Influence of Process Parameters on High Velocity Oxy-Fuel Sprayed Cr3C2-25%NiCr Coatings

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Preparation of Coatings

2.2. Wear Test at 500 °C

2.3. Characterization of Cr3C2-25NiCr Coatings and Worn Surface

3. Results and Discussion

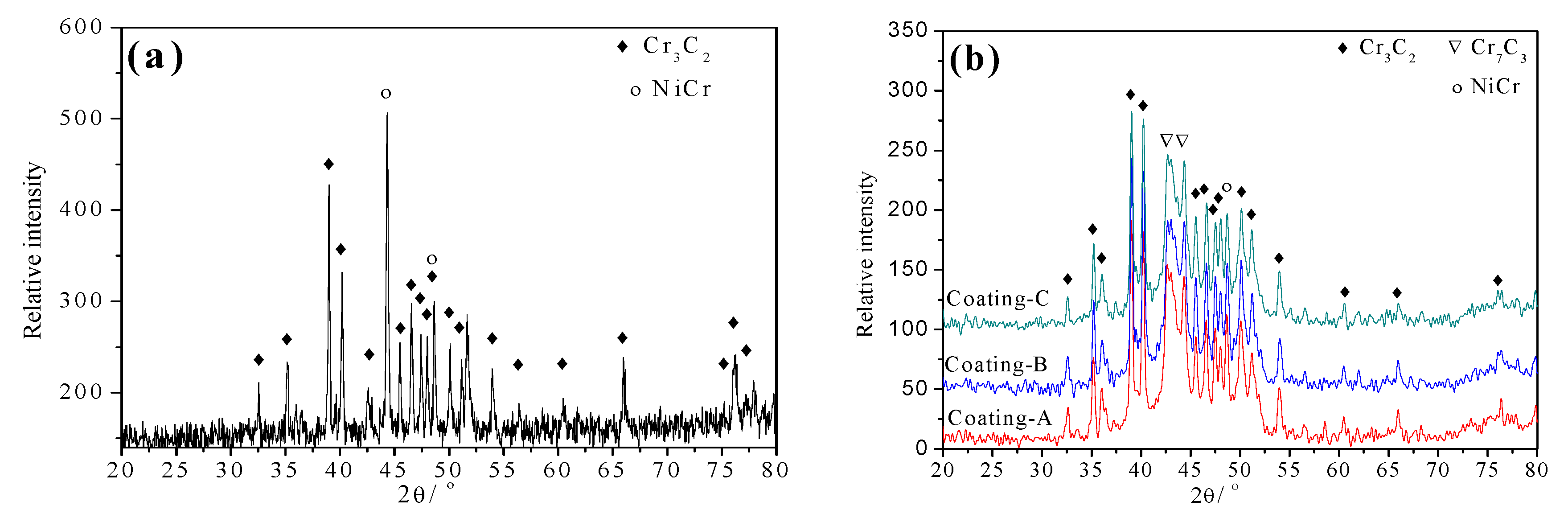

3.1. Phase Structures of Powder and Coatings

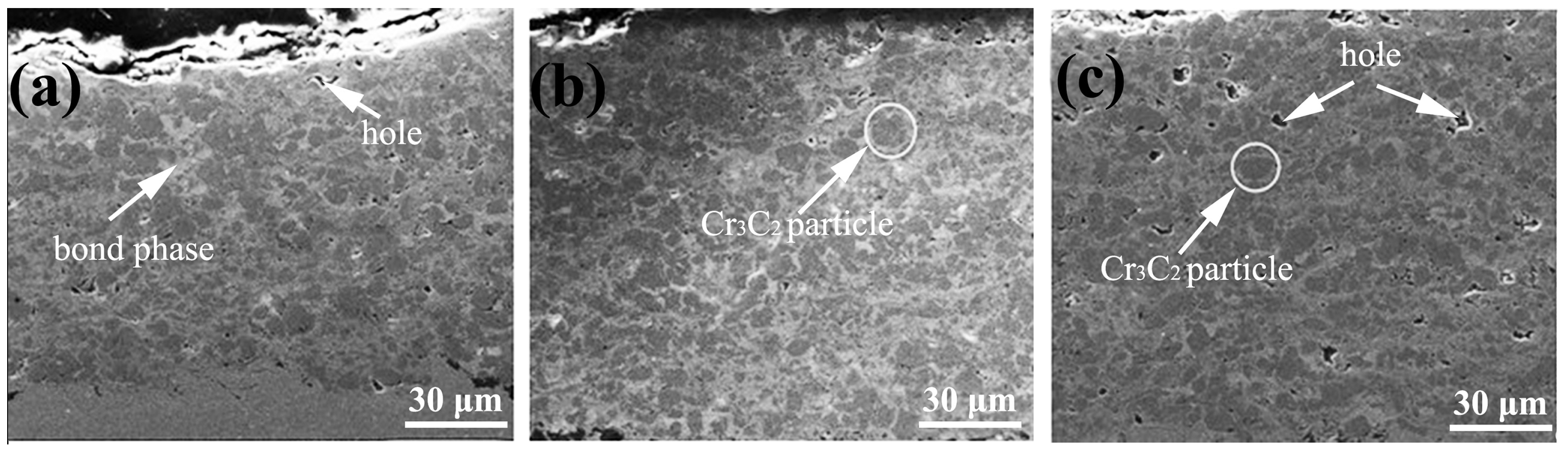

3.2. Cross-Sections of Cr3C2-25NiCr Coatings

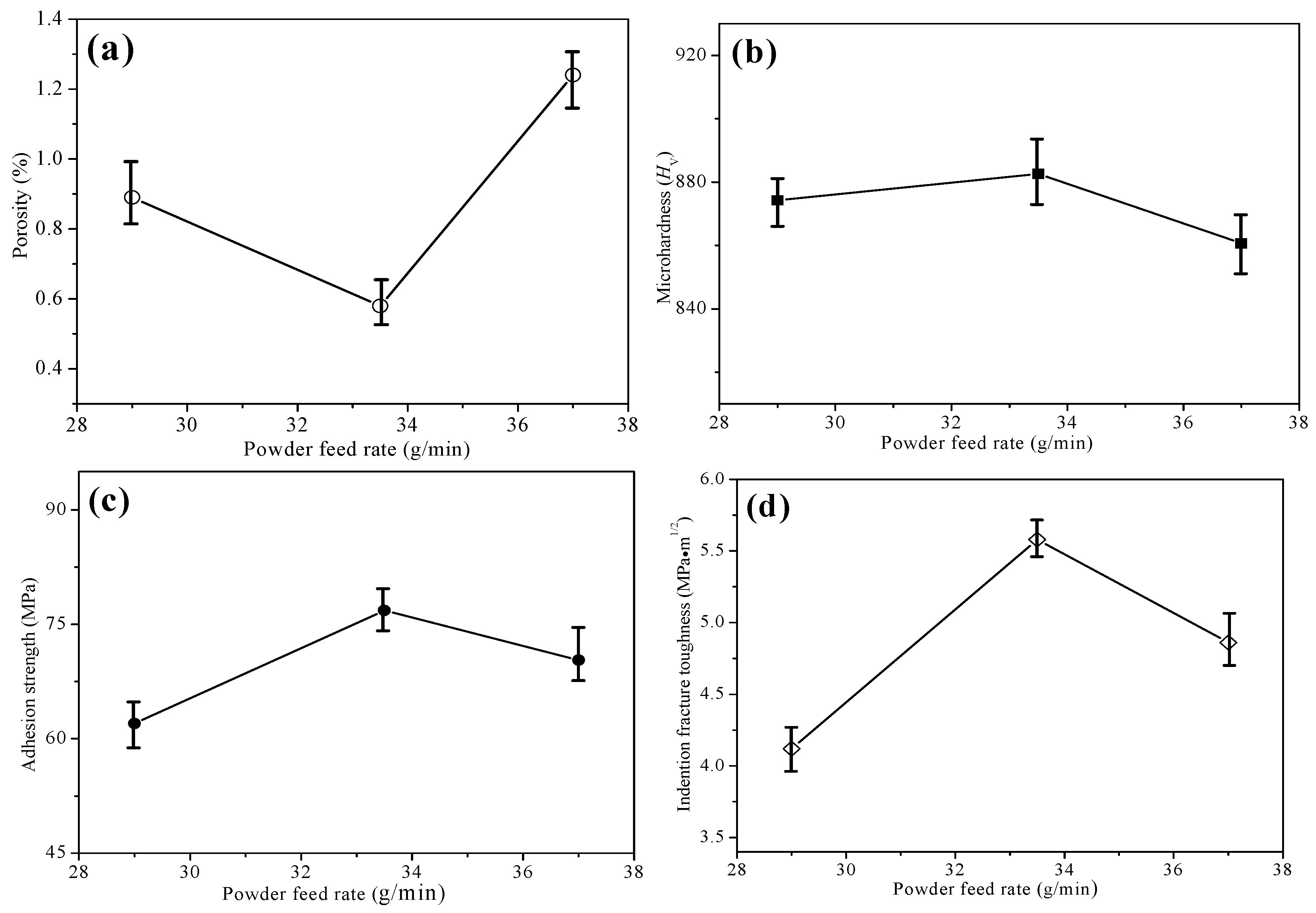

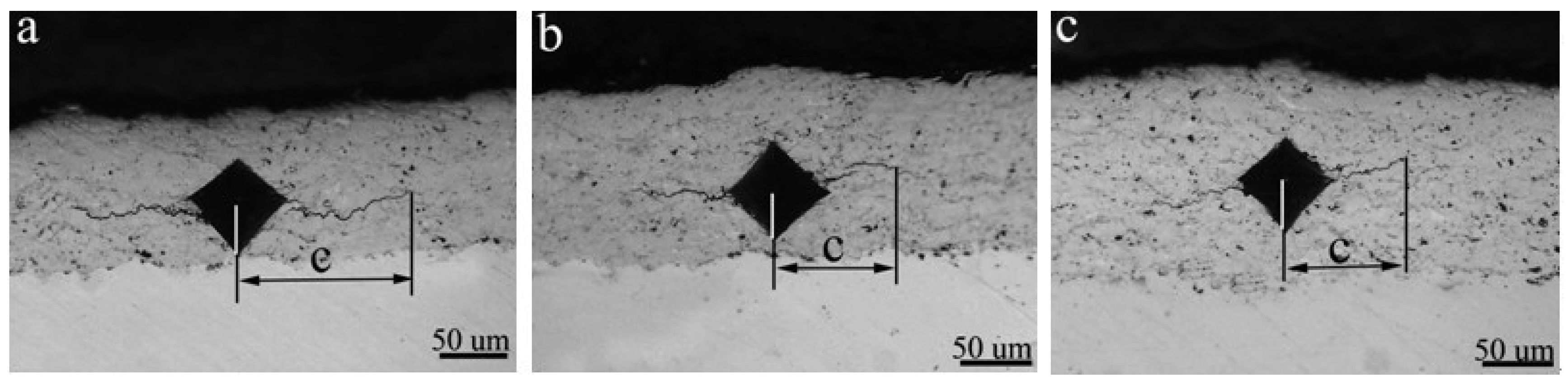

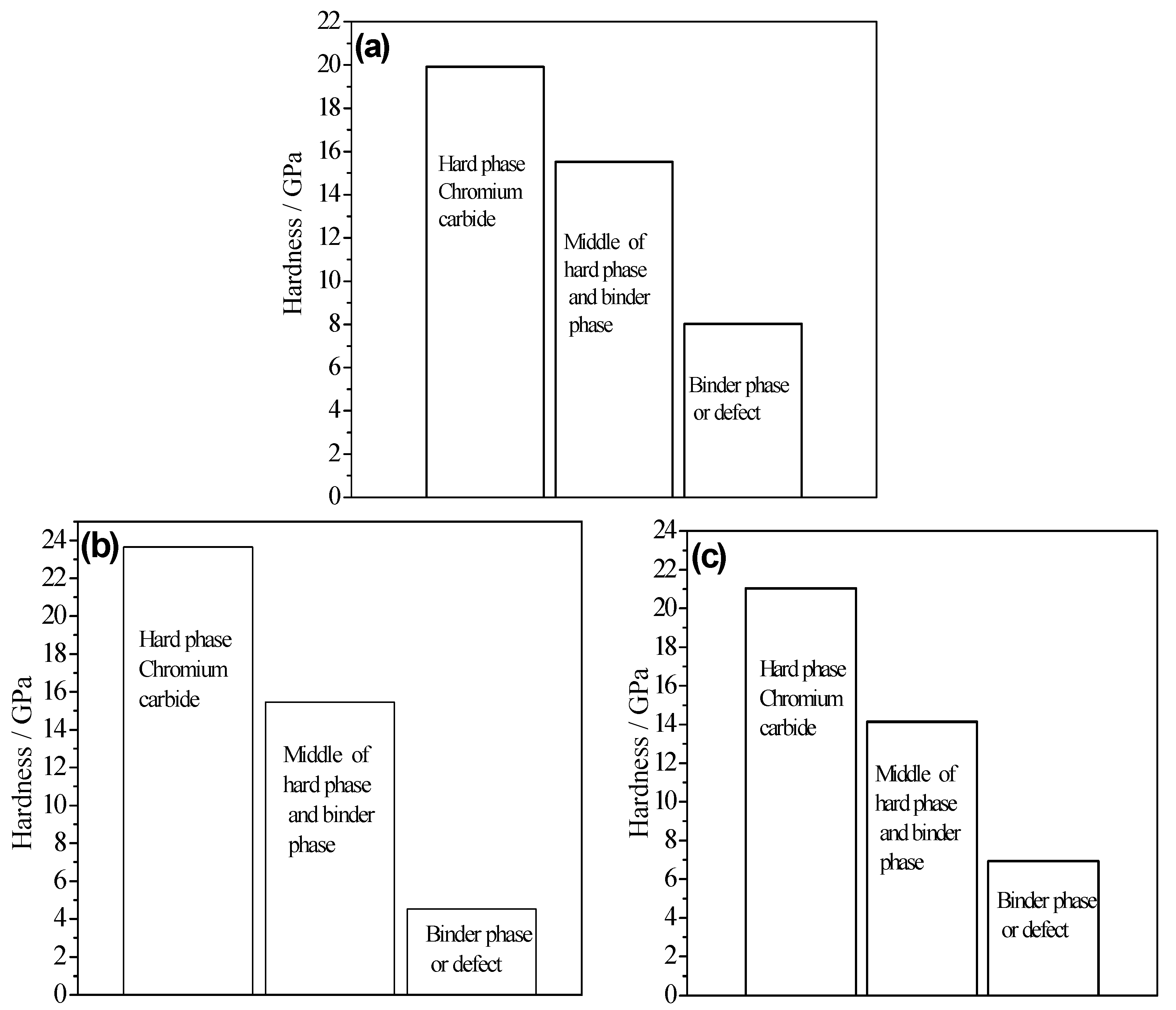

3.3. Mechanical Properties

