Atmospheric Pressure Plasma Coating of Wood and MDF with Polyester Powder

Abstract

:1. Introduction

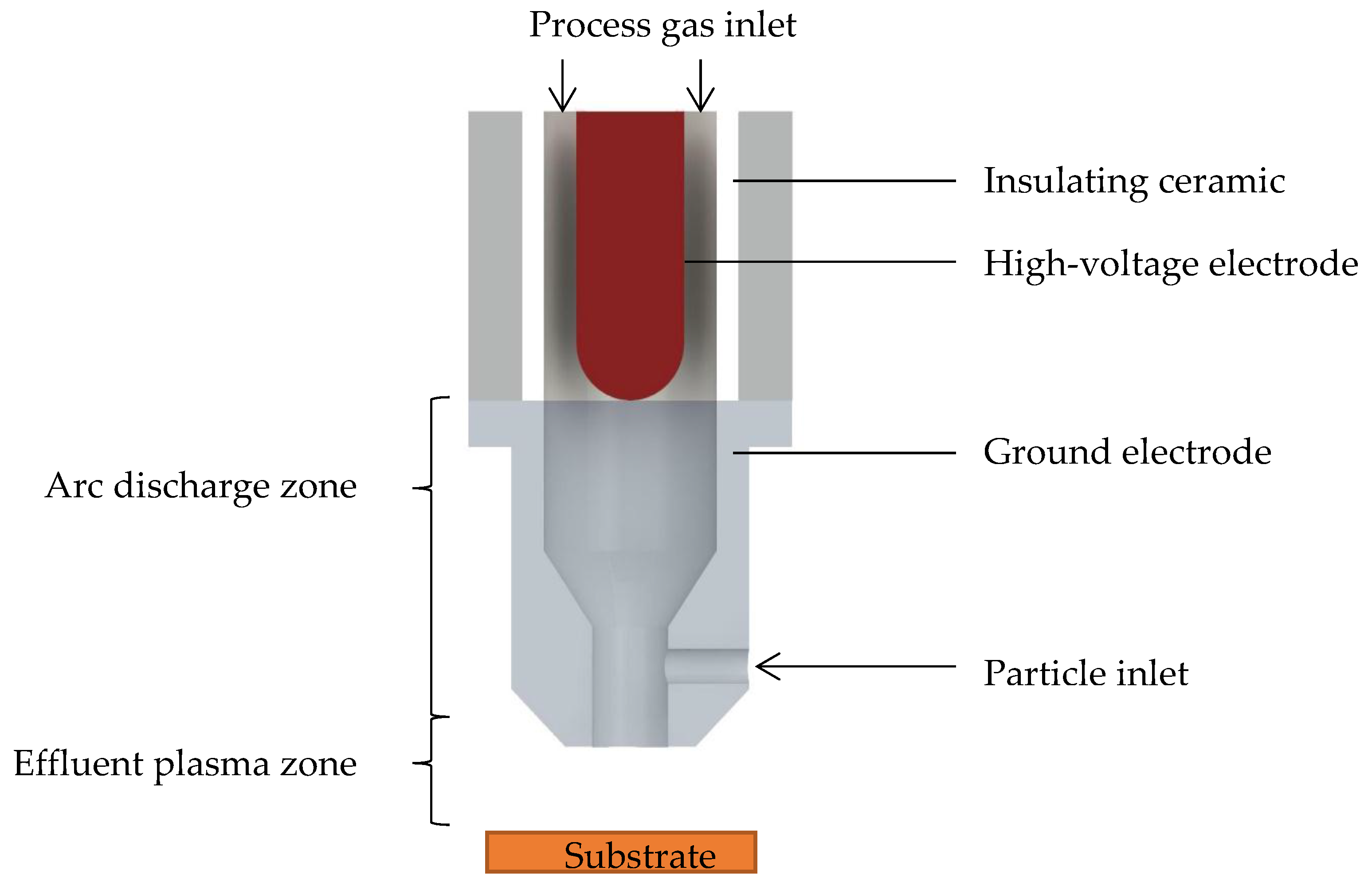

2. Materials and Methods

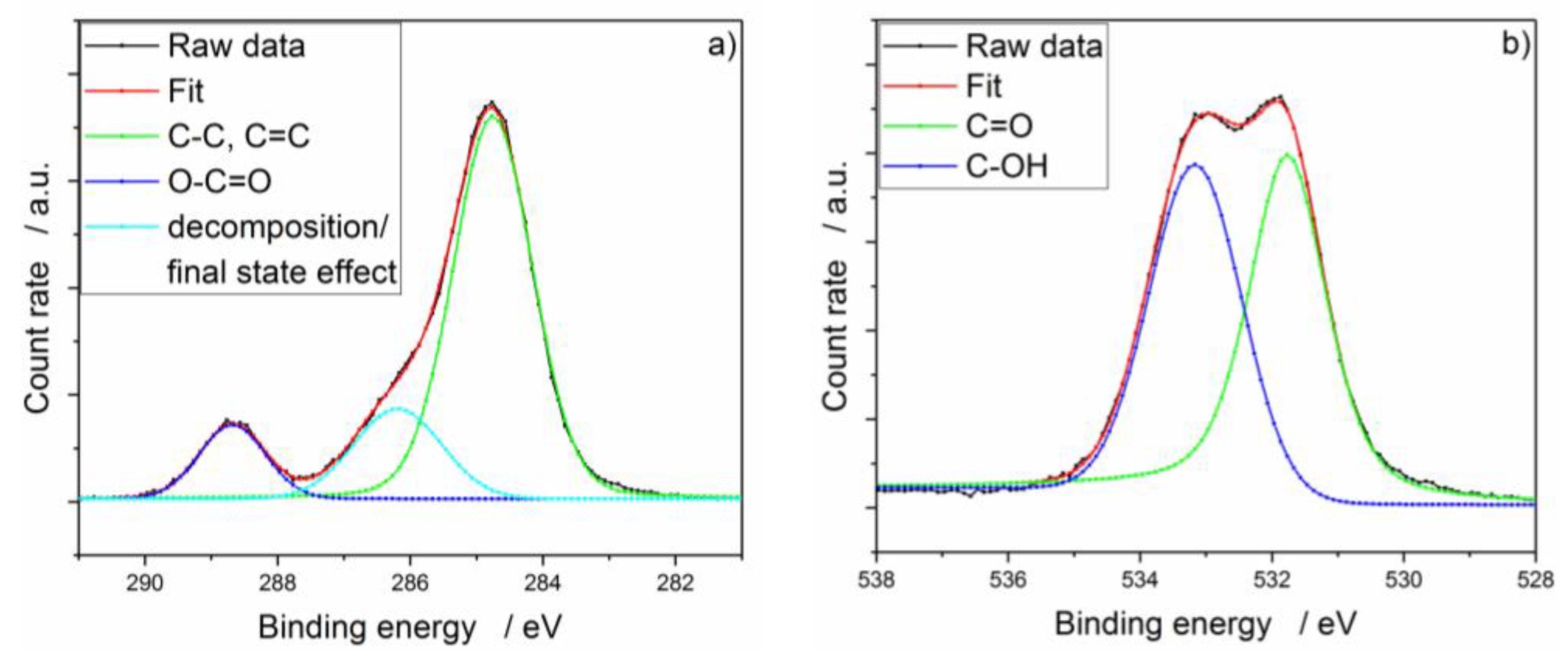

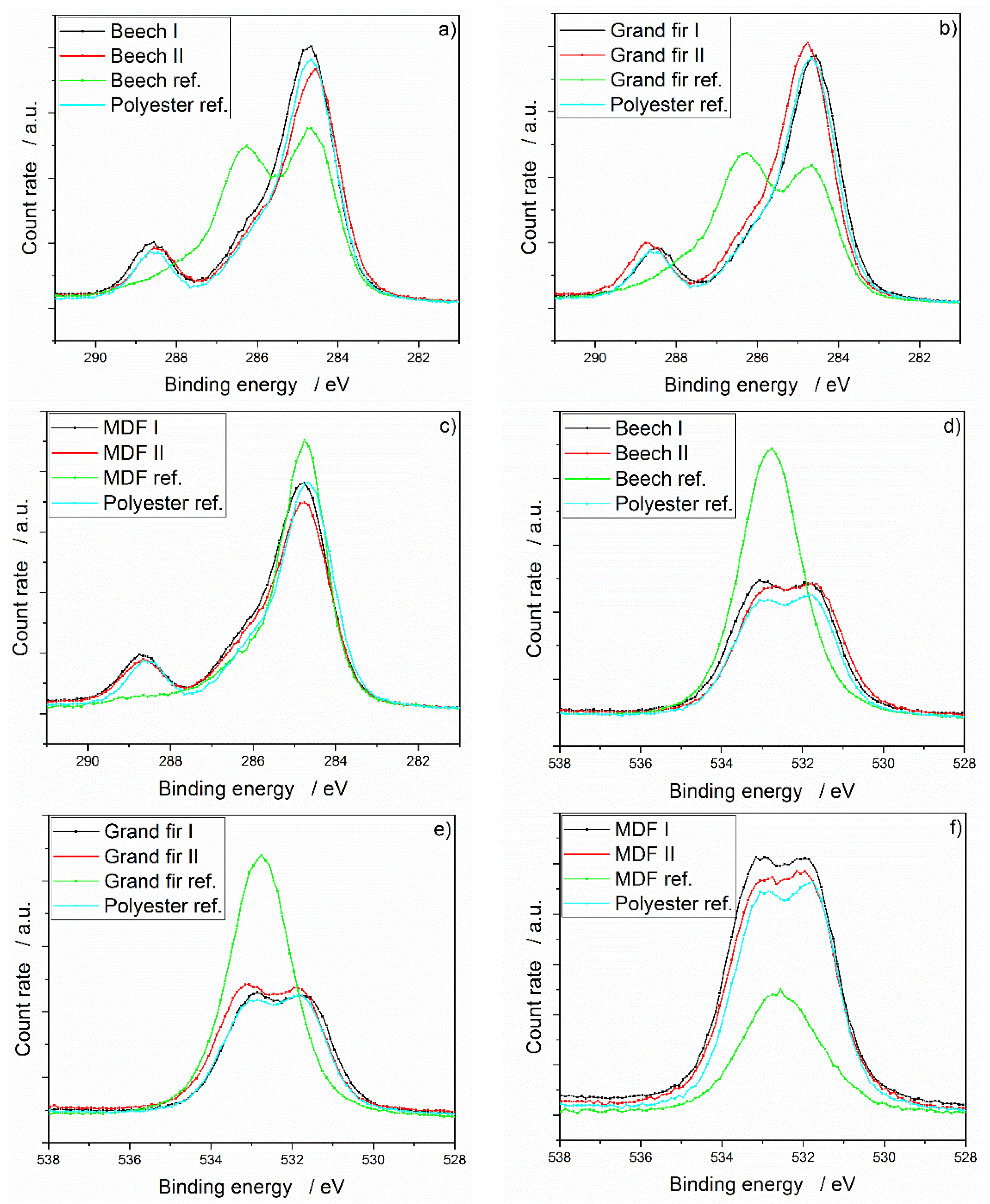

