on which a square ceramic insert with a size of 12 mm × 12 mm × 4.76 mm was installed with a small gap. During the course of the experiment, a force was applied to the punch rigidly attached to a universal test machine, INSTRON (Norwood, MA, USA), until the insert was destroyed. A critical requirement in the construction of the rigging was to ensure a strict application of the punch force to the sample. The diagrams of the force and the punch displacement along the

Fz axis, and the critical force at which destruction occurred were recorded.

2.5. Adhesive Bonding of Coatings and Surface Layers of Ceramic Inserts

A micro-scratch tester, MST CSEM (CSEM Instruments, Neuchâtel, Switzerland), was used to assess the strength of adhesive bonding of the coatings with the ceramic substrates, involving scribing by a diamond pyramid with a variable load from 1 to 40 N, while recording the acoustic emission signal spectrum. The scribing was implemented by an indenter in the form of a diamond cone with an angle at the apex of 120° and a tip radius of 100 μm. The coated ceramic samples traveled at a constant speed, and the recording and decoding of the acoustic emission signals were carried out using the developed software.

In order to analyze the adhesion of the coatings to the ceramic substrates further, auxiliary studies were carried out. This consisted of studying the shape and dimensions of the crater due to the abrasive wear of the coatings, which was formed by the targeted impact on the surface of the ceramic inserts using abrasive particles of the Al2O3 ceramic. They were moved with air flow at a pressure of 1 bar (the effect of air-abrasive flow); the time of exposure to the surface of the experimental samples was 5 s.

