In-Situ Heat Treatment Study on the Nanocrystalline Cr2O3 Film Using an Environmental Scanning Electron Microscope

Abstract

:1. Introduction

2. Experimental Details

2.1. Preparition of the Cr2O3 Film

2.2. Characterizations of the Cr2O3 Film

3. Results and Discussion

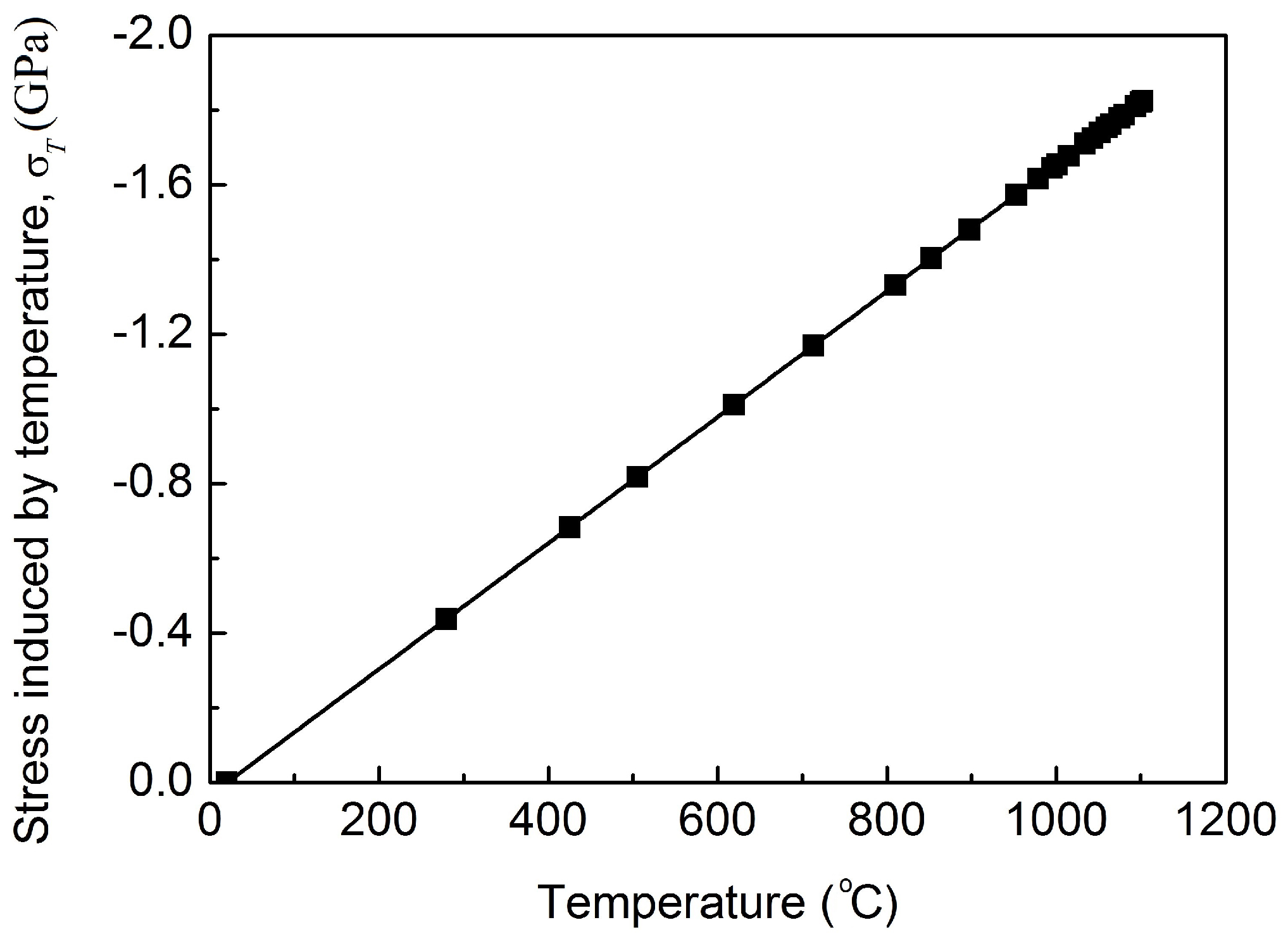

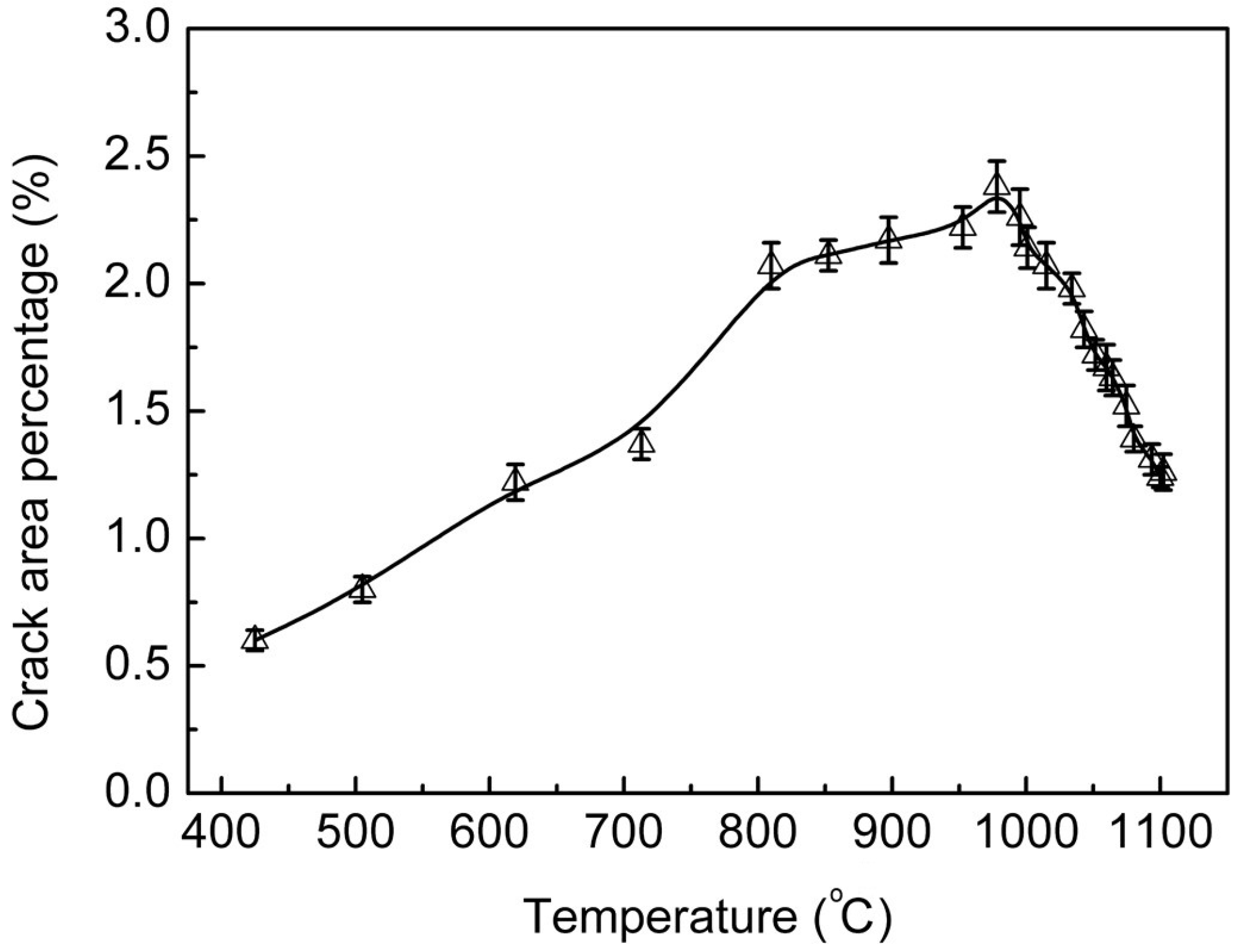

3.1. Percentage of Crack Area for the Heat-Treated Cr2O3 Film

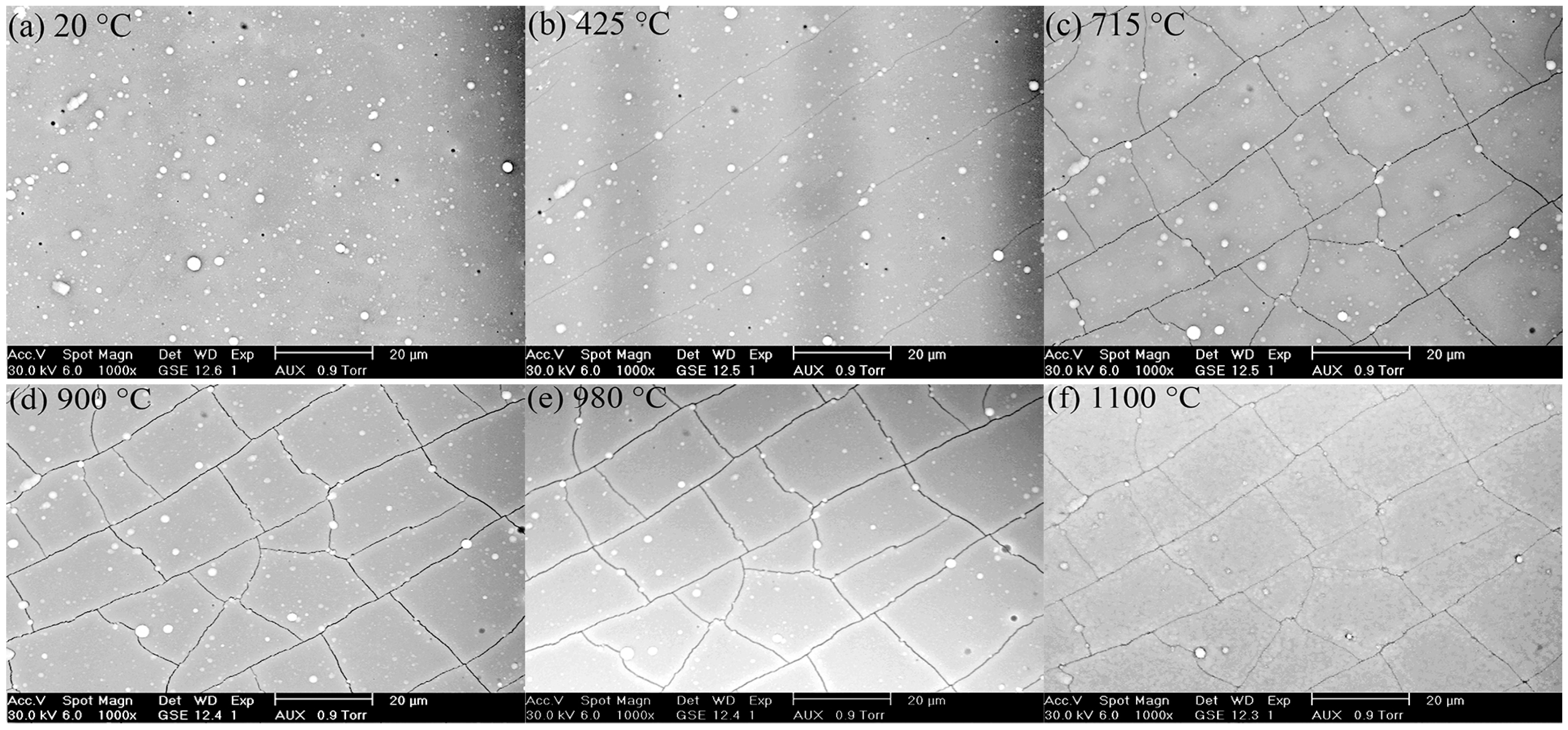

