Abstract

Ceramic cutting inserts coated with ten-fold alternating micro- and nanocrystalline diamond (MCD/NCD) layers grown by hot filament chemical vapor deposition (CVD) were tested in the machining of an Al based metallic matrix composite (MMC) containing 15 vol % Al2O3 particles. Inserts with total coating thicknesses of approximately 12 µm and 24 µm were produced and used in turning: cutting speed (v) of 250 to 1000 m·min−1; depth of cut (DOC) from 0.5 to 3 mm and feed (f) between 0.1 and 0.4 mm·rev−1. The main cutting force increases linearly with DOC (ca. 294 N per mm) and with feed (ca. 640 N per mm·rev−1). The thicker coatings work within the following limits: DOC up to 1.5 mm and maximum speeds of 750 m·min−1 for feeds up to 0.4 mm·rev−1. Flank wear is predominant but crater wear is also observed due to the negative tool normal rake. Layer-by-layer wear of the tool rake, and not total delamination from the substrate, evidenced one of the advantages of using a multilayer design. The MCD/NCD multilayer diamond coated indexable inserts have longer tool life than most CVD diamond systems and behave as well as most polycrystalline diamond (PCD) tools.

1. Introduction

The presence of the extremely hard ceramic particles in metal matrix composites (MMCs) reduces drastically the Lifetime of ordinary tools, a serious drawback at earlier stages of the development of MMCs [1]. Very hard materials, such as cubic boron nitride (CBN), and particularly those based on diamond, are the right choice for the tools, due to their extreme hardness, high wear resistance and thermal conductivity. Cobalt bonded diamond (PCD) early became the choice material due to its increased wear resistance, a prominent conclusion of the works of Durante et al. [2] and El-Gallab and Sklad [3]. Sub-surface damage is also minimized, particularly in finishing operations, as found by Hung et al. [1]. PCD tools, albeit their widespread use, also have shortcomings due to the presence of the binder phase. This is much less wear resistant than diamond, softens at high contact temperatures and may also induce graphitization of the diamond grains, thus limiting the maximum usable cutting speed [4]. Alternative hard tools are brazed thick CVD diamond plates or CVD direct coatings. The latter have the advantages of multiple tips per tool, allow the use of chip breakers [5], are easier to prepare and are much less geometry dependent, a critical issue for small drilling and milling tools. The performance of brazed CVD diamond plates matches or surpasses that of PCD tools, due to their binder-free pure diamond construction, that reduces the tendency for diamond grain pull out by the hard particles [6,7].

Regarding tools directly coated with a thin CVD diamond film, they may fail by delamination of the diamond coating after a few seconds [6] due to a combination of small thickness and most likely inadequate substrate and edge geometry. The thickness of a coating is by itself no guaranty that the tool life increases, as was found by D’Errico et al. [6], where turning inserts with 20 µm thick coatings had a ten times longer tool life than those with a 50 µm coating. This is due most likely to the increase of the cutting edge radius and subsequent increase of cutting forces, as was found for other workpiece materials [8]. Other authors [9] indicate that this dominant tool wear mechanism, coating failure, depends on the cutting speed and feed rate, and is due to the high interfacial stresses at the bonding surface. These arise from the high temperatures at the cutting tip and are due to different thermal expansions between the coating and substrate. Skordaris and co-authors [10,11,12] thoroughly studied the temperature-dependent residual stresses in the diamond film structure which significantly affect the interfacial fatigue strength of the diamond coatings during interrupted cutting operations. These effects may also arise in the turning of composites due to the existence of hard particles. Delamination of the diamond coating can be delayed if less aggressive machining conditions, such as smaller feeds, are used as was found by Chou and Liu [9], although at the cost of productivity. If adhesion is not an issue, then CVD diamond coatings generally wear out along the cutting edge due to the effects of localised forces and thermal load [13]. One of the first works where the adhesion of the diamond to hard metal substrate tools was studied and modified [14] showed that surface roughness and chemistry are of paramount importance. A finer microstructure of the substrate, etching of the tungsten carbide grains and removal of surface Co resulted in visible tool life improvements due to enhanced adhesion levels, when the right deposition parameters are used. Using hard metal tools as substrates, Kremer and co-workers addressed the effects of surface roughness [15], in 6 µm thick coatings, including the use of a bi-layered (micro-/nanocrystalline diamond) tool. The rougher single layer microcrystalline (MCD) coating had the best wear behaviour, with tool-life being limited by abrasive flank wear, while the bi-layer coating peeled easily due to the stresses imposed by adhesive wear and cutting edge attrition. Also using low surface roughness diamond coatings, Qin et al. obtained an opposite result when turning an Al–20%SiC composite [16]. The smoother nanocrystalline diamond (NCD) evidenced greater wear delamination resistance than MCD when used as 25–30 µm thick coatings on WC-Co indexable tool inserts. The same trend was observed by Shen et al. in a multi-layered architecture of micro/nano crystalline diamond coating of tungsten carbide (WC-Co) cutting inserts [17].