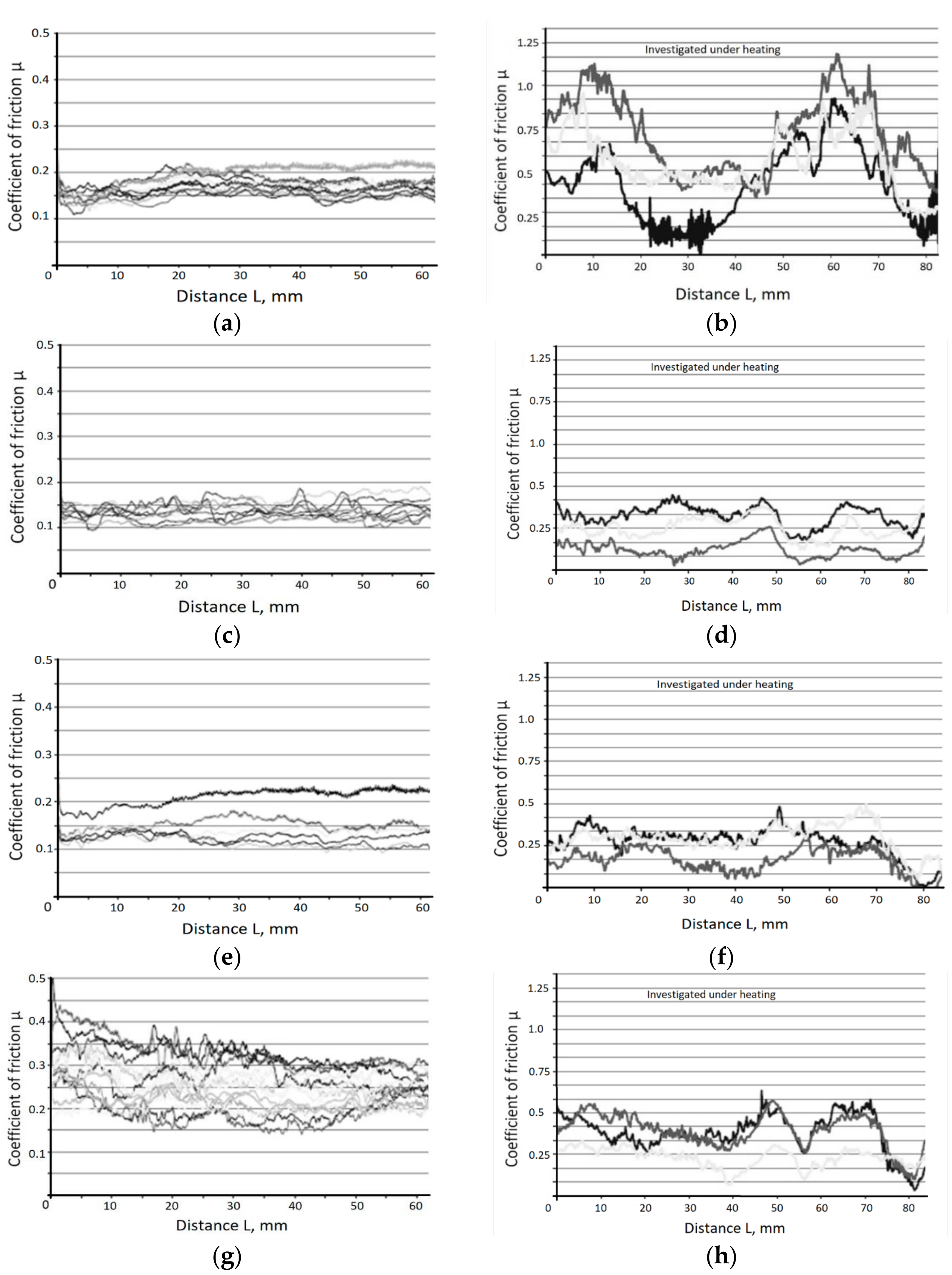

2.6. Friction Coefficient of Ceramic Inserts

The friction coefficient was measured on a test machine, Tetra Basalt N2 Precision Tribometer (Falex Tribology NV, Rotselaar, Belgium), to evaluate the frictional properties of the ceramic samples with the coatings. During the tests, the coefficient of sliding friction of the friction pair of the ceramic insert and the counter body made of hardened steel 102Cr6 (

Figure 5) was determined. The tests of all samples were carried out under conditions of dry friction at identical normal loads on the counter body (1 N), with the speed of relative displacement being 2 mm·s

−1, and the friction path being 90 mm.

Since, during the cutting process, the tool with the workpiece undergoes increased thermal loads, it was critical to measure the friction coefficient not only at room temperature, but also under heating conditions of the samples. An infrared heater and temperature sensors were used for forced heating of the samples to a temperature of 500 °C.

2.7. Operational Testing of Ceramic Cutting Inserts

The wear studies and operational tests of the original cutting inserts (without coatings) and the ceramic inserts with the various coatings were carried out during face milling on a milling machine, Willemin-Macodel 528S (Willemin-Macodel SA, Delemont, Switzerland). The cutting conditions were as follows: cutting speed (

V) = 380 m/min, feed (

S) = 0.1 mm/tooth, and depth (

t) = 1 mm. The cutting inserts of the ceramics with a special clamp were fixed in the cutter body as shown in

Figure 2, which ensured the following tool geometry: primary (front) clearance angle (α) = 10°, and back rake angle (γ) = −7°. The blank being processed was made of hardened steel 102Cr6 in the form of a parallelepiped with the following dimensions:

l = 800 mm,

b = 85 mm,

h = 85 mm.