3.2. Surface Morphologies

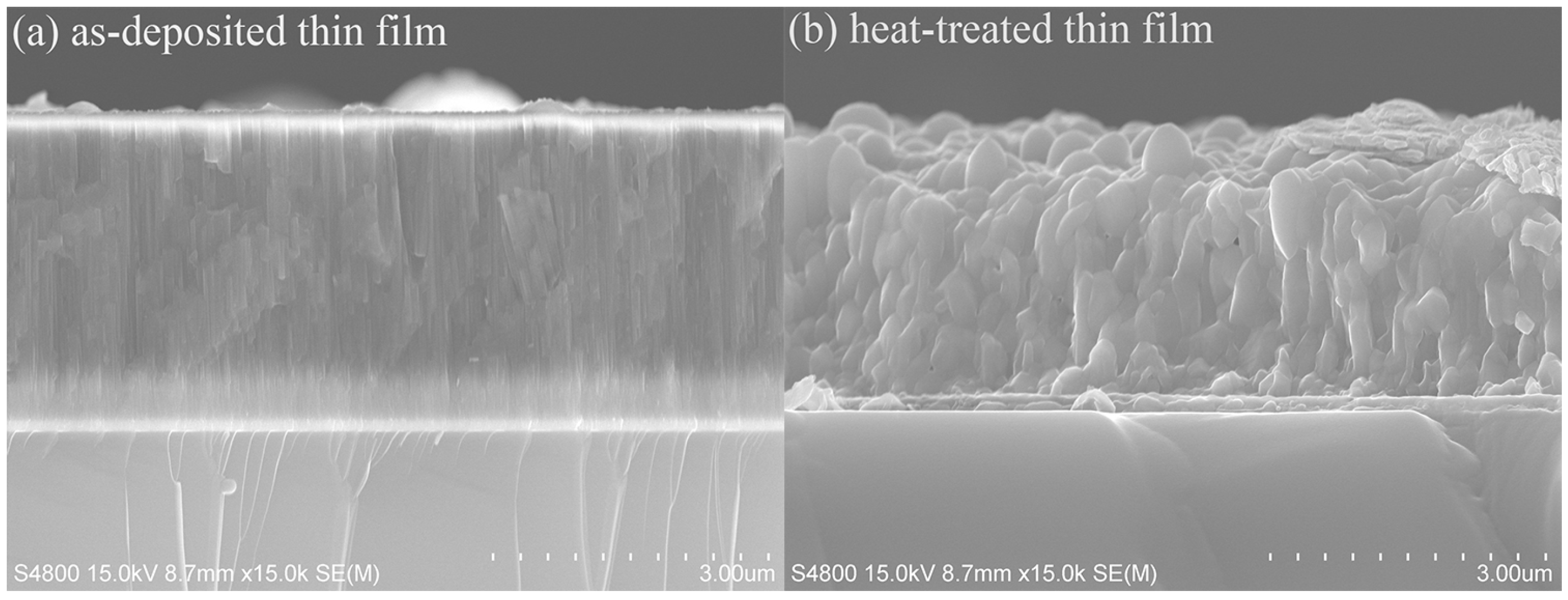

3.3. Fractured Cross-Section

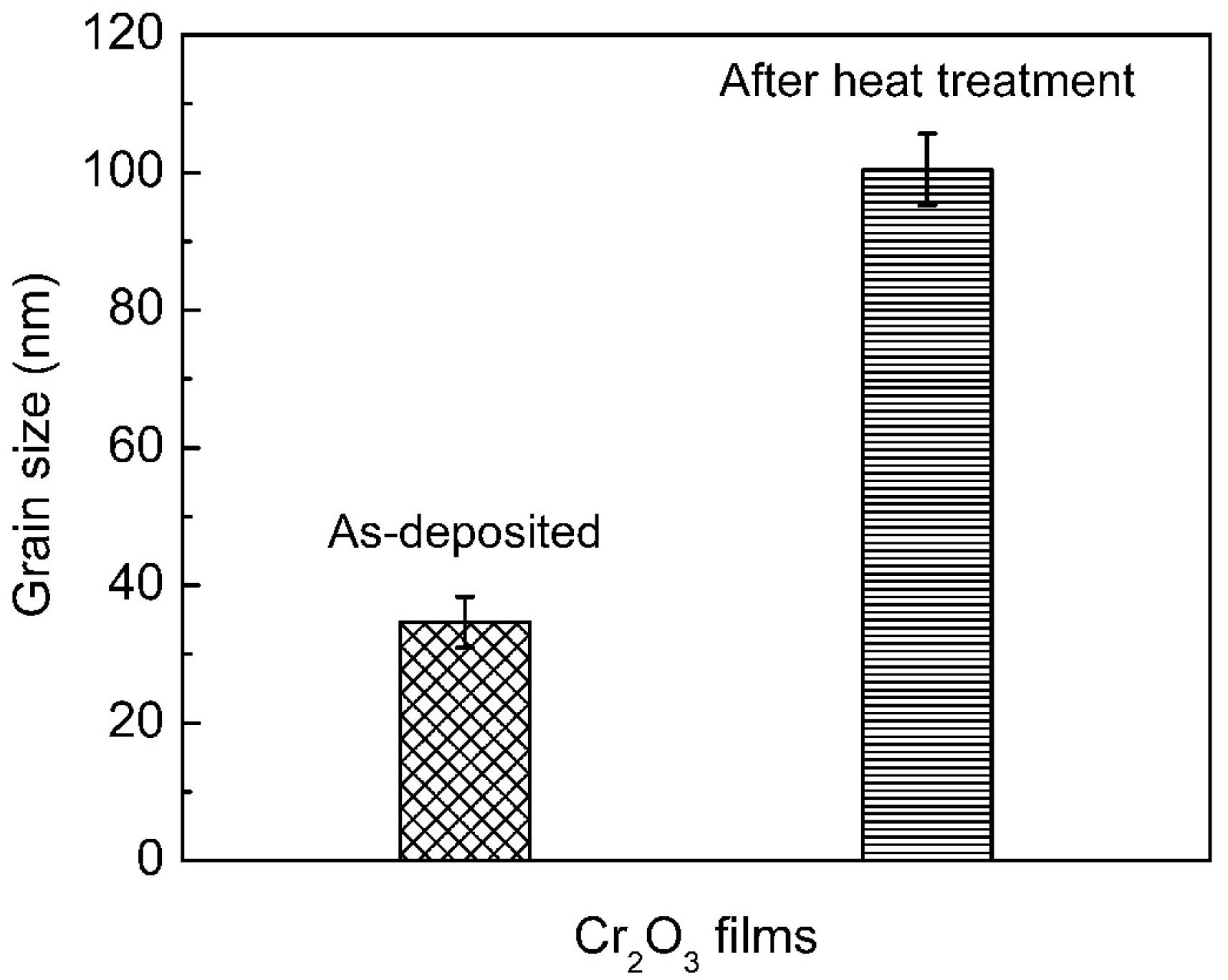

3.4. XRD Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Singh, B.K.; Mondal, B.; Mandal, N. Machinability evaluation and desirability function optimization of turning parameters for Cr2O3 doped zirconia toughened alumina (Cr–ZTA) cutting insert in high speed machining of steel. Ceram. Int. 2016, 42, 3338–3350. [Google Scholar] [CrossRef]

