The Potential of Functionalized Ceramic Particles in Coatings for Improved Scratch Resistance

Abstract

1. Introduction

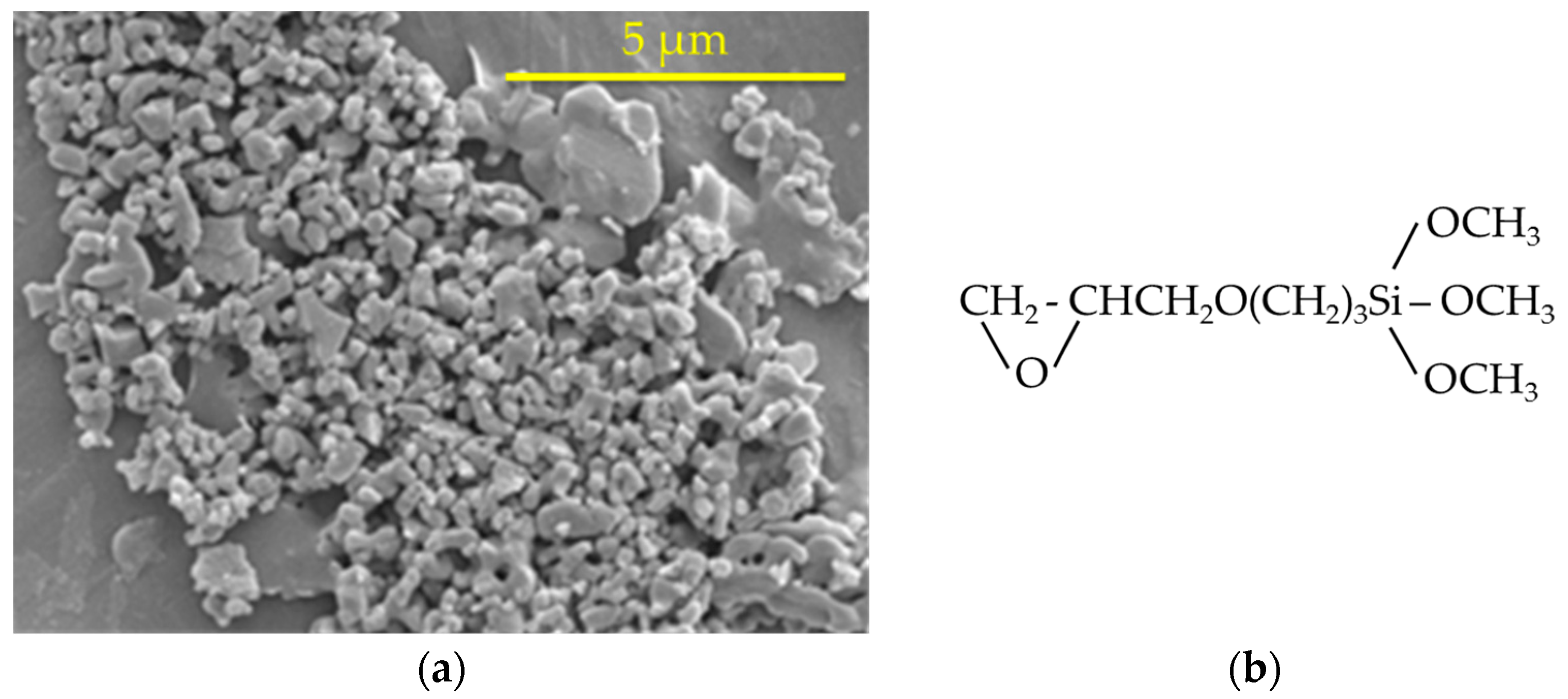

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