Successive nano- and micro-structured layers may absorb a part of the residual stresses and decelerate the crack propagation, contributing to a tool life augmentation when compared to nanocomposite coatings [12]. A similar multilayer configuration developed by the authors of the present paper more than tripled the critical load for delamination in pin-on-disk tribological sliding [18] and showed extended life in abrasive erosion tests [19]. It was shown that the use of an N = 4 coating system, starting with microcrystalline diamond and ending with a smoother NCD top coating yields much better results than lower order alternatives with N = 2 or N = 1 (either micro- or nano-crystalline), under laboratory conditions regarding tribological behavior and adhesion. Following these results, the N = 10 system here tested follows the trend observed in our previous work and is thus optimized regarding processing conditions.

In the present work, indexable triangular turning inserts were produced from a silicon nitride ceramic and coated with diamond in a multilayer approach that combines the very good adhesion of MCD with the top smoothness of NCD. These tools were tested for the first time in the machining of Al-matrix composites containing Al2O3 particles. Tool performance, cutting force, wear and tool life are analysed for two different thicknesses. Despite the research done over the years on the machining of Al base composites containing hard particles with diamond tools, there have been no reports so far that compare the merits of tools with cutting surfaces as different as a direct CVD coating and a brazed CVD or PCD tip can be. In this work, the tool life of such tools in the turning of SiC–Al and Al2O3–Al composites, gathered from several sources are graphically presented and compared with the results of the present work.

2. Materials and Methods

2.1. Al–Al2O3 Composite Workpiece

The workpiece material was a ∅20 cm × L40 cm cylinder of an Al based metallic matrix composite (MMC) of the type W6A.15A (aluminium wrought alloy 6061 reinforced with 15 vol % Al2O3 particles). Density measurements using Archimedes principle returned a density of 2.83 g·cm−3, while the bulk Vickers hardness measured using a 10 kgf load is HV = 113 kgf/mm2.

2.2. Cutting Inserts

Production of the ceramic cutting inserts followed the powder route using the HC Starck StarCeram (Munich, Germany) grade P ready-to-press spray-dried powder, a mixture of Si3N4, sintering aids (Al2O3 and Y2O3) and a polymeric binder. After uniaxial pressing in triangular dies with a central hole, the inserts were debinded under air at 500 °C during 4 h and then fully densified by pressureless sintering at 1750 °C for 2 h, in an atmosphere of 0.1 MPa N2. The sintered ceramic parts were ground to standard normalized triangle geometry (TNMA160408F) shaped inserts. The tool surfaces were then prepared for coating using a procedure for maximizing adhesion and detailed elsewhere [20].

2.3. Diamond Coating

Ten-fold multilayer micro-/nanocrystalline (MCD/NCD) diamond coatings were grown by hot filament chemical vapour deposition (HFCVD) technique on one of the rake faces of the inserts, thus yielding three cutting tips per tool. The coatings are made of five MCD and five NCD alternating layers with deposition conditions given in Table 1, always starting with MCD. Two types of inserts were produced: ML10x1 with 12–14 µm of total thickness; and ML10x2 where the thickness of each layer was nearly doubled resulting in 21–24 µm of total thickness. The average area surface roughness (Sa) of the coated faces of the inserts was measured using an optical profilometer, with a 10× objective and the vertical shift interferometry technique (Sensofar S-Neox, Barcelona, Spain).

Table 1.

Hot filament deposition parameters of each micro- and nanocrystalline diamond (MCD/NCD) layer.

2.4. Dry Turning

The dry turning tests were performed using a Mori Seiki CNC lathe (Nagoya, Japan) at the premises of Durit (Albergaria-a-Velha, Portugal), a company expert on precision hard metal products. The triangular inserts were fixed on a Walter (Tübingen, Germany) MTJNR2020 K 16 tool holder with the resulting tool angles being given in Table 2 [21].

Table 2.

Major cutting edge tool angles according to the tool-in-hand system, and corner radius [21].

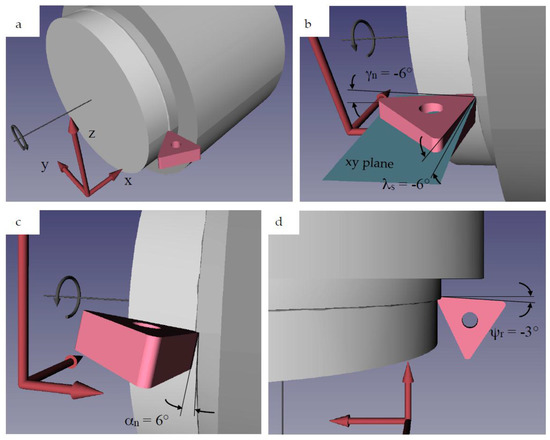

A schematic view of the insert during cutting can be seen in Figure 1. A 3-component measuring system for cutting force evaluation during turning (Kistler type 9129AA, Winterthur, Switzerland) was coupled to the lathe.

Figure 1.

(a) Schematic view of a TNMA160408F insert and the turning geometry resulting from the use of a MTJNL2020 K 16 tool holder (Tübingen, Germany); (b) detail of the insert showing that the tool normal rake and tool cutting edge inclination are negative; (c) insert with a 6° tool normal clearance; and (d) tool lead angle of −3°. Axis: x, feed direction (Ff); y, DOC direction (FDOC); z, primary motion direction = direction of the main component of cutting force (Fc).

