Combination of Zinc Oxide and Antimony Doped Tin Oxide Nanocoatings for Glazing Application

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Film Development by CSD

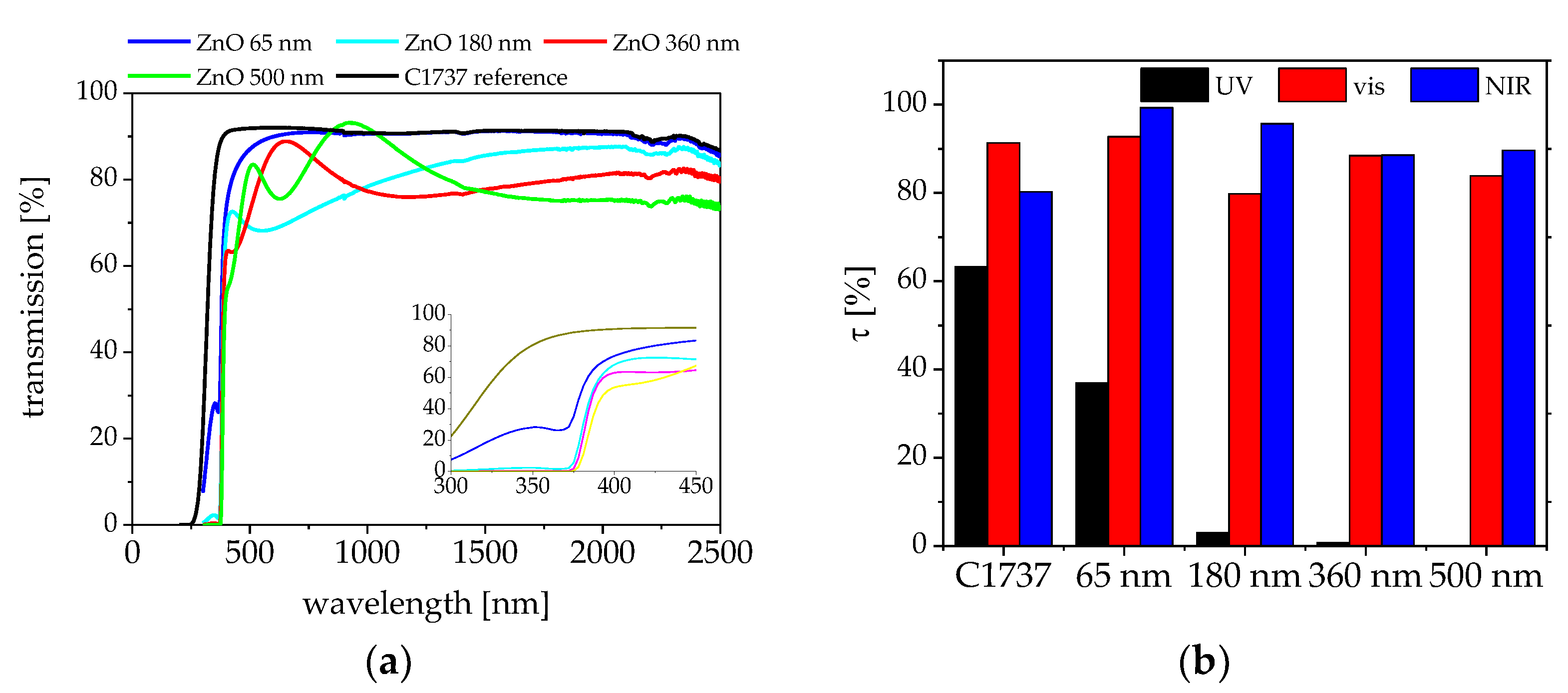

3.1.1. Zinc Oxide Films by CSD

