Ta–Zr–N Thin Films Fabricated through HIPIMS/RFMS Co-Sputtering

Abstract

:1. Introduction

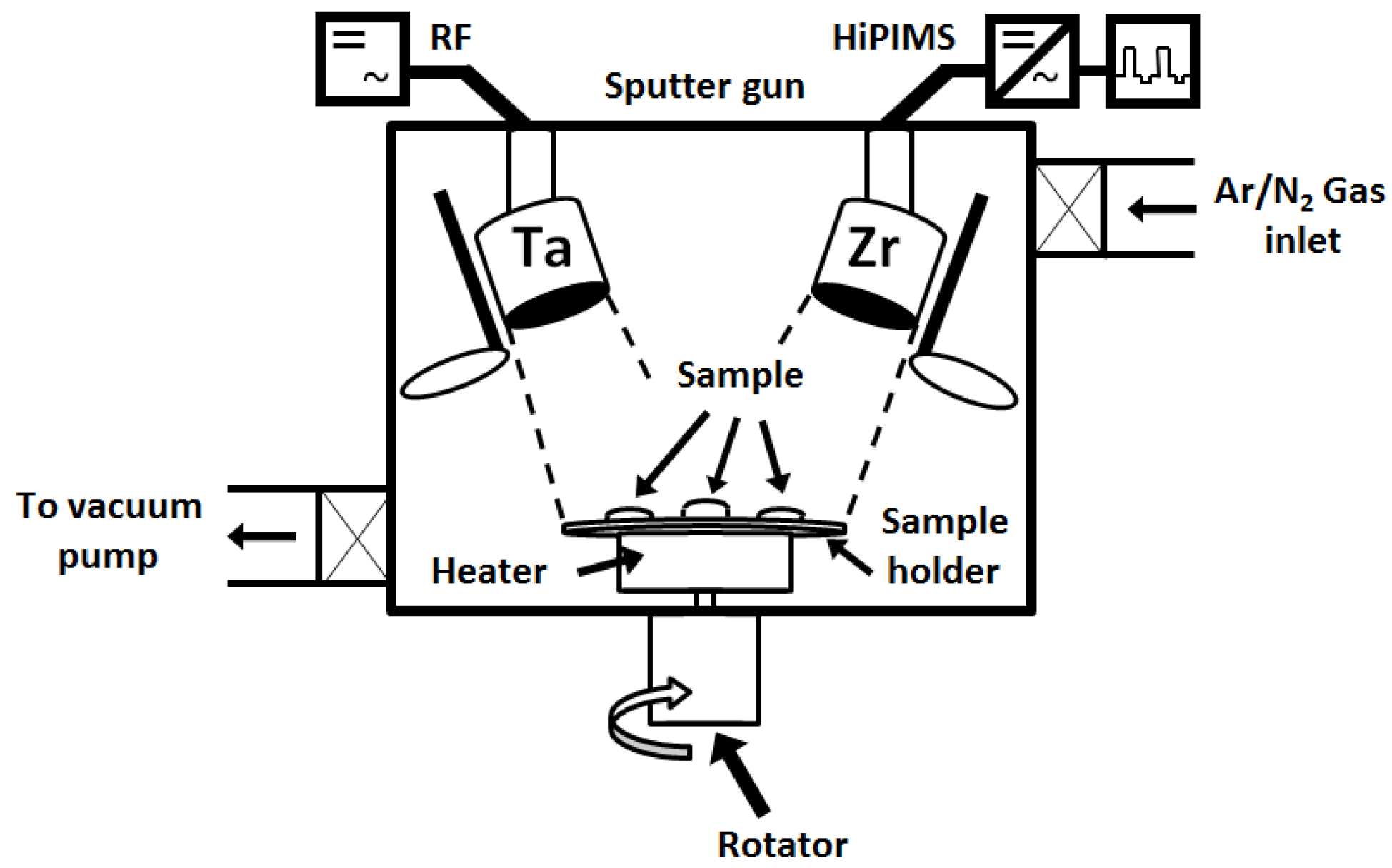

2. Materials and Methods

3. Results and Discussion

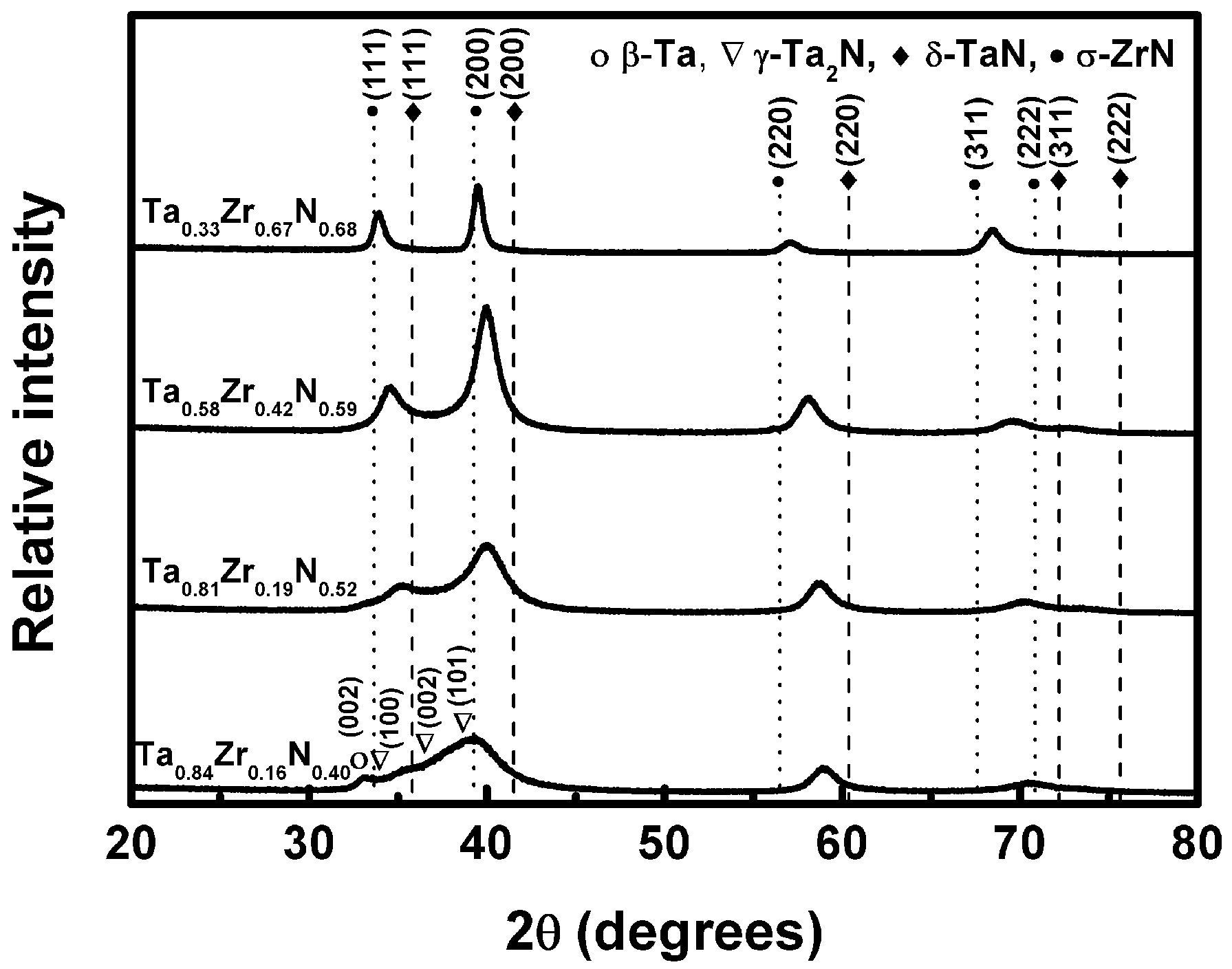

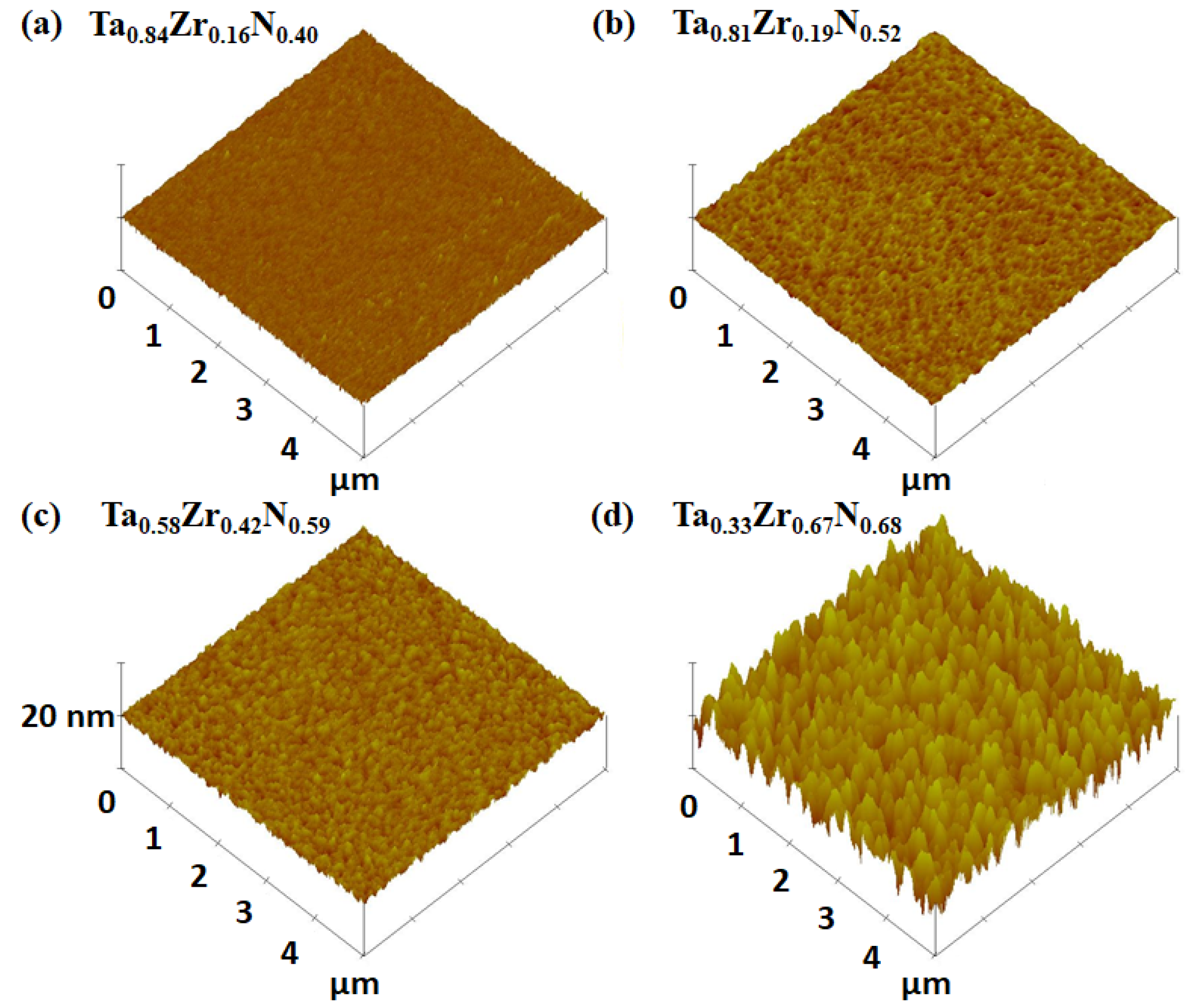

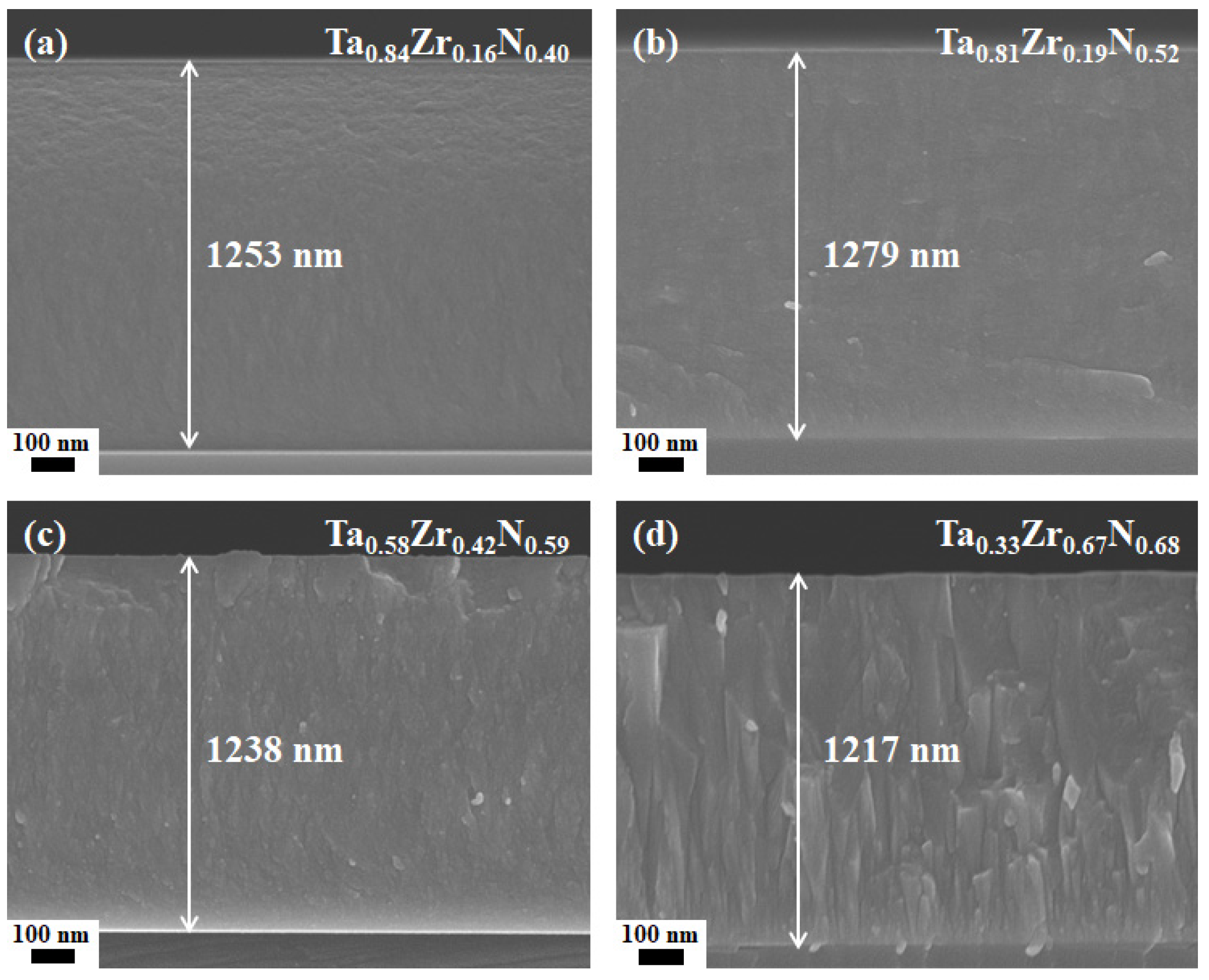

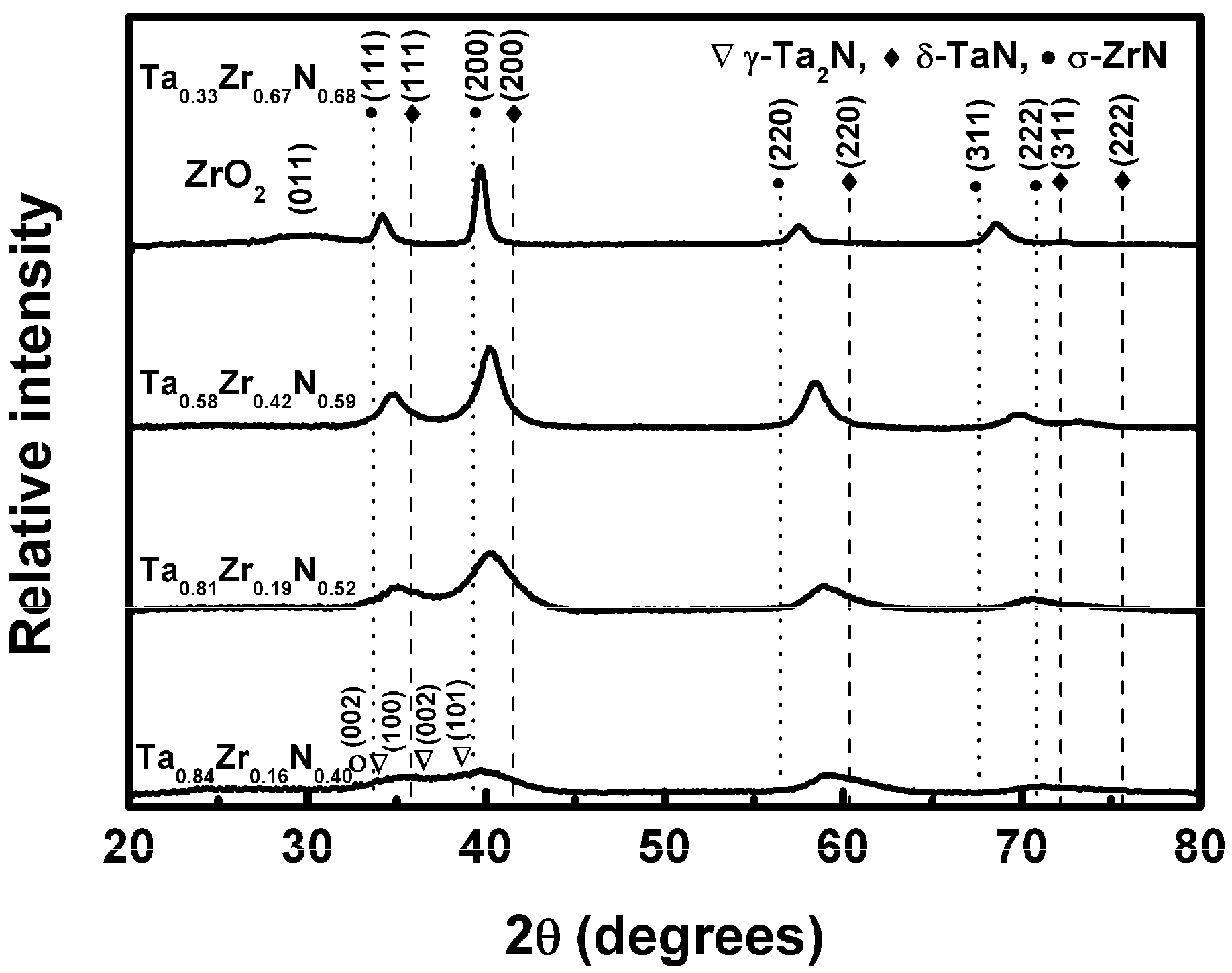

3.1. As-Deposited Ta–Zr–N Thin Films

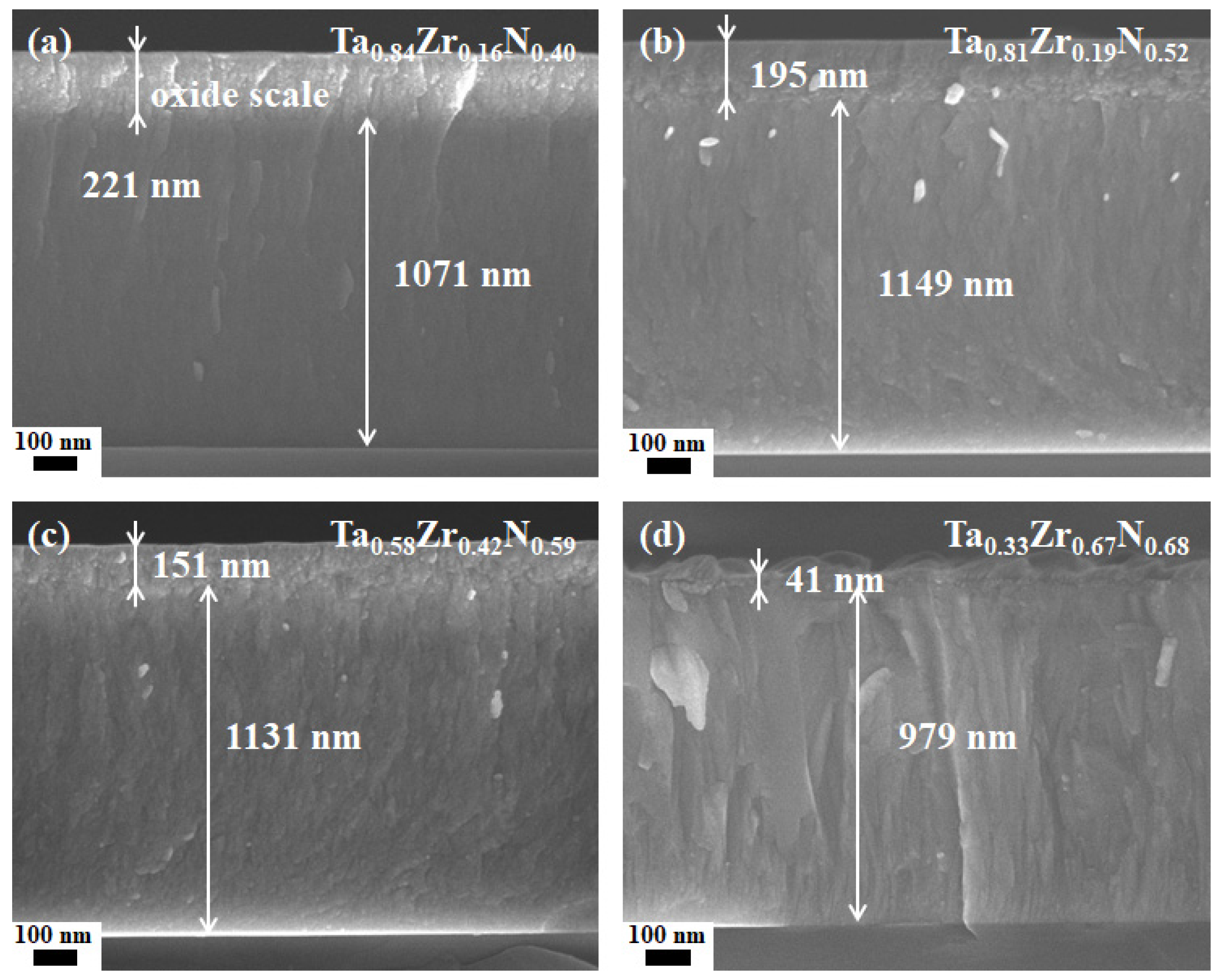

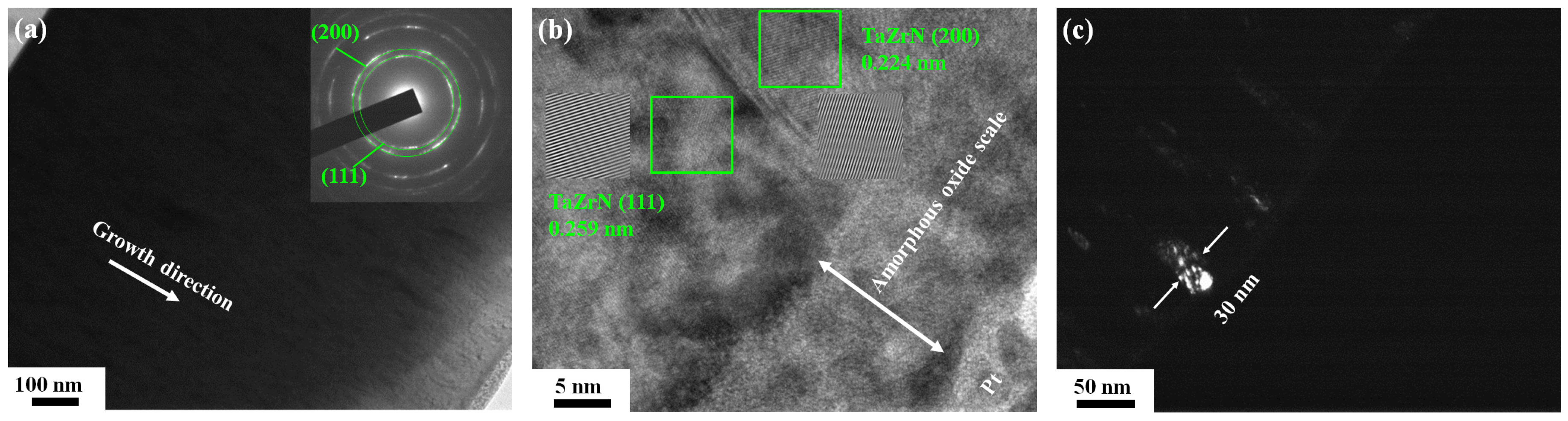

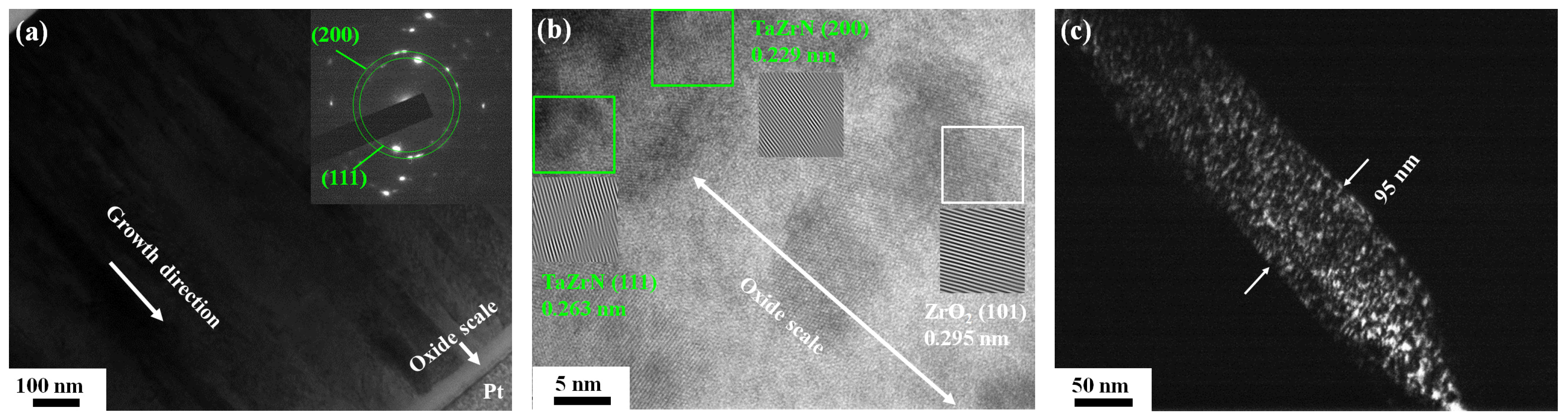

3.2. Ta–Zr–N Thin Films Annealed in a 15-ppm O2-N2 Atmosphere at 600 °C