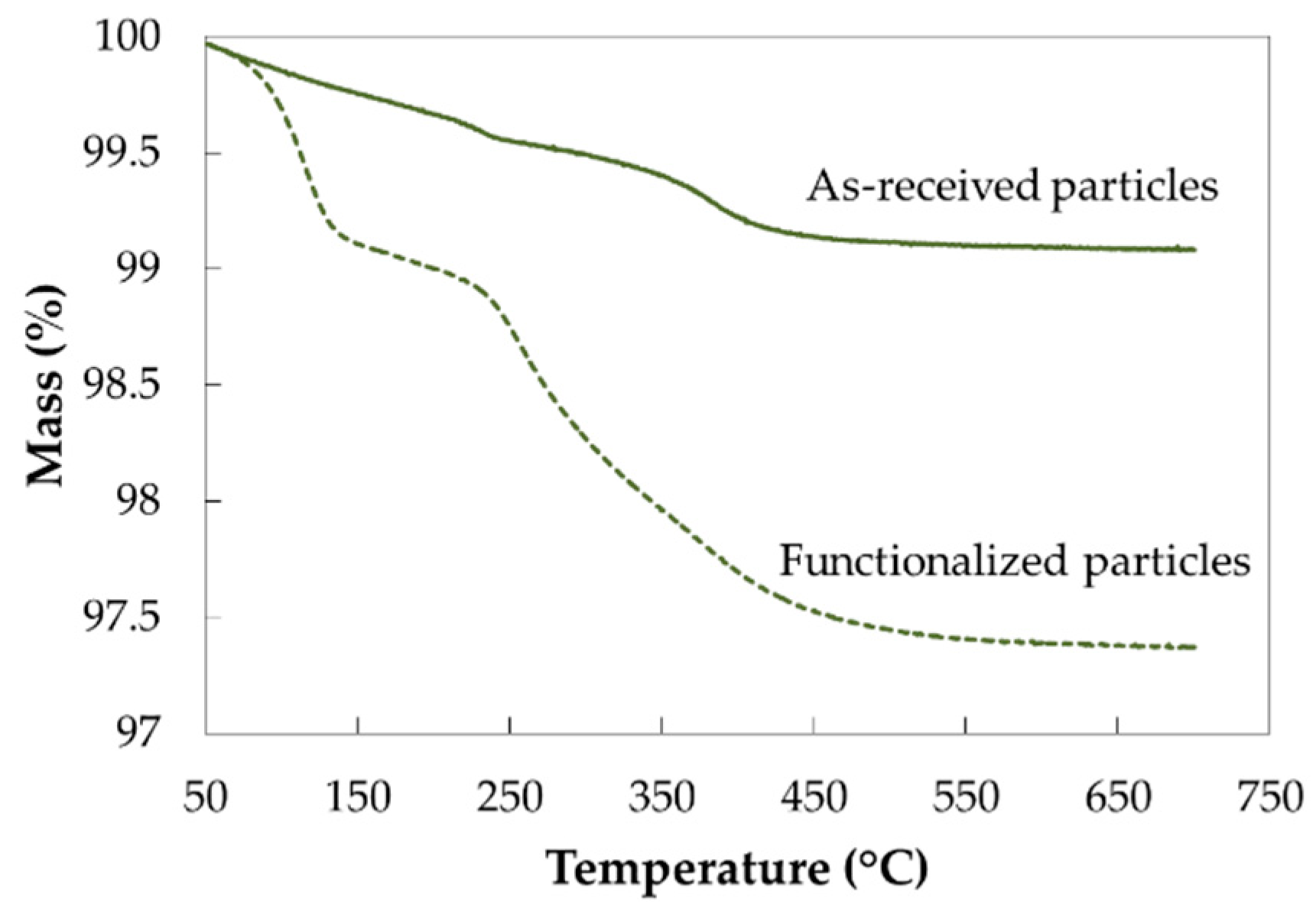

3.1. Thermogravimetric Analysis of Functionalized Alumina

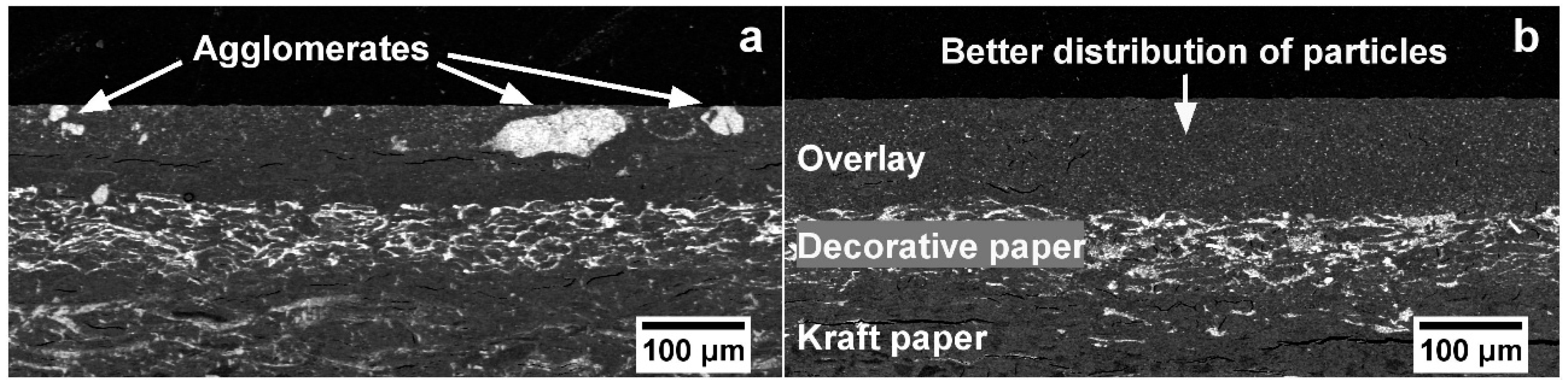

3.2. Cross-Sectional Analysis of the Laminates