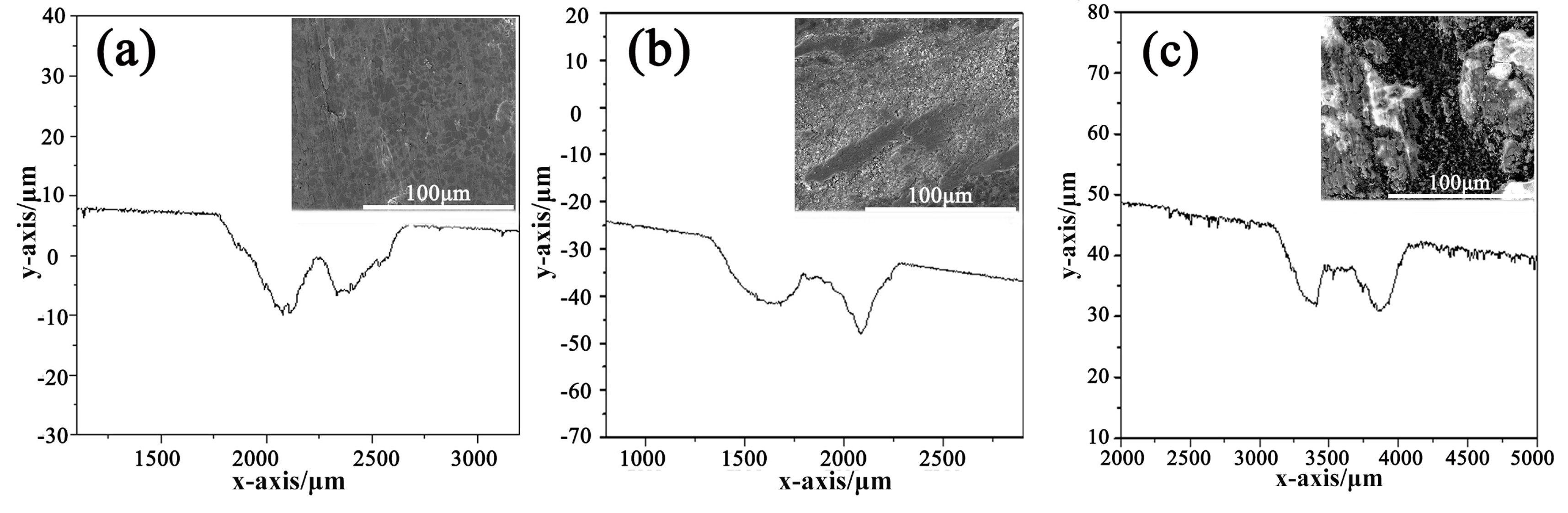

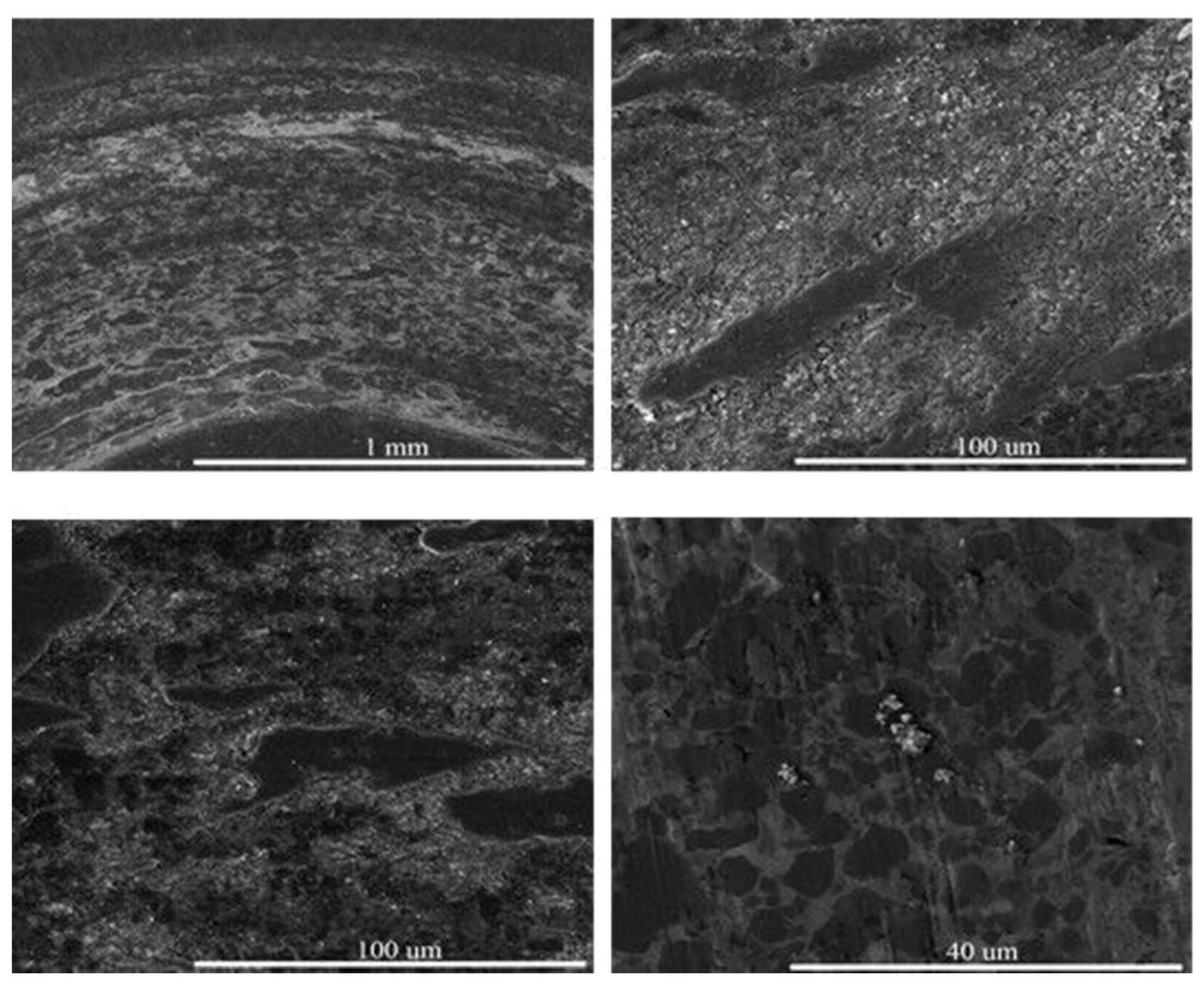

3.4. Wear Performance of Coatings

4. Conclusions

- HVOF sprayed chromium carbide-based coating possessed low porosity, high micro-hardness, and high adhesion strength.

- Powder feed rate had obvious effect on coating surface and mechanical properties (porosity, micro-hardness, and indention fracture toughness). The coating sprayed at 33.5 g/min possessed relative lower porosity, higher fracture toughness, and better elasticity. Thus, the HVOF sprayed Cr3C2-NiCr coating using WOKAStar 640 system (Sulzer Metco, Winterthur, Switzerland) had an appropriate powder feed rate of 33.5 g/min.