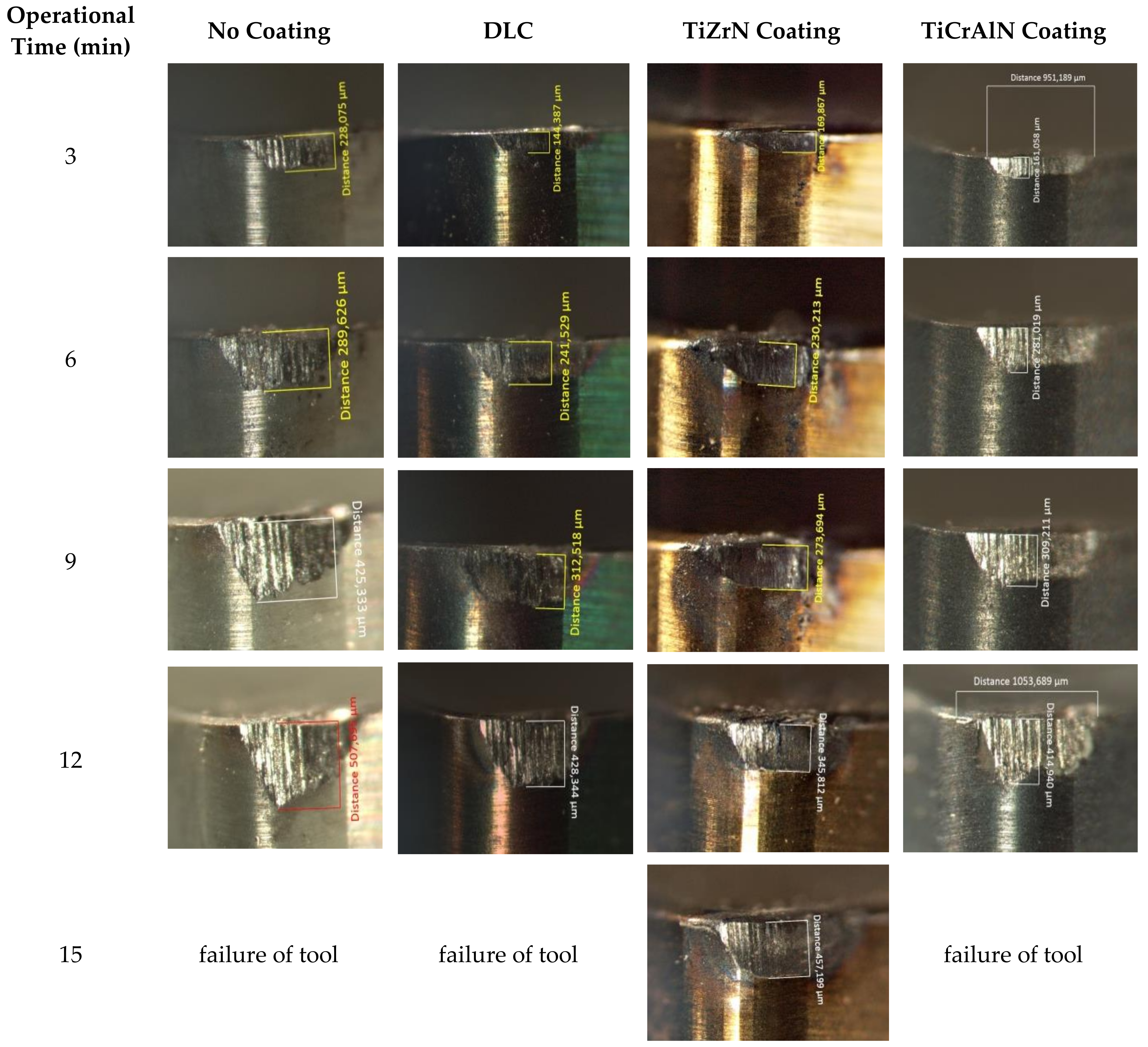

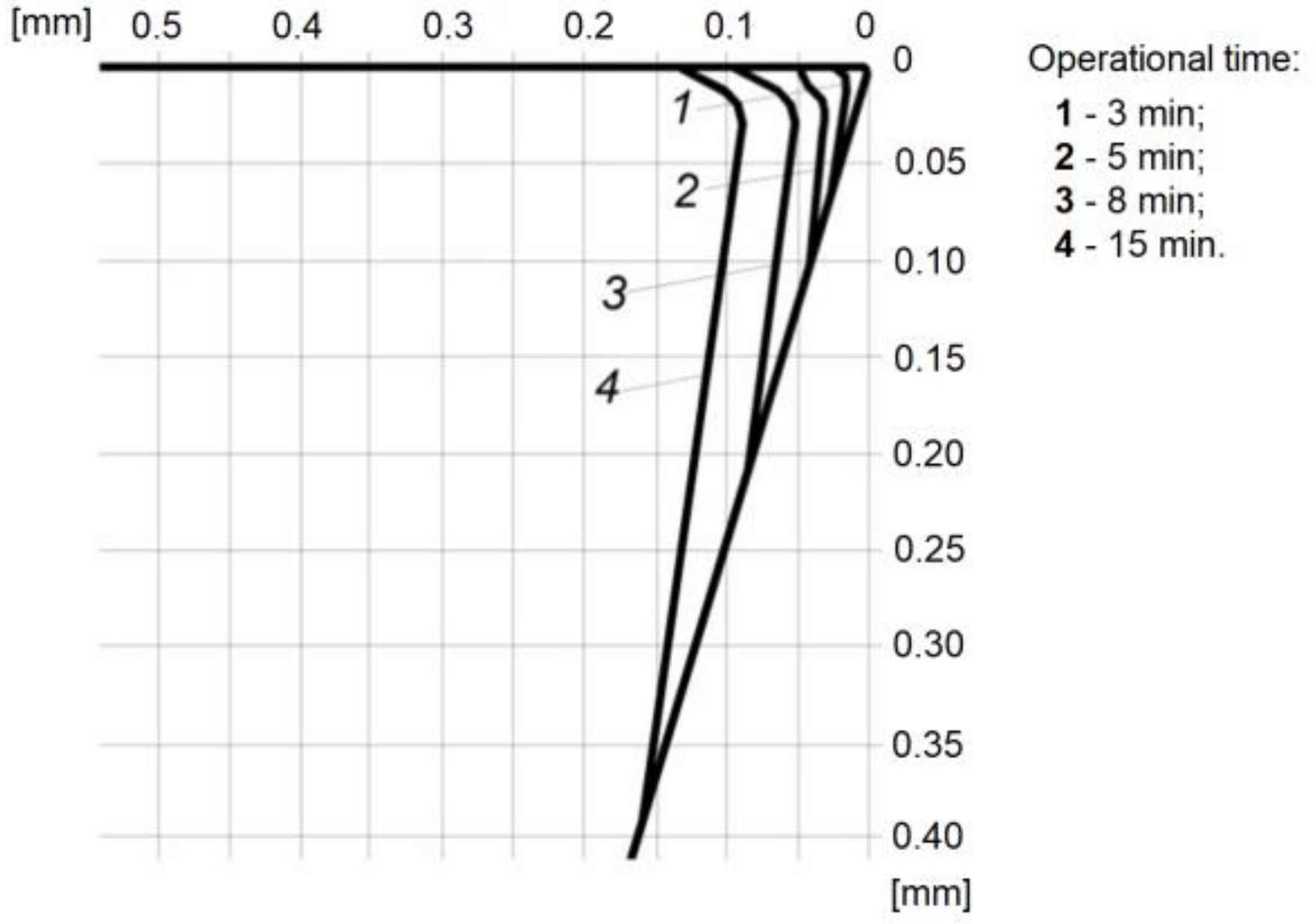

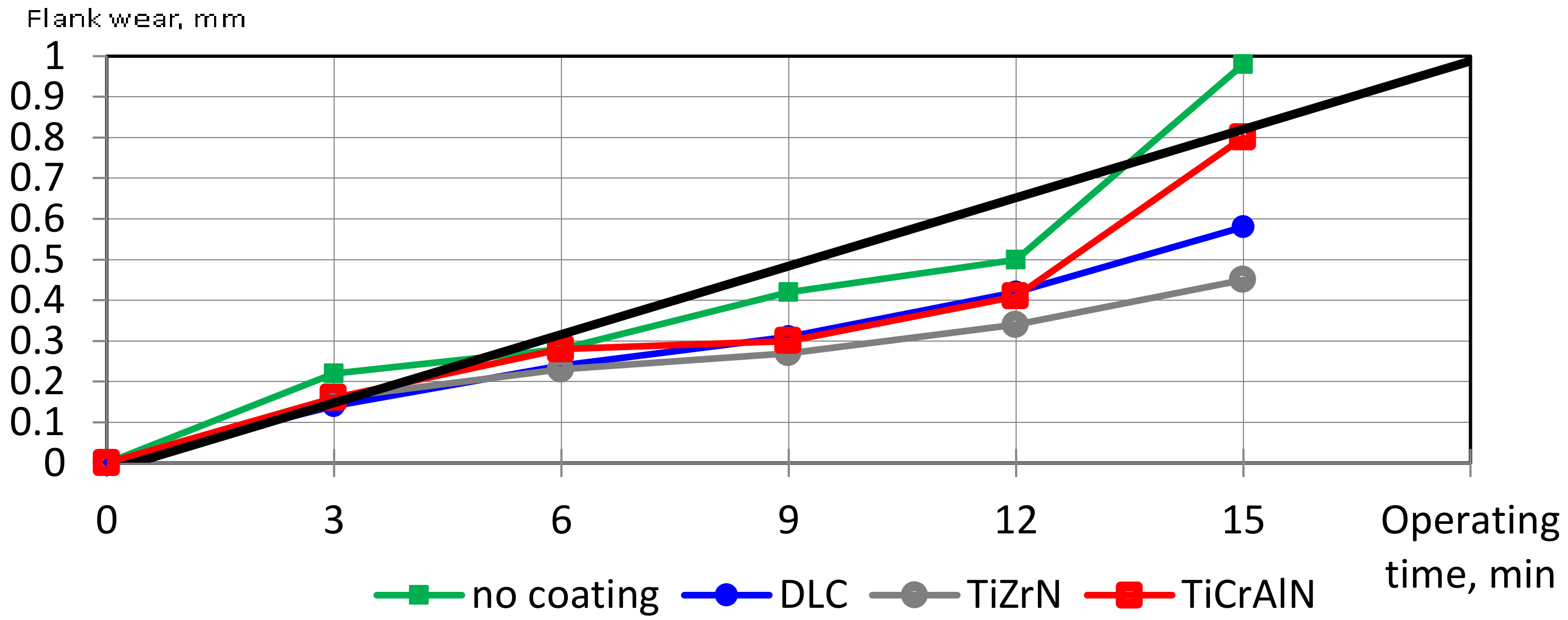

The failure criterion of the ceramic insert during the experiments was the wear of the rear surface hr, the limiting value of which was 0.45 mm. As seen during the preliminary experiments, the tool maintained its operative state until the moment the specified value was reached. Exceeding this value increased the number of chips at the cutting edge (sudden failures) several times, which can lead to the formation of defects on the workpiece. Every three minutes during the operation, the quantitative value of the insert wear along the back surface was monitored. The values were recorded for subsequent processing. Each experiment was repeated at least five times to avoid errors.

4. Discussion

The obtained results demonstrate the important influence of the coatings on the properties of the surface and the surface layer of ceramics, as well as their strength characteristics and the microgeometry of the tool. An increase in the operational characteristics of the ceramic inserts during the milling process was observed as a consequence.

