HFCVD Diamond-Coated Mechanical Seals

Abstract

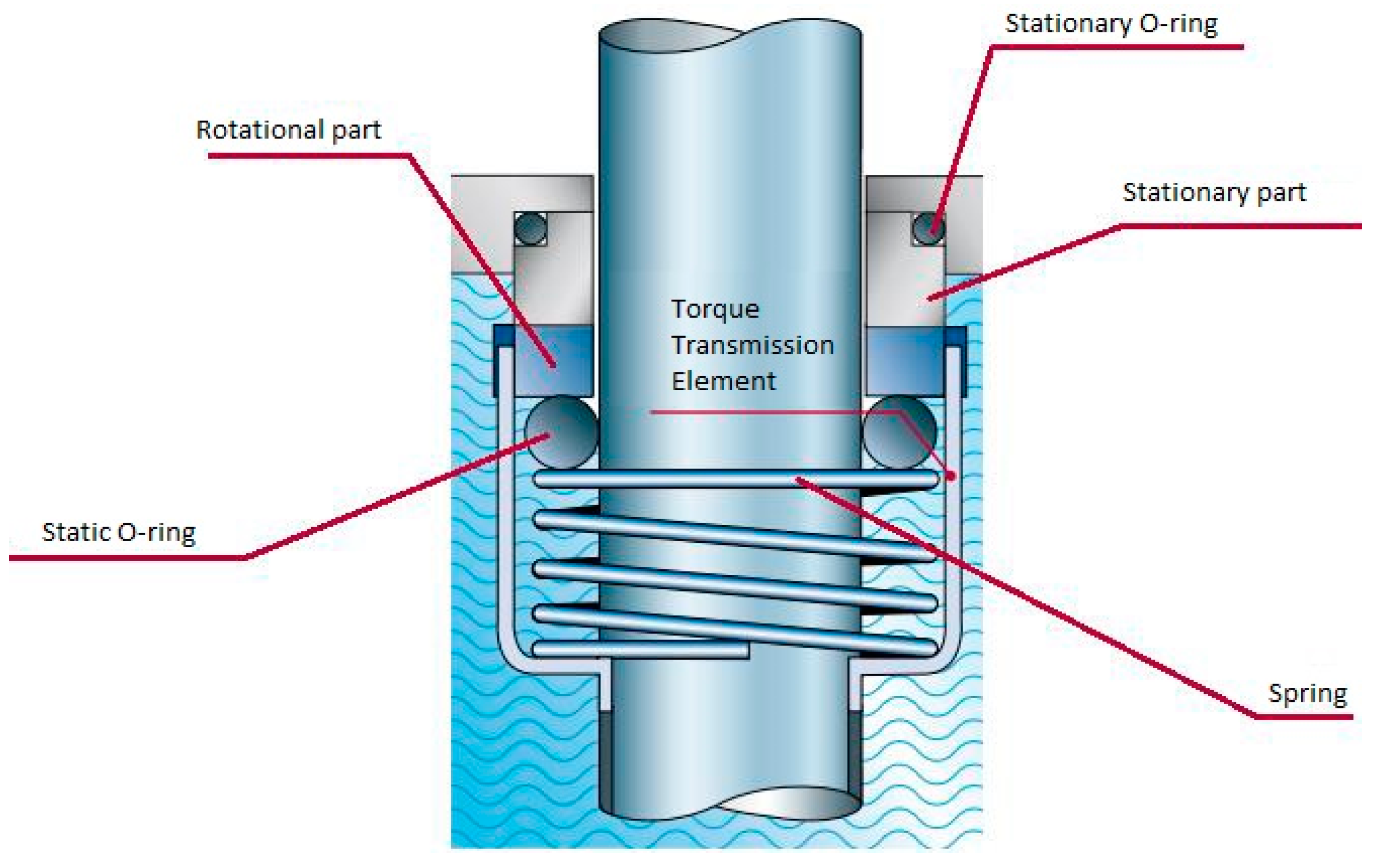

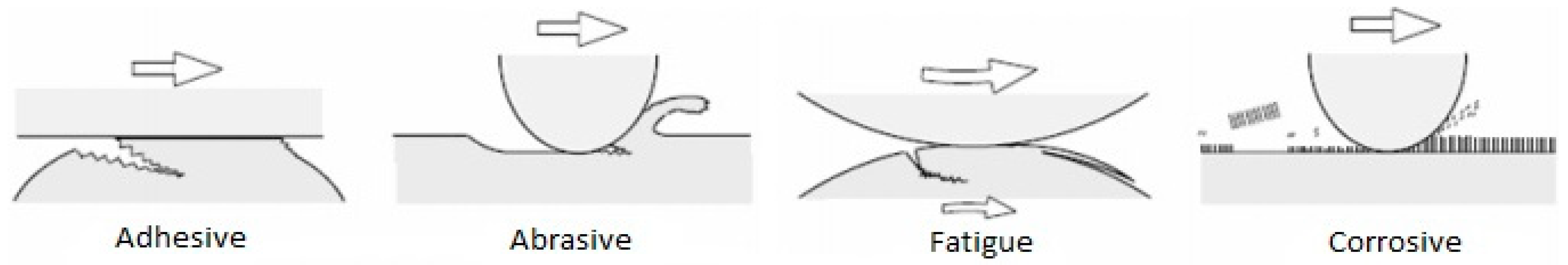

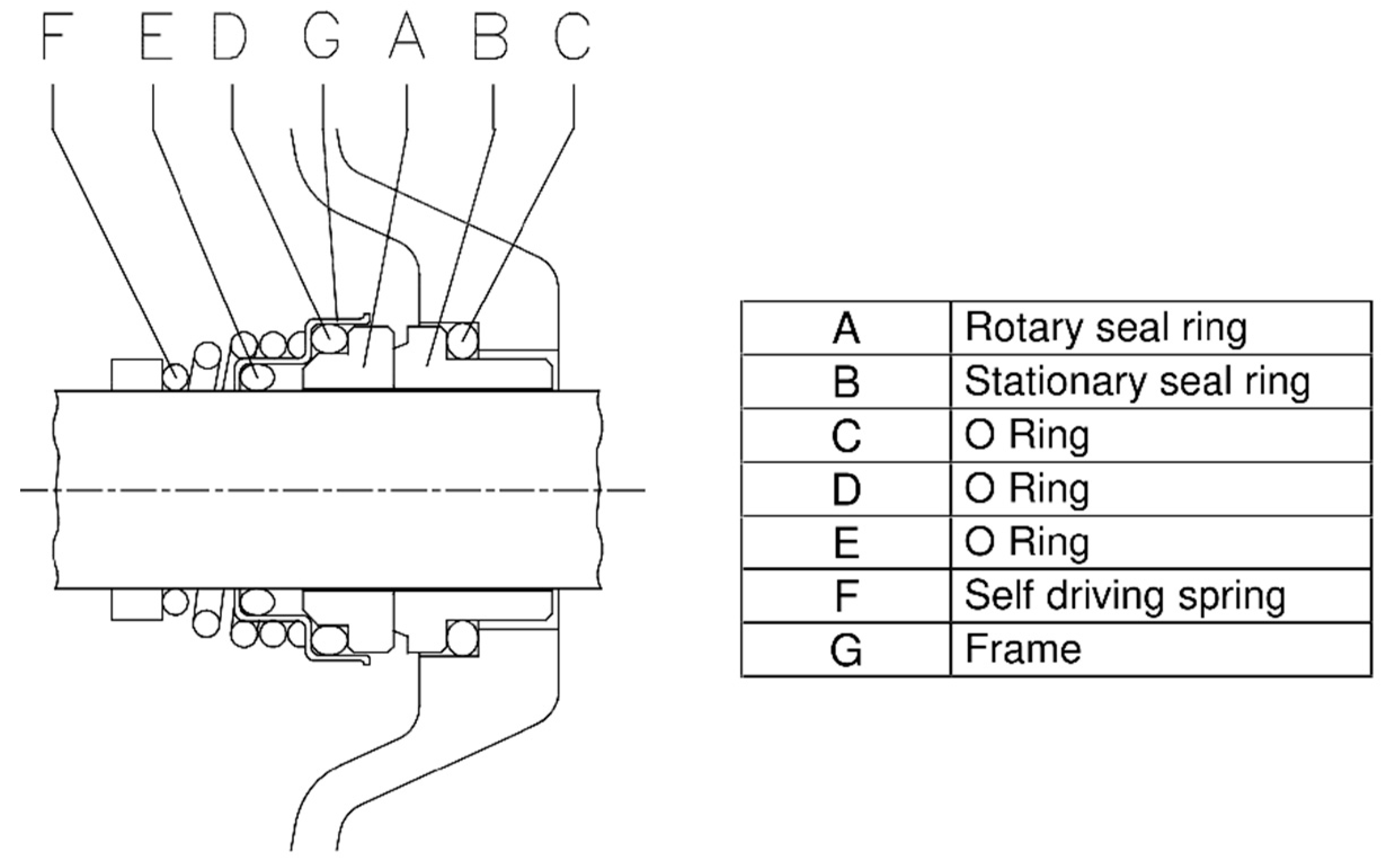

1. Introduction

2. Materials and Methods

3. Results

3.1. Seal Characterization

3.1.1. Roughness Measurements

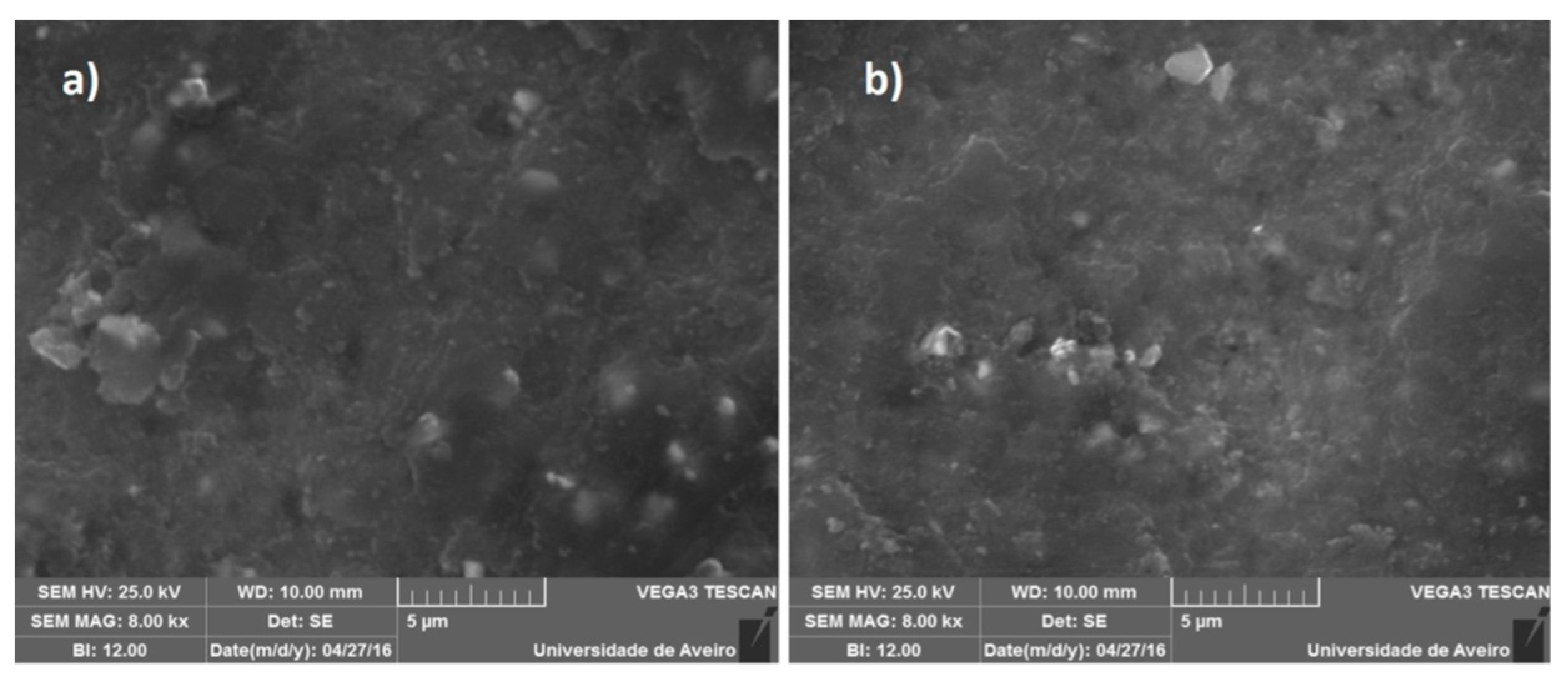

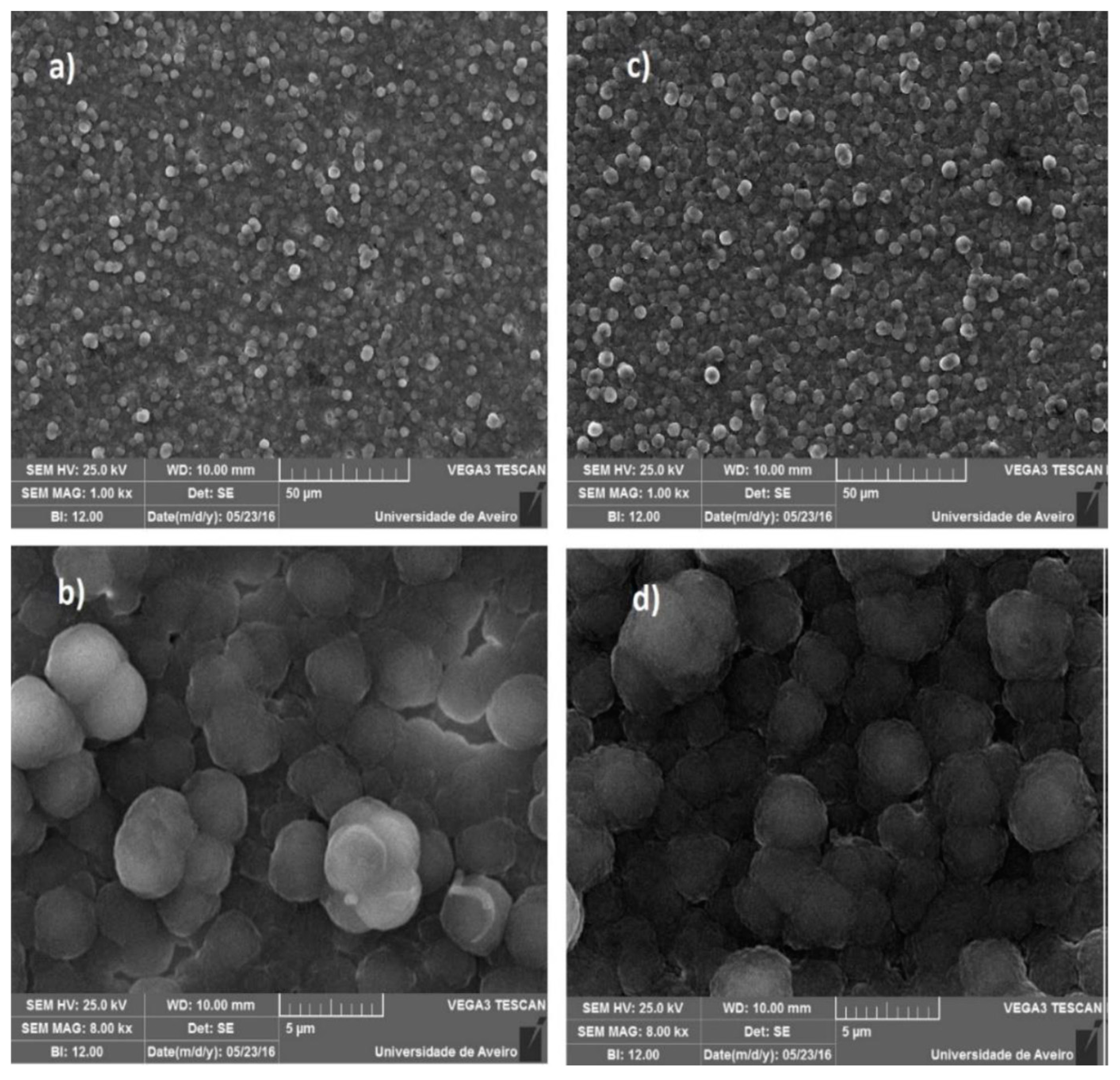

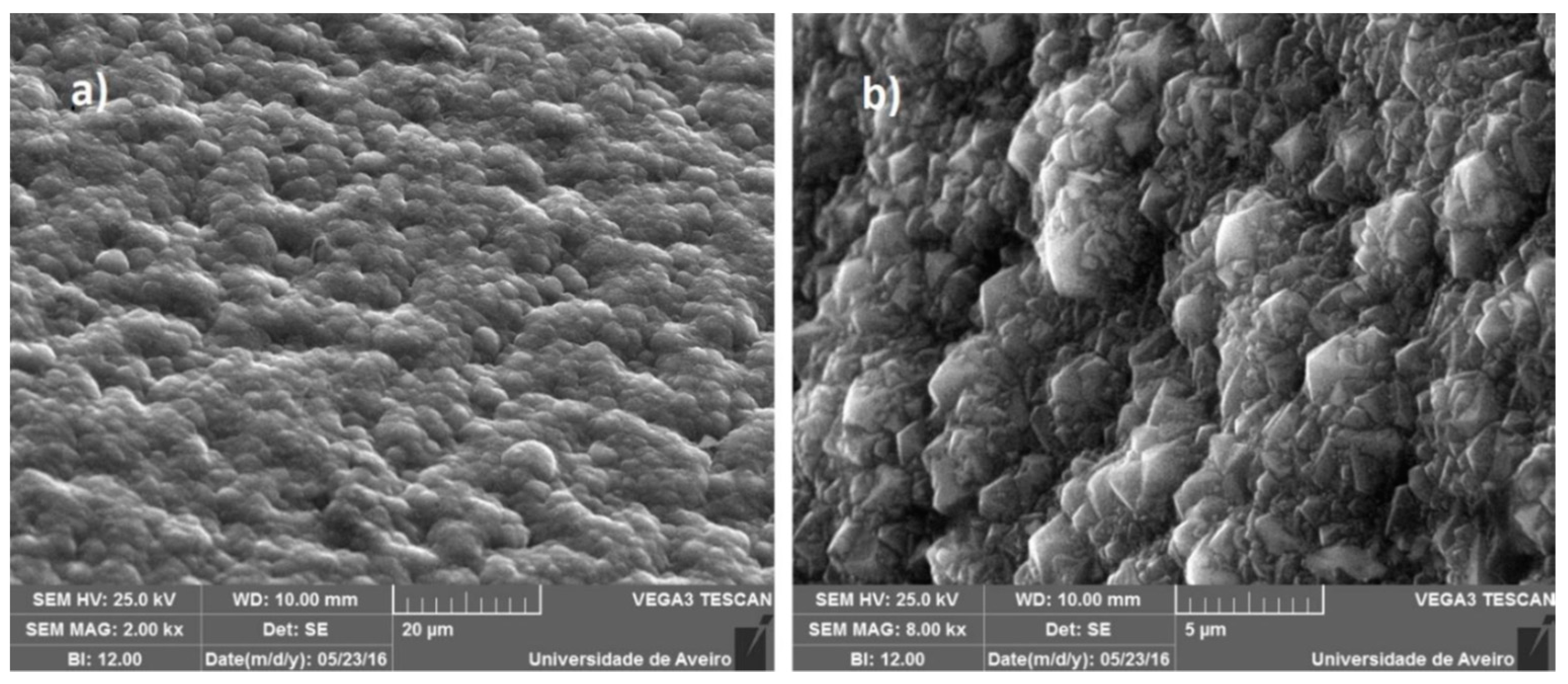

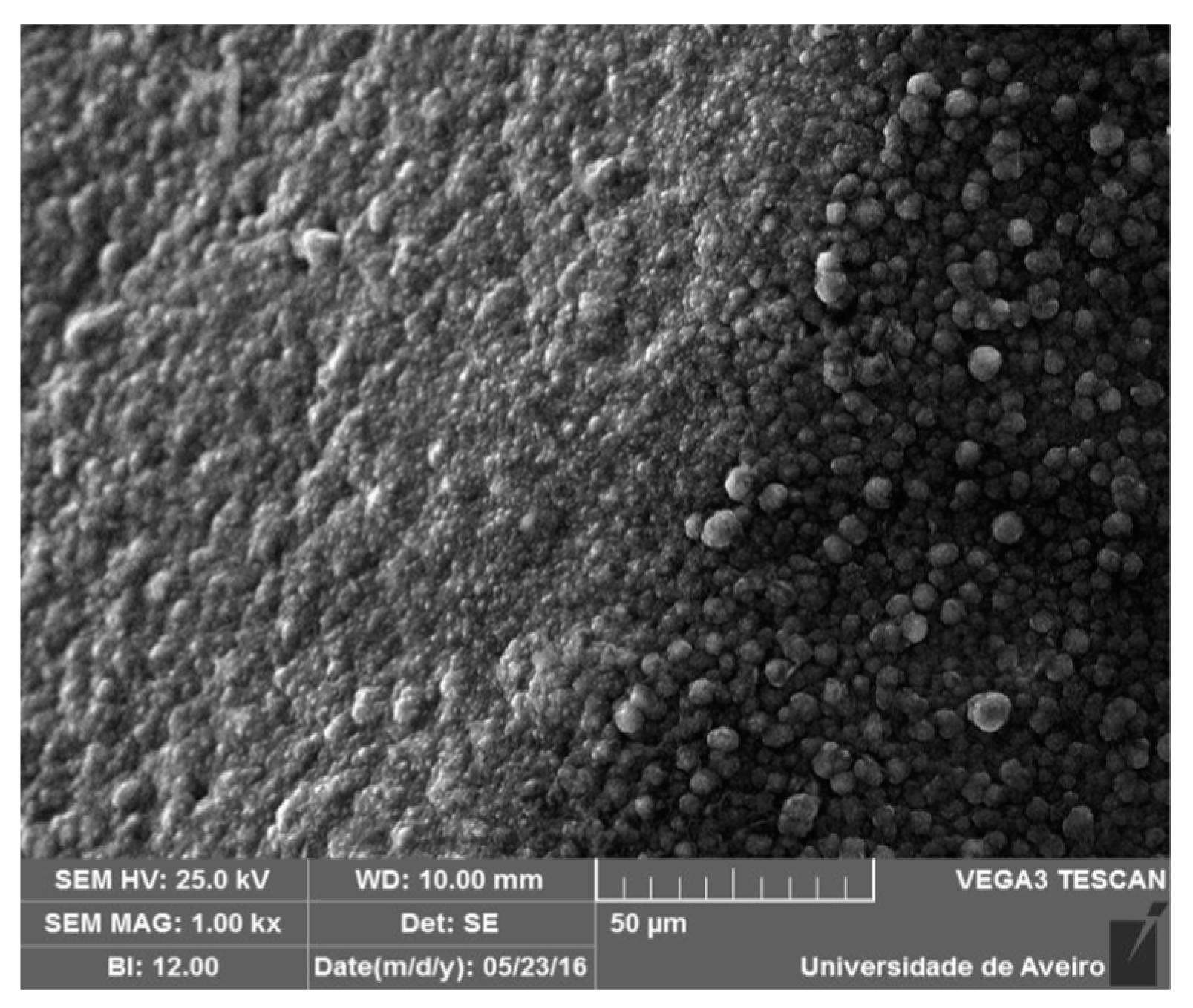

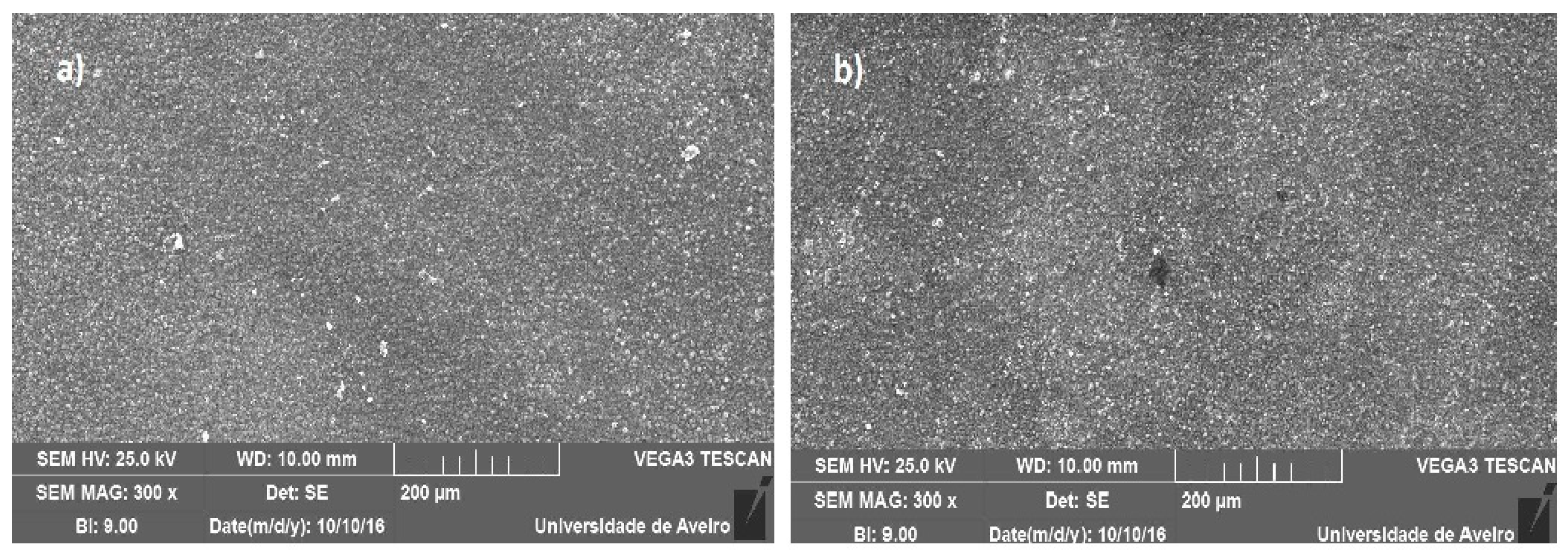

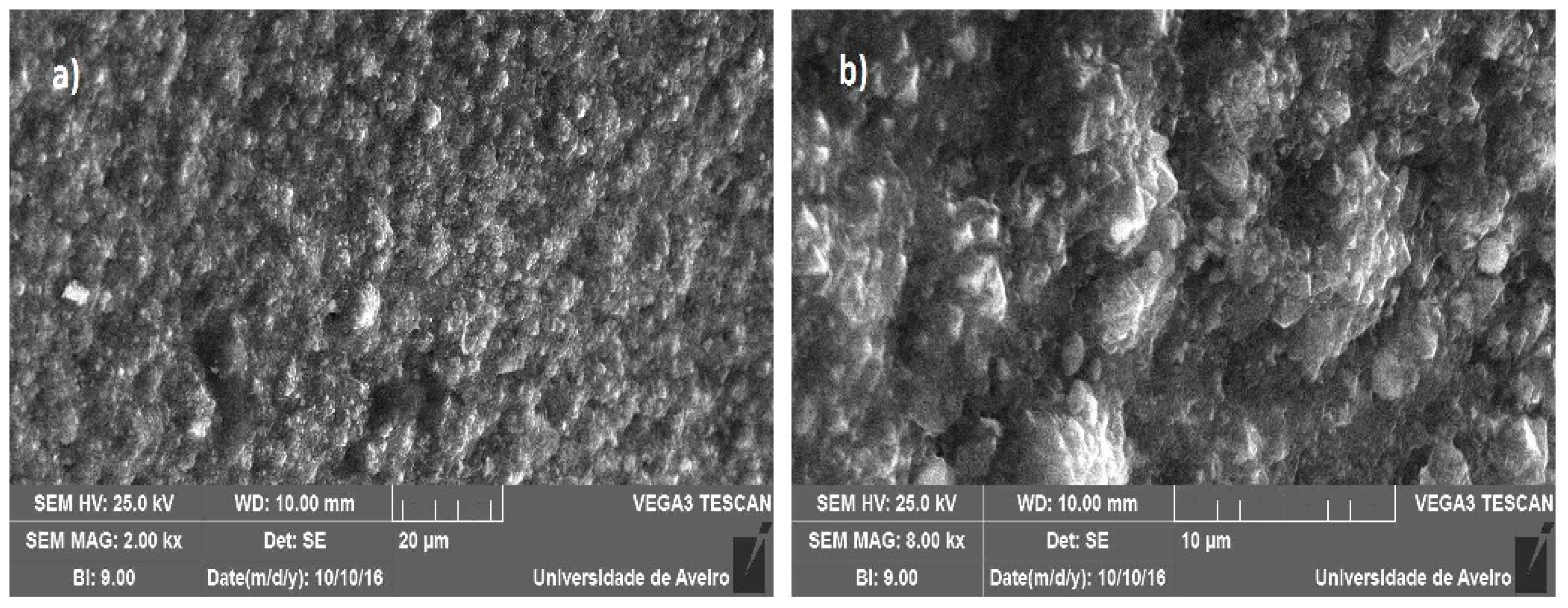

3.1.2. SEM Imaging

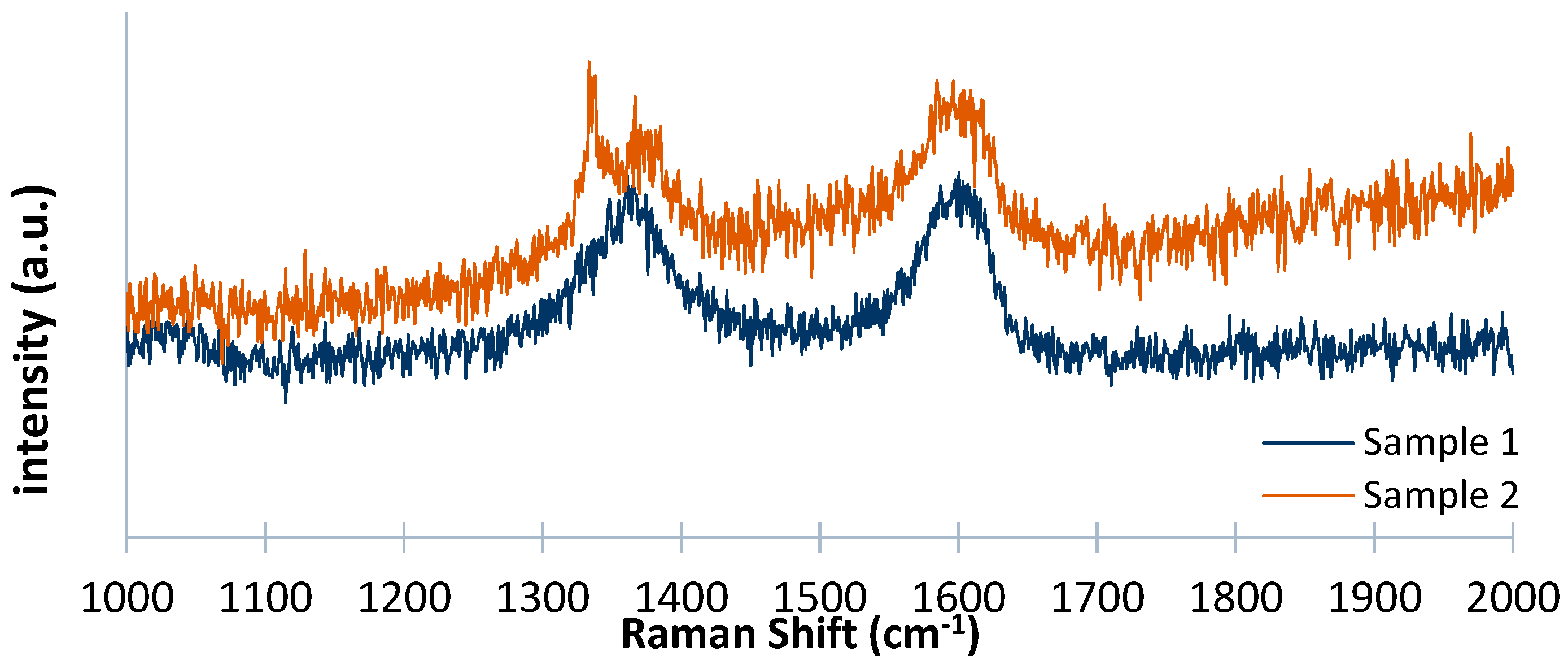

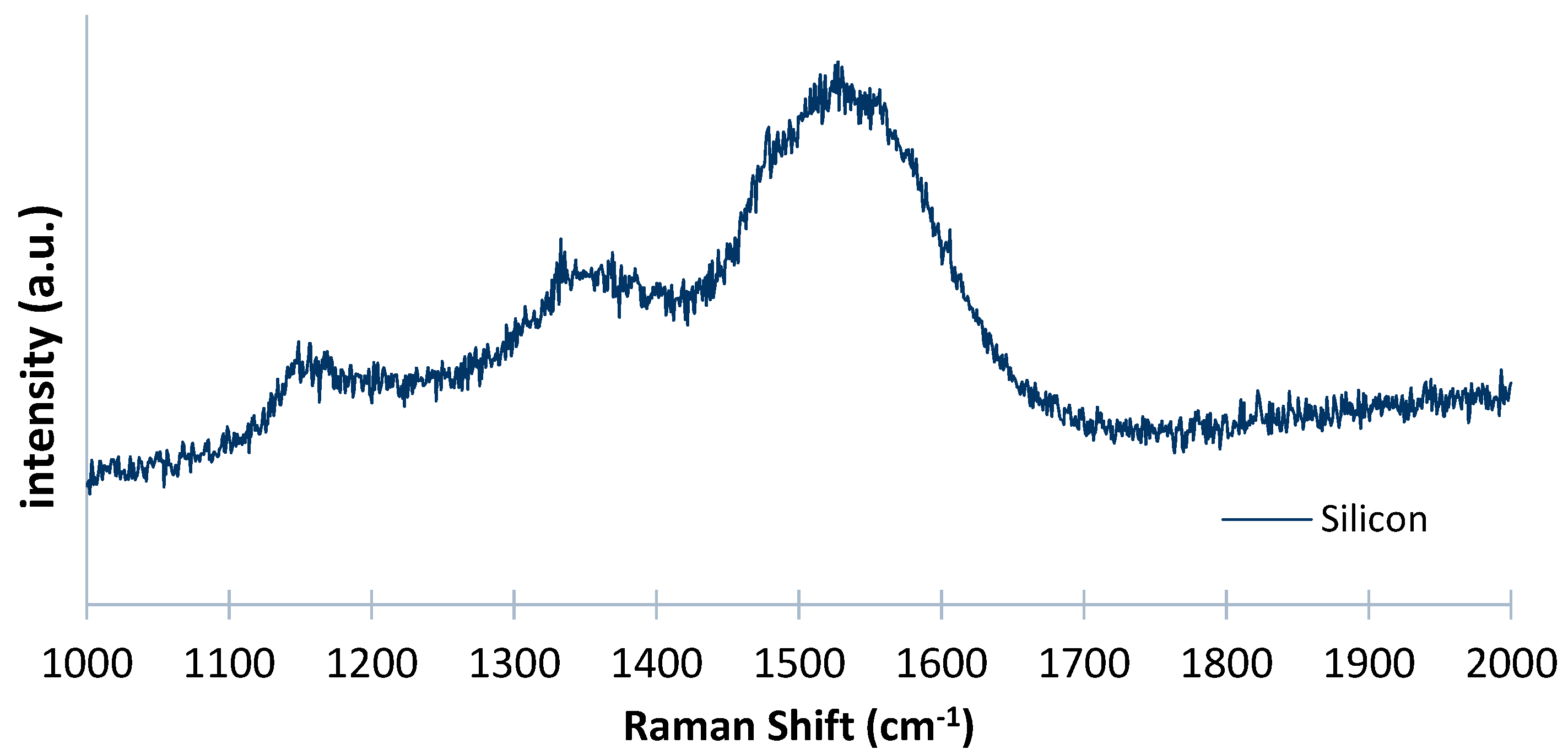

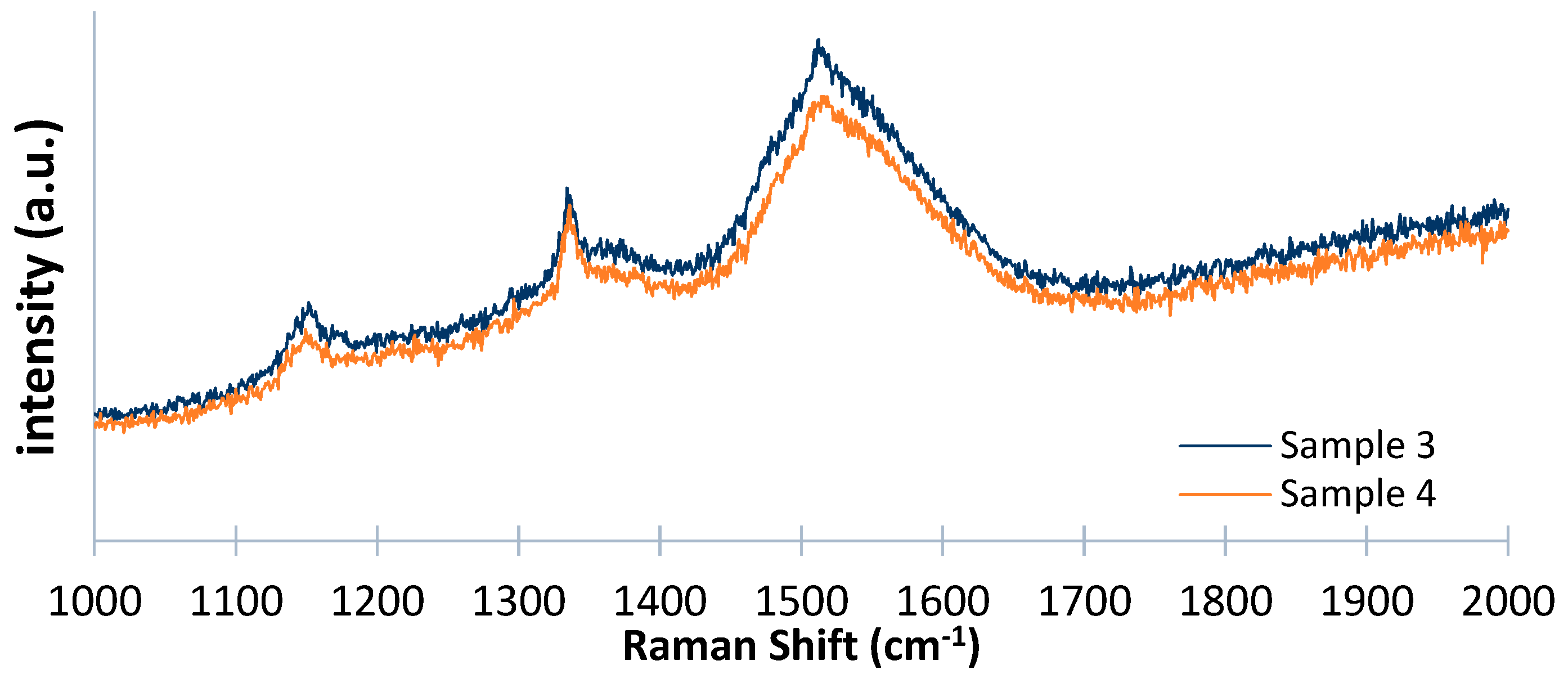

3.1.3. Raman Spectroscopy

3.1.4. Mass Measurements

3.2. Wear Tests and Characterization

3.2.1. SEM Analysis