The full set of tests, given in Table 3, intended to determine the effects of cutting speed (v) and feed (f) on the behaviour of the inserts with the thinner coating while the effect of the depth of cut (DOC) was studied solely for the ML10x2 inserts. The values of the machining length (L), spindle speed (n) and machining time (t) are also included. The signals from the three orthogonal components of the cutting force (main component, Fc, measured in the direction of primary motion; feed force, Ff, measured in the direction of feed motion, and depth-of-cut force, FDOC, in the radial direction of the workpiece) up to a maximum allowed value of 10 kN were amplified in a multichannel charge amplifier (Kistler 5070A, Winterthur, Switzerland) and a PC with a data acquisition board (PCMCIA, Keithley, Winterthur, Switzerland) recorded the information in real time for the duration of each test. All the tools were analysed under scanning electron microscopy (SEM) and with a 3D optical profilometer (Sensofar S-Neox, Barcelona, Spain) for evaluation of tool damage and qualitative and quantitative wear of the diamond coated tips. Analysis of the inserts was performed before and after cleaning in a 30 vol % NaOH solution to remove the Al alloy built up at the cutting edge.

Table 3.

Overall set parameters used in the metallic matrix composite (MMC) turning.

3. Results and Discussion

3.1. Multilayer MCD/NCD Coatings

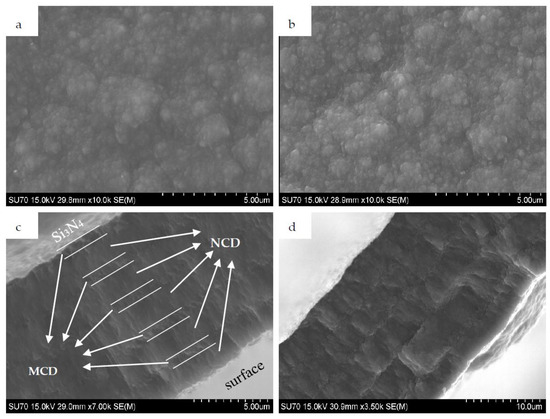

Representative top and cross-sectional SEM images of the two types of coatings, ML10x1 and ML10x2, are given in Figure 2. The free surfaces of the coatings (Figure 2a,b) present clusters of nanosized diamond particles without any crystalline facets as described for similar diamond multi-layered coatings [18]. The cross-sections obtained by fracture (Figure 2c,d) depict the multi-layered structure of the coatings, the MCD layers being much thinner than NCD. For the ML10x1 coatings, each MCD layer is about 0.7 µm thick while the NCD thickness is 1.7 µm. These values are nearly double for the ML10x2 coatings. This coating architecture relies on the strong adhesion of a first layer of MCD to the plasma etched Si3N4 ceramic substrate [22] and on the insertion of intermediate MCD layers creating MCD/NCD interfaces that act as energy sinks to crack propagation [19]. The top layer is of NCD to ensure a smoother surface, Ra (ML10x1) = 79 ± 7 nm and Ra (ML10x2) = 145 ± 6 nm, relatively to uncoated, etched substrates, or to substrates coated solely with MCD [18]. Thick NCD layers combined with thin MCD layers act in a way that further contributes to reduce the surface roughness of the tools. The larger surface roughness of the thicker coating (ML10x2) is merely a consequence of the larger thickness of the MCD and NCD layers in the ML10x2 inserts.

Figure 2.

Representative SEM micrographs of the surfaces of (a) ML10x1 and (b) ML10x2 inserts and respective cross sections in (c) and (d) (notice the scale difference in the bottom pictures).

3.2. Machining Performance

3.2.1. ML10x1-12 µm Thick CVD Diamond

Irrespectively of the cutting conditions, given in Table 3, there was always a gradual or a steep increase in all orthogonal components of the cutting force (Fc, FDOC, Ff) with machining time, this being usually related to wear of the cutting tip or delamination, respectively [23]. The SEM analysis showed VB values exceeding 500 µm after 1812 m and 476 m of turning at 250 m·min−1/0.1 mm·rev−1 and 500 m·min−1/0.4 mm·rev−1, respectively. The thinner coating, ML10x1 could not withstand the stresses at the cutting tip, with delamination occurring at the first moments of contact between the tool and the workpiece material or after a few seconds of machining, as was found by other authors [5,16]. In such thin coatings, the region of maximum stresses lies at the substrate/diamond interface or below, inducing prompt delamination [19]. PCD tools never show an abrupt increase of the cutting force in the machining of MMCs. Rather, wear of the cutting edge is continuous as is the increase of the cutting force and lathe power consumption with time, as was found by Ramesh et al. [24].