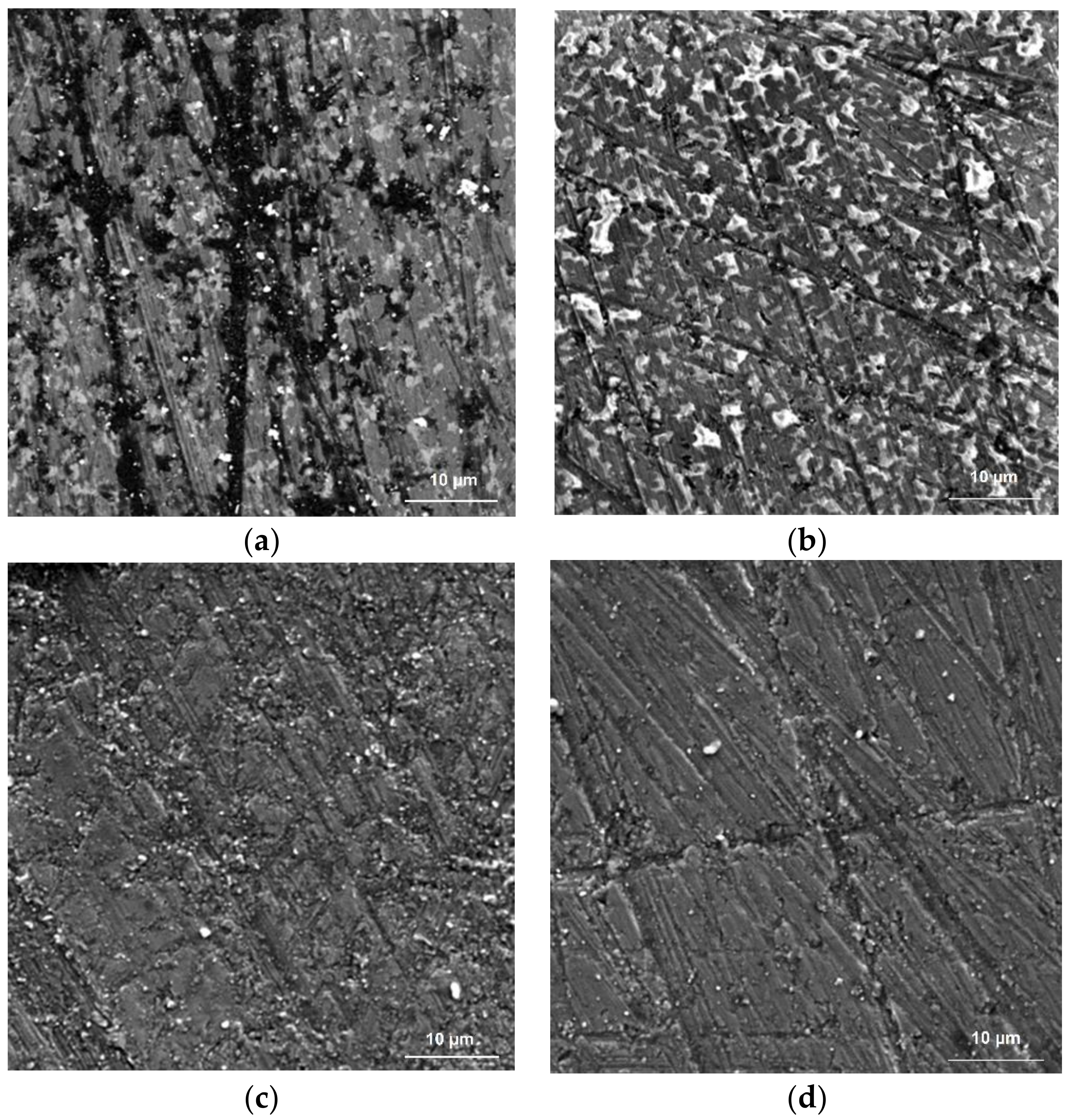

It is essential to understand that the smoothing and reduction of the surface micro-reflection level and the decrease in the surface defects of the ceramic inserts, which were observed in the profilograms and SEM images of the samples after deposition of the coatings (

Figure 6 and

Figure 7), are critical. The practice shows that even the most modern abrasive technologies cannot exclude the formation of certain defects on the surface of the ceramics, such as grain breaks, grinding scratches, burns, and residual abrasive in the cavities of microroughness. All these defects are the stress concentrators and the foci for the formation and development of the cracks in the structurally heterogeneous ceramic material, which creates excellent conditions for the subsequent crumbling or chipping of the working surfaces of the tool during operation.

