Influence of Cu Content on the Structure, Mechanical, Friction and Wear Properties of VCN–Cu Films

Abstract

1. Introduction

2. Experimental Details

2.1. Preparation of Films

2.2. Characterization of the Films

3. Results and Discussion

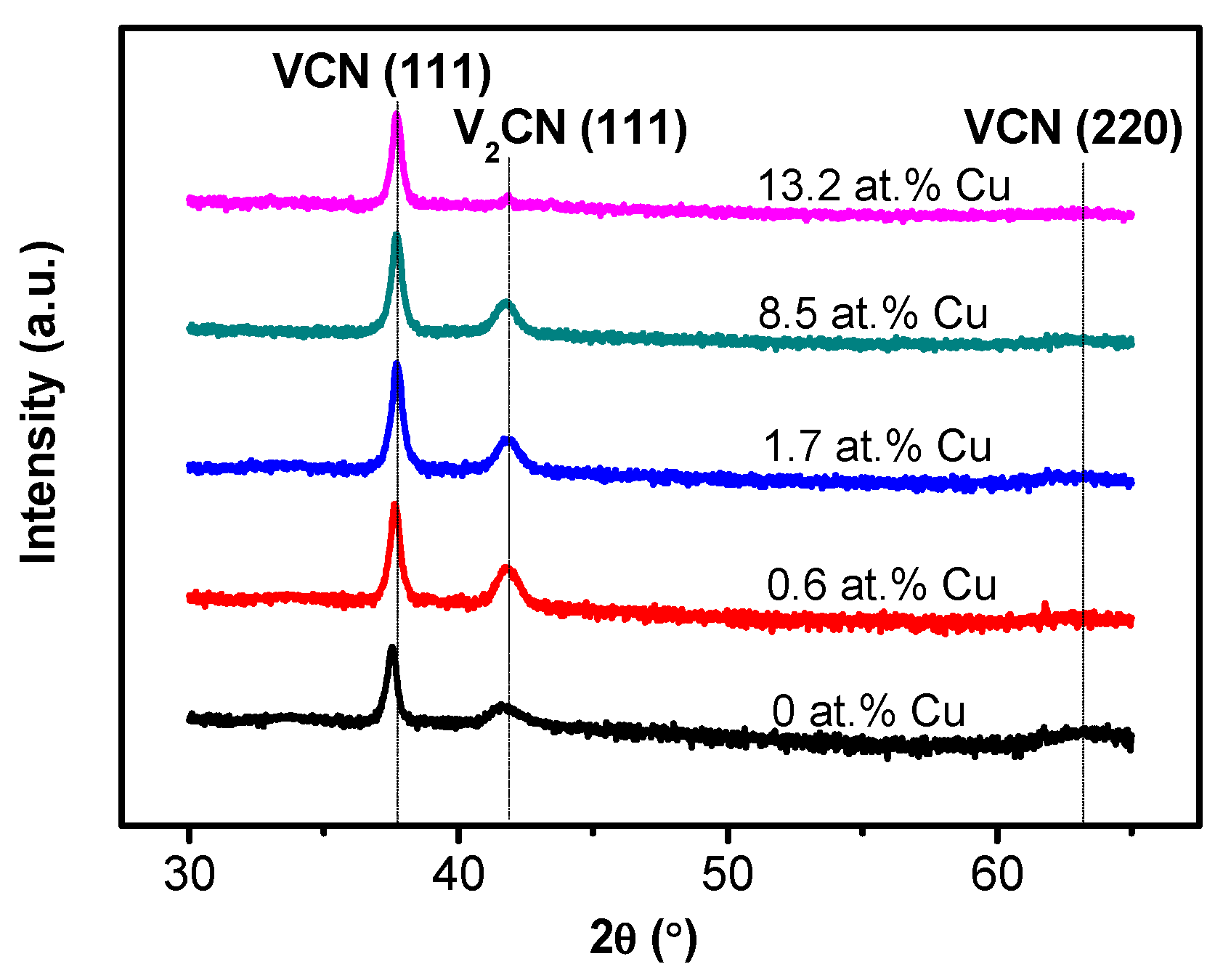

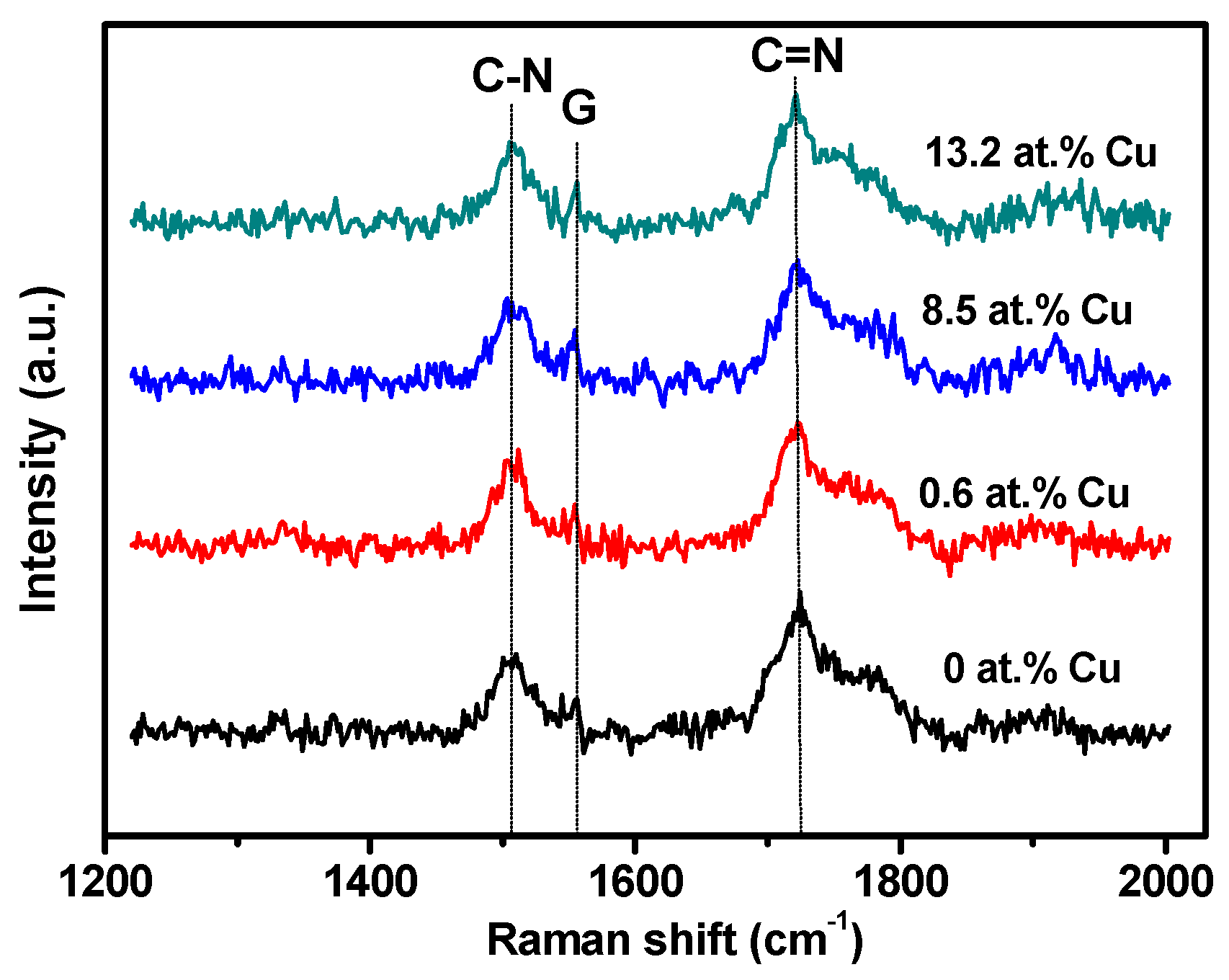

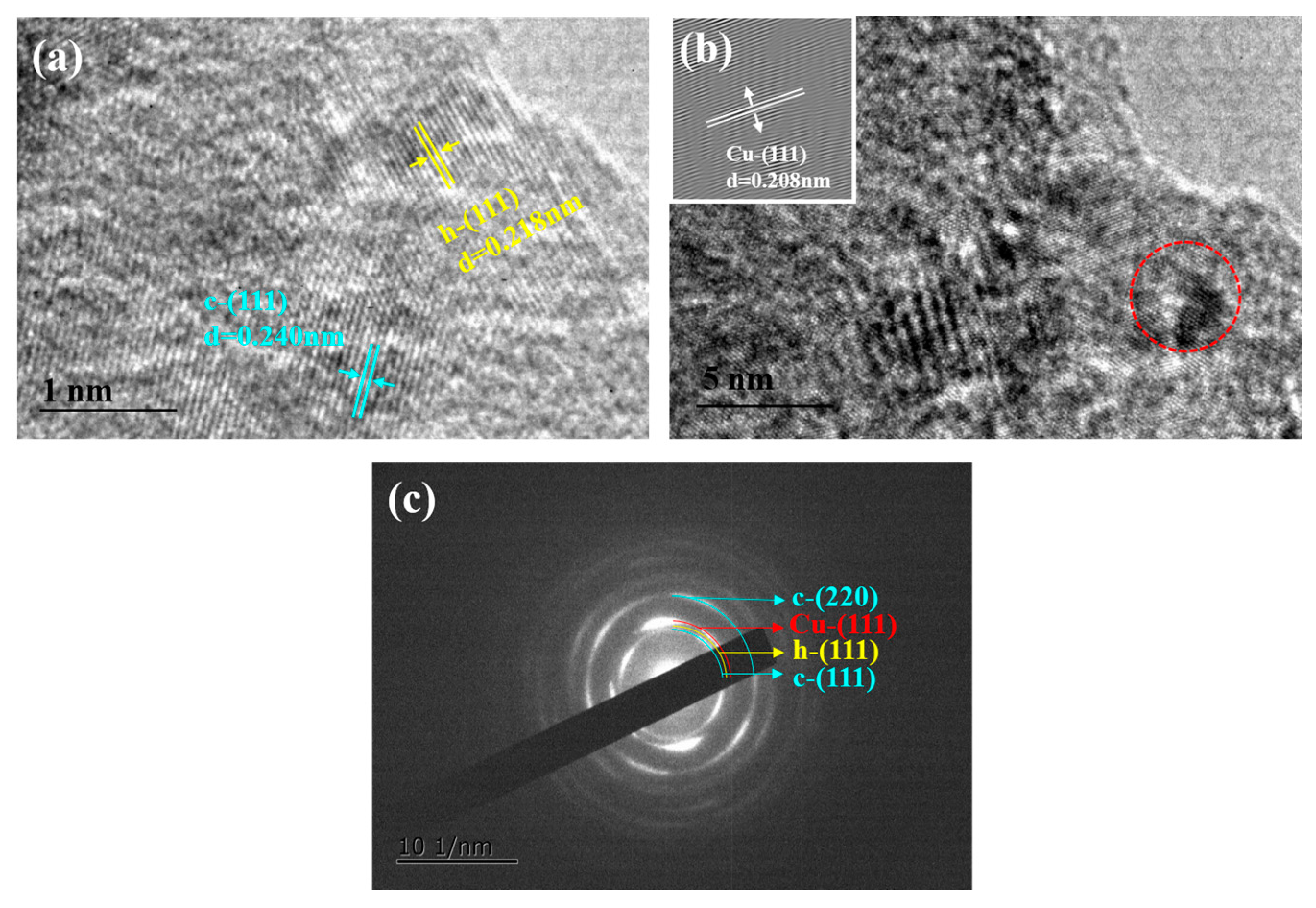

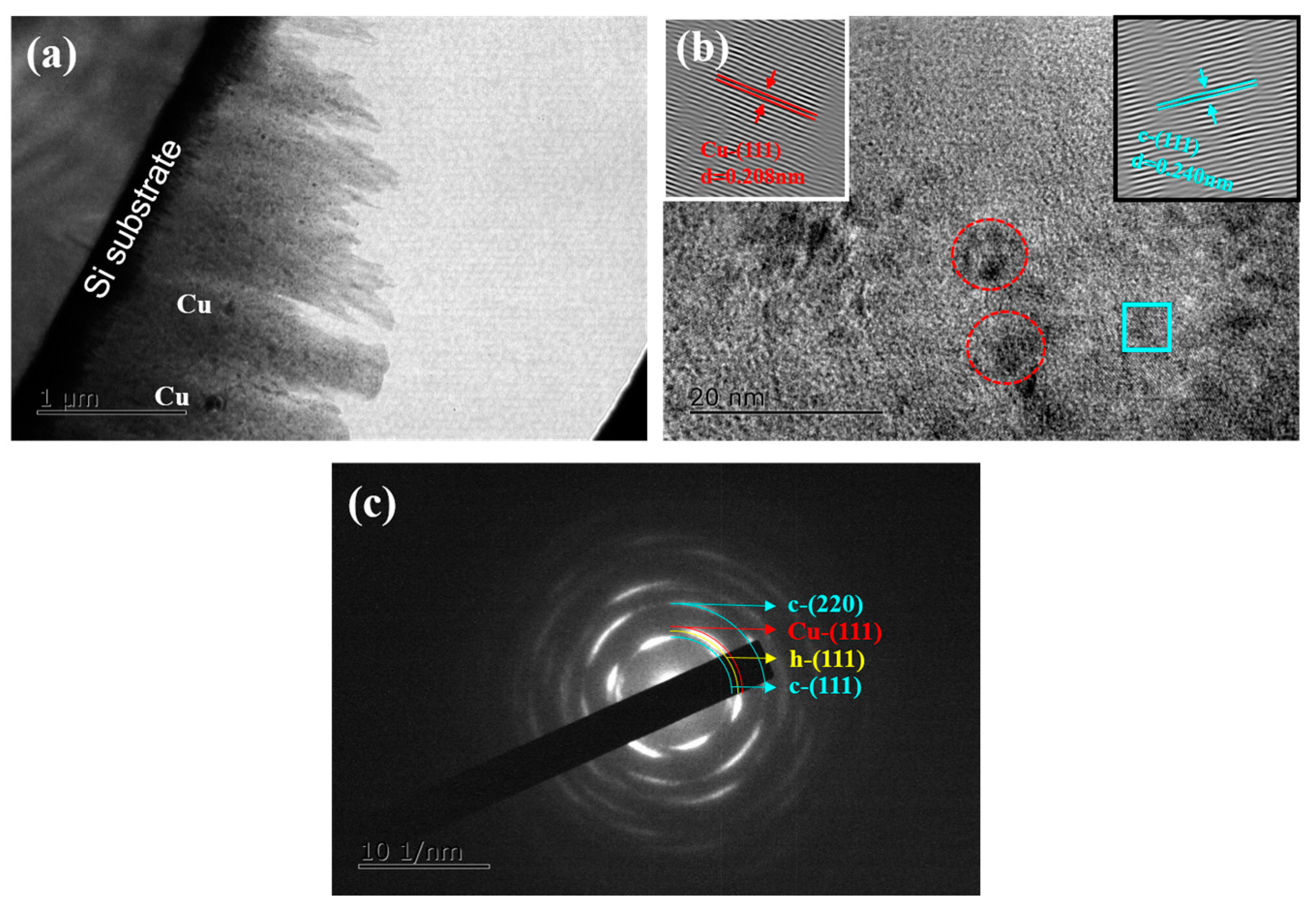

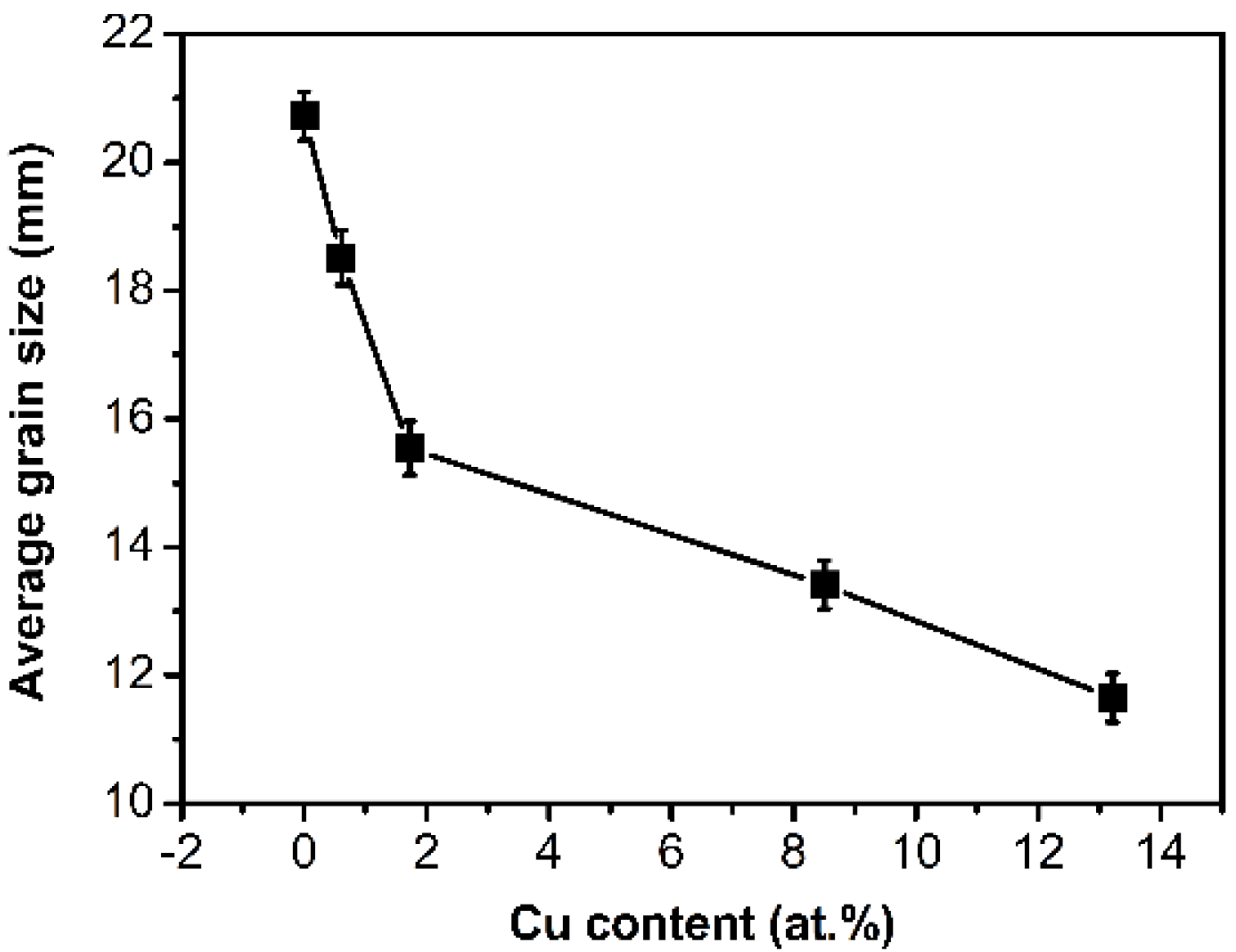

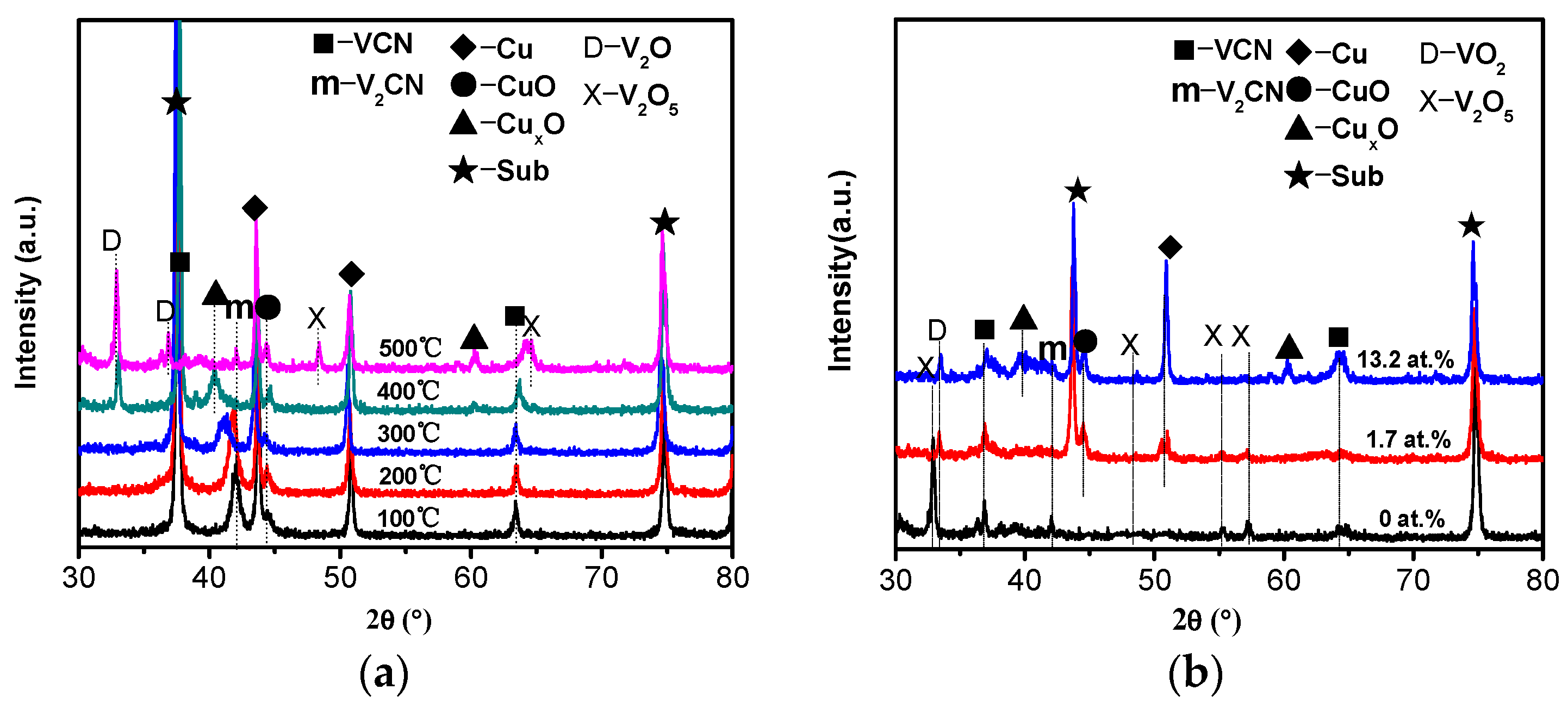

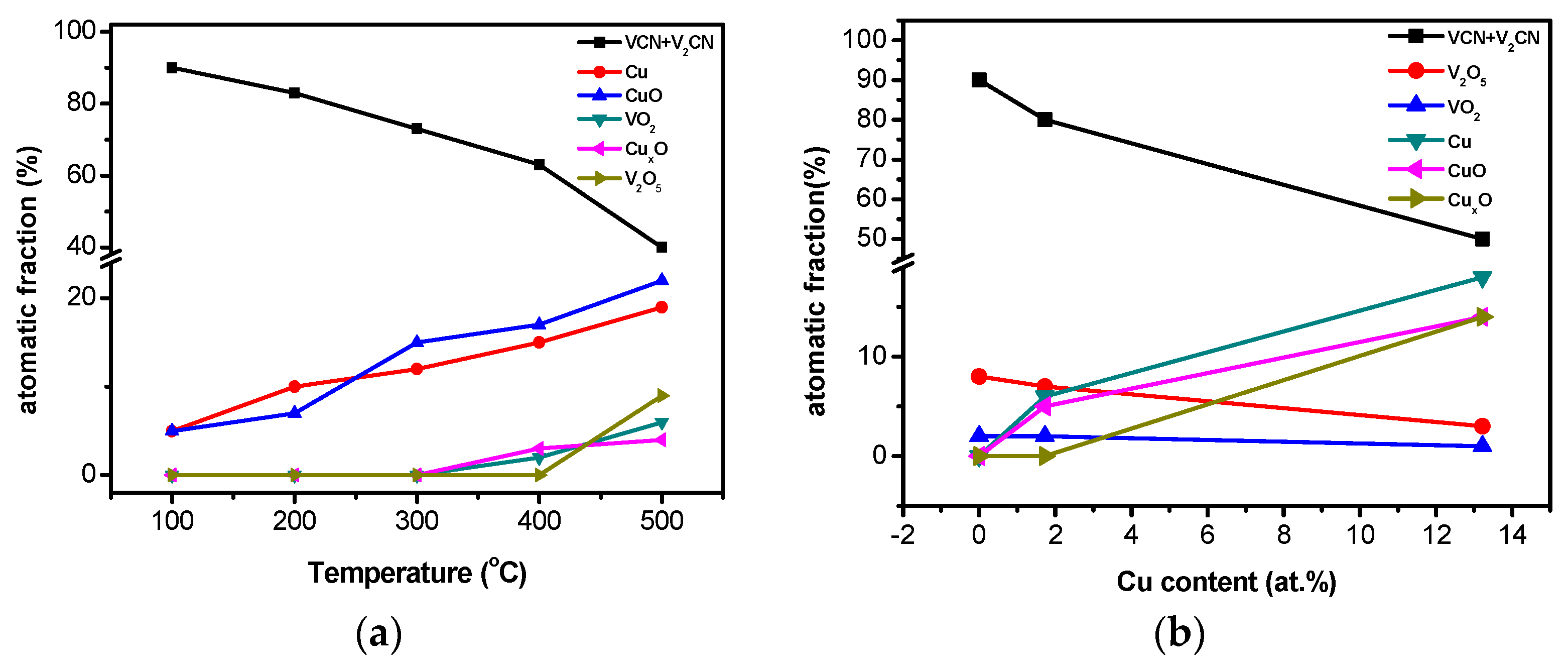

3.1. Composition and Phase Structure

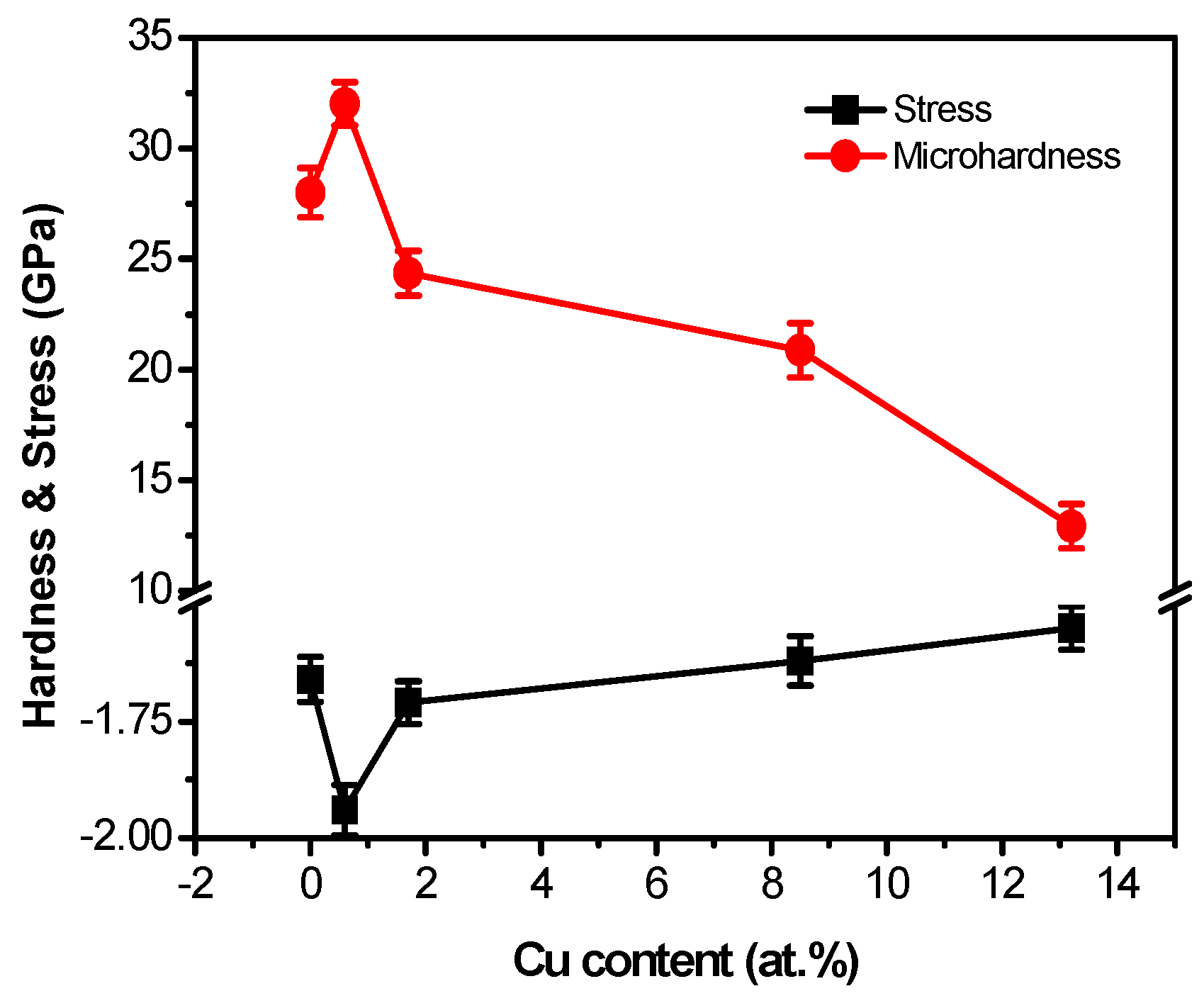

3.2. Mechanical Properties

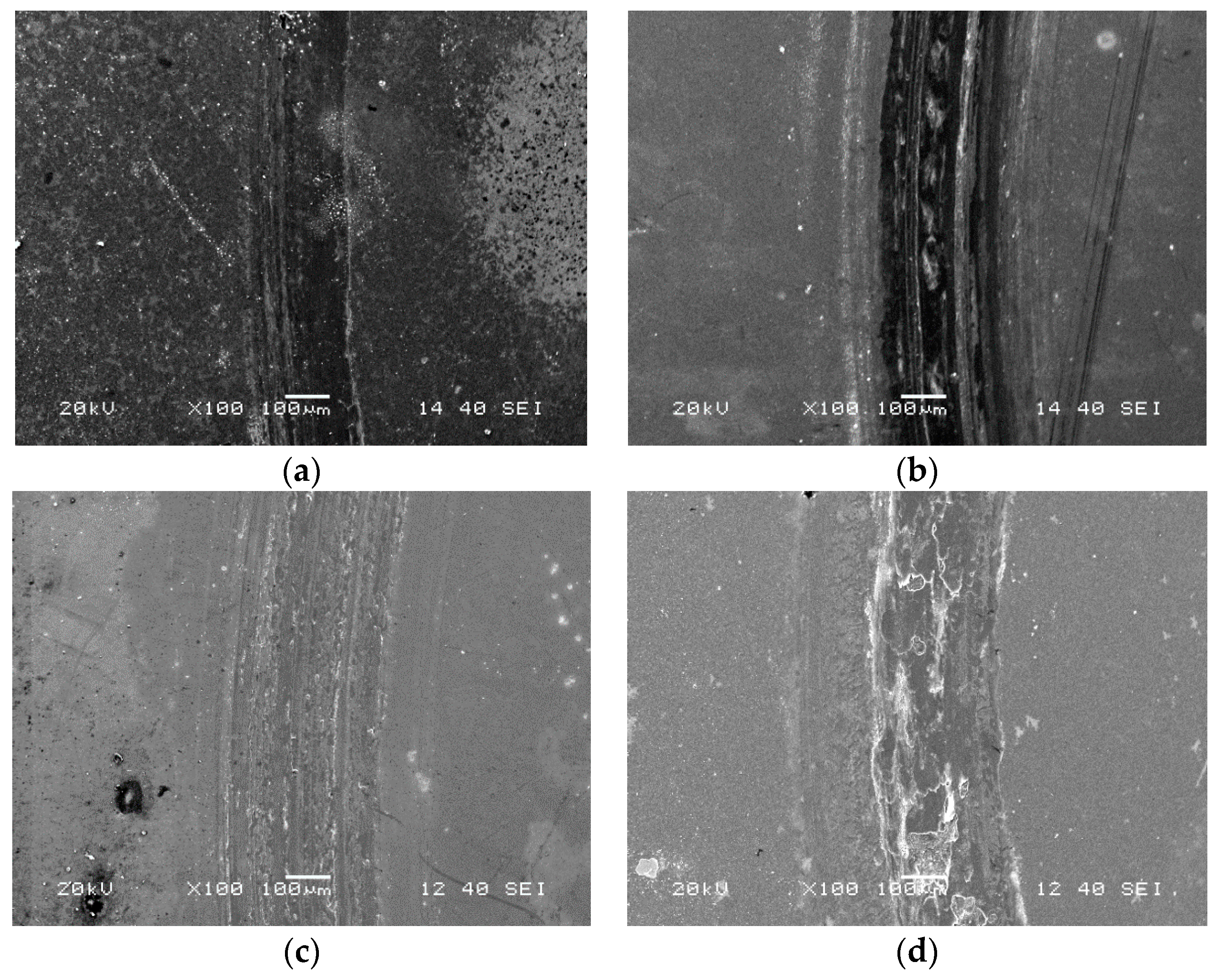

3.3. Friction and Wear Properties

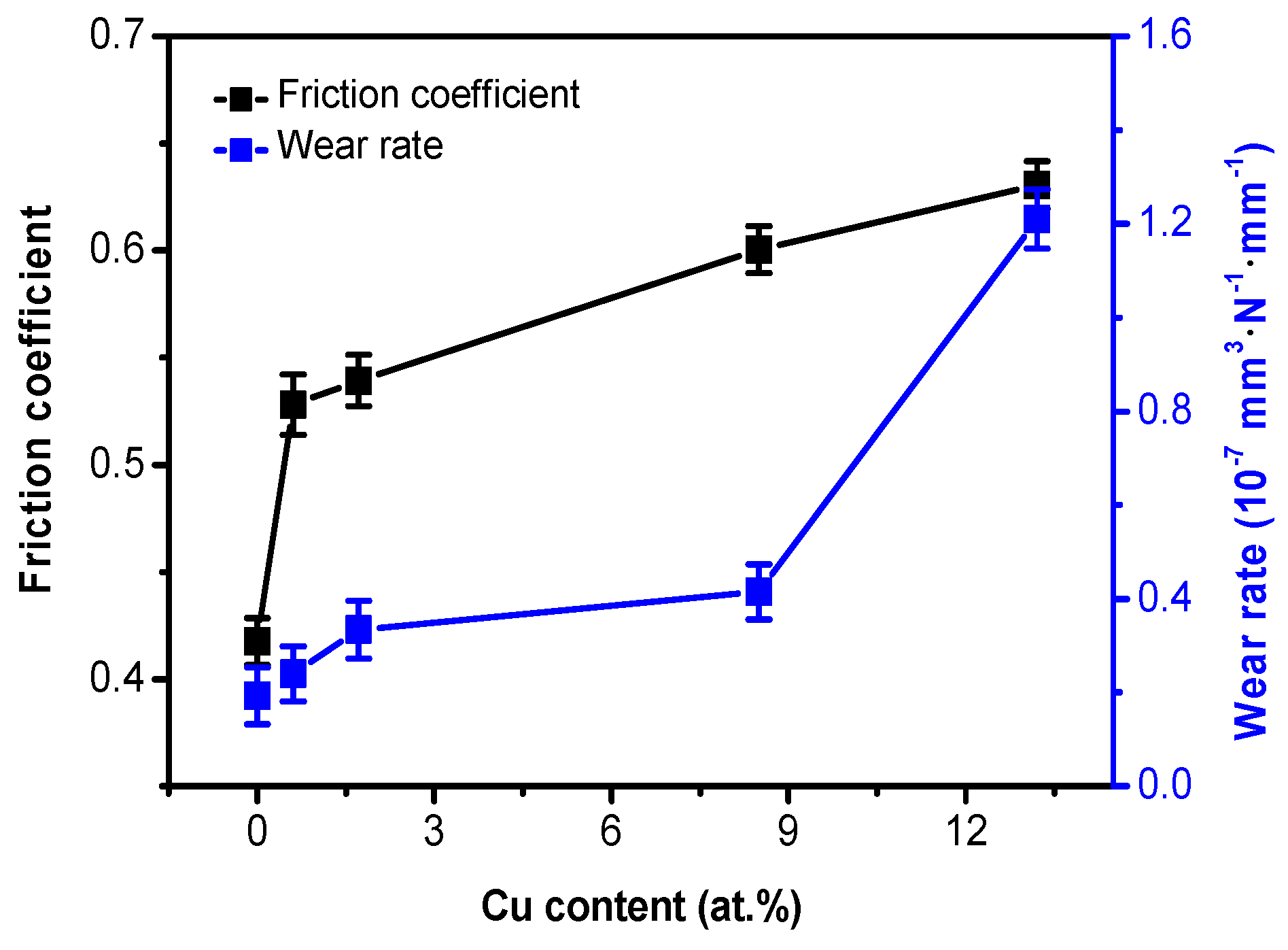

3.3.1. Friction and Wear Properties at Room Temperature