- Gago, R.; Vinnichenko, M.; Hübner, R.; Redondo-Cubero, A. Bonding structure and morphology of chromium oxide films grown by pulsed-DC reactive magnetron sputter deposition. J. Alloys Compd. 2016, 672, 529–535. [Google Scholar] [CrossRef]

- Vesel, A.; Mozetic, M.; Balat-Pichelin, M. Reduction of a thin chromium oxide film on Inconel surface upon treatment with hydrogen plasma. Appl. Surf. Sci. 2016, 387, 1140–1146. [Google Scholar] [CrossRef]

- Khojier, K.; Savaloni, H.; Ashkabusi, Z.; Dehnavi, N.Z. Structural, mechanical and tribological characterization of chromium oxide thin films prepared by post-annealing of Cr thin films. Appl. Surf. Sci. 2016, 284, 489–496. [Google Scholar] [CrossRef]

- Shaukat, S.; Khaleeq-ur-Rahman, M.; Ilyas, U.; Latif, A.; Rawat, R.S. Structural, morphological and optical changes in periodic fractal nanosymmetries of Ni doped chromium oxide ceramic nanostructures. Ceram. Int. 2016, 42, 4952–4963. [Google Scholar] [CrossRef]

- Cellard, A.; Garnier, V.; Fantozzi, G.; Baret, G.; Fort, P. Wear resistance of chromium oxide nanostructured coatings. Ceram. Int. 2009, 35, 913–916. [Google Scholar] [CrossRef]

- Li, N.-N.; Li, G.-L.; Wang, H.-D.; Kang, J.-J.; Dong, T.-S.; Wang, H.-J. Influence of TiO2 content on the mechanical and tribological properties of Cr2O3-based coating. Mater. Des. 2015, 88, 906–914. [Google Scholar] [CrossRef]