- The wear tests illustrated the HVOF sprayed Cr3C2-25NiCr coatings possessed good wear resistance at high temperature, which resulted from the stable friction coefficient and little peeling, crack, and deformation on the worn surface. The coating at the powder feed rate of 33.5 g/min had the best wear resistance due to the dense structure and enough fracture toughness.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kaur, M.; Singh, H.; Prakash, S. High-temperature corrosion studies of HVOF-sprayed Cr3C2-NiCr coating on SAE-347H boiler steel. J. Therm. Spray Technol. 2009, 18, 619–632. [Google Scholar] [CrossRef]

- He, J.H.; Ice, M.; Schoenung, J.M.; Shin, D.H.; Lavernia, E.J. Thermal stability of nanostructured Cr3C2-NiCr coatings. J. Therm. Spray Technol. 2001, 10, 293–300. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Lu, X.C.; Luo, H.B. Tribological properties of rare earth oxide added Cr3C2-NiCr coatings. Appl. Surf. Sci. 2007, 253, 4377–4385. [Google Scholar] [CrossRef]

- Li, C.J.; Ji, G.C.; Wang, Y.Y.; Sonoya, K. Dominant effect of carbide rebounding on the carbon loss during high velocity oxy-fuel spraying of Cr3C2-NiCr. Thin Solid Films 2002, 419, 137–143. [Google Scholar] [CrossRef]