3.3. Scratch Resistance Measured in Accordance with Standard NS-EN 438-2

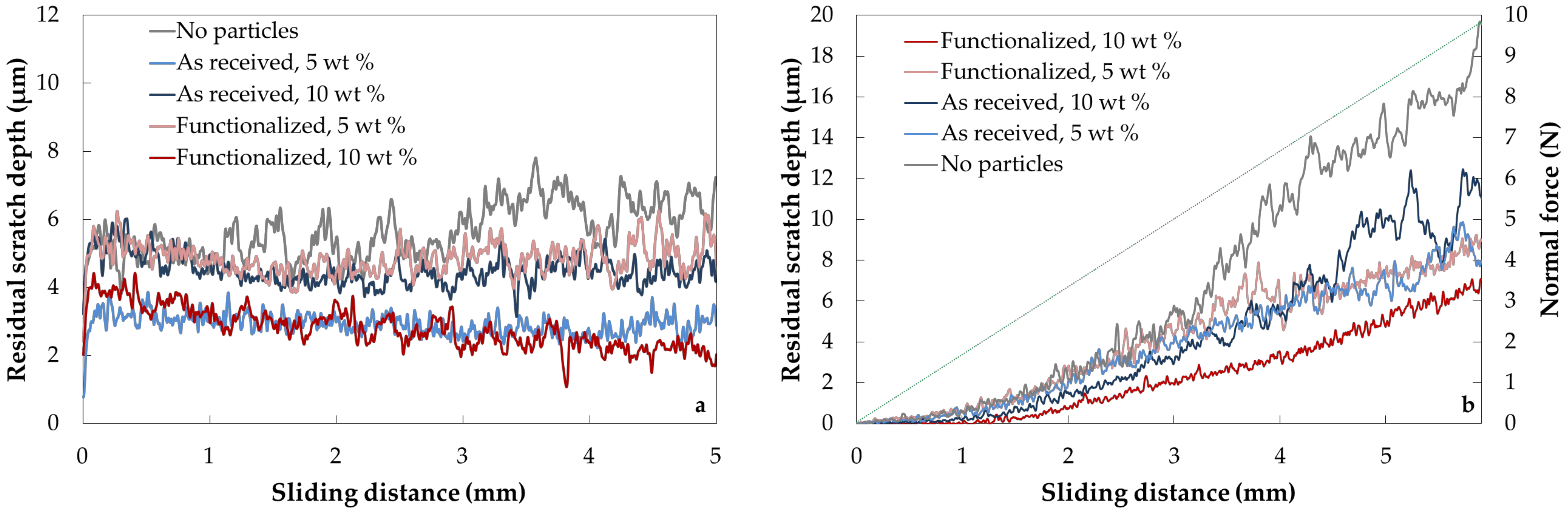

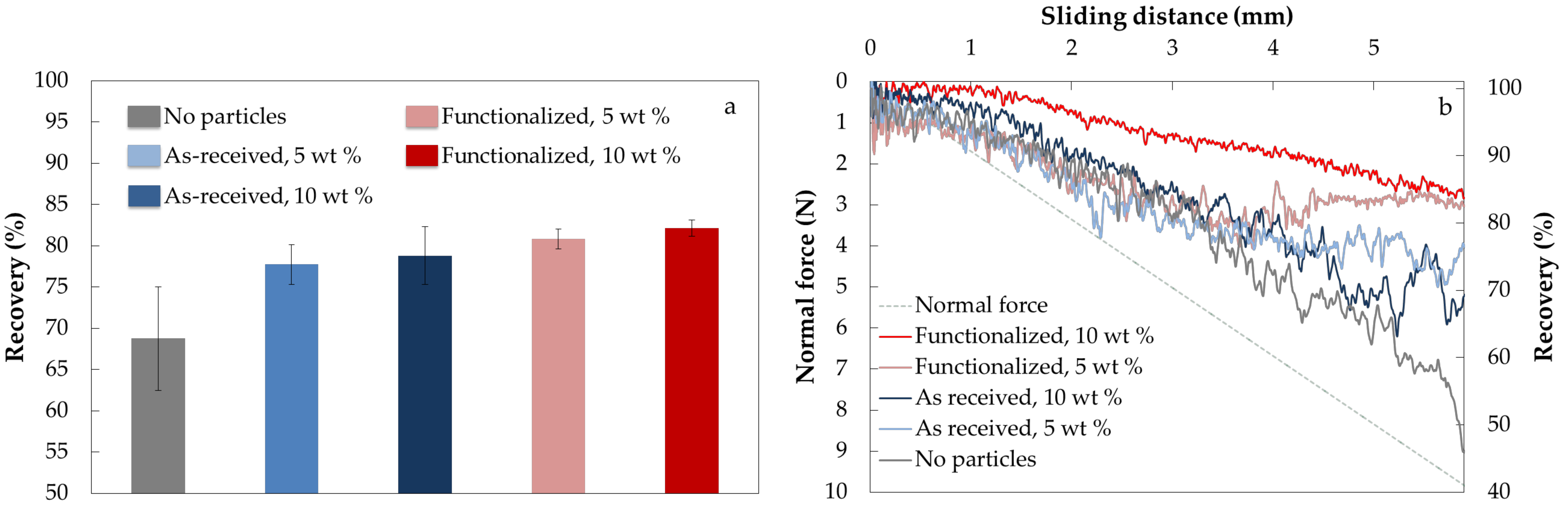

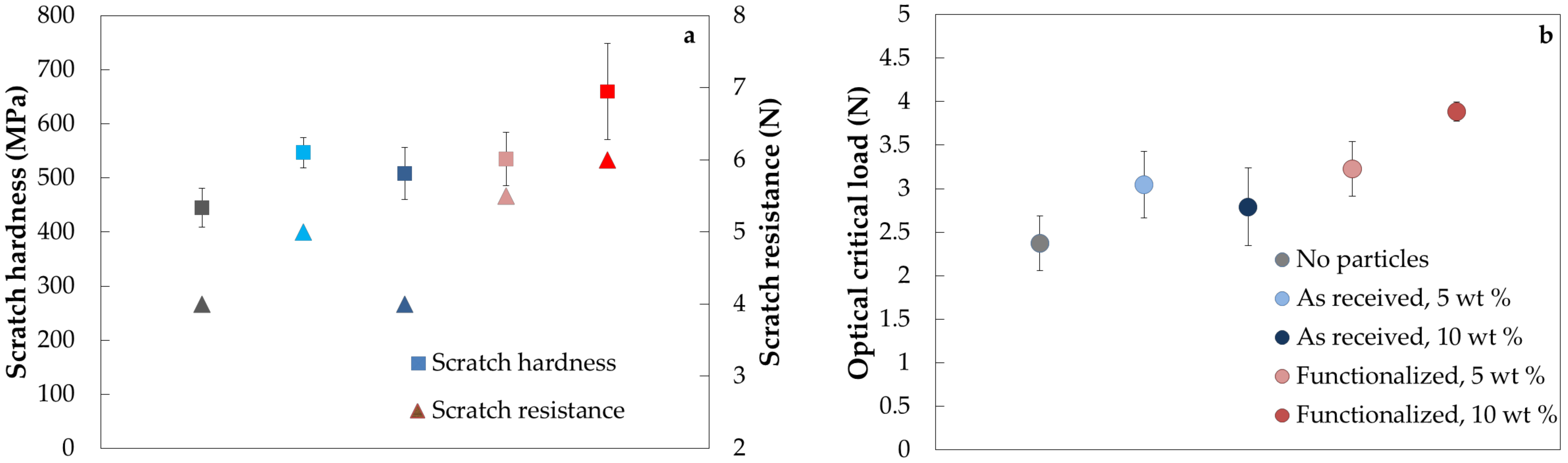