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Aouadi, S.M.; Filip, P.; Debessai, M. Characterization of tantalum zirconium nitride sputter-deposited nanocrystalline coatings. Surf. Coat. Technol. 2004, 187, 177–184. [Google Scholar] [CrossRef]

- Aouadi, S.M. Structural and mechanical properties of TaZrN films: Experimental and ab initio studies. J. Appl. Phys. 2006, 99, 053507. [Google Scholar] [CrossRef]

- Ruan, J.L.; Huang, J.L.; Lu, H.H.; Chen, J.S.; Lii, D.F. Effects of the Ta content on the microstructure and electrical property of reactively sputtered TaxZr1−xN thin films. Thin Solid Films 2011, 519, 4987–4991. [Google Scholar] [CrossRef]

- Abadias, G.; Kanoun, M.B.; Goumri-Said, S.; Koutsokeras, L.; Dub, S.N.; Djemia, P. Electronic structure and mechanical properties of ternary ZrTaN alloys studied by ab initio calculations and thin-film growth experiments. Phys. Rev. B 2014, 90, 114107. [Google Scholar] [CrossRef]

- Abadias, G.; Djemia, P.; Belliard, L. Alloying effects on the structure and elastic properties of hard coatings based on ternary transition metal (M = Ti, Zr or Ta) nitrides. Surf. Coat. Technol. 2014, 257, 129–137. [Google Scholar] [CrossRef]

- Chang, L.C.; Chang, C.Y.; Chen, Y.I. Mechanical properties and oxidation resistance of reactively sputtered Ta1−xZrxNy thin films. Surf. Coat. Technol. 2015, 280, 27–36. [Google Scholar] [CrossRef]