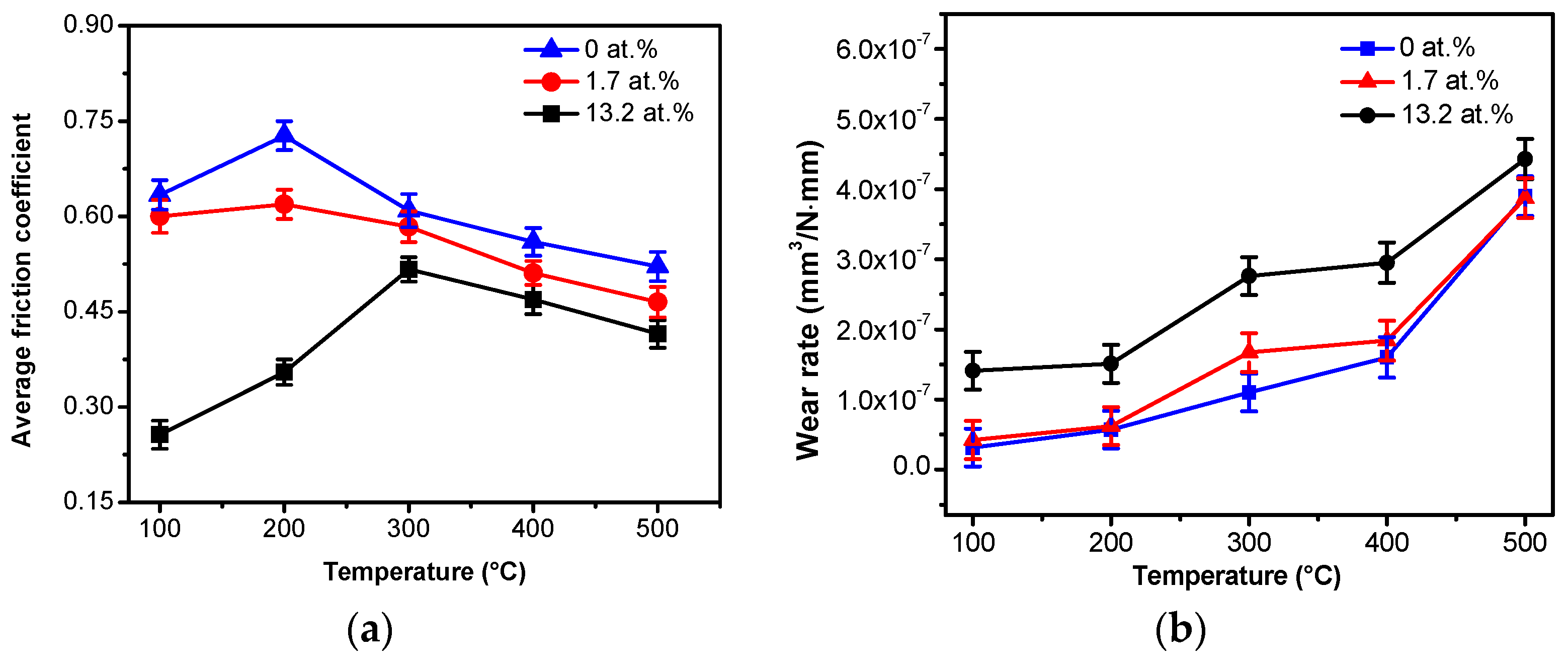

3.3.2. Friction and Wear Properties at Elevated Temperature

4. Conclusions

- VCN–Cu films were consisted of a mixture of fcc-VCN, hcp-V2CN, fcc-Cu, amorphous graphite and CNx phase.

- The hardness of VCN–Cu films first increased and then decreased with the increase of Cu content.

- At room temperature, the friction coefficient and wear rate increased with an increasing Cu content.

- In the temperature range of 100–500 °C, the friction coefficient of VCN–Cu film was lower than VCN film, while the wear rate showed the opposite trend. The incorporation of Cu improved the friction properties, but failed to improve the wear resistance.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pappacena, K.E.; Singh, D.; Ajayi, O.O.; Routbort, J.L.; Erilymaz, O.L.; Demas, N.G.; Chen, G. Residual