- Magnani, M.; Suegama, P.H.; Espallargas, N. Influence of HVOF parameters on the corrosion and wear resistance of WC-Co coatings sprayed on AA7050 T7. Surf. Coat. Technol. 2008, 202, 4746–4757. [Google Scholar] [CrossRef]

- Sun, G.; Zhang, Y.; Liu, C.; Luo, K.; Tao, X.; Li, P. Microstructure and wear resistance enhancement of cast steel rolls by laser surface alloying NiCr–Cr3C2. Mater. Des. 2010, 31, 2737–2744. [Google Scholar] [CrossRef]

- Milanti, A.; Koivuluoto, H.; Vuoristo, P.; Bolelli, G.; Bozza, F.; Lusvarghi, L. Microstructural Characteristics and Tribological Behavior of HVOF-Sprayed Novel Fe-Based Alloy Coatings. Coatings 2014, 4, 98–120. [Google Scholar] [CrossRef]

- Manjunatha, M.; Kulkarni, R.S.; Krishna, M. Investigation of HVOF Thermal sprayed Cr3C2-NiCr Cermet Carbide Coatings on Erosive Performance of AISI 316 Molybdenum steel. Procedia Mater. Sci. 2014, 5, 622–629. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Wang, Q.; Ying, G.B.; et al. Microstructure and cavitation-silt erosion behavior of high-velocity oxygen-fuel (HVOF) sprayed Cr3C2-NiCr coating. Surf. Coat. Technol. 2013, 225, 85–91. [Google Scholar] [CrossRef]