- Liu, S.C.; Chen, Y.I.; Tsai, H.Y.; Lin, K.C.; Chen, Y.H. Thermal stability of Ir–Re coatings annealed in oxygen-containing atmospheres. Surf. Coat. Technol. 2013, 237, 105–111. [Google Scholar] [CrossRef]

- Liu, S.C.; Chen, Y.I.; Shyu, J.J.; Tsai, H.Y.; Lin, K.Y.; Chen, Y.H.; Lin, K.C. The chemical inertness of Ir–Re and Ta–Ru coatings in molding B2O3–ZnO–La2O3-based glass. Surf. Coat. Technol. 2014, 259, 352–357. [Google Scholar] [CrossRef]

- Kouznetsov, V.; Macák, K.; Schneider, J.M.; Helmersson, U.; Petrov, I. Functional differences between the external and protoplasmic surfaces of plasma membranes in activating vaccinia virus infectivity. Surf. Coat. Technol. 1990, 122, 290–293. [Google Scholar] [CrossRef]

- Helmersson, U.; Lattemann, M.; Bohlmark, J.; Ehiasarian, A.P.; Gudmundsson, J.T. Ionized physical vapor deposition (IPVD): A review of technology and applications. Thin Solid Films 2006, 513, 1–24. [Google Scholar] [CrossRef]

- Purandare, Y.P.; Ehiasarian, A.P.; Hovsepian, P.E. Structure and properties of ZrN coatings deposited by high power impulse magnetron sputtering technology. J. Vac. Sci. Technol. A 2011, 29, 011004. [Google Scholar] [CrossRef]

- Schmidt, S.; Czigány, Z.; Greczynski, G.; Jensen, J.; Hultman, L. Influence of inert gases on the reactive high power pulsed magnetron sputtering process of carbon-nitride thin films. J. Vac. Sci. Technol. A 2013, 31, 011503. [Google Scholar] [CrossRef] [Green Version]

- Magnus, F.; Ingason, A.S.; Olafsson, S.; Gudmundsson, J.T. Nucleation and resistivity of ultrathin TiN films grown by high-power impulse magnetron sputtering. IEEE Electron. Dev. Lett. 2012, 33, 1045–1047. [Google Scholar] [CrossRef]

- Alami, J.; Sarakinos, K.; Mark, G.; Wuttig, M. On the deposition rate in a high power pulsed magnetron sputtering discharge. Appl. Phys. Lett. 2006, 89, 154104. [Google Scholar] [CrossRef]