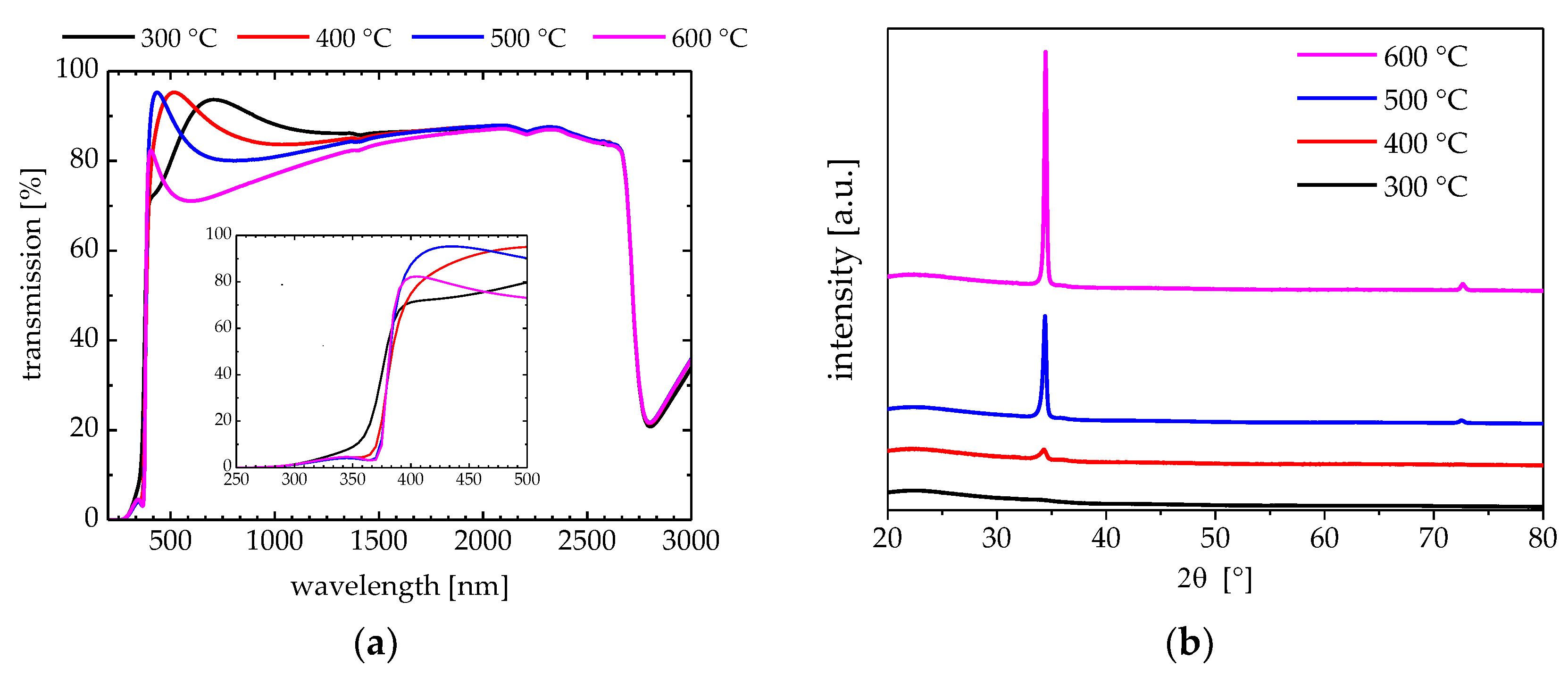

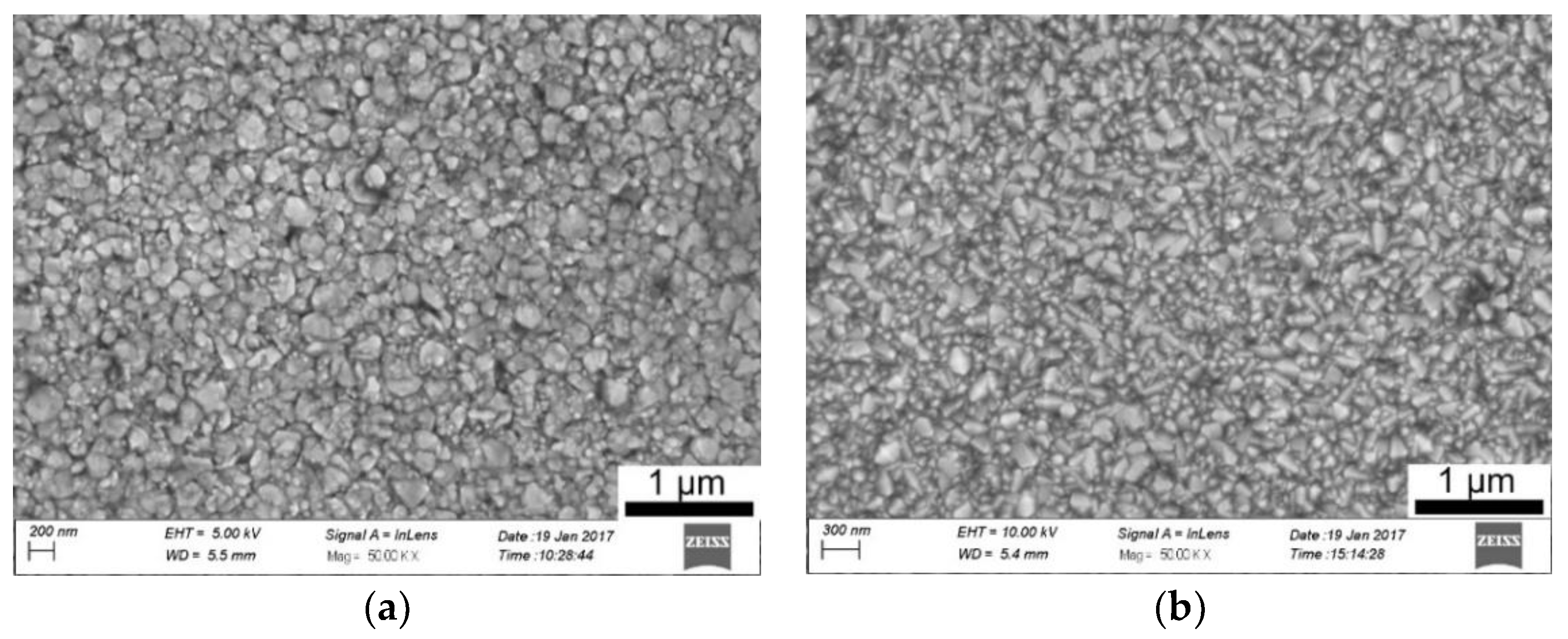

3.1.2. ATO Films by CSD

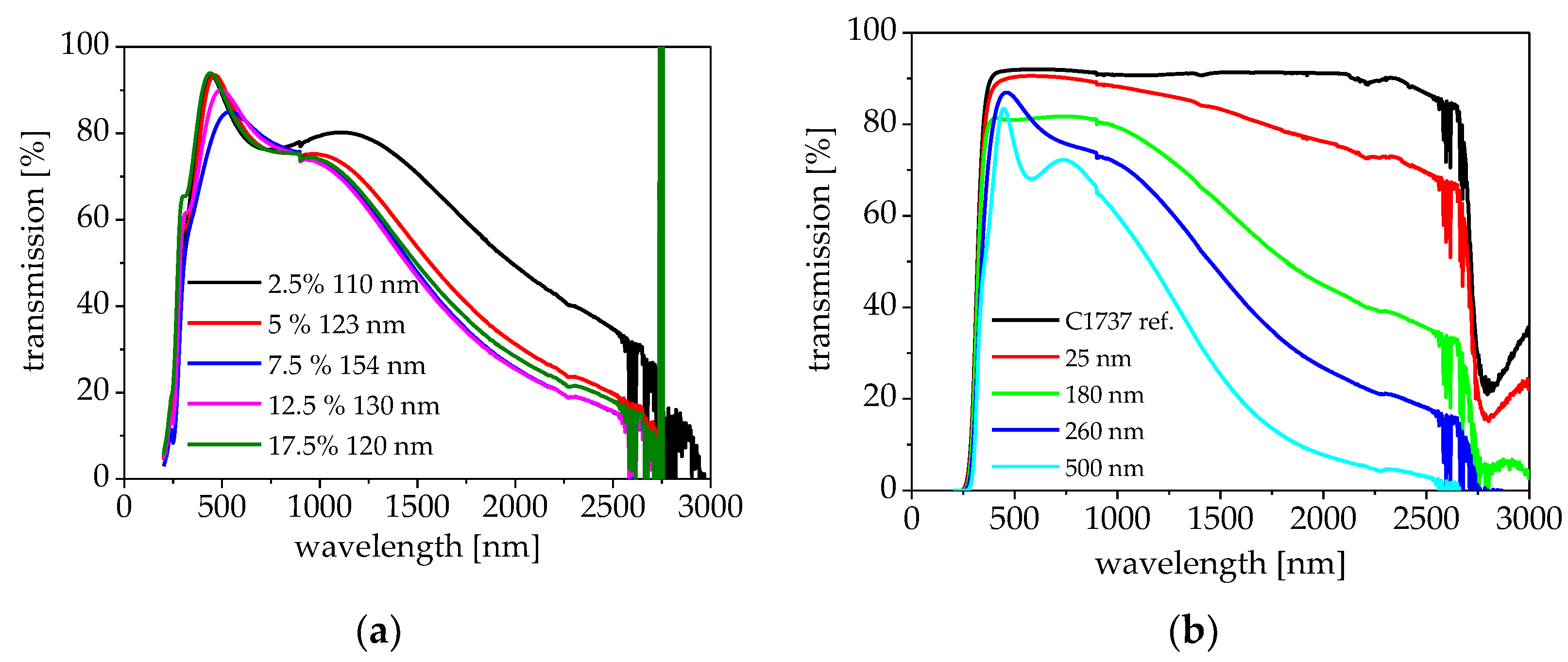

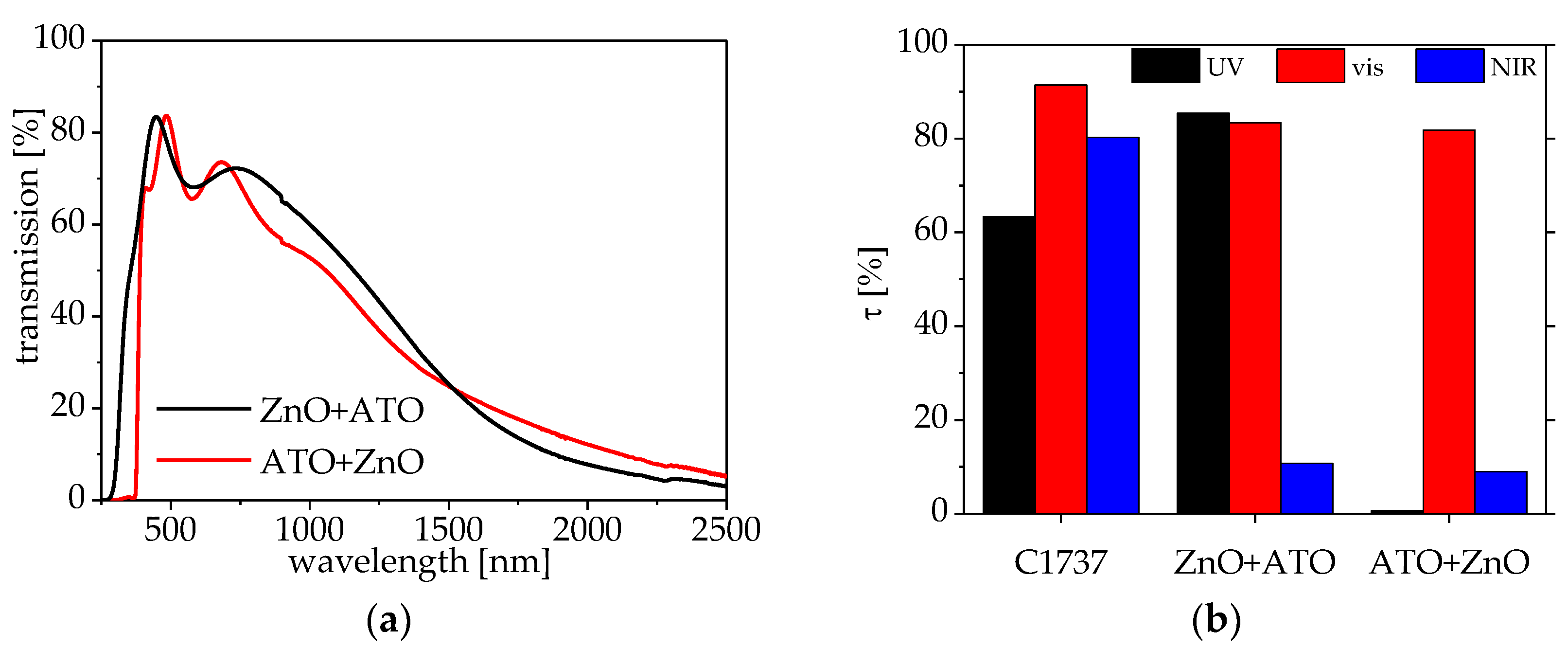

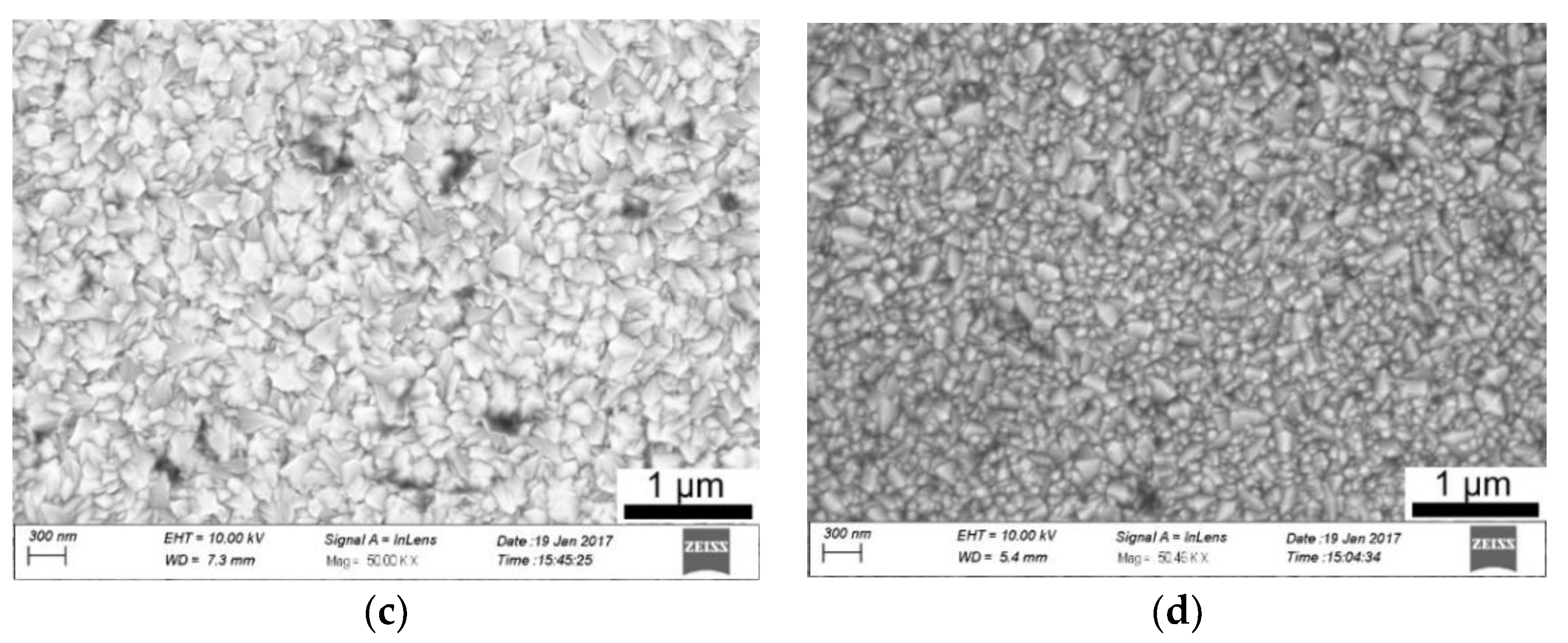