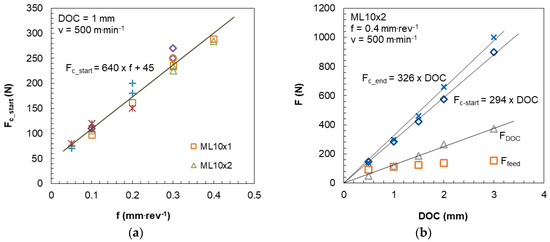

Due to the early fracture of the ML10x1 cutting inserts, only a limited analysis can be made regarding the effects of the cutting parameters on the cutting force in the machining of 15 vol % Al2O3 MMCs with these inserts. Therefore, just the initial values of the Fc force for each test were used to assess how this cutting geometry compares with others from literature, where that information was available, Figure 3a. Data-points collected from the literature fit the results obtained in the present work, with a general constant of approximately 640 N per mm·rev−1 of feed. An interesting finding that comes from this comparative analysis is that, unlike wear rates (Section 3.3), there is little sensitivity towards the type (Al2O3 or SiC) or amount (10%–20%) of reinforcing particles in what respects the absolute values of the cutting force. Data from a work of turning with PCD tools also fit the current work results despite the differences in cutting geometry and the use of lubrication [23]. Unlike this, and in a different work, quite smaller values for Fc and with very little sensitivity towards feed values were recorded [3] and are not considered here.

Figure 3.

(a) Variation of the initial values of the main cutting force with feed (f), at fixed DOC and cutting speed.  —30 µm CVD diamond coating [9];

—30 µm CVD diamond coating [9];  —hardmetal tool coated with 6 µm CVD diamond [15]; ◯—hardmetal tool coated with 25–30 µm CVD diamond [16]; ✴—PCD tool [23]; (b) Effect of depth of cut in the initial values of cutting force for the ML10x2 inserts and end values of Fc, for fixed feed and speed.

—hardmetal tool coated with 6 µm CVD diamond [15]; ◯—hardmetal tool coated with 25–30 µm CVD diamond [16]; ✴—PCD tool [23]; (b) Effect of depth of cut in the initial values of cutting force for the ML10x2 inserts and end values of Fc, for fixed feed and speed.

—30 µm CVD diamond coating [9];

—30 µm CVD diamond coating [9];  —hardmetal tool coated with 6 µm CVD diamond [15]; ◯—hardmetal tool coated with 25–30 µm CVD diamond [16]; ✴—PCD tool [23]; (b) Effect of depth of cut in the initial values of cutting force for the ML10x2 inserts and end values of Fc, for fixed feed and speed.

—hardmetal tool coated with 6 µm CVD diamond [15]; ◯—hardmetal tool coated with 25–30 µm CVD diamond [16]; ✴—PCD tool [23]; (b) Effect of depth of cut in the initial values of cutting force for the ML10x2 inserts and end values of Fc, for fixed feed and speed.

3.2.2. ML10x2-24 µm Thick CVD Diamond

The evolution of Fc with the feed for the ML10x2 inserts also fits the trend shown in the graph of Figure 3a. Data presented in Figure 3b illustrates the effect of DOC on the initial values of force components at fixed cutting speed and feed, where a constant of about 294 N per mm of DOC was obtained for the initial Fc values (Fc_start). It is also clear that, as expected, the radial component, FDOC, increases more rapidly than the axial Ffeed, surpassing it for depth of cut values above one millimetre. Due to the wear of the cutting tip, there is a slight increase of the cutting force throughout the turning operation. This is depicted when showing the effects of the DOC, where the linear constant increases to 326 N·mm−1 (Fc_end), as shown in Figure 3b. There were a few conditions where the ML10x2 tools could not withstand the mechanical stresses during turning. There was also delamination from the rake face for the highest cutting speed of 1000 m·min−1. However the tool keeps cutting without loss of dimensional tolerance of the workpiece, a parameter followed throughout the turning tests, even if high DOC values are used (3 mm). This indicates that only where there is delamination from the flank face, the machined diameter will be out of specification due to recession of the cutting edge.