stresses, interfacial adhesion and tribological properties of MoN/Cu composite coatings. Wear 2012, 278, 62–70. [Google Scholar] [CrossRef]

- Stone, D.S.; Migas, J.; Martini, A.; Smith, T.; Muratore, C.; Voevodin, A.A.; Aouadi, S.M. Adaptive NbN/Ag coatings for high temperature tribological applications. Surf. Coat. Technol. 2012, 206, 4316–4321. [Google Scholar] [CrossRef]

- Caicedo, J.C.; Zambrano, G.; Aperador, W.; Escobar–Alarcon, L.; Camps, E. Mechanical and electrochemical characterization of vanadium nitride (VN) thin films. Appl. Surf. Sci. 2011, 258, 312–320. [Google Scholar] [CrossRef]

- Wu, F.; Yu, L.; Ju, H.; Asempah, I.; Xu, J. Structural, mechanical and tribological properties of NbCN–Ag nanocomposite films deposited by reactive magnetron sputtering. Coatings 2018, 8, 50. [Google Scholar] [CrossRef]

- Suszko, T.; Gulbiński, W.; Jagielski, J. Mo2N/Cu thin films–the structure, mechanical and tribological properties. Surf. Coat. Technol. 2006, 200, 6288–6292. [Google Scholar] [CrossRef]

- Su, Y.; Yao, S.; Leu, Z.; Wei, C.; Wu, C. Comparison of tribological behavior of three films—TiN, TiCN and CrN—Grown by physical vapor deposition. Wear 1997, 213, 165–174. [Google Scholar] [CrossRef]

- Polcar, T.; Kubart, T.; Novák, R.; Kopecký, L.; Široký, P. Comparison of tribological behaviour of TiN, TiCN and CrN at elevated temperatures. Surf. Coat. Technol. 2005, 193, 192–199. [Google Scholar] [CrossRef]

- Auger, M.A.; Araiza, J.J.; Falcony, C.; Sánchez, O.; Albella, J.M. Hardness and tribology measurements on ZrN coatings deposited by reactive sputtering technique. Vacuum 2007, 81, 1462–1465. [Google Scholar] [CrossRef]