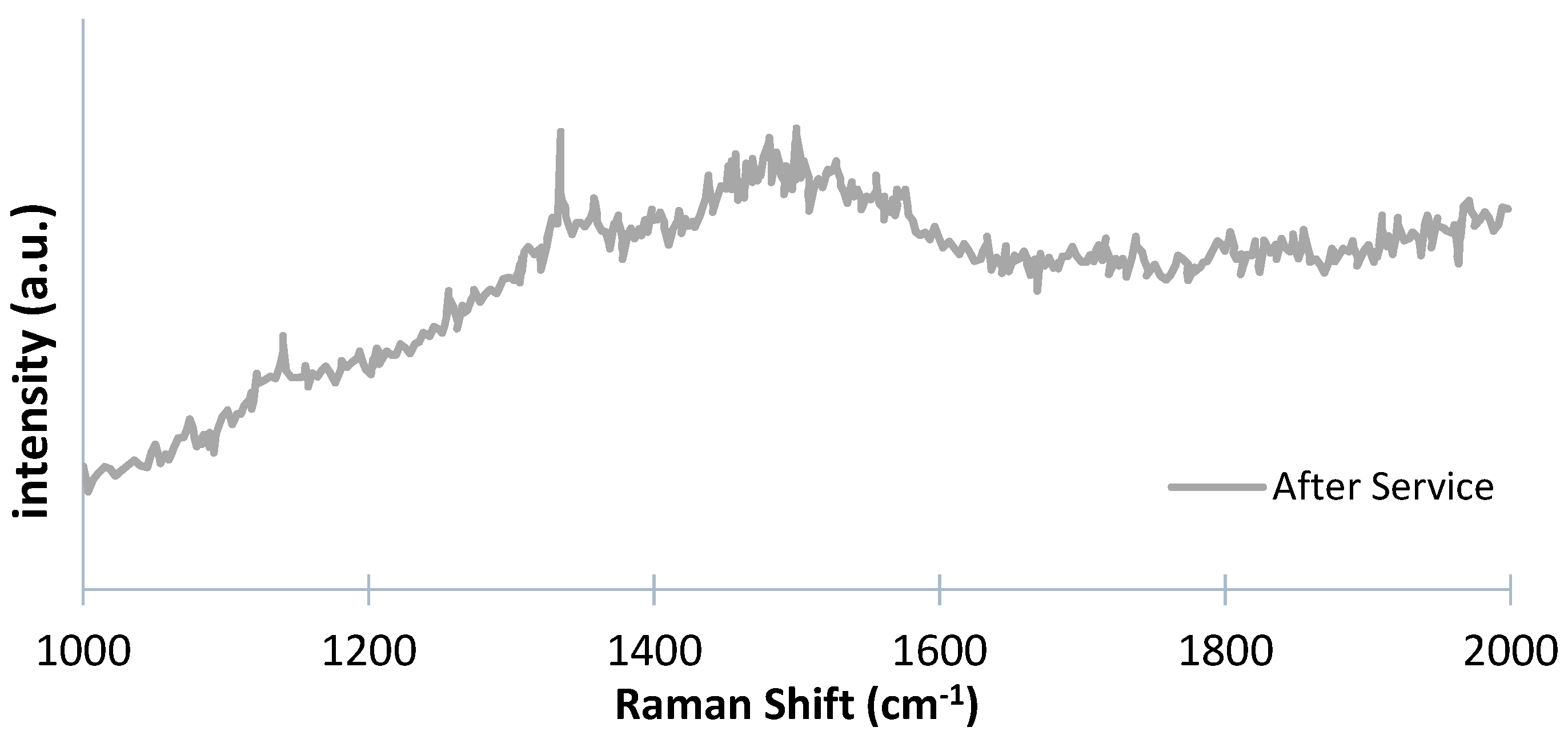

3.2.2. Raman Spectroscopy

3.2.3. Seal Mass after Pump Wear Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kelly, P.J.; Arnell, R.D.; Hudson, M.D.; Wilson, A.E.J.; Jones, G. Enhanced mechanical seal performance through CVD diamond films. Vacuum 2001, 61, 61–74. [Google Scholar] [CrossRef]

- Santos, J.A.; Ruch, V.F.; Grácio, J. Mechanical properties of nanocrystalline diamond coating on WC substrate with different interlayers. In Proceedings of the NANOSMAT 5th International Conference on Surface, Coatins and Nanostructured Materials, Reims, France, 19–21 October 2010. [Google Scholar]

- Rodrigues, A.J. Estudo de Causas de Falhas em Selos Mecânicos de Bombas Centrífugas Para Circulação de Óleo Térmico; Master’s Thesis, Universidade Estadual Paulista Júlio de Mesquita Filho, Guaratinguetá, Brazil, February 2012. [Google Scholar]