Thus, it can be confirmed that the deposition of the coating contributes to the reduction of the surface defects, which are traditionally formed in the surface layer of the ceramics during its manufacturing. It is essential to understand the coating with 2–3 μm of thickness does not smooth the microroughness itself, but reproduces or copies the relief of the surface of the sample. The reduction in the height of microroughness and the noticeable change in the regular microrelief occur during the deposition of coatings in the vacuum chamber of the operational unit (

Figure 3). The removal of submicron layers occurs during the stage of surface cleaning and activation when the high-energy gas atoms (24) bombard the surface of the ceramic samples (11).

The transformation of the microgeometry of the cutting inserts described above, namely the significant reduction in the radius of the rounding of the cutting edge (

R, essentially the tool sharpening), is also a consequence of the bombarding high-energy gas atoms provided by the coating technology developed in the study (

Figure 8). It is an original effect which was observed during deposition of the coating on the ceramic tool, since most coatings increased the radius of the rounding of the cutting edge. A similar phenomenon was observed and described in detail in [

50], where a beam of high-energy gas atoms sharpened the knife blade made of dielectric ceramics based on zirconium dioxide. In that work, the radius of the cutting edge of the knife decreased from 5 to 1 μm, and its value directly depended on the distance between the axis of the beam of gas atoms and the cutting edge of the blade.

This geometric parameter has a simultaneously important and ambiguous influence on the cutting ability of the tool. On the one hand, the increase in R helps increase the strength of the cutting edge of the tool, which is a positive result. Mainly, this is correct in the case when machining with a ceramic tool is implemented under conditions of increased heat load. On the other hand, the increase in R limits the minimum possible depth of material cutting in the case of finishing and super-machining. If the radius (R) is too large and the cutting depths are small, the cutting edge will not cut, but the surface layer of the workpiece will be kneaded. Thus, the described feature of the proposed technology and its effect on the radius (R) must be taken into account when designing and applying a coating onto ceramic inserts.

Attention should be paid to the results of the strength tests of the ceramic inserts after deposition of the coatings, which show an increase in the values of destructive forces of up to 32% (

Figure 9). There is no doubt that it is a consequence of the already discussed decrease in the height of surface microroughness and the reduction in the number of surface defects of the ceramic inserts, which are the stress concentrators and the foci for crack development. Thus, the bulk properties of the ceramic, its strength characteristics, can be transformed by acting on the surface layer of the ceramic during the coating process. Here, it is necessary to emphasize that the influence of applying coatings using the advanced technology occurs exclusively on the surface layer and does not affect the product volume (the temperature in the vacuum chamber was on the order of 600 °C; this temperature is not significant for heat-resistant ceramics). Moreover, heating to higher temperatures occurs in the near-surface layers of the samples due to high-energy atoms.

The obtained results for the evaluation of the strength of adhesion bonding of the coatings with the ceramic inserts demonstrate a satisfactory outcome. Delamination of the coatings after application of the load was not observed for all test samples (

Figure 10). This indicates that the surface of the ceramic samples was well purified and activated by high-energy atoms in the process of coating.

A comparison of the wear craters formed on the coated samples during the targeted action of the air-abrasive flow showed that the largest delamination area was formed on the samples with the TiCrAlN coating (

Figure 11).

The results of investigating the friction coefficient of the three different coatings showed that the TiCrAlN coating was the least stable both at room temperature and under heating conditions. The results obtained correlated with the results of the subsequent experiments. It was the TiCrAlN coating that showed the least wear resistance of the three coatings studied, conforming with the natural laws.