- He, N.; Li, H.; Ji, L.; Liu, X.; Zhou, H.; Chen, J. Toughness measurement and toughening mechanisms of arc ion plating Cr2O3 films treated by annealing. Ceram. Int. 2015, 41, 9534–9541. [Google Scholar] [CrossRef]

- Garraud, A.; Combette, P.; Giani, A. Thermal stability of Pt/Cr and Pt/Cr2O3 thin-film layers on a SiNx/Si substrate for thermal sensor applications. Thin Solid Films 2013, 540, 256–260. [Google Scholar] [CrossRef]

- He, D.; Li, S.; Liu, X.; Zhang, C.; Yu, Q.; Wang, S.; Jiang, L. Preparation of Cr2O3 film by MOCVD as hydrogen permeation barrier. Fusion Eng. Des. 2014, 89, 35–39. [Google Scholar] [CrossRef]

- Demirci, E.; Öztürk, M.; Öcal, M.T.; Öztürk, O.; Akdoğan, N. Investigation of spin canting phenomena in perpendicularly exchange biased Pt/Co/Pt/Cr2O3 thin films. Thin Solid Films 2015, 591, 72–75. [Google Scholar] [CrossRef]

- Hutchins, M.G. Selective thin film coatings for the conversion of solar radiation. Surf. Coat. Technol. 1983, 20, 301–320. [Google Scholar] [CrossRef]

- Wang, T.-G.; Jeong, D.; Liu, Y.; Wang, Q.; Iyengar, S.; Melin, S.; Kim, K.H. Study on nanocrystalline Cr2O3 films deposited by arc ion plating: I. composition, morphology, and microstructure analysis. Surf. Coat. Technol. 2012, 206, 2629–2637. [Google Scholar] [CrossRef]

- Ji, A.; Wang, W.; Song, G.; Wang, Q.; Sun, C.; Wen, L. Microstructures and mechanical properties of chromium oxide films by arc ion plating. Mater. Lett. 2004, 58, 1993–1998. [Google Scholar] [CrossRef]

- Ho, W.Y.; Huang, D.H.; Huang, L.T.; Hsu, C.H.; Wang, D.Y. Study of characteristics of Cr2O3/CrN duplex coatings for aluminum die casting applications. Surf. Coat. Technol. 2004, 172, 177–178. [Google Scholar] [CrossRef]

- Wang, J.; Gupta, A.; Klein, T.M. Plasma enhanced chemical vapor deposition of Cr2O3 thin films using chromium hexacarbonyl (Cr(CO)6) precursor. Thin Solid Films 2008, 516, 7366–7372. [Google Scholar] [CrossRef]

- Wang, T.G.; Jeong, D.; Liu, Y.; Wang, Q.; Iyengar, S.; Melin, S.; Kim, K.H. Study on nanocrystalline Cr2O3 films deposited by arc ion plating: II. Mechanical and tribological properties. Surf. Coat. Technol. 2012, 206, 2638–2644. [Google Scholar] [CrossRef]

- Wang, T.-G.; Liu, Y.; Sina, H.; Shi, C.; Iyengar, S.; Melin, S.; Kim, K.H. High-temperature thermal stability of nanocrystalline Cr2O3 films deposited on silicon wafers by arc ion plating. Surf. Coat. Technol. 2013, 228, 140–147. [Google Scholar] [CrossRef]

- Shi, C.-M.; Wang, T.-G.; Pei, Z.-L.; Gong, J.; Sun, C. Effects of the Thickness ratio of CrN vs. Cr2O3 layer on the properties of double-layered CrN/Cr2O3 coatings deposited by arc ion plating. J. Mater. Sci. Technol. 2014, 30, 473–479. [Google Scholar] [CrossRef]

- Shi, C.-M.; Wang, T.-G.; Pei, Z.-L.; Gong, J.; Sun, C. Microstructure, interface, and properties of multilayered CrN/Cr2O3 coatings prepared by arc ion plating. J. Mater. Sci. Technol. 2014, 30, 1193–1201. [Google Scholar] [CrossRef]