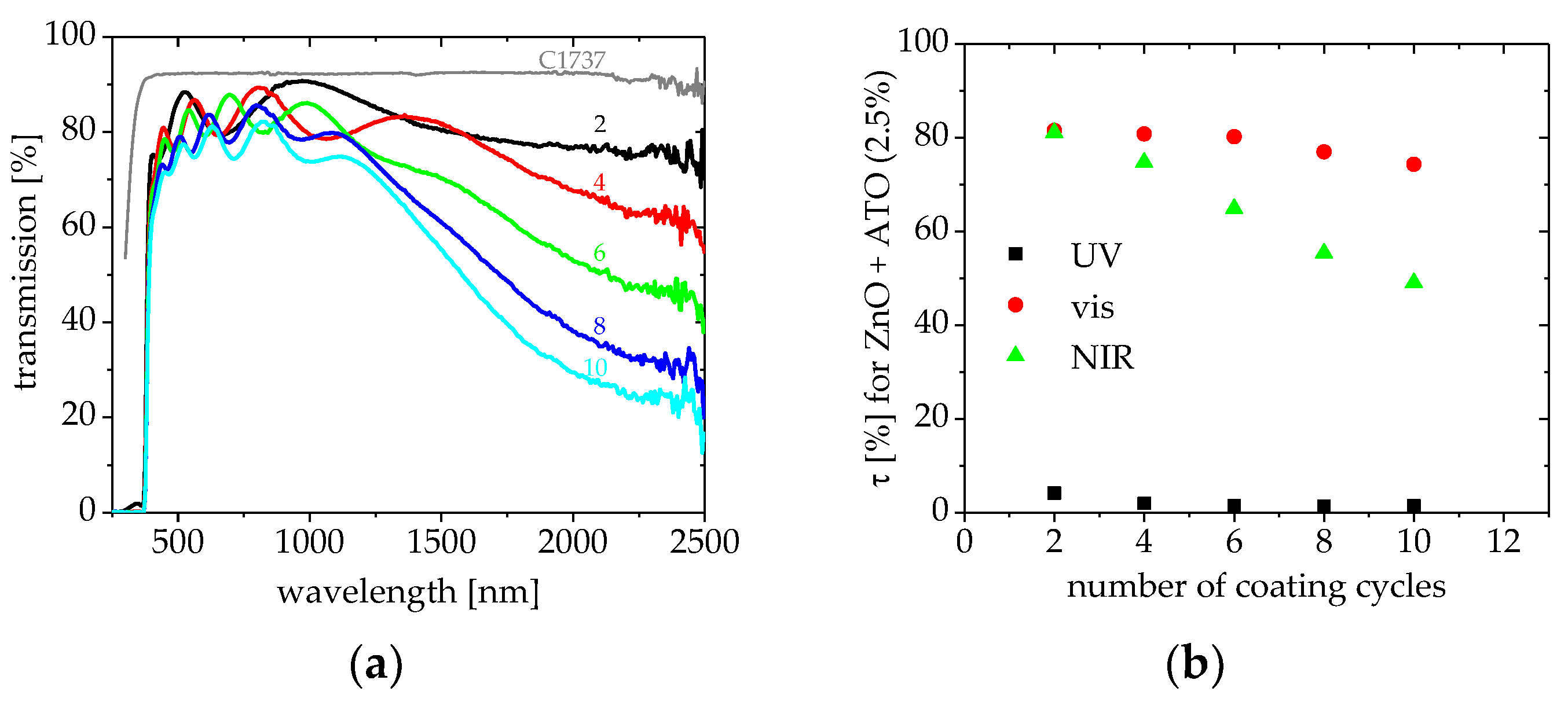

3.1.3. Combination of ATO and ZnO Films by CSD

3.2. Application of CVD Processes

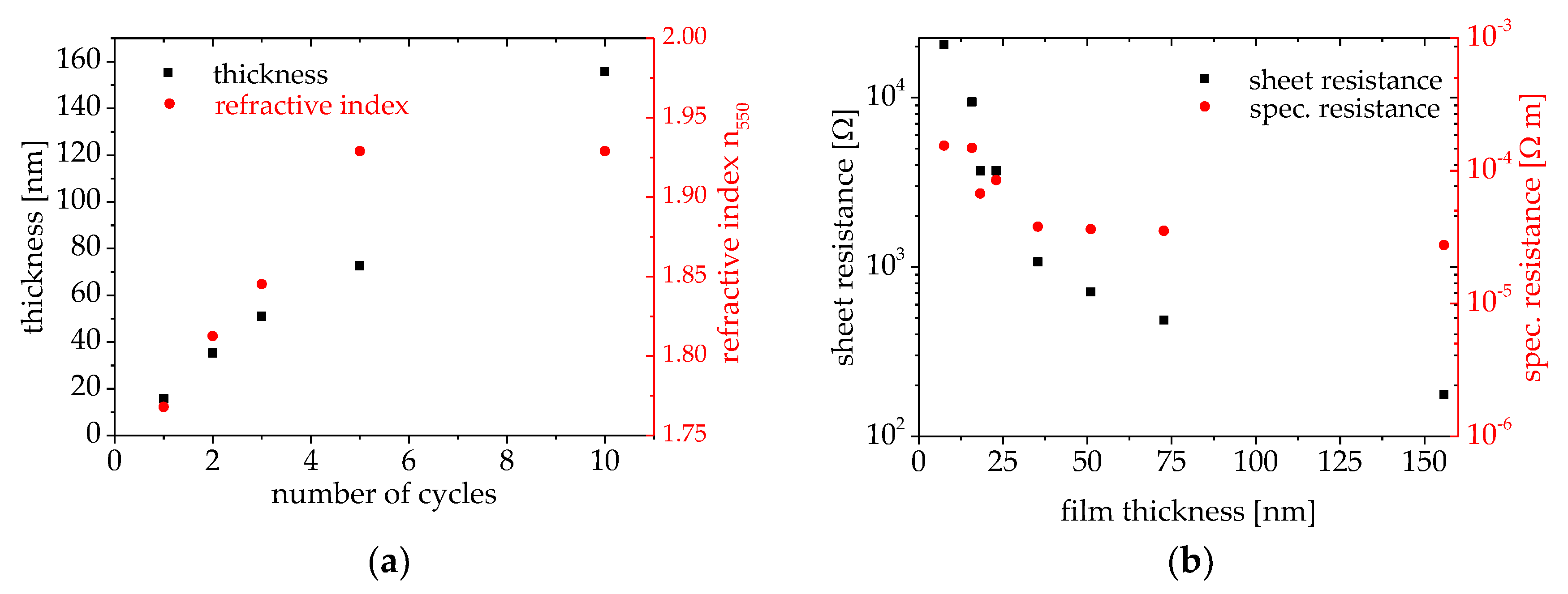

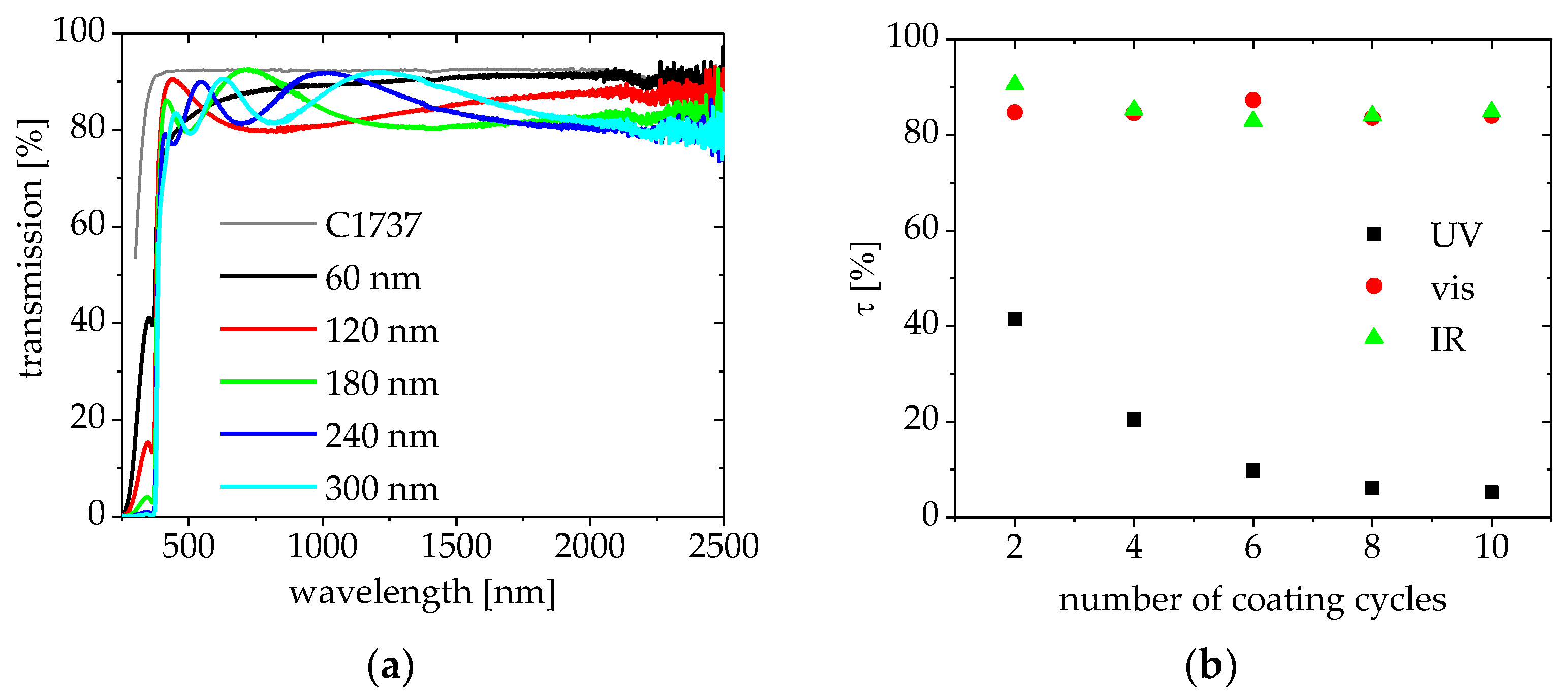