- Jones, G.A. On the tribological behaviour of mechanical seal face materials in dry line contact: Part II. Bulk ceramics, diamond and diamond-like carbon films. Wear 2004, 256, 433–455. [Google Scholar] [CrossRef]

- Hollman, P.; Björkman, H.; Alahelisten, A.; Hogmark, S. Diamond coatings applied to mechanical face seals. Surf. Coat. Technol. 1998, 105, 169–174. [Google Scholar] [CrossRef]

- Santos, J.A.; Neto, V.F.; Ruch, D.; Grácio, J. Nanocrystalline diamond coatings for mechanical seals applications. J. Nanosci. Nanotechnol. 2012, 12, 6835–6839. [Google Scholar] [CrossRef] [PubMed]

- May, P.W. Diamond thin films: A 21st-century material. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2000, 358, 473–495. [Google Scholar] [CrossRef]

- Lee, S.-T.; Lin, Z.; Jiang, X. CVD diamond films: Nucleation and growth. Mater. Sci. Eng. R Rep. 1999, 25, 123–154. [Google Scholar] [CrossRef]

- Chen, N.; Pu, L.; Sun, F.; He, P.; Zhu, Q.; Ren, J. Tribological behavior of HFCVD multilayer diamond film on silicon carbide. Surf. Coat. Technol. 2015, 272, 66–71. [Google Scholar] [CrossRef]

- Chen, N.C.; Sun, F.H. Friction and wear performances of hot filament chemical vapor deposition multilayer diamond films coated on silicon carbide under water lubrication. J. Shanghai Jiaotong Univ. 2013, 18, 237–242. [Google Scholar] [CrossRef]

- Luo, J.-L.; Ying, X.-T.; Wang, P.-N.; Chen, L.-Y. Growth and optical properties of nanocrystalline/microcrystalline diamond multilayer films. J. Korean Phys. Soc. 2005, 46, 224–228. [Google Scholar]