- Greczynski, G.; Lu, J.; Jensen, J.; Bolz, S.; Kölker, W.; Schiffers, C.; Lemmer, O.; Greene, J.E.; Hultman, L. A review of metal-ion-flux-controlled growth of metastable TiAlN by HIPIMS/DCMS Co-sputtering. Surf. Coat. Technol. 2014, 257, 15–25. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, T.; Yun, J.M.; Kang, M.C.; Wang, Q.; Kim, K.H. Microstructure, mechanical, oxidation and corrosion properties of the Cr-Al-Si-N coatings deposited by a hybrid sputtering system. Coatings 2017, 7, 119. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Simmons, G.; Wang, H. Single Crystal Young’s Constants and Calculated Aggregate Properties: A Handbook; MIT Press: Cambridge, MA, USA, 1971. [Google Scholar]

- Janssen, G.C.A.M.; Abdalla, M.M.; van Keulen, F.; Pujada, B.R.; van Venrooy, B. Celebrating the 100th anniversary of the Stoney equation for film stress: Developments from polycrystalline steel strips to single crystal silicon wafers. Thin Solid Films 2009, 517, 1858–1867. [Google Scholar] [CrossRef]

- Thod, L.E. Transition Metal Carbides and Nitrides; Academic Press: New York, NY, USA, 1971. [Google Scholar]

- Matenoglou, G.M.; Koutsokeras, L.E.; Lekka, C.E.; Abadias, G.; Kosmidis, C.; Evangelakis, G.A.; Patsalas, P. Structure, stability and bonding of ternary transition metal nitrides. Surf. Coat. Technol. 2009, 204, 911–914. [Google Scholar] [CrossRef]

- Barin, I. Thermochemical Data of Pure Substances, 3rd ed.; VCH: New York, NY, USA, 1995. [Google Scholar]

- Hurkmans, T.; Lewis, D.B.; Paritong, H.; Brooks, J.S.; Münz, W.D. Influence of ion bombardment on structure and properties of unbalanced magnetron grown CrNx coatings. Surf. Coat. Technol. 1999, 114, 52–59. [Google Scholar] [CrossRef]

- Musil, J.; Šícha, J.; Heřman, D.; Čerstvý, R. Role of energy in low-temperature high-rate formation of hydrophilic TiO2 thin films using pulsed magnetron sputtering. J. Vac. Sci. Technol. A 2007, 25, 666–674. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Musil, J.; Jaroš, M.; Čerstvý, R.; Haviar, S. Evolution of microstructure and macrostress in sputtered hard Ti(Al,V)N films with increasing energy delivered during their growth by bombarding ions. J. Vac. Sci. Technol. A 2017, 35, 020601. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Niinomi, M.; Akahori, T. Changes in mechanical properties of Ti alloys in relation to alloying additions of Ta and Hf. Mater. Sci. Eng. A 2008, 483–484, 153–156. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Anders, A.; Brown, I.G. Nanoindentation and nanoscratching of hard carbon coatings for magnetic disks. Mater. Res. Soc. Symp. Proc. 1995, 383, 447–452. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

- Chang, L.C.; Chang, C.Y.; Chen, Y.I.; Kao, H.L. Mechanical properties and oxidation behavior of ZrNx thin films fabricated through high-power impulse magnetron sputtering deposition. J. Vac. Sci. Technol. A 2016, 34, 02D107. [Google Scholar] [CrossRef]

- Bielawski, M. Residual stress control in TiN/Si coatings deposited by unbalanced magnetron sputtering. Surf. Coat. Technol. 2006, 200, 3987–3995. [Google Scholar] [CrossRef]

- Chen, Y.I.; Wang, H.H. Oxidation resistance and mechanical properties of Cr–Ta–Si–N coatings in glass molding processes. Surf. Coat. Technol. 2014, 260, 118–125. [Google Scholar] [CrossRef]

- Chen, Y.I.; Cheng, Y.R.; Chang, L.C.; Lu, T.S. Chemical inertness of Ta–Si–N coatings in glass molding. Thin Solid Films 2015, 584, 66–71. [Google Scholar] [CrossRef]

| Sample | RF Power WTa | HIPIMS Power WZr | Zr Power Density (W/cm2) | Deposition Time (min) | Coating Thickness (nm) | Deposition Rate (nm/min) |

|---|---|---|---|---|---|---|

| A | 100 | 400 | 1656 | 210 | 1217 | 5.80 |

| B | 200 | 400 | 1632 | 140 | 1238 | 8.84 |

| C | 300 | 400 | 1576 | 105 | 1279 | 12.18 |

| D | 400 | 400 | 1500 | 85 | 1253 | 14.75 |

| Sample | Annealing Time (h) | Chemical Composition (at %) | Atomic Ratio | ||||

|---|---|---|---|---|---|---|---|

| Ta | Zr | N | O | Zr/(Ta + Zr) | N/(Ta + Zr) | ||

| A Ta0.33Zr0.67N0.68 | 0 | 19.0 ± 0.0 | 39.1 ± 0.5 | 39.6 ± 0.2 | 2.3 ± 0.2 | 0.67 | 0.68 |

| 4 | 17.5 ± 0.4 | 35.9 ± 0.3 | 34.0 ± 0.7 | 12.6 ± 1.0 | 0.67 | 0.64 | |

| 8 | 16.3 ± 0.4 | 33.6 ± 0.5 | 30.9 ± 0.3 | 19.2 ± 1.3 | 0.67 | 0.62 | |

| B Ta0.58Zr0.42N0.59 | 0 | 36.3 ± 0.1 | 26.1 ± 0.2 | 36.6 ± 0.1 | 1.0 ± 0.0 | 0.42 | 0.59 |