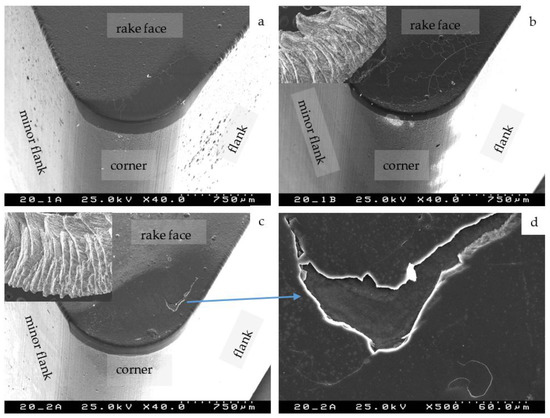

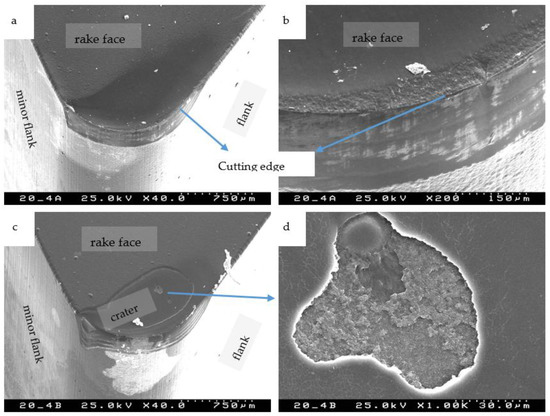

From the results of the present work, in line with data published by others, there are a set of cutting conditions for the diamond coated inserts to be successfully used. In this case with silicon nitride coated with a 21–24 µm thick multilayer system, those parameters depend upon the workpiece material and the substrate/diamond system, including all the possible surface treatments and deposition methods. For these ML10x2 inserts, the limits are: DOC values below 1.5 mm for feeds of 0.4 mm·rev−1; maximum speeds of 750 m·min−1; and feeds up to 0.4 mm·rev−1. Within these boundaries, there is no delamination and the inserts wear out at the flank and corner forming a wear land that increases progressively with time, just as for PCD inserts. The SEM micrographs in Figure 4 of the cutting tips after cleaning the built up edge, illustrate this behaviour. DOC notch is absent from the major cutting edge due to the negative tool lead angle and it is almost negligible in the minor cutting edge, Figure 4a. As said previously, the cutting geometry, namely the negative tool normal rake, affects the wear of the rake face: crater wear is seldom, if ever, mentioned in the turning of MMCs, indicating that most tools are used with a positive tool normal rake. In the present work, and despite the short serrated chips produced for all cutting conditions (see inset micrographs in Figure 4), there is marked evidence of the formation of a crater. From the SEM micrographs of the cutting tips it is also clear that some cracks appear at the surface layer of the rake face or may even cross several layers. Despite this, overall tool integrity was kept, even if the upper layer was removed partially, as can be seen for the 750 m·min−1 test, Figure 4c,d.

Figure 4.

(a) SEM micrographs of ML10x2 cutting inserts after machining at v = 500 m·min−1 and DOC = 1.0 mm: (a) f = 0.1 mm·rev−1, L = 1708 m; (b) f = 0.4 mm·rev−1, L = 422 m. After machining at v = 750 m·min−1, DOC = 1.0 mm, f = 0.4 mm·rev−1, L = 413 m (c,d). Inset SEM micrographs of turning chips (chip width close to DOC values).

3.2.3. ML10x2-Multi-Pass Tests

The four-pass tests, Table 3, done under dry and lubricated conditions, returned worn cutting tips after machining longer lengths than the above reported, Figure 5, for dry (Figure 5a,b) and lubricated (Figure 5c,d) conditions. The multilayer structure of the coating becomes obvious in the flank, and more pronounced craters are also formed, particularly in the lubricated test, Figure 5c,d, but never exposing the substrate. The latter two SEM micrographs illustrate clearly the benefits of this multilayer strategy for the diamond coating, as fractures in the tool rake face propagate in steps along the NCD/MCD interfaces to the nearest interface, resulting in successive partial wear. This mechanism delays total delamination of the diamond coating from the substrate, unlike what would happen with monolayer coatings. This gradual loosening of material without total film spallation was already observed in erosion tests of multilayer diamond coatings with SiC particles [19]. In that work, the multilayer films presented a much improved erosion relatively to the mono-layer coatings of MCD and NCD that suffered from faster wear with substrate exposure.

Figure 5.

(a) SEM micrographs of the ML10x2 cutting inserts after machining at v = 500 m·min−1, DOC = 1.0 mm, f = 0.3 mm·rev−1: (a,b) L = 1975 m (four pass, dry ); (c,d) L = 1878 m (four pass, lubricated).

The worn surfaces shown in the SEM micrographs of Figure 4 and Figure 5 are very smooth, being polished by the action of the hard Al2O3 reinforcing particles of the MMC material. Wear should thus occur by a micro-scale abrasive wear mechanism. The microstructural observation in Figure 5c also shows that the notch formation occurs at the minor cutting edge and not only at the major cutting edge due to the −3° tool lead angle imposed by the tool holder.

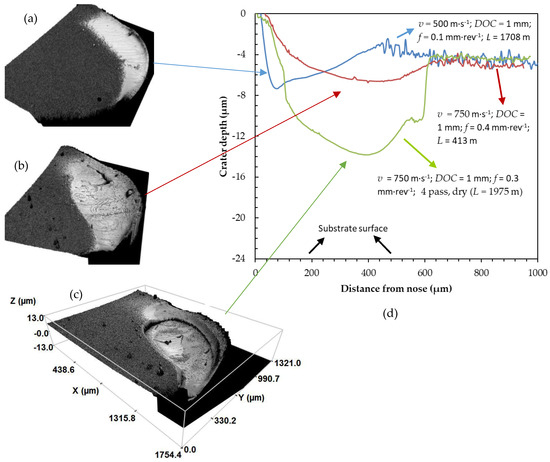

3.2.4. Crater Wear

One should also bear in mind that the cutting geometry used in the present work relies on negative tool normal rake and tool cutting edge inclination (λs = −6°), this resulting in a strong rubbing of the turning chips on the tool rake face with the resulting crater being also visible on the micrographs of Figure 5. The SEM analysis was complemented with 3D optical profilometry for quantifying the depth of the craters on the worn surfaces, as shown in Figure 6. The stack images and the profiles of the wear craters show that their width is a function of the feed value. When comparing Figure 6a,c and the data in Figure 6d, it is clear that, while the machining length is nearly the same, the crater is much deeper for the harsher cutting conditions. The increase in feed from 0.1 to 0.3 mm·rev−1 and cutting speed increases the friction forces on the cutting edge and rake face and thus the crater depth.