3.4. Scratch Resistance Measured through Micro Scratch Testing

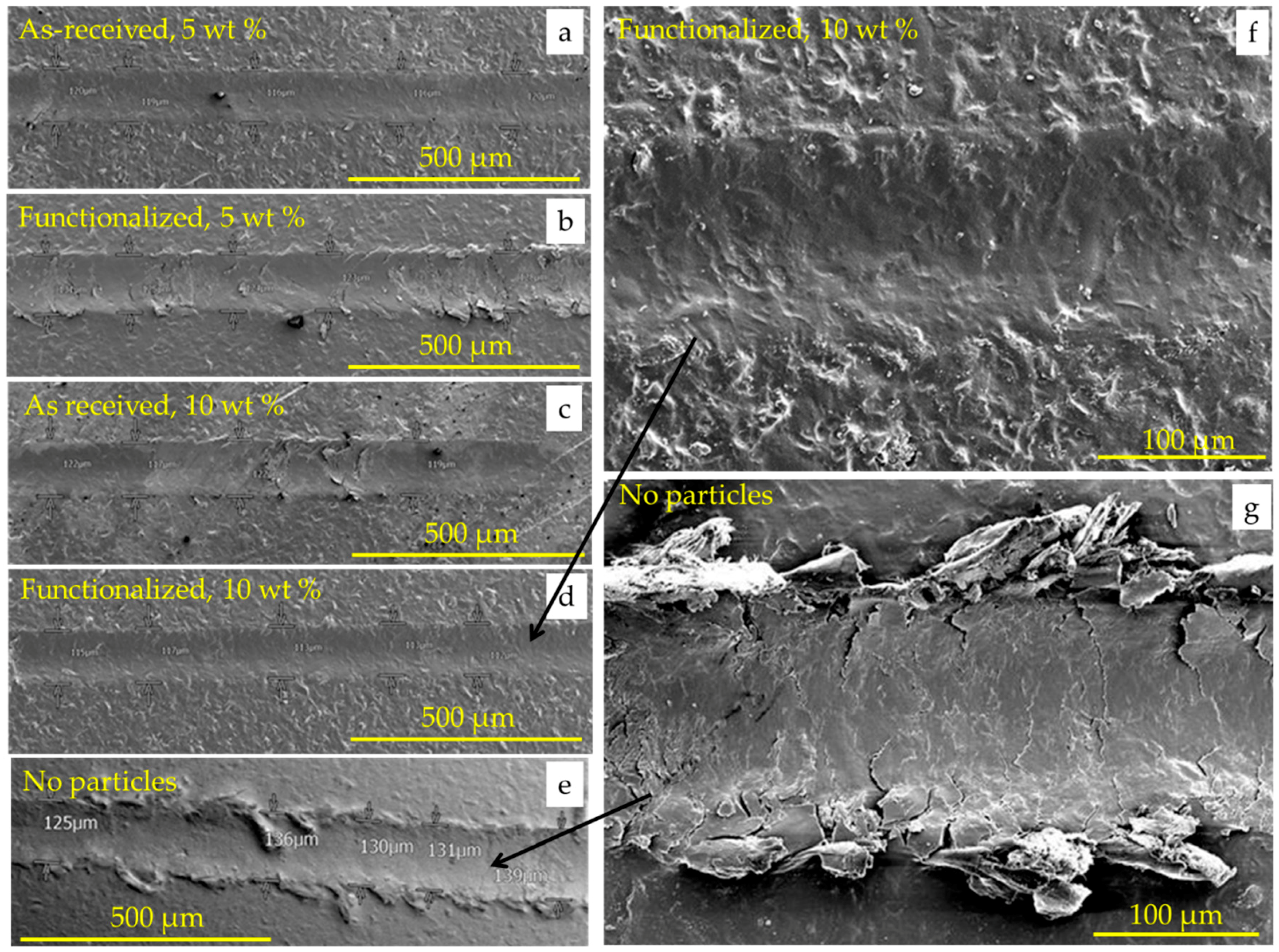

3.5. Scratch Microstructure and Scratch Behavior

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lepedat, K.; Wagner, R.; Lang, J. Laminates. In Phenolic Resins: A Century of Progress; Springer: Berlin/Heidelberg, Germany, 2010; pp. 243–261. [Google Scholar]