- Murugan, K.; Ragupathy, A.; Balasubramanian, V.; Sridhar, K. Optimizing HVOF spray process parameters to attain minimum porosity and maximum hardness in WC-10Co-4Cr coatings. Surf. Coat. Technol. 2014, 247, 90–102. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.H.; Li, L.X.; Yang, G.B. The parameters optimization and abrasion wear mechanism of liquid fuel HVOF sprayed bimodal WC-12Co coating. Surf. Coat. Technol. 2012, 206, 2233–2241. [Google Scholar] [CrossRef]

- Fukumoto, H. The application of cermet coating on piston ring by HVOF. In Proceedings of the 14th International Thermal Spray Conference, Kobe, Japan, 22–26 May 1995. [Google Scholar]

- Mateen, A.; Saha, G.C.; Khan, T.I.; Khalid, F.A. Tribological behaviour of HVOF sprayed near-nanostructured and microstructured WC-17wt %Co coatings. Surf. Coat. Technol. 2011, 206, 1077–1084. [Google Scholar] [CrossRef]

- Lee, C.W.; Han, J.H.; Yoon, J.; Shin, M.C.; Kwun, S.I. A study on powder mixing for high fracture toughness and wear resistance of WC-Co-Cr coatings sprayed by HVOF. Surf. Coat. Technol. 2010, 204, 2223–2229. [Google Scholar] [CrossRef]

- Ji, G.C.; Li, C.J.; Wang, Y.Y.; Li, W.Y. Microstructural characterization and abrasive wear performance of HVOF sprayed Cr3C2–NiCr coating. Surf. Coat. Technol. 2006, 200, 6749–6757. [Google Scholar] [CrossRef]

- Qiao, Y.F.; Fischer, T.E.; Andrew, D. The effects of fuel chemistry and feedstock powder structure on the mechanical and tribological properties of HVOF thermal-sprayed WC–Co coatings with very fine structures. Surf. Coat. Technol. 2003, 172, 24–41. [Google Scholar] [CrossRef]

- ASTM C 633-79 Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings; ASTM International: West Conshohocken, PA, USA, 1999.

- Murthy, J.K.N.; Prasad, K.S.; Gopinath, K.; Venkataraman, B. Characterisation of HVOF sprayed Cr3C2-50 (Ni20Cr) coating and the influence of binder properties on solid particle erosion behavior. Surf. Coat. Technol. 2010, 204, 3975–3985. [Google Scholar] [CrossRef]

- Sahraoui, T.; Fenineche, N.E. Structure and wear behaviour of HVOF sprayed Cr3C2-NiCr and WC–Co coatings. Materc. Des. 2003, 24, 309–313. [Google Scholar]

- Mohanty, M.; Smith, R.W.; De Bonte, M.; Celis, J.P.; Lugscheider, E. Sliding Wear Behaviour of Thermally Sprayed 75/25 Cr3C2-NiCr Wear Resistant Coatings. Wear 1996, 198, 261–266. [Google Scholar] [CrossRef]

- Vuoristo, P.; Niemi, K.; Makela, A.; Mantyla, T. Abrasion Wear Resistance of Detonation Gun Sprayed Carbide Coatings. In Proceedings of the 7th International Metallurgy and Materials Congress, Ankara, Turkey, 4–8 May 1993; Volume 2, pp. 1295–1302. [Google Scholar]

- Roy, M.; Pauschitz, A.; Bernardi, J.; Koch, T.; Franek, F. Microstructure and Mechanical Properties of HVOF Sprayed Nanocrystalline Cr3C2–25 (Ni20Cr) Coating. Therm. Spray Technol. 2006, 15, 372–381. [Google Scholar] [CrossRef]

- Celik, E.; Culhaa, O.; Uyulgan, B.; Ak Azem, N.F.; Ozdemir, I.; Turk, A. Assessment of microstructural and mechanical properties of HVOF sprayed WC-based cermet coatings for a roller cylinder. Surf. Coat. Technol. 2006, 200, 4320–4328. [Google Scholar] [CrossRef]

- Davenas, J. Modification of surfaces of polymers by ion bombardment for improvement of mechanical properties. Surf. Coat. Technol. 1991, 45, 229–235. [Google Scholar] [CrossRef]