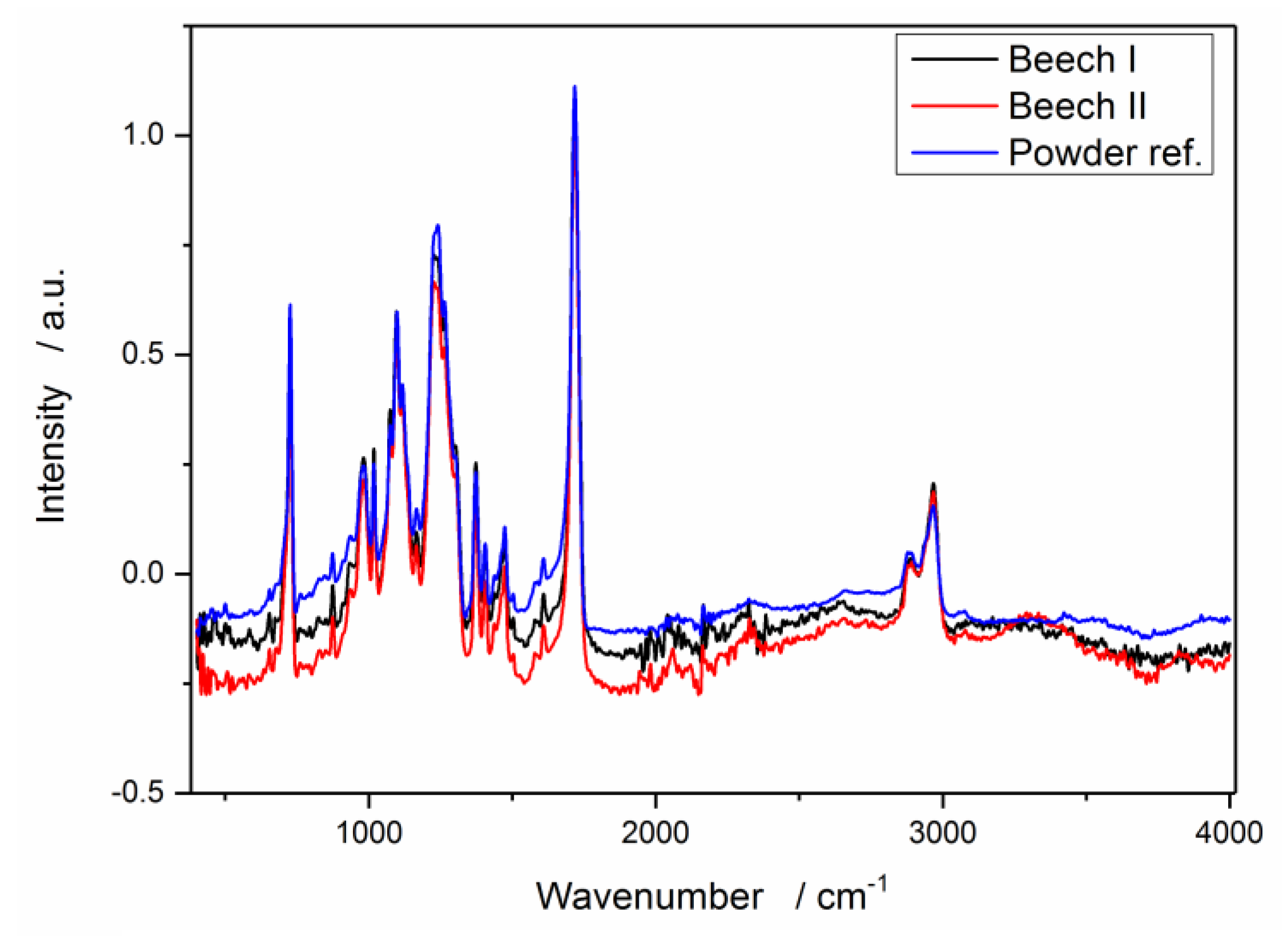

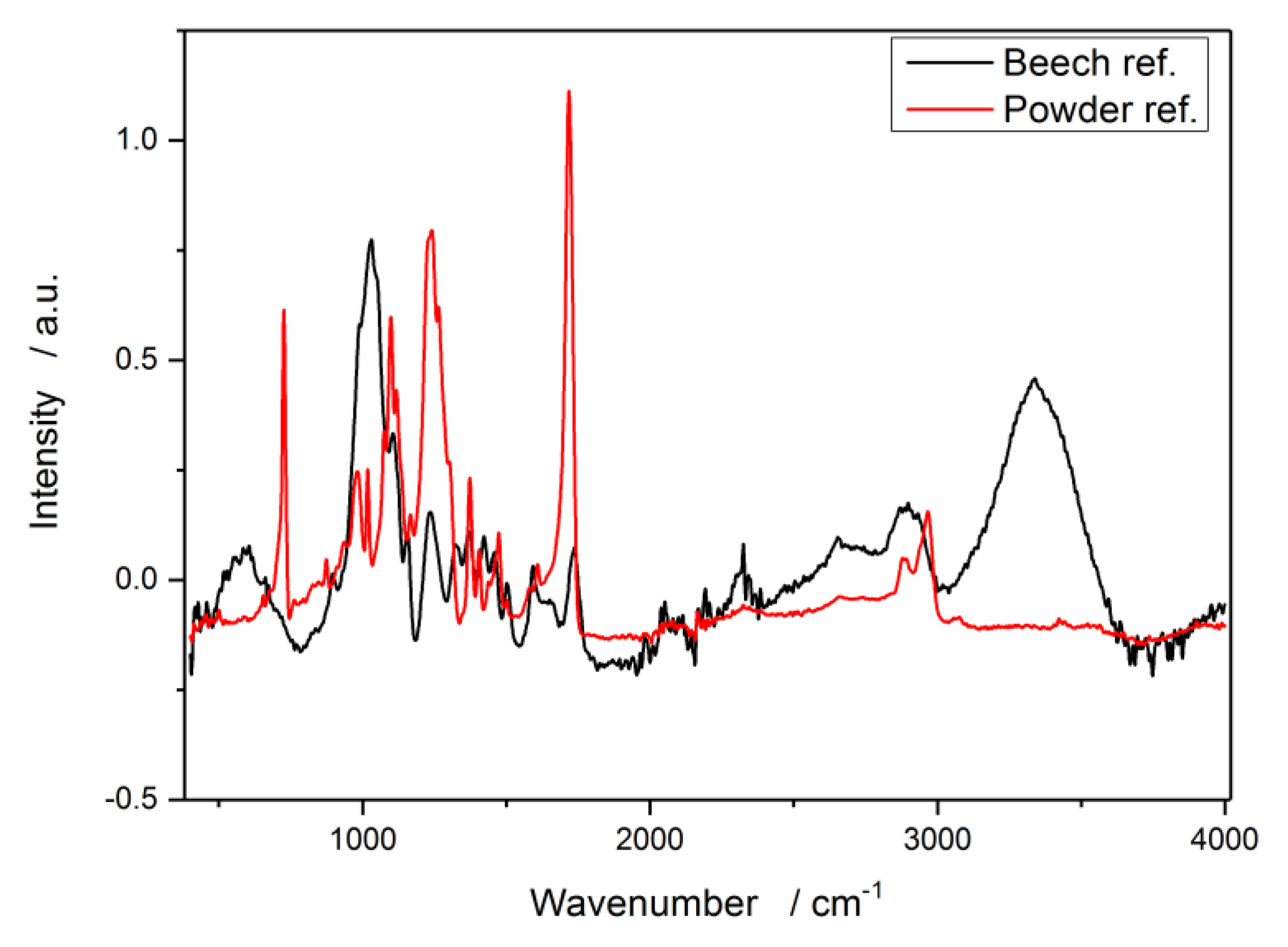

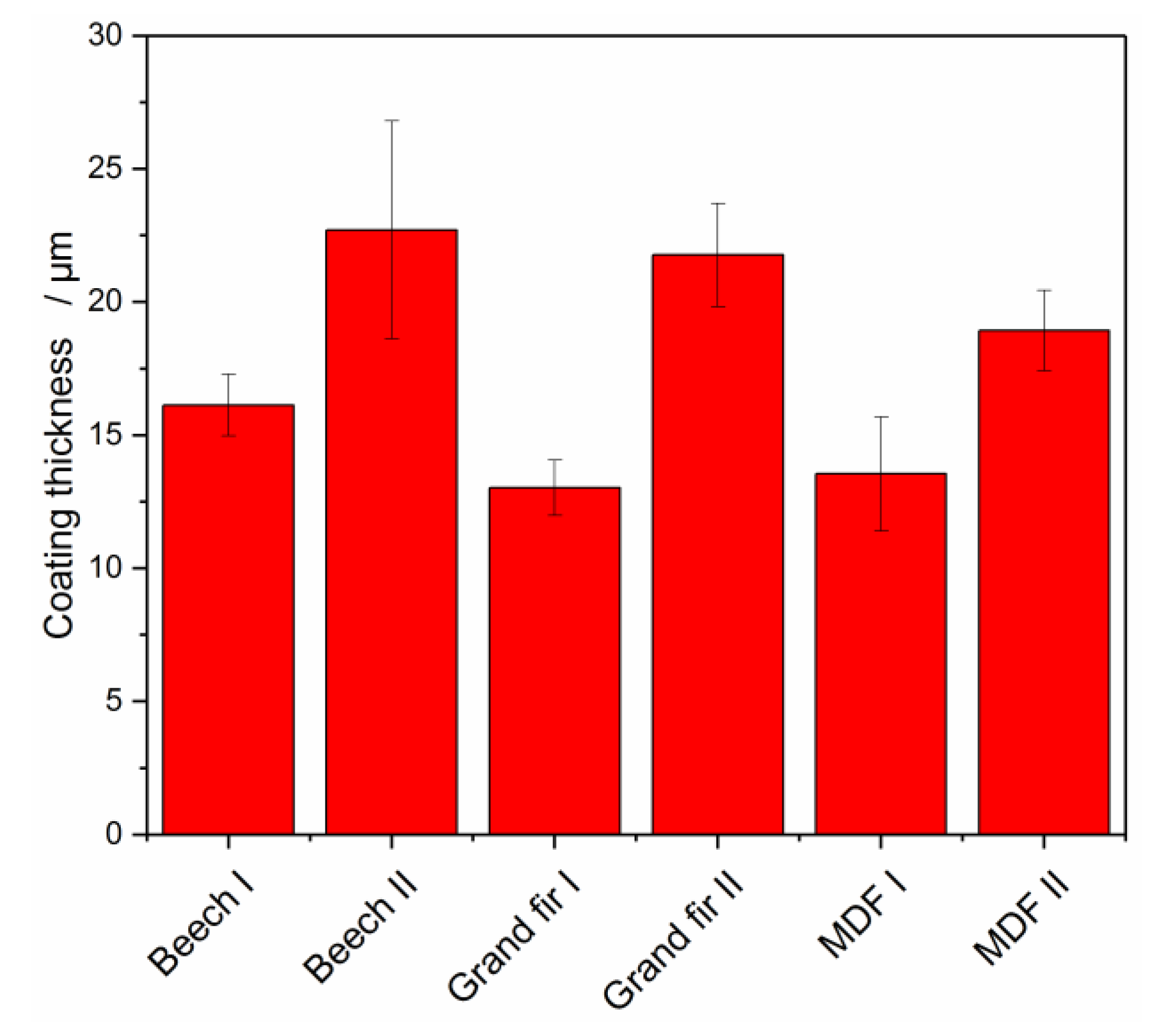

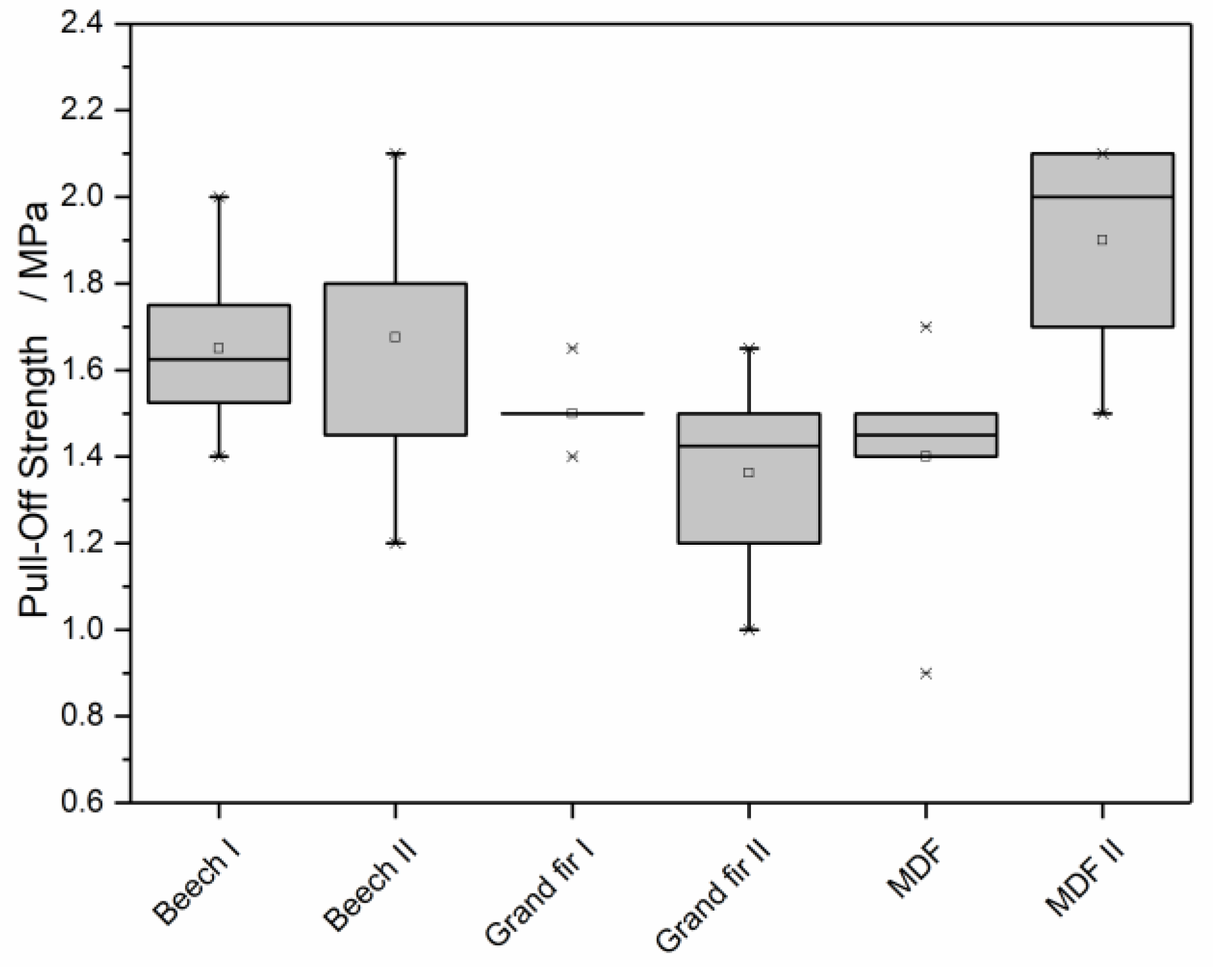

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pearnchob, N.; Bodmeier, R. Dry polymer powder coating and comparison with conventional liquid-based coatings for Eudragit® RS, ethylcellulose and shellac. Eur. J. Pharm. Biopharm. 2003, 56, 363–369. [Google Scholar] [CrossRef]

- Rossi, S.; Fedel, M.; Petrolli, S.; Deflorian, F. Accelerated weathering and chemical resistance of polyurethane powder coatings. J. Coat. Technol. Res. 2016, 13, 427–437. [Google Scholar] [CrossRef]

- Belder, E.; Rutten, H.; Perera, D. Cure characterization of powder coatings. Prog. Org. Coat. 2001, 42, 142–149. [Google Scholar] [CrossRef]

- Misev, T.; van der Linde, R. Powder coatings technology: New developments at the turn of the century. Prog. Org. Coat. 1998, 34, 160–168. [Google Scholar] [CrossRef]

- Barletta, M.; Vesco, S.; Trovalusci, F. Effect of the substrate and interface on micro-scratch deformation of epoxy-polyester powder coatings. Prog. Org. Coat. 2012, 74, 712–718. [Google Scholar] [CrossRef]