- Krupička, A.; Johansson, M.; Hult, A. Use and interpretation of scratch tests on ductile polymer coatings. Prog. Org. Coat. 2003, 46, 32–48. [Google Scholar] [CrossRef]

- Hara, Y.; Mori, T.; Fujitani, T. Relationship between viscoelasticity and scratch morphology of coating films. Prog. Org. Coat. 2000, 40, 39–47. [Google Scholar] [CrossRef]

- Sobhani, H.; Khorasani, M.M. Optimization of scratch resistance and mechanical properties in wollastonite-reinforced polypropylene copolymers. Polym. Adv. Technol. 2016, 27, 765–773. [Google Scholar] [CrossRef]

- Nemli, G. Factors affecting some quality properties of the decorative surface overlays. J. Mater. Process. Technol. 2008, 195, 218–223. [Google Scholar] [CrossRef]

- Hossain, M.M.; Jiang, H.; Sue, H.-J. Effect of constitutive behavior on scratch visibility resistance of polymers—A finite element method parametric study. Wear 2011, 270, 751–759. [Google Scholar] [CrossRef]

- Browning, R.L.; Jiang, H.; Sue, H.-J. Scratch behavior of polymeric materials. In Tribology of Polymeric Nanocomposites: Friction and Wear of Bulk Materials and Coatings, 2nd ed.; Friedrich, K., Schlarb, A.K., Eds.; Butterworth-Heinemann: Oxford, UK, 2013; pp. 513–550. [Google Scholar]

- Brostow, W.; Cassidy, P.E.; Macossay, J.; Pietkiewicz, D.; Venumbaka, S. Connection of surface tension with multiple tribological properties in epoxy + fluoropolymer systems. Polym. Int. 2003, 52, 1498–1505. [Google Scholar] [CrossRef]

- Xiang, C.; Sue, H.J.; Chu, J.; Coleman, B. Scratch behavior and material property relationship in polymers. J. Polym. Sci. 2000, 39, 47–59. [Google Scholar] [CrossRef]

- Jin, P.W.; Benca, K.R.; Quarmby, I.C.; Kurpiewski, T.; Ferrell, V.E. Enhanced Scratch Resistant Coatings Using Inorganic Fillers. U.S. Patent 6,844,374, 18 January 2005. [Google Scholar]

- Barna, E.; Bommer, B.; Kürsteiner, J.; Vital, A.; Trzebiatowski, O.V.; Koch, W.; Schmid, B.; Graule, T. Innovative, scratch proof nanocomposites for clear coatings. Compos. Part A 2005, 36, 473–480. [Google Scholar] [CrossRef]

- Kurkcu, P.; Andena, L.; Pavan, A. An experimental investigation of the scratch behaviour of polymers—2: Influence of hard or soft fillers. Wear 2014, 317, 277–290. [Google Scholar] [CrossRef]

- Antunes, P.V.; Ramalho, A.; Carrilho, E.V.P. Mechanical and wear behaviours of nano and microfilled polymeric composite: Effect of filler fraction and size. Mater. Des. 2014, 61, 50–60. [Google Scholar] [CrossRef]

- Chauhan, S.R.; Thakur, S. Effects of particle size, particle loading and sliding distance on the friction and wear properties of cenosphere particulate filled vinylester composites. Mater. Des. 2013, 51, 398–408. [Google Scholar] [CrossRef]

- Niezgoda, S.; Gupta, V.; Knight, R.; Cairncross, R.A.; Twardowski, T.E. Effect of reinforcement size on the scratch resistance and crystallinity of HVOF sprayed nylon-11/ceramic composite coatings. J. Therm. Spray Technol. 2006, 15, 731–738. [Google Scholar] [CrossRef]

- Farzaneh, S.; Tcharkhtchi, A. Viscoelastic properties of polypropylene reinforced with mica in Tα and Tαc transition zones. Int. J. Polym. Sci. 2011, 2011, 427095. [Google Scholar] [CrossRef]

- Sangermano, M.; Messori, M. Scratch resistance enhancement of polymer coatings. Macromol. Mater. Eng. 2010, 295, 603–612. [Google Scholar] [CrossRef]