- Jacobs, L.; Hyland, M.M.; De Bonte, M. Comparative Study of WC-Cermet Coatings Sprayed via the HVOF and the HVAF Process. Therm. Spray Technol. 1998, 7, 213–218. [Google Scholar] [CrossRef]

- Murthy, J.K.N.; Venkataraman, B. Abrasive wear behaviour of WC–CoCr and Cr3C2–20(NiCr) deposited by HVOF and detonation spray processes. Surf. Coat. Technol. 2006, 200, 2642–2652. [Google Scholar] [CrossRef]

- Bartali, R.; Micheli, V.; Gottardi, G.; Vaccari, A.; Laidani, N. Nanoindentation: Unload-to-load work ratio analysis in amorphous carbon films for mechanical properties. Surf. Coat. Technol. 2010, 204, 2073–2076. [Google Scholar] [CrossRef]

- Beegan, D.; Chowdhury, S.; Laugier, M.T. Work of indentation methods for determining copper film hardness. Surf. Coat. Technol. 2005, 192, 57–63. [Google Scholar] [CrossRef]

- Kiruchi, N.; Kitagawa, M.; Sato, A.; Kusano, E.; Nanto, H.; Kinbara, A. Elastic and plastic energies in sputtered multilayered TiaTiN films estimated by nanoindentation. Surf. Coat. Technol. 2000, 126, 131–135. [Google Scholar]

| Coating | Combustion Pressure (bar) | Powder Feed Rate (g/min) | Fuel (L/h) | Oxygen (NLPM) | Spray Distance (mm) |

|---|---|---|---|---|---|

| A | 10.6 | 29 × 2 | 25.4 | 877 | 340 |

| B | 10.4 | 33.5 × 2 | 24.9 | 877 | 340 |

| C | 10.6 | 37 × 2 | 25.4 | 877 | 340 |

| Coatings | Porosity (%) | Adhesion Strength (MPa) | Indention Fracture Toughness (MPa m1/2) | Hardness (HV) |

|---|---|---|---|---|

| A | 0.89 ± 0.09 | 62.0 ± 2.8 | 4.12 ± 0.2 | 874.2 ± 11.4 |

| B | 0.58 ± 0.14 | 73.8 ± 3.2 | 5.58 ± 0.3 | 882.6 ± 13.2 |

| C | 1.12 ± 0.20 | 61.3 ± 1.8 | 4.86 ± 0.7 | 860.6 ± 10.3 |

| Coating Type | Friction Coefficient | Wear rate (10−15 m3/N·m) |

|---|---|---|

| A | 0.33 ± 0.04 | 7.07 ± 0.84 |

| B | 0.30 ± 0.02 | 6.47 ± 0.68 |

| C | 0.37 ± 0.07 | 7.31 ± 1.27 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, M.; Lin, Y.; Ke, P.; Wang, S.; Zhang, S.; Zhen, Z.; Ge, L. Influence of Process Parameters on High Velocity Oxy-Fuel Sprayed Cr3C2-25%NiCr Coatings. Coatings 2017, 7, 98. https://doi.org/10.3390/coatings7070098

Xie M, Lin Y, Ke P, Wang S, Zhang S, Zhen Z, Ge L. Influence of Process Parameters on High Velocity Oxy-Fuel Sprayed Cr3C2-25%NiCr Coatings. Coatings. 2017; 7(7):98. https://doi.org/10.3390/coatings7070098

Chicago/Turabian StyleXie, Mingxiang, Yue Lin, Peng Ke, Shuoyu Wang, Shihong Zhang, Zhicheng Zhen, and Liangshui Ge. 2017. "Influence of Process Parameters on High Velocity Oxy-Fuel Sprayed Cr3C2-25%NiCr Coatings" Coatings 7, no. 7: 98. https://doi.org/10.3390/coatings7070098

APA StyleXie, M., Lin, Y., Ke, P., Wang, S., Zhang, S., Zhen, Z., & Ge, L. (2017). Influence of Process Parameters on High Velocity Oxy-Fuel Sprayed Cr3C2-25%NiCr Coatings. Coatings, 7(7), 98. https://doi.org/10.3390/coatings7070098