- Piazza, D.; Silveira, D.S.; Lorandi, N.P.; Birriel, E.J.; Scienza, L.C.; Zattera, A.J. Polyester-based powder coatings with montmorillonite nanoparticles applied on carbon steel. Prog. Org. Coat. 2012, 73, 42–46. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Sonawane, N.; Siju, C.R. Epoxy powder coatings containing polyaniline for enhanced corrosion protection. Prog. Org. Coat. 2009, 64, 383–386. [Google Scholar] [CrossRef]

- Gavrilova, V.A.; Kashapov, N.F.; Kashapov, R.N. Plasma application of protective polymer-powder coatings to ultrasonic sensors. Biomed. Eng. 2011, 45, 198–200. [Google Scholar] [CrossRef]

- Hedayati, M.; Salehi, M.; Bagheri, R.; Panjepour, M.; Naeimi, F. Tribological and mechanical properties of amorphous and semi-crystalline PEEK/SiO2 nanocomposite coatings deposited on the plain carbon steel by electrostatic powder spray technique. Prog. Org. Coat. 2012, 74, 50–58. [Google Scholar] [CrossRef]

- Kalaee, M.; Akhlaghi, S.; Nouri, A.; Mazinani, S.; Mortezaei, M.; Afshari, M.; Mostafanezhad, D.; Allahbakhsh, A.; Dehaghi, H.A.; Amirsadri, A.; et al. Effect of nano-sized calcium carbonate on cure kinetics and properties of polyester/epoxy blend powder coatings. Prog. Org. Coat. 2011, 71, 173–180. [Google Scholar] [CrossRef]

- Hu, R.-G.; Zhang, S.; Bu, J.-F.; Lin, C.-J.; Song, G.-L. Recent progress in corrosion protection of magnesium alloys by organic coatings. Prog. Org. Coat. 2012, 73, 129–141. [Google Scholar] [CrossRef]

- Bessières, J.; Maurin, V.; George, B.; Molina, S.; Masson, E.; Merlin, A. Wood-coating layer studies by X-ray imaging. Wood Sci. Technol. 2013, 47, 853–867. [Google Scholar] [CrossRef]

- Wuzella, G.; Kandelbauer, A.; Mahendran, A.R.; Teischinger, A. Thermochemical and isoconversional kinetic analysis of a polyester–epoxy hybrid powder coating resin for wood based panel finishing. Prog. Org. Coat. 2011, 70, 186–191. [Google Scholar] [CrossRef]

- Badila, M.; Jocham, C.; Zhang, W.; Schmidt, T.; Wuzella, G.; Müller, U.; Kandelbauer, A. Powder coating of veneered particle board surfaces by hot pressing. Prog. Org. Coat. 2014, 77, 1547–1553. [Google Scholar] [CrossRef]

- TIGER Coatings GmbH & Co. KG. Drylac® Produktdatenblatt: SERIE 530. Available online: http://www.tiger-coatings.com/fileadmin/user_upload/documentmanager_tiger-coatings_com/product-data-sheets/tiger-drylac/wood/TIGER_PDS_series530_1183_dt.pdf (accessed on 24 July 2017).

- Wallenhorst, L.M.; Loewenthal, L.; Avramidis, G.; Gerhard, C.; Militz, H.; Ohms, G.; Viöl, W. Topographic, optical and chemical properties of zinc particle coatings deposited by means of atmospheric pressure plasma. Appl. Surf. Sci. 2017, 410, 485–493. [Google Scholar] [CrossRef]

- Gascón-Garrido, P.; Mainusch, N.; Militz, H.; Viöl, W.; Mai, C. Effects of copper-plasma deposition on weathering properties of wood surfaces. Appl. Surf. Sci. 2016, 366, 112–119. [Google Scholar] [CrossRef]

- AkzoNobel Powder Coatings B.V. Product Data Sheet: Interpon 610. Available online: http://www.interpon.de/interpon_tds/interpon-610/ (accessed on 14 August 2017).

- ASTM D4541-02 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers; ASTM International: West Conshohocken, PA, USA, 2002.

- DIN EN ISO 4624:2016-08 Paints and Varnishes—Pull-off Test for Adhesion (ISO 4624:2016); European Committee for Standardization: Brussels, Belgium, 2016.

- DIN EN ISO 2813:2015-02 Paints and Varnishes—Determination of Gloss Value at 20°, 60° and 85° (ISO 2813:2014); European Committee for Standardization: Brussels, Belgium, 2015.