It should dwell on the results of experiments comparing the friction coefficients of the ceramic samples with the coatings and the original samples without coating under heating conditions (

Figure 12). It is well known that the temperature in the processing zone during cutting and the temperature of the heating of the samples are significantly higher than that during the tribological tests. Today, it is practically impossible to reproduce the real loads that the tool experiences during the cutting process, and to obtain informative results on the values of friction coefficients of the samples at the same time. Nevertheless, the results obtained under heating conditions for the ceramic inserts (500 °C) show rather interesting experimental trends, and can be used as a basis for further research.

The results showed the extreme instability of uncoated samples. The coefficient of friction varied substantially within the range of 0.12–1.2. The effect of the high heat resistance of ceramics used in the cutting tools can be explained as follows, and it is related to the behavior of the counter body material from hardened steel 102Cr6 under heating conditions. Presumably, oxidants are formed under heating conditions in the presence of oxygen on the surface of the counter body under their physicochemical properties, which differ from those of the underlying material. Thus, an intermediate solid layer is formed between the ceramic insert and the counter body under heating conditions, which changes the resistance of deformation of the surface layer of the counter body. Firstly, the coefficient of friction grows with the rise in temperature, before reaching a maximum value, and subsequently decreasing. This pattern repeats cyclically. Presumably, the characteristics of the dependence can be explained by the following facts:

Firstly, the coefficient of friction grows due to the oxidation of the surface and the formation of solid metal oxides that impede the deformation of the counter body;

Next, the oxide film softens with the further rise in temperature, and it begins to play the role of a lubricant, reducing the coefficient of friction.

The coating deposed onto the cutting insert essentially acts as a solid lubricant, which acts as an intermediate layer between the counter body and the ceramic tool that entirely or partially isolates them from each other. This explains the more stable behavior of coated ceramic inserts in comparison with the uncoated samples during the tribological tests under heating conditions, and it allows understanding the nature of the changes occurring in the coefficient of friction. Here, it is necessary to take into account the surface changes that occur during the application of coatings in the microrelief. The dependence of the coefficient of friction on the roughness of a surface is quite complex and ambiguous, but there is an effect of its decrease.

The phenomena occurring during the tribological tests proceed identically during the interaction between the tool and the workpiece during the cutting process; they influence the results of the operational tests as well (

Figure 13,

Figure 14 and

Figure 15).

It was found that the coatings effectively reduced the wear rate of the Al2O3 + TiC and Al2O3 + SiC ceramic inserts across a wide range of cutting conditions during the milling of hardened steel 102Cr6. The maximum effect was achieved with the TiZrN coating. The time to failure (operational durability) increased 1.8-fold in comparison with the uncoated inserts. The effect of depositing diamond-like coatings was less significant. The operational durability increased 1.5-fold in comparison with the uncoated inserts. The achieved increase in operational durability was a direct consequence of the changes in the properties of the surface and the surface layer of the ceramic described above, as well as the improvement of the strength characteristics.

The TiCrAlN coating of the ceramic inserts proved to be the least effective during the milling of hardened steel 102Cr6, which correlates with the results of the previous experiments. It also showed results inferior to that of the TiZrN coating and the diamond-like coating in evaluating the strength of adhesion bonding, and during the tribological tests. Perhaps this is caused by the affinity of the material of the TiCrAlN coating and the material of the workpiece, as well as their mutual diffusion of chromium at high temperatures that occur during the cutting process. It does not mean that the TiCrAlN coating cannot be recommended for coating ceramic tools; it means that the optimal conditions for its application will be different from those presented in the article. This could also be the subject of separate studies.

In conclusion, it should be mentioned that the choice of coating composition for the ceramic cutting inserts is an extraordinarily complex and ambiguous task. A coating can be effective for some cutting conditions, and can turn out to be utterly useless for others. It is necessary to choose or develop the coating composition that will create a compatible and efficient system in combination with the main ceramic material for each type of cutting process (e.g., turning, milling) and processing conditions (e.g., finishing, semi-finished) for each specific pair of tool and material to be processed.