Figure 6.

(a–c) Stacked image obtained by optical profilometry of the rake face near the nose of the inserts after machining under different turning conditions; (d) Graphic with depth profiles across the wear crater, from the nose of the tool towards the centre of the triangular inserts.

3.3. Tool Life

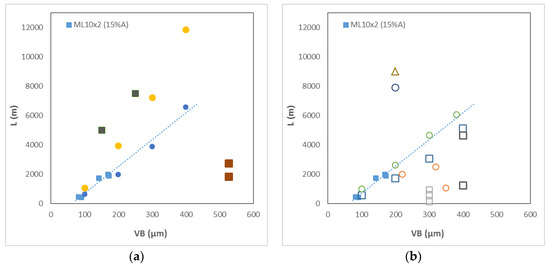

Under non-fracture conditions, the tool life, as determined by a given width of the flank wear land (VB), is a function of the cutting conditions which conducts to highly disperse data. To make it even more difficult a comparison between the results of different works, it is evident that the tool material, be it uncoated hard metal, CBN, PCD, thick CVD or diamond coatings, strongly affects the outcome of tool life assessment. For the latter type of tool material, the maximum value of VB is limited by the thickness of the coating, for the cutting geometry used. In the case of the present work, the 6° tool normal clearance, −6° tool normal rake and a thickness of 24 µm for the multilayer diamond coating of the ML10x2 inserts, result in a VB maximum value of approximately 250 µm before the base material of the cutting edge is exposed, and this could be an indication of the end of tool usefulness. If no delamination or fracture of the cutting edge is observed, the usual standard tool life criterion of a fixed average VB value of 0.3 mm [24] is here used to compare literature and the present work data. As for the ML10x1 inserts there was delamination for all tests they were excluded from this analysis. For the ML10x2 inserts that did not delaminate, the VB values measured were always smaller than the threshold value for substrate exposure.

Qin et al. [16] tested NCD and MCD coatings on hard metal substrates on the machining of an A359/SiC-20p composite at 240 m·min−1, 480 m·min−1 with 0.15 and 0.30 mm·rev−1 at a fixed DOC value of 1.0 mm. The lifetime of the tools was much shorter than the values here reported because, unlike the results of the present work, the coating seemingly just delaminated after a certain amount of turning time without a gradual increase in VB.

The data points in the charts of Figure 7 were collected from different works in the machining of MMCs at speeds around 500 m·min−1, using PCD, CVD diamond coated tools and one with thick CVD diamond tip, and are compared with the tool life or wear behaviour of the surviving ML10x2 inserts used in the present work. These data are compared with literature results of turning MMCs containing Al2O3 (Figure 7a) or SiC (Figure 7b) hard particles. Since the wear mode presented by all the tools shown in the graphic is gradual wear of the cutting edge and flank, the tool life is translated into the cutting length. This gives a more accurate view of the abrasive effects at the contact between tool and workpiece. Despite being at the lower end of the graphs in Figure 7a,b, the tendency shown by the inserts used in the present work is within that of the best CVD diamond coated tools tested, behaving better than most. PCD tools have dissimilar behaviour relatively to CVD tools as some excel while others are at the same level or behave worse than CVD coated ones. In Figure 7, data taken from the work of Durante et al. [2] revealed the little influence of the nature of the abrasive particles on tool life (see points PCD [2] 20% A in Figure 7a and PCD [2] 20% SiC in Figure 7b), despite the fact that the hardness of SiC particles is about 1.7 times higher than that of Al2O3 [25]. The same authors showed that if MMCs contain higher fractions of filler particles (see points PCD [2] 10% A and PCD [2] 20% A), their abrasive effect is clear in the tool life of PCD inserts in the machining of Al–Al2O3 composites [2]. The diamond grain size and binder content in PCD grades have an important role on the surface finishing of the workpiece and cutting forces but also tool wear behaviour [26].

Figure 7.

Tool machining length given as a function of flank wear of diamond tools (squares for CVD coated inserts, circles for PCD inserts and triangle for brazed thick CVD; filled symbols—workpiece material contains Al2O3; open symbols—reinforcing particles are SiC; dotted line corresponds to an extrapolation of ML10x2 results (filled blue squares). (a) ■—CVD/15% Al2O3, present work; ■—CVD/10% Al2O3 [14]; ■—CVD/10% Al2O3 [6]; ●—PCD/10% Al2O3 [2]; ●—PCD/20% Al2O3 [2]; (b) ■—CVD/15% Al2O3, present work; □—CVD/20% SiC [16]; □—CVD/20% SiC [2]; □—CVD/20% SiC [6]; ◯—PCD/20% SiC [2]; ◯—PCD/20% SiC [6]; ◯—PCD/20% SiC [23]; △—Thick CVD/20% SiC [6].