- Santecchia, E.; Hamouda, A.M.S.; Musharavati, F.; Zalnezhad, E.; Cabibbo, M.; Spigarelli, S. Wear resistance investigation of titanium nitride–based coatings. Ceram. Int. 2015, 41, 10349–10379. [Google Scholar] [CrossRef]

- Franz, R.; Mitterer, C. Vanadium containing self–adaptive low–friction hard coatings for high–temperature applications: A review. Surf. Coat. Technol. 2013, 228, 1–13. [Google Scholar] [CrossRef]

- Yu, L.; Li, Y.; Ju, H.; Xu, J. Microstructure, mechanical and tribological properties of magnetron sputtered VCN films. Surf. Eng. 2017, 33, 919–924. [Google Scholar] [CrossRef]

- Mu, Y.; Liu, M.; Zhao, Y. Carbon doping to improve the high temperature tribological properties of VN coating. Tribol. Int. 2016, 97, 327–336. [Google Scholar] [CrossRef]

- Mitterer, C.; Fateh, N.; Munnik, F. Microstructure–property relations of reactively magnetron sputtered VCxNy films. Surf. Coat. Technol. 2011, 205, 3805–3809. [Google Scholar] [CrossRef]

- Chao, M.; Rong, F. Formation and mechanism of the third body of copper under low and high friction speed. Sci. Technol. Eng. 2010, 15, 036. (In Chinese) [Google Scholar]

- Maruda, R.W.; Feldshtein, E.E.; Legutko, S.; Królczyk, G.M. Improving the efficiency of running-in for a bronze–stainless steel friction pair. J. Frict. Wear 2015, 36, 548–553. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Feldshtein, E.; Nieslony, P.; Tyliszczak, B.; Pusavec, F. Tool wear characterizations in finish turning of AISI 1045 carbon steel for MQCL conditions. Wear 2017, 372, 54–67. [Google Scholar] [CrossRef]

- Yu, L.; Zhao, H.; Ju, H.; Xu, J. Influence of Cu content on the structure, mechanical and tribological properties of W2N–Cu films. Thin Solid Films 2017, 624, 144–151. [Google Scholar] [CrossRef]

- Xu, J.; Chen, J.; Yu, L. Influence of Si content on the microstructure and mechanical properties of VSiN films deposited by reactive magnetron sputtering. Vacuum 2016, 131, 51–57. [Google Scholar] [CrossRef]

- Shi, J.; Muders, C.M.; Kumar, A.; Jiang, X.; Pei, Z.L.; Gong, J.; Sun, C. Study on nanocomposite Ti–Al–Si–Cu–N films with various Si contents deposited by cathodic vacuum arc ion plating. Appl. Surf. Sci. 2012, 258, 9642–9649. [Google Scholar] [CrossRef]

- Ye, F.; Zhao, H.; Tian, X. Influence of niobium addition on structure and mechanical properties of W–Nb–N coatings. Vacuum 2017, 144, 8–13. [Google Scholar] [CrossRef]