- Cayton, R.H.; Brotzman, R.W. Nanocomposite coatings—Applications and properties. Mater. Res. Soc. Symp. Proc. 2011, 703, V8.1. [Google Scholar] [CrossRef]

- Wang, Y.; Lim, S.; Luo, J.L.; Xu, Z.H. Tribological and corrosion behaviors of Al2O3/polymer nanocomposite coatings. Wear 2006, 260, 976–983. [Google Scholar] [CrossRef]

- Bauer, F.; Gläsel, H.-J.; Decker, U.; Ernst, H.; Freyer, A.; Hartmann, E.; Sauerland, V.; Mehnert, R. Trialkoxysilane grafting onto nanoparticles for the preparation of clear coat polyacrylate systems with excellent scratch performance. Prog. Org. Coat. 2003, 47, 147–153. [Google Scholar] [CrossRef]

- Ye, S.; Azarnoush, S.; Smith, I.R.; Cramer, N.B.; Stansbury, J.W.; Bowman, C.N. Using hyperbranched oligomer functionalized glass fillers to reduce shrinkage stress. Dent. Mater. 2012, 28, 1004–1011. [Google Scholar] [CrossRef] [PubMed]

- Mallakpour, S.; Madani, M. A review of current coupling agents for modification of metal oxide nanoparticles. Prog. Org. Coat. 2015, 86, 194–207. [Google Scholar] [CrossRef]

- Ambrósio, J.D.; Balarim, C.V.M.; de Carvalho, G.B. Preparation, characterization, and mechanical/tribological properties of polyamide 11/Titanium dioxide nanocomposites. Polym. Compos. 2016, 37, 1415–1424. [Google Scholar] [CrossRef]

- Barna, E.; Rentsch, D.; Bommer, B.; Vital, A.; Trzebiatowski, O.V.; Graule, T. Surface modification of nanoparticles for scratch resistant clear coatings. Kautsch. Gummi Kunstst. 2007, 60, 49–51. [Google Scholar]

- Solvent Stabilizer Systems. 2017. Available online: https://www.sigmaaldrich.com/chemistry/solvents/learning-center/stabilizer-systems.html (accessed on 14 December 2017).

- Ap-silane 51, 2015. Available online: https://static1.squarespace.com/static/57a6c9e1440243dad487f1d6/t/57b32c5746c3c465f616adbc/1471360088338/AP-SILANE+51+-+TDS.pdf (accessed on 30 March 2018).

- Guo, Z.; Pereira, T.; Choi, O.; Wang, Y.; Hahn, H.T. Surface functionalized alumina nanoparticle filled polymeric nanocomposites with enhanced mechanical properties. J. Mater. Chem. 2006, 16, 2800–2808. [Google Scholar] [CrossRef]

- ASTM D7027-13 Standard Test Method for Evaluation of Scratch Resistance of Polymeric Coatings and Plastics Using an Instrumented Scratch Machine; ASTM International: West Conshohocken, PA, USA, 2013.

- Bucaille, J.L.; Felder, E.; Hochstetter, G. Mechanical analysis of the scratch test on elastic and perfectly plastic materials with the three-dimensional finite element modeling. Wear 2001, 249, 422–432. [Google Scholar] [CrossRef]

- Rangarajan, P.; Sinha, M.; Watkins, V.; Harding, K.; Sparks, J. Scratch visibility of polymers measured using optical imaging. Polym. Eng. Sci. 2003, 43, 749–758. [Google Scholar] [CrossRef]

- BS EN 438-2:2016 High-Pressure Decorative Laminates (HPL). Sheets Based on Thermosetting Resins (Usually Called Laminates). Part 2: Determination of Properties; British Standards Institution: London, UK, 2016.