| 4 | 29.3 ± 0.5 | 23.0 ± 0.8 | 28.2 ± 0.5 | 19.5 ± 1.5 | 0.44 | 0.54 | |

| 8 | 27.5 ± 0.5 | 21.8 ± 0.1 | 26.8 ± 0.3 | 23.9 ± 0.3 | 0.44 | 0.54 | |

| C Ta0.81Zr0.19N0.52 | 0 | 52.5 ± 0.2 | 12.5 ± 0.7 | 33.5 ± 0.2 | 1.5 ± 0.3 | 0.19 | 0.52 |

| 4 | 35.8 ± 0.4 | 16.1 ± 0.4 | 24.1 ± 0.0 | 24.0 ± 0.3 | 0.31 | 0.46 | |

| 8 | 33.0 ± 0.3 | 14.9 ± 0.3 | 22.7 ± 0.3 | 29.4 ± 0.3 | 0.31 | 0.47 | |

| D Ta0.84Zr0.16N0.40 | 0 | 59.3 ± 0.7 | 11.0 ± 0.2 | 28.3 ± 0.8 | 1.4 ± 0.1 | 0.16 | 0.40 |

| 4 | 36.3 ± 0.5 | 11.1 ± 0.8 | 20.5 ± 0.2 | 32.1 ± 0.3 | 0.23 | 0.43 | |

| 8 | 35.3 ± 0.7 | 11.1 ± 0.2 | 18.8 ± 0.3 | 34.8 ± 0.6 | 0.24 | 0.41 | |

| Sample | TA (h) | Thickness | Surface | H | E | H3/E2 | We | Residual | |

|---|---|---|---|---|---|---|---|---|---|

| Film | Oxide | Roughness | Stress | ||||||

| (nm) | (nm) | (nm) | (GPa) | (GPa) | (GPa) | % | (GPa) | ||

| Ta0.33Zr0.67N0.68 | 0 | 1217 | 0 | 2.54 ± 0.01 | 30.2 ± 0.9 | 306 ± 7 | 0.30 | 67 | −4.18 ± 0.04 |

| 4 | 1176 | 0 | 2.93 ± 0.02 | 28.3 ± 1.6 | 283 ± 4 | 0.28 | 63 | – | |

| 8 | 979 | 41 | 3.55 ± 0.58 | 19.3 ± 1.6 | 235 ± 7 | 0.13 | 56 | – | |

| Ta0.58Zr0.42N0.59 | 0 | 1238 | 0 | 0.52 ± 0.02 | 35.0 ± 0.6 | 311 ± 3 | 0.44 | 73 | −6.17 ± 0.47 |

| 4 | 1208 | 62 | 0.80 ± 0.00 | 25.7 ± 0.4 | 262 ± 3 | 0.25 | 62 | – | |

| 8 | 1131 | 151 | 1.65 ± 0.28 | 24.8 ± 0.5 | 268 ± 4 | 0.21 | 59 | – | |

| Ta0.81Zr0.19N0.52 | 0 | 1279 | 0 | 0.36 ± 0.06 | 35.5 ± 0.4 | 299 ± 3 | 0.50 | 76 | −4.84 ± 0.04 |

| 4 | 1192 | 136 | 1.06 ± 0.10 | 21.5 ± 0.4 | 254 ± 6 | 0.15 | 56 | −3.46 ± 0.19 | |

| 8 | 1149 | 195 | 1.40 ± 0.24 | 19.5 ± 0.3 | 244 ± 3 | 0.13 | 50 | −2.80 ± 0.01 | |

| Ta0.84Zr0.16N0.40 | 0 | 1253 | 0 | 0.37 ± 0.01 | 31.9 ± 0.8 | 258 ± 11 | 0.49 | 75 | −4.65 ± 0.20 |

| 4 | 1164 | 131 | 0.54 ± 0.02 | 20.9 ± 0.5 | 251 ± 3 | 0.14 | 56 | −2.60 ± 0.17 | |

| 8 | 1071 | 221 | 1.15 ± 0.29 | 18.0 ± 0.3 | 235 ± 2 | 0.11 | 52 | −2.80 ± 0.00 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, L.-C.; Chang, C.-Y.; You, Y.-W. Ta–Zr–N Thin Films Fabricated through HIPIMS/RFMS Co-Sputtering. Coatings 2017, 7, 189. https://doi.org/10.3390/coatings7110189

Chang L-C, Chang C-Y, You Y-W. Ta–Zr–N Thin Films Fabricated through HIPIMS/RFMS Co-Sputtering. Coatings. 2017; 7(11):189. https://doi.org/10.3390/coatings7110189

Chicago/Turabian StyleChang, Li-Chun, Ching-Yen Chang, and Ya-Wen You. 2017. "Ta–Zr–N Thin Films Fabricated through HIPIMS/RFMS Co-Sputtering" Coatings 7, no. 11: 189. https://doi.org/10.3390/coatings7110189

APA StyleChang, L.-C., Chang, C.-Y., & You, Y.-W. (2017). Ta–Zr–N Thin Films Fabricated through HIPIMS/RFMS Co-Sputtering. Coatings, 7(11), 189. https://doi.org/10.3390/coatings7110189