- GRUNDFOS Management A/S. Mechanical Shaft Seals for Pumps, 1st ed.; GRUNDFOS Management A/S: Bjerringbro, Denmark, 2009. [Google Scholar]

- West, C.; Netzel, J. Diamond—Its effect on the seal industry. World Pumps 2008, 2008, 50–52. [Google Scholar] [CrossRef]

- Ekk Technologies Mechanical Seals. Available online: https://www.ekkeagle.com/en/technology/mechanical/ (accessed on 9 March 2018).

- Spitsyn, B.V.; Bouilov, L.L.; Alexenko, A.E. Origin, state of the art and some prospects of the diamond CVD. Braz. J. Phys. 2000, 30, 471–481. [Google Scholar] [CrossRef]

- Tjong, S.C.; Chen, H. Nanocrystalline materials and coatings. Mater. Sci. Eng. R Rep. 2004, 45, 1–88. [Google Scholar] [CrossRef]

- Matsumoto, S.; Sato, Y.; Kamo, M.; Setaka, N. Vapor deposition of diamond particles from methane. Jpn. J. Appl. Phys. 1982, 21, L183–L185. [Google Scholar] [CrossRef]

- Gruen, D.M. Nanocrystalline diamond films. Annu. Rev. Mater. Sci. 1999, 29, 211–259. [Google Scholar] [CrossRef]

- Krauss, A.R.; Auciello, O.; Gruen, D.M.; Jayatissa, A.; Sumant, A.; Tucek, J.; Mancini, D.C.; Moldovan, N.; Erdemir, A.; Ersoy, D.; et al. Ultrananocrystalline diamond thin films for MEMS and moving mechanical assembly devices. Diam. Relat. Mater. 2001, 10, 1952–1961. [Google Scholar] [CrossRef]

- Cabral, G.; Madaleno, J.C.; Titus, E.; Ali, N.; Grácio, J. Diamond chemical vapour deposition on seeded cemented tungsten carbide substrates. Thin Solid Films 2006, 515, 158–163. [Google Scholar] [CrossRef]

- Silva, V.A.; Fernandes, A.J.; Costa, F.M.; Silva, R. Deposição direta de diamante CVD em compósitos cerâmicos Si3N4/SiC. Rev. Bras. Apl. Vácuo 2000, 19, 27–32. [Google Scholar]

- Fujiy, O.K.; Trava-Airoldi, V.J.; Corat, E.J.; Ferreira, M.J.; Amorim, A.; Moro, J.R. Growth rate of the CVD diamond films on molybdenum surfaces. Taxa de crescimento de filmes de diamante CVD em superfícies de molibdênio. Rev. Esc. Minas 2007, 60, 227–231. [Google Scholar] [CrossRef]

- Nakamura, Y.; Sakagami, S.; Amamoto, Y.; Watanabe, Y. Measurement of internal stresses in CVD diamond films. Thin Solid Films 1997, 308–309, 249–253. [Google Scholar] [CrossRef]

- Liang, X.; Wang, L.; Zhu, H.; Yang, D. Effect of pressure on nanocrystalline diamond films deposition by hot filament CVD technique from CH4/H2 gas mixture. Surf. Coat. Technol. 2007, 202, 261–267. [Google Scholar] [CrossRef]