- George, G.A. High resolution XPS of organic polymers—The scienta ESCA 300 data base. Polym. Int. 1994, 33, 439–440. [Google Scholar] [CrossRef]

- Marschewski, M.; Otto, C.; Wegewitz, L.; Höfft, O.; Schmidt, A.; Maus-Friedrichs, W. Adsorption analysis of thin films of terephthalic acid on Au and Al studied by MIES, UPS and XPS. Appl. Surf. Sci. 2015, 339, 9–14. [Google Scholar] [CrossRef]

- Franke, M.; Marchini, F.; Zhang, L.; Tariq, Q.; Tsud, N.; Vorokhta, M.; Vondráček, M.; Prince, K.; Röckert, M.; Williams, F.J.; et al. Temperature-dependent reactions of phthalic acid on Ag(100). J. Phys. Chem. C 2015, 119, 23580–23585. [Google Scholar] [CrossRef]

- Stepanow, S.; Strunskus, T.; Lingenfelder, M.; Dmitriev, A.; Spillmann, H.; Lin, N.; Barth, J.V.; Wöll, C.; Kern, K. Deprotonation-driven phase transformations in terephthalic acid self-assembly on Cu(100). J. Phys. Chem. B 2004, 108, 19392–19397. [Google Scholar] [CrossRef]

- Davies, M.C.; Khan, M.A.; Domb, A.; Langer, R.; Watts, J.F.; Paul, A.J. The analysis of the surface chemical structure of biomedical aliphatic polyanhydrides using XPS and ToF-SIMS. J. Appl. Polym. Sci. 1991, 42, 1597–1605. [Google Scholar] [CrossRef]

- DIN EN 319:1993-08 Particleboards and Fibreboards; Determination of Tensile Strength Perpendicular to the Plane of the Board; European Committee for Standardization: Brussels, Belgium, 1993.

| Parameter | Value |

|---|---|

| Working distance | 20 mm |

| Process gas flow rate | 60 L/min |

| Powder feed rate | 4.3 m3/h |

| Substrate scan speed | 40 mm/s |

| Powder feed speed | 150 mm/h |

| Process gas | Compressed air |

| Substrate | C1s (at. %) | N1s (at. %) | O1s (at. %) |

|---|---|---|---|

| Beech I | 77.57 | 0.36 | 22.07 |

| Beech II | 76.11 | 0.75 | 23.15 |

| Beech reference | 71.29 | 0.46 | 28.25 |

| Grand fir I | 78.07 | 0.32 | 21.61 |

| Grand fir II | 77.52 | 0.54 | 21.94 |

| Grand fir reference | 68.74 | 0.46 | 30.8 |

| MDF I | 76.87 | 0.48 | 22.66 |

| MDF II | 76.10 | 0.92 | 22.98 |

| MDF reference | 86.85 | 2.65 | 10.49 |

| Powder reference | 78.52 | 0.42 | 21.06 |

| Substrate | 60° (GU) | 85° (GU) |

|---|---|---|

| Beech I | 21.2 ± 3.8 | 12.8 ± 2.5 |

| Beech II | 10.3 ± 2.0 | 7.5 ± 1.8 |

| Beech reference | 4.8 ± 0.6 | 9.2 ± 2.3 |

| Grand fir I | 12.1 ± 3.6 | 3.5 ± 1.7 |

| Grand fir II | 18.5 ± 5.2 | 7.1 ± 1.8 |

| Grand fir reference | 5.4 ± 0.9 | 3.6 ± 1.8 |

| MDF I | 2.9 ± 0.7 | 0.7 ± 0.3 |

| MDF II | 3.81 ± 1.0 | 1.1 ± 0.5 |

| MDF reference | 1.9 ± 0.1 | 0.34 ± 0.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Köhler, R.; Sauerbier, P.; Militz, H.; Viöl, W. Atmospheric Pressure Plasma Coating of Wood and MDF with Polyester Powder. Coatings 2017, 7, 171. https://doi.org/10.3390/coatings7100171

Köhler R, Sauerbier P, Militz H, Viöl W. Atmospheric Pressure Plasma Coating of Wood and MDF with Polyester Powder. Coatings. 2017; 7(10):171. https://doi.org/10.3390/coatings7100171

Chicago/Turabian StyleKöhler, Robert, Philipp Sauerbier, Holger Militz, and Wolfgang Viöl. 2017. "Atmospheric Pressure Plasma Coating of Wood and MDF with Polyester Powder" Coatings 7, no. 10: 171. https://doi.org/10.3390/coatings7100171

APA StyleKöhler, R., Sauerbier, P., Militz, H., & Viöl, W. (2017). Atmospheric Pressure Plasma Coating of Wood and MDF with Polyester Powder. Coatings, 7(10), 171. https://doi.org/10.3390/coatings7100171