Very important is also the fact that the inserts used in the present work have three usable cutting tips per deposition, while PCD tools have a single block brazed to one tip. So, the useful tool life of the ML10x2 triangular CVD diamond coated inserts will be three times the values recorded for a single cutting tip. The dotted lines in Figure 7a,b correspond to the extrapolation of the results of the present work to larger values of VB. They could be achieved if thicker coatings were used, e.g., a 38-µm thick coating would yield a maximum VB of 0.4 mm without exposing the substrate. This would place the tool life of the presently used inserts in the range of 6000 m per corner and thus of about 18,000 m per insert, which puts the present silicon nitride ceramic substrate/multilayer diamond coating system at the top of the performance range.

4. Conclusions

Silicon nitride ceramic triangular inserts were produced and coated with ~12 and ~24 µm thick, ten-fold multilayer micro-/nanocrystalline (MCD/NCD) diamond films by hot filament CVD, starting with MCD for maximizing adhesion and ending with NCD on top to ensure smoothness.

The tool life of triangular ceramic inserts coated with multilayered MCD/NCD films were tested in the dry turning of an Al based metallic matrix composite containing 15 vol % Al2O3 particles.

The thicker coatings (24 µm thick) perform well within the following limits: DOC values below 1.5 mm for feeds of 0.4 mm·rev−1; maximum speeds of 750 m·min−1; and feeds up to 0.4 mm·rev−1.

Within the limits of viable working machining parameters, the multilayer diamond coated inserts behave better than most reported CVD diamond systems and as well as most reports using PCD tools, especially when considering the existence of three tips per tool, as opposed to one for PCD or brazed CVD thick films.

For delamination-free turning conditions, the wear of the flank and corner occurs progressively, with the worn surfaces having a smooth appearance, typical of a micro-scale abrasive wear mechanism.

Crater wear is also present, due to the negative tool normal rake, and for the longer machining tests, some surface cracks may appear. Crater wear occurs by successive wear of the layers, delaying total delamination of the diamond coating from the substrate, unlike what would happen with monolayer coatings.

Optical profilometry was used to measure the depth of the wear craters, showing that the substrate was not reached even after 2000 m of machining length.

Acknowledgments

Leichtmetall Kompetenzzentrum Ranshofen (LKR, Braunau am Inn, Austria) of the Austrian Institute of Technology is acknowledged for gently ceding the workpiece cylinder. Financial support for the conduct of the research was given by project CICECO-Aveiro Institute of Materials (Ref. FCT UID /CTM /50011/2013), financed by national funds through the FCT/MEC and when applicable co-financed by FEDER under the PT2020 Partnership Agreement.

Author Contributions

Mohammadmehdi Shabani contributed with the experimental components regarding tool preparation, diamond deposition and machining; Joaquim Sacramento was in charge of the machining tests at Durit; Filipe J. Oliveira conceived and designed the experiments and together with Rui F. Silva analysed the data and contributed substantially in the writing of the paper.

Conflicts of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Hung, N.P.; Boey, F.Y.C.; Khor, K.A.; Phua, Y.S.; Lee, H.F. Machinability of aluminum alloys reinforced with silicon carbide particulates. J. Mater. Process. Technol. 1996, 56, 966–977. [Google Scholar] [CrossRef]

- Durante, S.; Rutelli, G.; Rabezzana, F. Aluminum-based MMC machining with diamond-coated cutting tools. Surf. Coat. Technol. 1997, 94–95, 632–640. [Google Scholar] [CrossRef]

- El-Gallab, M.; Sklad, M. Machining of Al/SiC particulate metal-matrix composites. Part I: Tool performance. J. Mater. Process. Technol. 1998, 83, 151–158. [Google Scholar] [CrossRef]

- Lin, J.T.; Bhattacharyya, D.; Lane, C. Case Study—Machinability of a silicon carbide reinforced matrix composite aluminium metal. Wear 1995, 181–183, 883–888. [Google Scholar] [CrossRef]

- Vandevelde, T.C.S.; Vandierendonck, K.; van Stappen, M.; Du Mong, W.; Perremans, P. Cutting applications of DLC, hard carbon and diamond films. Surf. Coat. Technol. 1999, 113, 80–85. [Google Scholar] [CrossRef]

- D’Errico, G.E.; Calzavarini, R. Turning of metal matrix composites. J. Mater. Process. Technol. 2001, 119, 257–260. [Google Scholar] [CrossRef]

- Weinert, K.; Buschka, M.; Niehues, J.; Schoberth, A. Spanende Bearbeitung von Bauteilen aus Al-Matrix-Verbundwerkstoffen (Machining of Components of Al Matrix Composites). Materialwiss. Werkstofftech. 2001, 32, 447–461. [Google Scholar] [CrossRef]

- Almeida, F.A.; Oliveira, F.J.; Sousa, M.; Fernandes, A.J.S.; Sacramento, J.; Silva, R.F. Machining hardmetal with CVD diamond direct coated ceramic tools: Effect of tool edge geometry. Diam. Relat. Mater. 2005, 14, 651–656. [Google Scholar] [CrossRef]