- Song, G.H.; Yoon, J.H.; Kim, H.S.; Sun, C.; Huang, R.F.; Wen, L.S. Influence of hot filaments arranging on substrate temperature during HFCVD of diamond films. Mater. Lett. 2002, 56, 832–837. [Google Scholar] [CrossRef]

- Lin, T.; Yu, G.Y.; Wee, A.T.S.; Shen, Z.X. Compositional mapping of the argon-methane-hydrogen system for polycrystalline to nanocrystalline diamond film growth in a hot-filament chemical vapor deposition system. Appl. Phys. Lett. 2000, 77, 2692–2694. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhang, F.; Gao, Q.J.; Yu, D.P.; Peng, X.F.; Lin, X.D. Synthesis of nano-crystalline diamond film in hot filament chemical vapour deposition by adding Ar. Chin. Phys. Lett. 2001, 18, 286–288. [Google Scholar] [CrossRef]

- Tomé, M.A.; Fernandes, A.J.S.; Oliveira, F.J.; Silva, R.F.; Carrapichano, J.M. High performance sealing with CVD diamond self-mated rings. Diam. Relat. Mater. 2005, 14, 617–621. [Google Scholar] [CrossRef]

- Camargo, S.S.; Gomes, J.R.; Carrapichano, J.M.; Silva, R.F.; Achete, C.A. Silicon-incorporated diamond-like coatings for Si3N4 mechanical seals. Thin Solid Films 2005, 482, 221–225. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Elam, J.W.; Erdemir, A.; Carlisle, J.A.; Auciello, O.; Libera, J.A.; Pellin, M.J.; Gruen, D.M.; Hryn, J.N. Development of ultrananocrystalline diamond (UNCD) coatings for multipurpose mechanical pump seals. Wear 2011, 270, 325–331. [Google Scholar] [CrossRef]

- Moro, J.R.; Nascente, P.A.P.; Trava-Airoldi, V.J.; Corat, E.J.; Alves, A.R.; Alves, A. Crescimentos sucessivos de filmes de diamante cvd em grandes áreas. Rev. Bras. Apl. Vácuo 2007, 26, 83–87. [Google Scholar]

- Liu, H.; Dandy, D.S. Diamond chemical vapor deposition: Nucleation and early growth stages. In Diamond Chemical Vapor Deposition; Noyes Publication: Saddle River, NJ, USA, 1995; pp. 46–126. ISBN 9780815513803. [Google Scholar]

- Cabral, E.G.S.S. Development and Application of Diamond Coatings onto Cutting Tools to Machine EDM Electrodes for Mould Industry. Ph.D. Thesis, University of Aveiro, Aveiro, Portugal, December 2006. [Google Scholar]

- Polini, R.; Delogu, M.; Marcheselli, G. Adherent diamond coatings on cemented tungsten carbide substrates with new Fe/Ni/Co binder phase. Thin Solid Films 2006, 494, 133–140. [Google Scholar] [CrossRef]

- Feng, J.; Li, S.; Luo, H.; Wei, Q.; Wang, B.; Li, J.; Hu, D.; Mei, J.; Yu, Z. Preparation and characterization of ultrananocrystalline diamond films in H2/Ar/CH4 gas mixtures system with novel filament structure. J. Cent. South Univ. 2015, 22, 4097–4104. [Google Scholar] [CrossRef]

- Kuzmany, H.; Pfeiffer, R.; Salk, N.; Günther, B. The mystery of the 1140 cm−1 Raman line in nanocrystalline diamond films. Carbon 2004, 42, 911–917. [Google Scholar] [CrossRef]

- Kromka, A.; Breza, J.; Kadlečíková, M.; Janík, J.; Balon, F. Identification of carbon phases and analysis of diamond/substrate interfaces by Raman spectroscopy. Carbon 2005, 43, 425–429. [Google Scholar] [CrossRef]

- Cebik, J.; McDonough, J.K.; Peerally, F.; Medrano, R.; Neitzel, I.; Gogotsi, Y.; Osswald, S. Raman spectroscopy study of the nanodiamond-to-carbon onion transformation. Nanotechnology 2013, 24, 205703. [Google Scholar] [CrossRef] [PubMed]

- Donnet, C.; Erdemir, A. Tribology of Diamond-Like Carbon Films; Springer: Berlin, Germany, 2008; ISBN 978-0-387-30264-5. [Google Scholar]

| Parameters | Samples 1 and 2 | Samples 3 and 4 | ||

|---|---|---|---|---|

| 1st Deposition Microcrystalline Layer | 2nd Deposition Nanocrystalline Layer | 1st Deposition Microcrystalline Layer | 2nd Deposition Nanocrystalline Layer | |

| Gas flow (sccm) | 200 | 200 | 200 | 200 |

| CH4 (sccm) | 2 | 2 | 2 | 2 |

| H2 (sccm) | 198 | 34 | 198 | 34 |

| Ar (sccm) | 0 | 164 | 0 | 164 |

| Filament/Substrate distance (mm) | 8 | 8 | 8 | 8 |

| Power intensity (VxA) | 24 × 43 | 22 × 35 | 30 × 32 | 25 × 33 |

| Pressure (Torr) | 30 | 30 | 30 | 30 |

| Deposition time (h) | 3 | 5 | 3 | 5 |

| Substrate temperature (°C) | 500 | 375 | 450 | 375 |

| Roughness Parameter | Sample 1 | Sample 2 |

|---|---|---|

| Ra (µm) | 0.075 | 0.093 |

| Rt (µm) | 0.916 | 0.910 |

| Roughness Parameter | Sample 1 | Sample 2 | Sample 3 | Sample 4 |

|---|---|---|---|---|

| Ra (µm) | 0.077 | 0.072 | 0.078 | 0.077 |

| Rt (µm) | 0.19 | 0.17 | 0.2 | 0.17 |

| Parameter | Sample 1 | Sample 2 | Sample 3 | Sample 4 |

|---|---|---|---|---|

| Mass (g) | 37.853 | 37.891 | 37.992 | 37.872 |

| Parameter | Value |

|---|---|

| Work fluid | Water |

| Work temperature | 20 °C |

| Work pressure | 1 atm |

| Rotational speed | 3000 rpm |

| Working time | 5 h |

| Sliding distance of the seals | 86 km |

| Sample | Before Test | After Test | Loss of Material |

|---|---|---|---|

| Sample 3 (static) | 37.992 g | 37.921 g | 0.001 g |

| Sample 4 (dynamic) | 37.872 g | 37.869 g | 0.003 g |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simões, R.; Martins, B.; Santos, J.; Neto, V. HFCVD Diamond-Coated Mechanical Seals. Coatings 2018, 8, 172. https://doi.org/10.3390/coatings8050172

Simões R, Martins B, Santos J, Neto V. HFCVD Diamond-Coated Mechanical Seals. Coatings. 2018; 8(5):172. https://doi.org/10.3390/coatings8050172

Chicago/Turabian StyleSimões, Raul, Bruno Martins, José Santos, and Victor Neto. 2018. "HFCVD Diamond-Coated Mechanical Seals" Coatings 8, no. 5: 172. https://doi.org/10.3390/coatings8050172

APA StyleSimões, R., Martins, B., Santos, J., & Neto, V. (2018). HFCVD Diamond-Coated Mechanical Seals. Coatings, 8(5), 172. https://doi.org/10.3390/coatings8050172