- Srinivasan, N.S. Dynamic study of changes in structure and morphology during the heating and sintering of iron powder. Powder Technol. 2002, 124, 40–44. [Google Scholar] [CrossRef]

- Zeman, P.; Musil, J. Difference in high-temperature oxidation resistance of amorphous Zr–Si–N and W–Si–N films with a high Si content. Appl. Surf. Sci. 2006, 252, 8319–8325. [Google Scholar] [CrossRef]

- He, N.; Ji, L.; Liu, X.; Li, H.; Zhou, H.; Chen, J. Role of annealing temperatures on the evolution of microstructure and properties of Cr2O3 films. Appl. Surf. Sci. 2015, 357, 1472–1480. [Google Scholar] [CrossRef]

- Ananth, M.P.; Ramesh, R. Sliding wear characteristics of solid lubricant coating on titanium alloy surface modified by laser texturing and ternary hard coatings. Trans. Nonferr. Met. Soc. Chin. 2017, 27, 839–847. [Google Scholar] [CrossRef]

- Baloyi, N.M.; Popoola, A.P.I.; Pityana, S.L. Microstructure, hardness and corrosion properties of laser processed Ti6Al4V-based composites. Trans. Nonferr. Met. Soc. Chin. 2015, 25, 2912–2923. [Google Scholar] [CrossRef]

- Kacsich, T.; Lieb, K.P. Oxidation of thin CrN and Cr2N films analyzed via nuclear reaction analysis and Rutherford backscattering spectrometry. Thin Solid Films 1994, 245, 4–6. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Kovač, J.; Gselman, P.; Bončina, T.; Paskvale, S.; Čekada, M.; Kek Merl, D.; Panjan, M. Oxidation resistance of CrN/(Cr,V)N hard coatings deposited by DC magnetron sputtering. Thin Solid Films 2015, 591, 323–329. [Google Scholar] [CrossRef]

- Obeydavi, A.; Dastafkan, K.; Rahimi, M.; Dezfouli, M.A.G. Insights into post-annealing and silver doping effects on the internal microstructure of ZnO nanoparticles through X-ray diffraction probe. Solid State Sci. 2017, 69, 71–81. [Google Scholar] [CrossRef]

- Tabbal, M.; Kahwaji, S.; Christidis, T.C.; Nsouli, B.; Zahraman, K. Pulsed laser deposition of nanostructured dichromium trioxide thin films. Thin Solid Films 2006, 515, 1976–1984. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Base pressure (Pa) | 3.5 × 10−3 |

| Working pressure (Pa) | 3.0 × 10−1 |

| Deposition temperature (°C) | 300 |

| Arc current (A) | 55 |

| DC bias voltage (V) | −100 |

| Ar:O2 gas flow ratio (sccm) | 40:20 |

| Substrate rotation speed (rpm) | 25 |

| Film thickness (μm) | ~3.5 |

| Distance between the target and substrate (mm) | 350 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.-G.; Dong, Y.; Liu, Y.; Iyengar, S.; Kim, K.H.; Yang, Z. In-Situ Heat Treatment Study on the Nanocrystalline Cr2O3 Film Using an Environmental Scanning Electron Microscope. Coatings 2017, 7, 225. https://doi.org/10.3390/coatings7120225

Wang T-G, Dong Y, Liu Y, Iyengar S, Kim KH, Yang Z. In-Situ Heat Treatment Study on the Nanocrystalline Cr2O3 Film Using an Environmental Scanning Electron Microscope. Coatings. 2017; 7(12):225. https://doi.org/10.3390/coatings7120225

Chicago/Turabian StyleWang, Tie-Gang, Yu Dong, Yanmei Liu, Srinivasan Iyengar, Kwang Ho Kim, and Zubing Yang. 2017. "In-Situ Heat Treatment Study on the Nanocrystalline Cr2O3 Film Using an Environmental Scanning Electron Microscope" Coatings 7, no. 12: 225. https://doi.org/10.3390/coatings7120225

APA StyleWang, T.-G., Dong, Y., Liu, Y., Iyengar, S., Kim, K. H., & Yang, Z. (2017). In-Situ Heat Treatment Study on the Nanocrystalline Cr2O3 Film Using an Environmental Scanning Electron Microscope. Coatings, 7(12), 225. https://doi.org/10.3390/coatings7120225