- Chou, Y.K.; Liu, J. CVD diamond tool performance in metal matrix composite machining. Surf. Coat. Technol. 2005, 200, 1872–1878. [Google Scholar] [CrossRef]

- Skordaris, G. Temperature-Dependent Fatigue Strength of Diamond Coating-Substrate Interface Quantified via the Shear Failure Stress. J. Mater. Eng. Perform. 2015, 24, 3335–3342. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Skordaris, G.; Bouzakis, E.; Charalampous, P.; Kotsanis, T.; Tasoulas, D.; Kombogiannis, S.; Lemmer, O. Effect of the Interface Fatigue Strength of NCD Coated Hardmetal Inserts on Their Cutting Performance in Milling. Diam. Relat. Mater. 2015, 59, 80–89. [Google Scholar] [CrossRef]

- Skordaris, G.; Bouzakis, K.-D.; Charalampous, P.; Kotsanis, T.; Bouzakis, E.; Lemmer, O. Effect of structure and residual stresses of diamond coated cemented carbide tools on the film adhesion and developed wear mechanisms in milling. CIRP Ann. Manuf. Technol. 2016, 65, 101–104. [Google Scholar] [CrossRef]

- Iuliano, L.; Settineri, L.; Gatto, A. High-speed turning experiments on metal matrix composites. Compos. Part A 1998, 29, 1501–1509. [Google Scholar] [CrossRef]

- Polini, R.; Casadei, F.; D’Antonio, P.; Traversa, E. Dry turning of alumina/aluminum composites with CVD diamond coated Co-cemented tungsten carbide tools. Surf. Coat. Technol. 2003, 166, 127–134. [Google Scholar] [CrossRef]

- Kremer, A.; Devillez, A.; Dominiak, S.; Dudzinski, D.; El Mansori, M. Machinability of Al/SiC particulate metal-matrix composites under dry conditions with CVD diamond-coated carbide tools. Mach. Sci. Technol. 2008, 12, 214–233. [Google Scholar] [CrossRef]

- Qin, F.; Hu, J.; Chou, Y.K.; Thompson, R.G. Delamination wear of nano-diamond coated cutting tools in composite machining. Wear 2009, 267, 991–995. [Google Scholar] [CrossRef]

- Shen, B.; Sun, F.H. The Cutting Performance of Ultra-Smooth Composite Diamond Coated WC-Co Inserts in Dry Turning Al/SiC-MMC. Adv. Mater. Res. 2011, 325, 400–405. [Google Scholar] [CrossRef]

- Salgueiredo, E.; Abreu, C.S.; Amaral, M.; Oliveira, F.J.; Gomes, J.R.; Silva, R.F. Self-mated tribological systems based on multilayer micro/nanocrystalline CVD diamond coatings. Wear 2013, 303, 225–234. [Google Scholar] [CrossRef]

- Salgueiredo, E.; Almeida, F.A.; Amaral, M.; Neto, M.A.; Oliveira, F.J.; Silva, R.F. A multilayer approach for enhancing the erosive wear resistance of CVD diamond coatings. Wear 2013, 297, 1064–1073. [Google Scholar] [CrossRef]

- Abreu, C.S.; Amaral, M.; Oliveira, F.J.; Fernandes, A.J.S.; Gomes, J.R.; Silva, R.F. Enhanced performance of HFCVD nanocrystalline diamond self-mated tribosystems by plasma pretreatments on silicon nitride substrates. Diam. Relat. Mater. 2006, 15, 2024–2028. [Google Scholar] [CrossRef]

- Basic Nomenclature and Definitions for Single—Point Cutting Tools; ANSI B94.50; American National Standard Institute: Washington, DC, USA, 1975.

- Almeida, F.A.; Amaral, M.; Oliveira, F.J.; Fernandes, A.J.S.; Silva, R.F. Nano to micrometric HFCVD diamond adhesion strength to Si3N4. Vacuum 2007, 81, 1443–1447. [Google Scholar] [CrossRef]

- Davim, J.P.; Baptista, A.M. Relationship between cutting force and PCD cutting tool wear in machining silicon carbide reinforced aluminium. J. Mater. Process. Technol. 2000, 103, 417–423. [Google Scholar] [CrossRef]

- Ramesh, M.V.; Lee, W.B.; Cheung, C.F.; Chan, K.C. A parametric analysis of cutting forces in single-point diamond turning of Al6061/SiCp metal matrix composites (MMCs) forces in single-point diamond turning. Mater. Manuf. Processes 2001, 16, 61–78. [Google Scholar] [CrossRef]

- Kamiya, H.; Takahara, T.; Sakurai, Y.; Jimbo, G.; Wada, S. Erosion wear properties of toughened ceramics and composites. In Advanced Materials '93: Ceramics, Powders, Corrosion and Advanced Processing; Elsevier Science: Amsterdam, The Netherlands, 1994; pp. 313–316. [Google Scholar]

- Muthukrishnan, N.; Murugan, M.; Rao, K.P. Machinability issues in turning of Al-SiC (10p) metal matrix composites. Int. J. Adv. Manuf. Technol. 2007, 39, 211–218. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).