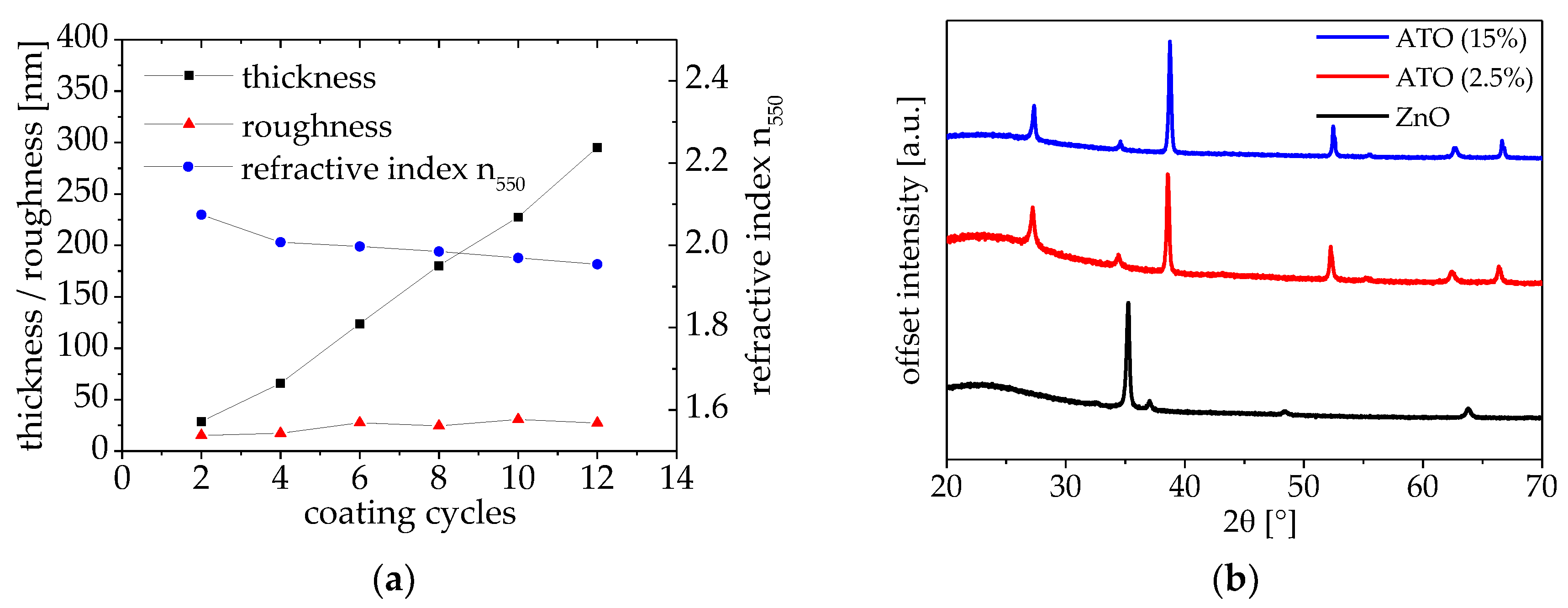

3.2.1. Single Layer Deposition by CVD

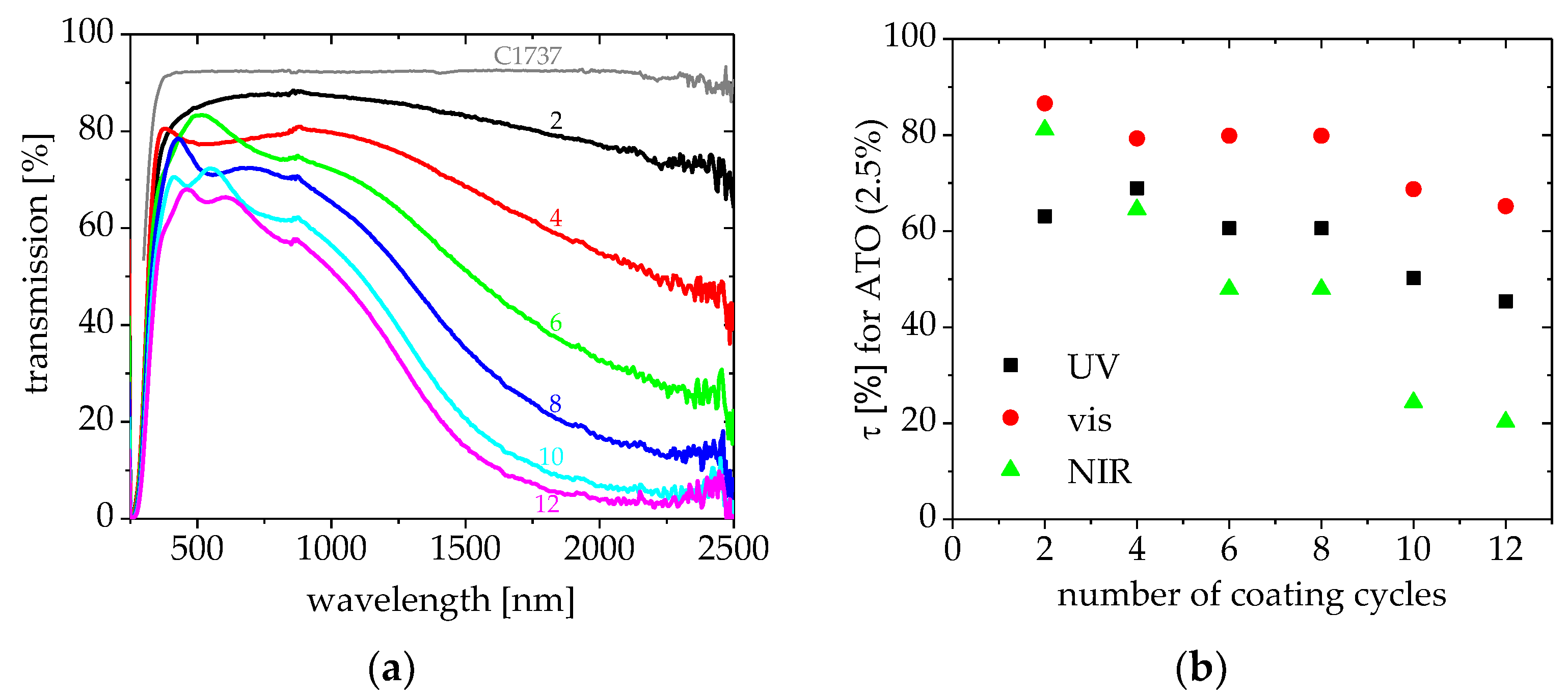

3.2.2. Combination of ZnO and ATO Films by CVD

3.3. Comparison of CVD and CSD

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jelle, B.P.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 96, 1–28. [Google Scholar] [CrossRef]

- Lahn, G.; Stevens, P. Burning Oil to Keep Cool: The Hidden Energy Crisis in Saudi Arabia; Chatham House: London, UK, 2011. [Google Scholar]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Kanu, S.S.; Binions, R. Thin films for solar control applications. Proc. RSC A Math. Phys. Eng. Sci. 2009, 466, 19–44. [Google Scholar] [CrossRef]

- Ghosh, A.; Mallick, T.K. Evaluation of optical properties and protection factors of a PDLC switchable glazing for low energy building integration. Sol. Energy Mater. Sol. Cells 2018, 176, 391–396. [Google Scholar] [CrossRef]