- Shtansky, D.V.; Bondarev, A.V.; Kiryukhantsev-Korneev, P.V.; Rojas, T.C.; Godinho, V.; Fernandez, A. Structure and tribological properties of MoCN–Ag coatings in the temperature range of 25–700° C. Appl. Surf. Sci. 2013, 273, 408–414. [Google Scholar] [CrossRef]

- Bondarev, A.V.; Golizadeh, M.; Shvyndina, N.V.; Shchetinin, I.V.; Shtansky, D.V. Microstructure, mechanical, and tribological properties of Ag-free and Ag-doped VCN coatings. Surf. Coat. Technol. 2017, 331, 77–84. [Google Scholar] [CrossRef]

- Carvalho, I.; Henriques, M.; Oliveira, J.C.; Alves, C.F.A.A.; Piedade, P.; Carvalho, S. Influence of surface features on the adhesion of Staphylococcus epidermidis to Ag–TiCN thin films. Sci. Technol. Adv. Mater. 2013, 14, 35009–35018. [Google Scholar] [CrossRef] [PubMed]

- Ezirmik, V.; Senel, E.; Kazmanli, K.; Erdemir, A.; Urgen, M. Effect of copper addition on the temperature dependent reciprocating wear behaviour of CrN coatings. Surf. Coat. Technol. 2007, 202, 866–870. [Google Scholar] [CrossRef]

- Tan, S.; Zhang, X.; Wu, X.; Fang, F.; Jiang, J. Comparison study on structure of Si and Cu doping CrN films by reactive sputtering. Appl. Surf. Sci. 2011, 257, 5595–5600. [Google Scholar] [CrossRef]

- Sanjinés, R.; Hones, P.; Lévy, F. Hexagonal nitride coatings: electronic and mechanical properties of V2N, Cr2N and δ-MoN. Thin Solid Films 1998, 332, 225–229. [Google Scholar] [CrossRef]

- Xu, X.; Zhuo, L.; Xia, D.; Wei, B.; Hao, X. Nanoindentation and friction/wear behaviors of magnetron sputtered CNx/SiC bilayer films on Titanium (TA2) substrate. Mocaxue Xuebao 2009, 29, 256–260. (In Chinese) [Google Scholar]

- Xu, J.; Ju, H.; Yu, L. Effects of Mo content on the microstructure and friction and wear properties of TiMoN films. Acta Metall. Sin. 2012, 48, 1132–1138. (In Chinese) [Google Scholar] [CrossRef]

- Yu, L.; Sun, C.; Xu, J. Cu Doping and improvement of mechanical and tribological properties of NbCN composite coating. Chin. J. Vac. Sci. Technol. 2016, 36, 377–384. (In Chinese) [Google Scholar]

- Wei, Y.; Gong, C. Effects of pulsed bias duty ratio on microstructure and mechanical properties of TiN/TiAlN multilayer coatings. Appl. Surf. Sci. 2011, 257, 7881–7886. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, J.; Sun, L.; Yang, G.; Zhang, Z.; Zhang, P. Friction reducing anti-wear and self-repairing properties of nano-Cu additive in lubricanting oil. J. Mech. Eng. 2010, 46, 74–79. (In Chinese) [Google Scholar] [CrossRef]

- Xu, J.; Cao, J.; Yu, L. Microstructures, mechannical properties and friction properties of TiVCN composite films. Acta Metall. Sin. 2012, 48, 555–560. (In Chinese) [Google Scholar] [CrossRef]

- Gassner, G.; Mayrhofer, P.H.; Kutschej, K.; Mitterer, C.; Kathrein, M. A new low friction concept for high temperatures: lubricious oxide formation on sputtered VN coatings. Tribol. Lett. 2004, 17, 751–756. [Google Scholar] [CrossRef]

- Erdemir, A. A crystal-chemical approach to lubrication by solid oxides. Tribol. Lett. 2000, 8, 97–102. [Google Scholar] [CrossRef]

| VCN–Cu Composite Films | Experimental Parameters |

|---|---|

| Base pressure | <6.0 × 10−4 Pa |

| Total pressure | 0.3 Pa |

| Ar flow rate | 10 sccm |

| N2 flow rate | 7 sccm |

| Base rotation speed | 3 r/min |

| V target power | 200 W |

| C target power | 90 W |

| Cu target power | 0 W, 10 W, 15 W, 20 W, 25 W |

| Negative bias of the substrate | – |

| Deposition temperature | Room temperature |

| Deposition time | 2 h |

| Power of Copper Target (W) | Chemical Composition (at.%) | |||

|---|---|---|---|---|

| V | C | N | Cu | |

| 0 | 31.5 ± 2.2 | 16.9 ± 0.7 | 51.6 ± 2.8 | 0 |

| 10 | 31.2 ± 2.0 | 16.7 ± 0.7 | 51.5 ± 2.7 | 0.6 ± 0.1 |

| 15 | 30.6 ± 1.9 | 16.6 ± 0.6 | 51.1 ± 2.5 | 1.7 ± 0.2 |

| 20 | 26.9 ± 1.8 | 13.9 ± 0.5 | 50.7 ± 2.5 | 8.5 ± 0.3 |

| 25 | 24.3 ± 1.6 | 12.6 ± 0.4 | 49.9 ± 2.4 | 13.2 ± 0.4 |

| Cu Content | λ (nm) | BVN (111) (°) |

|---|---|---|

| 0 at.% | 0.154 | 0.400 ± 0.002 |

| 0.6 at.% | 0.448 ± 0.003 | |

| 1.7 at.% | 0.534 ± 0.002 | |

| 8.5 at.% | 0.619 ± 0.001 | |

| 13.2 at.% | 0.713 ± 0.002 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, F.; Yu, L.; Ju, H.; Xu, J.; Shi, J. Influence of Cu Content on the Structure, Mechanical, Friction and Wear Properties of VCN–Cu Films. Coatings 2018, 8, 95. https://doi.org/10.3390/coatings8030095

Wu F, Yu L, Ju H, Xu J, Shi J. Influence of Cu Content on the Structure, Mechanical, Friction and Wear Properties of VCN–Cu Films. Coatings. 2018; 8(3):95. https://doi.org/10.3390/coatings8030095

Chicago/Turabian StyleWu, Fanjing, Lihua Yu, Hongbo Ju, Junhua Xu, and Ji Shi. 2018. "Influence of Cu Content on the Structure, Mechanical, Friction and Wear Properties of VCN–Cu Films" Coatings 8, no. 3: 95. https://doi.org/10.3390/coatings8030095

APA StyleWu, F., Yu, L., Ju, H., Xu, J., & Shi, J. (2018). Influence of Cu Content on the Structure, Mechanical, Friction and Wear Properties of VCN–Cu Films. Coatings, 8(3), 95. https://doi.org/10.3390/coatings8030095