- Rajesh, J.J.; Bijwe, J. Investigations on scratch behaviour of various polyamides. Wear 2005, 259, 661–668. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Sinha, S.K. Scratch resistance and localised damage characteristics of polymer surfaces—A review. Materialwiss. Werkstofftech. 2003, 34, 989–1002. [Google Scholar] [CrossRef]

- Al-Rub, R.K.A.; Tehrani, A.H.; Darabi, M.K. Application of a large deformation nonlinear-viscoelastic viscoplastic viscodamage constitutive model to polymers and their composites. Int. J. Damage Mech. 2015, 24, 198–244. [Google Scholar] [CrossRef]

- Wong, M.; Moyse, A.; Lee, F.; Sue, H.-J. Study of surface damage of polypropylene under progressive loading. J. Mater. Sci. 2004, 39, 3293–3308. [Google Scholar] [CrossRef]

- Rothon, R.N. Particulate Fillers for Polymers; Rapra review reports, Vol. 12; Smithers Rapra Publishing: Shrewsbury, UK, 2002. [Google Scholar]

- Khalilnezhad, P.; Sajjadi, S.A.; Zebarjad, S.M. Effect of nanodiamond surface functionalization using oleylamine on the scratch behavior of polyacrylic/nanodiamond nanocomposite. Diam. Relat. Mater. 2014, 45, 7–11. [Google Scholar] [CrossRef]

- Lin, L.; Blackman, G.S.; Matheson, R.R. A new approach to characterize scratch and mar resistance of automotive coatings. Prog. Org. Coat. 2000, 40, 85–91. [Google Scholar] [CrossRef]

- Brostow, W.; Deborde, J.-L.; Jaklewicz, M.; Olszynski, P. Tribology with emphasis on polymers: Friction, scratch resistance and wear. J. Mater. Educ. 2003, 24, 119–132. [Google Scholar]

- Brostow, W.; Hagg Lobland, H.E.; Narkis, M. Sliding wear, viscoelasticity, and brittleness of polymers. J. Mater. Res. 2006, 21, 2422–2428. [Google Scholar] [CrossRef]

- Zhou, S.; Wu, L.; Sun, J.; Shen, W. The change of the properties of acrylic-based polyurethane via addition of nano-silica. Prog. Org. Coat. 2002, 45, 33–42. [Google Scholar] [CrossRef]

- Lange, J.; Luisier, A.; Hult, A. Influence of crosslink density, glass transition temperature and addition of pigment and wax on the scratch resistance of an epoxy coating. J. Coat. Technol. 1997, 69, 77–82. [Google Scholar] [CrossRef]

- Rink, H.-P. Polymeric engineering for automotive coating applications. In Automotive Paints and Coatings; Streitberger, H.-J., Kreis, W., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Chichester, UK, 2008; pp. 211–257. [Google Scholar]

- Droste, D.H.; Dibenedetto, A.T. The glass transition temperature of filled polymers and its effect on their physical properties. J. Appl. Polym. Sci. 1969, 13, 2149–2168. [Google Scholar] [CrossRef]

| Alumina Particle Concentration (wt %) | Functionalization | Scratch Resistance (N) | Scratch Width (µm) |

|---|---|---|---|

| 0 | – | 4 | 131 ± 5 |

| 5 | No | 5 | 118 ± 3 |

| 10 | No | 4 | 123 ± 6 |

| 5 | Yes | 5/6 | 120 ± 5 |

| 10 | Yes | 6 | 108 ± 7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rusu, C.L.; Brodin, M.; Hausvik, T.I.; Hindersland, L.K.; Chinga-Carrasco, G.; Einarsrud, M.-A.; Lein, H.L. The Potential of Functionalized Ceramic Particles in Coatings for Improved Scratch Resistance. Coatings 2018, 8, 224. https://doi.org/10.3390/coatings8060224

Rusu CL, Brodin M, Hausvik TI, Hindersland LK, Chinga-Carrasco G, Einarsrud M-A, Lein HL. The Potential of Functionalized Ceramic Particles in Coatings for Improved Scratch Resistance. Coatings. 2018; 8(6):224. https://doi.org/10.3390/coatings8060224

Chicago/Turabian StyleRusu, Caterina Lesaint, Malin Brodin, Tor Inge Hausvik, Leif Kåre Hindersland, Gary Chinga-Carrasco, Mari-Ann Einarsrud, and Hilde Lea Lein. 2018. "The Potential of Functionalized Ceramic Particles in Coatings for Improved Scratch Resistance" Coatings 8, no. 6: 224. https://doi.org/10.3390/coatings8060224

APA StyleRusu, C. L., Brodin, M., Hausvik, T. I., Hindersland, L. K., Chinga-Carrasco, G., Einarsrud, M.-A., & Lein, H. L. (2018). The Potential of Functionalized Ceramic Particles in Coatings for Improved Scratch Resistance. Coatings, 8(6), 224. https://doi.org/10.3390/coatings8060224