- Parker, D.S. Research highlights from a large scale residential monitoring study in a hot climate. Energy Build. 2003, 35, 863–876. [Google Scholar] [CrossRef]

- Leftheriotis, G.; Yianoulis, P. Characterisation and stability of low-emittance multiple coatings for glazing applications. Sol. Energy Mater. Sol. Cells 1999, 58, 185–197. [Google Scholar] [CrossRef]

- Kulczyk-Malecka, J.; Kelly, P.J.; West, G.; Clarke, G.; Ridealgh, J.A.; Almtoft, K.P.; Greer, A.L.; Barber, Z.H. Investigation of silver diffusion in TiO2/Ag/TiO2 coatings. Acta Mater. 2014, 66, 396–404. [Google Scholar] [CrossRef]

- Alamri, S.N. The temperature behavior of smart windows under direct solar radiation. Sol. Energy Mater. Sol. Cells 2009, 93, 1657–1662. [Google Scholar] [CrossRef]

- Granqvist, C.G. Transparent conductors as solar energy materials: A panoramic review. Sol. Energy Mater. Sol. Cells 2007, 91, 1529–1598. [Google Scholar] [CrossRef]

- Minami, T. Transparent conducting oxide semiconductors for transparent electrodes. Semicond. Sci. Technol. 2005, 20, S35–S44. [Google Scholar] [CrossRef]

- Znaidi, L. Sol-gel-deposited ZnO thin films: A review. Mater. Sci. Eng. B 2010, 174, 18–30. [Google Scholar] [CrossRef]

- Lee, S.; Park, B. Structural, electrical and optical characteristics of SnO2: Sb thin films by ultrasonic spray pyrolysis. Thin Solid Films 2006, 510, 154–158. [Google Scholar] [CrossRef]

- Hou, X.; Choy, K.-L. Processing and applications of aerosol-assisted chemical vapor deposition. Chem. Vap. Depos. 2006, 12, 583–596. [Google Scholar] [CrossRef]

- Ohyama, M.; Kozuka, H.; Yoko, T. Sol-Gel Preparation of Transparent and Conductive Aluminum-Doped Zinc Oxide Films with Highly Preferential Crystal Orientation. J. Am. Ceram. Soc. 1998, 81, 1622–1632. [Google Scholar] [CrossRef]

- Puetz, J.; Chalvet, F.N.; Aegerter, M.A. Wet chemical deposition of transparent conducting coatings in glass tubes. Thin Solid Films 2003, 442, 53–59. [Google Scholar] [CrossRef]

- Abendroth, T.; Schumm, B.; Alajlan, S.A.; Almogbel, A.M.; Mäder, G.; Härtel, P.; Althues, H.; Kaskel, S. Optical and thermal properties of transparent infrared blocking antimony doped tin oxide thin films. Thin Solid Films 2017, 624, 152–159. [Google Scholar] [CrossRef]

- Paraguay D., F.; Estrada L., W.; Acosta N., D.R.; Andrade, E.; Miki-Yoshida, M. Growth, structure and optical characterization of high quality ZnO thin films obtained by spray pyrolysis. Thin Solid Films 1999, 350, 192–202. [Google Scholar] [CrossRef]

- Assia, S.; Ratiba, O.; El Mahdi, M.; Mohamed, K. Optical reflectance of pure and doped tin oxide: From thin films to poly-crystalline silicon/thin film device. Int. J. Chem. Biomol. Eng. 2009, 2, 48. [Google Scholar]

- Kim, K.; Yoon, S.; Lee, W.; Ho Kim, K. Surface morphologies and electrical properties of antimony-doped tin oxide films deposited by plasma-enhanced chemical vapor deposition. Surf. Coat. Technol. 2001, 138, 229–236. [Google Scholar] [CrossRef]

- Kojima, M.; Kato, H.; Gatto, M. Blackening of tin oxide thin films heavily doped with antimony. Philos. Mag. B 1993, 68, 215–222. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schumm, B.; Abendroth, T.; Alajlan, S.A.; Almogbel, A.M.; Althues, H.; Härtel, P.; Mäder, G.; Kaskel, S. Combination of Zinc Oxide and Antimony Doped Tin Oxide Nanocoatings for Glazing Application. Coatings 2018, 8, 248. https://doi.org/10.3390/coatings8070248

Schumm B, Abendroth T, Alajlan SA, Almogbel AM, Althues H, Härtel P, Mäder G, Kaskel S. Combination of Zinc Oxide and Antimony Doped Tin Oxide Nanocoatings for Glazing Application. Coatings. 2018; 8(7):248. https://doi.org/10.3390/coatings8070248

Chicago/Turabian StyleSchumm, Benjamin, Thomas Abendroth, Saleh A. Alajlan, Ahmed M. Almogbel, Holger Althues, Paul Härtel, Gerrit Mäder, and Stefan Kaskel. 2018. "Combination of Zinc Oxide and Antimony Doped Tin Oxide Nanocoatings for Glazing Application" Coatings 8, no. 7: 248. https://doi.org/10.3390/coatings8070248

APA StyleSchumm, B., Abendroth, T., Alajlan, S. A., Almogbel, A. M., Althues, H., Härtel, P., Mäder, G., & Kaskel, S. (2018). Combination of Zinc Oxide and Antimony Doped Tin Oxide Nanocoatings for Glazing Application. Coatings, 8(7), 248. https://doi.org/10.3390/coatings8070248